Study on Mechanical Properties of Nanopores in CoCrFeMnNi High-Entropy Alloy Used as Drug-Eluting Stent

Abstract

1. Introduction

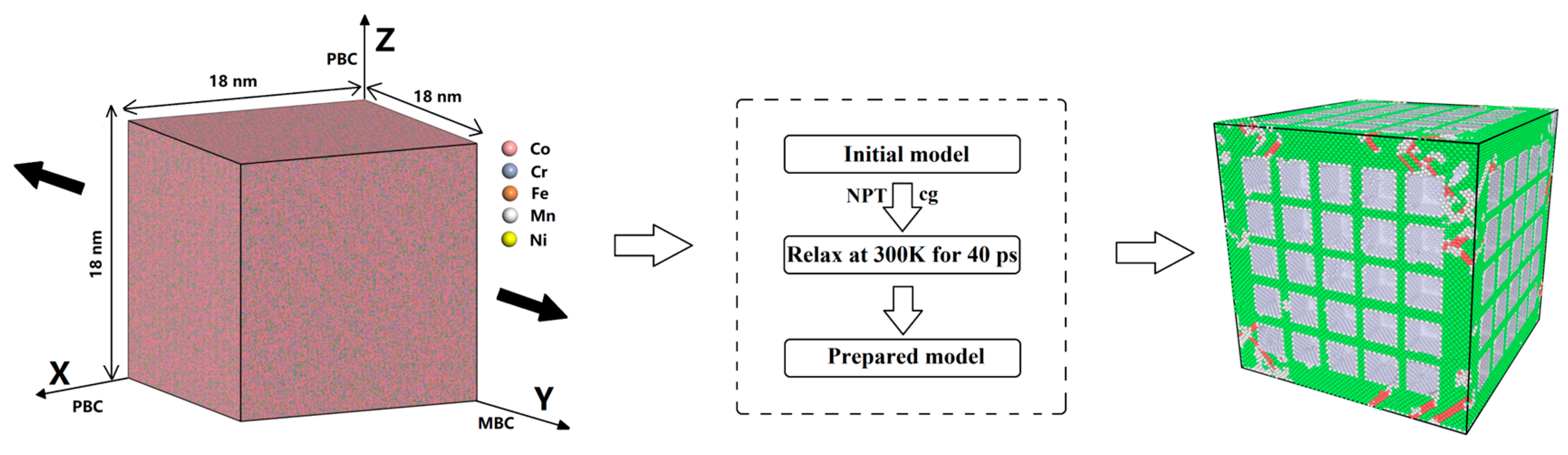

2. Modeling and Simulation Methods

2.1. Force Potential

2.2. Method and Software

3. Results and Discussion

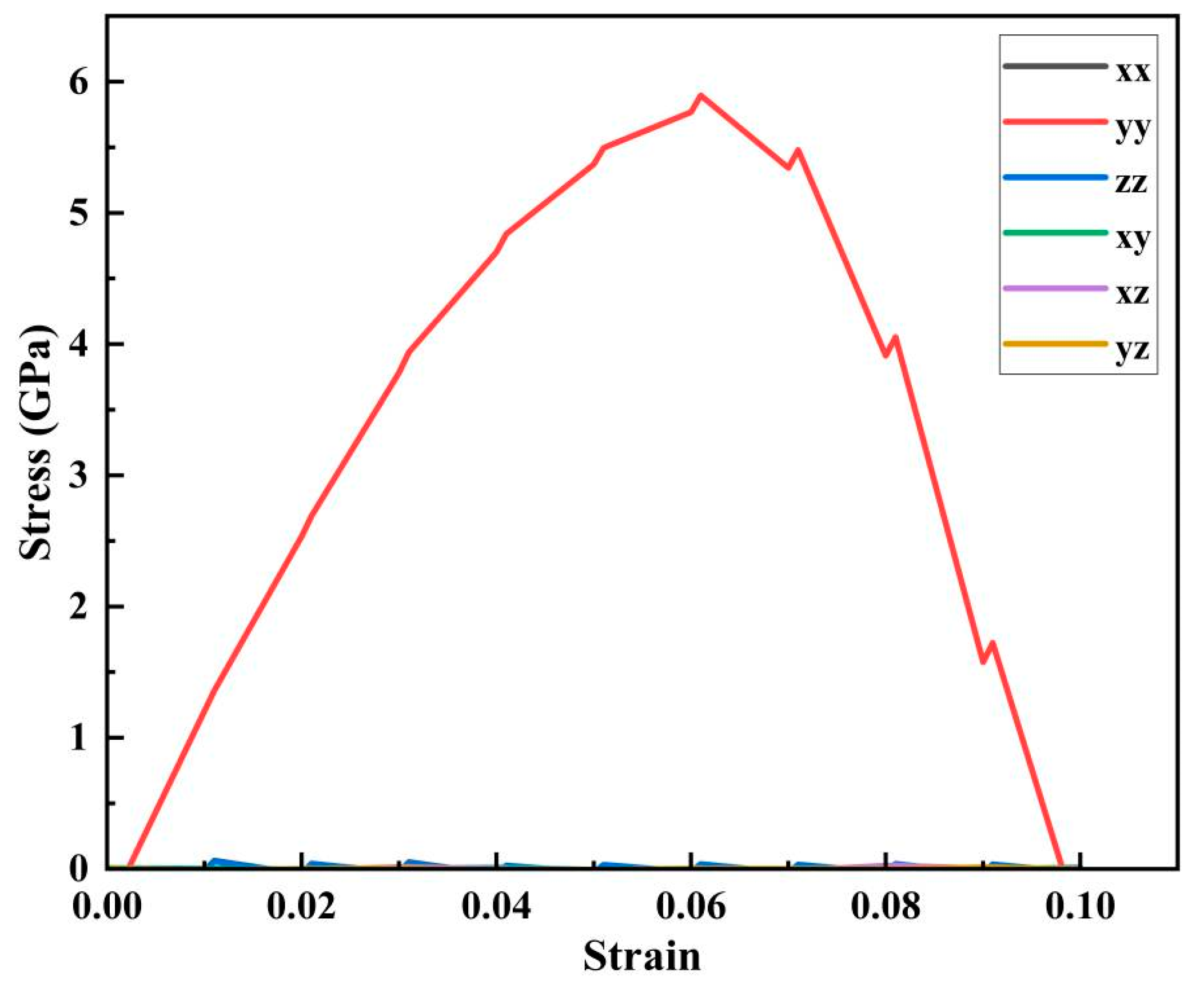

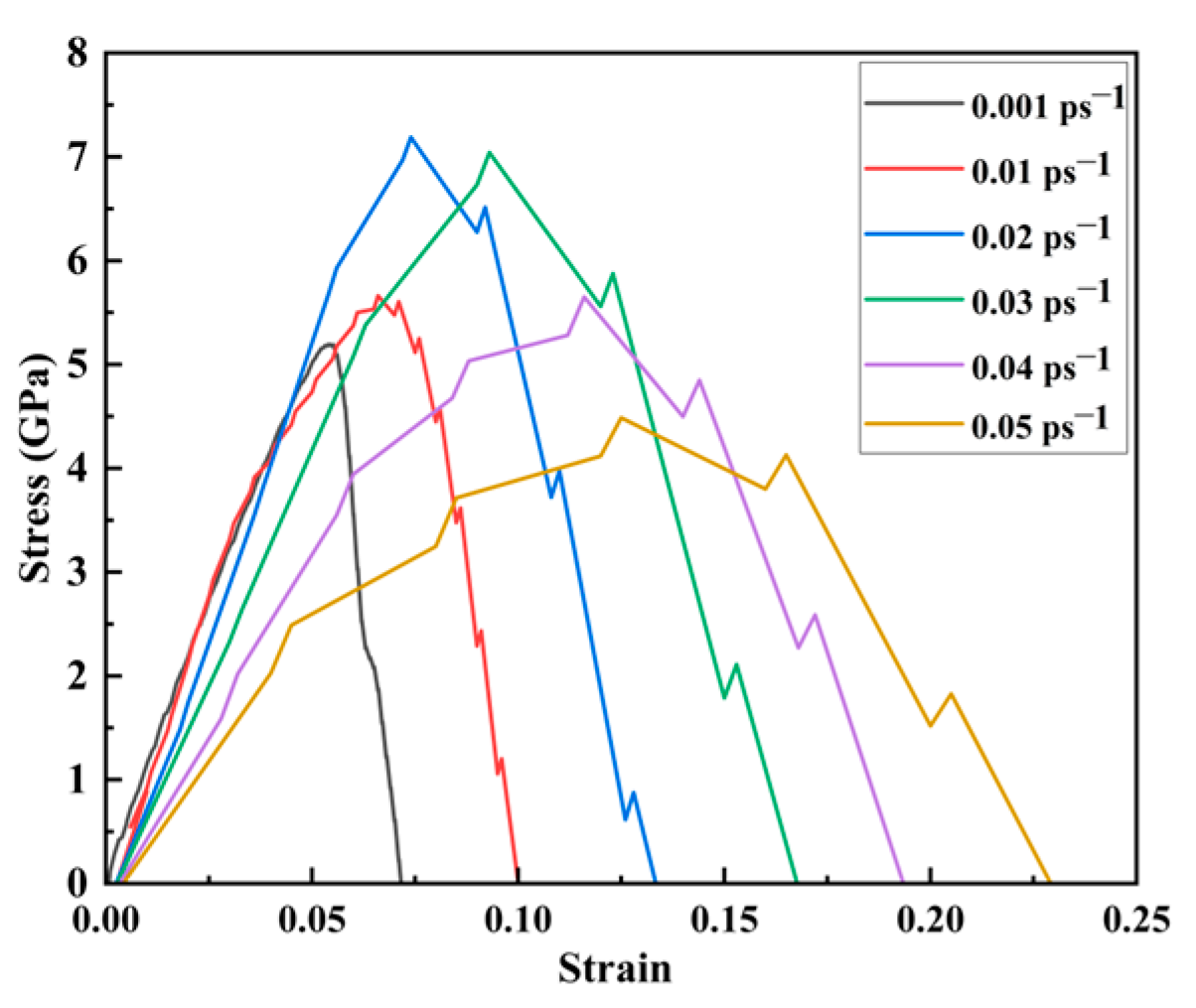

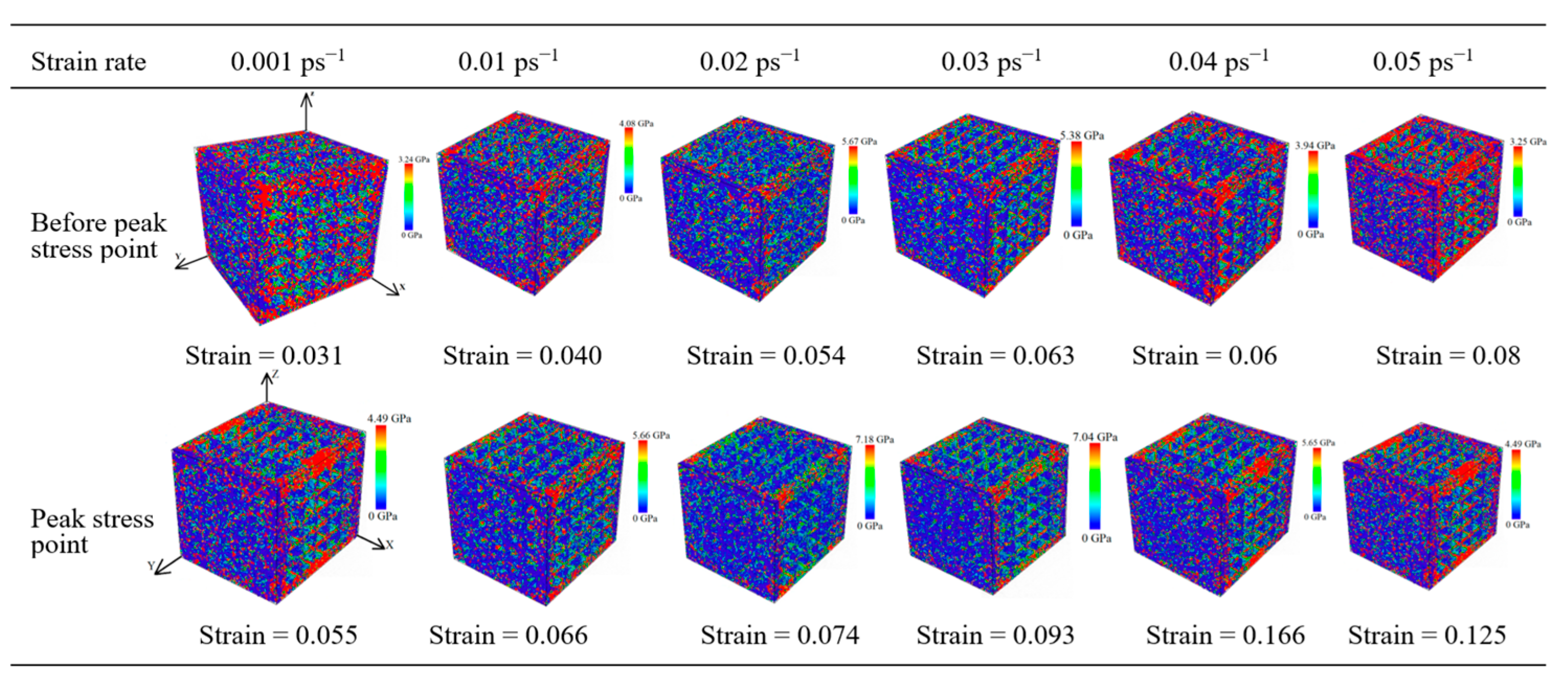

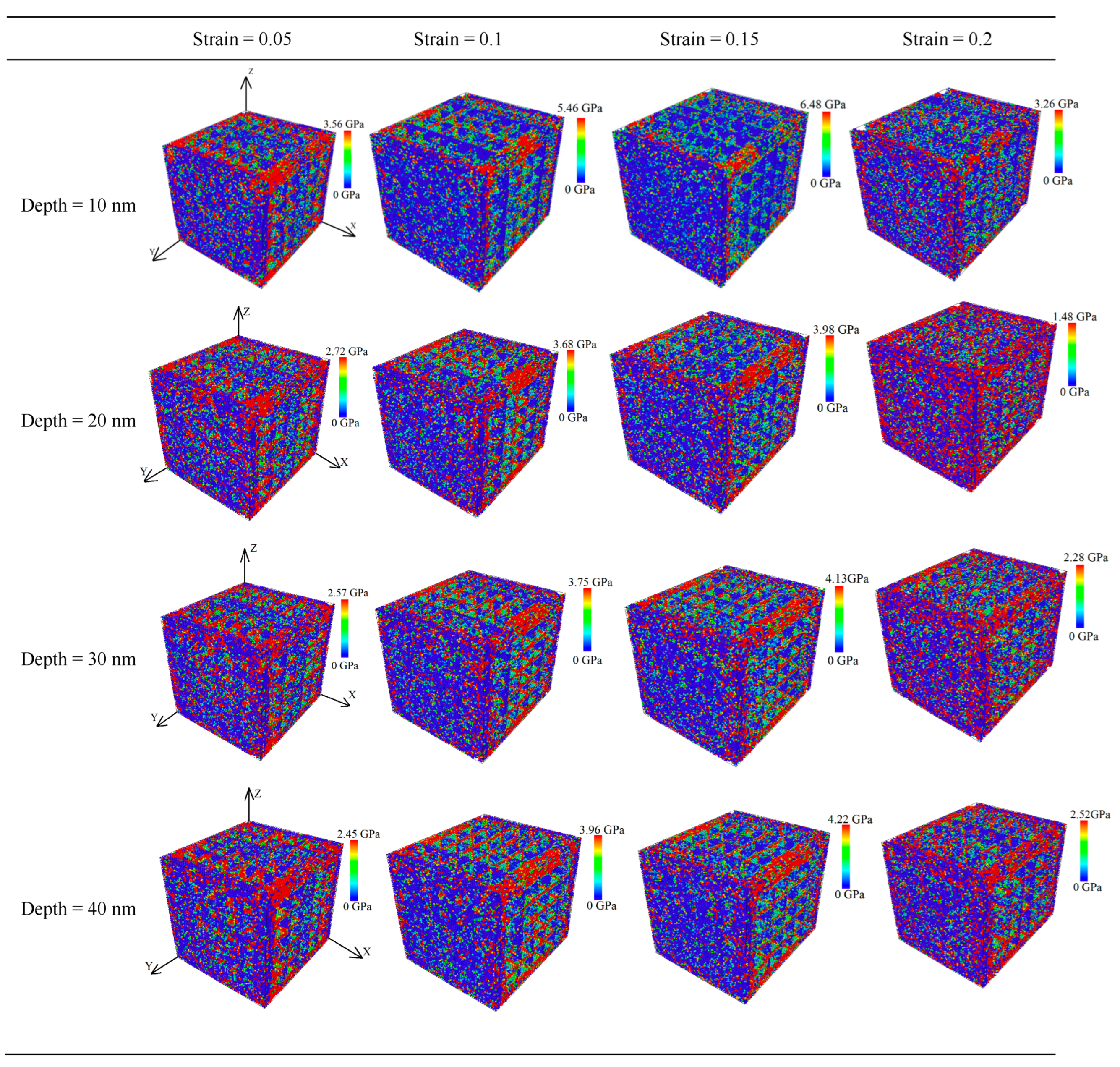

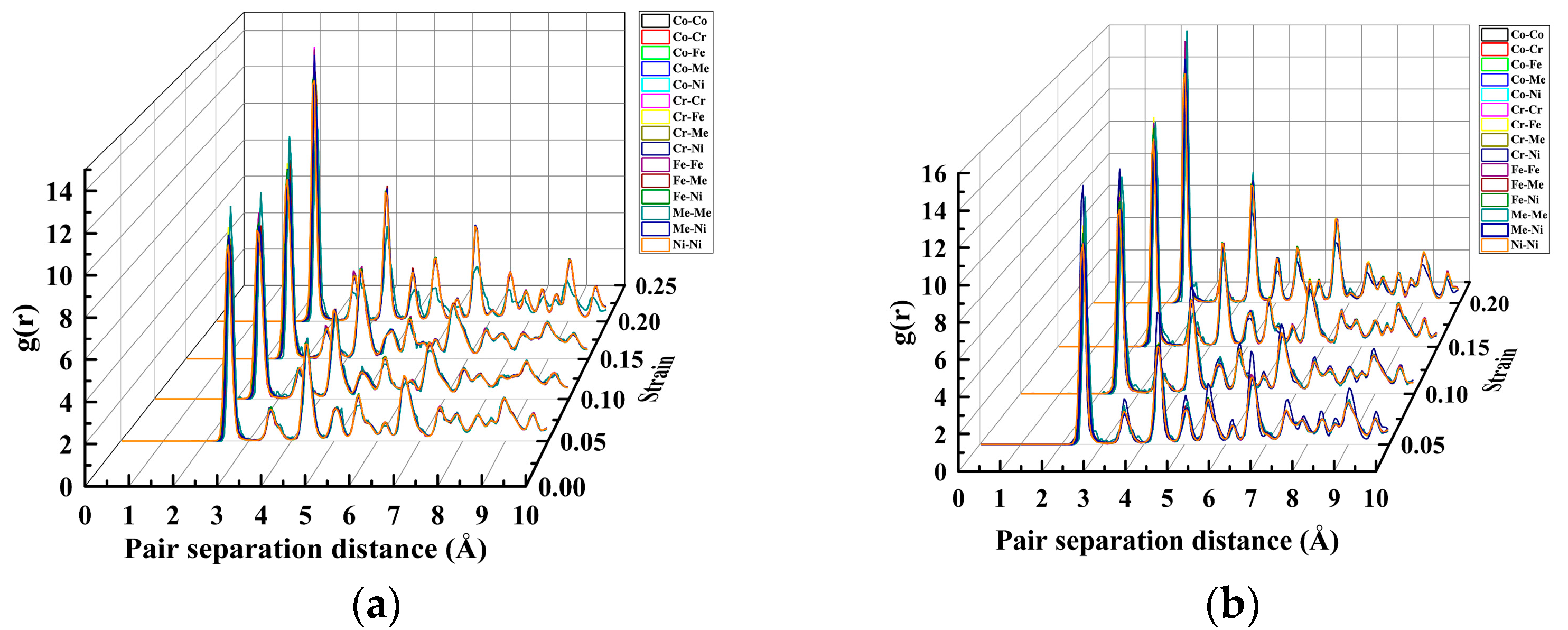

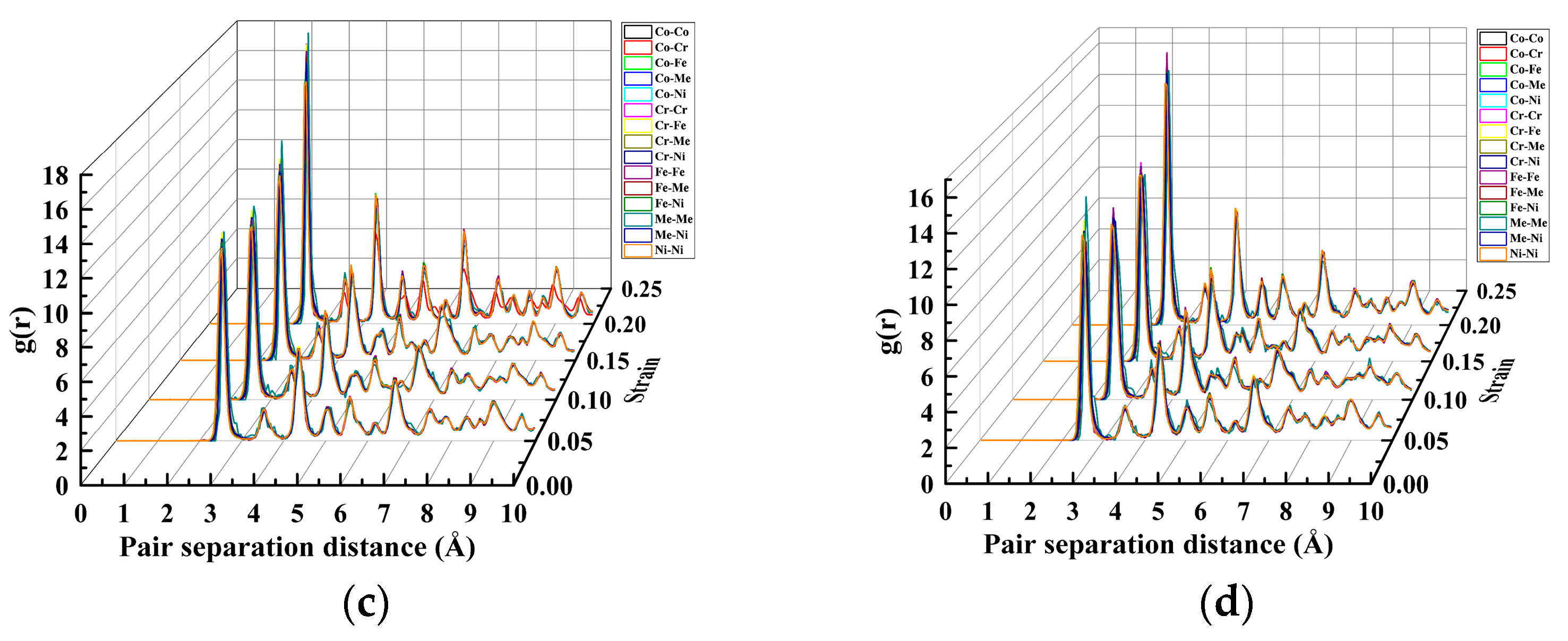

3.1. Analysis of the Stress Evolution Mechanism of the High-Entropy Alloy Containing Nanopores under Different Tensile Strain Rates

3.2. Tensile Mechanics Evolution of the CoCrFeMnNi High-Entropy Alloy with Different Depths of Nanopores

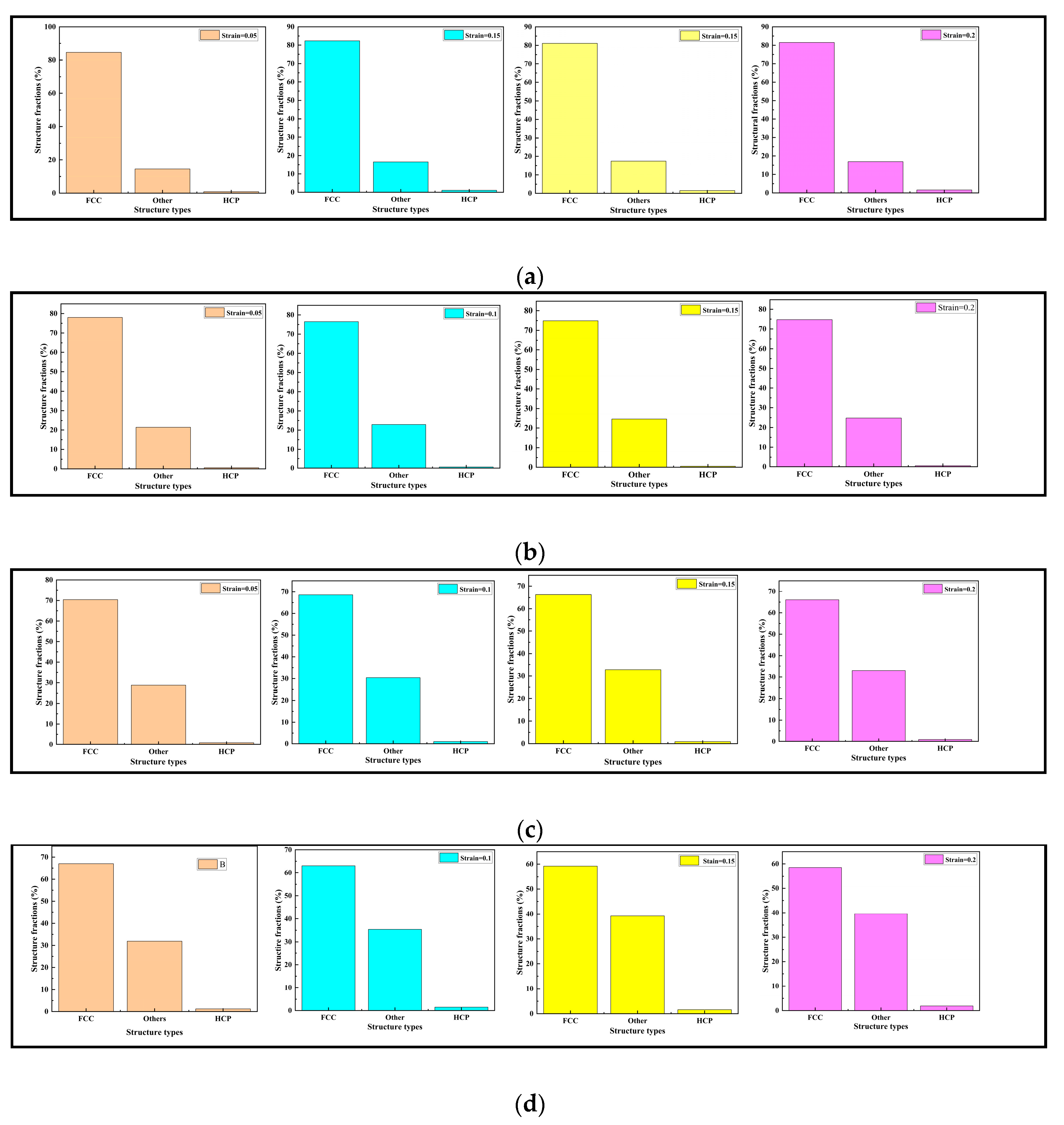

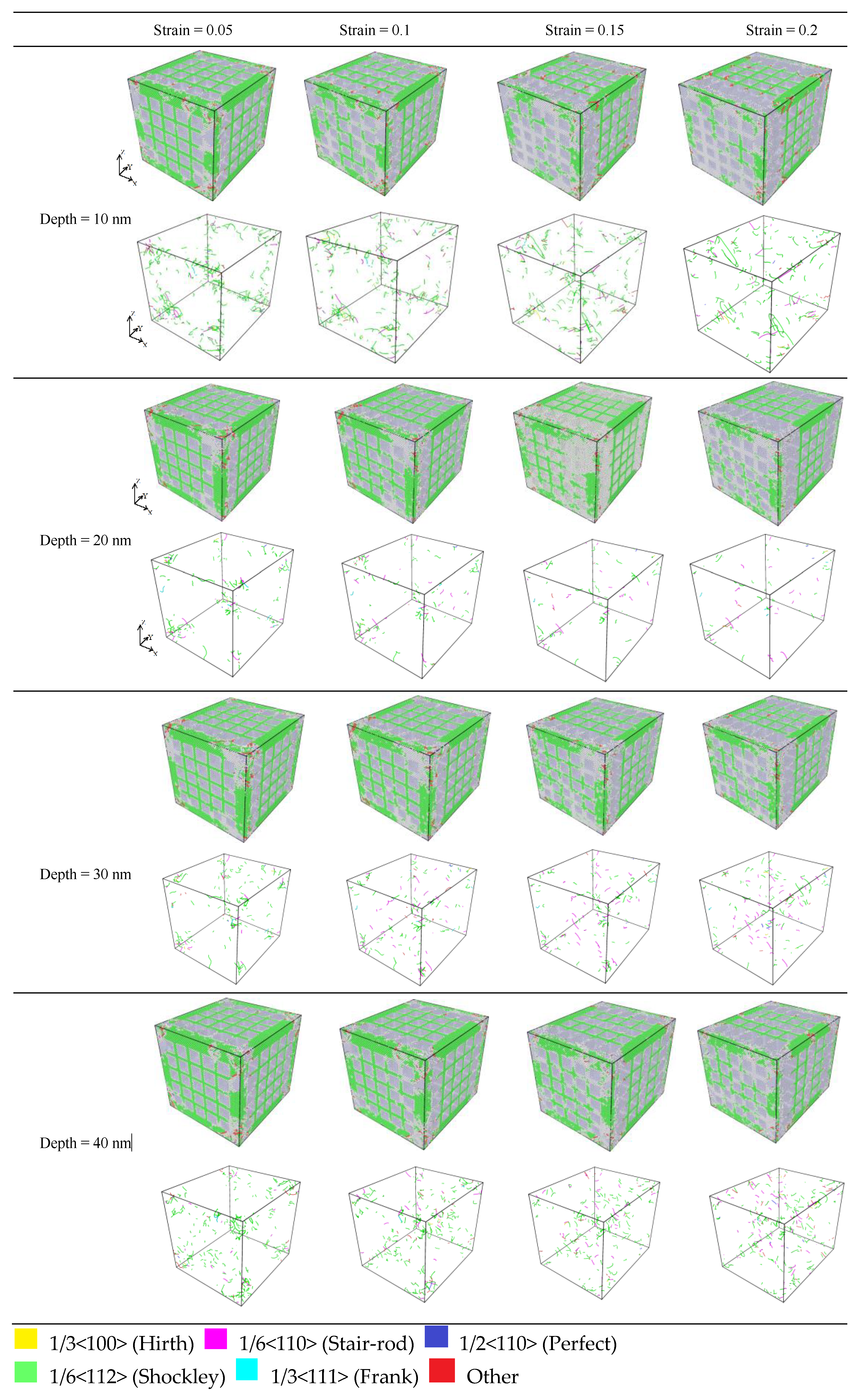

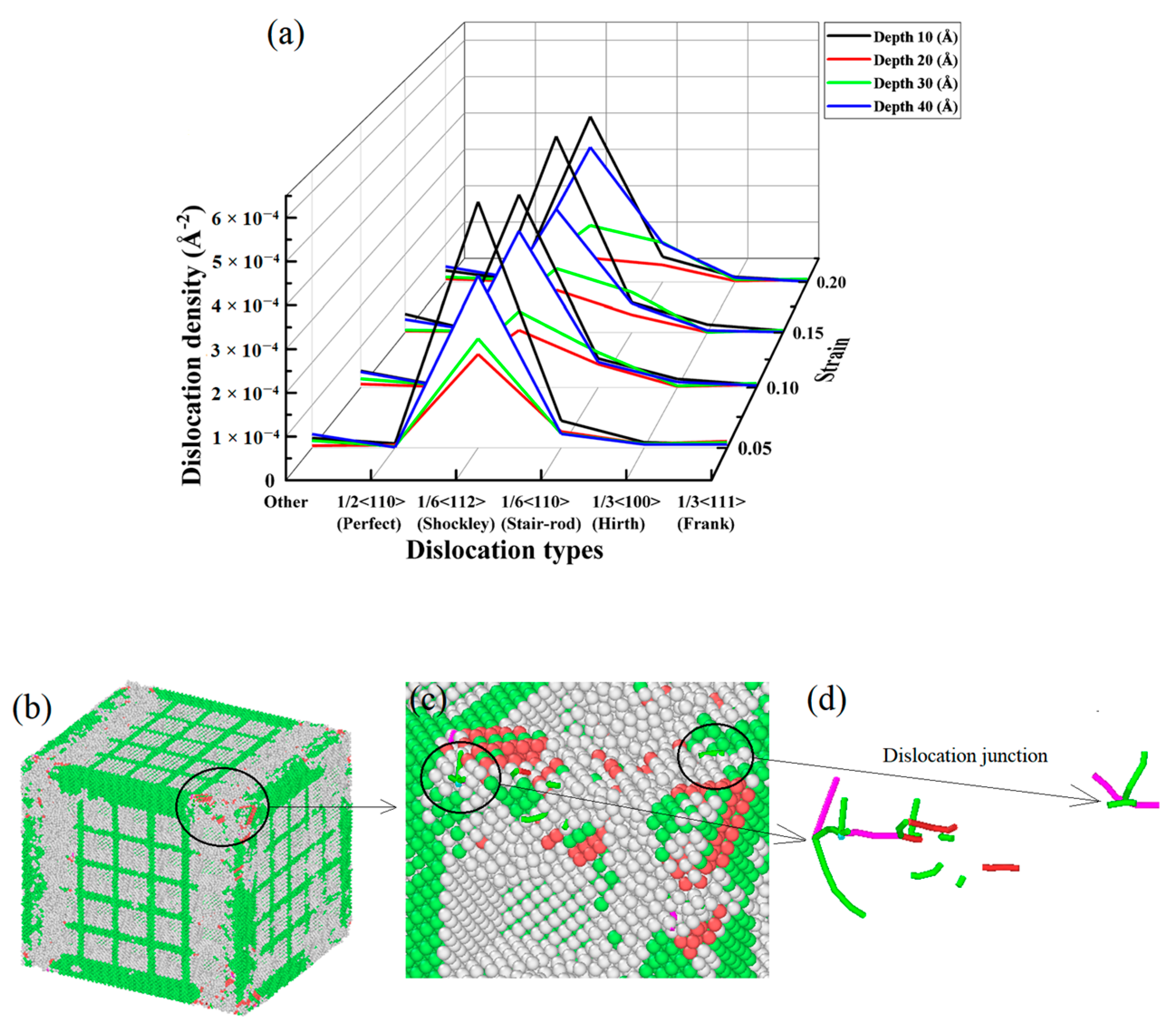

Crystal Structure and Dislocation Evolution Mechanism of the CoCrFeMnNi High-Entropy Alloy Containing Nanopores at Different Depths

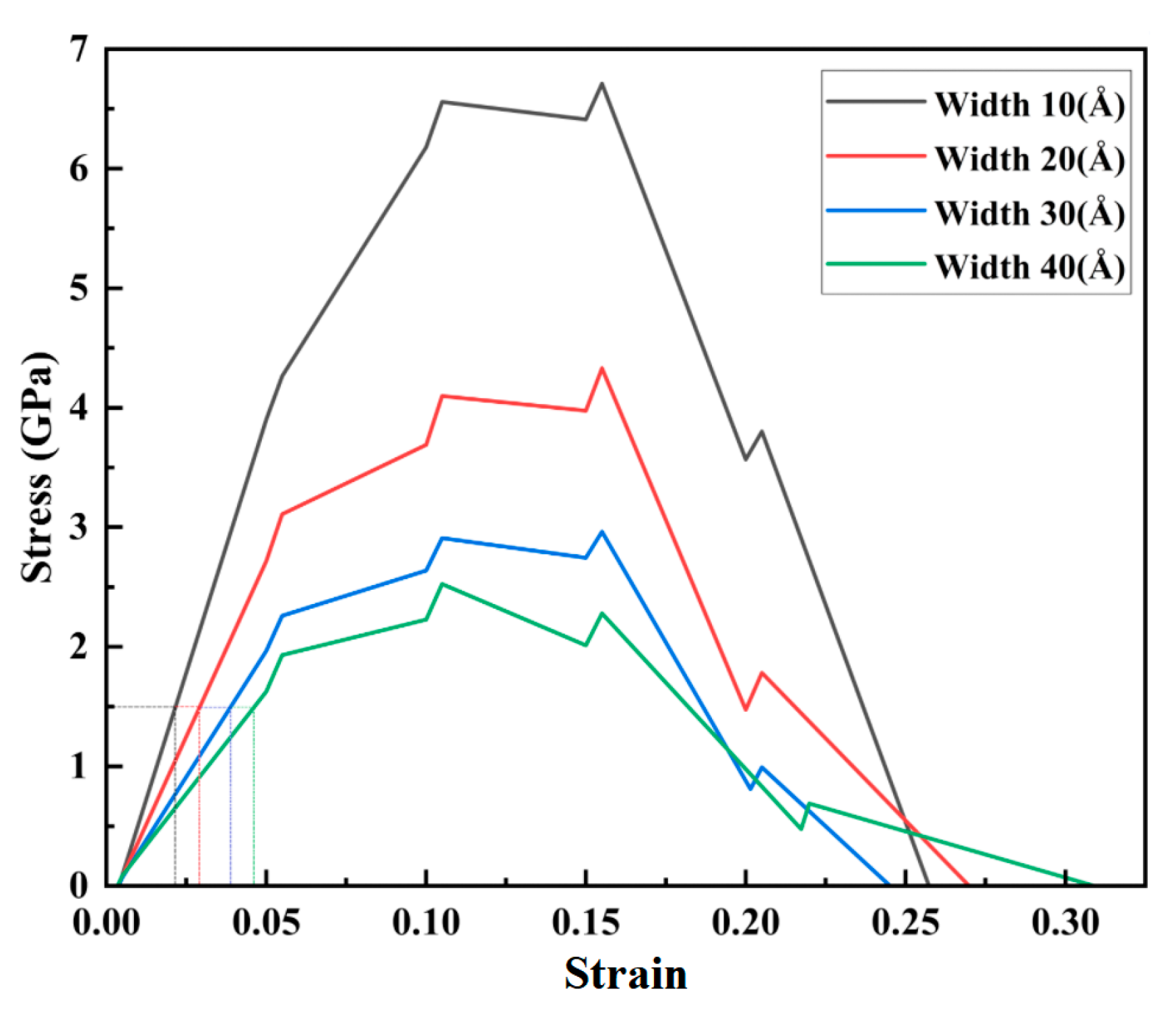

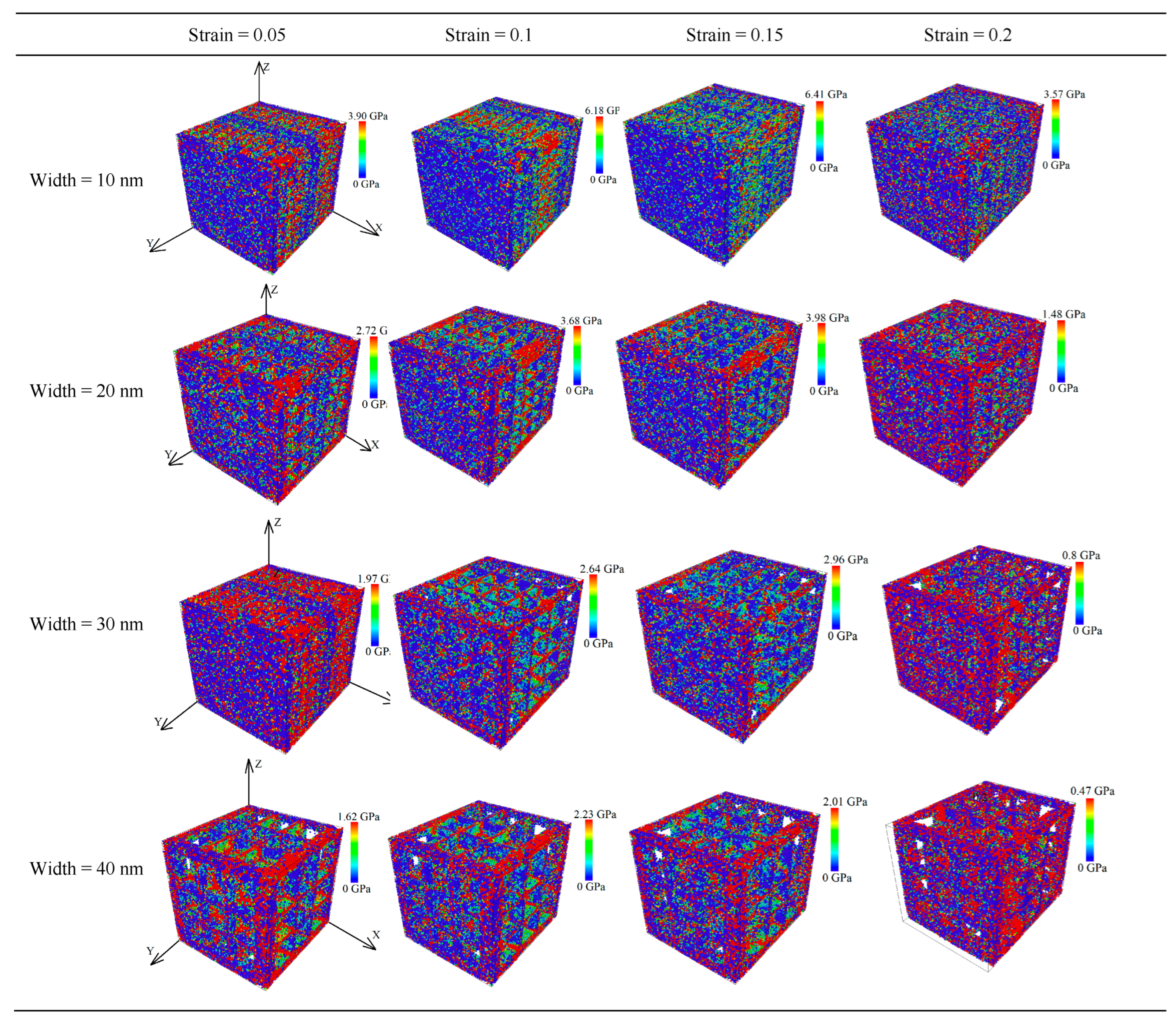

3.3. Analysis of the Stress Evolution Mechanism of High-Entropy Alloys Containing Nanopores of Different Dimensions and Widths

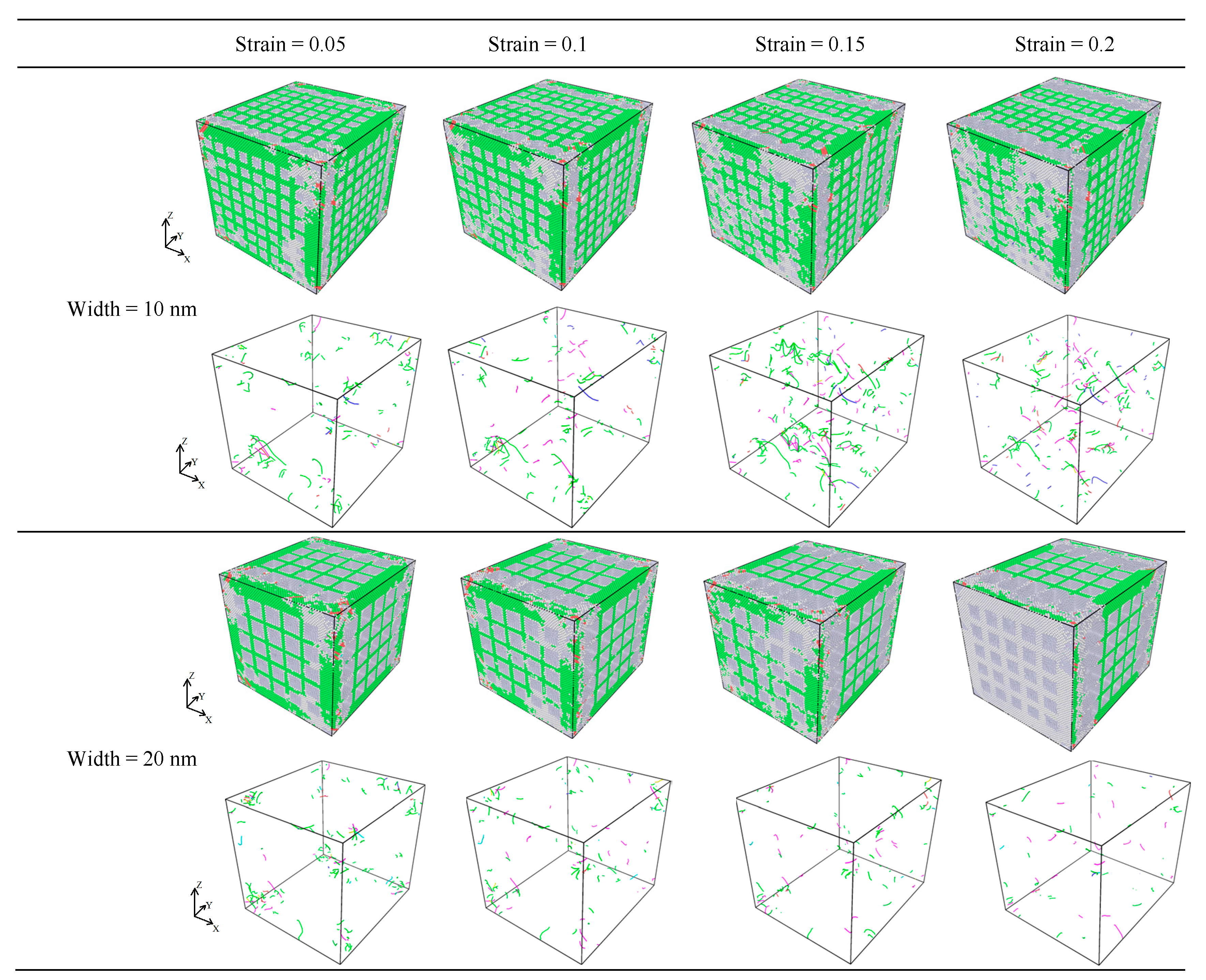

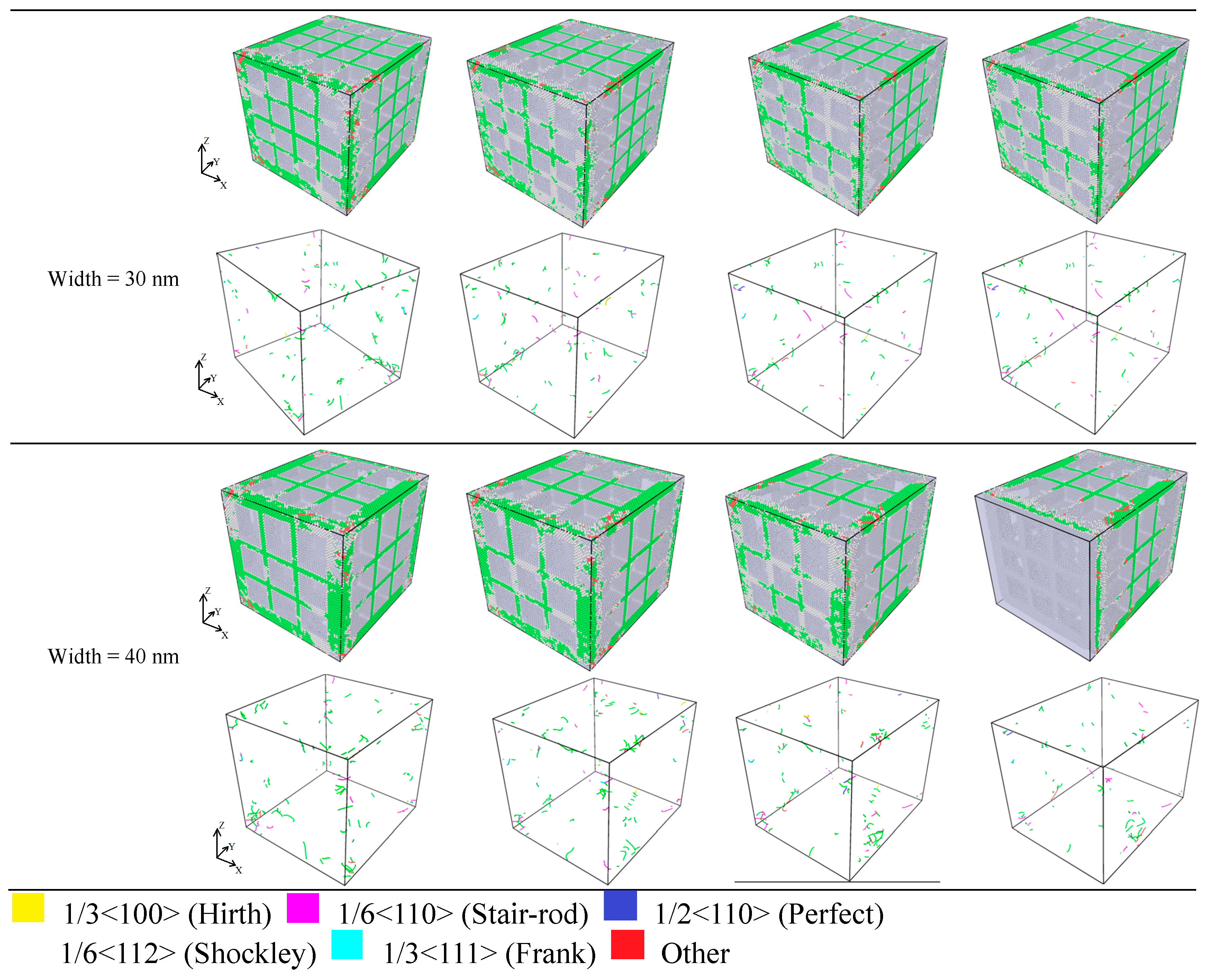

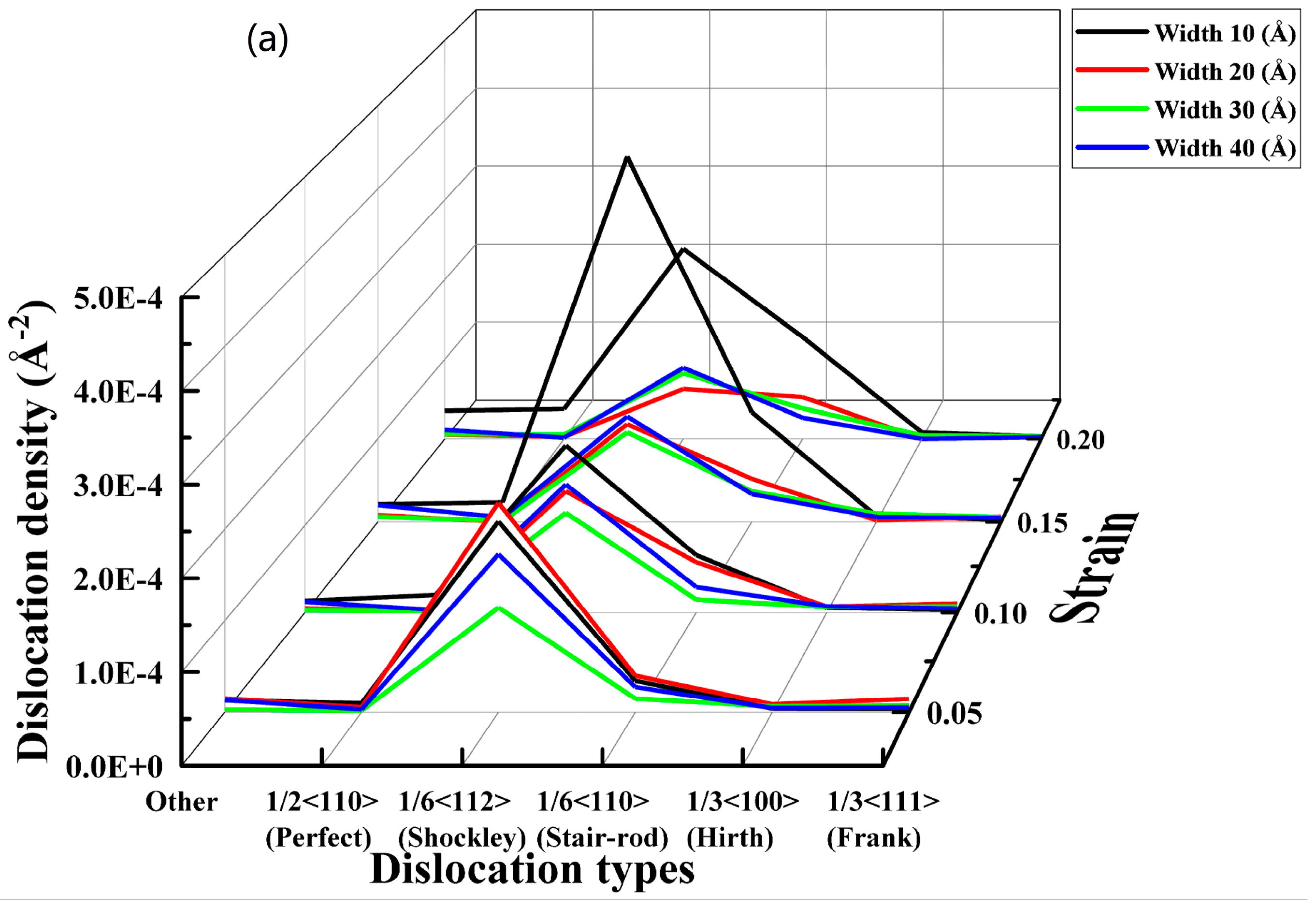

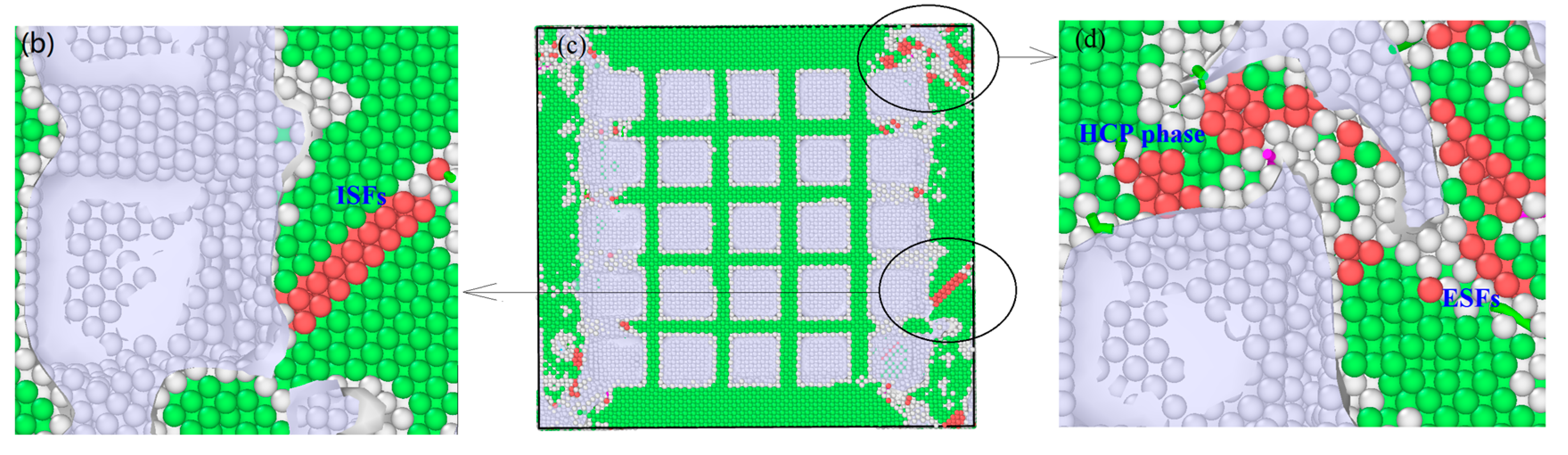

Influence of Different Nanopore Widths on the Dislocation Evolution of the High-Entropy Alloy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roth, G.A.; Mensah, G.A.; Johnson, C.O.; Addolorato, G.; Ammirati, E.; Baddour, L.M.; Barengo, N.C.; Beaton, A.Z.; Benjamin, E.J.; Benziger, C.P.; et al. Global Burden of Cardiovascular Diseases and Risk Factors, 1990–2019: Update From the GBD 2019 Study. J. Am. Coll. Cardiol. 2020, 76, 2982–3021. [Google Scholar] [CrossRef] [PubMed]

- GBD 2019 Risk Factors Collaborators. Global burden of 87 risk factors in 204 countries and territories, 1990–2019: A systematic analysis for the Global Burden of Disease Study 2019. Lancet 2020, 396, 1223–1249. [Google Scholar] [CrossRef] [PubMed]

- Helmus, M.; Medlin, D. Medical device materials II. In Proceedings of the Materials & Processes for Medical Devices Conference 2004, Materials Park, St. Paul, MN, USA, 25–27 August 2004; Brill Academic Publishers: Leiden, The Netherlands, 2005. [Google Scholar]

- Kang, H.-J.; Kim, D.J.; Park, S.-J.; Yoo, J.-B.; Ryu, Y. Controlled drug release using nanoporous anodic aluminum oxide on stent. Thin Solid Films 2007, 515, 5184–5187. [Google Scholar] [CrossRef]

- Burt, H.M.; Hunter, W.L. Drug-eluting stents: A multidisciplinary success story. Adv. Drug Deliv. Rev. 2006, 58, 350–357. [Google Scholar] [CrossRef] [PubMed]

- Saleh, Y.E.; Gepreel, M.A.; Allam, N.K. Functional nanoarchitectures for enhanced drug eluting stents. Sci. Rep. 2017, 7, 40291. [Google Scholar] [CrossRef] [PubMed]

- Lansky, A.J.; Costa, R.A.; Mintz, G.S.; Tsuchiya, Y.; Midei, M.; Cox, D.A.; O’shaughnessy, C.; Applegate, R.A.; Cannon, L.A.; Mooney, M.; et al. Non-polymer-based paclitaxel-coated coronary stents for treating patients with de novo coronary lesions: Angiographic follow-up of the DELIVER clinical trial. Circulation 2004, 109, 1948–1954. [Google Scholar] [CrossRef] [PubMed]

- Chan, K.; Armstrong, J.; Withers, S.; Malik, N.; Cumberland, D.; Gunn, J.; Holt, C. Vascular delivery of c-myc antisense from cationically modified phosphorylcholine coated stents. Biomaterials 2007, 28, 1218–1224. [Google Scholar] [CrossRef]

- Finn, A.V.; Gold, H.K. One-year clinical results with the slow-release, polymer-based, paclitaxel-eluting TAXUS stent in patients with diabetes mellitus. Circulation 2004, 110, 1942–1947. [Google Scholar] [CrossRef][Green Version]

- Campo, G.; Tebaldi, M.; Vranckx, P.; Biscaglia, S.; Tumscitz, C.; Ferrari, R.; Valgimigli, M. Short- versus long-term duration of dual antiplatelet therapy in patients treated for in-stent restenosis: A prodigy trial substudy (Prolonging Dual Antiplatelet Treatment After Grading Stent-Induced Intimal Hyperplasia). J. Am. Coll. Cardiol. 2014, 63, 506–512. [Google Scholar] [CrossRef]

- Lei, J.; Vodovotz, Y.; Tzeng, E.; Billiar, T.R. Nitric oxide, a protective molecule in the cardiovascular system. Nitric Oxide 2013, 35, 175–185. [Google Scholar] [CrossRef]

- Furchgott, R.F.; Zawadzki, J.V. The obligatory role of endothelial cells in the relaxation of arterial smooth muscle by acetylcholine. Nature 1980, 288, 373–376. [Google Scholar] [CrossRef] [PubMed]

- Huan, Z.; Fratila-Apachitei, L.E.; Apachitei, I.; Duszczyk, J. Characterization of porous TiO2 surfaces formed on 316L stainless steel by plasma electrolytic oxidation for stent applications. J. Funct. Biomater. 2012, 3, 349–360. [Google Scholar] [CrossRef] [PubMed]

- Kothwala, D.; Sudheer, S.K.; Prathibha, S.; Engineer, C.; Raval, A.; Kotadia, H. Laser microfabrication of L605 cobalt-chromium cardiovascular stent implants with modulated pulsed Nd:YAG laser. J. Micro/Nanolithogr. MEMS MOEMS 2008, 7, 033012. [Google Scholar] [CrossRef]

- Ruan, X.; Yuan, W.; Hu, Y.; Li, J.; Wu, W.; Xia, R. Chiral constrained stent: Effect of structural design on the mechanical and intravascular stent deployment performances. Mech. Mater. 2020, 148, 103509. [Google Scholar] [CrossRef]

- Eshghi, N.; Hojjati, M.; Imani, M.; Goudarzi, A. Finite Element Analysis of Mechanical Behaviors of Coronary Stent. Procedia Eng. 2011, 10, 3056–3061. [Google Scholar] [CrossRef]

- Bae, I.-H.; Lim, K.-S.; Park, J.-K.; Park, D.-S.; Lee, S.-Y.; Jang, E.-J.; Ji, M.S.; Sim, D.S.; Hong, Y.J.; Ahn, Y.; et al. Mechanical behavior and in vivo properties of newly designed bare metal stent for enhanced flexibility. J. Ind. Eng. Chem. 2015, 21, 1295–1300. [Google Scholar] [CrossRef]

- Qi, Y.; Chen, X.; Feng, M. Molecular dynamics-based analysis of the effect of voids and HCP-Phase inclusion on deformation of single-crystal CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2020, 791, 139444. [Google Scholar] [CrossRef]

- Qiu, Y.; Qi, Y.; Zheng, H.; He, T.; Feng, M. Atomistic simulation of nanoindentation response of dual-phase nanocrystalline CoCrFeMnNi high-entropy alloy. J. Appl. Phys. 2021, 130, 125102. [Google Scholar] [CrossRef]

- Phan, T.; Jones, J.E.; Chen, M.; Bowles, D.K.; Fay, W.P.; Yu, Q. A biocompatibility study of plasma nanocoatings onto cobalt chromium L605 alloy for cardiovascular stent applications. Materials 2022, 15, 5968. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Gröger, R.; Vitek, V.; Dlouhy, A. Effective pair potential for random fcc CoCrFeMnNi alloys. Model. Simul. Mater. Sci. Eng. 2020, 28, 075006. [Google Scholar] [CrossRef]

- Ashcroft, N.W.; Mermin, N.D.; Smoluchowski, R. Solid State Physics. Phys. Today 1977, 30, 61–65. [Google Scholar] [CrossRef]

- Kittel, C.; Dexter, D.L. Introduction to solid state physics. Am. J. Phys. 1954, 21, 650. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Pradeep, K.; Kuběnová, M.; Raabe, D.; Eggeler, G.; George, E. Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Mater. 2016, 112, 40–52. [Google Scholar] [CrossRef]

- Grippo, L.; Lucidi, S. A globally convergent version of the Polak-Ribière conjugate gradient method. Math. Program. 1997, 78, 375–391. [Google Scholar] [CrossRef]

- Daramola, A.; Bonny, G.; Adjanor, G.; Domain, C.; Monnet, G.; Fraczkiewicz, A. Development of a plasticity-oriented interatomic potential for CrFeMnNi high entropy alloys. Comput. Mater. Sci. 2022, 203, 111165. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Qi, Y.; Xu, H.; He, T.; Wang, M.; Feng, M. Atomistic simulation of deformation behaviors polycrystalline CoCrFeMnNi high-entropy alloy under uniaxial loading. Int. J. Refract. Met. Hard Mater. 2021, 95, 105415. [Google Scholar] [CrossRef]

| Element 1 | Element 2 | |||

|---|---|---|---|---|

| Co | Co | 2.271 | 0.227 | |

| Cr | Cr | 2.315 | 0.222 | |

| Fe | Fe | 2.301 | 0.232 | 6.60 |

| Mn | Mn | 2.505 | 0.122 | |

| Ni | Ni | 2.264 | 0.230 | |

| Co | Cr | 2.293 | 0.225 | |

| Co | Fe | 2.286 | 0.230 | 6.60 |

| Co | Mn | 2.388 | 0.166 | |

| Co | Ni | 2.268 | 0.229 | |

| Cr | Fe | 2.308 | 0.227 | 6.60 |

| Cr | Mn | 2.410 | 0.164 | |

| Cr | Ni | 2.289 | 0.226 | |

| Fe | Mn | 2.403 | 0.168 | 6.60 |

| Fe | Ni | 2.283 | 0.231 | |

| Mn | Ni | 2.384 | 0.167 | 6.60 |

| Element | Cr | Fe | Mn | Ni | Co |

|---|---|---|---|---|---|

| Content (%) | 0.2 | 0.03 | 0.015 | 0.1 | Balance |

| Box Dimension (Å) | Pore Width (nm) | Pore Depth (nm) | Tensile Rate |

|---|---|---|---|

| 40 | 40 | 0.0001/Ps | |

| 180 × 180 × 180 | 30 | 30 | 0.001/Ps |

| 20 | 20 | 0.002/Ps | |

| 10 | 10 | 0.003/Ps | |

| - | - | 0.004/Ps | |

| - | - | 0.005/Ps |

| Analysis Classification | Number | Pore Width (nm) | Pore Depth (nm) | Strain Rate (ps−1) |

|---|---|---|---|---|

| Different tensile rate | ① | 20 | 20 | 0.0001 |

| ② | 20 | 20 | 0.001 | |

| ③ | 20 | 20 | 0.002 | |

| ④ | 20 | 20 | 0.003 | |

| ⑤ | 20 | 20 | 0.004 | |

| ⑥ | 20 | 20 | 0.005 | |

| Different pore width | ⑦ | 10 | 10 | 0.005 |

| ⑧ | 20 | 10 | 0.005 | |

| ⑨ | 30 | 10 | 0.005 | |

| ⑩ | 40 | 10 | 0.005 | |

| Different pore depth | ⑪ | 20 | 10 | 0.005 |

| ⑫ | 20 | 20 | 0.005 | |

| ⑬ | 20 | 30 | 0.005 | |

| ⑭ | 20 | 40 | 0.005 |

| Width | Structure | Fraction (%) | Variable (%) | |

|---|---|---|---|---|

| Strain (0.05) | Strain (0.2) | |||

| 10 nm | FCC | 77.4 | 75 | −2.4 |

| Other | 22.1 | 24.2 | +2.1 | |

| HCP | 0.5 | 0.8 | +0.3 | |

| 30 nm | FCC | 78 | 75.2 | −2.8 |

| Other | 21.4 | 24.3 | +2.9 | |

| HCP | 0.6 | 0.5 | −0.1 | |

| 40 nm | FCC | 79.4 | 77.2 | −2.2 |

| Other | 20.2 | 22.2 | +2.0 | |

| HCP | 0.4 | 0.6 | +0.2 | |

| 50 nm | FCC | 80.62 | 76.9 | −3.72 |

| Other | 18.83 | 22.6 | +3.77 | |

| HCP | 0.544 | 0.5 | −0.044 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Ji, C.; Hou, D.; Jiang, S.; Yang, Z.; Dong, F.; Liu, S. Study on Mechanical Properties of Nanopores in CoCrFeMnNi High-Entropy Alloy Used as Drug-Eluting Stent. Materials 2024, 17, 3314. https://doi.org/10.3390/ma17133314

Zhou Z, Ji C, Hou D, Jiang S, Yang Z, Dong F, Liu S. Study on Mechanical Properties of Nanopores in CoCrFeMnNi High-Entropy Alloy Used as Drug-Eluting Stent. Materials. 2024; 17(13):3314. https://doi.org/10.3390/ma17133314

Chicago/Turabian StyleZhou, Zhen, Chaoyue Ji, Dongyang Hou, Shunyong Jiang, Zihan Yang, Fang Dong, and Sheng Liu. 2024. "Study on Mechanical Properties of Nanopores in CoCrFeMnNi High-Entropy Alloy Used as Drug-Eluting Stent" Materials 17, no. 13: 3314. https://doi.org/10.3390/ma17133314

APA StyleZhou, Z., Ji, C., Hou, D., Jiang, S., Yang, Z., Dong, F., & Liu, S. (2024). Study on Mechanical Properties of Nanopores in CoCrFeMnNi High-Entropy Alloy Used as Drug-Eluting Stent. Materials, 17(13), 3314. https://doi.org/10.3390/ma17133314