Investigation of Grain Boundary Effects in Sm0.2Ce0.8O2−x Thin Film Memristors

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis of SDC20 Powder

2.2. Thin Film Preparation of the Resistive Switching Devices

2.3. Resistive Switching Device Fabrication

2.4. Electrical Characterization of Resistive Switching Device

3. Results and Discussion

3.1. Powder Characterization and Analysis

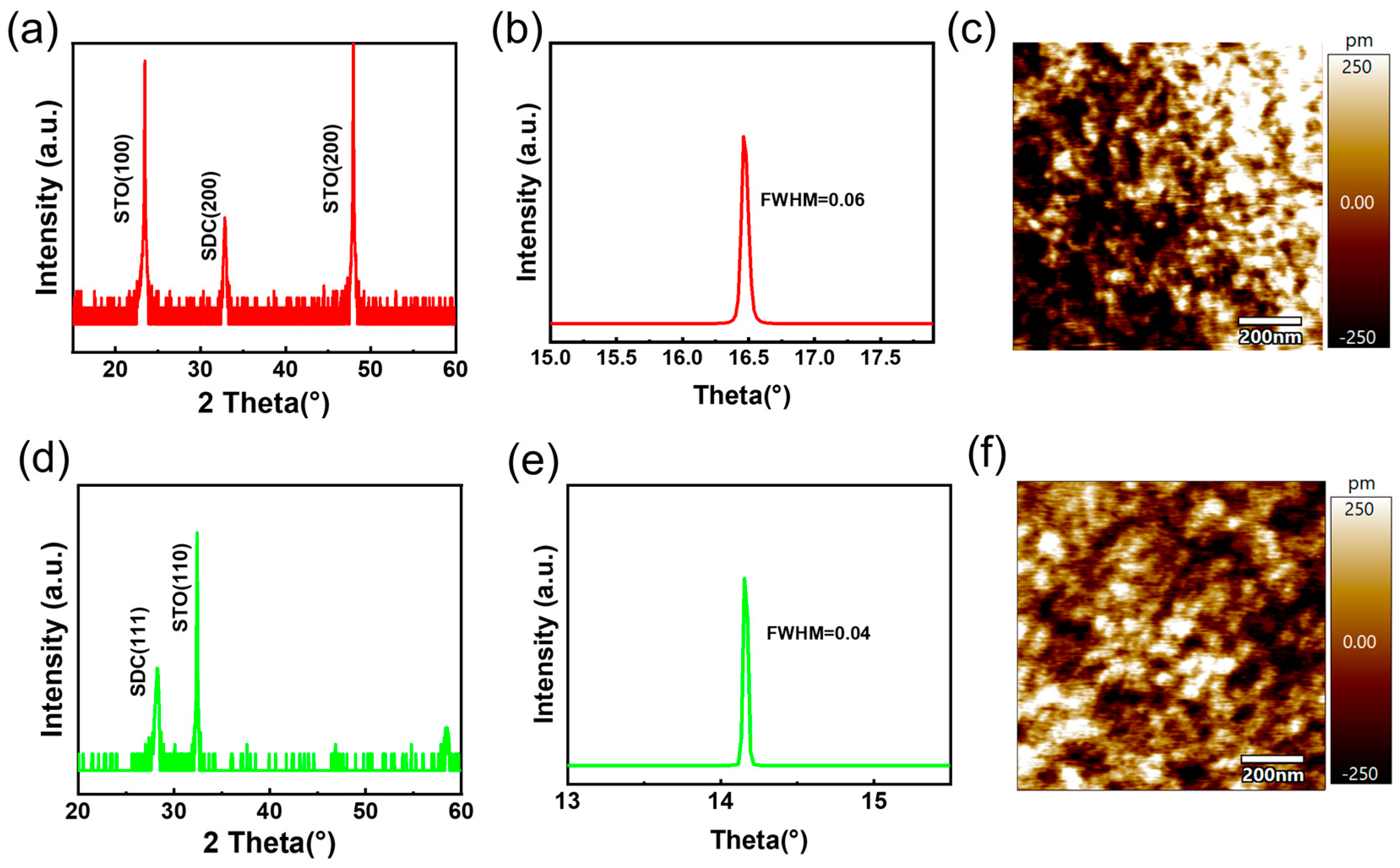

3.2. Characterization and Analysis of SDC20 Thin Films

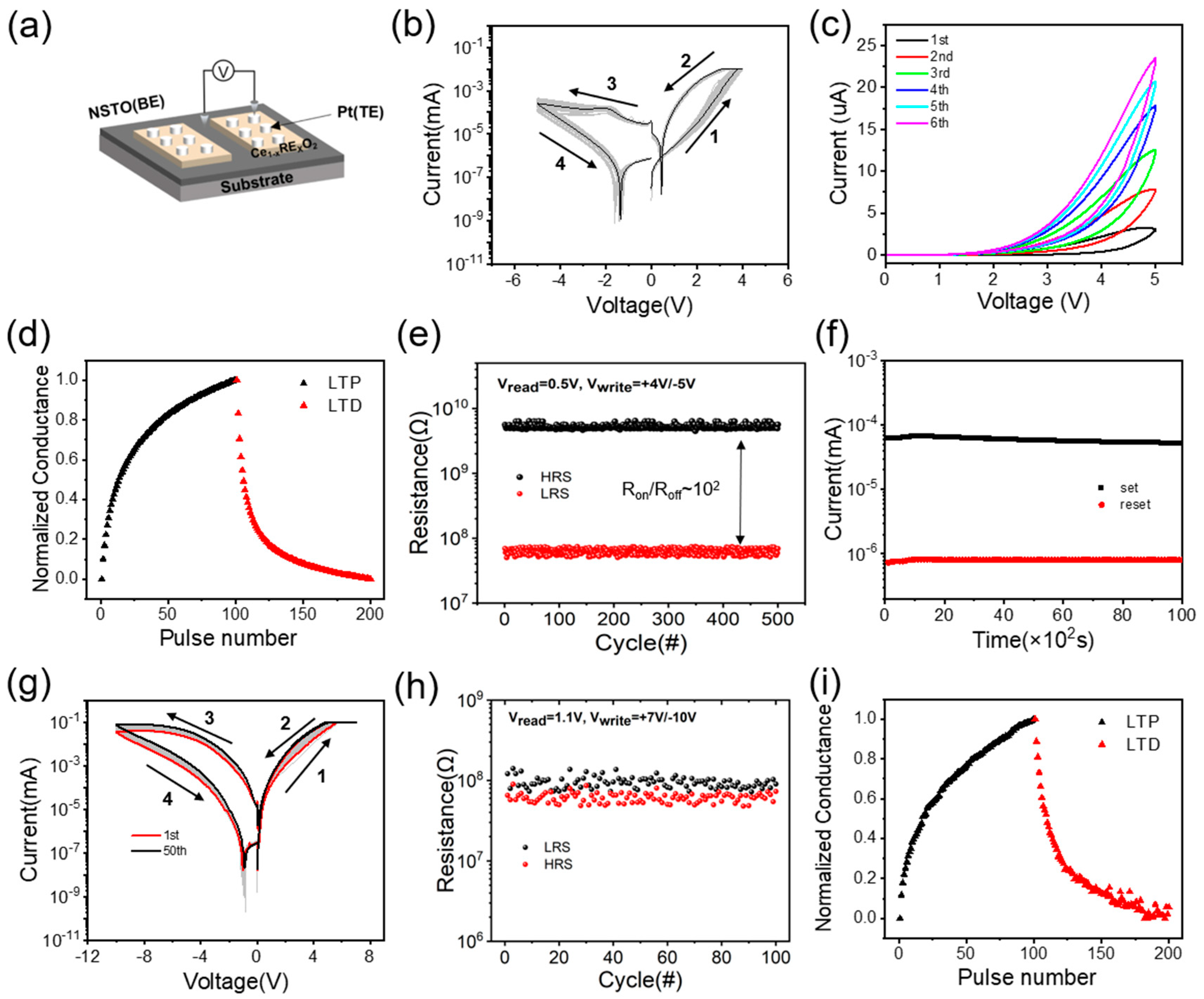

3.3. Electrical Characterization of the Devices

3.4. I–V Curve Fitting Analysis

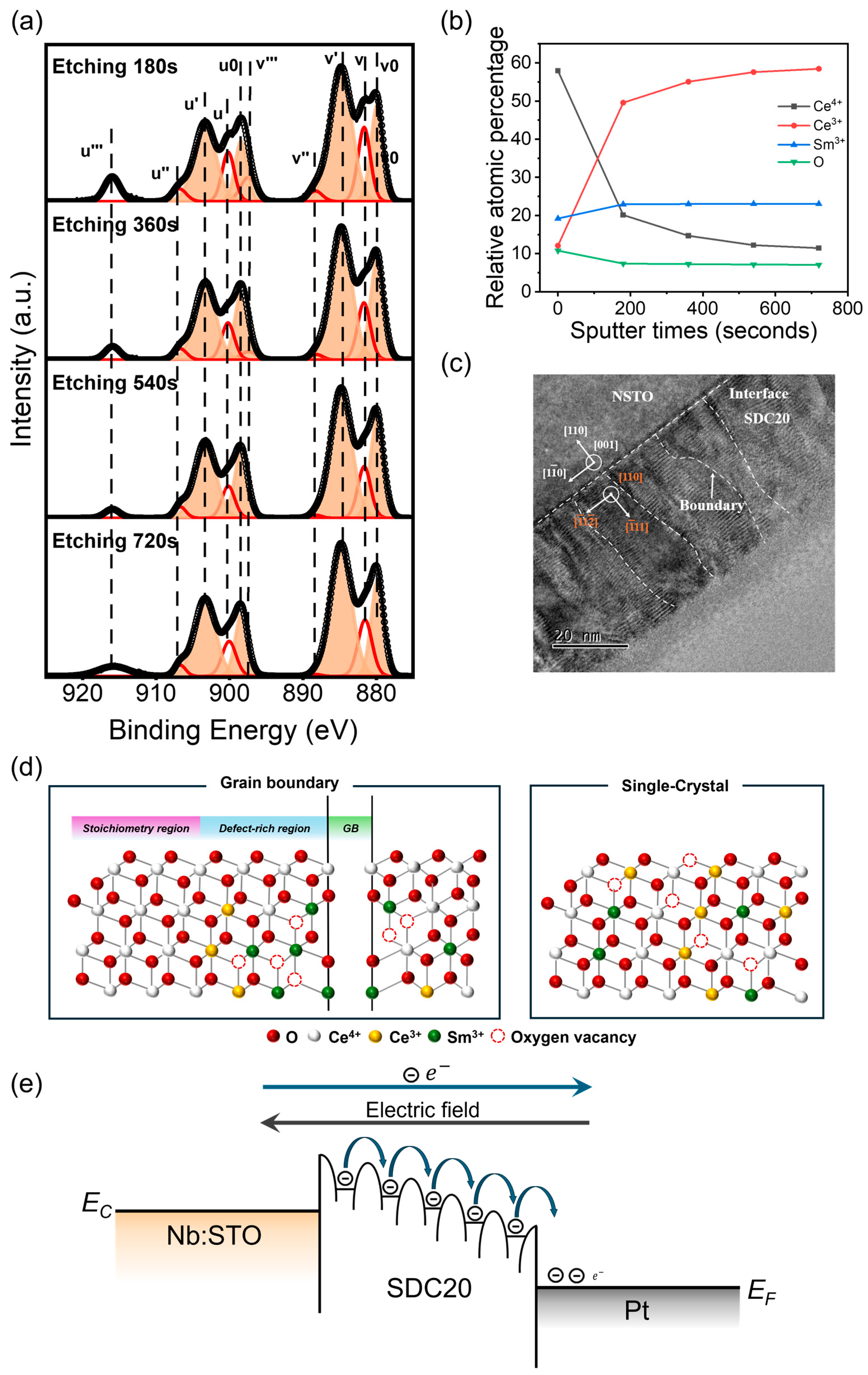

3.5. XPS Analysis and Switching Mechanism Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, K.; Chen, J.; Yan, X.J.A.F.M. The future of memristors: Materials engineering and neural networks. Adv. Funct. Mater. 2021, 31, 2006773. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.; Hwang, S.; Kim, M.-H.; Chang, Y.-F.; Park, B.-G. Analog synaptic behavior of a silicon nitride memristor. ACS Appl. Mater. Interfaces 2017, 9, 40420–40427. [Google Scholar] [CrossRef]

- Backus, J. Can programming be liberated from the von Neumann style? A functional style and its algebra of programs. Commun. ACM 1978, 21, 613–641. [Google Scholar] [CrossRef]

- Moore, G.E. Cramming more components onto integrated circuits. Proc. IEEE 1998, 86, 82–85. [Google Scholar] [CrossRef]

- Tseng, T.-Y.; Sze, S.M. Nonvolatile Memories: Materials, Devices, and Applications, Vol. 2; American Scientific Publishers: Stevenson Ranch, CA, USA, 2012. [Google Scholar]

- Cavallini, M.; Hemmatian, Z.; Riminucci, A.; Prezioso, M.; Morandi, V.; Murgia, M. Regenerable resistive switching in silicon oxide based nanojunctions. Adv. Mater. 2012, 24, 1197–1201. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Sun, Z.; Zhong, L.; Natelson, D.; Tour, J.M. Resistive switches and memories from silicon oxide. Nano Lett. 2010, 10, 4105–4110. [Google Scholar] [CrossRef]

- Kim, K.M.; Kim, G.H.; Song, S.J.; Seok, J.Y.; Lee, M.H.; Yoon, J.H.; Hwang, C.S. Electrically configurable electroforming and bipolar resistive switching in Pt/TiO2/Pt structures. Nanotechnology 2010, 21, 305203. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.M.; Lee, S.R.; Kim, S.; Chang, M.; Hwang, C.S. Self-limited switching in Ta2O5/TaOx memristors exhibiting uniform multilevel changes in resistance. Adv. Funct. Mater. 2015, 25, 1527–1534. [Google Scholar] [CrossRef]

- Rahaman, S.Z.; Lin, Y.-D.; Lee, H.-Y.; Chen, Y.-S.; Chen, P.-S.; Chen, W.-S.; Hsu, C.-H.; Tsai, K.-H.; Tsai, M.-J.; Wang, P.-H. The role of Ti buffer layer thickness on the resistive switching properties of hafnium oxide-based resistive switching memories. Langmuir 2017, 33, 4654–4665. [Google Scholar] [CrossRef]

- Liu, L.; Xiong, W.; Liu, Y.; Chen, K.; Xu, Z.; Zhou, Y.; Han, J.; Ye, C.; Chen, X.; Song, Z. Designing high-performance storage in HfO2/BiFeO3 memristor for artificial synapse applications. Adv. Electron. Mater. 2020, 6, 1901012. [Google Scholar] [CrossRef]

- Nili, H.; Walia, S.; Balendhran, S.; Strukov, D.B.; Bhaskaran, M.; Sriram, S. Nanoscale resistive switching in amorphous perovskite oxide (a-SrTiO3) memristors. Adv. Funct. Mater. 2014, 24, 6741–6750. [Google Scholar] [CrossRef]

- Campbell, C.T.; Peden, C.H. Oxygen vacancies and catalysis on ceria surfaces. Science 2005, 309, 713–714. [Google Scholar] [CrossRef] [PubMed]

- Han, W.-Q.; Wu, L.; Zhu, Y. Formation and oxidation state of CeO2−x nanotubes. J. Am. Chem. Soc. 2005, 127, 12814–12815. [Google Scholar] [CrossRef] [PubMed]

- Chiu, F.-C.; Lai, C.-M. Optical and electrical characterizations of cerium oxide thin films. J. Phys. D Appl. Phys. 2010, 43, 075104. [Google Scholar] [CrossRef]

- Schmitt, R.; Nenning, A.; Kraynis, O.; Korobko, R.; Frenkel, A.I.; Lubomirsky, I.; Haile, S.M.; Rupp, J.L. A review of defect structure and chemistry in ceria and its solid solutions. Chem. Soc. Rev. 2020, 49, 554–592. [Google Scholar] [CrossRef] [PubMed]

- Di Martino, G.; Demetriadou, A.; Li, W.; Kos, D.; Zhu, B.; Wang, X.; de Nijs, B.; Wang, H.; MacManus-Driscoll, J.; Baumberg, J.J. Real-time in situ optical tracking of oxygen vacancy migration in memristors. Nat. Electron. 2020, 3, 687–693. [Google Scholar] [CrossRef]

- She, Y.; Wang, F.; Zhao, X.; Zhang, Z.; Li, C.; Pan, H.; Hu, K.; Song, Z.; Zhang, K. Oxygen vacancy-dependent synaptic dynamic behavior of TiOx-based transparent memristor. IEEE Trans. Electron Devices 2021, 68, 1950–1955. [Google Scholar] [CrossRef]

- Hwang, H.-G.; Pyo, Y.; Woo, J.-U.; Kim, I.-S.; Kim, S.-W.; Kim, D.-S.; Kim, B.; Jeong, J.; Nahm, S. Engineering synaptic plasticity through the control of oxygen vacancy concentration for the improvement of learning accuracy in a Ta2O5 memristor. J. Alloys Compd. 2022, 902, 163764. [Google Scholar] [CrossRef]

- Rana, A.M.; Ismail, M.; Ahmed, E.; Talib, I.; Khan, T.; Hussain, M.; Nadeem, M. Thickness effect on the bipolar switching mechanism for nonvolatile resistive memory devices based on CeO2 thin films. Mater. Sci. Semicond. Process. 2015, 39, 211–216. [Google Scholar] [CrossRef]

- Schmitt, R.; Spring, J.; Korobko, R.; Rupp, J.L.M. Design of Oxygen Vacancy Configuration for Memristive Systems. ACS Nano 2017, 11, 8881–8891. [Google Scholar] [CrossRef]

- Lupetin, P.; Giannici, F.; Gregori, G.; Martorana, A.; Maier, J. Effects of grain boundary decoration on the electrical conduction of nanocrystalline CeO2. J. Electrochem. Soc. 2012, 159, B417. [Google Scholar] [CrossRef]

- Kumar, V.; Chen, W.-F.; Zhang, X.; Jiang, Y.; Koshy, P.; Sorrell, C.C. Properties and performance of photocatalytic CeO2, TiO2, and CeO2–TiO2 layered thin films. Ceram. Int. 2019, 45, 22085–22094. [Google Scholar] [CrossRef]

- Dou, H.; Hellenbrand, M.; Xiao, M.; Hu, Z.; Kunwar, S.; Chen, A.; MacManus-Driscoll, J.L.; Jia, Q.; Wang, H. Engineering of Grain Boundaries in CeO2 Enabling Tailorable Resistive Switching Properties. Adv. Electron. Mater. 2023, 9, 2201186. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Hu, X.; Chen, S.; Qiu, Z.; Wang, Y.; Zhang, H.; Yu, Y.; Yang, B.; Yang, Y.; et al. Grain boundary boosting the thermal stability of Pt/CeO2 thin films. Nano Res. 2023, 16, 3278–3286. [Google Scholar] [CrossRef]

- Cavallini, M.; Gentili, D. Atomic vacancies in transition metal dichalcogenides: Properties, fabrication, and limits. ChemPlusChem 2022, 87, e202100562. [Google Scholar] [CrossRef] [PubMed]

- Dongale, T.; Patil, K.; Gaikwad, P.; Kamat, R. Investigating conduction mechanism and frequency dependency of nanostructured memristor device. Mater. Sci. Semicond. Process. 2015, 38, 228–233. [Google Scholar] [CrossRef]

- Jeong, D.S.; Hwang, C.S. Tunneling-assisted Poole-Frenkel conduction mechanism in HfO2 thin films. J. Appl. Phys. 2005, 98, 113701. [Google Scholar] [CrossRef]

- Foglietti, V.; Yang, N.; Aruta, C.; Di Pietrantonio, F.; Cannatà, D.; Benetti, M.; Balestrino, G. High plasticity reversible resistive switching in heteroepitaxial metal/CeO2−x/Nb: SrTiO3/Ti/Pt structures. Nanotechnology 2016, 27, 375705. [Google Scholar] [CrossRef] [PubMed]

- Burroughs, P.; Hamnett, A.; Orchard, A.F.; Thornton, G. Dalton Transactions, Satellite structure in the X-ray photoelectron spectra of some binary and mixed oxides of lanthanum and cerium. J. Chem. Soc. Dalton Trans. 1976, 17, 1686–1698. [Google Scholar] [CrossRef]

- Sanghavi, R.; Devanathan, R.; Nandasiri, M.I.; Kuchibhatla, S.; Kovarik, L.; Thevuthasan, S.; Prasad, S. Integrated experimental and modeling study of the ionic conductivity of samaria-doped ceria thin films. Solid State Ion. 2011, 204, 13–19. [Google Scholar] [CrossRef]

- Lei, Y.; Ito, Y.; Browning, N.D.; Mazanec, T.J. Segregation effects at grain boundaries in fluorite-structured ceramics. J. Am. Ceram. Soc. 2002, 85, 2359–2363. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Wang, L.; Yang, N. Investigation of Grain Boundary Effects in Sm0.2Ce0.8O2−x Thin Film Memristors. Materials 2024, 17, 3360. https://doi.org/10.3390/ma17133360

Shi W, Wang L, Yang N. Investigation of Grain Boundary Effects in Sm0.2Ce0.8O2−x Thin Film Memristors. Materials. 2024; 17(13):3360. https://doi.org/10.3390/ma17133360

Chicago/Turabian StyleShi, Weikai, Luyao Wang, and Nan Yang. 2024. "Investigation of Grain Boundary Effects in Sm0.2Ce0.8O2−x Thin Film Memristors" Materials 17, no. 13: 3360. https://doi.org/10.3390/ma17133360

APA StyleShi, W., Wang, L., & Yang, N. (2024). Investigation of Grain Boundary Effects in Sm0.2Ce0.8O2−x Thin Film Memristors. Materials, 17(13), 3360. https://doi.org/10.3390/ma17133360