Development of Carbon Black Coating on TPU Elastic Powder for Selective Laser Sintering

Abstract

:1. Introduction

2. Material and Methods

2.1. Material Selection

2.2. Experimental Process

3. Results and Discussion

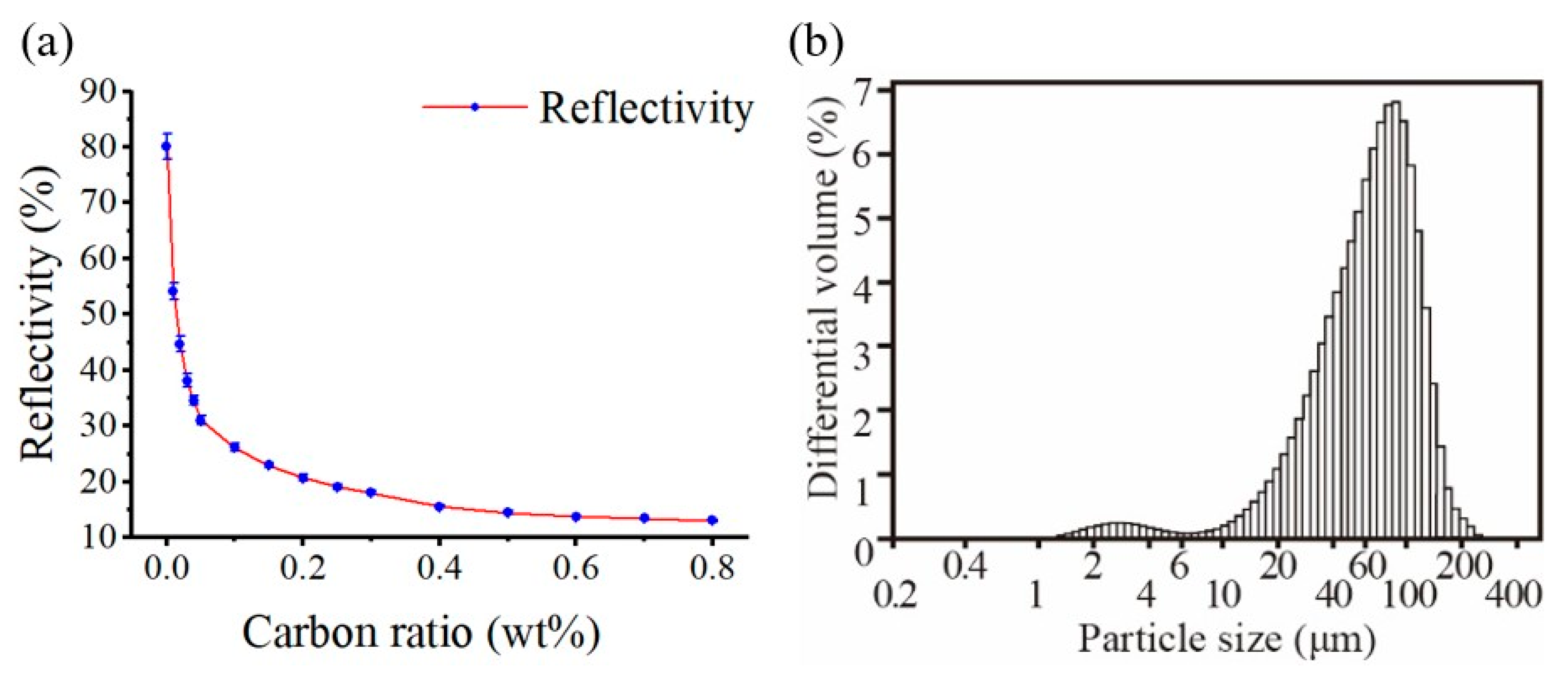

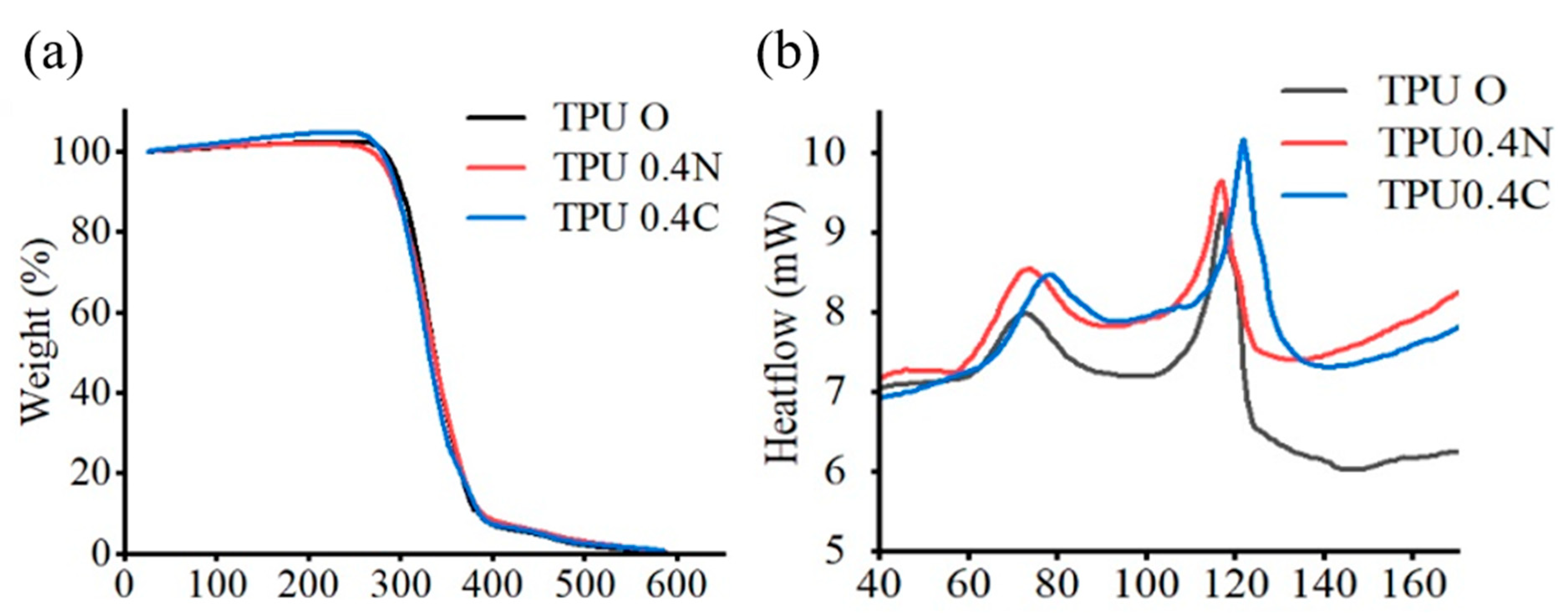

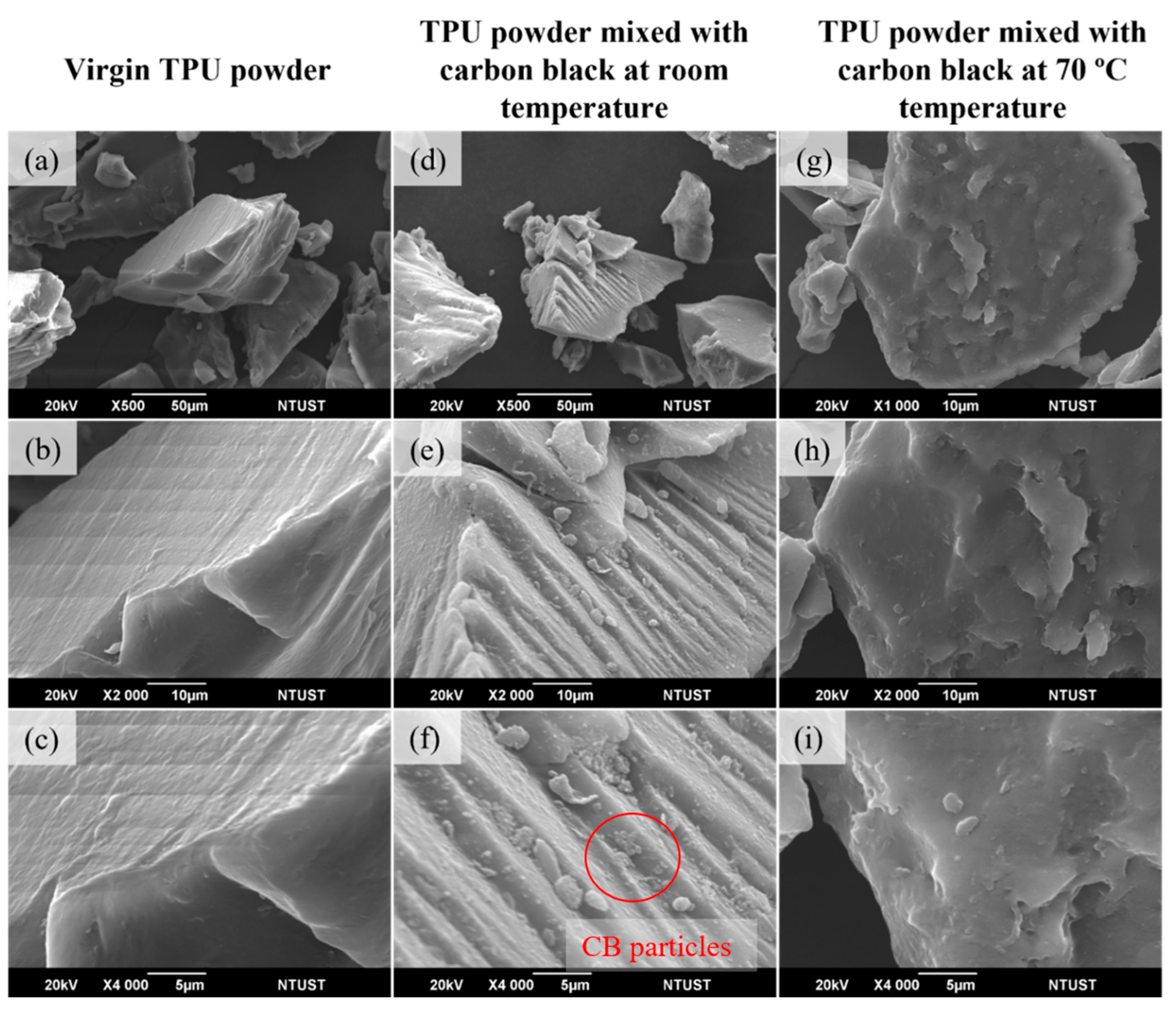

3.1. Material Characterization

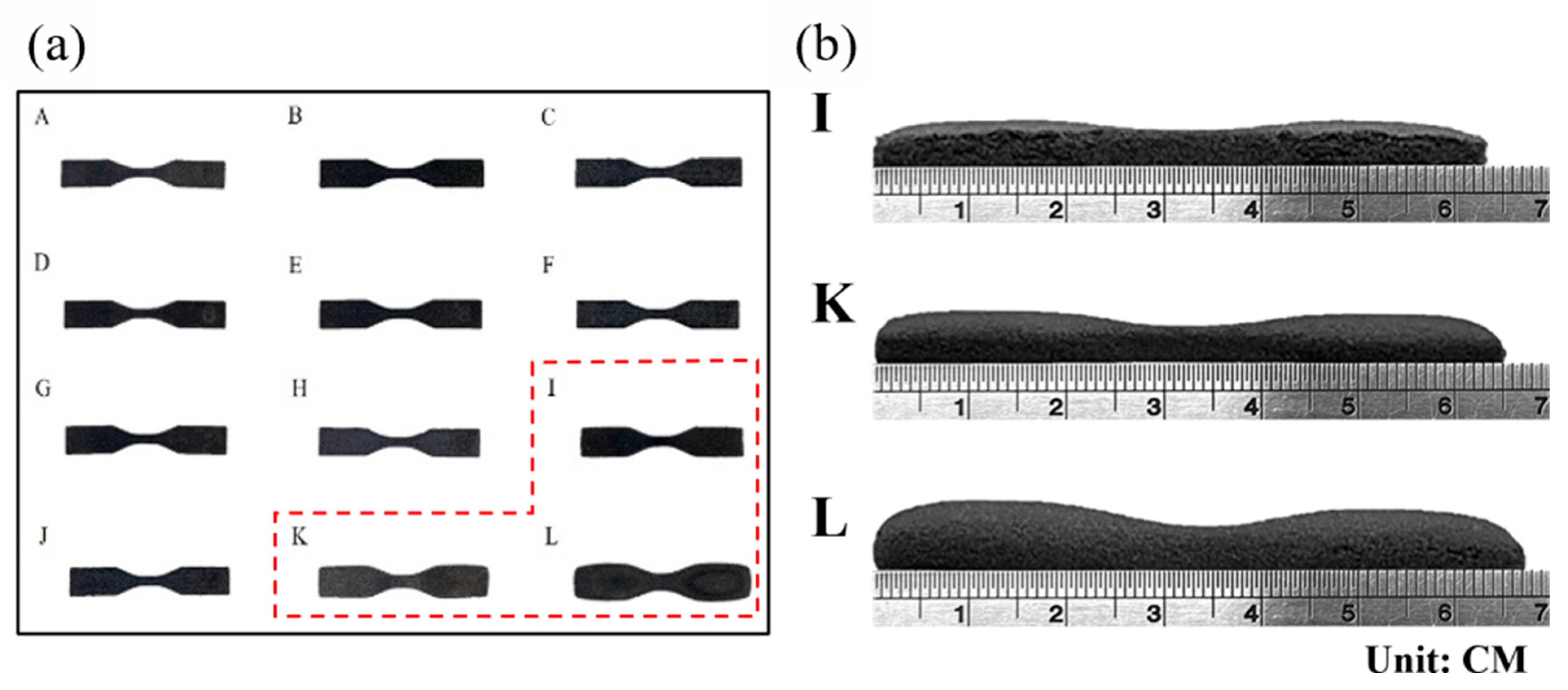

3.2. Printed Dimension in TPU

3.3. Influence of Print Layer Thickness in TPU

3.4. Influence of Print Temperature and Energy

3.5. Influence of Carbon Black Added in TPU

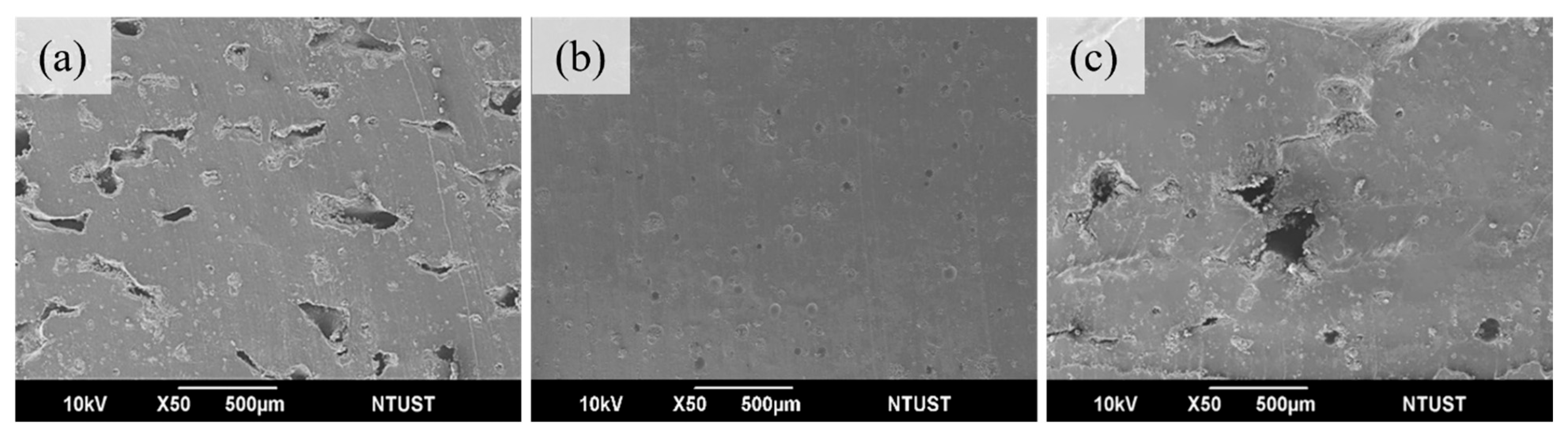

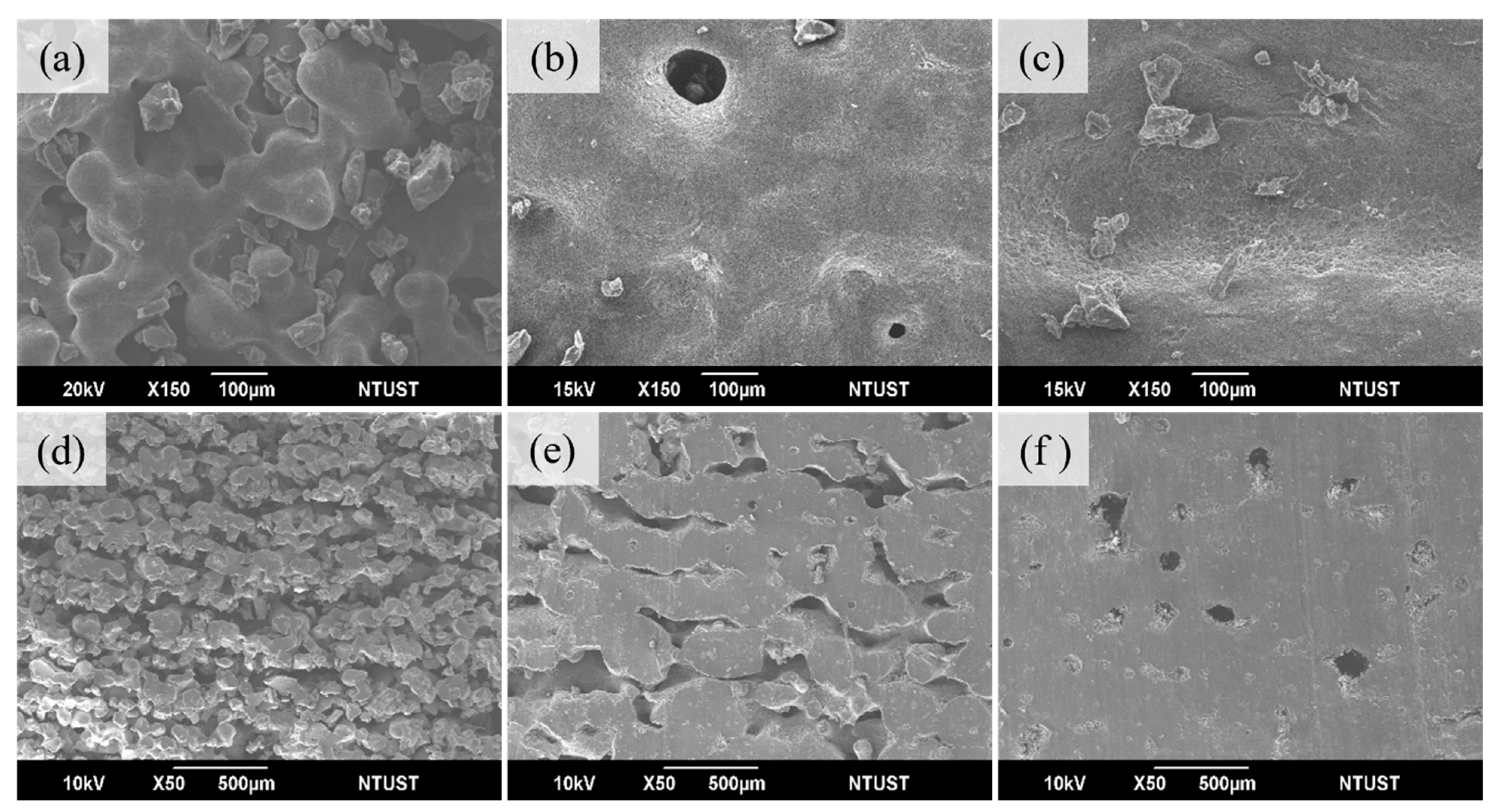

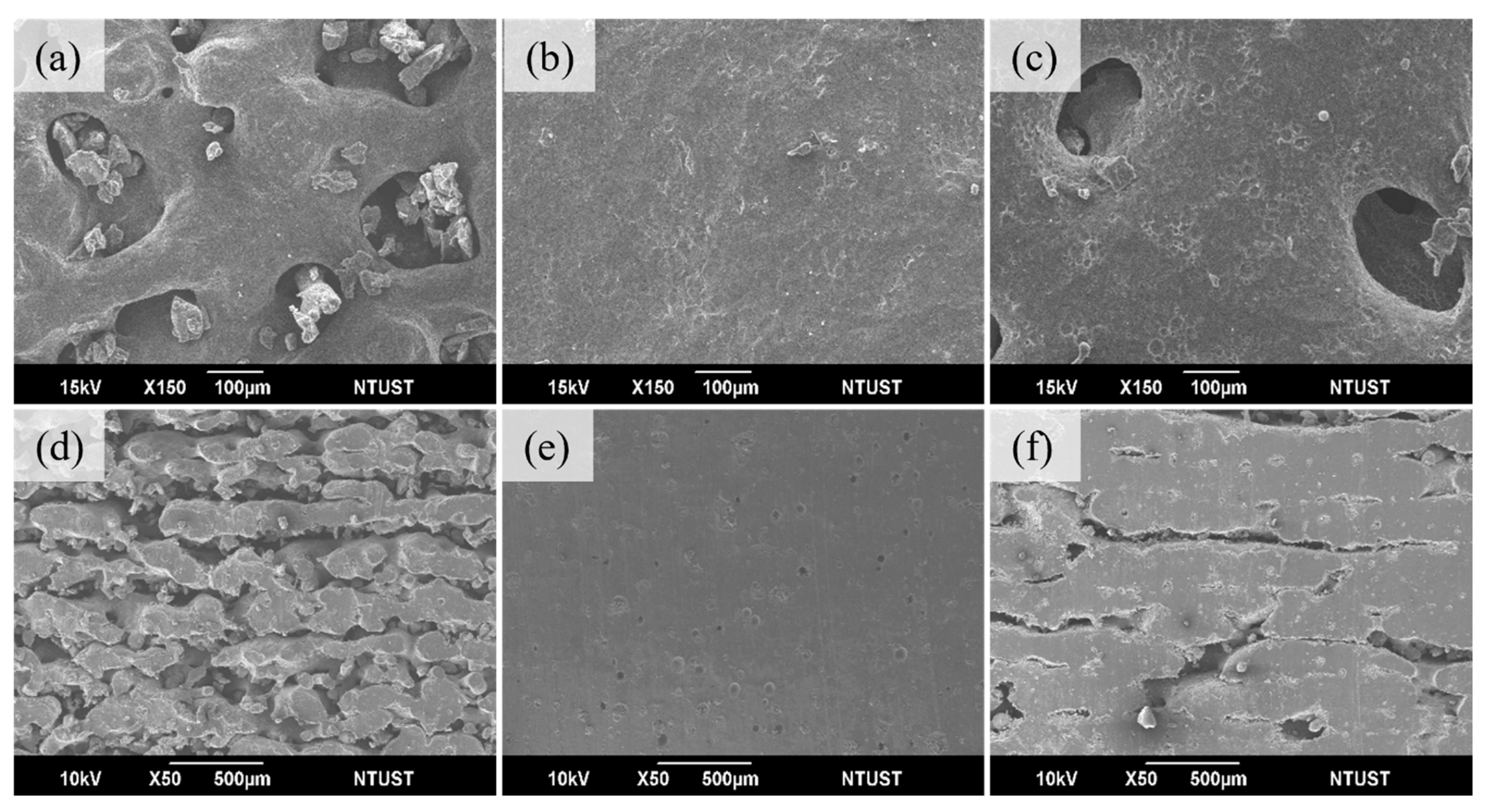

3.6. Porosities Observation and Printed Application

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer International Publishing: New York, NY, USA, 2021. [Google Scholar]

- Prajapati, M.J.; Bhat, C.; Kumar, A.; Verma, S.; Lin, S.-C.; Jeng, J.-Y. Supportless Lattice Structure for Additive Manufacturing of Functional Products and the Evaluation of Its Mechanical Property at Variable Strain Rates. Materials 2022, 15, 7954. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, A.; Wegener, K. Polymer Powders for Selective Laser Sintering (SLS). In Proceedings of the AIP Conference Proceedings, Cleveland, OH, USA, 22 May 2015; American Institute of Physics Inc.: College Park, MD, USA, 2015; Volume 1664, p. 160009. [Google Scholar]

- Shen, F.; Yuan, S.; Guo, Y.; Zhao, B.; Bai, J.; Qwamizadeh, M.; Chua, C.K.; Wei, J.; Zhou, K. Energy Absorption of Thermoplastic Polyurethane Lattice Structures via 3D Printing: Modeling and Prediction. Int. J. Appl. Mech. 2016, 8, 1640006. [Google Scholar] [CrossRef]

- Yuan, S.; Chua, C.K.; Zhou, K. 3D-Printed Mechanical Metamaterials with High Energy Absorption. Adv. Mater. Technol. 2019, 4, 1800419. [Google Scholar] [CrossRef]

- Prajapati, M.J.; Kumar, A.; Lin, S.C.; Jeng, J.Y. Multi-Material Additive Manufacturing with Lightweight Closed-Cell Foam-Filled Lattice Structures for Enhanced Mechanical and Functional Properties. Addit. Manuf. 2022, 54, 102766. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process Phenomena and Material Properties in Selective Laser Sintering of Polymers: A Review. Materials 2022, 15, 183. [Google Scholar] [CrossRef]

- Zhuang, Y.; Guo, Y.; Li, J.; Jiang, K.; Zhang, H.; Meng, D. Study on Process and Parameter Optimisation of Selective Laser Sintering of Thermoplastic Polyurethane/Carbon Nanotube Powder. Int. J. Adv. Manuf. Technol. 2021, 116, 993–1001. [Google Scholar] [CrossRef]

- Qi, H.J.; Boyce, M.C. Stress-Strain Behavior of Thermoplastic Polyurethanes. Mech. Mater. 2005, 37, 817–839. [Google Scholar] [CrossRef]

- Prajapati, M.J.; Kumar, A.; Lin, S.C.; Jeng, J.Y. Closed-Cell Metamaterial Composites 3D Printed with Hybrid FFF Process for Tunable Mechanical and Functional Properties. Thin Walled Struct. 2023, 192, 111168. [Google Scholar] [CrossRef]

- Xu, T.; Shen, W.; Lin, X.; Xie, Y.M. Mechanical Properties of Additively Manufactured Thermoplastic Polyurethane (TPU) Material Affected by Various Processing Parameters. Polymers 2020, 12, 3010. [Google Scholar] [CrossRef]

- Choi, J.; Moon, D.S.; Jang, J.U.; Yin, W.B.; Lee, B.; Lee, K.J. Synthesis of Highly Functionalized Thermoplastic Polyurethanes and Their Potential Applications. Polymer 2017, 116, 287–294. [Google Scholar] [CrossRef]

- Desai, S.M.; Sonawane, R.Y.; More, A.P. Thermoplastic Polyurethane for Three-Dimensional Printing Applications: A Review. Polym. Adv. Technol. 2023, 34, 2061–2082. [Google Scholar] [CrossRef]

- Solouki Bonab, V.; Manas-Zloczower, I. Revisiting Thermoplastic Polyurethane, from Composition to Morphology and Properties. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1553–1564. [Google Scholar] [CrossRef]

- Jabri, F.; Ouballouch, A.; Lasri, L.; EL Alaiji, R. A Review on Selective Laser Sintering 3D Printing Technology for Polymer Materials. In Casablanca International Conference on Additive Manufacturing; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 63–71. [Google Scholar]

- Morano, C.; Pagnotta, L. Additive Manufactured Parts Produced Using Selective Laser Sintering Technology: Comparison between Porosity of Pure and Blended Polymers. Polymers 2023, 15, 4446. [Google Scholar] [CrossRef]

- Wang, P.; Li, J.; Wang, G.; He, L.; Yu, Y.; Xu, B. Multimaterial Additive Manufacturing of LTCC Matrix and Silver Conductors for 3D Ceramic Electronics. Adv. Mater. Technol. 2022, 7, 2101462. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, W.; Hu, H.; Rui, Z.; Ye, J.; Wang, Z.; Wang, Y.; Shen, H. Preparation of SiO2/Si3N4ws/PU Reinforced Coating and Its Reinforcement Mechanism for SLS-Molded TPU Materials. J. Appl. Polym. Sci. 2023, 140, e54355. [Google Scholar] [CrossRef]

- Zhou, M.; Zhu, W.; Yu, S.; Tian, Y.; Zhou, K. Selective Laser Sintering of Carbon Nanotube–Coated Thermoplastic Polyurethane: Mechanical, Electrical, and Piezoresistive Properties. Compos. Part C Open Access 2022, 7, 100212. [Google Scholar] [CrossRef]

- Ding, B.; Zhang, Y.; Wang, J.; Mei, S.; Chen, X.; Li, S.; Zhao, W.; Zhang, X.; Shi, G.; He, Y.; et al. Selective Laser Sintering 3D-Printed Conductive Thermoplastic Polyether-Block-Amide Elastomer/Carbon Nanotube Composites for Strain Sensing System and Electro-Induced Shape Memory. Compos. Commun. 2022, 35, 101280. [Google Scholar] [CrossRef]

- Hong, R.; Zhao, Z.; Leng, J.; Wu, J.; Zhang, J. Two-Step Approach Based on Selective Laser Sintering for High Performance Carbon Black/ Polyamide 12 Composite with 3D Segregated Conductive Network. Compos. Part B Eng. 2019, 176, 107214. [Google Scholar] [CrossRef]

- Xi, S.; Zhang, P.; Huang, Y.; Kong, M.; Yang, Q.; Li, G. Laser Sintering of Cryogenically Ground Polymer Powders into High-Performance Parts: The Role of Dry Particle Coating with a Conductive Flow Agent. Polymer 2020, 186, 122044. [Google Scholar] [CrossRef]

- Hupfeld, T.; Sommereyns, A.; Riahi, F.; Doñate-Buendía, C.; Gann, S.; Schmidt, M.; Gökce, B.; Barcikowski, S. Analysis of the Nanoparticle Dispersion and Its Effect on the Crystalline Microstructure in Carbon-Additivated PA12 Feedstock Material for Laser Powder Bed Fusion. Materials 2020, 13, 3312. [Google Scholar] [CrossRef]

- Sommereyns, A.; Hupfeld, T.; Gann, S.; Wang, T.; Wu, C.; Zhuravlev, E.; Lüddecke, A.; Baumann, S.; Rudloff, J.; Lang, M.; et al. Influence of Sub-Monolayer Quantities of Carbon Nanoparticles on the Melting and Crystallization Behavior of Polyamide 12 Powders for Additive Manufacturing. Mater. Des. 2021, 201, 109487. [Google Scholar] [CrossRef]

- Wencke, Y.L.; Kutlu, Y.; Seefeldt, M.; Esen, C.; Ostendorf, A.; Luinstra, G.A. Additive Manufacturing of PA12 Carbon Nanotube Composites with a Novel Laser Polymer Deposition Process. J. Appl. Polym. Sci. 2021, 138, 50395. [Google Scholar] [CrossRef]

- Kusoglu, I.M.; Doñate-buendía, C.; Barcikowski, S.; Gökce, B. Laser Powder Bed Fusion of Polymers: Quantitative Research Direction Indices. Materials 2021, 14, 1169. [Google Scholar] [CrossRef]

- Thiele, M.; Kutlu, Y.; Dobbelstein, H.; Petermann, M.; Esen, C.; Ostendorf, A. Direct Generation of 3D Structures by Laser Polymer Deposition. J. Laser Appl. 2021, 33, 022002. [Google Scholar] [CrossRef]

| Carbon Ratios (%) | 0 | 0.03 | 0.04 | 0.05 | 0.1 | 0.15 | 0.2 | 0.25 |

|---|---|---|---|---|---|---|---|---|

| Reflectivity (%) | 80.12 ±1.69 | 38.16 ±1.15 | 34.56 ±0.76 | 31.00 ±0.82 | 26.16 ±0.75 | 22.93 ±0.46 | 20.67 ±0.58 | 19.14 ±0.36 |

| Carbon ratios (%) | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 100 | |

| Reflectivity (%) | 18.02 ±0.29 | 15.59 ±0.26 | 14.47 ±0.34 | 13.79 ±0.21 | 13.45 ±0.16 | 13.06 ±0.18 | 7.53 ±0.02 |

| No. | Theoretical Thickness | Measured Thickness | Error (%) |

|---|---|---|---|

| I | 3.2 | 4.67 | +45.9 |

| K | 5.32 | +66.3 | |

| L | 6.84 | +113.8 |

| No. | Layer Thickness (μm) | Density (g/cm3) | Tensile Strength (MPa) |

|---|---|---|---|

| 1 | 100 | 1.05 | 4.1 ± 0.58 |

| 2 | 125 | 1.09 | 7.9 ± 0.27 |

| 3 | 150 | 1.07 | 5.7 ± 0.43 |

| Material Type | Preheat Temp. (°C) | Energy Density (J/mm2) | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| 0.011 | 24 | 0.1 ± 0.04 | 40.7 ± 3.6 | ||

| TPU04C | 35 | 0.028 | 65 | 1.8 ± 0.27 | 137.3 ± 5.3 |

| 0.044 | 72 | 3.2 ± 0.29 | 164.9 ± 7.6 |

| Material Type | Preheat Temp. (°C) | Energy Density (J/mm2) | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| 0.011 | 41 | 0.4 ± 0.05 | 64.5 ± 4.7 | ||

| TPU04C | 55 | 0.028 | 70 | 3.1± 0.13 | 182.4 ± 8.4 |

| 0.044 | 74 | 5.6 ± 0.42 | 271.8 ± 6.7 |

| Material Type | Preheat Temp. (°C) | Energy Density (J/mm2) | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|

| 0.011 | 53 | 1.1 ± 0.05 | 104.7 ±5.1 | ||

| TPU04C | 75 | 0.028 | 78 | 7.9± 0.27 | 364.9 ± 6.6 |

| 0.044 | NA | NA | NA |

| Material Type | Density (g/cm3) | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Reflectivity (%) |

|---|---|---|---|---|---|

| Virgin TPU | 1.11 | 80 | 10 | >300 | 80.12 ±1.69 |

| TPU02C | 1.01 | 74 | 6.1 ± 0.36 | 320.7 ± 13.6 | 17.73 ± 0.28 |

| TPU04C | 1.09 | 78 | 7.9 ± 0.27 | 364.9 ± 6.6 | 13.81 ± 0.23 |

| TPU06C | 1.08 | 78 | 7.1 ± 0.29 | 341.6 ± 8.3 | 13.34 ± 0.19 |

| TPU04C | Sinterit TPU | |

|---|---|---|

| Tensile strength (MPa) | 7.9 ± 0.27 | 6.3 ± 0.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chao, Y.-D.; Liu, S.-C.; Yeh, D.-Q.; Kumar, A.; Tsai, J.-T.; Prajapati, M.J.; Jeng, J.-Y. Development of Carbon Black Coating on TPU Elastic Powder for Selective Laser Sintering. Materials 2024, 17, 3363. https://doi.org/10.3390/ma17133363

Chao Y-D, Liu S-C, Yeh D-Q, Kumar A, Tsai J-T, Prajapati MJ, Jeng J-Y. Development of Carbon Black Coating on TPU Elastic Powder for Selective Laser Sintering. Materials. 2024; 17(13):3363. https://doi.org/10.3390/ma17133363

Chicago/Turabian StyleChao, Yu-Deh, Shu-Cheng Liu, Dong-Quan Yeh, Ajeet Kumar, Jung-Ting Tsai, Mayur Jiyalal Prajapati, and Jeng-Ywan Jeng. 2024. "Development of Carbon Black Coating on TPU Elastic Powder for Selective Laser Sintering" Materials 17, no. 13: 3363. https://doi.org/10.3390/ma17133363

APA StyleChao, Y.-D., Liu, S.-C., Yeh, D.-Q., Kumar, A., Tsai, J.-T., Prajapati, M. J., & Jeng, J.-Y. (2024). Development of Carbon Black Coating on TPU Elastic Powder for Selective Laser Sintering. Materials, 17(13), 3363. https://doi.org/10.3390/ma17133363