Effect of Energy Density on the Mechanical Properties of 1.2709 Maraging Steel Produced by Laser Powder Bed Fusion

Abstract

:1. Introduction

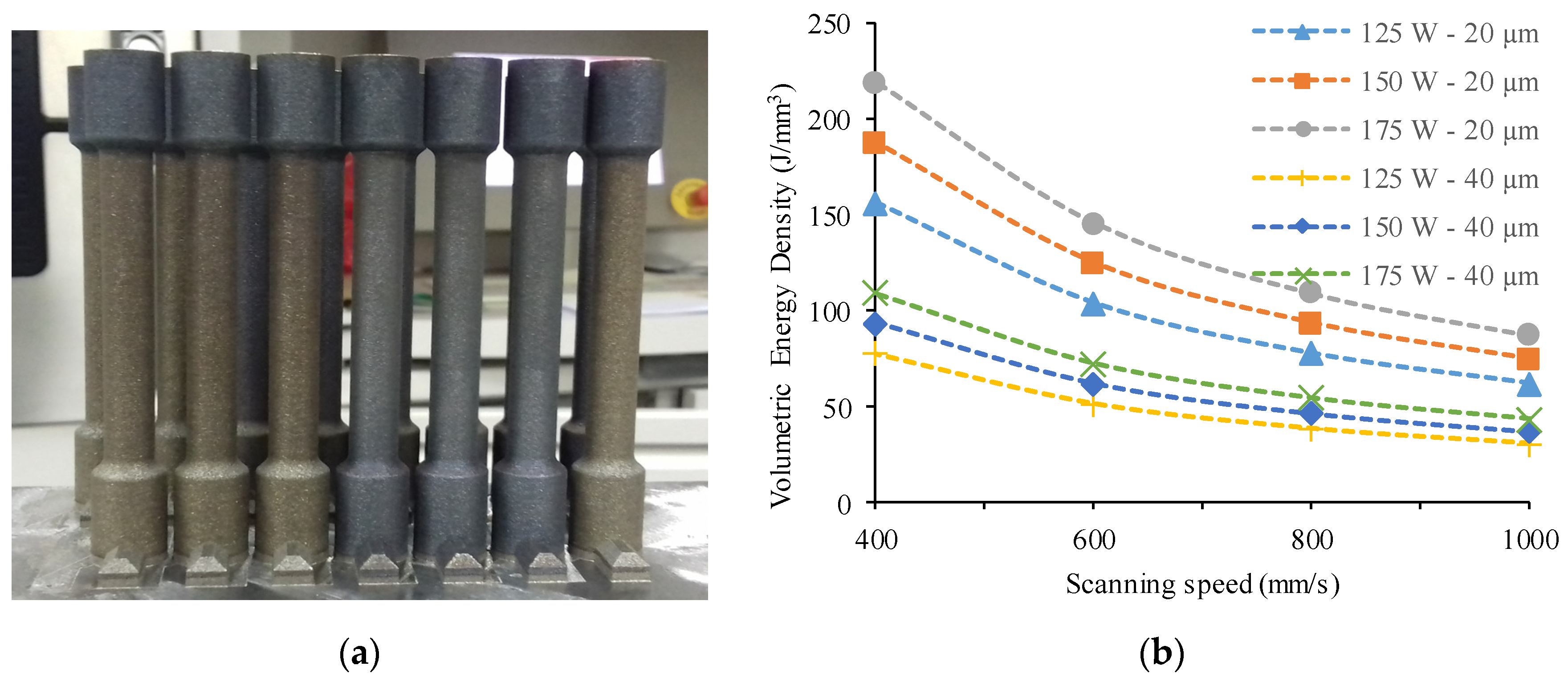

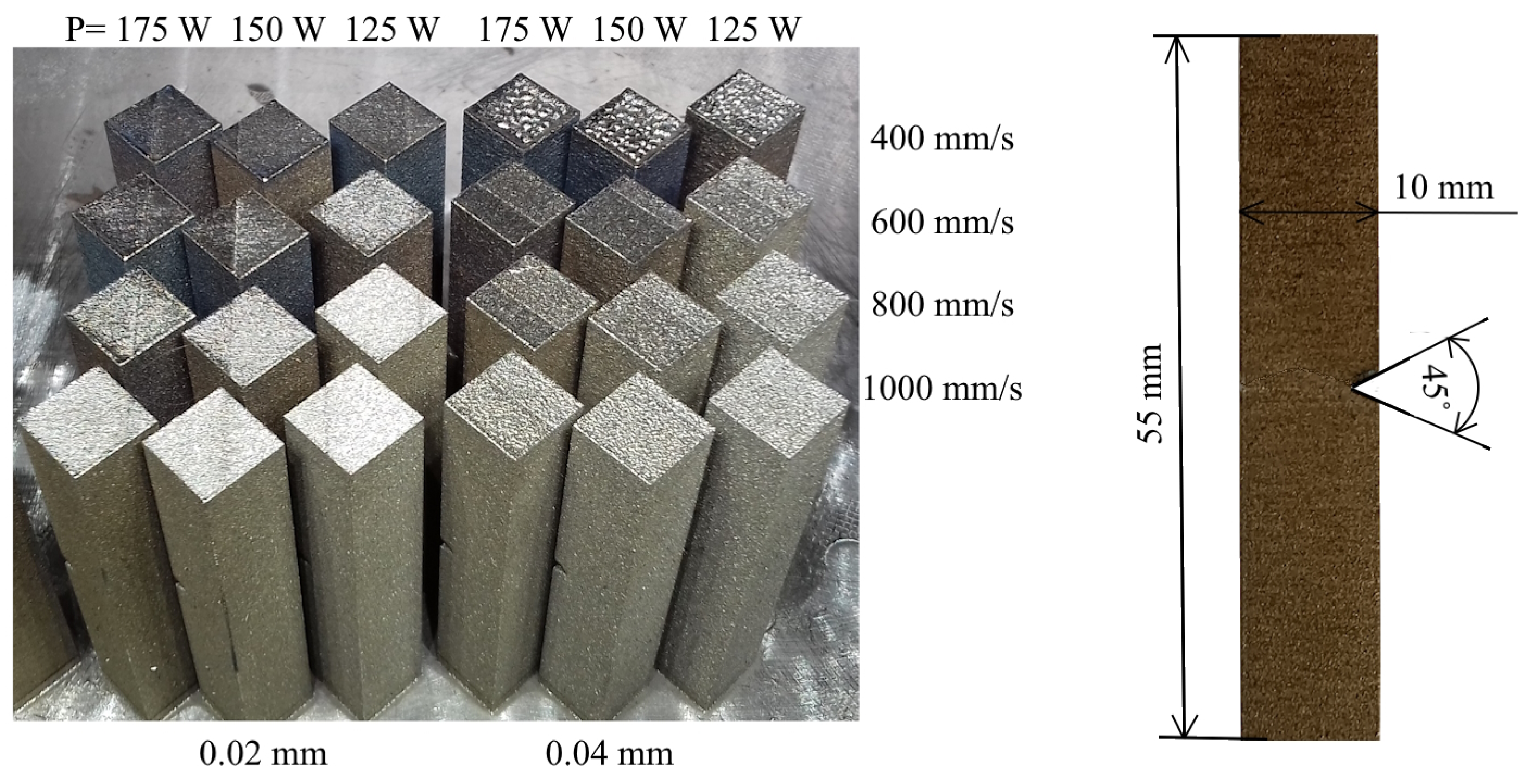

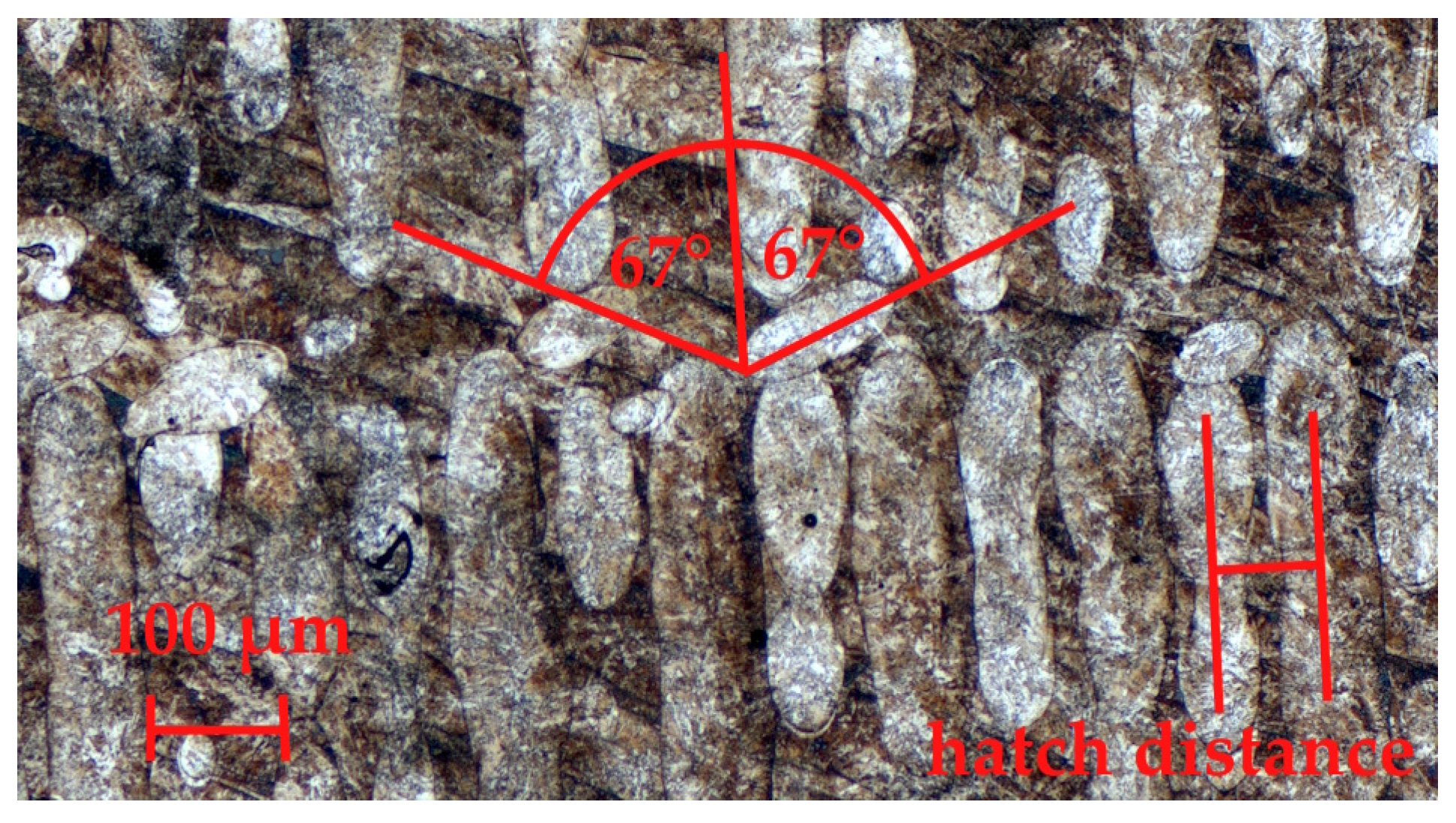

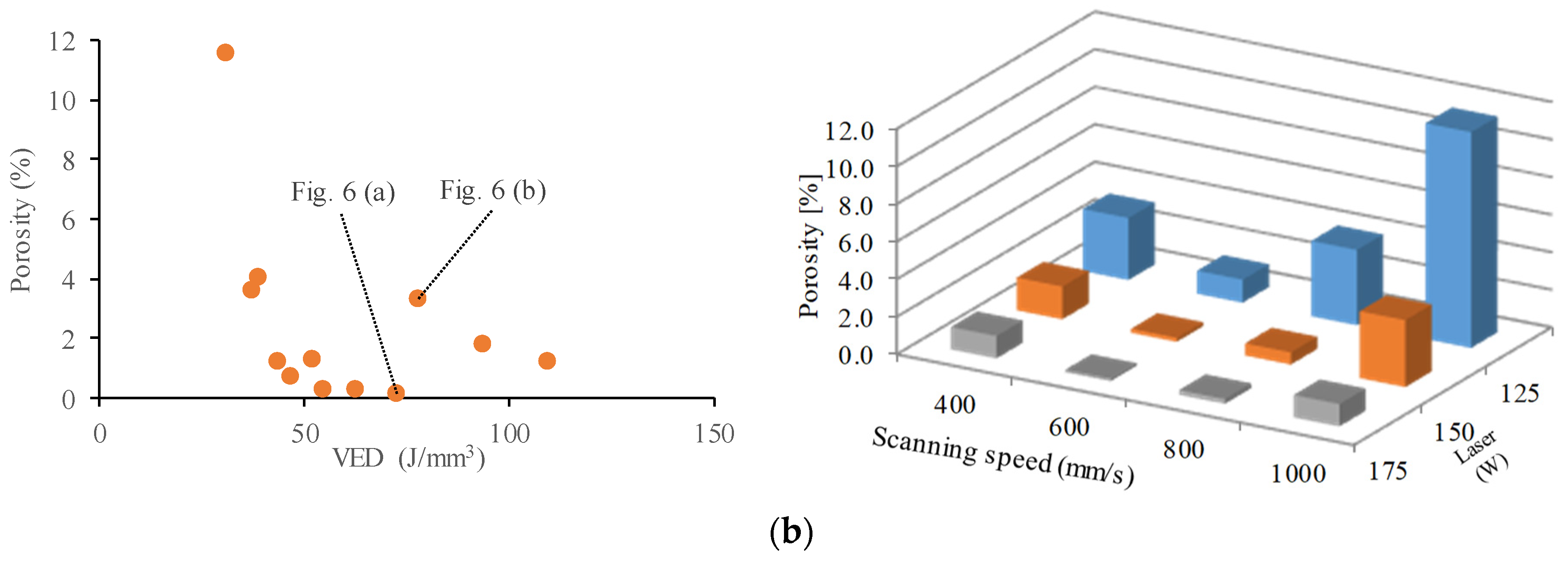

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- Highly dense samples were achieved, and the experiment results show that a relative density of 99.97% could be achieved for 1.2709 using the LPBF technique;

- The optimal process parameters for the lowest porosity were P = 150 W, v = 600 mm/s, and t = 0.02 mm;

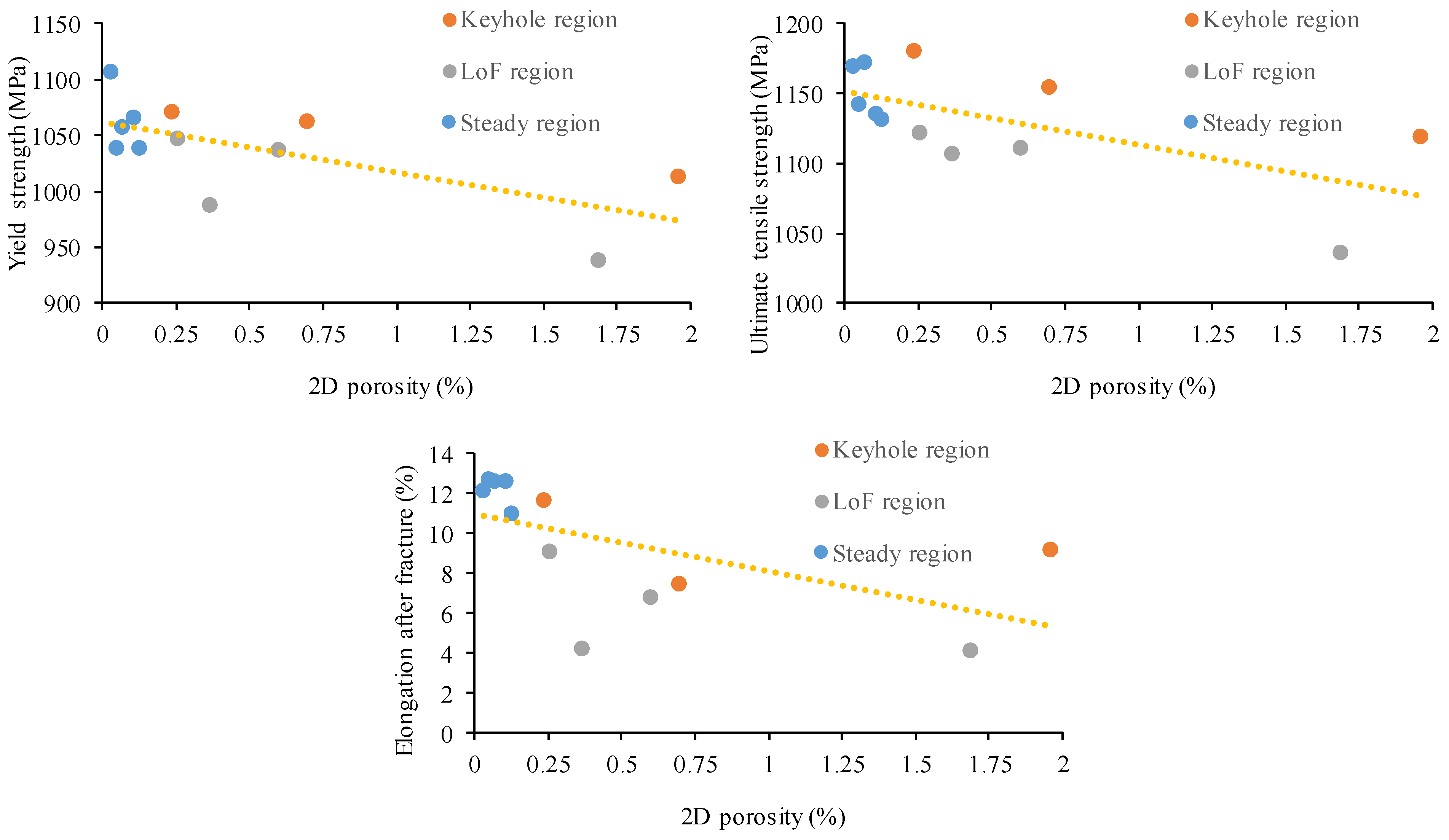

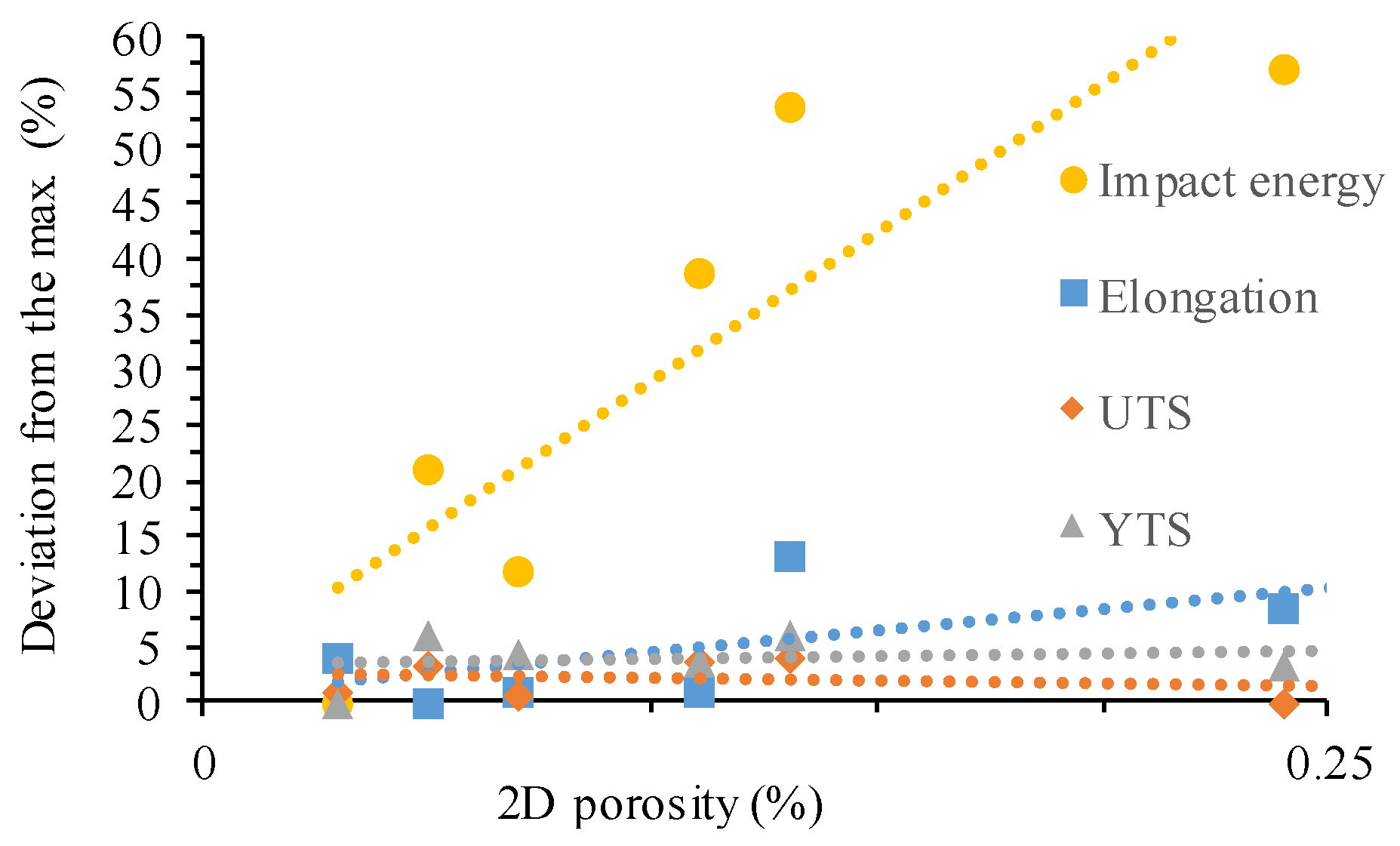

- A porosity below 0.25% has almost no effect on the resulting tensile properties;

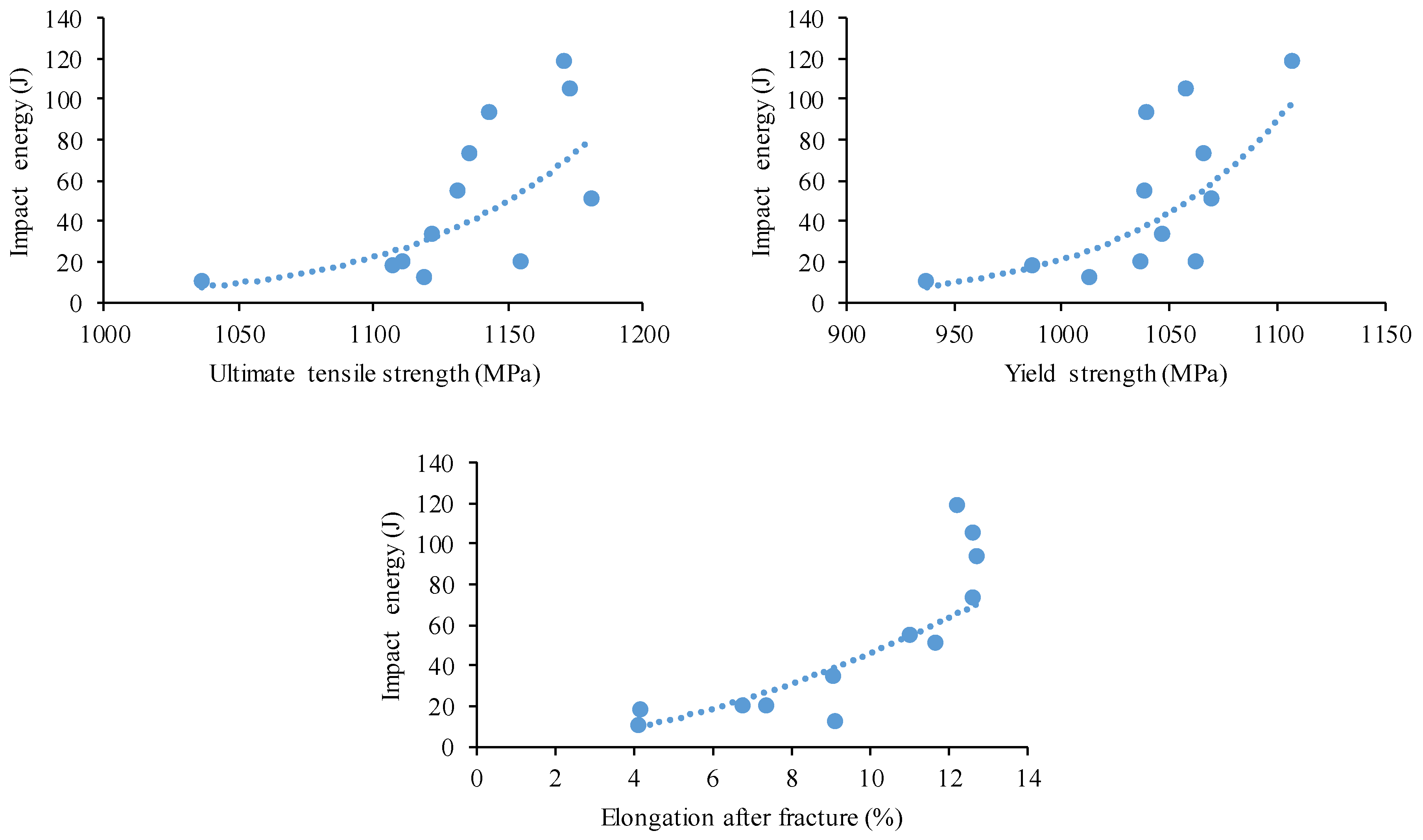

- Porosity has a significant influence on impact energy, even for samples with low porosity, and the impact energy drops abruptly as porosity increases; therefore, impact testing may be used for parameter optimization;

- The maximum absorbed energy value achieved was 119 J. When comparing this result with the highest-impact energy values of as-built LPBF 1.2709 specimens available in the literature, an improvement of more than 20% was achieved;

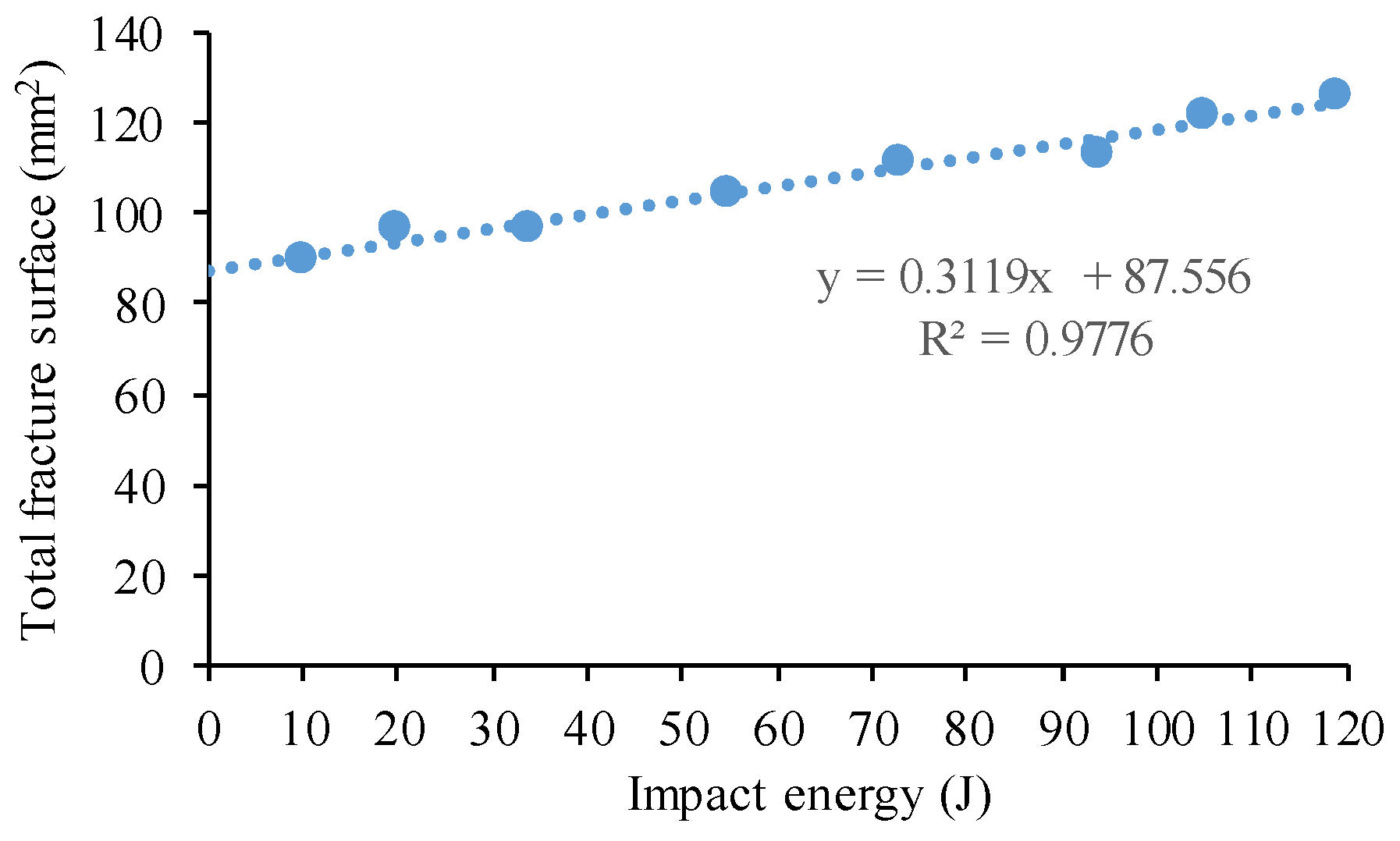

- A linear relationship between the Charpy impact energy and the inverse of porosity was found;

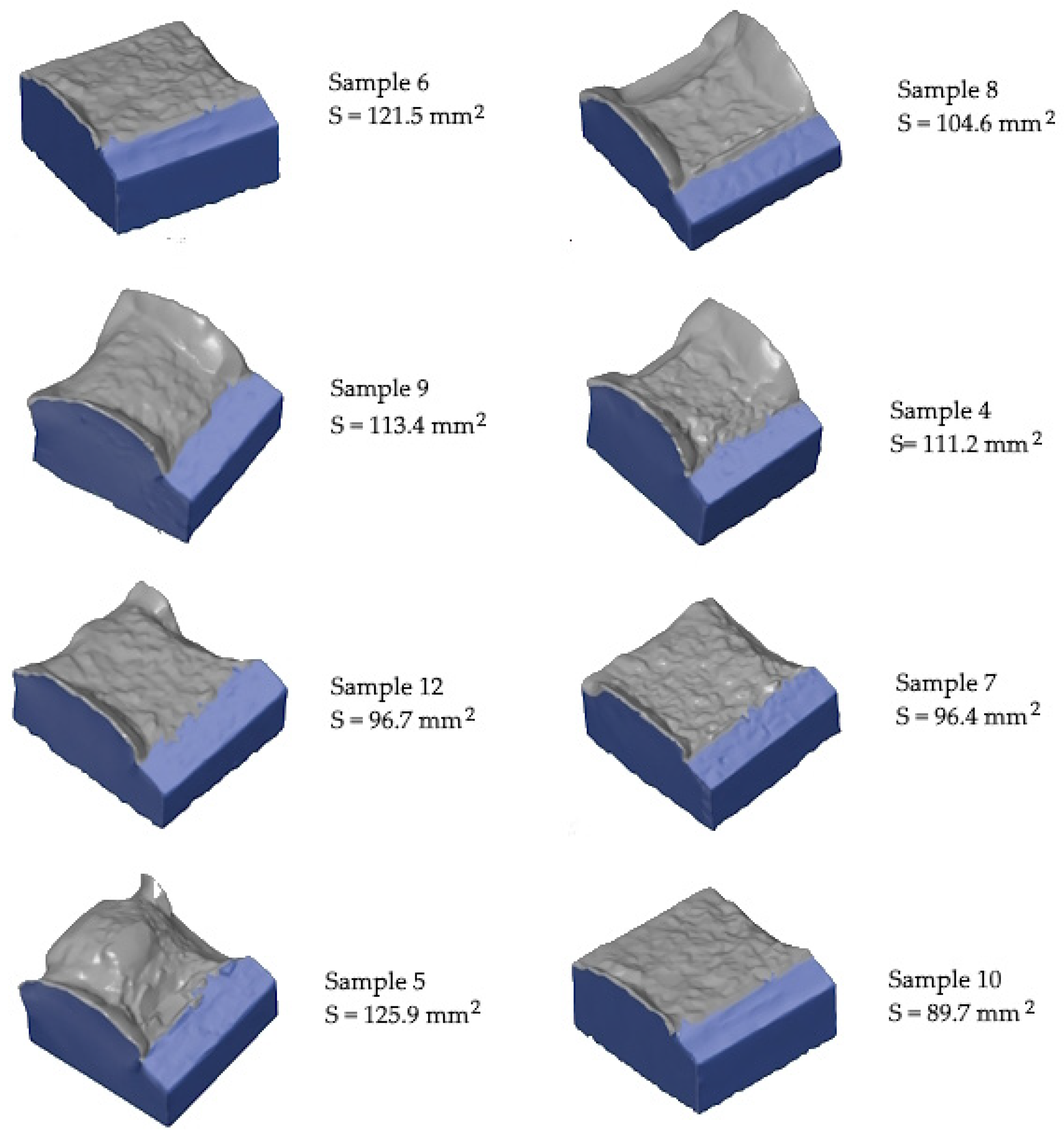

- A linear correlation between the Charpy impact energy and the area of 3D fracture surface was observed.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Matos, F.; Godina, R.; Jacinto, C.; Carvalho, H.; Ribeiro, I.; Peças, P. Additive Manufacturing: Exploring the Social Changes and Impacts. Sustainability 2019, 11, 3757. [Google Scholar] [CrossRef]

- Molnár, I.; Morovič, L. Design and manufacture of orthopedic corset using 3D digitization and additive manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 448, 012058. [Google Scholar] [CrossRef]

- Costas, M.; Edwards-Mowforth, M.; Kristoffersen, M.; Teixeira-Dias, F.; Brøtan, V.; Paulsen, C.O.; Børvik, T. Ballistic impact resistance of additive manufactured high-strength maraging steel: An experimental study. Int. J. Prot. Struct. 2021, 12, 577–603. [Google Scholar] [CrossRef]

- Kovács, S.E.; Varga, L.; Szentes, Z. Analysis of a Special, 3D Metal-Printed HPDC Tool Material. Int. J. Eng. Manag. Sci. 2020, 5, 251–265. [Google Scholar] [CrossRef]

- Petroušek, P.; Kvačkaj, T.; Bidulská, J.; Bidulský, R.; Grande, M.A.; Manfredi, D.; Weiss, K.-P.; Kočiško, R.; Lupták, M.; Pokorný, I. Investigation of the Properties of 316L Stainless Steel after AM and Heat Treatment. Materials 2023, 16, 3935. [Google Scholar] [CrossRef] [PubMed]

- Kónya, J.; Hargitai, H.; Jaber, H.; Pinke, P.; Kovács, T.A. Effect of Surface Modifications on Surface Roughness of Ti6Al4V Alloy Manufactured by 3D Printing, Casting, and Wrought. Materials 2023, 16, 3989. [Google Scholar] [CrossRef]

- Actis Grande, M.; Živčák, J.; Bidulská, J.; Bidulský, R.; Petroušek, P.; Hudák, R. Porosity Quantification of Additive Manufactured Ti6Al4V and CoCrW Alloys Produced by L-PBF. Arch. Metall. Mater. 2022, 67, 83–89. [Google Scholar]

- Safyari, M.; Haunreiter, F.; Furuta, S.; Khoo, P.L.; Mayrhofer, F.; Kobayashi, M.; Moshtaghi, M. Manipulating nanostructure during wire arc additive manufacturing defeats hydrogen embrittlement. Corros. Sci. 2024, 233, 112088. [Google Scholar] [CrossRef]

- Orosz, T.; Horváth, T.; Tóth, B.; Kuczmann, M.; Kocsis, B. Iron Loss Calculation Methods for Numerical Analysis of 3D-Printed Rotating Machines: A Review. Energies 2023, 16, 6547. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Giovagnoli, M.; Silvi, G.; Merlin, M.; Di Giovanni, M.T. Optimisation of process parameters for an additively manufactured AlSi10Mg alloy: Limitations of the energy density-based approach on porosity and mechanical properties estimation. Mater. Sci. Eng. A 2021, 802, 140613. [Google Scholar] [CrossRef]

- Dutt, A.K.; Bansal, G.K.; Tripathy, S.; Gopala Krishna, K.; Srivastava, V.C.; Ghosh Chowdhury, S. Optimization of Selective Laser Melting (SLM) Additive Manufacturing Process Parameters of 316L Austenitic Stainless Steel. Trans. Indian Inst. Met. 2023, 76, 335–345. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review on the effects of process-induced porosity on the mechanical properties of alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Wits, W.W.; Carmignato, S.; Zanini, F.; Vaneker, T.H.J. Porosity testing methods for the quality assessment of selective laser melted parts. CIRP Ann. 2016, 65, 201–204. [Google Scholar] [CrossRef]

- Snell, R.; Tammas-Williams, S.; Chechik, L.; Lyle, A.; Hernández-Nava, E.; Boig, C.; Panoutsos, G.; Todd, I. Methods for Rapid Pore Classification in Metal Additive Manufacturing. JOM 2020, 72, 101–109. [Google Scholar] [CrossRef]

- Taghian, M.; Mosallanejad, M.H.; Lannunziata, E.; Del Greco, G.; Iuliano, L.; Saboori, A. Laser powder bed fusion of metallic components: Latest progress in productivity, quality, and cost perspectives. J. Mater. Res. Technol. 2023, 27, 6484–6500. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, W.; Chen, X. Effect of SLM Process Parameters on Relative Density of Maraging Steel (18Ni-300) Formed Parts. IOP Conf. Ser. Mater. Sci. Eng. 2020, 774, 012027. [Google Scholar] [CrossRef]

- Mugwagwa, L.; Yadroitsev, I.; Matope, S. Effect of Process Parameters on Residual Stresses, Distortions, and Porosity in Selective Laser Melting of Maraging Steel 300. Metals 2019, 9, 1042. [Google Scholar] [CrossRef]

- Maodzeka, D.K.; Olakanmi, E.O.; Mosalagae, M.; Hagedorn-Hansen, D.; Pityana, S.L. Hybrid optimisation studies on the microstructural properties and wear resistance of maraging steel 1.2709 parts produced by laser powder bed fusion. Opt. Laser Technol. 2023, 159, 108914. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.-G.; Lee, J.-H.; Zhang, J. Additive Manufacturing of Metallic Materials: A Review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Andronov, V.; Šimota, J.; Beránek, L.; Blažek, J.; Rušar, F. Optimization of Process Parameters for Additively Produced Tool Steel 1.2709 with a Layer Thickness of 100 μm. Materials 2021, 14, 2852. [Google Scholar] [CrossRef] [PubMed]

- Kučerová, L.; Burdová, K.; Jeníček, Š.; Chena, I. Effect of solution annealing and precipitation hardening at 250 °C–550 °C on microstructure and mechanical properties of additively manufactured 1.2709 maraging steel. Mater. Sci. Eng. A 2021, 814, 141195. [Google Scholar] [CrossRef]

- Hrbáčková, T.; Simson, T.; Koch, J.; Wolf, G. The effect of heat treatment on mechanical properties and microstructure of additively manufactured components. IOP Conf. Ser. Mater. Sci. Eng. 2018, 461, 012026. [Google Scholar] [CrossRef]

- Girelli, L.; Giovagnoli, M.; Tocci, M.; Pola, A.; Fortini, A.; Merlin, M.; La Vecchia, G.M. Evaluation of the impact behaviour of AlSi10Mg alloy produced using laser additive manufacturing. Mater. Sci. Eng. A 2019, 748, 38–51. [Google Scholar] [CrossRef]

- Jarfors, A.E.W.; Shashidhar, A.C.G.H.; Yepur, H.K.; Steggo, J.; Andersson, N.-E.; Stolt, R. Build Strategy and Impact Strength of SLM Produced Maraging Steel (1.2709). Metals 2021, 11, 51. [Google Scholar] [CrossRef]

- Kan, W.H.; Gao, M.; Zhang, X.; Liang, E.; Chiu, N.S.L.; Lim, C.V.S.; Huang, A. The influence of porosity on Ti-6Al-4V parts fabricated by laser powder bed fusion in the pursuit of process efficiency. Int. J. Adv. Manuf. Technol. 2022, 119, 5417–5438. [Google Scholar] [CrossRef]

- ASTM E23; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Hatos, I.; Fekete, I.; Harangozó, D.; Hargitai, H. Influence of Local Porosity on the Mechanical Properties of Direct Metal Laser-Sintered 1.2709 Alloy. Stroj. Vestn. J. Mech. Eng. 2020, 66, 351–357. [Google Scholar] [CrossRef]

- Wang, D.; Han, H.; Sa, B.; Li, K.; Yan, J.; Zhang, J.; Liu, J.; He, Z.; Wang, N.; Yan, M.; et al. A review and a statistical analysis of porosity in metals additively manufactured by laser powder bed fusion. Opto-Electron. Adv. 2022, 5, 210058. [Google Scholar] [CrossRef]

- Mierzejewska, Ż.A. Effect of Laser Energy Density, Internal Porosity and Heat Treatment on Mechanical Behavior of Biomedical Ti6Al4V Alloy Obtained with DMLS Technology. Materials 2019, 12, 2331. [Google Scholar] [CrossRef]

- Simson, T.; Koch, J.; Rosenthal, J.; Kepka, M.; Zetek, M.; Zetková, I.; Wolf, G.; Tomčík, P.; Kulhánek, J. Mechanical Properties of 18Ni-300 maraging steel manufactured by LPBF. Procedia Struct. Integr. 2019, 17, 843–849. [Google Scholar] [CrossRef]

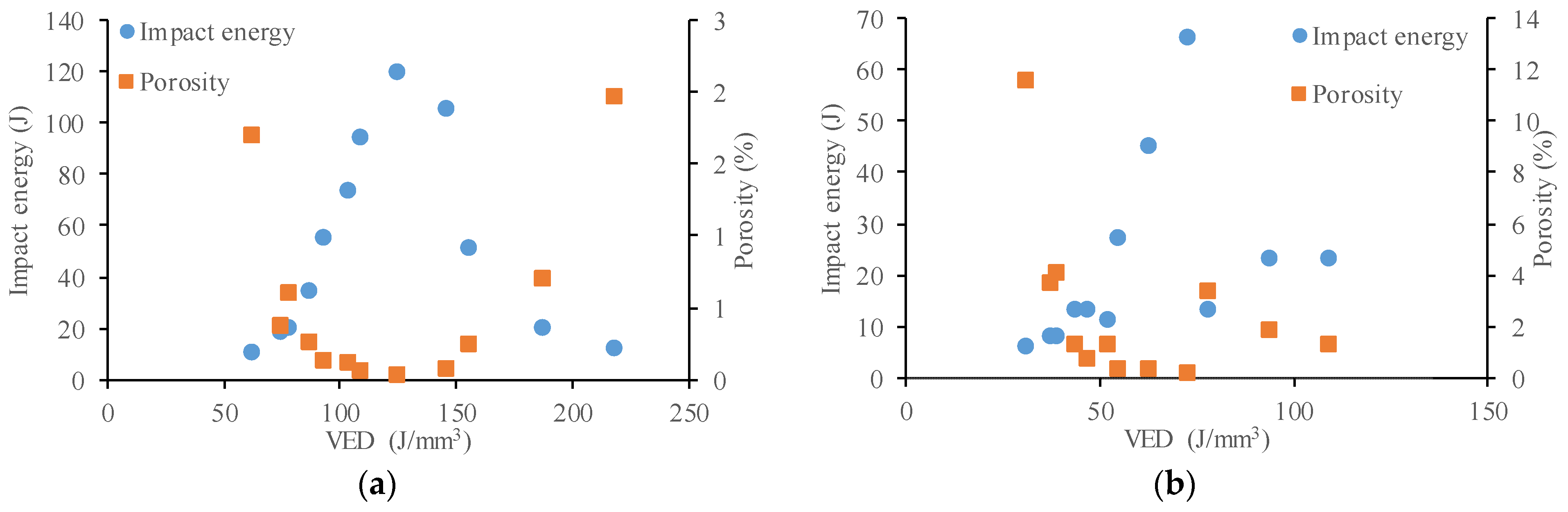

| Sample | P | v | t | VED | Impact Energy | Porosity |

|---|---|---|---|---|---|---|

| W | mm/s | mm | J/mm3 | J | % | |

| 1 | 125 | 400 | 0.02 | 156.3 | 51 | 0.24 |

| 2 | 150 | 400 | 0.02 | 187.5 | 20 | 0.7 |

| 3 | 175 | 400 | 0.02 | 218.8 | 12 | 1.96 |

| 4 | 125 | 600 | 0.02 | 104.2 | 73 | 0.11 |

| 5 | 150 | 600 | 0.02 | 125.0 | 119 | 0.03 |

| 6 | 175 | 600 | 0.02 | 145.8 | 105 | 0.07 |

| 7 | 125 | 800 | 0.02 | 78.1 | 20 | 0.6 |

| 8 | 150 | 800 | 0.02 | 93.8 | 55 | 0.13 |

| 9 | 175 | 800 | 0.02 | 109.4 | 94 | 0.05 |

| 10 | 125 | 1000 | 0.02 | 62.5 | 10 | 1.69 |

| 11 | 150 | 1000 | 0.02 | 75.0 | 18 | 0.37 |

| 12 | 175 | 1000 | 0.02 | 87.5 | 34 | 0.26 |

| 13 | 125 | 400 | 0.04 | 78.1 | 13 | 3.3 |

| 14 | 150 | 400 | 0.04 | 93.8 | 23 | 1.74 |

| 15 | 175 | 400 | 0.04 | 109.4 | 23 | 1.19 |

| 16 | 125 | 600 | 0.04 | 52.1 | 11 | 1.22 |

| 17 | 150 | 600 | 0.04 | 62.5 | 45 | 0.21 |

| 18 | 175 | 600 | 0.04 | 72.9 | 66 | 0.11 |

| 19 | 125 | 800 | 0.04 | 39.1 | 8 | 4.01 |

| 20 | 150 | 800 | 0.04 | 46.9 | 13 | 0.65 |

| 21 | 175 | 800 | 0.04 | 54.7 | 27 | 0.25 |

| 22 | 125 | 1000 | 0.04 | 31.3 | 6 | 11.48 |

| 23 | 150 | 1000 | 0.04 | 37.5 | 8 | 3.56 |

| 24 | 175 | 1000 | 0.04 | 43.8 | 13 | 1.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hatos, I.; Hargitai, H.; Fekete, G.; Fekete, I. Effect of Energy Density on the Mechanical Properties of 1.2709 Maraging Steel Produced by Laser Powder Bed Fusion. Materials 2024, 17, 3432. https://doi.org/10.3390/ma17143432

Hatos I, Hargitai H, Fekete G, Fekete I. Effect of Energy Density on the Mechanical Properties of 1.2709 Maraging Steel Produced by Laser Powder Bed Fusion. Materials. 2024; 17(14):3432. https://doi.org/10.3390/ma17143432

Chicago/Turabian StyleHatos, István, Hajnalka Hargitai, Gusztáv Fekete, and Imre Fekete. 2024. "Effect of Energy Density on the Mechanical Properties of 1.2709 Maraging Steel Produced by Laser Powder Bed Fusion" Materials 17, no. 14: 3432. https://doi.org/10.3390/ma17143432