The Evaluation and Prediction of Flame Retardancy of Asphalt Mixture Based on PCA-RBF Neural Network Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Asphalt

2.2. Aggregate

2.3. Warm Mix Agent

2.4. Flame Retardant

2.5. Gradation Design

2.6. Preparation of Asphalt Mixture

2.7. Methods

2.7.1. Conventional Performance Test

2.7.2. Limiting Oxygen Index (LOI) Test

2.7.3. Thermogravimetry (TG) Test

2.7.4. Differential Scanning Calorimetry (DSC) Test

2.7.5. Gas Chromatography–Mass Spectrometry (GC-MS) Test

2.7.6. Pavement Performance Test

2.7.7. Combustion Test

3. Results

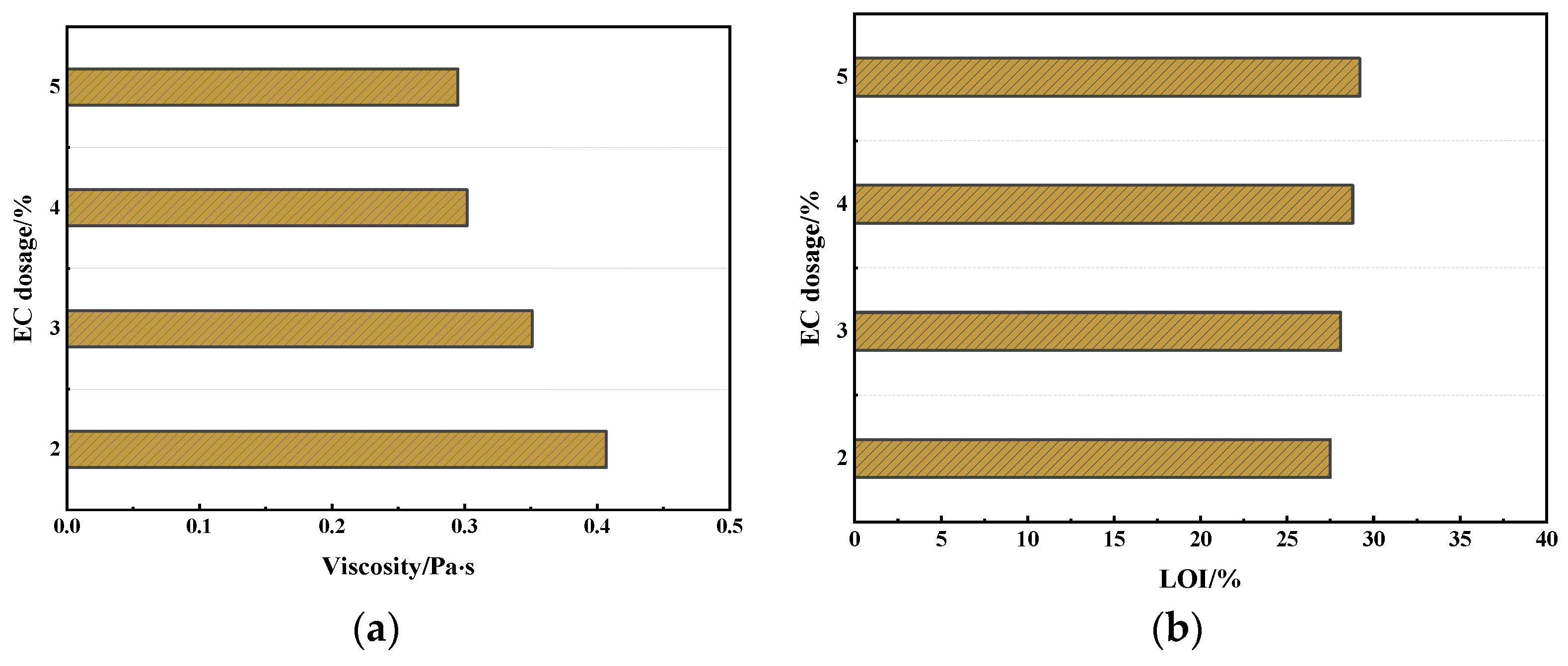

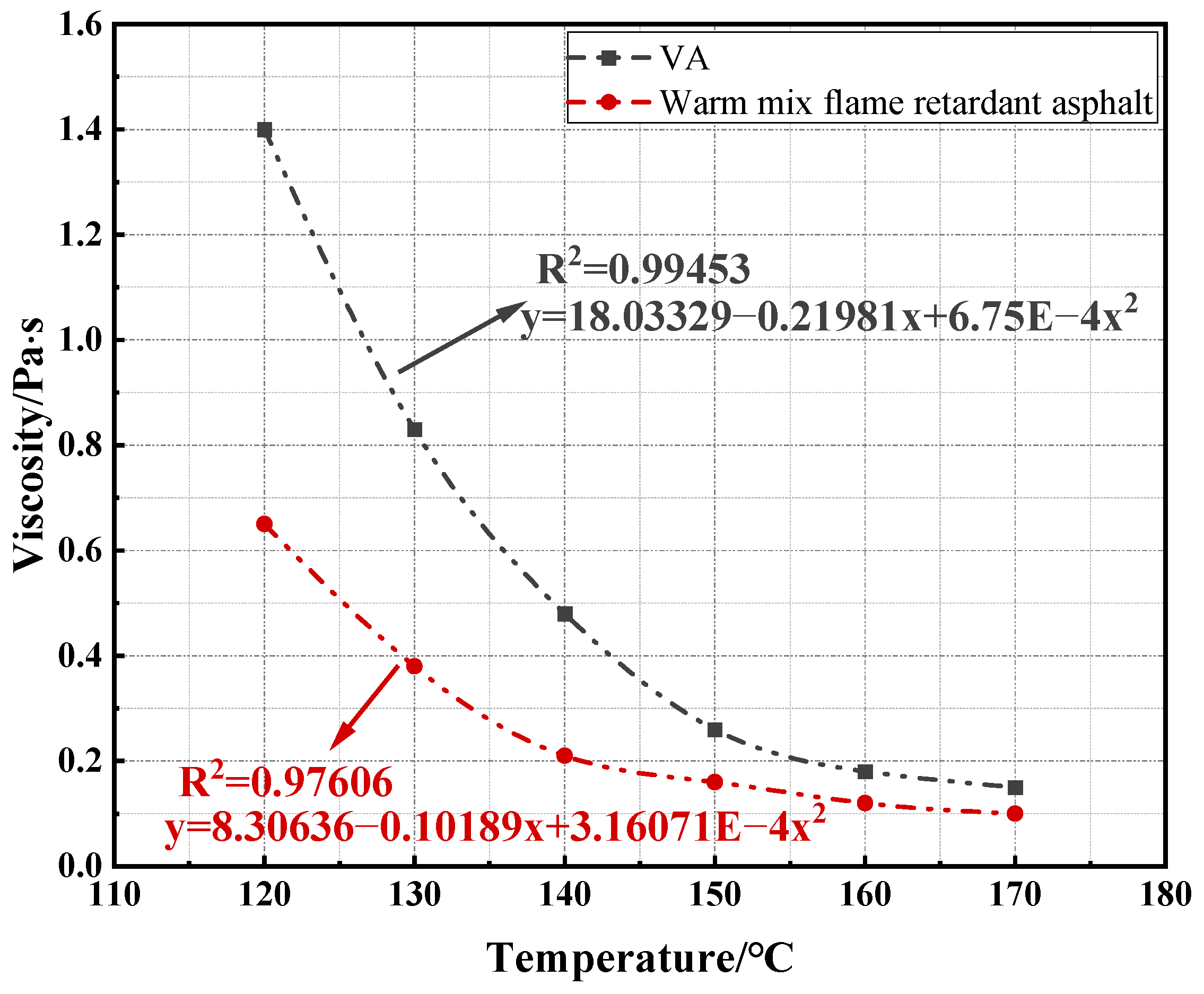

3.1. Design of Warm Mix Flame Retardant Asphalt

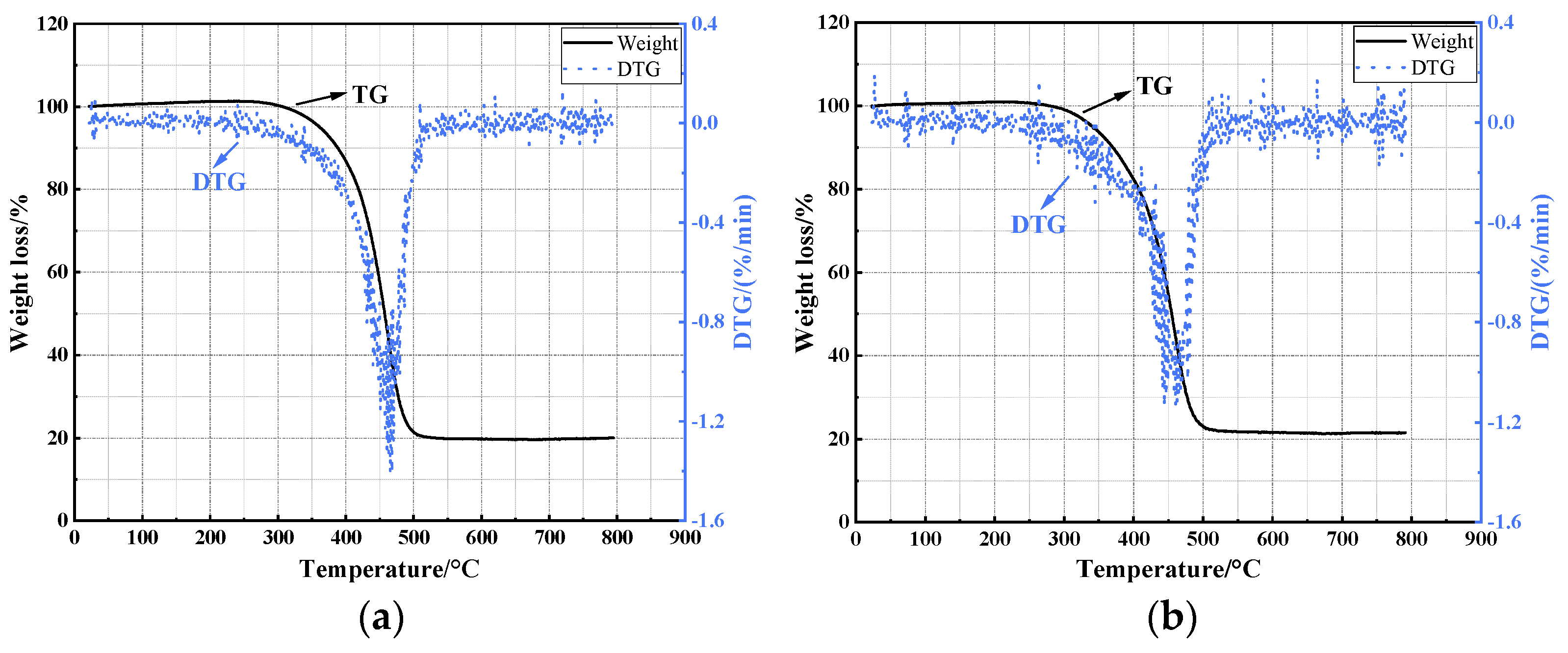

3.2. Thermal Stability Analysis of Warm Mix Flame Retardant Asphalt

3.3. Evaluation of Pavement Performance of Mixture

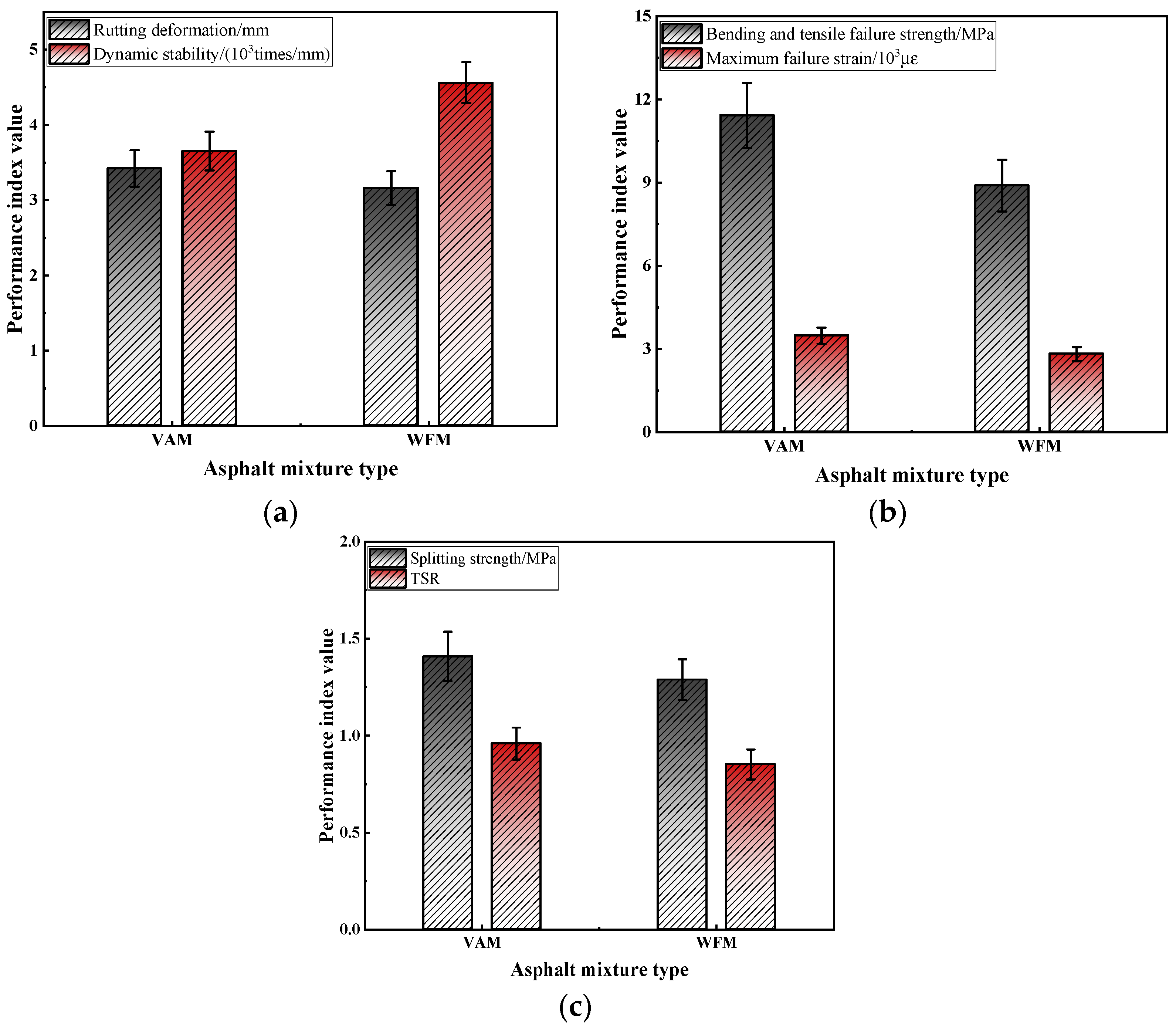

3.4. Evaluation of Flame Retardant Effect

3.4.1. Combustion Time

3.4.2. Mass Loss Rate

3.4.3. Stability

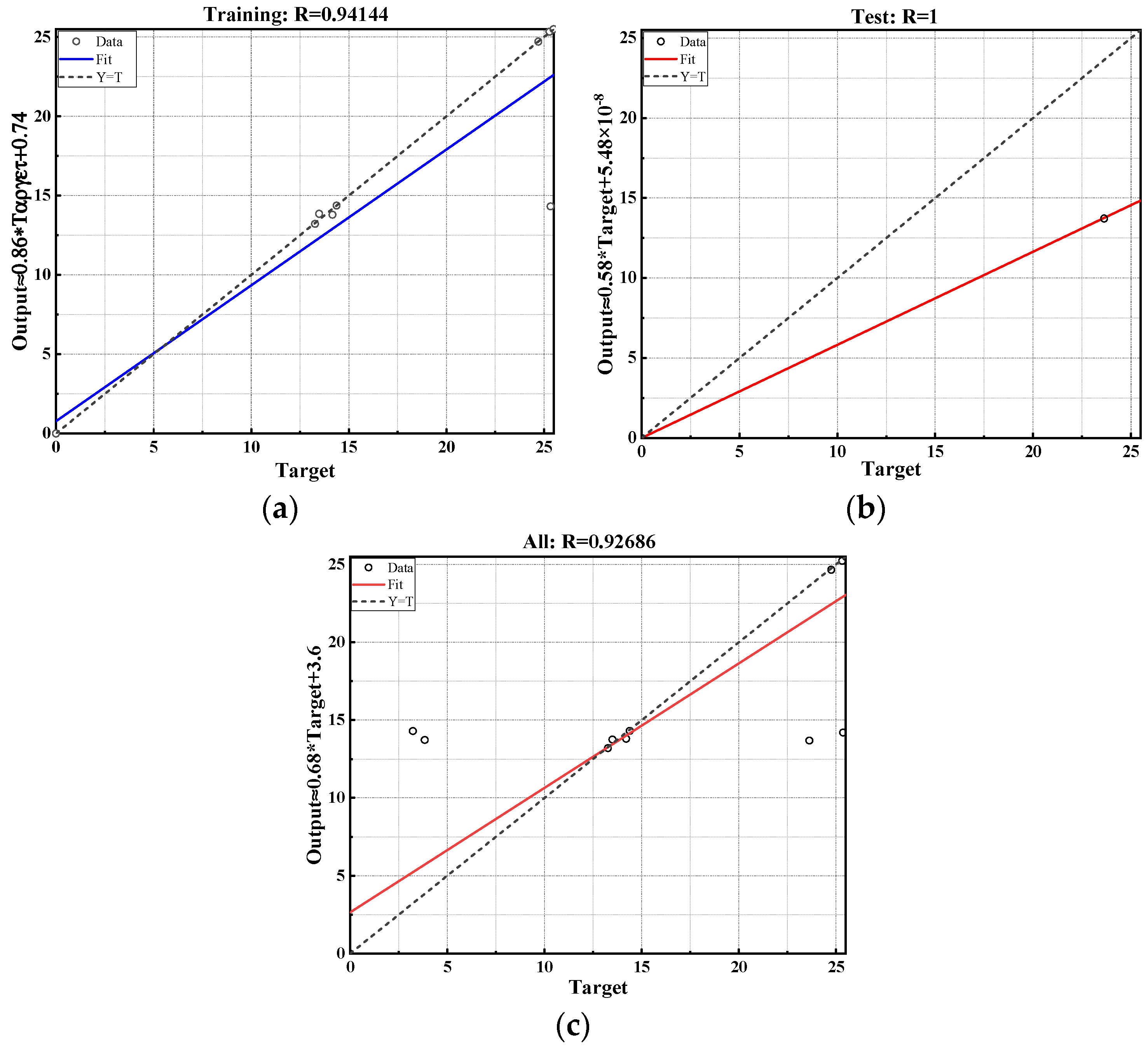

3.5. Prediction and Evaluation of Flame Retardancy

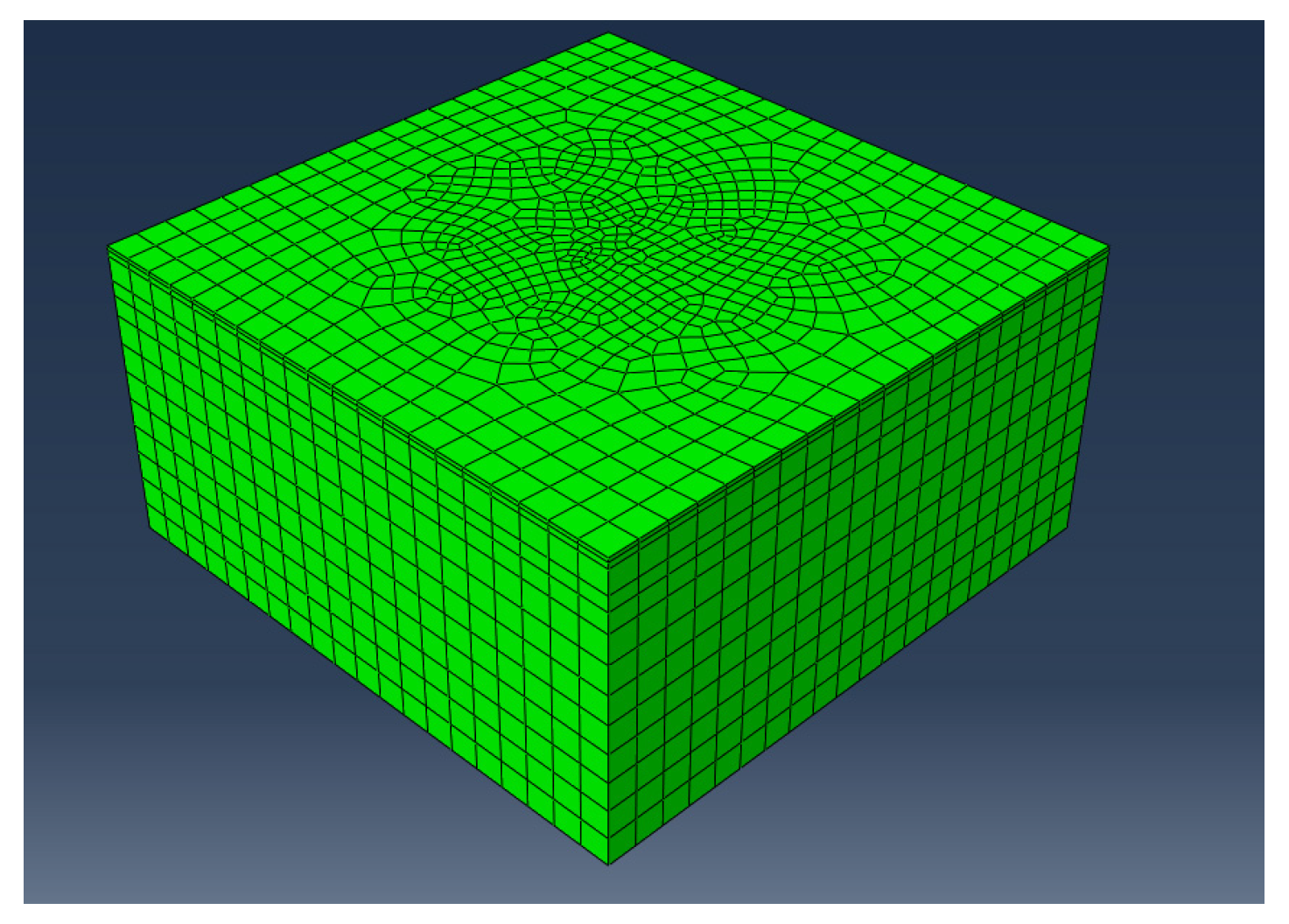

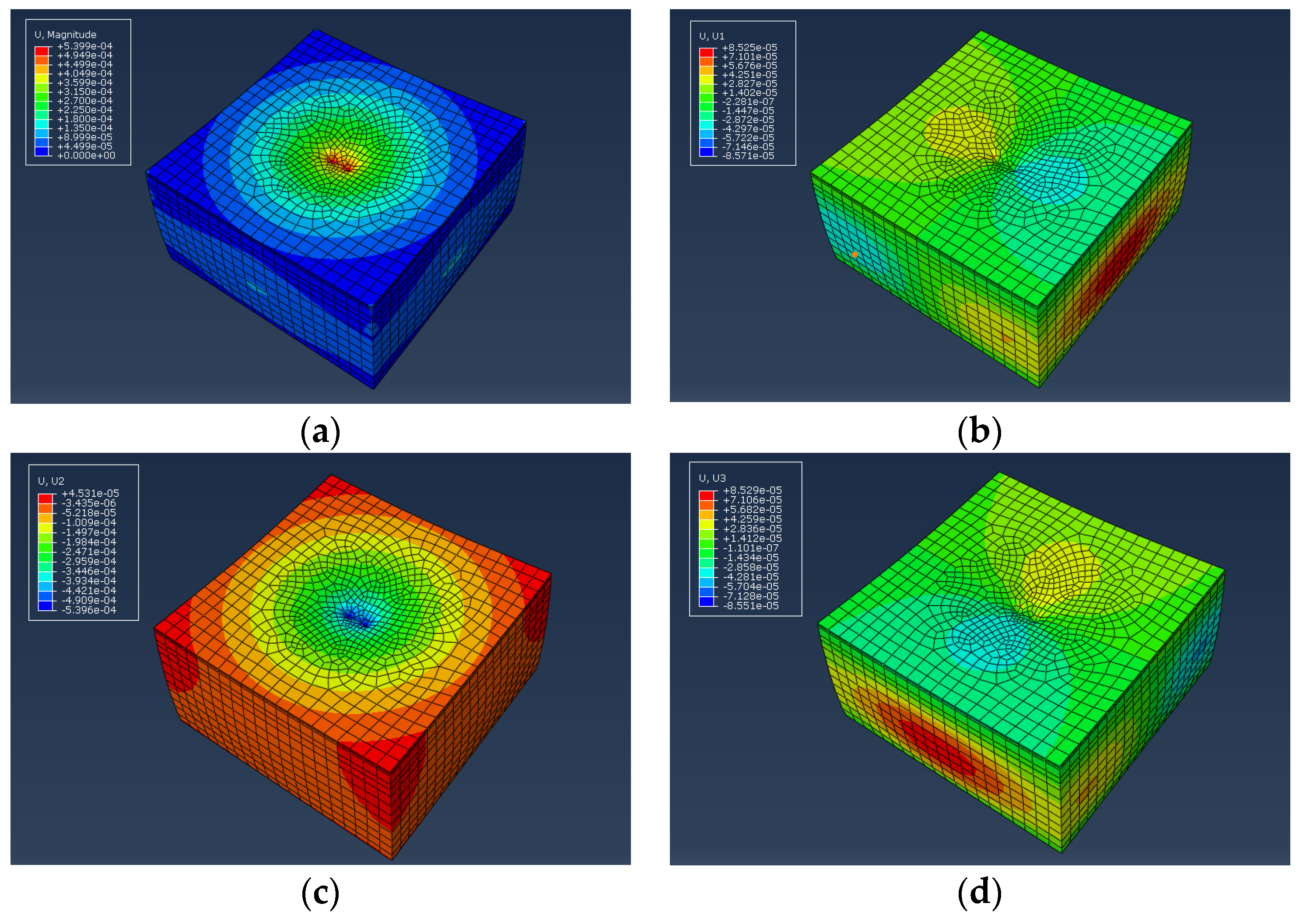

3.6. Analysis of Pavement Structural Dynamic Response

4. Conclusions

- (1)

- The optimal dosage of FR is 12%, and the optimal dosage of EC is 4%. The viscosity–temperature curves indicate that the mixing and compaction temperatures of the modified mixtures decreased by approximately 12 °C. This demonstrates that the addition of EC can reduce the mixing and compaction temperatures of asphalt mixtures, achieving the desired warm mix effect.

- (2)

- After the warm mix and flame retardant modification of VAM, the high–temperature performance indicators of the mixture showed an increasing trend, while the low-temperature performance and moisture stability indicators exhibited a decreasing trend. This indicates that the high-temperature performance of the mixture is improved after the warm mix and flame retardant modification, but the low-temperature performance and moisture stability are attenuated.

- (3)

- Considering the test results of combustion time, mass loss rate, and stability, the WFM exhibits a better flame retardancy compared to VAM, which indicates that the EC and FR used in this study significantly improve the flame retardancy of the asphalt mixtures.

- (4)

- The RBF neural network model demonstrates that the flame retardancy prediction model established in this study has high accuracy, enabling effective evaluation of the flame retardancy of the asphalt mixtures. The PCA model reveals that combustion time has the most significant impact on flame retardancy. Therefore, it is important to carefully consider the effect of combustion time on the flame retardancy when designing a WFM.

- (5)

- The finite element model reveals that the displacements in all directions of WFM are slightly smaller than VAM, indicating that the warm mix flame retardant modification method designed in this study benefits the service performance of the asphalt mixture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, S.; Zhang, H.; Wang, J. Research on alkaline filler flame-retarded asphalt pavement. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2006, 21, 146–148. [Google Scholar]

- Jiang, X.; Zhu, H.; Yan, Z.; Zhang, F.; Huang, X.; Leng, Z.; Yan, C.; Hua, N.; Lu, D.; Zhang, X.; et al. Fire-Retarding Asphalt Pavement for Urban Road Tunnels: A State-of-the-Art Review and Beyond. Fire Technol. 2024, 1–41. [Google Scholar] [CrossRef]

- Wan, Z.; Zheng, B.; Xie, X.; Yang, J.; Zhou, H.; Shilong Wan, R.; Wang, J.; Wang, J.; Luo, W.; Xue, R.; et al. Preparation method and performance test of Evotherm pre-wet treatment aluminum hydroxide type warm-mixed flame-retardant asphalt. Constr. Build. Mater. 2020, 262, 120618. [Google Scholar] [CrossRef]

- Cong, P.; Yu, J.; Wu, S.; Luo, X. Laboratory investigation of the properties of asphalt and its mixtures modified with flame retardant. Constr. Build. Mater. 2008, 22, 1037–1042. [Google Scholar] [CrossRef]

- Li, J.; Liu, F.; Hu, M.; Zhou, C.; Su, L.; Cao, P. Investigation on the Performance of Fire and Smoke Suppressing Asphalt Materials for Tunnels. Processes 2023, 11, 3038. [Google Scholar] [CrossRef]

- Chen, R.; Gong, J.; Jiang, Y.; Wang, Q.; Xi, Z.; Xie, H. Halogen-free flame retarded cold-mix epoxy asphalt binders: Rheological, thermal and mechanical characterization. Constr. Build. Mater. 2018, 186, 863–870. [Google Scholar] [CrossRef]

- Yu, J.; Cong, P.; Wu, S. Investigation of the properties of asphalt and its mixtures containing flame retardant modifier. Constr. Build. Mater. 2009, 23, 2277–2282. [Google Scholar]

- Bi, Q.-Q.; Li, Y.-M.; He, L.; Li, Z.; Wang, D.-Y. Nanoporous flame retardants: Toward asphalt with enhanced fire safety and smoke suppression behavior. Compos. Commun. 2024, 47, 101869. [Google Scholar] [CrossRef]

- Li, J.; He, Z.; Yu, L.; He, L.; Shen, Z.U. Multi-Objective Optimization and Performance Characterization of Asphalt Modified by Nanocomposite Flame-Retardant Based on Response Surface Methodology. Materials 2021, 14, 4367. [Google Scholar] [CrossRef]

- Yang, X.; Shen, A.; Jiang, Y.; Meng, Y.; Wu, H. Properties and mechanism of flame retardance and smoke suppression in asphalt binder containing organic montmorillonite. Constr. Build. Mater. 2021, 302, 124148. [Google Scholar] [CrossRef]

- Xu, T.; Huang, X. Combustion Properties and Multistage Kinetics Models of Asphalt Binder Filled with Flame Retardant. Combust. Sci. Technol. 2011, 183, 1027–1038. [Google Scholar] [CrossRef]

- Shen, A.; Wu, H.; Guo, Y.; Yang, X.; He, Z.; Li, Y. Effect of Layered Double Hydroxide on Rheological and Flame-Retardant Properties of Styrene-Butadiene-Styrene-Modified Asphalt. J. Mater. Civ. Eng. 2021, 33, 04020454. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Z.; Wang, Z.; Sun, J.; Wei, Y.; Zhang, D. Preparation and properties of flame-retardant asphalt containing polyurethane and eco-friendly flame retardants. Constr. Build. Mater. 2023, 375, 130996. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.P.; Liao, K.J. Study on Properties of Flame Retardant Asphalt for Tunnel. Pet. Sci. Technol. 2010, 28, 1096–1107. [Google Scholar] [CrossRef]

- Wang, H.; Yin, P. A new flame retardant and its effect on the asphalt mixture. Case Stud. Constr. Mater. 2023, 18, e01748. [Google Scholar] [CrossRef]

- Wu, S.; Mo, L.; Cong, P.; Yu, J.; Luo, X. Flammability and rheological behavior of mixed flame retardant modified asphalt binders. Fuel 2008, 87, 120–124. [Google Scholar] [CrossRef]

- Tan, Y.; He, Z.; Li, X.; Jiang, B.; Li, J.; Zhang, Y. Research on the Flame Retardancy Properties and Mechanism of Modified Asphalt with Halloysite Nanotubes and Conventional Flame Retardant. Materials 2020, 13, 4509. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liu, S.; Xue, Z.; Cao, W. Experimental research on combined effects of flame retardant and warm mixture asphalt additive on asphalt binders and bituminous mixtures. Constr. Build. Mater. 2014, 54, 533–540. [Google Scholar] [CrossRef]

- Tan, Y.; Xie, J.; Wang, Z.; Li, X.; He, Z. Preparation, properties, and mechanism of warm mix flame retardant modified asphalt based on surface activity principle. J. Build. Eng. 2023, 76, 107117. [Google Scholar] [CrossRef]

- Li, R.; Zhang, K.; Wu, J.; Liu, W. Performance of Warm-Mixed Flame Retardant Modified Asphalt Binder. Appl. Sci. 2019, 9, 1491. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, N.; Yang, F.; Ren, Y.; Wu, S.; Wang, F.; Xie, J. Rheology and volatile organic compounds characteristics of warm-mix flame retardant asphalt. Constr. Build. Mater. 2021, 298, 123691. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Z.; Deng, X.; You, Z. Flame Resistance of Asphalt Mixtures with Flame Retardants through a Comprehensive Testing Program. J. Mater. Civ. Eng. 2017, 29, 04016266. [Google Scholar] [CrossRef]

- Xia, W.; Dong, M.; Xu, T. Synergistic suppressions of porous warm mix agent and composite flame retardant on combustion and fume release of asphalt pavement. J. Clean. Prod. 2024, 443, 141003. [Google Scholar] [CrossRef]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. People’s Communications Press: Beijing, China, 2004.

- Rathore, M.; Haritonovs, V.; Zaumanis, M. Performance Evaluation of Warm Asphalt Mixtures Containing Chemical Additive and Effect of Incorporating High Reclaimed Asphalt Content. Materials 2021, 14, 3793. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Luo, Y.; Chen, F.; Han, F. Performance evaluation of new warm mix asphalt and water stability of its mixture based on laboratory tests. Constr. Build. Mater. 2020, 241, 118017. [Google Scholar] [CrossRef]

- Qiu, Y.; Xie, Q.; Ding, H.; Xuan, W. A novel method for determining the wax precipitation temperature in wax-based warm mix asphalt. Int. J. Pavement Eng. 2023, 24, 132316. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Traffic Press: Beijing, China, 2011.

- Chen, R.; Zhao, R.; Liu, Y.; Xi, Z.; Cai, J.; Zhang, J.; Wang, Q.; Xie, H. Development of eco-friendly fire-retarded warm-mix epoxy asphalt binders using reactive polymeric flame retardants for road tunnel pavements. Constr. Build. Mater. 2021, 284, 122752. [Google Scholar] [CrossRef]

- Yang, X.; Shen, A.; Su, Y.; Zhao, W. Effects of alumina trihydrate (ATH) and organic montmorillonite (OMMT) on asphalt fume emission and flame retardancy properties of SBS-modified asphalt. Constr. Build. Mater. 2020, 236, 117576. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, Y.; Tan, G.; Shi, C. Pavement performance evaluation of asphalt mixtures containing oil shale waste. Road Mater. Pavement Des. 2018, 21, 179–200. [Google Scholar]

- Li, B.; Wen, Y.; Li, X.; Li, X. Laboratory Evaluation of Pavement Performance and Burning Behavior of Flame-Retardant Asphalt Mixtures. J. Test. Eval. 2017, 45, 9–17. [Google Scholar]

- Xia, W.; Wang, S.; Xu, T.; Jin, G. Flame retarding and smoke suppressing mechanisms of nano composite flame retardants on bitumen and bituminous mixture. Constr. Build. Mater. 2021, 266, 121203. [Google Scholar] [CrossRef]

- Luo, H.; Huang, X.; Rongyan, T.; Ding, H.; Huang, J.; Wang, D.; Liu, Y.; Hong, Z. Advanced method for measuring asphalt viscosity: Rotational plate viscosity method and its application to asphalt construction temperature prediction. Constr. Build. Mater. 2021, 301, 124129. [Google Scholar] [CrossRef]

- Yin, P.; Pan, B. Effect of RAP content on fatigue performance of hot-mixed recycled asphalt mixture. Constr. Build. Mater. 2022, 328, 127077. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, J.; Philbin, S.P.; Li, H.; Yang, J.; Feng, Y.; Ballesteros-Pérez, P.; Skitmore, M. Dynamic Quality Monitoring System to Assess the Quality of Asphalt Concrete Pavement. Buildings 2021, 11, 577. [Google Scholar] [CrossRef]

- Sun, M.; Li, B.; Yi, Z.; Cao, K.; Li, A.; Wang, Y. Optimization of surface free energy parameters for asphalt binder-aggregate system based on RBF neural network model. Constr. Build. Mater. 2022, 357, 129382. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, Y.; Zhao, P.; Liu, C. Study on aging behavior and prediction of SBS modified asphalt with various contents based on PCA and PLS analysis. Constr. Build. Mater. 2020, 265, 120732. [Google Scholar] [CrossRef]

- Wang, K.; Yuan, Y.; Han, S.; Yang, H. Application of attenuated total reflectance Fourier transform infrared (ATR-FTIR) and principal component analysis (PCA) for quick identifying of the bitumen produced by different manufacturers. Road Mater. Pavement Des. 2017, 19, 1940–1949. [Google Scholar] [CrossRef]

- Zhang, Q.; Ji, T.; Wang, Z.; Xiao, L. Experimental Study and Calculation of a Three-Dimensional Finite Element Model of Infiltration in Drainage Asphalt Pavement. Materials 2020, 13, 3909. [Google Scholar] [CrossRef]

- Wu, K.; Deng, Q.; Deng, N.; Cai, X.; Huang, W. Size Effects of Finite Element Model for Three-Dimensional Microstructural Modeling of Asphalt Mixture. Adv. Mater. Sci. Eng. 2019, 2019, 1754567. [Google Scholar] [CrossRef]

| Index | Test Value | Requirement | Test Method |

|---|---|---|---|

| Penetration at 25 °C/(0.1 mm) | 55.6 | 40–60 | T0604 |

| Ductility at 5 °C/cm | 363 | ≥20 | T0605 |

| Softening point/°C | 74.1 | ≥60 | T0606 |

| Dynamic viscosity at 60 °C/(Pa/s) | 2.52 | — | T0620 |

| Mass loss rate after RTFOT aging/% | 0.48 | −1.0–1.0 | T0609 |

| Index | Test Value | Requirement | Test Method |

|---|---|---|---|

| Crushing value/% | 9.6 | ≤26 | T0316 |

| Abrasion value/% | 14.2 | ≤28 | T0317 |

| Apparent relative density/(g/cm−3) | 2.817 | ≥2.60 | T0304 |

| Water absorption/% | 0.75 | <2 | T0304 |

| Index | Test Value |

|---|---|

| Density/(g/cm3) | 0.95 |

| Melting point/°C | 100 |

| Flash point/°C | 279 |

| Solubility | Water immiscible |

| Appearance | Faint yellow granules |

| Material Type | Appearance | Density/(g/cm3) | Solubility | Toxicity |

|---|---|---|---|---|

| Magnesium hydroxide | White powder | 2.38 | Water immiscible | Non-toxic |

| Diatomite | White powder | 2.26 | Water immiscible | Non-toxic |

| Aluminum hydroxide | White powder | 2.42 | Water immiscible | Non-toxic |

| VA | Concentration/(ng/L) | Warm Mix Flame Retardant Asphalt | Concentration/(ng/L) |

|---|---|---|---|

| toluene | 139.5 | acrolein | 87.3 |

| acetone | 62.1 | acetone | 65.9 |

| p/m-xylene | 53.4 | propane | 43.2.8 |

| acrolein | 53.2 | n-butane | 39.2 |

| propane | 48.5 | ethane | 35.9 |

| propylene | 41.6 | n-pentane | 32.3 |

| ethane | 40.7 | propylene | 24.3 |

| n-butane | 39.1 | benzene | 23.9 |

| n-hexane | 38.7 | n-hexane | 23.3 |

| n-pentane | 37.6 | heptane | 21.4 |

| Variable | Initial Eigenvalue | Extraction of the Square Sum of Loads | ||||

|---|---|---|---|---|---|---|

| Total | Variance Percentage/% | Cumulative/% | Total | Variance Percentage/% | Cumulative/% | |

| x1 | 1.887 | 62.893 | 62.893 | 1.887 | 62.893 | 62.893 |

| x2 | 1.002 | 33.396 | 96.289 | 1.002 | 33.396 | 96.289 |

| x3 | 0.111 | 3.711 | 100 | |||

| Variable | Principal Component 1 | Principal Component 2 | Score Coefficient 1 | Score Coefficient 2 | Weight Coefficient |

|---|---|---|---|---|---|

| x1 | 0.972 | 0.007 | 0.515 | 0.007 | 0.363438612 |

| x2 | 0.962 | −0.141 | 0.51 | −0.141 | 0.319604899 |

| x3 | 0.13 | 0.991 | 0.069 | 0.989 | 0.316956489 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, P.; Wang, H.; Tan, Y. The Evaluation and Prediction of Flame Retardancy of Asphalt Mixture Based on PCA-RBF Neural Network Model. Materials 2024, 17, 3298. https://doi.org/10.3390/ma17133298

Yin P, Wang H, Tan Y. The Evaluation and Prediction of Flame Retardancy of Asphalt Mixture Based on PCA-RBF Neural Network Model. Materials. 2024; 17(13):3298. https://doi.org/10.3390/ma17133298

Chicago/Turabian StyleYin, Peng, Haowu Wang, and Yangwei Tan. 2024. "The Evaluation and Prediction of Flame Retardancy of Asphalt Mixture Based on PCA-RBF Neural Network Model" Materials 17, no. 13: 3298. https://doi.org/10.3390/ma17133298

APA StyleYin, P., Wang, H., & Tan, Y. (2024). The Evaluation and Prediction of Flame Retardancy of Asphalt Mixture Based on PCA-RBF Neural Network Model. Materials, 17(13), 3298. https://doi.org/10.3390/ma17133298