Dynamic Response of Ti-6Al-2Zr-1Mo-1V Alloy Manufactured by Laser Powder-Bed Fusion

Abstract

:1. Introduction

2. Materials and Methods

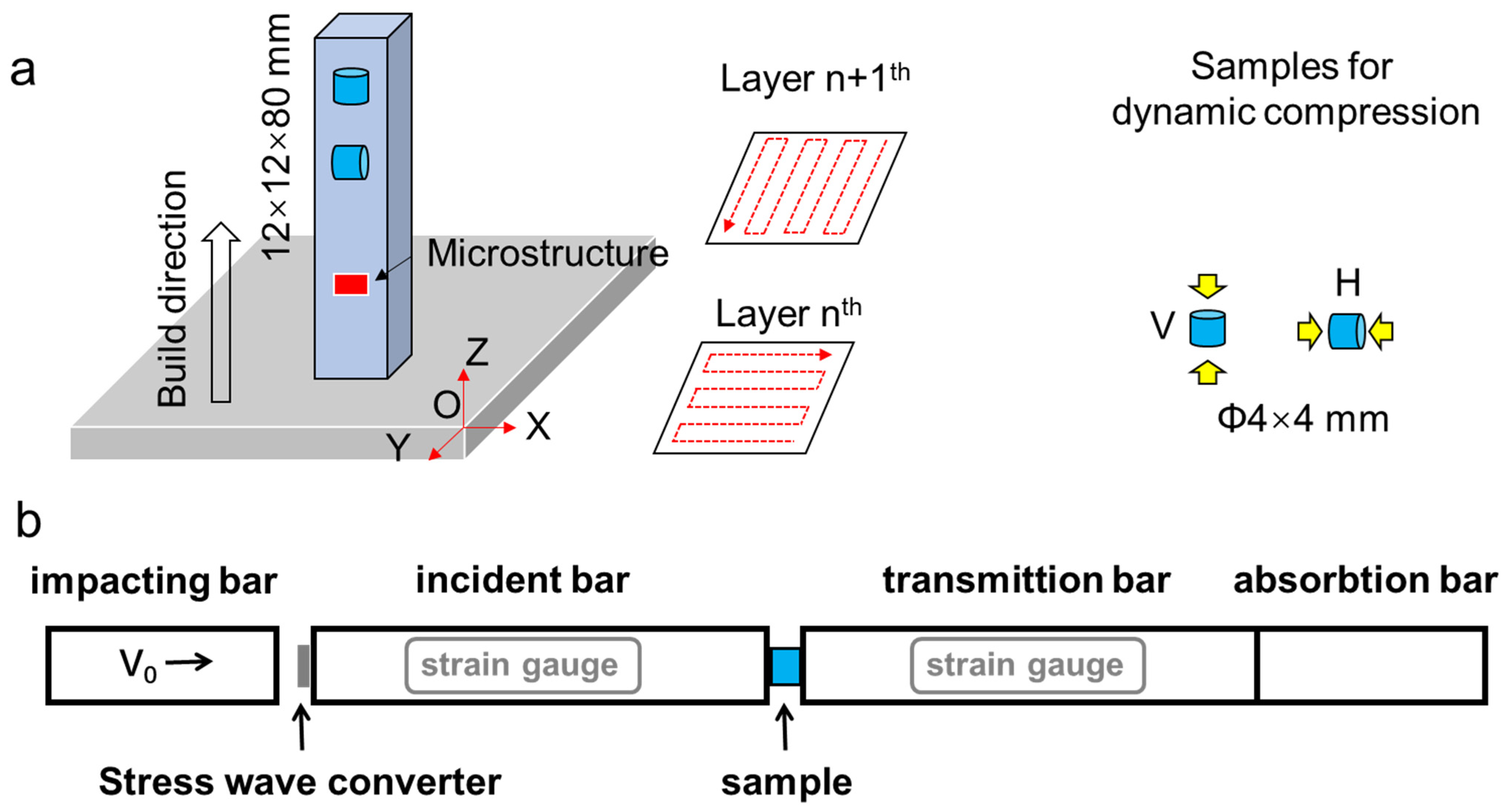

2.1. Sample Preparation

2.2. Compression Test

2.3. Microstructural Observation

3. Results

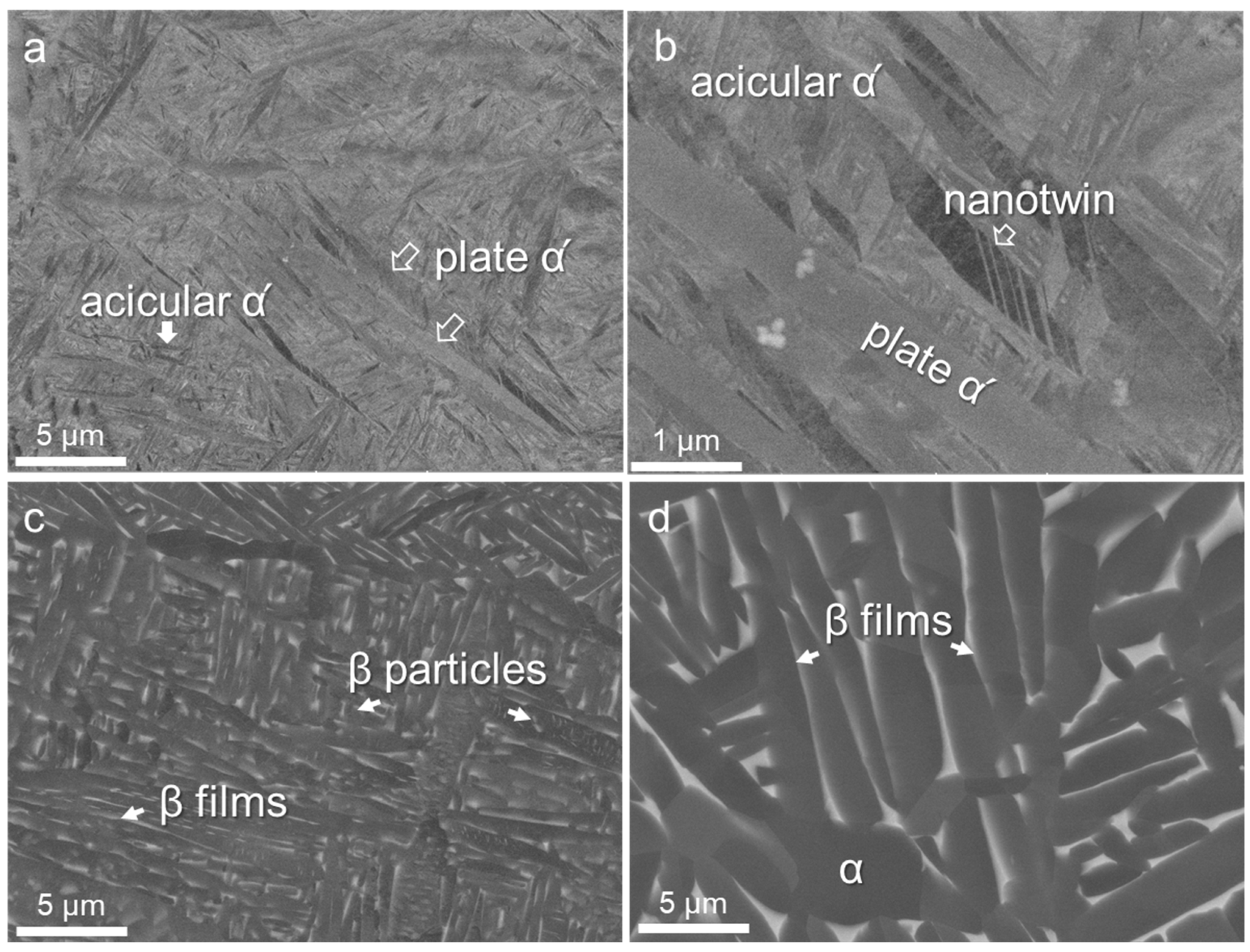

3.1. Microstructures

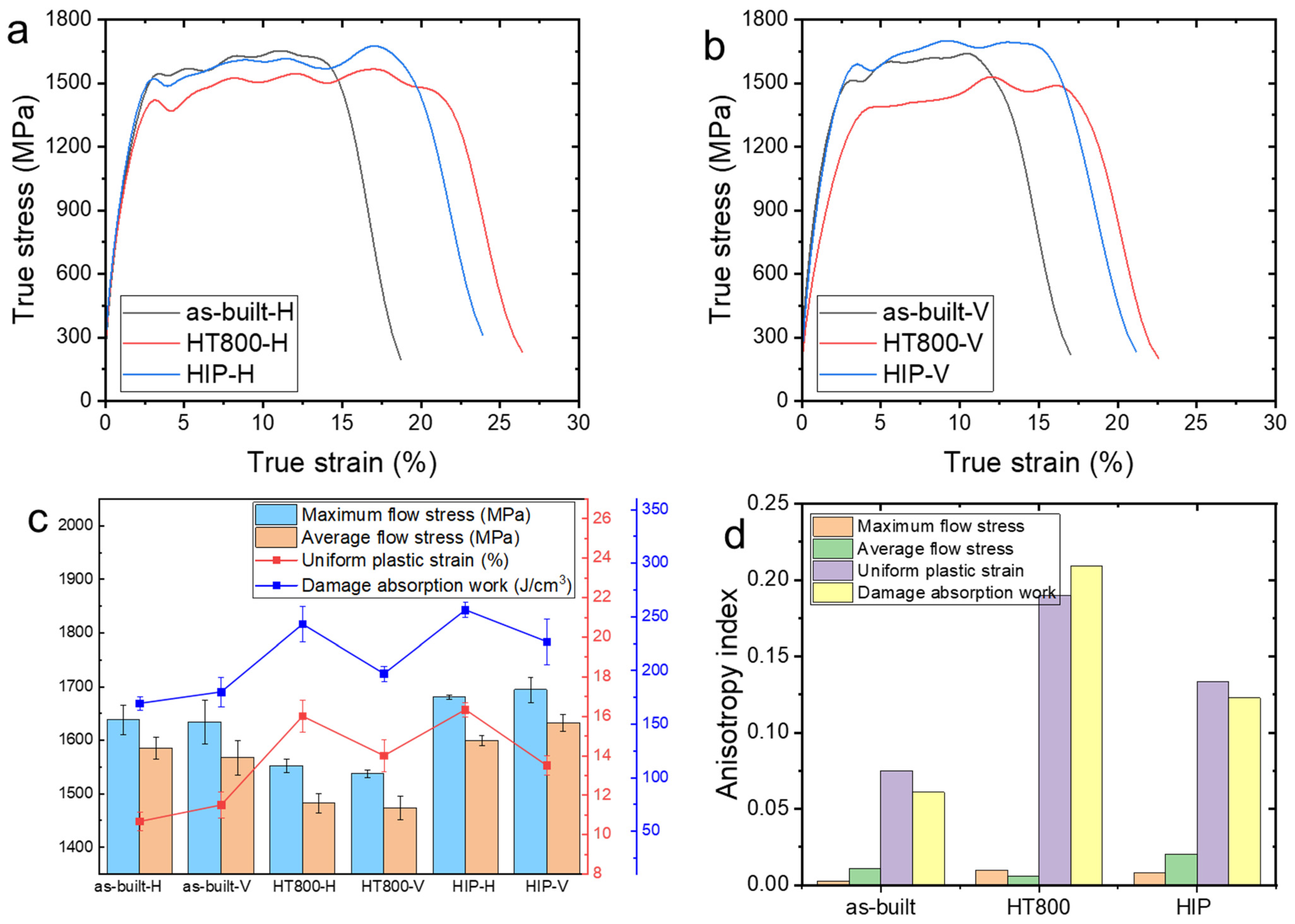

3.2. Dynamic Compression Properties

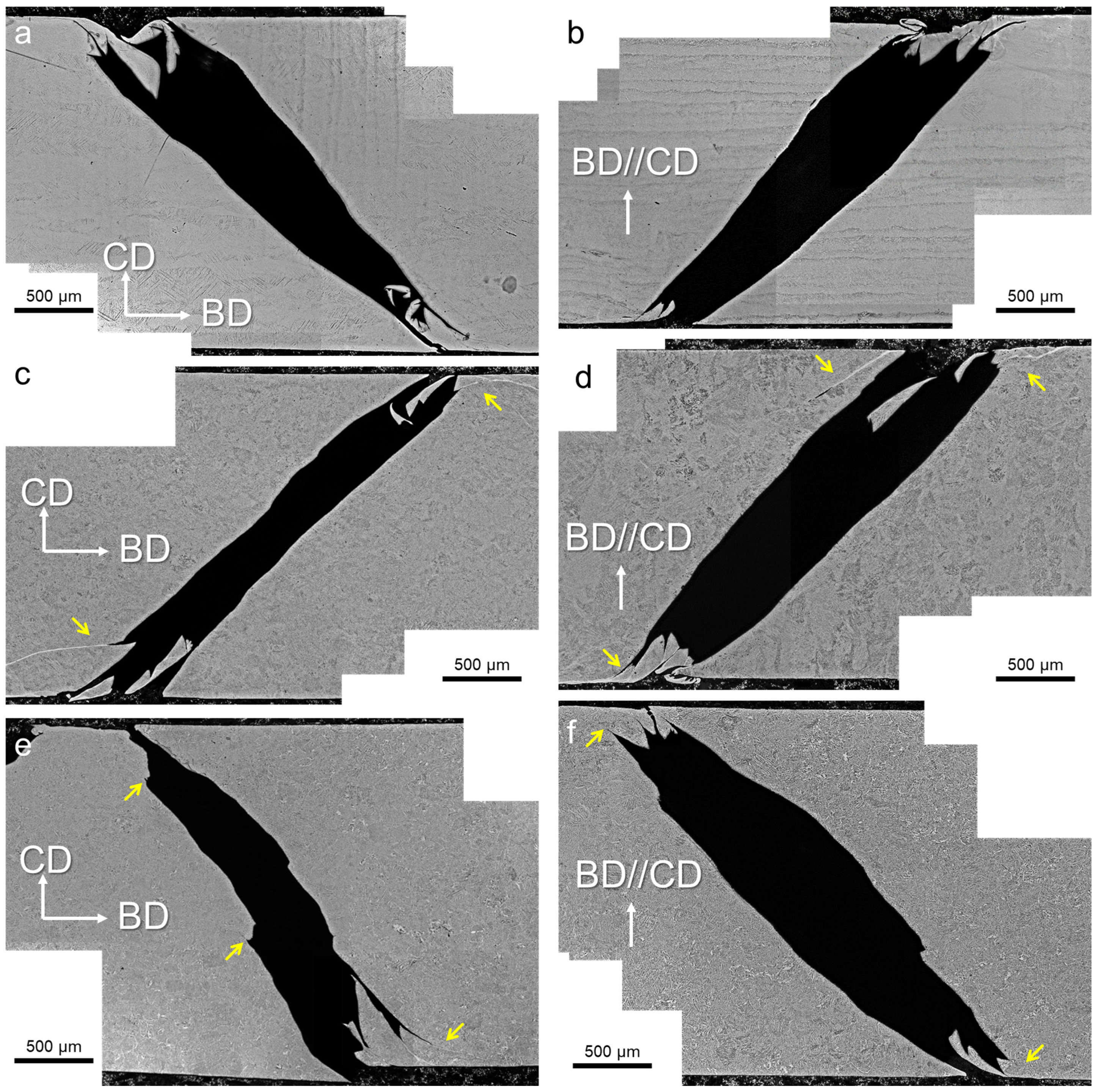

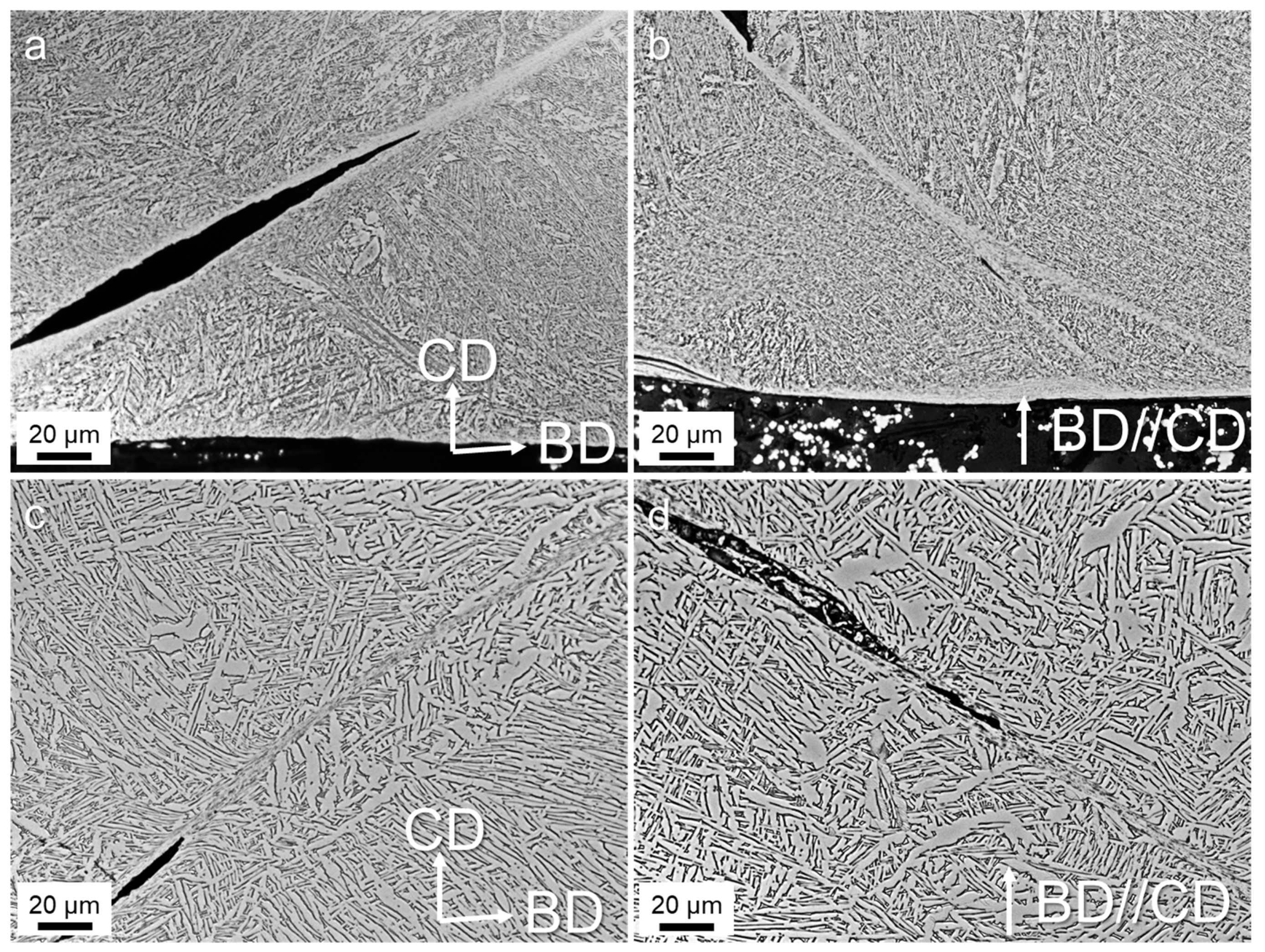

3.3. Fracture Morphology

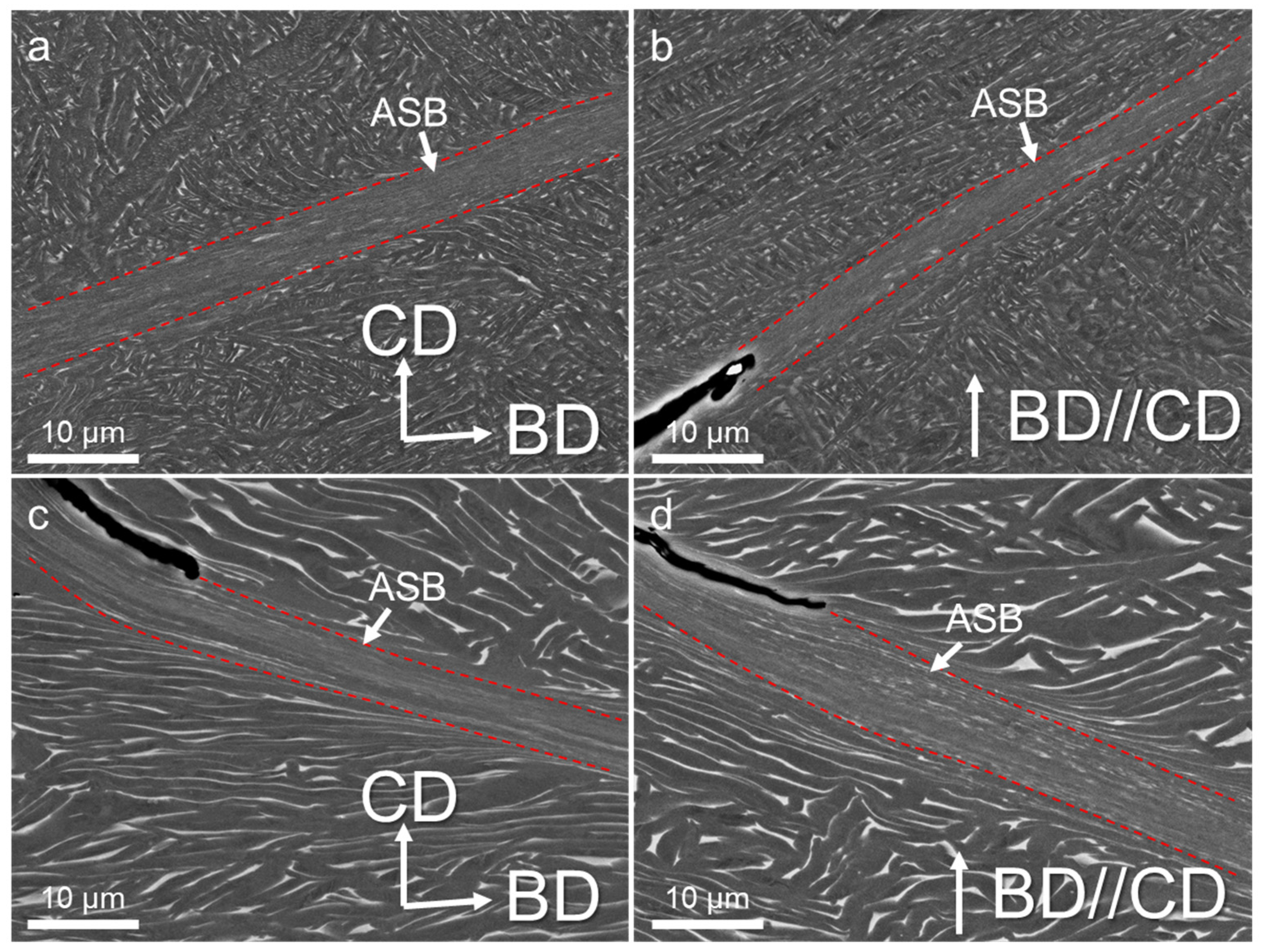

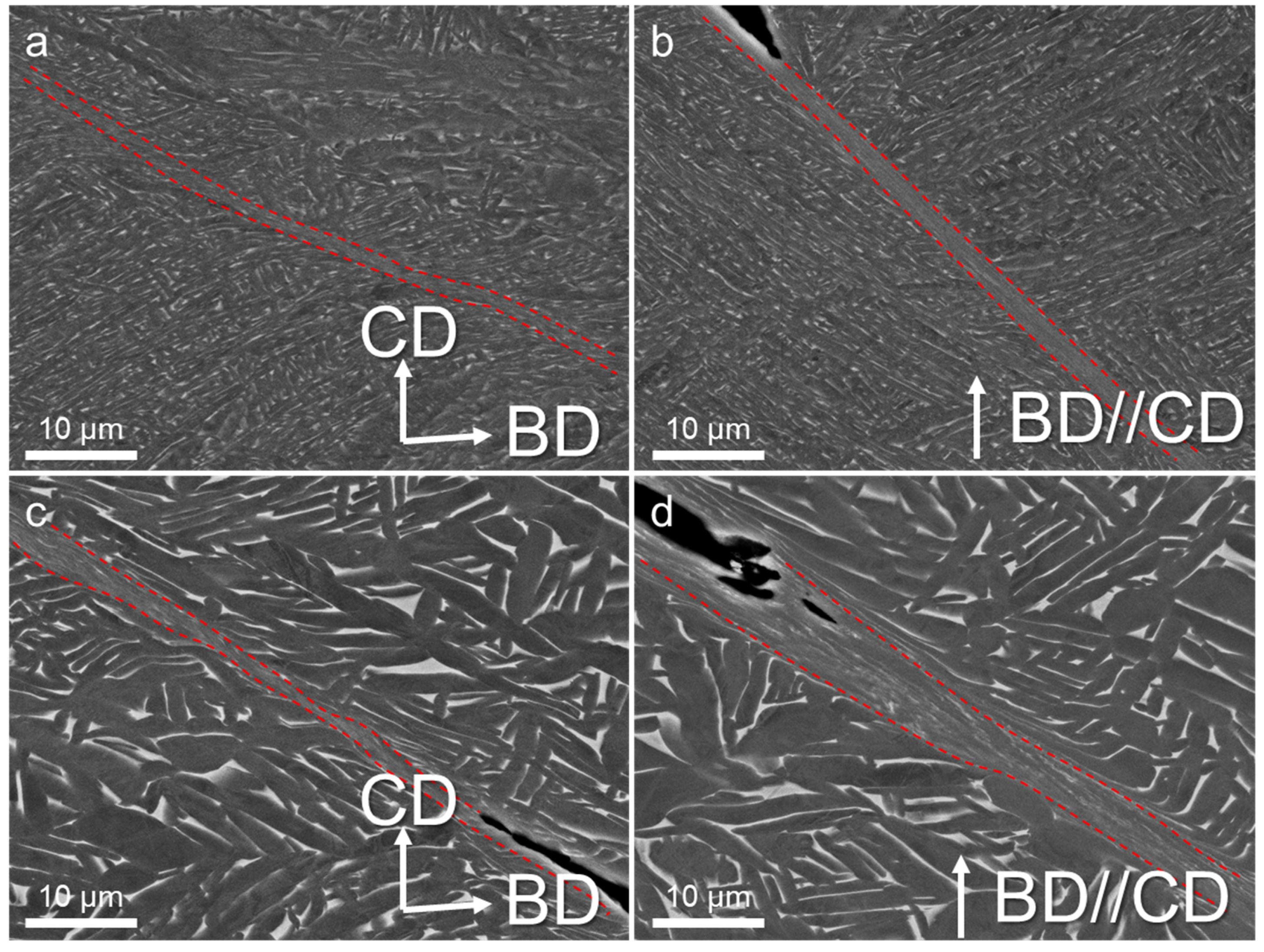

3.4. Deformation Mechanism

4. Conclusions

- (1)

- The as-built sample exhibited a martensitic structure consisting of plate-like and acicular-type α′. The α′ also contained a considerable number of substructures, such as dislocations and nanotwins. Post-heat treatment at 800 °C resulted in the formation of an α + β lamellar structure, consisting of fine α-laths (1–2 μm thick), β particles (nanoscale size distributed in the α-laths), and β films between α-laths. The HIP sample exhibited a coarsened α + β lamellar structure consisting of thick α-laths (2−5 μm thick) and β films.

- (2)

- Post-heat treatment at 800 °C led to reduced flow stress but enhanced uniform plastic strain and damage absorption work. However, the HIP process exhibited both enhanced flow stress, uniform plastic strain, and damage absorption work owing to the microstructure coarsening. The loading direction had little effect on the maximum stress and average flow stress. However, there was a significant anisotropy of uniform plastic strain and damage absorption energy. The HT800 and HIP samples had higher uniform plastic strain and damage absorption energy when they were loaded perpendicular to the build direction. The samples had a higher load-bearing capacity when dynamically loaded perpendicular to the build direction.

- (3)

- The main failure mechanism of the samples was a shear mode, accompanied by the formation of adiabatic shear bands. Cracks were easily initiated and propagated along the shear bands. The coarsened microstructure tended to make the crack propagation difficult.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Thomas, D. Costs, benefits, and adoption of additive manufacturing: A supply chain perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Yang, T.; Gong, N.; Wu, J.; Wu, X.; Zhang, D.Z.; Murr, L.E. Additive manufacturing of ultra-high strength steels: A review. J. Alloys Compd. 2023, 965, 171390. [Google Scholar] [CrossRef]

- Pothala, S. Recent Advances of Metallic Bio-Materials in Additive Manufacturing in Biomedical Implants—A Review. Mater. Today Proc. 2023; in press. [Google Scholar]

- Madigana, C.S.; Vaddula, A.; Yerramsetti, S.D.; Buddaraju, K.M. Additive Manufacturing of Titanium and Nickel-Based Superalloys: A Review. Mater. Today Proc. 2023; in press. [Google Scholar]

- Lu, K. The Future of Metals. Science 2010, 328, 319–320. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems11The Golden Jubilee Issue—Selected topics in Materials Science and Engineering: Past, Present and Future, edited by S. Suresh. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Gao, P.F.; Yang, H.; Fan, X.G.; Yan, S.L. Microstructural features of TA15 titanium alloy under different temperature routes in isothermal local loading forming. Mater. Sci. Eng. A 2012, 540, 245–252. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, S.; Yang, H. Nucleation and growth mechanism of α-lamellae of Ti alloy TA15 cooling from an α + β phase field. Acta Mater. 2013, 61, 2057–2064. [Google Scholar] [CrossRef]

- Shi, X.; Zhao, C.; Cao, Z.; Zhang, T.; Wang, Z.; Qiao, J. Mechanical behavior of a near α titanium alloy under dynamic compression: Characterization and modeling. Prog. Nat. Sci. Mater. Int. 2019, 29, 432–439. [Google Scholar] [CrossRef]

- Xu, X.; Ali, T.; Wang, L.; Cheng, H.; Zhou, Z.; Ning, Z.; Liu, X.; Liu, A.; Zhang, B.; Cheng, X. Research on dynamic compression properties and deformation mechanism of Ti6321 titanium alloy. J. Mater. Res. Technol. 2020, 9, 11509–11516. [Google Scholar]

- Chen, W.; Liu, Y.; Gang, L.; Zhou, L.; Qiu, W.; Ren, Y.; Niu, Y.; Chen, J.; Li, C. Twinning transfer in a near β-Ti alloy under high strain rate dynamic loading. J. Mater. Res. Technol. 2023, 25, 6777–6781. [Google Scholar] [CrossRef]

- Cheng, F.; Wang, H.; Li, Z.; Cheng, X.; Zheng, D.; Zhang, S.; Hu, X.; Zhang, H.; Liu, M. Dynamic compression deformation behavior of laser directed energy deposited α + β duplex titanium alloy with basket-weave morphology. Addit. Manuf. 2023, 61, 103336. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, Y.; Qiao, Y.; Xie, J.; Xu, Q.; Qi, Y.; Zhang, W.; Chen, P. Effect of build orientation on dynamic compressive behaviour of Ti-6Al-4V alloy fabricated by selective laser melting. Mater. Sci. Eng. A 2023, 862, 144440. [Google Scholar] [CrossRef]

- Chen, R.; Tan, C.; You, Z.; Li, Z.; Zhang, S.; Nie, Z.; Yu, X.; Zhao, X. Effect of α phase on high-strain rate deformation behavior of laser melting deposited Ti-6.5Al-1Mo-1V-2Zr titanium alloy. Mater. Sci. Eng. A 2019, 750, 81–90. [Google Scholar] [CrossRef]

- Xue, L.; Xiao, J.; Nie, Z.; Hao, F.; Chen, R.; Liu, C.; Yu, X.; Tan, C. Dynamic response of Ti-6.5Al–1Mo–1V–2Zr-0.1B alloy fabricated by wire arc additive manufacturing. Mater. Sci. Eng. A 2021, 800, 140310. [Google Scholar] [CrossRef]

- Meyers, M.A.; Nesterenko, V.F.; LaSalvia, J.C.; Xue, Q. Shear localization in dynamic deformation of materials: Microstructural evolution and self-organization. Mater. Sci. Eng. A 2001, 317, 204–225. [Google Scholar] [CrossRef]

- He, S.; Zeng, W.; Jia, R.; Xu, J.; Zhang, X. The mechanical response and failure mechanism of a near α titanium alloy under high-strain-rate compression at different temperatures. Mater. Sci. Eng. A 2021, 814, 140749. [Google Scholar] [CrossRef]

- Li, Y.S.; Tao, N.R.; Lu, K. Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater. 2008, 56, 230–241. [Google Scholar] [CrossRef]

- Xue, Q.; Meyers, M.A.; Nesterenko, V.F. Self-organization of shear bands in titanium and Ti–6Al–4V alloy. Acta Mater. 2002, 50, 575–596. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, H.; Maierdan, A.; Li, N.; Wang, C.; Li, C. Dynamic Response of Ti-6Al-2Zr-1Mo-1V Alloy Manufactured by Laser Powder-Bed Fusion. Materials 2024, 17, 3361. https://doi.org/10.3390/ma17133361

Qin H, Maierdan A, Li N, Wang C, Li C. Dynamic Response of Ti-6Al-2Zr-1Mo-1V Alloy Manufactured by Laser Powder-Bed Fusion. Materials. 2024; 17(13):3361. https://doi.org/10.3390/ma17133361

Chicago/Turabian StyleQin, Hanzhao, Alafate Maierdan, Nan Li, Changshun Wang, and Chenglin Li. 2024. "Dynamic Response of Ti-6Al-2Zr-1Mo-1V Alloy Manufactured by Laser Powder-Bed Fusion" Materials 17, no. 13: 3361. https://doi.org/10.3390/ma17133361