On the Feasibility of an LCD-Based Real-Time Converter for Ionizing Radiation Imaging

Abstract

:1. Introduction

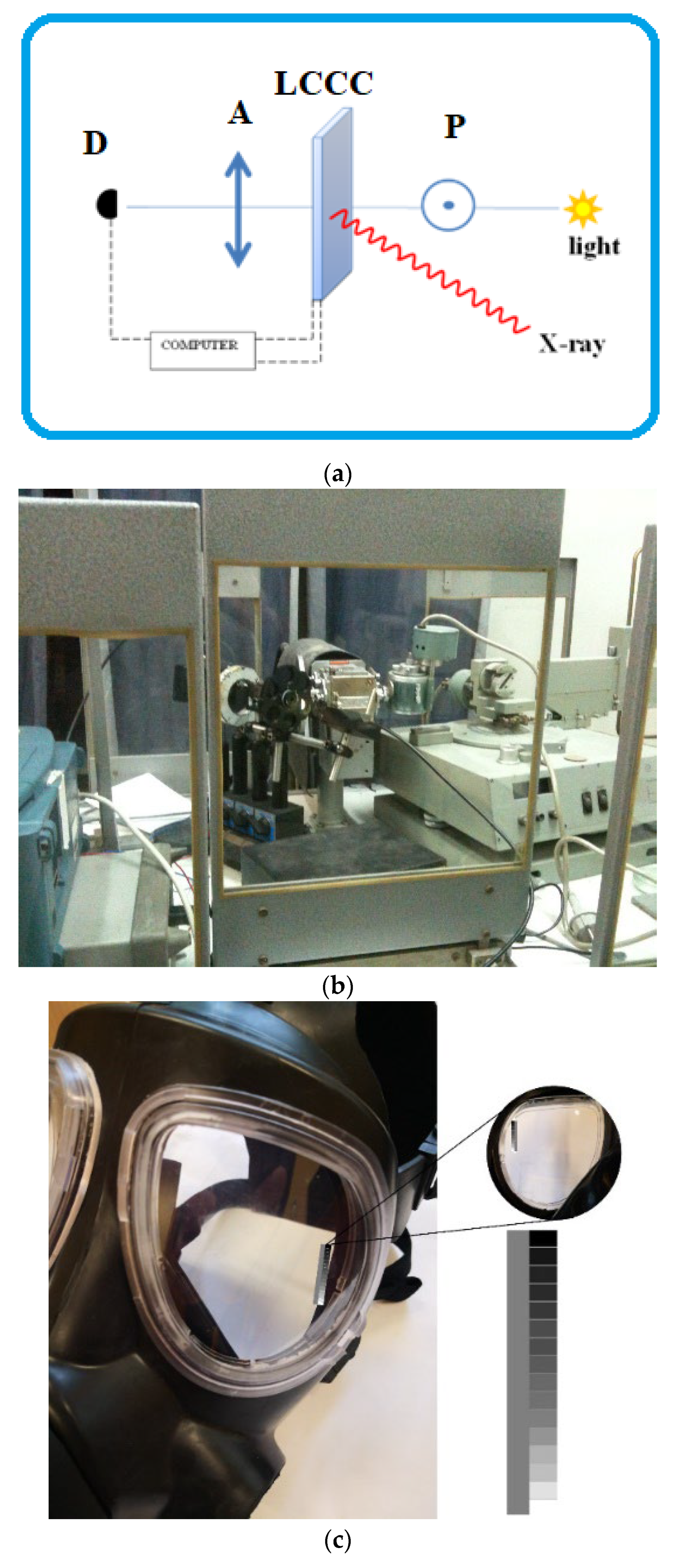

- (a)

- using a minimum of components, which makes the CC simpler than the devices mentioned above,

- (b)

- real-time imaging of the IoR intensity distribution and reading with the naked eye,

- (c)

- design of the CC allowing for working in transmission and/or reflection mode,

- (d)

- final readout operating with a visible light,

- (e)

- increased sensitivity for IoR detection,

- (f)

- low power consumption.

2. Ionizing Radiation

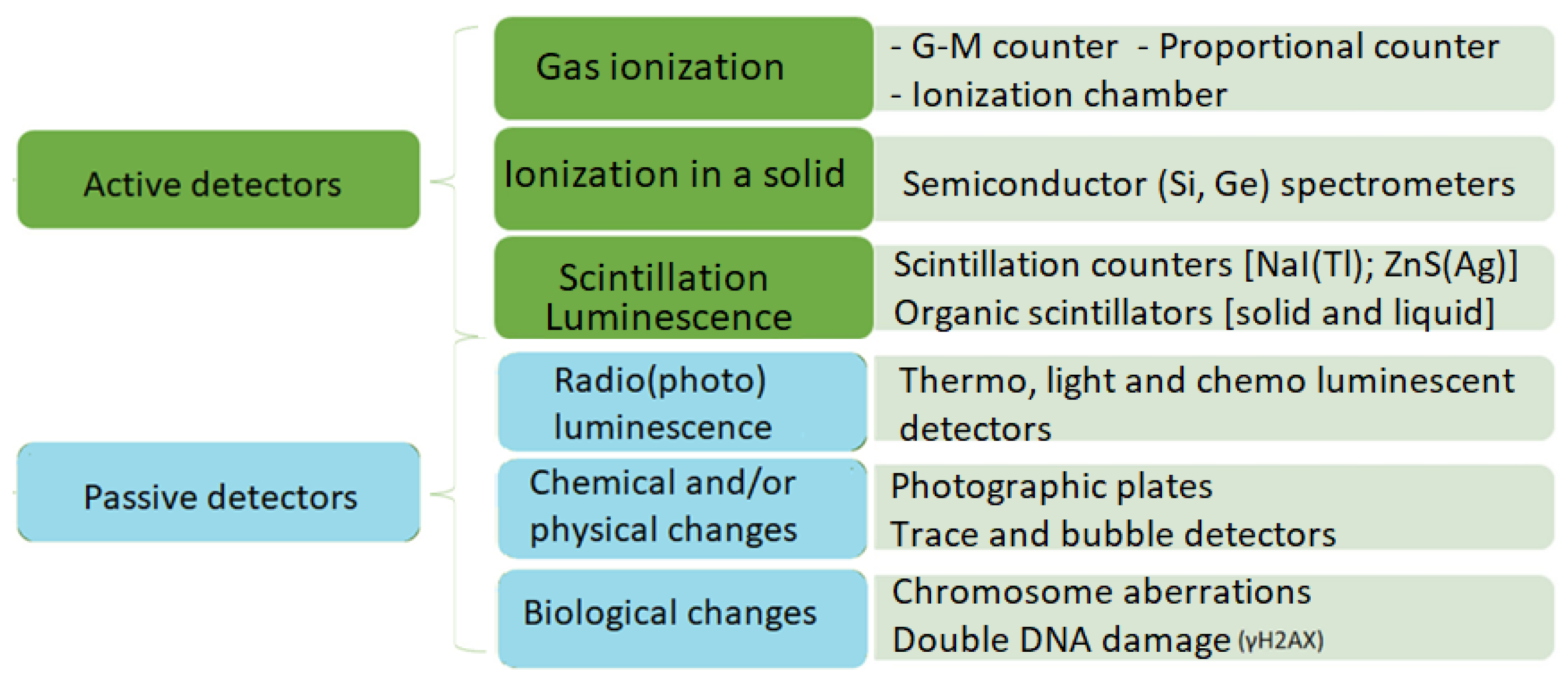

2.1. Radiation Detectors and Active and Passive Radiation Imaging

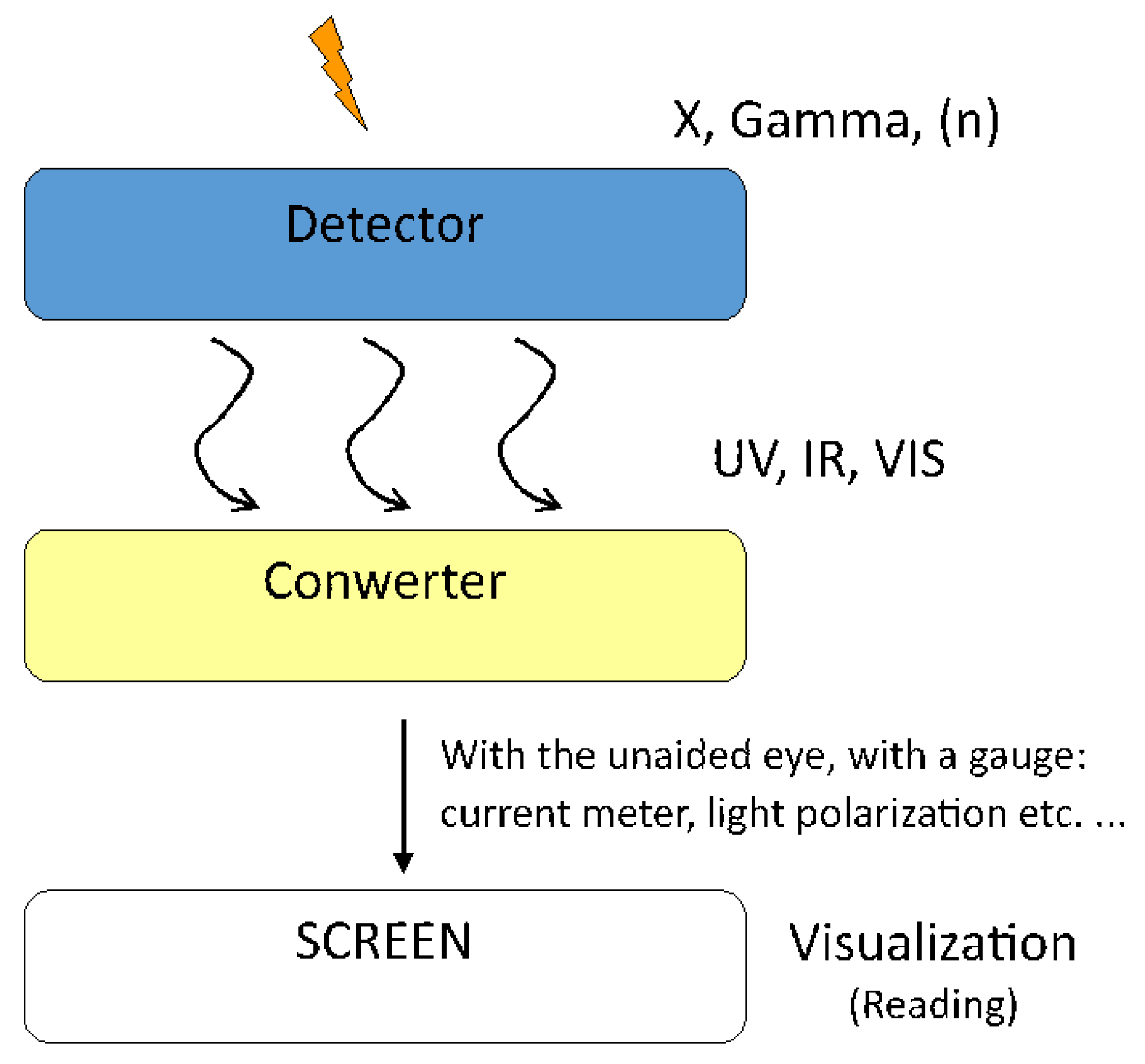

2.2. LCD Technologies and Their Potential for the Detection and Readout of IoR

2.3. Current Solutions and Vision of the Future

3. Experimental Part

3.1. Materials and Methods

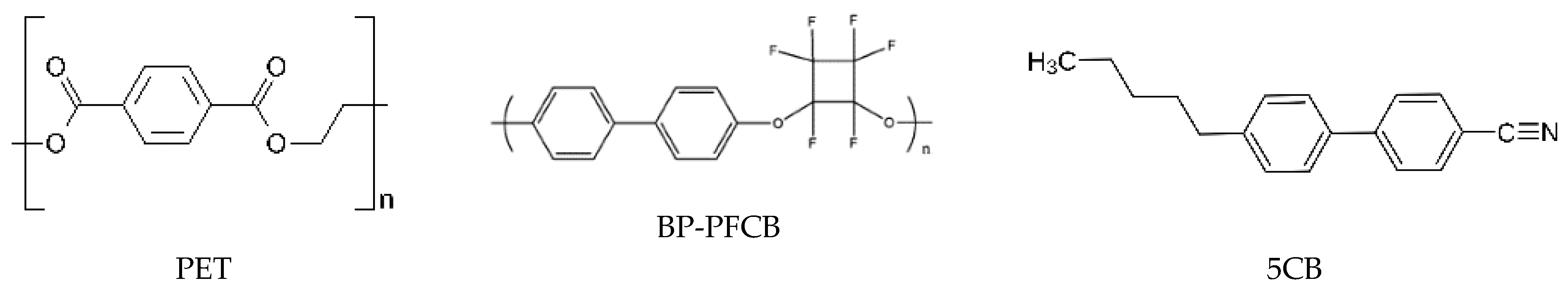

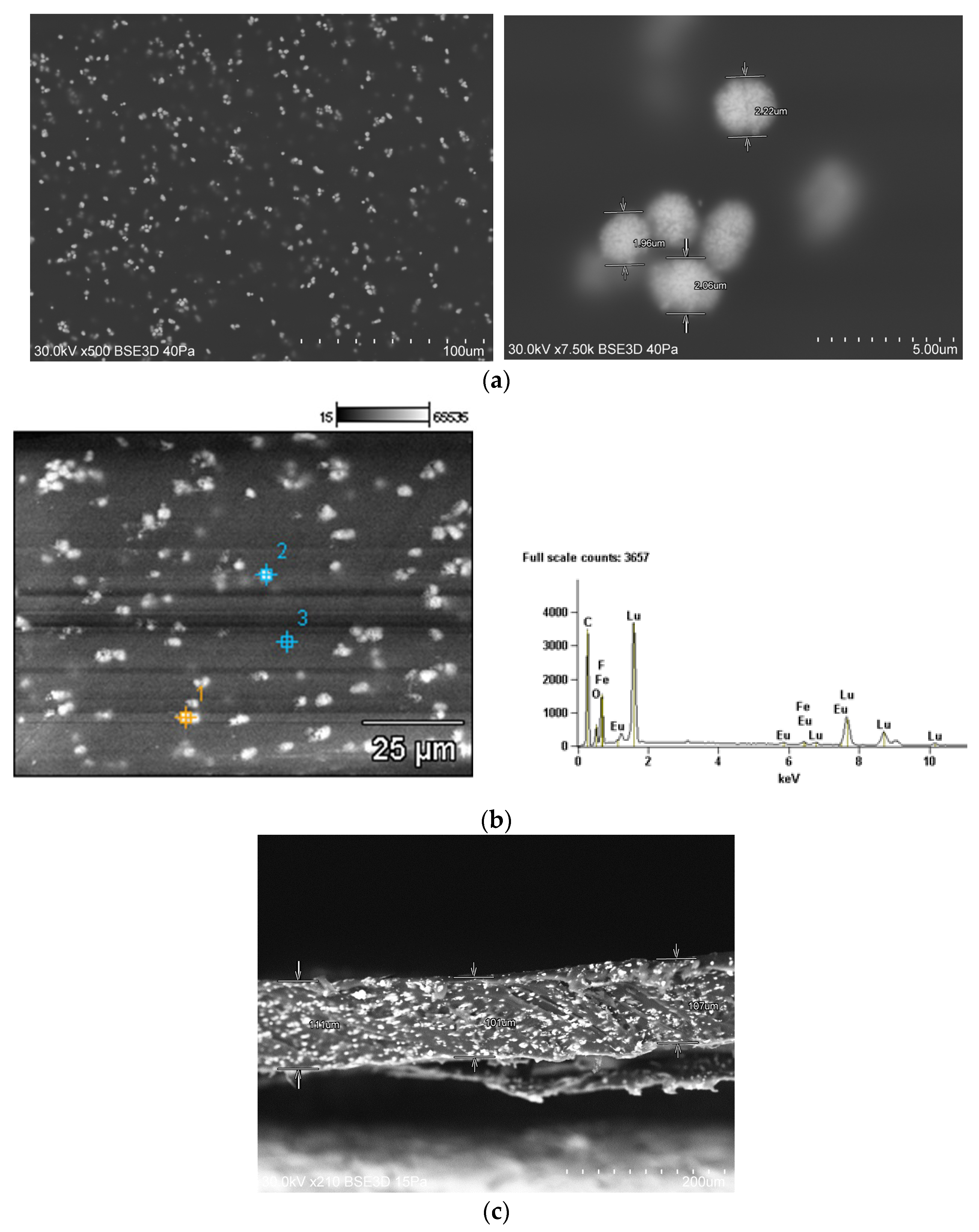

3.2. Aspects of Selected Materials

- (i)

- (ii)

- (iii)

- (iv)

- durability: the luminescence of Lu2O3:Eu is durable and does not degrade with time and irradiation intensity.

- (i)

- photoelectric effect: α-Se exhibits a high electron–hole pair extraction efficiency when affected by radiation at the visible range, which makes it an ideal material for use in the fabrication of photovoltaic cells [68]; moreover, α-Se remains the only amorphous photoconductor where while drifting in an electric field, charges (here, holes are of higher charge mobility than for electrons) can avoid energy dissipation and hence can acquire enough energy to initiate impact ionization and secondary charge creation;

- (ii)

- light absorption: α-Se absorbs the electromagnetic radiation at VIS and IR ranges [69];

- (iii)

- X-ray sensitivity: α-Se has high X-ray sensitivity, making it an ideal material for applications in medical imaging [70];

- (iv)

- (v)

- electrical properties: α-Se also has unique electrical properties, like a low current activation temperature, which means it can function at lower voltages than traditional semiconductor materials [73].

4. Results and Discussion

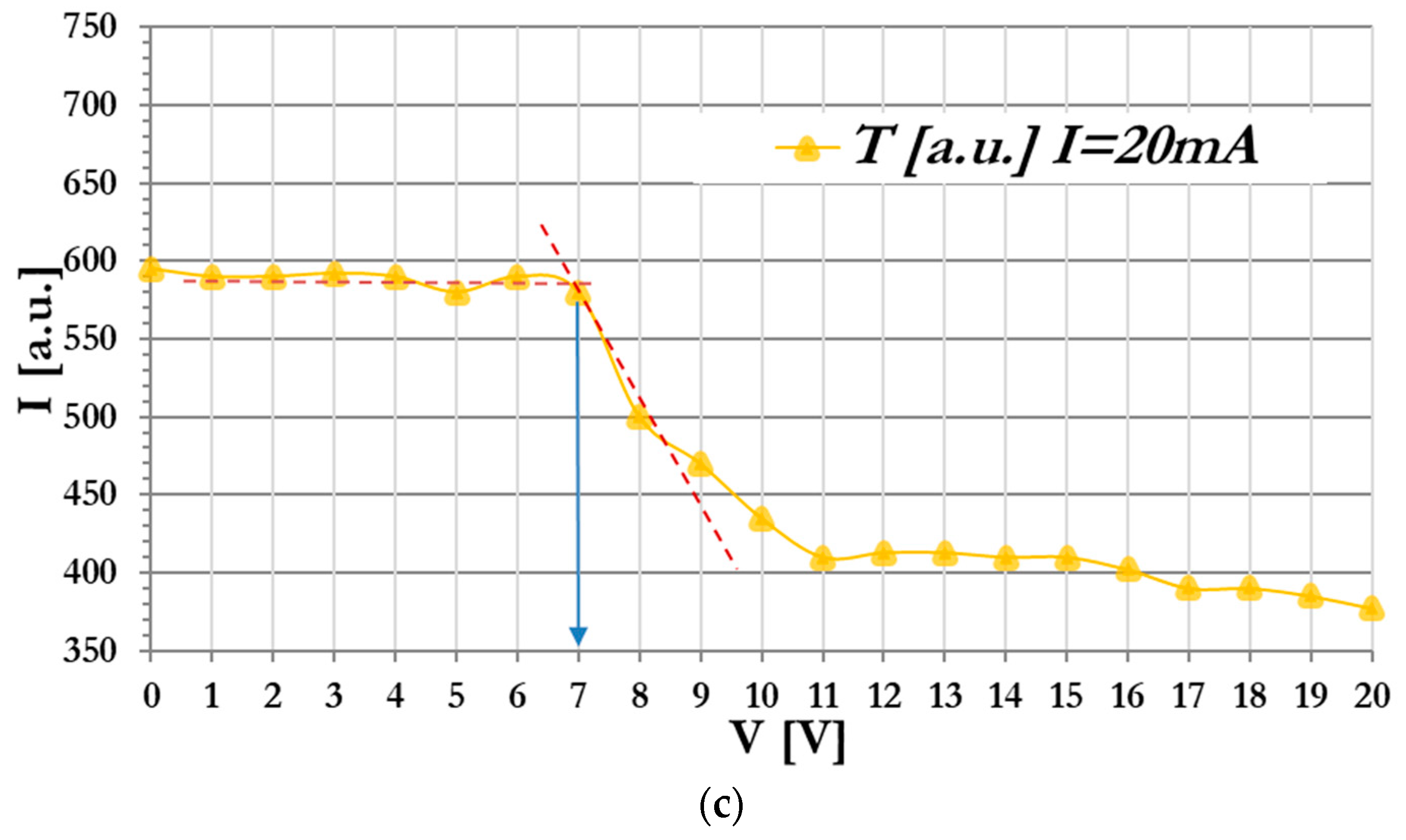

Selected Opto-Electrical Parameters of Cascade Converter

5. Conclusions

- ⮚

- Construction based on three layers only, which has a beneficial effect on minimizing both the time and costs of converter production (technological aspects) and is an advantage of the proposed CC.

- ⮚

- The CC, according to the proposed technology, registers lower radiation energies than other traditionally used measuring devices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huignard, J.P.; Le Berre, S.; Mayeux, C.; Micheron, F. Liquid-Crystal Image Converter Device. U.S. Patent 4368386A, 11 January 1983. [Google Scholar]

- Rieppo, P.; Bahadur, B.; Rowlands, J. Amorphous selenium liquid crystal light valve for X-ray imaging. In Proceedings of the Medical Imaging 1995, San Diego, CA, USA, 26 February–2 March 1995. [Google Scholar]

- Germann, S.; Stiles, J.A.R.; Rowlands, J.A.; Oakham, P.; Webster, C.A.; Koprinarov, I. X-ray Light Valve Based Digital Radiographic Imaging Systems. U.S. Patent 7687792, 30 March 2010. [Google Scholar]

- Rieppo, P.-K.M.; Rowlands, J.A. Apparatus for Generating Multiple X-ray Images of an Object from a Single X-ray Exposure. U.S. Patent 5847499, 8 December 1998. [Google Scholar]

- Huang, Z.S. Flat Panel Detector for Radiation Imaging with Reduced Electronic Noise. U.S. Patent 5929449, 27 July 1999. [Google Scholar]

- Lança, L.; Silva, A. Digital radiography detectors—A technical overview: Part 1. Radiography 2009, 15, 58–62. [Google Scholar] [CrossRef]

- Miah, M.H.; Khandaker, M.U.; Islam, M.A.; Nur-E-Alam, M.; Osman, H.; Ullah, M.H. Perovskite materials in X-ray detection and imaging: Recent progress, challenges, and future prospects. RSC Adv. 2024, 14, 6656–6698. [Google Scholar] [CrossRef]

- Girolami, M.; Matteocci, F.; Pettinato, S.; Serpente, V.; Bolli, E.; Paci, B.; Generosi, A.; Salvatori, S.; Di Carlo, A.; Trucchi, D.M. Metal-Halide Perovskite Submicrometer-Thick Films for Ultra-Stable Self-Powered Direct X-Ray Detectors. Nano-Micro Lett. 2024, 16, 182. [Google Scholar] [CrossRef] [PubMed]

- Pettinato, S.; Girolami, M.; Stravato, A.; Serpente, V.; Musio, D.; Rossi, M.C.; Trucchi, D.M.; Olivieri, R.; Salvatori, S. A Highly Versatile X-ray and Electron Beam Diamond Dosimeter for Radiation Therapy and Protection. Materials 2023, 16, 824. [Google Scholar] [CrossRef] [PubMed]

- Bloomer, C.; Newton, M.E.; Rehm, G.; Salter, P.S. A single-crystal diamond X-ray pixel detector with embedded graphitic electrodes. J. Synchrotron Rad. 2020, 27, 599–607. [Google Scholar] [CrossRef] [PubMed]

- Girolami, M.; Allegrini, P.; Conte, G.; Trucchi, D.M.; Ralchenko, V.G.; Salvatori, S. Diamond Detectors for UV and X-ray Source Imaging. IEEE Electron Device Lett. 2012, 33, 224–226. [Google Scholar] [CrossRef]

- Januszko, A.; Zych, E. Kaskadowy Konwerter Promieniowania Jonizującego Oraz Urządzenie do Diagnostyki Obrazowej w Czasie Rzeczywistym (Cascade Converter of Ionizing Radiation and a Device for Real-Time Imaging Diagnostics). PL Patent 224639 B1, 31 January 2017. [Google Scholar]

- Practical Radiation Technical Manual; International Atomic Energy Agency: Vienna, Austria, 2004.

- Metcalfe, N.; Kron, T.; Hoban, P. The Physics of Radiotherapy X-rays and Electrons; Medical Physics Publishing: Madison, WI, USA, 2007. [Google Scholar]

- Yaffe, M.J.; Rowlands, J.A. X-ray detectors for digital radiography. Phys. Med. Biol. 1997, 42, 1. [Google Scholar] [CrossRef] [PubMed]

- Shapiro, J. Radiation Protection: A Guide for Scientists and Physicians; Harvard University Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Smirnov, D.A. Radiation Dosimetry: Instrumentation and Methods; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Wadhwa, P.K.; Sharma, V.P. Industrial Radiography and Non-Destructive Testing; Narosa Publishing House: New Delhi, India, 2000. [Google Scholar]

- Blitz, J. Electrical and Magnetic Methods of Non-Destructive Testing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Lamarsh, J.; Baratta, A. Introduction to Nuclear Engineering; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Merz, E.R.; Walter, C.E. The Management of Radioactive Waste; Springer: Berlin/Heidelberg, Germany, 1989. [Google Scholar]

- Krane, K.S. Introductory Nuclear Physics; Wiley: Hoboken, NJ, USA, 1987. [Google Scholar]

- Gaisser, T.K.; Engel, R.; Resconi, E. Cosmic Rays and Particle Physics; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Knoll, G.F. Radiation Detection and Measurement; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Elvira, V.H.; Roteta, M.; Fernández-Sotillo, A.; García-Toraño, E. Design and optimization of a proportional counter for the absolute determination of low-energy X-ray emission rates. Rev. Sci. Instrum. 2020, 91, 103304. [Google Scholar] [CrossRef] [PubMed]

- Grupen, C.; Shwartz, B. Particle Detectors; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- L’Annunziata, M.F. Handbook of Radioactivity Analysis; Academic Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Boumans, P.W.J.M. Inductively Coupled Plasma Emission Spectroscopy Part II: Applications and Fundamentals; Wiley-Interscience: Hoboken, NJ, USA, 1987. [Google Scholar]

- Heath, R.L. Scintillation Spectrometry Gamma-ray Spectrum Catalog; Atomic Energy Commission, Phillips Petroleum Company: Idaho Falls, ID, USA, 1964. [Google Scholar]

- McCulloch, M.T. Geochronology and Thermochronology by the 40Ar/39Ar Method; Oxford University Press: Oxford, UK, 1985. [Google Scholar]

- Taylor, R.E. Radiocarbon Dating: An Archaeological Perspective; Academic Press: Cambridge, MA, USA, 1987. [Google Scholar]

- Mettler, F.A., Jr.; Guiberteau, M.J. Essentials of Nuclear Medicine Imaging; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Chesney, D.A.; Chesney, M.P. Radiographic Imaging; McGraw-Hill Medical: New York, NY, USA, 2001. [Google Scholar]

- Bowen, H.J.M. Radioactive Tracers in Biology: An Introduction to Tracer Methodology; Elsevier: Amsterdam, The Netherlands, 1969. [Google Scholar]

- Halperin, E.C.; Perez, C.A.; Brady, L.W. Perez & Brady’s Principles and Practice of Radiation Oncology; Lippincott Williams & Wilkins: Philadelphia, PA, USA, 2008. [Google Scholar]

- International Atomic Energy Agency (IAEA). Characterization of Radioactive Waste Forms and Packages; IAEA-TECDOC-1239; International Atomic Energy Agency (IAEA): Vienna, Austria, 2001. [Google Scholar]

- Martin, J.E.; Harbison, S.A. An Introduction to Radiation Protection; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Heusser, G.; Laubenstein, M.; Neder, H. Low-level germanium gamma-ray spectrometry at the μBq/kg level and future developments towards higher sensitivity. Radioact. Environ. 2006, 8, 495–510. [Google Scholar] [CrossRef]

- Jenkins, R.; Gould, R.W.; Gedcke, D. Quantitative X-ray Spectrometry; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Faure, G.; Mensing, T.M. Isotopes: Principles and Applications; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Cherry, S.R.; Sorenson, J.A.; Phelps, M.E. Physics in Nuclear Medicine; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Caretto, N.; Chiodini, N.; Moretti, F.; Origgi, D.; Tosi, G.; Vedda, A. Feasibility of dose assessment in radiological diagnostic equipments using Ce-doped radio-luminescent optical fibers. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2010, 612, 407–411. [Google Scholar] [CrossRef]

- Buchele, P.; Richter, M.; Tedde, S.F.; Matt, G.J.; Ankah, G.N.; Fischer, R.; Biele, M.; Metzger, W.; Lilliu, S.; Bikondoa, O.; et al. X-ray imaging with scintillator-sensitized hybrid organic photodetectors. Nat. Photonics 2015, 9, 843–849. [Google Scholar] [CrossRef]

- Hall, E.J.; Giaccia, A.J. Radiobiology for the Radiologist; Lippincott Williams & Wilkins: Philadelphia, PA, USA, 2012. [Google Scholar]

- UNSCEAR (United Nations Scientific Committee on the Effects of Atomic Radiation). Sources and Effects of Ionizing Radiation; United Nations: New York, NY, USA, 2008. [Google Scholar]

- Hyde, E.K. Radiochemistry and Nuclear Methods of Analysis; Wiley-Interscience: Hoboken, NJ, USA, 1984. [Google Scholar]

- Flynn, D.F.; Goans, R.E. Nuclear Terrorism: Recognizing and Dealing with the Growing Threat; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Ahmad, M.I.; Rahim, M.H.A.; Nordin, R.; Mohamed, F.; Abu-Samah, A.; Abdullah, N.F. Ionizing Radiation Monitoring Technology at the Verge of Internet of Things. Sensors 2021, 21, 7629. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.-Q.; Ge, L. Colorimetric Sensors: Methods and Applications. Sensors 2023, 23, 9887. [Google Scholar] [CrossRef] [PubMed]

- Tsoulfanidis, N.; Landsberger, S. Measurement & Detection of Radiation, 4th ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2015; ISBN 978-1-4822-1548-9. [Google Scholar]

- Castellano, J.A. Liquid Gold: The Story of Liquid Crystal Displays and the Creation of an Industry; World Scientific Publishing: Singapore, 2005; ISBN 978-981-238-956-5. [Google Scholar]

- Didion, J.E.; Smith, K.; Layne, J.E. Modifying twisted nematic LCD screens to create dichromatic visual stimuli with LEDs. Methods Ecol. Evol. 2020, 11, 690–696. [Google Scholar] [CrossRef]

- Kuo, C.-T.; Li, C.-Y.; Lin, S.-H.; Yeh, H.-C. Electrically controllable Fresnel lens in 90° twisted nematic liquid crystals. Opt. Express 2015, 23, 26041–26048. [Google Scholar] [CrossRef] [PubMed]

- Januszko, A.; Miniewicz, A. Self-Diffraction Studies in a-Se-Nematic Liquid Crystal Cell. Adv. Mater. Opt. Electron. 1996, 6, 272–278. [Google Scholar] [CrossRef]

- Zych, E.; Hreniak, D.; Strek, W. Spectroscopic Properties of Lu2O3/Eu3+ Nanocrystalline Powders and Sintered Ceramics. J. Phys. Chem. B 2002, 106, 3805–3812. [Google Scholar] [CrossRef]

- Kalaw, G.J.D.; Wahome, J.A.N.; Zhu, Y.; Balkus, K.J., Jr.; Musselman, I.H.; Yang, D.-J.; Ferraris, J.P. Perfluorocyclobutyl (PFCB)-based polymer blends for proton exchange membrane fuel cells (PEMFCs). J. Membr. Sci. 2013, 431, 86–95. [Google Scholar] [CrossRef]

- Wu, J.; Lund, B.R.; Batchelor, B.; Dei, D.K.; Liff, S.M.; Smith, D.W., Jr. Suzuki polycondensation and post-polymerization modification toward electro-optic perfluorocyclobutyl (PFCB) aryl ether polymers: Synthesis and characterization. J. Fluor. Chem. 2015, 180, 227–233. [Google Scholar] [CrossRef]

- Hreniak, D.; Zych, E.; Kepinski, L.; Strek, W. Structural and spectroscopic studies of Lu2O3/Eu3+ nanocrystallites embedded in SiO2 sol–gel ceramics. J. Phys. Chem. Solids 2003, 64, 111–119. [Google Scholar] [CrossRef]

- Shimizu, K.; Furuya, K.; Katsu, M. Red phosphor Lu2O3: Eu3+ for white light-emitting diodes. J. Electrochem. Soc. 2010, 157, H952–H955. [Google Scholar]

- Liu, X.; Zheng, J.; Xu, Z.; Zuo, Y.; Guo, H.; Jing, W.; Feng, H. X-ray induced coloration behavior of Lu2O3:Eu transparent ceramics and the impact of ZrO2 and HfO2 sintering additives. Opt. Mater. 2022, 131, 112641. [Google Scholar] [CrossRef]

- Ropp, R.C. Encyclopedia of the Alkaline Earth Compounds; Elsevier: Oxford, UK, 2013; ISBN 978-0-444-59550-8. [Google Scholar]

- Yu, H.; Li, Q.; Liu, C.; Jing, W.; Yang, X.; Yang, M.; Mao, R. Comparison of Photoluminescence and Scintillation Properties Between Lu2O3:Eu Single Crystal and Transparent Ceramic. IEEE Trans. Nucl. Sci. 2021, 68, 477–482. [Google Scholar]

- Gruzintsev, A.N.; Emel’chenko, G.A.; Yermolayeva, Y.V.; Masalov, V.M.; Tolmachev, A.V.; Benalloul, P.; Barthou, C. Spontaneous and Stimulated Red Luminescence of Lu2O3:Eu Nanocrystals. Fiz. Tverd. Tela 2011, 53, 1198–1202. [Google Scholar] [CrossRef]

- Luo, D.H.; Huang, F.X.; Chen, X.H.; Huang, Y.Y.; Zhang, W.K.; Chen, H.Z. Phosphors in phosphor-converted white light-emitting diodes: Recent advances in materials, techniques and properties. Mater. Sci. Eng. R Rep. 2013, 74, 61–112. [Google Scholar]

- Chen, L.; Chang, J.; Ding, D.; Feng, H. Preparation, luminescent properties and X-ray imaging result of Lu2O3:Eu structured scintillation film on sapphire substrate by LCVD method. Mater. Lett. 2021, 282, 128689. [Google Scholar] [CrossRef]

- Hanejko, F.G.; Jensen, K.M. Advanced phosphor materials for high power white LEDs. MRS Proc. 1997, 457, 165–170. [Google Scholar]

- Zych, E.; Trojan-Piegza, J. Low-temperature luminescence of Lu2O3:Eu ceramics upon excitation with synchrotron radiation in the vicinity of band gap energy. Chem. Mater. 2006, 18, 2194–2199. [Google Scholar] [CrossRef]

- Chang, Y.; Huang LZhou, Y.; Wang, J.; Zhai, W. Controlled Localized Phase Transition of Selenium for Color-Selective Photodetectors. ACS Appl. Mater. Interfaces 2022, 14, 5624. [Google Scholar] [CrossRef]

- Gotoh, T. Defect absorption in selenium films by photothermal deflection spectroscopy. Eur. Phys. J. Appl. Phys. 2020, 89, 10301. [Google Scholar] [CrossRef]

- He, X.; Deng, Y.; Ouyang, D.; Zhang, N.; Wan, J.; Murthy, A.A.; Spanopoulos, I.; Islam, S.M.; Tu, Q.; Xing, G.; et al. Recent Development of Halide Perovskite Materials and Devices for Ionizing Radiation Detection. Chem. Rev. 2023, 123, 1207–1261. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Dong, M.; Li, C.; Shao, S.; Hu, T.; Kang, D. Improved thermal stability of antimony-doped amorphous selenium film for X-ray flat-panel detectors. Phys. Status Solidi A–Appl. Mater. Sci. 2013, 210, 580–584. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Wang, X.D.; Zhang, W. First-principles investigation of amorphous Ge-Sb-Se-Te optical phase-change materials. Opt. Mater. 2022, 12, 2497–2506. [Google Scholar] [CrossRef]

- Tie, S.; Dong, S.; Yuan, R.; Cai, B.; Zhu, J.; Zheng, X. Halide perovskites for sensitive, stable and scalable X-ray detection and imaging. Chem. Commun. 2023, 59, 5016–5029. [Google Scholar] [CrossRef] [PubMed]

- Ekgasit, S.; Fulleborn, M.; Siesler, H.W. Orientation of liquid crystalline 5CB under an external electric field. Vib. Spectrosc. 1999, 19, 85–91. [Google Scholar] [CrossRef]

- Ge, J.J.; Li, C.Y.; Xue, G.; Mann, I.K.; Zhang, D.; Wang, S.-Y.; Harris, F.W.; Cheng, S.Z.D.; Hong, S.-C.; Zhuang, X.; et al. Rubbing-Induced Molecular Reorientation on an Alignment Surface of an Aromatic Polyimide Containing Cyanobiphenyl Side Chains. J. Am. Chem. Soc. 2001, 123, 5768–5776. [Google Scholar] [CrossRef]

| Methods | Advantages | Limitations | Ref. |

|---|---|---|---|

| Gas ionizing radiation counters |

|

| [48] |

| Solid ionizing radiation counters |

|

| [48] |

| Scintillation radiation detectors |

|

| [48] |

| The thermo-luminescence (TL) method |

|

| [48] |

| The photo-colorimetric method (PC) |

|

| [49] |

| The biological method (BioM) |

|

| [50] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Januszko, A.; Zych, E.; Piecek, W.; Pellowski, W.; Bogdanowicz, K.A.; Iwan, A. On the Feasibility of an LCD-Based Real-Time Converter for Ionizing Radiation Imaging. Materials 2024, 17, 3320. https://doi.org/10.3390/ma17133320

Januszko A, Zych E, Piecek W, Pellowski W, Bogdanowicz KA, Iwan A. On the Feasibility of an LCD-Based Real-Time Converter for Ionizing Radiation Imaging. Materials. 2024; 17(13):3320. https://doi.org/10.3390/ma17133320

Chicago/Turabian StyleJanuszko, Adam, Eugeniusz Zych, Wiktor Piecek, Witalis Pellowski, Krzysztof A. Bogdanowicz, and Agnieszka Iwan. 2024. "On the Feasibility of an LCD-Based Real-Time Converter for Ionizing Radiation Imaging" Materials 17, no. 13: 3320. https://doi.org/10.3390/ma17133320