Mechanical Properties of Silicon Carbide Composites Reinforced with Reduced Graphene Oxide

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

- Sintering Challenges and Additives:

- Silicon carbide (SiC) is inherently difficult to sinter, necessitating the use of sintering aids.

- Boron was chosen as a sintering activator, facilitating the liquid sintering process.

- Reduced graphene oxide (rGO) served dual roles as a reinforcing phase and as a carbon source.

- Phase Transformation and Microstructure:

- Due to the instability of the β–SiC phase, a phase transformation occurs during the sintering process at 2000 °C.

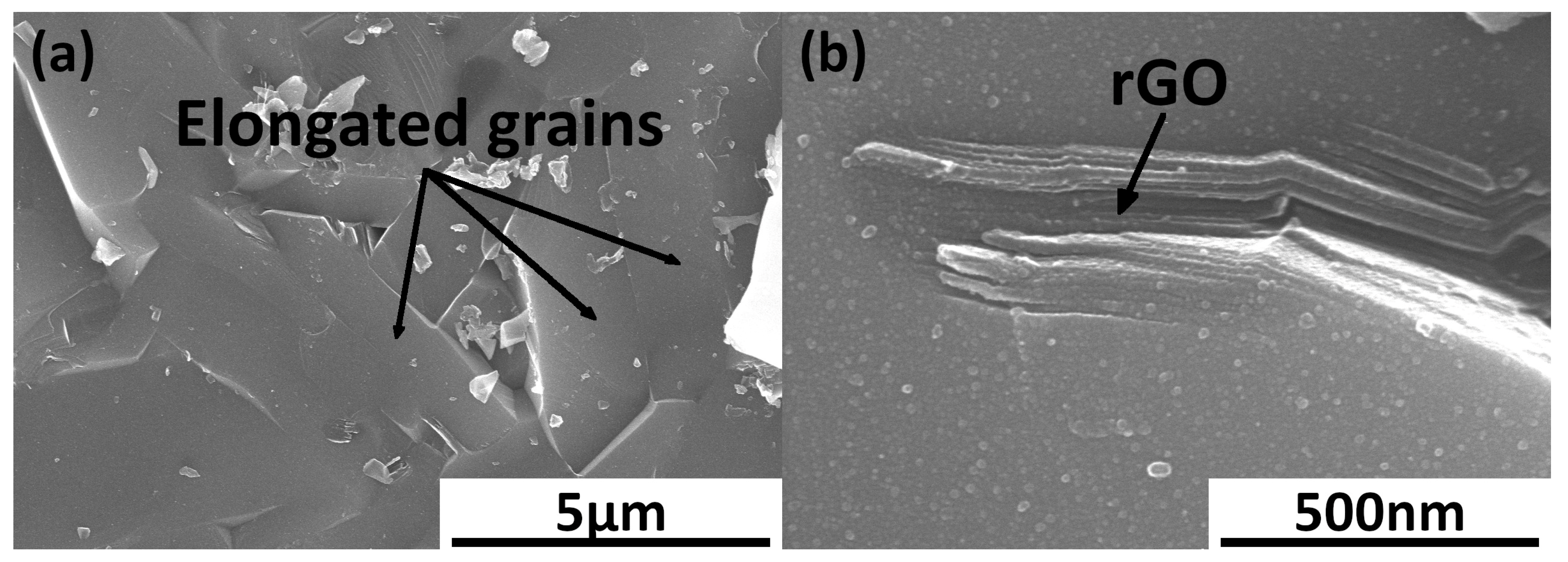

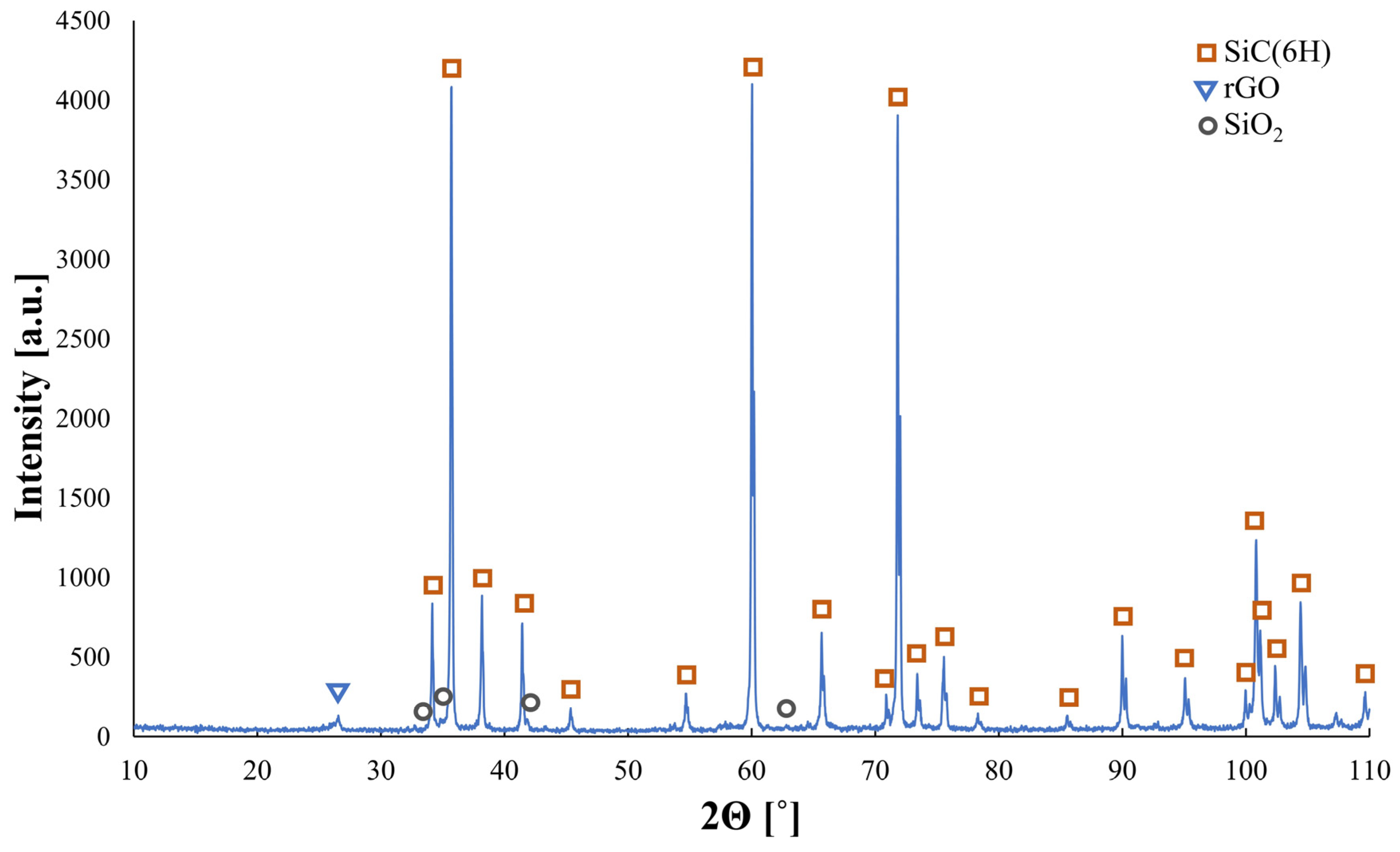

- XRD analysis confirmed the formation of hexagonal α–SiC and the presence of elongated grains in the microstructure.

- The produced composites comprise three phases: α–SiC (6H), rGO, and SiO2.

- Raman Spectroscopy Analysis:

- Raman spectroscopy revealed a shift in the characteristic peaks for rGO towards higher values in the composites compared to the rGO powder.

- This shift indicates a lower number of defects in the rGO within the sintered samples.

- The reduced ID/IG ratio and the appearance of a D’ band in the composites further confirm the decrease in rGO defects, attributable to further reduction during the sintering process.

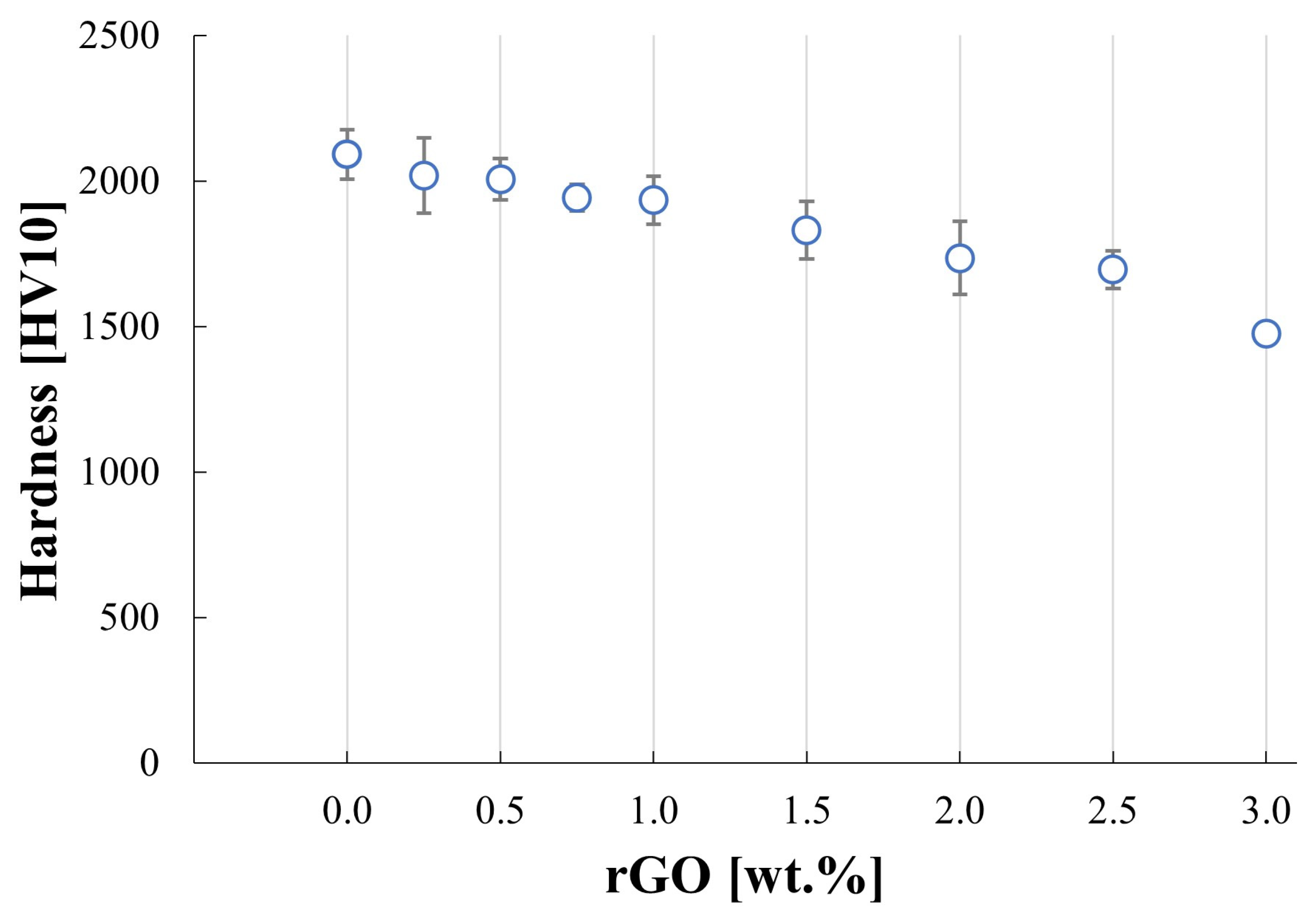

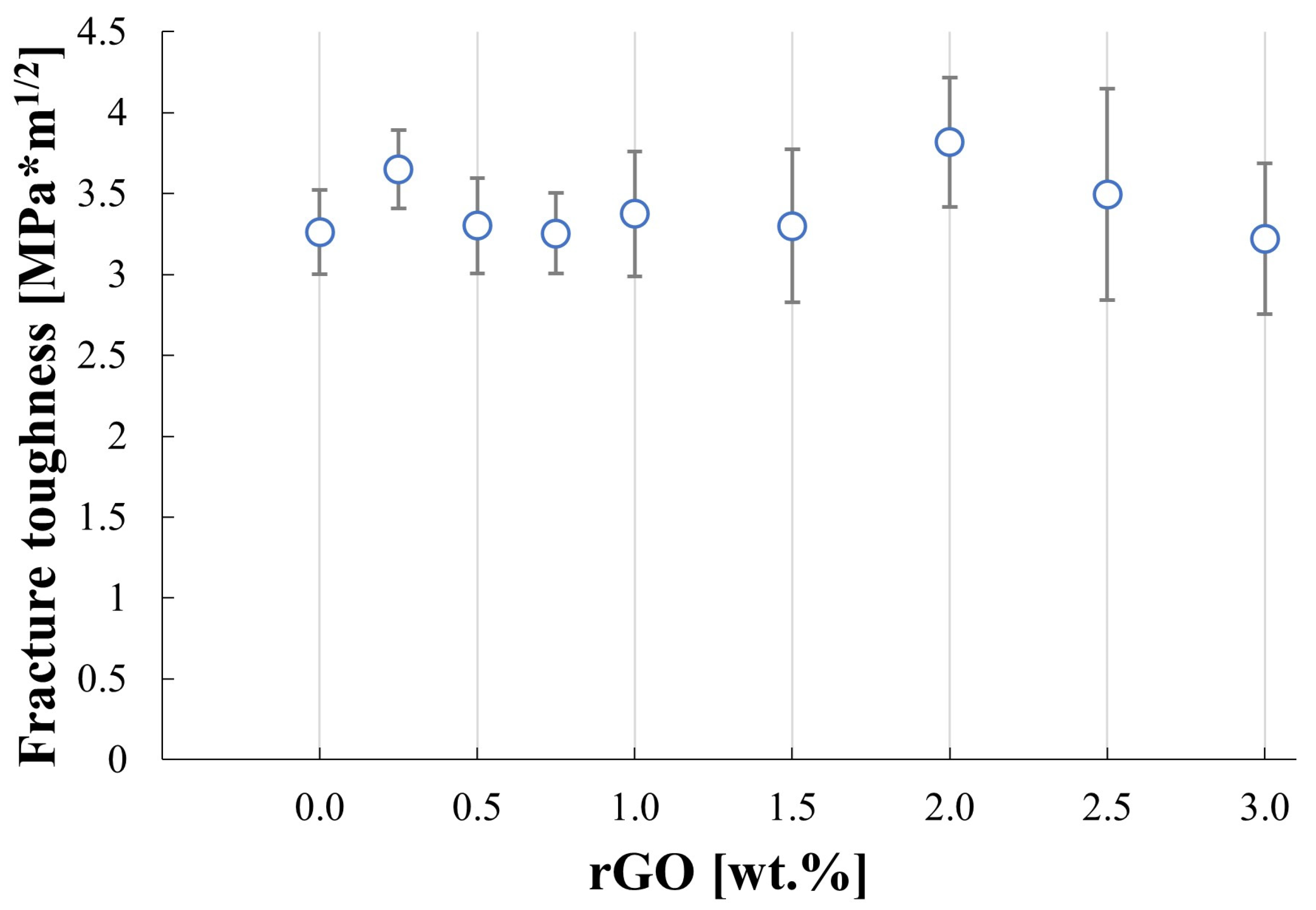

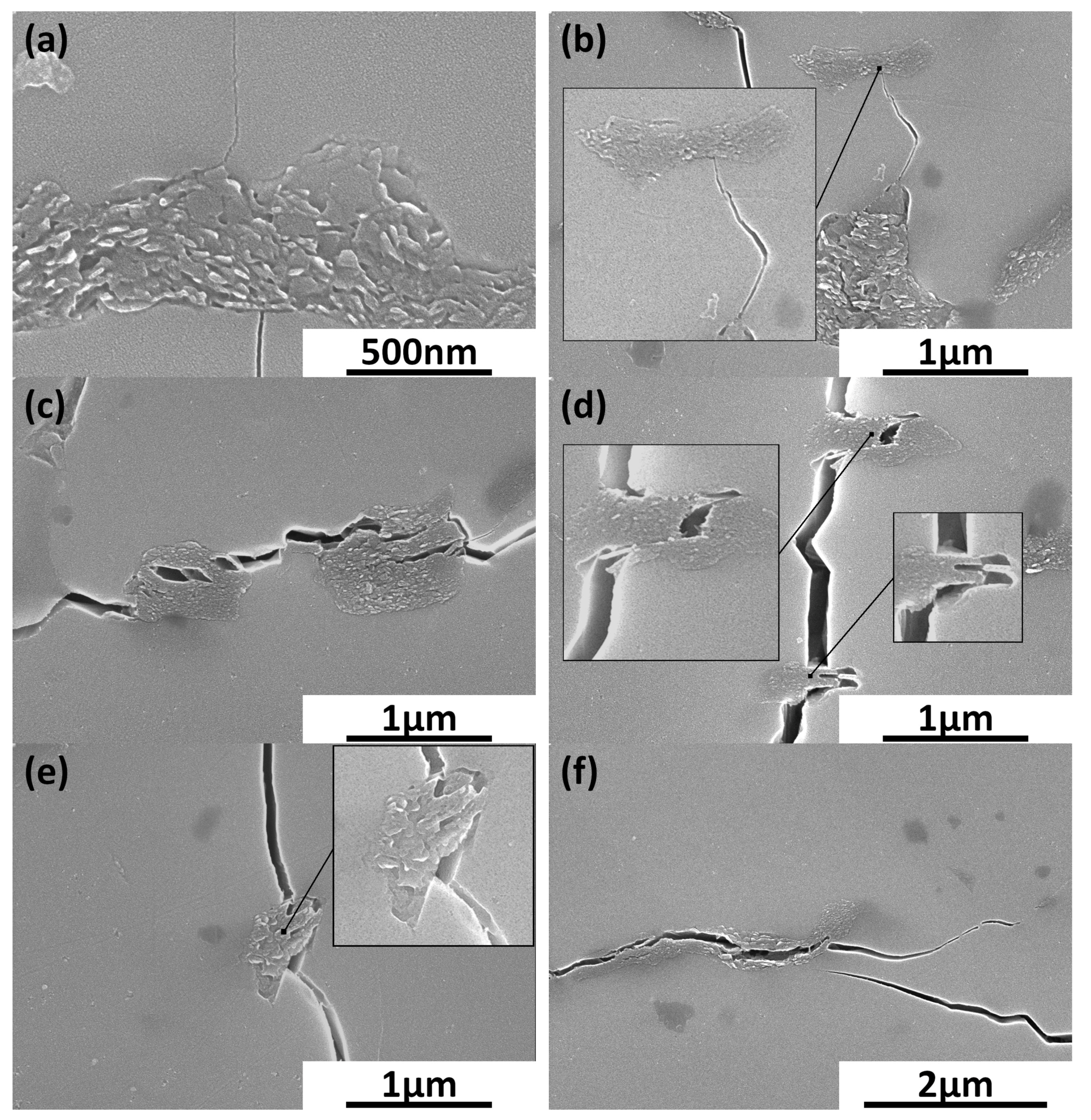

- Mechanical Properties:

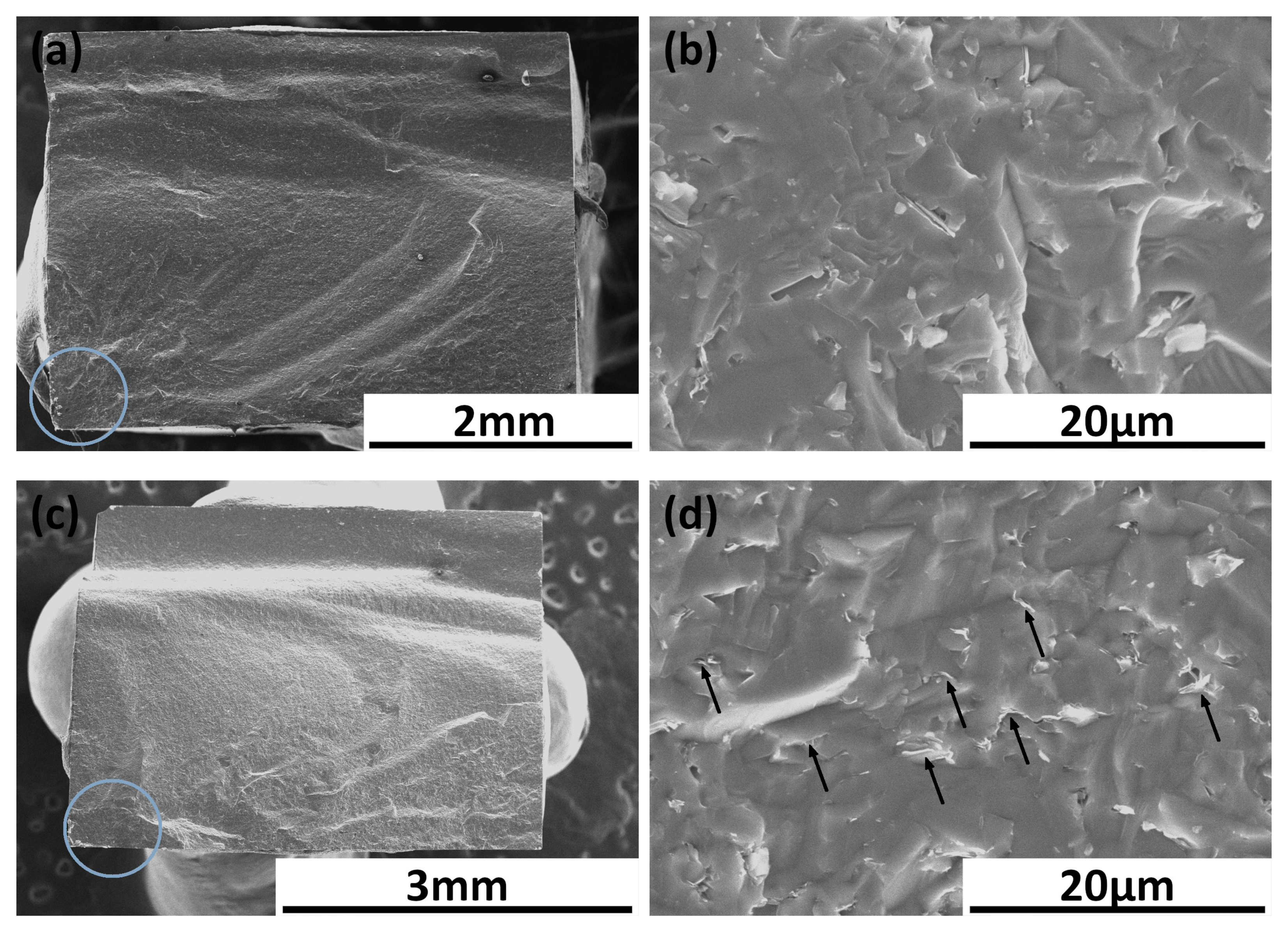

- Fracture toughness measurements showed a high standard deviation due to the presence of rGO agglomerates in the microstructure.

- Identified toughening mechanisms, such as crack deflection, bridging, and branching, are less effective due to the loosely connected rGO particles within the agglomerates.

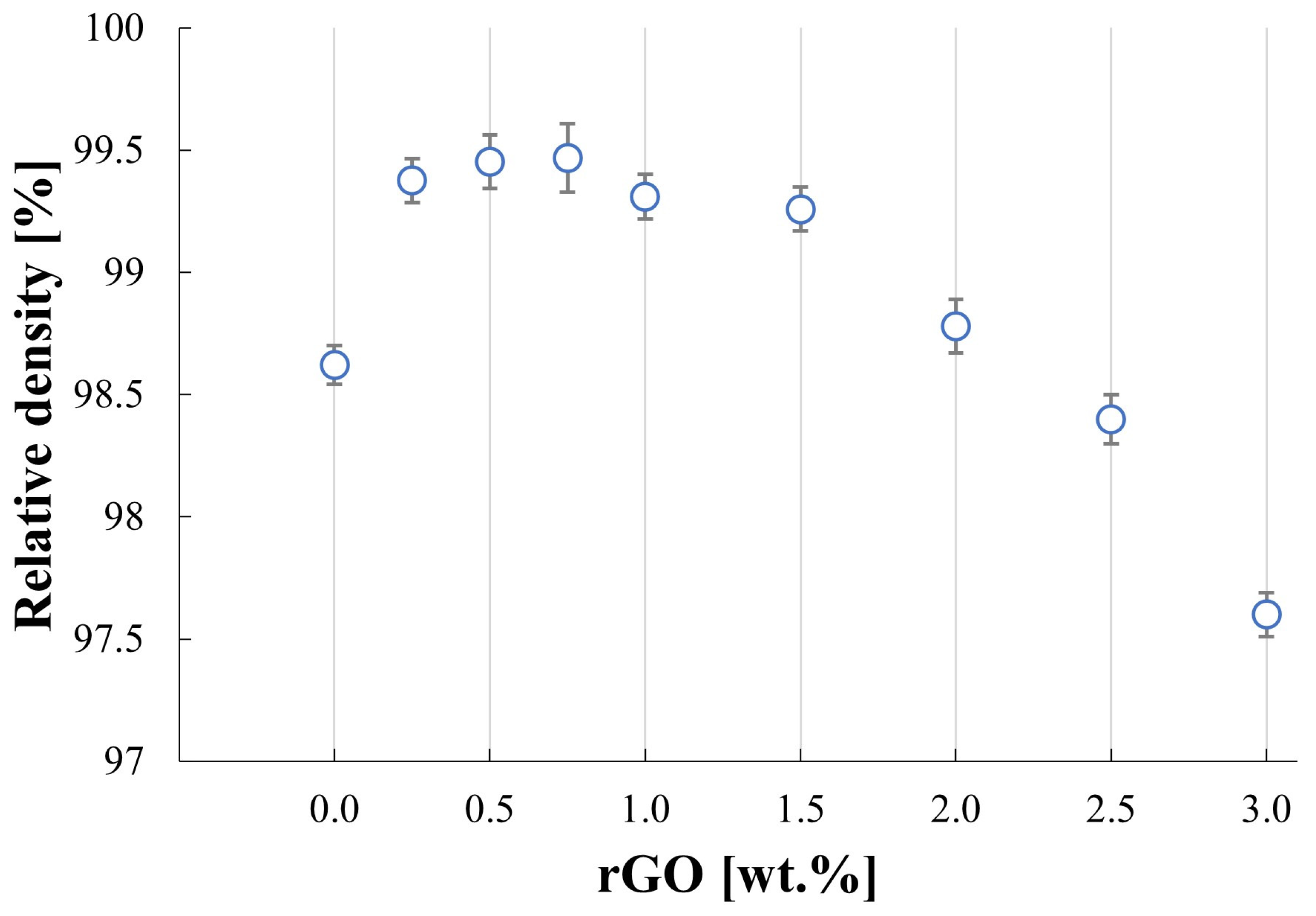

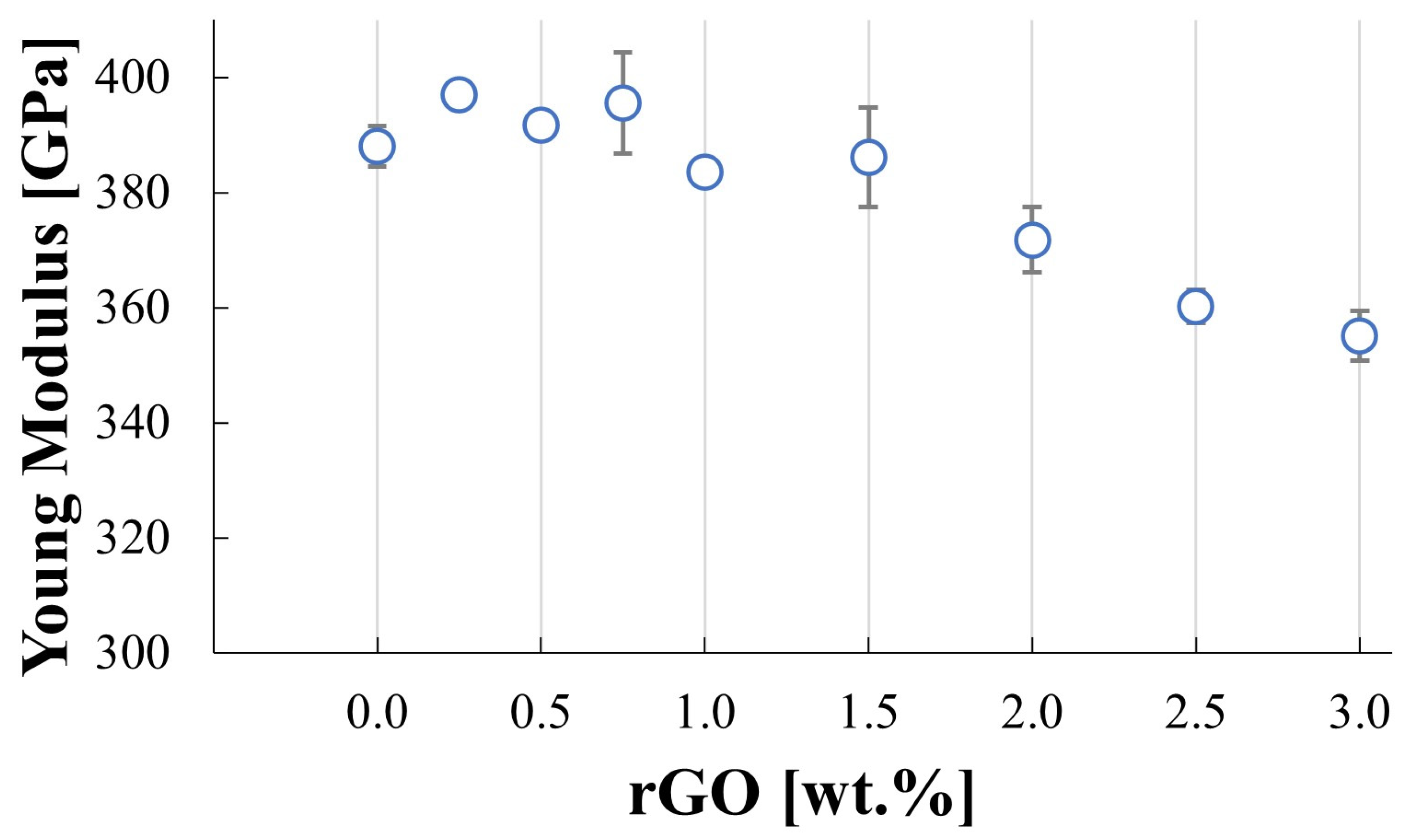

- The addition of rGO to the SiC matrix resulted in a decrease in the Young’s modulus values, which correlates well with density results.

- Despite SEM observations indicating a strong SiC–rGO interface, the presence of agglomerates significantly impacts the physical properties.

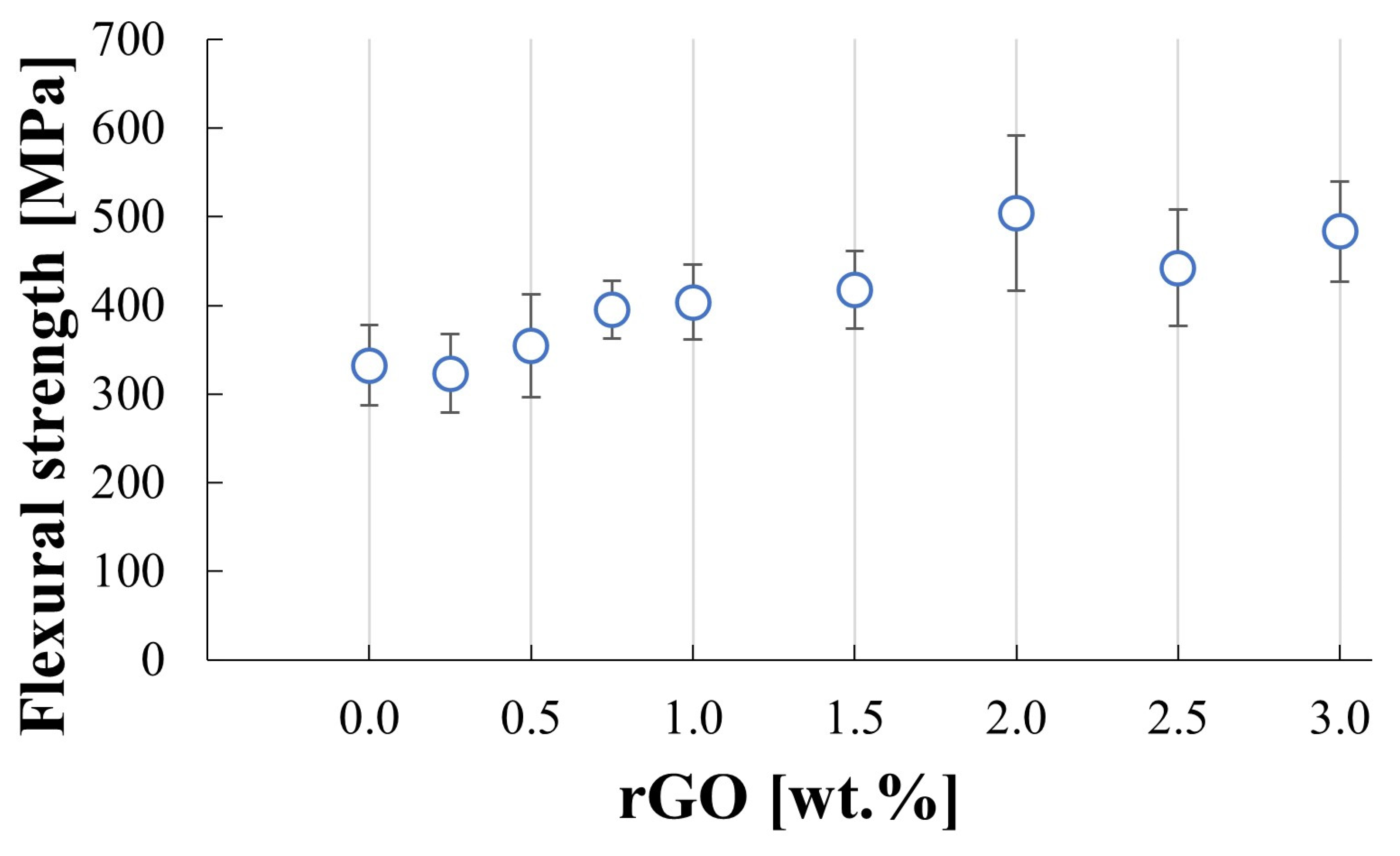

- Flexural Strength and rGO Alignment:

- Composite beams were cut such that the rGO particles aligned perpendicular to the load direction applied in the three-point bending test.

- An increase in the rGO content in the matrix led to an increase in flexural strength.

- Fracture origins were located on the convex side of the beams, where tensile strains are present.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Riedel, R. Handbook of Ceramic Hard Materials; VILEY-VCH Verlag GmbH: Weinheim, Germany, 2000. [Google Scholar]

- Liu, Y.; Li, G.; Huan, L.; Cao, S. Advancements in silicon carbide-based supercapacitors: Materials, performance, and emerging applications. Nanoscale 2023, 16, 504–526. [Google Scholar] [CrossRef] [PubMed]

- Limeng, L.; Feng, Y.; Yu, Z. Electric current pulse activated 6H ⟶ 3C transformation in silicon carbide compacts. J. Am. Ceram. Soc. 2011, 94, 2767–2771. [Google Scholar] [CrossRef]

- Katoh, Y.; Snead, L.L.; Henager, C.H., Jr.; Hasegawa, A.; Kohyama, A.; Riccardi, B.; Hegeman, H. Current Status and Critical Issues for Development of SiC Composites for Fusion Applications. J. Nucl. Mater. 2007, 367–370, 659–671. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, L.; Cheng, L.; Zhang, J.; Yang, S.; Liu, H. Wear mechanism of the C/SiC brake materials. Tribol. Int. 2011, 44, 25–28. [Google Scholar] [CrossRef]

- Prochazka, S.; Scanlan, R.M. Effect of boron and carbon on sintering of SiC. J. Am. Ceram. Soc. 1975, 58, 72. [Google Scholar] [CrossRef]

- Stobierski, L.; Gubernat, A. Sintering of silicon carbide I. Effect of carbon. Ceram. Int. 2003, 29, 287–292. [Google Scholar] [CrossRef]

- Petrus, M.; Woźniak, J.; Jastrzębska, A.; Kostecki, M.; Cygan, T.; Olszyna, A. The effect of the morphology of carbon used as a sintering aid on the sinterability of silicon carbide. Ceram. Int. 2018, 44, 7020–7025. [Google Scholar] [CrossRef]

- Stobierski, L.; Gubernat, A. Sintering of silicon carbide II. Effect of boron. Ceram. Int. 2003, 29, 355–361. [Google Scholar] [CrossRef]

- Nguyen, V.-H.; Delbari, S.A.; Asl, M.S.; Le, Q.V.; Shokouhimehr, M.; Namini, A.S.; Mohammadi, M. Microstructure–property correlation in nano-diamond and TiN added TiC-based ceramics. Ceram. Int. 2021, 47, 449–460. [Google Scholar] [CrossRef]

- Cygan, T.; Woźniak, J.; Broniszewski, K.; Kulikowski, K.; Moszczyńska, D.; Adamczyk-Cieślak, B.; Kurkowska, M.; Olszyna, A. Analysis of microstructure and mechanical properties of alumina composites reinforced with Ti2AlN MAX phases. Int. J. Refract. Met. Hard Mater. 2024, 122, 106725. [Google Scholar] [CrossRef]

- Xu, G.; Yan, Z.; Lu, H.; Cai, J.; Wang, R.; Fang, F.; Cai, C.; Suo, J. Thermal shock resistance and toughening mechanism of W/Ta and W/TiN/Ta laminated composites. Int. J. Refract. Met. Hard Mater. 2022, 105, 105810. [Google Scholar] [CrossRef]

- Broniszewski, K.; Woźniak, J.; Cygan, T.; Kostecki, M.; Moszczyńska, D.; Chmielewski, M.; Dydek, K.; Olszyna, A. Effect of Anisotropy of Reduced Graphene Oxide on Thermal and Electrical Properties in Silicon Carbide Matrix Composites. Nanomaterials 2024, 14, 555. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Jiang, D.; Chen, Z.; Liu, X.; Zhang, X.; Liao, Z.; Huang, Z. Fabrication and property of SiC/rGO composite. Inorg. Mater. 2018, 33, 1147–1153. [Google Scholar] [CrossRef]

- Xia, H.; Zhang, X.; Shi, Z.; Zhao, C.; Li, Y.; Wang, J.; Qiao, G. Mechanical and thermal properties of reduced graphene oxide reinforced aluminum nitride ceramic composites. Mater. Sci. Eng. A 2015, 639, 29–36. [Google Scholar] [CrossRef]

- Chen, C.; Han, X.; Shen, H.; Tan, Y.; Zhang, H.; Quin, Y.; Peng, S. Preferentially oriented SiC/graphene composites for enhanced mechanical and thermal properties. Ceram. Int. 2020, 46, 23173–23179. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, D.; Zhang, X.; Liao, Z.; Huang, Z. Enhancing toughness and strength of SiC ceramics with reduced graphene oxide by HP sintering. J. Eur. Ceram. Soc. 2018, 38, 4329–4337. [Google Scholar] [CrossRef]

- Belmonte, M.; Nistal, A.; Boutbien, P.; Roman-Manso, B.; Osendi, M.I.; Miranzo, P. Toughened and strengthened silicon carbide ceramics by adding graphene-based fillers. Scr. Mater. 2016, 113, 127–130. [Google Scholar] [CrossRef]

- Llorente, J.; Roman-Manso, B.; Miranzo, P.; Belmonte, M. Tribological performance under dry sliding conditions of graphene/silicon carbide composites. J. Am. Ceram. Soc. 2016, 36, 429–435. [Google Scholar] [CrossRef]

- Carl, B. Powder Metallurgy Handbook; NY Research Press: New York, NY, USA, 2015. [Google Scholar]

- Ponton, C.B.; Rawlings, R.D. Vickers indentation fracture toughness test Part 1 review of literature and formulation of standardised indentation toughness equations. Mater. Sci. Tech. Lond. 1989, 5, 865–872. [Google Scholar] [CrossRef]

- PN–EN 841PN–1; Advanced Technical Ceramics—Monolithic Ceramics—Mechanical Properties at Room Temperature—Part 1: Determination of Flexural Strength. Polski Komitet Normalizacyjny: Warsaw, Poland, 2007.

- Petrus, M.; Woźniak, J.; Cygan, T.; Adamczyk-Cieślak, B.; Kostecki, K.; Olszyna, A. Sintering behaviour of silicon carbide matrix composites reinforced with multilayer graphene. Ceram. Int. 2017, 43, 5007–5013. [Google Scholar] [CrossRef]

- Petrus, M.; Woźniak, J.; Cygan, T.; Lachowski, A.; Rozmysłowska–Wojciechowska, A.; Wojciechowski, T.; Ziemkowska, W.; Chlubny, L.; Jastrzębska, A.; Adamczyk-Cieślak, B.; et al. Silicon carbide nanocomposites reinforced with disordered graphitic carbon formed in situ through oxidation of Ti3C2 MXene during sintering. Arch. Civ. Mech. Eng. 2021, 21, 87. [Google Scholar] [CrossRef]

- Gachovska, T.K.; Hudgins, J.L. Silicon Carbide Polytypes. In Power Electronics Handbook, 5th ed.; Rashid, M.H., Ed.; Butterworth-Heinemann Inc.: Oksford, UK, 2023; Volume 4.2.1. [Google Scholar] [CrossRef]

- Stobierski, L. Ceramika Węglikowa; PTC: Kraków, Poland, 2006. [Google Scholar]

- Ragaru, C.; Lancin, M.; Marhic, C. α⇒β Phase Transformation in SiC: Link between Polytypism, Dihedral Angle and Nucleation Mechanism of α Twins. J. Eur. Ceram. Soc. 1999, 19, 2701–2709. [Google Scholar] [CrossRef]

- Khan, A.; Jadhav, A.; Khobragade, J.M.; Kadam, A.V. Extraction of excessively reduced graphene oxide from discarded dry cell batteries by anodic exfoliation method. J. Mater. Sci. Mater. Electron. 2023, 34, 62. [Google Scholar] [CrossRef]

- Mikhaylov, P.A.; Vinogradov, M.I.; Levin, I.S.; Shandryuk, G.A.; Lubenchenko, A.V.; Kulichikhin, V.G. Synthesis and characterization of polyethylene terephthalate-reduced graphene oxide composites. IOP Conf. Ser. Mater. Sci. Eng. 2019, 693, 012036. [Google Scholar] [CrossRef]

- Jepps, N.W.; Page, T.F. Polytypic transformations in silicon carbide. J. Am. Ceram. Soc. 1981, 64, C-177. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Li, X.; Xu, L.; Cao, X.; Wang, Y.; Wang, Z.; Meng, C.; Zhu, W.; Ouyang, X. Enhancing Toughness in Boron Carbide with Reduced Graphene Oxide. J. Am. Ceram. Soc. 2016, 99, 257–264. [Google Scholar] [CrossRef]

- Gomez-Navarro, C.; Burghard, M.; Kern, K. Elastic Properties of Chemically Derived Single Graphene Sheets. Nano Lett. 2008, 8, 2045–2049. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Wang, M.; Chen, Y.; Gao, J.; Ma, T. Mechanical properties and microstructure of reaction sintering SiC ceramics reinforced with graphene-based fillers. Appl. Phys. A 2019, 125, 680. [Google Scholar] [CrossRef]

- Sedlák, R.; KovalĿíková, A.; Girman, V.; Múdra, E.; Rutkowski, P.; Dubiel, A.; Dusza, J. Fracture characteristics of SiC/graphene platelet composites. J. Eur. Ceram. Soc. 2017, 37, 4307–4314. [Google Scholar] [CrossRef]

- Miranzo, P.; García, E.; Ramírez, C.; González-Julián, J.; Belmonte, M.; Osendi, M.I. Anisotropic thermal conductivity of silicon nitride ceramics containing carbon nanostructures. J. Eur. Ceram. Soc. 2012, 32, 1847–1854. [Google Scholar] [CrossRef]

- Rutkowski, P.; Stobierski, L.; Górny, G. Thermal stability and conductivity of hot-pressed Si3 N4–graphene composites. J. Therm. Anal. Calorim. 2014, 116, 321–328. [Google Scholar] [CrossRef]

| Powder | APS 1 | Manufacturer |

|---|---|---|

| Silicon carbide | 0.42 µm | Alfa Aesar (Ward Hill, MA, USA) |

| rGO | <40 µm | Łukasiewicz Research Network (Warsaw, Poland) |

| Boron | 0.39 µm | International Enzymes Limited (Fareham, UK) |

| Carbon | <100 nm | Sigma-Aldrich (Burlington, VT, USA) |

| Composite | Hardness | Fracture Toughness [MPa*m1/2] | Flexural Strength [MPa] | Ref |

|---|---|---|---|---|

| SiC–0.5% wt. rGO | 2006 HV10 | 3.30 | 323 | - |

| SiC–2% wt. rGO | 1735 HV10 | 3.82 | 503 | - |

| SiC–1% wt. GNP | 26.3 GPa | 6.50 | 560 | [16] |

| SiC–2% wt. GPLs | 20.82 GPa | 3.70 | 290 | [35] |

| SiC–1% wt. MLG | 26.64 GPa | 4.1 | - | [23] |

| SiC–1% wt. GO | - | 3.4 | 239 | [34] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Broniszewski, K.; Woźniak, J.; Cygan, T.; Moszczyńska, D.; Olszyna, A. Mechanical Properties of Silicon Carbide Composites Reinforced with Reduced Graphene Oxide. Materials 2024, 17, 3370. https://doi.org/10.3390/ma17133370

Broniszewski K, Woźniak J, Cygan T, Moszczyńska D, Olszyna A. Mechanical Properties of Silicon Carbide Composites Reinforced with Reduced Graphene Oxide. Materials. 2024; 17(13):3370. https://doi.org/10.3390/ma17133370

Chicago/Turabian StyleBroniszewski, Kamil, Jarosław Woźniak, Tomasz Cygan, Dorota Moszczyńska, and Andrzej Olszyna. 2024. "Mechanical Properties of Silicon Carbide Composites Reinforced with Reduced Graphene Oxide" Materials 17, no. 13: 3370. https://doi.org/10.3390/ma17133370

APA StyleBroniszewski, K., Woźniak, J., Cygan, T., Moszczyńska, D., & Olszyna, A. (2024). Mechanical Properties of Silicon Carbide Composites Reinforced with Reduced Graphene Oxide. Materials, 17(13), 3370. https://doi.org/10.3390/ma17133370