A Review of Diamond Materials and Applications in Power Semiconductor Devices

Abstract

:1. Introduction

2. Diamond Materials and Processes for Power Applications

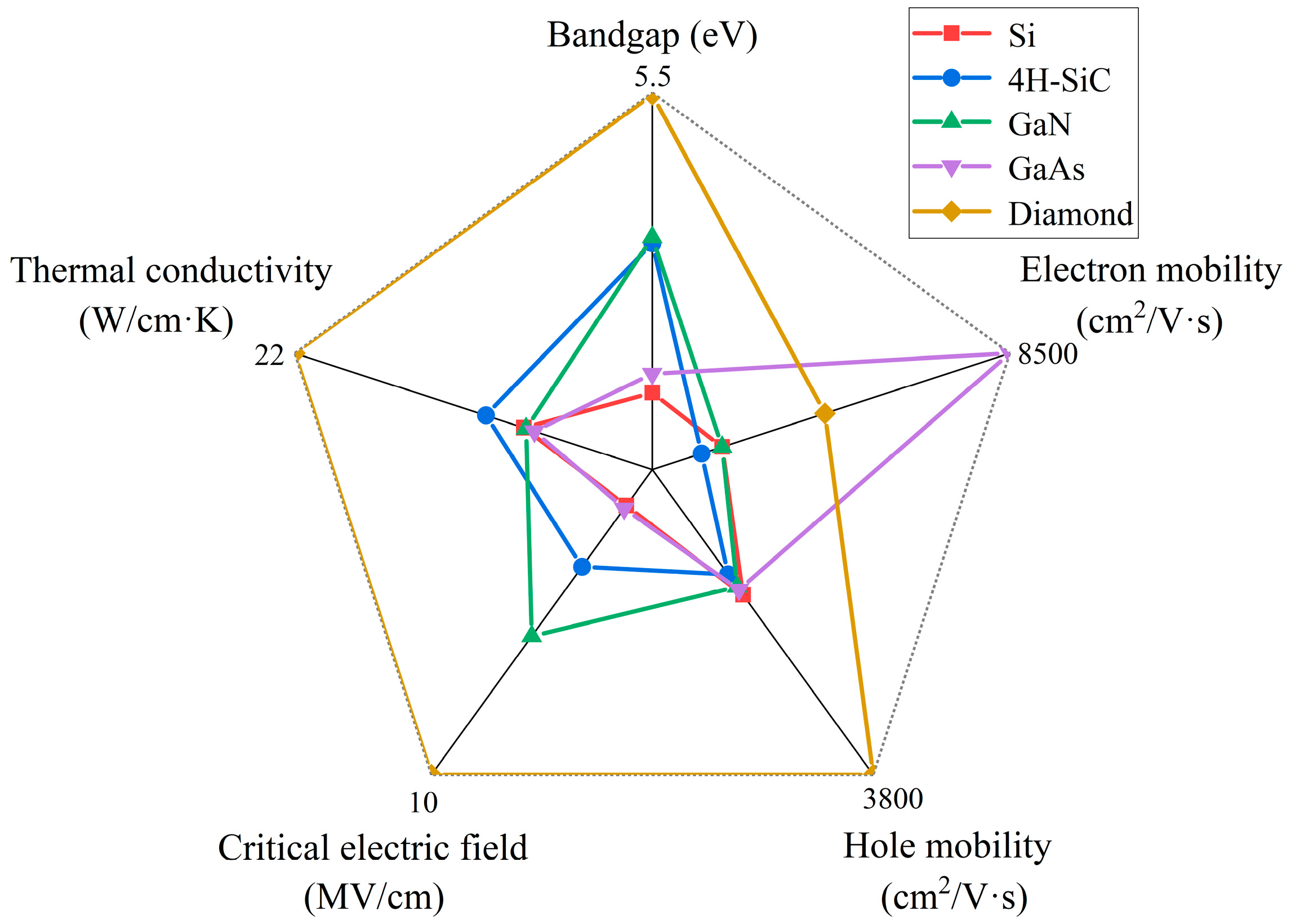

2.1. Diamond Properties

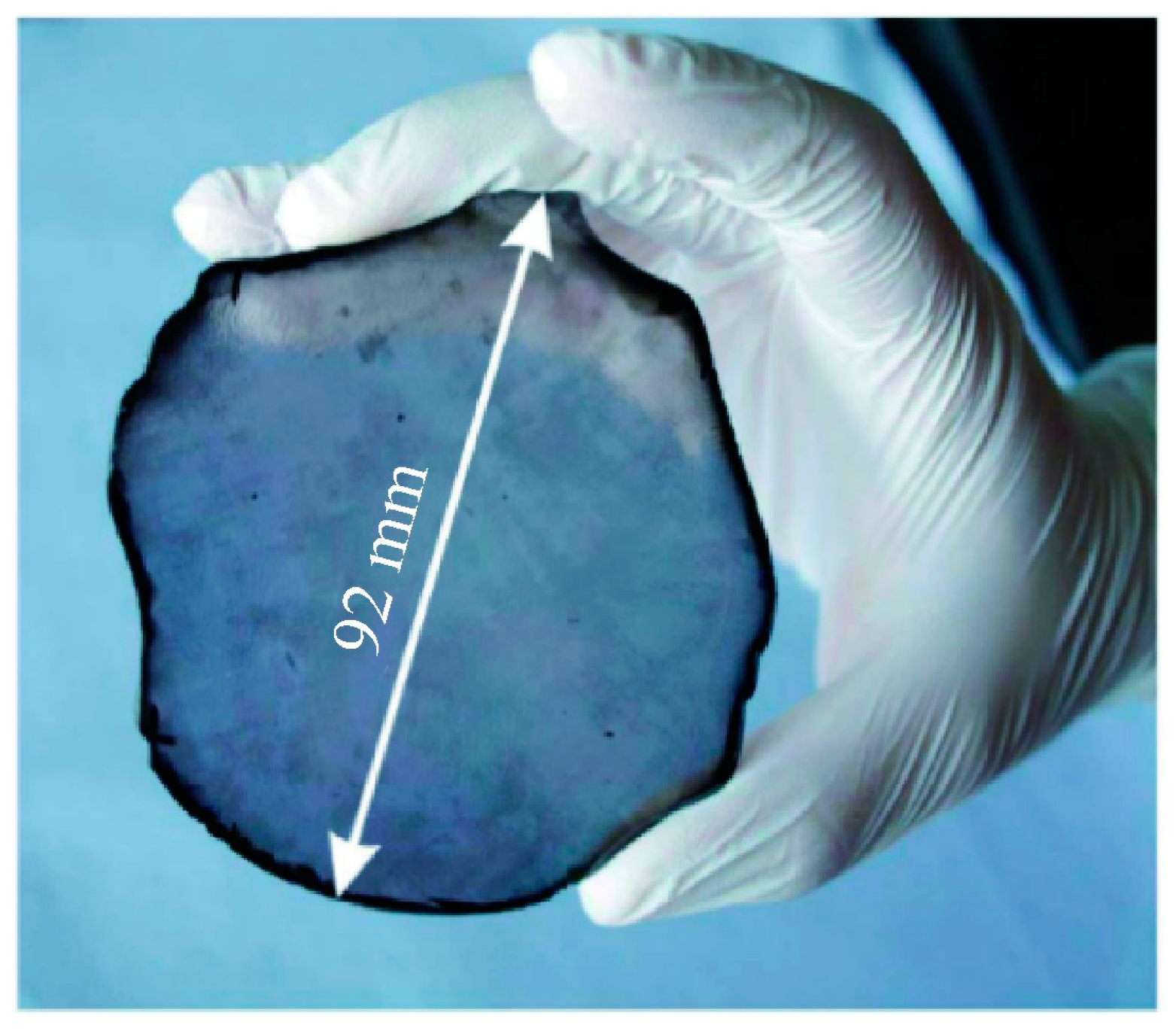

2.2. Diamond Substrate and Growth

2.3. Diamond Etching

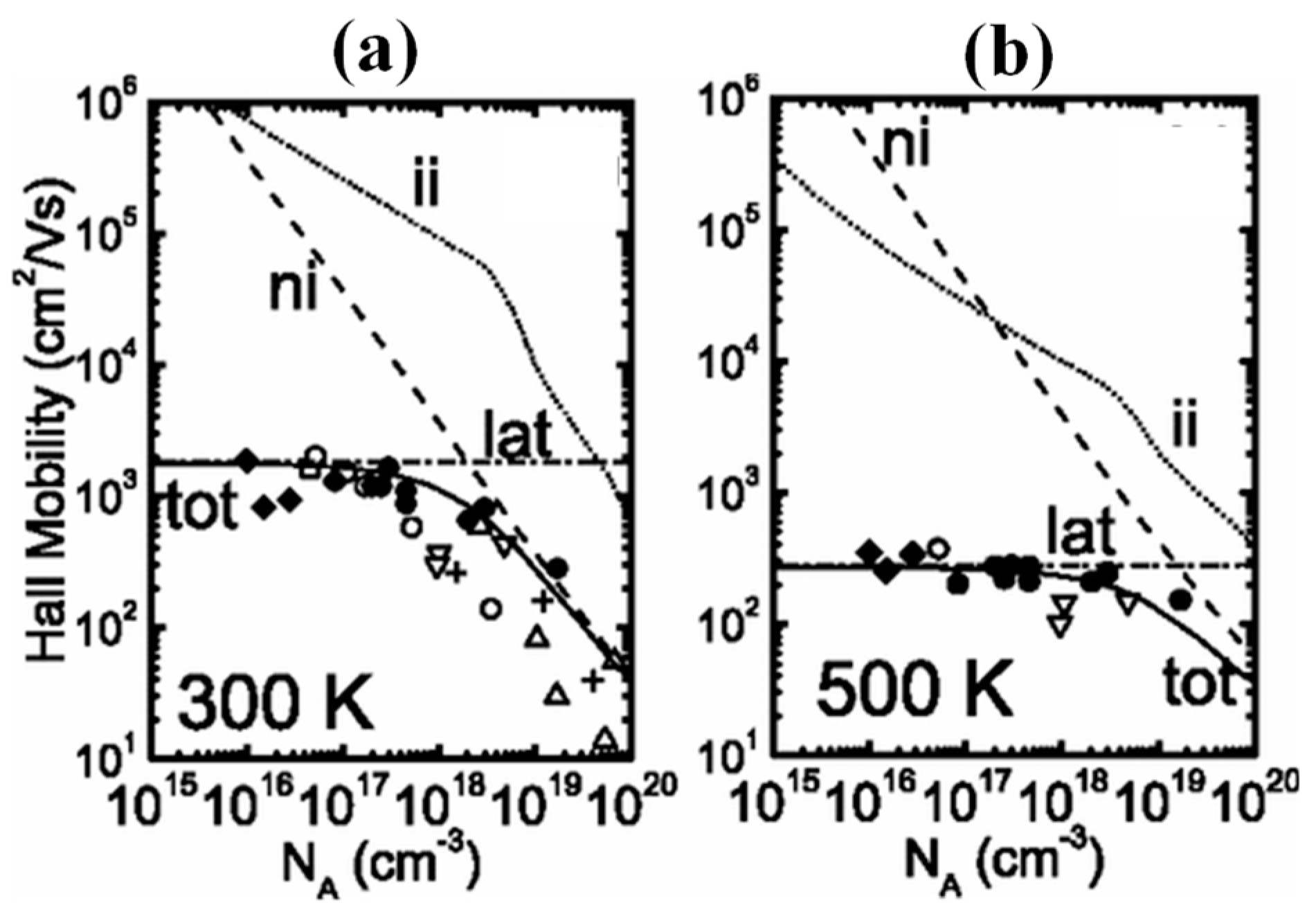

2.4. Diamond Doping

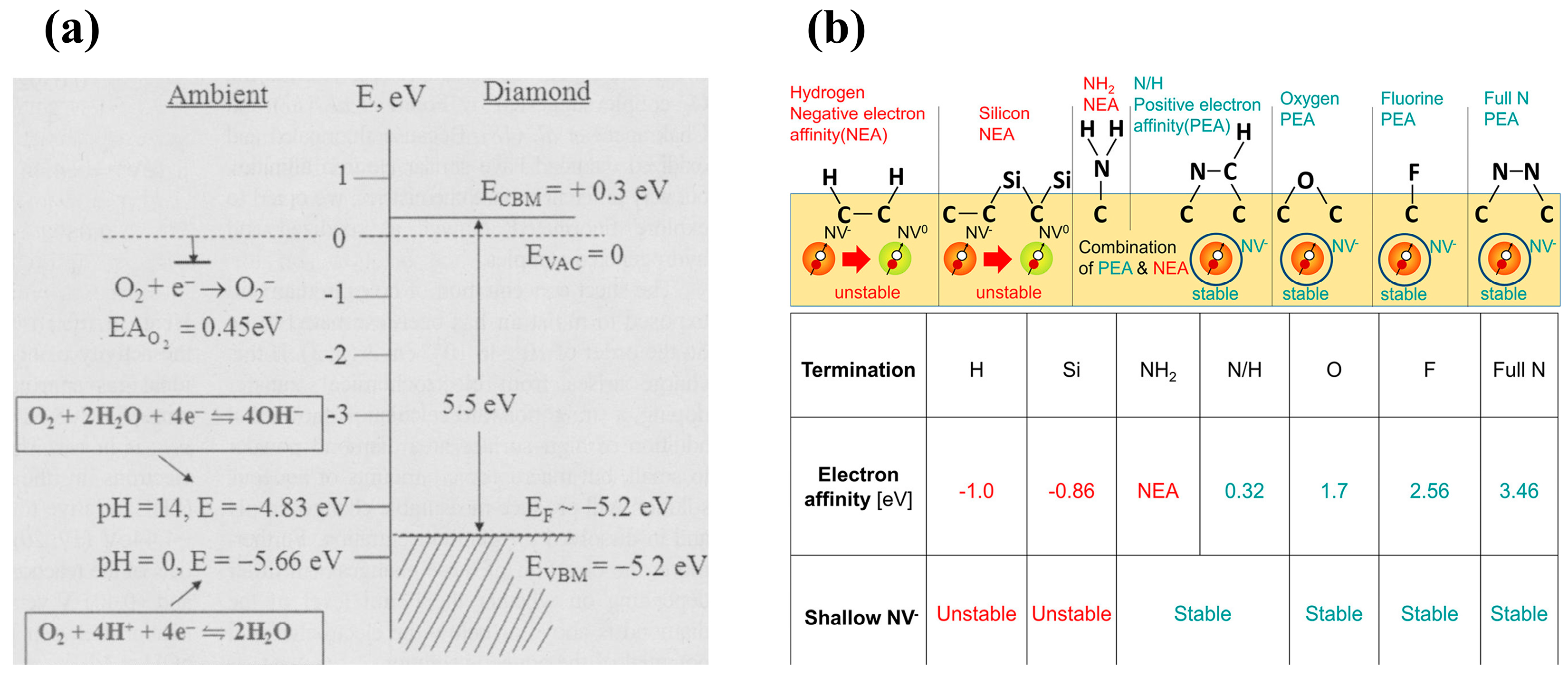

2.5. Terminal Technology

3. Diamond-Based Diodes

3.1. Schottky and Ohmic Contact

3.2. Device Structure of Diamond Diodes

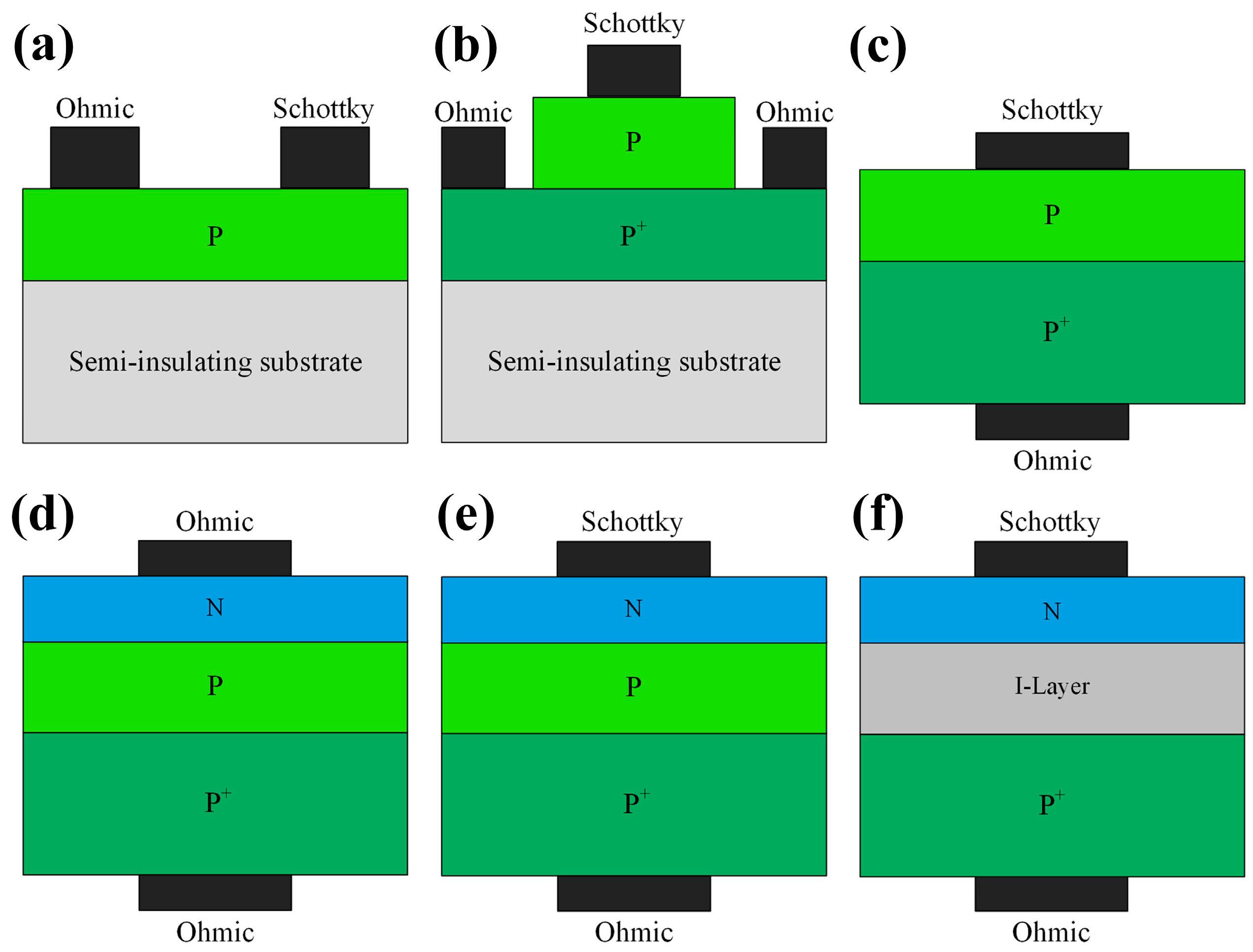

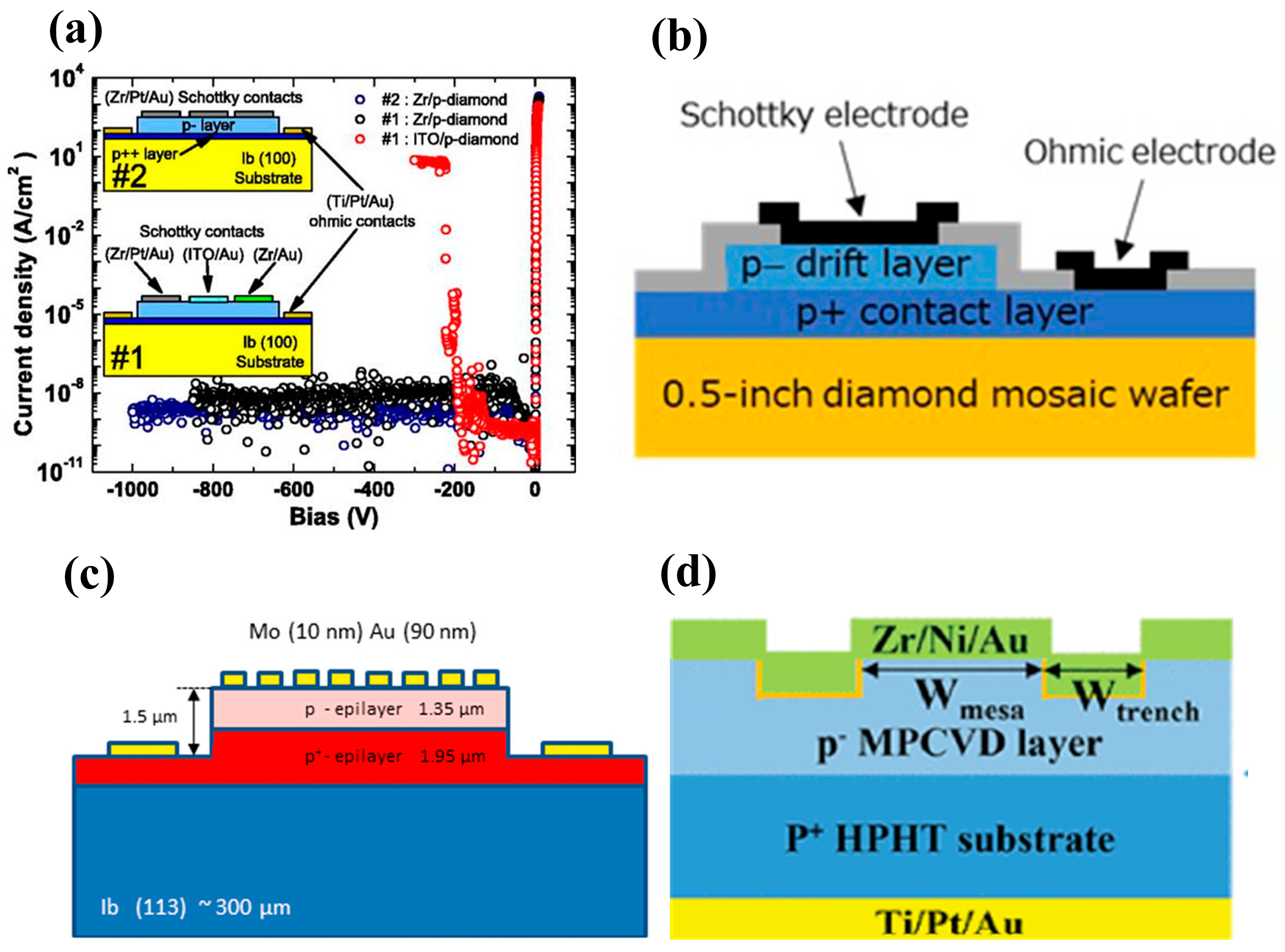

3.2.1. VSBDs

3.2.2. PVSBDs/TMBS

3.2.3. LSBDs

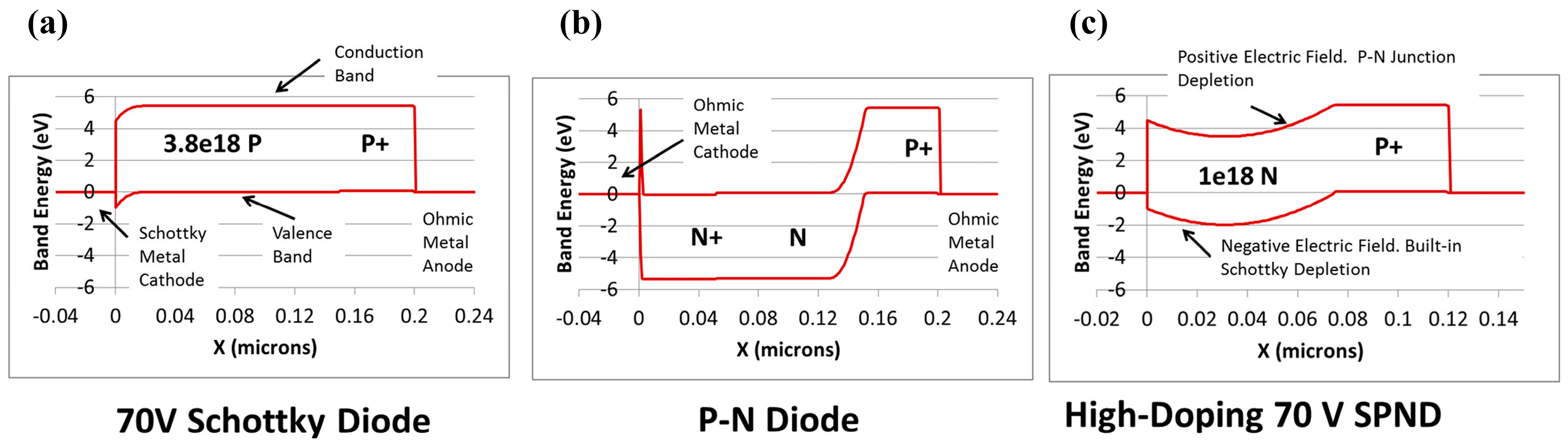

3.2.4. PNDs/SPNDs/SPINDs

4. Diamond Field-Effect Transistors

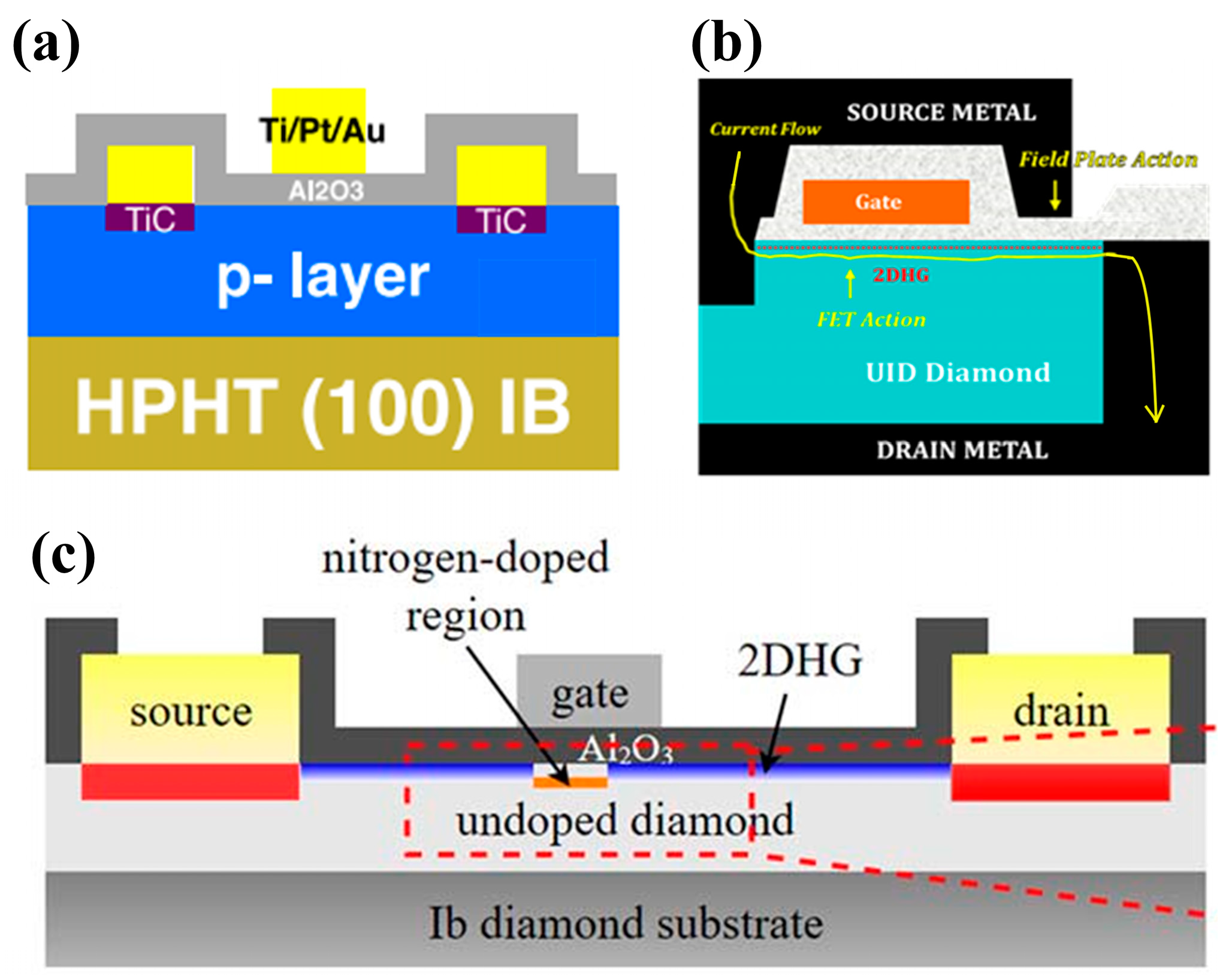

4.1. 2DHG

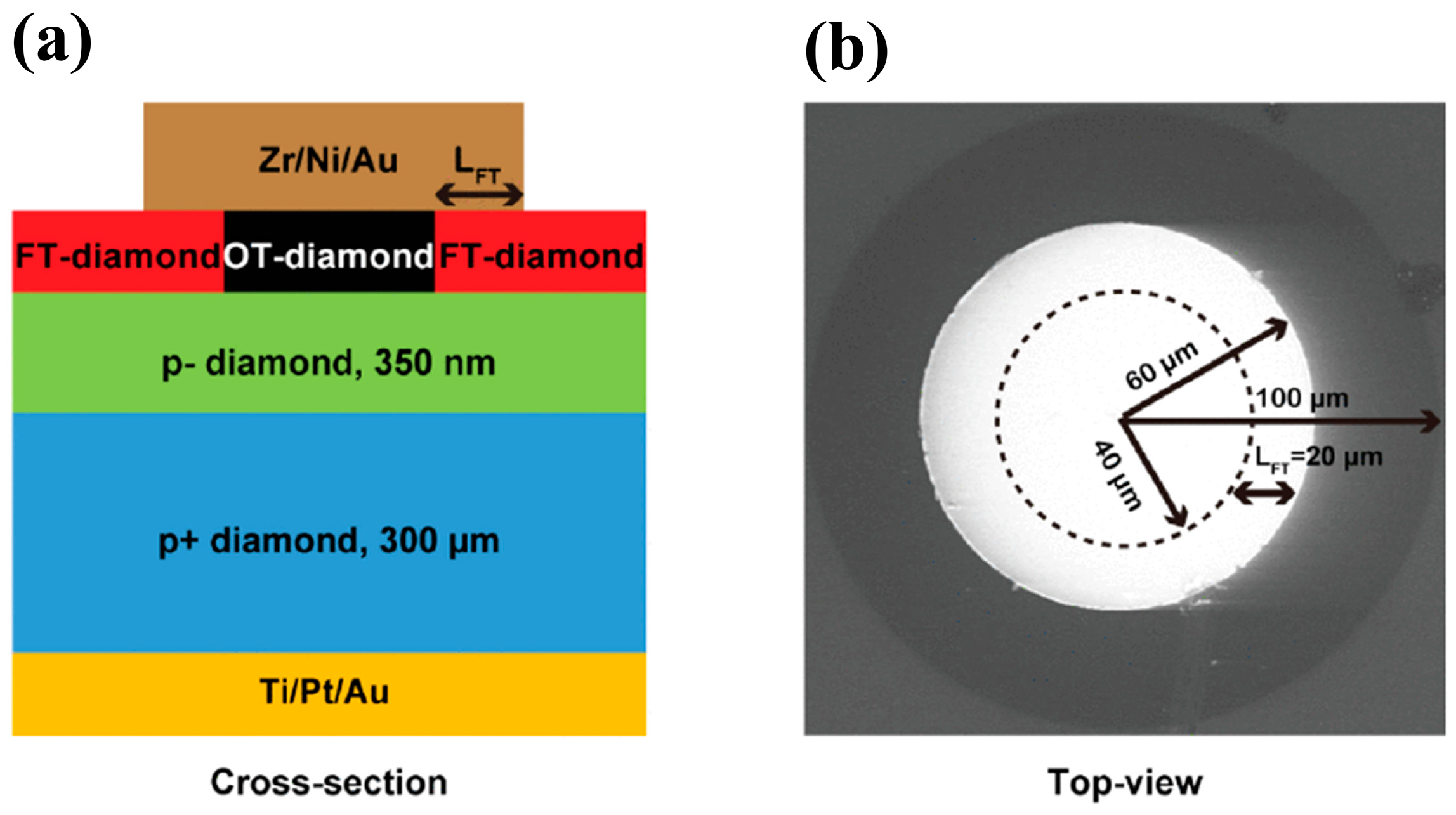

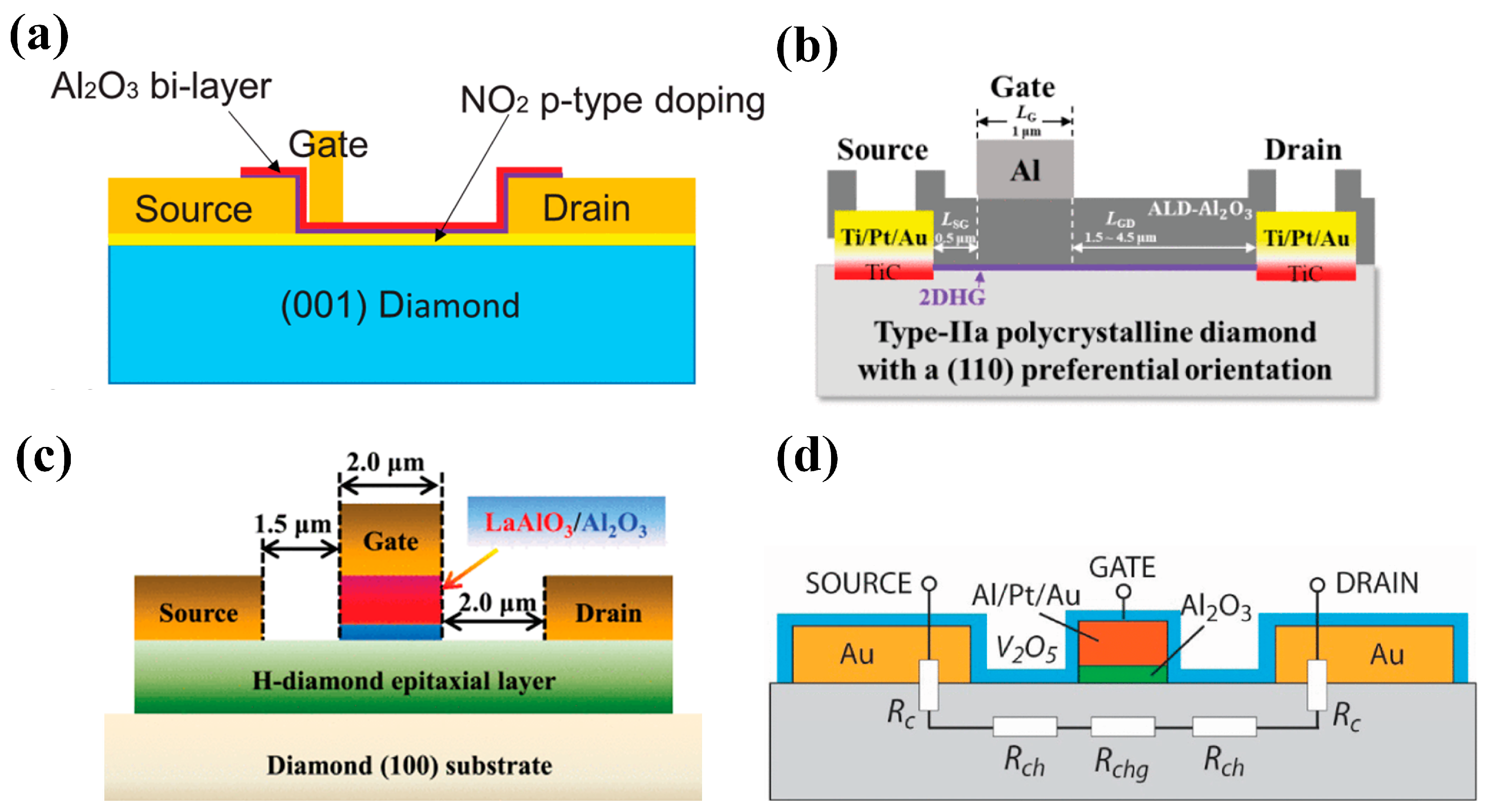

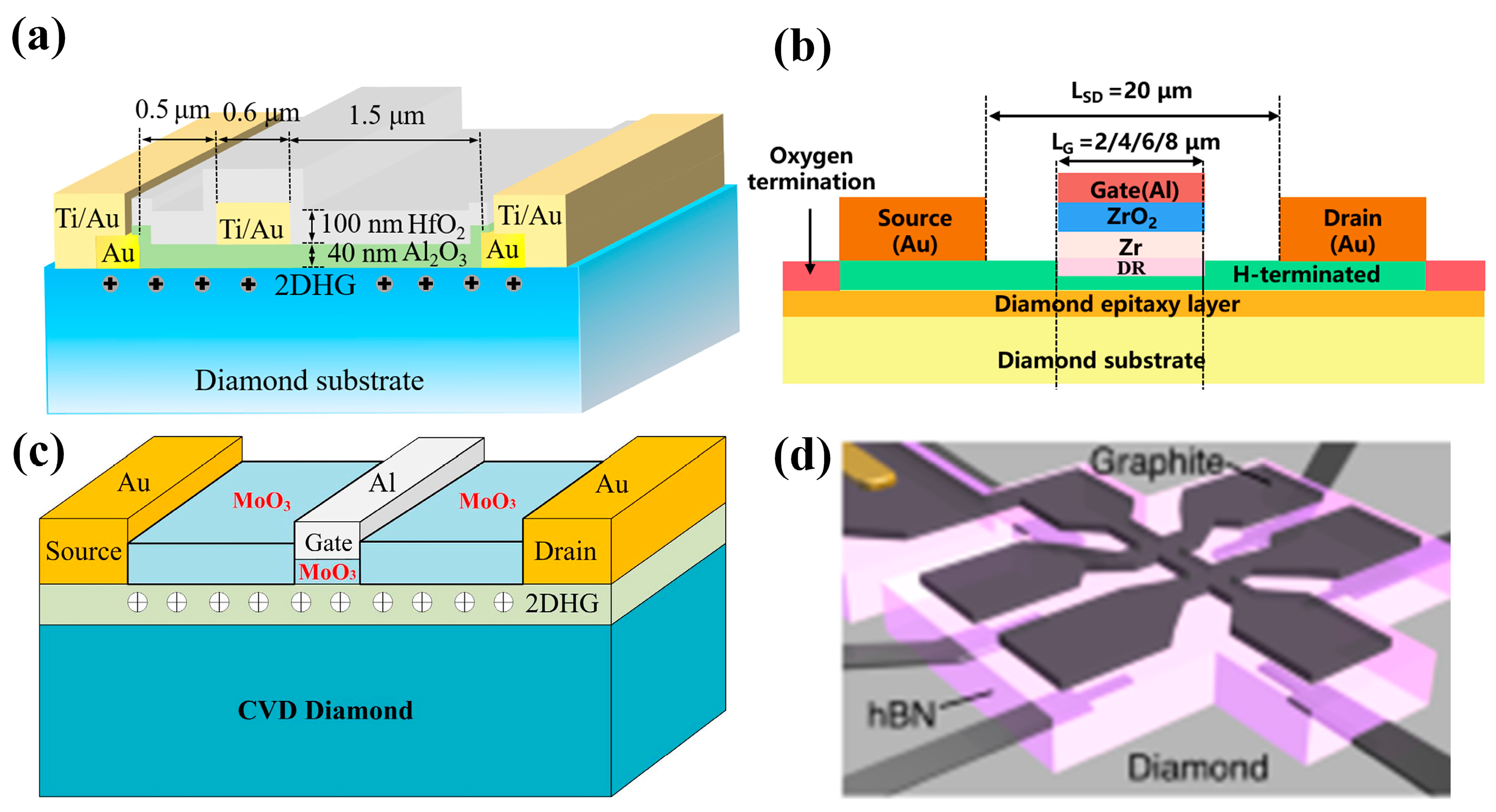

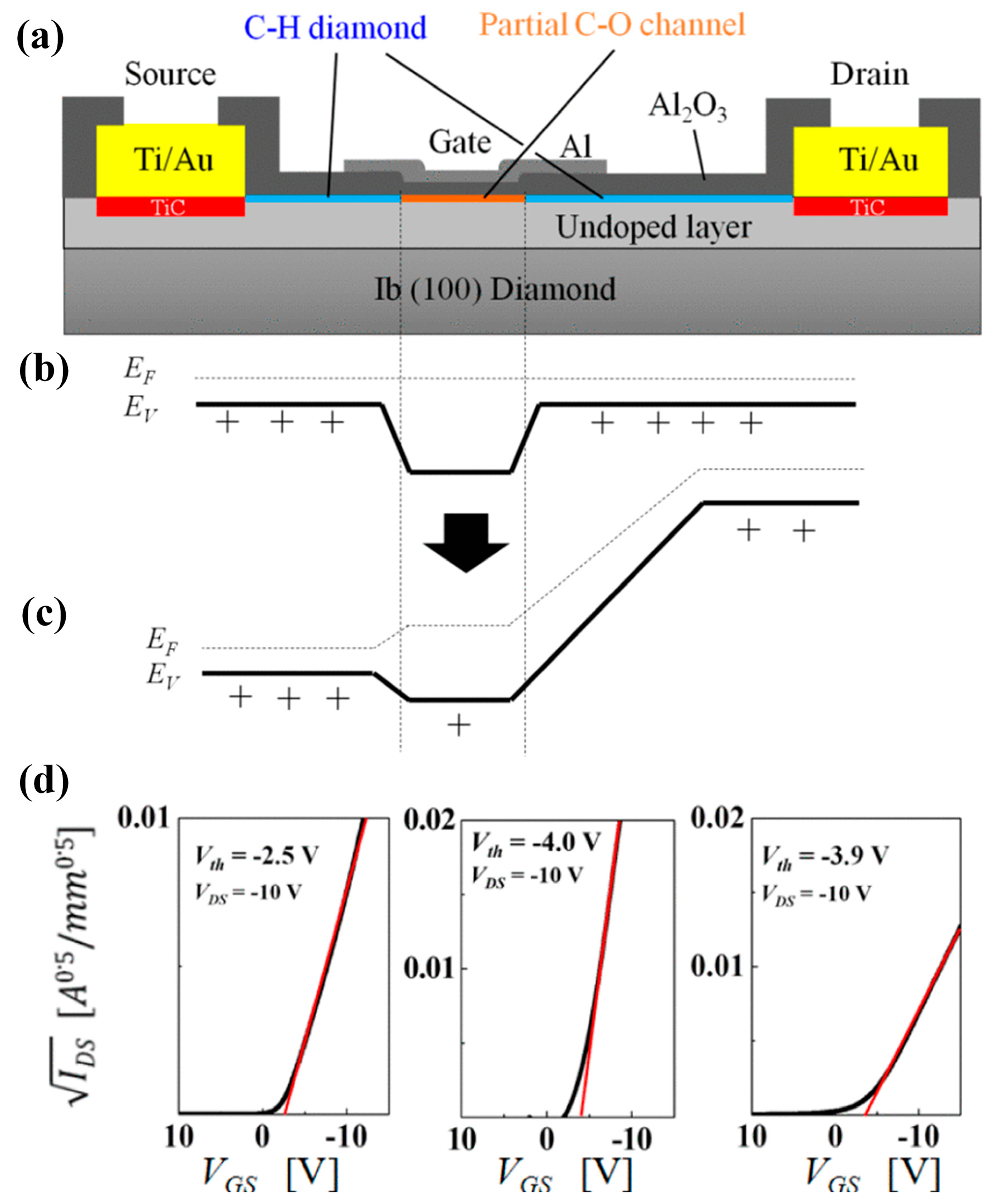

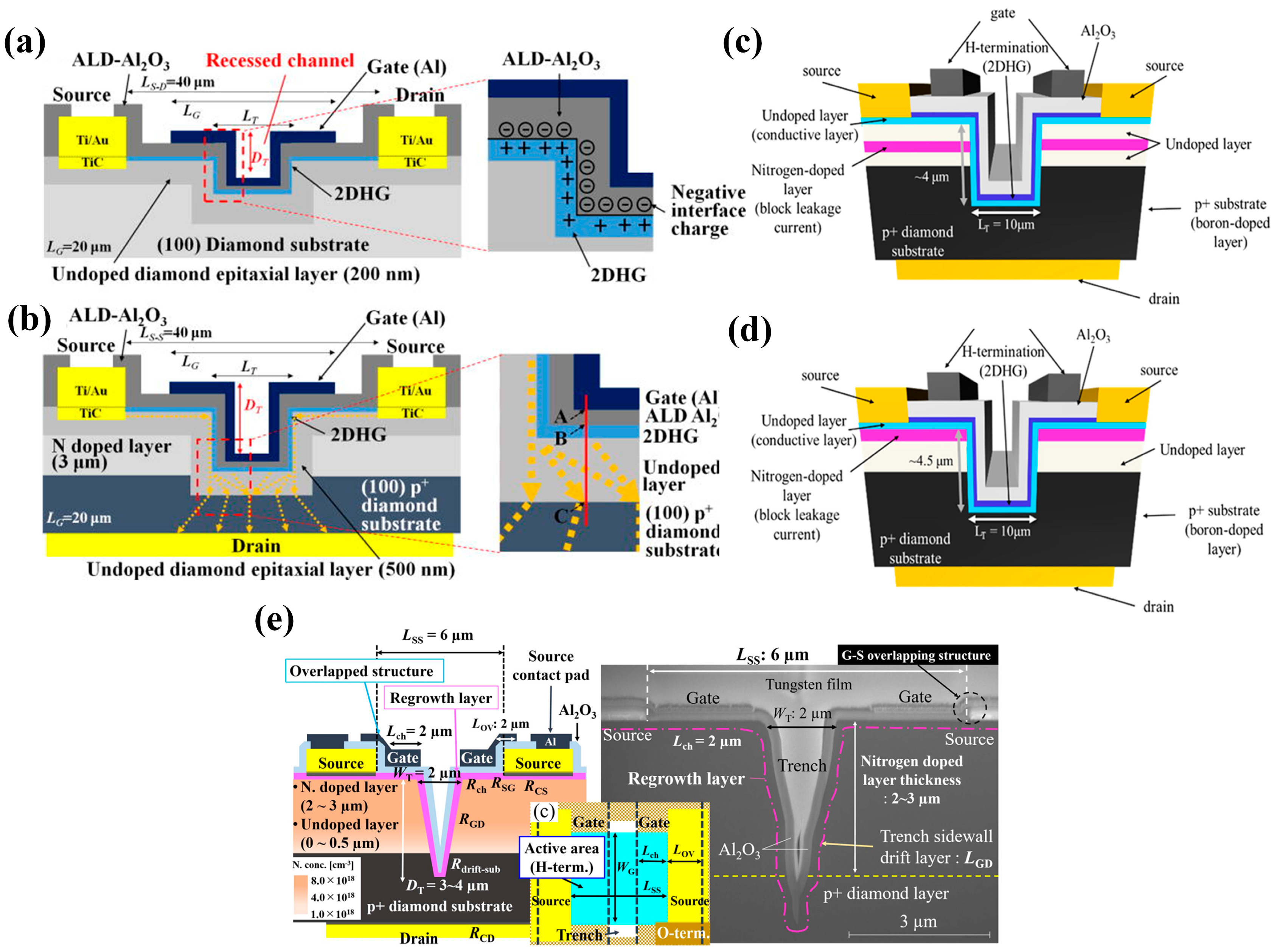

4.2. 2DHG FETs—Development and Optimization

4.3. Other Structures: VMOSFETs, BJTs, JFETs, and So On

4.4. Summary

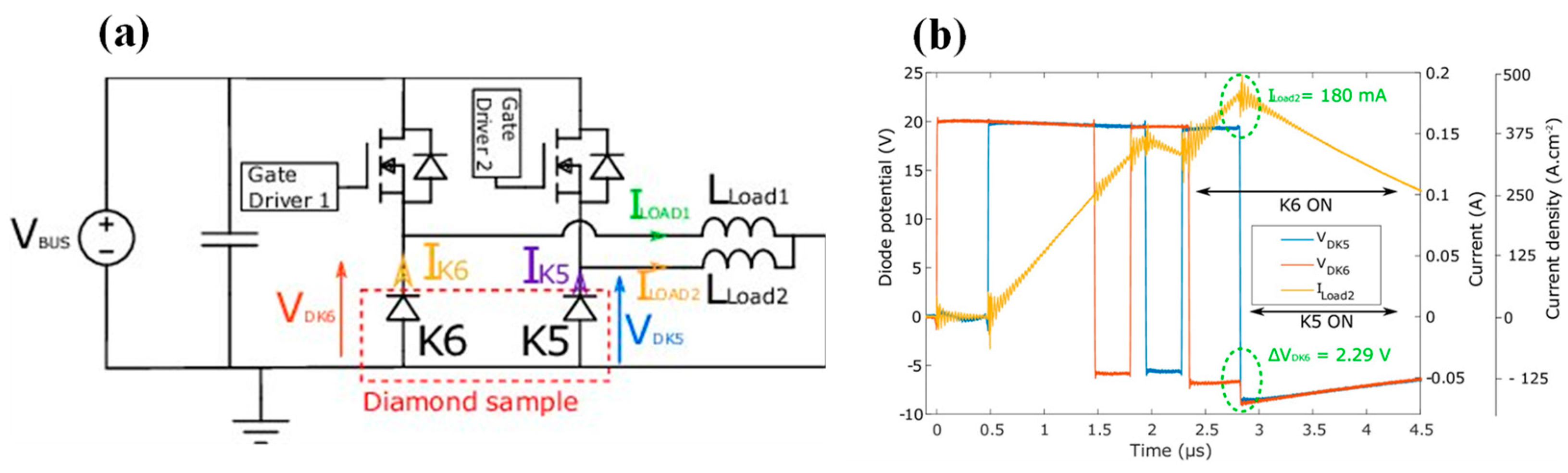

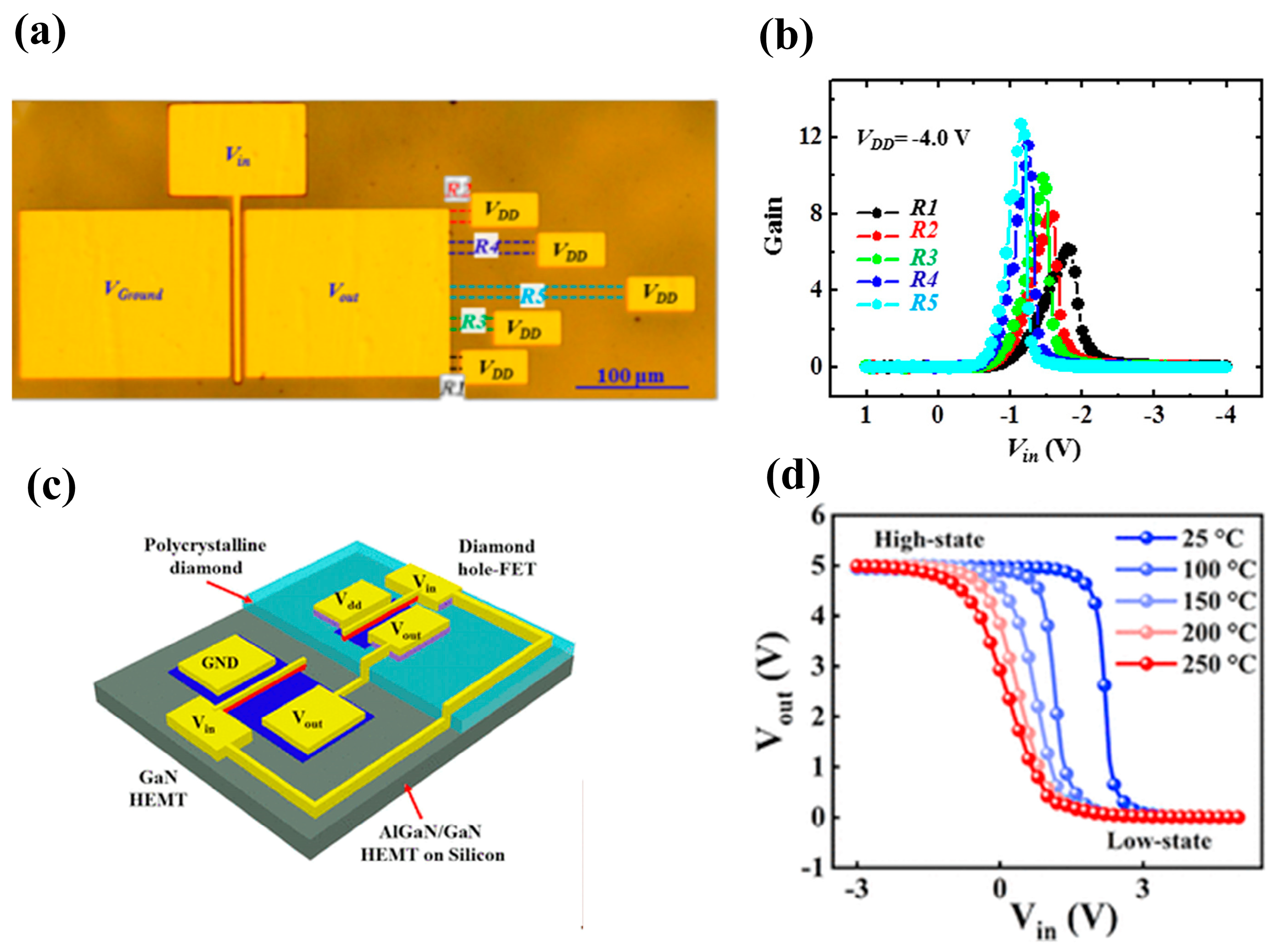

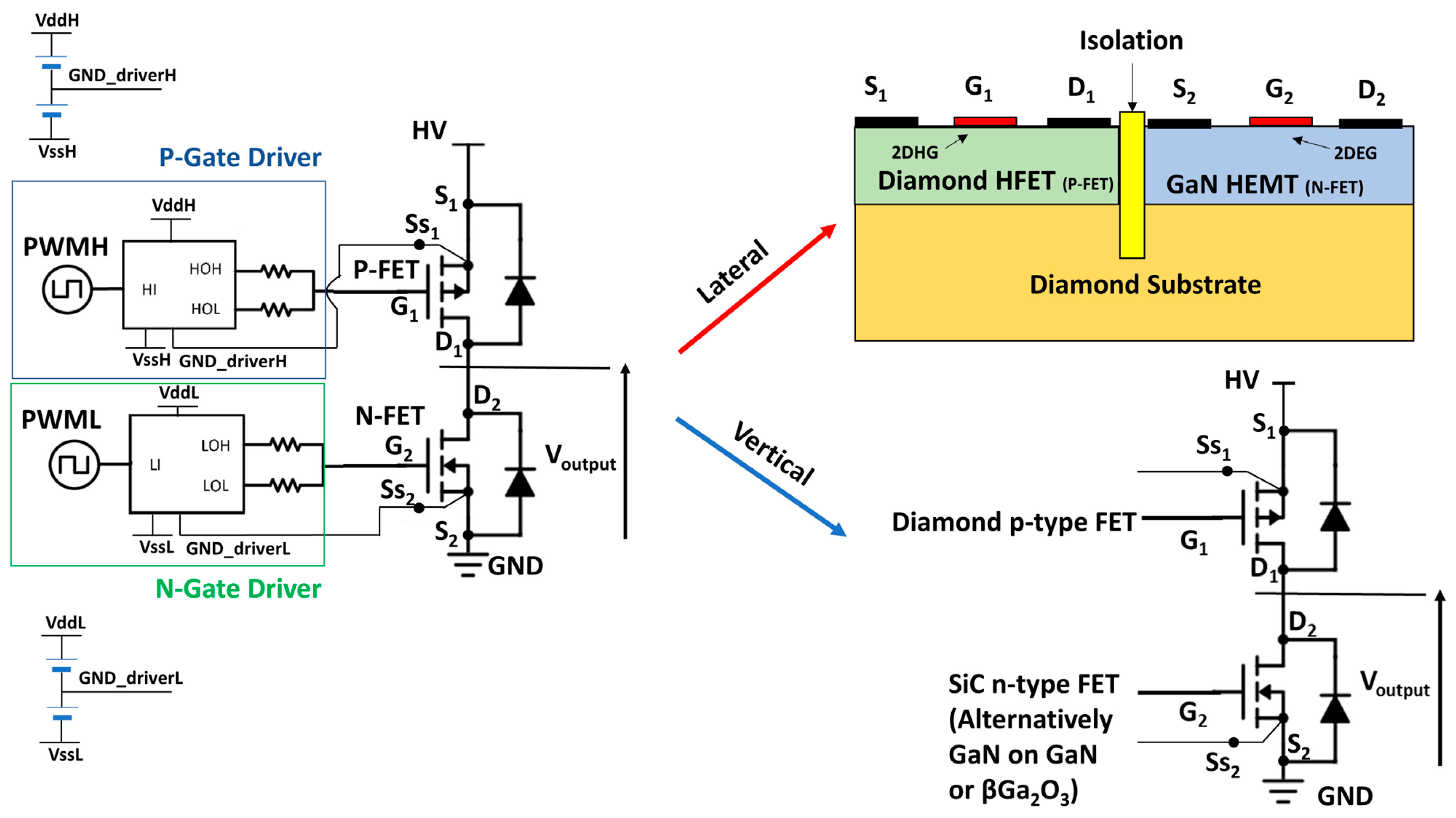

5. Application of Diamond in Electrical Circuits

6. Summary and Prospect

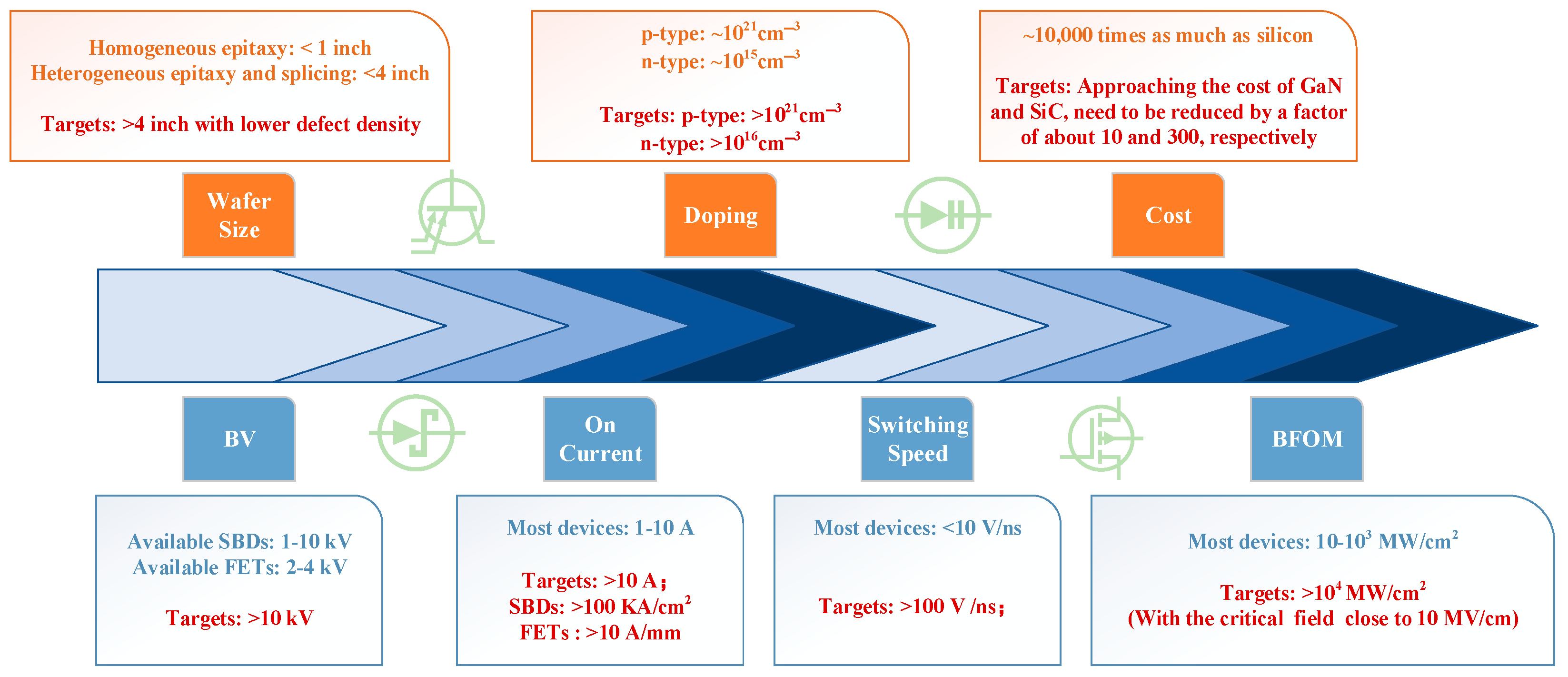

6.1. Status and Challenges of Diamond Parameters, Commercialization, and Integration

- (a)

- BV: For diode devices, the current vertical devices generally achieve greater than 1 kV with the highest close to 10 kV applications; the future goal is to break through 10 kV without affecting the on-state current. For field-effect transistors, the current maximum breakdown voltage of 2~4 kV; the future should break through more than 10 kV.

- (b)

- On current: The open-state current of most devices is in the range of 1~10 A, and the future goal should be to realize the application of more than 10 A. The current density of a diode is expected to break through 100 KA/cm2, and the field-effect tube breaks through 10 A/mm.

- (c)

- Switching speed: The current diamond diode slew rate is less than 10 V/ns; future expectations exceed 100 V/ns.

- (d)

- BFOM: The current BFOM values for diamond diodes and FETs are mainly in the range of 10 to 103 MV/cm2, and ideally one should expect more than 104 MV/cm2 at the maximum breakdown field strength close to 10 MV/cm [242].

- (a)

- Material quality and cost control: High-quality electronic-grade diamond wafers are expensive to produce and are usually small in size (less than 1 inch). Future wafers grown by HPHT and MPCVD should exceed 2 inch, and wafers obtained by heterogeneous epitaxy and splicing methods should exceed 4 inch.

- (b)

- Doping technology: There is a lack of effective n-type doping methods and a low concentration of p-type doping holes. The article has already mentioned the search for new growth directions to improve doping efficiency and the technology of achieving n-type doping through co-doping. In the future, it is expected to obtain p-type doping concentrations above 1021 cm−3 and n-type doping concentrations above 1016 cm−3 to achieve high-power applications.

- (c)

- Reliability: The reliability and lifetime of diamond devices have not yet been fully proven. There is less research on reliability testing, which needs to be achieved by building more simulation models and testing actual devices.

- (d)

- Thermal management and packaging: According to the research, diamond seems to be the only semiconductor with a sharp decrease in resistivity with temperature. While this is certainly an advantage, it also poses some problems in that the optimal operating state of the diamond device changes at different temperatures, which makes designing difficult. Due to this unique temperature characteristic, no encapsulation technology currently exists for diamonds. Electromagnetic compatibility (EMC) issues need to be considered. Special materials and designs are used to improve the reliability and long-term stability of the package and may include integrated thermal structures to help dissipate heat [243].

- (e)

- Device performance: As summarized in this review, diamond devices need to further improve breakdown voltage and reduce Ron. The current experimental device samples are small, and the parameters are not stable enough, and stable performance is required for commercial products. This will be achieved by refining doping techniques and introducing more power device structures, such as Insulated Gate Bipolar Transistors (IGBTs), resurf structures, and super-junction structures, which all rely on the realization of p-n junctions.

- (f)

- Cost: This is a major obstacle to the commercialization of diamond. The current production cost of diamond is much higher than Si, SiC, and GaN, the mature semiconductor materials. The price of diamond materials used for semiconductor research is several thousand to tens of thousands of times higher than that of silicon materials.

6.2. Commercialization Trends and Outlook

6.3. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baliga, B.J. Modern Power Devices; John Wiley & Sons: Nashville, TN, USA, 1986; ISBN 9780471819868. [Google Scholar]

- Yue, H. New progress in wide and ultra-wide bandgap semiconductor devices. Sci. Technol. Rev. 2019, 37, 58–61. [Google Scholar]

- Li, C.; Chen, G.; Li, Y.Z.; Zhou, J.J.; Li, X. Application of B implantation in widegap semiconductor materials and devices. Res. Prog. SSE 2011, 31, 233–235+291. [Google Scholar]

- Zhao, L.; Ge, Q.; Zhou, Z.; Yang, B.; Li, Y. Research of high-power converter based on the wide band gap power semiconductor devices for rail transit electrical drive. In Proceedings of the 2018 1st Workshop on Wide Bandgap Power Devices and Applications in Asia (WiPDA Asia), Xi’an, China, 16–18 May 2018; pp. 1–4. [Google Scholar]

- Zhang, L.; Yuan, X.; Wu, X.; Shi, C.; Zhang, J.; Zhang, Y. Performance evaluation of high-power SiC MOSFET modules in comparison to Si IGBT modules. IEEE Trans. Power Electron. 2019, 34, 1181–1196. [Google Scholar] [CrossRef]

- Dingle, R.; Störmer, H.L.; Gossard, A.C.; Wiegmann, W. Electron mobilities in modulation-doped semiconductor heterojunction superlattices. Appl. Phys. Lett. 1978, 33, 665–667. [Google Scholar] [CrossRef]

- Fujita, S. Wide-bandgap semiconductor materials: For their full bloom. Jpn. J. Appl. Phys. 2015, 54, 030101. [Google Scholar] [CrossRef]

- Qin, Y.; Albano, B.; Spencer, J.; Lundh, J.S.; Wang, B.; Buttay, C.; Tadjer, M.; DiMarino, C.; Zhang, Y. Thermal management and packaging of wide and ultra-wide bandgap power devices: A review and perspective. J. Phys. D Appl. Phys. 2023, 56, 093001. [Google Scholar] [CrossRef]

- Ramkumar, M.S.; Priya, R.; Rajakumari, R.F.; Valsalan, P.; Chakravarthi, M.K.; Latha, G.C.P.; Mathupriya, S.; Rajan, K. Review and evaluation of power devices and semiconductor materials based on Si, SiC, and Ga-N. J. Nanomater. 2022, 2022, 8648284. [Google Scholar] [CrossRef]

- Adappa, R.; Suryanarayana, K.; Swathi Hatwar, H.; Ravikiran Rao, M. Review of SiC based Power Semiconductor Devices and their Applications. In Proceedings of the 2019 2nd International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT), Kannur, India, 5–6 July 2019; pp. 1197–1202. [Google Scholar]

- O’Leary, S.K.; Foutz, B.E.; Shur, M.S.; Eastman, L.F. Steady-state and transient electron transport within the III–V nitride semiconductors, GaN, AlN, and InN: A review. J. Mater. Sci. Mater. Electron. 2006, 17, 87–126. [Google Scholar] [CrossRef]

- Kimoto, T.; Cooper, J.A. Fundamentals of Silicon Carbide Technology: Growth, Characterization, Devices and Applications; John Wiley & Sons: Nashville, TN, USA, 2014; ISBN 9781118313527. [Google Scholar]

- Spaziani, L.; Lu, L. Silicon, GaN and SiC: There’s room for all: An application space overview of device considerations. In Proceedings of the 2018 IEEE 30th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Chicago, IL, USA, 13–17 May 2018; pp. 8–11. [Google Scholar]

- Soukiassian, P.; Amy, F. Silicon carbide surface oxidation and SiO2/SiC interface formation investigated by soft X-ray synchrotron radiation. J. Electron. Spectros. Relat. Phenom. 2005, 144, 783–788. [Google Scholar] [CrossRef]

- Buffolo, M.; Caria, A.; Piva, F.; Roccato, N.; Casu, C.; De Santi, C.; Trivellin, N.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Defects and reliability of GaN-based LEDs: Review and perspectives. Phys. Status Solidi (A) 2022, 219, 2100727. [Google Scholar] [CrossRef]

- Zhang, L.Q.; Zhang, S.M.; Jiang, D.S.; Zhu, J.J.; Zhao, D.G.; Yang, H. Characteristics of GaN based laser diode. Infrared Laser Eng. 2009, 38, 41–44. [Google Scholar]

- He, J.; Wei, J.; Yang, S.; Wang, Y.; Zhong, K.; Chen, K.J. Frequency- and temperature-dependent gate reliability of Schottky-type p -GaN gate HEMTs. IEEE Trans. Electron. Devices 2019, 66, 3453–3458. [Google Scholar] [CrossRef]

- Rajashekara, K.; Akin, B. A review of cryogenic power electronics—Status and applications. In Proceedings of the 2013 International Electric Machines & Drives Conference, Chicago, IL, USA, 12–15 May 2013; pp. 899–904. [Google Scholar]

- Higashiwaki, M.; Sasaki, K.; Kuramata, A.; Masui, T.; Yamakoshi, S. Gallium oxide (Ga2O3) metal-semiconductor field-effect transistors on single-crystal β-Ga2O3 (010) substrates. Appl. Phys. Lett. 2012, 100, 013504. [Google Scholar] [CrossRef]

- Pearton, S.J.; Yang, J.; Cary, P.H.I.V.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A review of Ga2O3 materials, processing, and devices. Appl. Phys. Rev. 2018, 5, 011301. [Google Scholar]

- Umezawa, H. Recent advances in diamond power semiconductor devices. Mater. Sci. Semicond. Process. 2018, 78, 147–156. [Google Scholar] [CrossRef]

- Umezawa, H.; Nagase, M.; Kato, Y.; Shikata, S.-I. High temperature application of diamond power device. Diam. Relat. Mater. 2012, 24, 201–205. [Google Scholar] [CrossRef]

- Irokawa, Y.; Víllora, E.A.G.; Shimamura, K. Shottky barrier diodes on AlN free-standing substrates. Jpn. J. Appl. Phys. 2012, 51, 040206. [Google Scholar] [CrossRef]

- Yuan, Y.; Hao, W.; Mu, W.; Wang, Z.; Chen, X.; Liu, Q.; Xu, G.; Wang, C.; Zhou, H.; Zou, Y.; et al. Toward emerging gallium oxide semiconductors: A roadmap. Fundam. Res. 2021, 1, 697–716. [Google Scholar]

- Li, L.; Liao, F.; Hu, X.T. The possibility of N-P codoping to realize P type β-Ga2O3. Superlattices Microstruct. 2020, 141, 106502. [Google Scholar] [CrossRef]

- Bell, M.D.; Leivo, W.J. Rectification, photoconductivity, and photovoltaic effect in semiconducting Diamond. Phys. Rev. 1958, 111, 1227–1231. [Google Scholar] [CrossRef]

- Liu, M.; Xu, P.P.; Zhang, J.C.; Liu, B.; Zhang, L.W. A 4.2-to-5.4 GHz stacked GaAs HBT power amplifier for C-band applications. Circuit World 2020, 46, 243–248. [Google Scholar] [CrossRef]

- Perez, G.; Marechal, A.; Chicot, G.; Lefranc, P.; Jeannin, P.O.; Eon, D.; Rouger, N. Diamond semiconductor performances in power electronics applications. Diam. Relat. Mater. 2020, 110, 108154. [Google Scholar] [CrossRef]

- Isberg, J.; Hammersberg, J.; Johansson, E.; Wikström, T.; Twitchen, D.J.; Whitehead, A.J.; Coe, S.E.; Scarsbrook, G.A. High carrier mobility in single-crystal plasma-deposited diamond. Science 2002, 297, 1670–1672. [Google Scholar] [CrossRef]

- Yu, X.; Zhou, J.; Wang, Y.; Qiu, F.; Kong, Y.; Wang, H.; Chen, T. Breakdown enhancement of diamond Schottky barrier diodes using boron implanted edge terminations. Diam. Relat. Mater. 2019, 92, 146–149. [Google Scholar] [CrossRef]

- Liu, E.K. Semiconductor Physics; Electronic Industry Press: Beijing, China, 2017. [Google Scholar]

- Balmer, R.S.; Brandon, J.R.; Clewes, S.L.; Dhillon, H.K.; Dodson, J.M.; Friel, I.; Inglis, P.N.; Madgwick, T.D.; Markham, M.L.; Mollart, T.P.; et al. Chemical vapour deposition synthetic diamond: Materials, technology and applications. J. Phys. Condens. Matter 2009, 21, 364221. [Google Scholar] [CrossRef]

- Chu, C.J.; Hauge, R.H.; Margrave, J.L.; D’Evelyn, M.P. Growth kinetics of (100), (110), and (111) homoepitaxial diamond films. Appl. Phys. Lett. 1992, 61, 1393–1395. [Google Scholar] [CrossRef]

- Tsao, J.Y.; Chowdhury, S.; Hollis, M.A.; Jena, D.; Johnson, N.M.; Jones, K.A.; Kaplar, R.J.; Rajan, S.; Van de Walle, C.G.; Bellotti, E.; et al. Ultrawide-bandgap semiconductors: Research opportunities and challenges. Adv. Electron. Mater. 2018, 4, 1600501. [Google Scholar]

- Bar-Cohen, A.; Albrecht, J.D.; Maurer, J.J. Near-junction thermal management for wide bandgap devices. In Proceedings of the 2011 IEEE Compound Semiconductor Integrated Circuit Symposium (CSICS), Waikoloa, HI, USA, 16–19 October 2011; pp. 1–5. [Google Scholar]

- Chemical Semiconductors. Akhan Semiconductor to Expand Market for Diamond Electronic Products [EB/OL]. Available online: https://www.compoundsemiconductorchina.net/labfab-news.asp?id=3608 (accessed on 26 August 2021).

- Arnault, J.-C.; Saada, S.; Ralchenko, V. Chemical vapor deposition single-crystal Diamond: A review. Phys. Status Solidi Rapid Res. Lett. 2022, 16, 2100354. [Google Scholar] [CrossRef]

- Imanishi, S.; Horikawa, K.; Oi, N.; Okubo, S.; Kageura, T.; Hiraiwa, A.; Kawarada, H. 3.8 W/mm RF power density for ALD Al2O3-based two-dimensional hole gas Diamond MOSFET operating at saturation velocity. IEEE Electron. Device Lett. 2019, 40, 279–282. [Google Scholar] [CrossRef]

- Saha, N.C.; Kim, S.-W.; Oishi, T.; Kasu, M. 875-MW/cm² low-resistance NO2 p-type doped chemical mechanical planarized Diamond MOSFETs. IEEE Electron. Device Lett. 2022, 43, 777–780. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Y.; He, D. A chemical adsorption growth model for hot filament chemical vapor deposition diamond. Diam. Relat. Mater. 2000, 9, 1668–1672. [Google Scholar] [CrossRef]

- Zhang, Y.; Zang, C.; Ma, H.; Liang, Z.; Zhou, L.; Li, S.; Jia, X. HPHT synthesis of large single crystal diamond doped with high nitrogen concentration. Diam. Relat. Mater. 2008, 17, 209–211. [Google Scholar] [CrossRef]

- He, Q.; Su, K.; Zhang, J.; Ren, Z.; Xing, Y.; Zhang, J.; Lei, Y.; Hao, Y. High mobility normally-OFF hydrogenated Diamond field effect transistors with BaF2 gate insulator formed by electron beam evaporator. IEEE Trans. Electron. Devices 2022, 69, 1206–1210. [Google Scholar] [CrossRef]

- Bundy, F.P.; Hall, H.T.; Strong, H.M.; Wentorfjun, R.H. Man-made diamonds. Nature 1955, 176, 51–55. [Google Scholar] [CrossRef]

- Kamo, M.; Sato, Y.; Matsumoto, S.; Setaka, N. Diamond synthesis from gas phase in microwave plasma. J. Cryst. Growth 1983, 62, 642–644. [Google Scholar] [CrossRef]

- Derjaguin, B.V.; Fedoseev, D.V.; Lukyanovich, V.M.; Spitzin, B.V.; Ryabov, V.A.; Lavrentyev, A.V. Filamentary diamond crystals. J. Cryst. Growth 1968, 2, 380–384. [Google Scholar] [CrossRef]

- Sokol, A.G.; Pal’yanov, Y.N. Diamond formation in the system MgO-SiO-HO-C at 7. 5 GPa and 1600 °C. Contrib. Mineral. Petrol. 2008, 155, 33–43. [Google Scholar]

- Fagan, A.J.; Luth, R.W. Growth of diamond in hydrous silicate melts. Contrib. Mineral. Petrol. 2011, 161, 229–236. [Google Scholar] [CrossRef]

- Shu, G.; Ralchenko, V.G.; Bolshakov, A.P.; Zavedeev, E.V.; Khomich, A.A.; Pivovarov, P.A.; Ashkinazi, E.E.; Konov, V.I.; Dai, B.; Han, J.; et al. Evolution of surface relief of epitaxial diamond films upon growth resumption by microwave plasma chemical vapor deposition. CrystEngComm 2020, 22, 2138–2146. [Google Scholar] [CrossRef]

- May, P.W. Diamond thin films: A 21st-century material. Philos. Trans. A Math. Phys. Eng. Sci. 2000, 358, 473–495. [Google Scholar] [CrossRef]

- Vikharev, A.L.; Lobaev, M.A.; Gorbachev, A.M.; Radishev, D.B.; Isaev, V.A.; Bogdanov, S.A. Investigation of homoepitaxial growth by microwave plasma CVD providing high growth rate and high quality of diamond simultaneously. Mater. Today Commun. 2020, 22, 100816. [Google Scholar] [CrossRef]

- Widmann, C.J.; Müller-Sebert, W.; Lang, N.; Nebel, C.E. Homoepitaxial growth of single crystalline CVD-diamond. Diam. Relat. Mater. 2016, 64, 1–7. [Google Scholar] [CrossRef]

- Mallik, A.K.; Bysakh, S.; Pal, K.S.; Dandapat, N.; Guha, B.K.; Datta, S.; Basu, D. Large area deposition of polycrystalline Diamond coatings by microwave plasma CVD. Trans. Indian Ceram. Soc. 2013, 72, 225–232. [Google Scholar] [CrossRef]

- Dai, Z.; Bednarski-Meinke, C.; Loloee, R.; Golding, B. Epitaxial (100) iridium on A-plane sapphire: A system for wafer-scale diamond heteroepitaxy. Appl. Phys. Lett. 2003, 82, 3847–3849. [Google Scholar] [CrossRef]

- Nad, S.; Charris, A.; Asmussen, J. MPACVD growth of single crystalline diamond substrates with PCD rimless and expanding surfaces. Appl. Phys. Lett. 2016, 109, 162103. [Google Scholar] [CrossRef]

- Yamada, H.; Chayahara, A.; Mokuno, Y.; Kato, Y.; Shikata, S. A 2-in. mosaic wafer made of a single-crystal diamond. Appl. Phys. Lett. 2014, 104, 102110. [Google Scholar] [CrossRef]

- Liang, Q.; Chin, C.Y.; Lai, J.; Yan, C.S.; Meng, Y.; Mao, H.K.; Hemley, R.J. Enhanced growth of high quality single crystal diamond by microwave plasma assisted chemical vapor deposition at high gas pressures. Appl. Phys. Lett. 2009, 94, 024103. [Google Scholar] [CrossRef]

- Su, Y.; Li, H.D.; Cheng, S.H.; Zhang, Q.; Wang, Q.L.; Lv, X.Y.; Zou, G.T.; Pei, X.Q.; Xie, J.G. Effect of NO on high-rate homoepitaxial growth of CVD single crystal diamonds. J. Cryst. Growth 2012, 351, 51–55. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, H.D.; Cheng, S.H.; Wang, Q.L.; Li, L.A.; Lv, X.Y.; Zou, G.T. The effect of CO2 on the high-rate homoepitaxial growth of CVD single crystal diamonds. Diam. Relat. Mater. 2011, 20, 496–500. [Google Scholar] [CrossRef]

- Schreck, M.; Gsell, S.; Brescia, R.; Fischer, M. Ion bombardment induced buried lateral growth: The key mechanism for the synthesis of single crystal diamond wafers. Sci. Rep. 2017, 7, 44462. [Google Scholar] [CrossRef]

- Toros, A.; Kiss, M.; Graziosi, T.; Mi, S.; Berrazouane, R.; Naamoun, M.; Vukajlovic Plestina, J.; Gallo, P.; Quack, N. Reactive ion etching of single crystal diamond by inductively coupled plasma: State of the art and catalog of recipes. Diam. Relat. Mater. 2020, 108, 107839. [Google Scholar] [CrossRef]

- Wang, J.S.; Wan, L.; Chen, J.; Yan, J.W. Surface patterning of synthetic diamond crystallites using nickel powder. Diam. Relat. Mater. 2016, 66, 206–212. [Google Scholar] [CrossRef]

- Hiromu Shiomi, H.S. Reactive ion etching of Diamond in O2 and CF4 plasma, and fabrication of porous Diamond for field emitter cathodes. Jpn. J. Appl. Phys. 1997, 36, 7745. [Google Scholar] [CrossRef]

- Whetten, T.J.; Armstead, A.A.; Grzybowski, T.A.; Ruoff, A.L. Etching of diamond with argon and oxygen ion beams. J. Vac. Sci. Technol. A 1984, 2, 477–480. [Google Scholar] [CrossRef]

- Grogan, D.F.; Zhao, T.; Bovard, B.G.; Macleod, H.A. Planarizing technique for ion-beam polishing of diamond films. Appl. Opt. 1992, 31, 1483–1487. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.L.; Gu, E.; Dawson, M.D.; Friel, I.; Scarsbrook, G.A. Etching and micro-optics fabrication in diamond using chlorine-based inductively-coupled plasma. Diam. Relat. Mater. 2008, 17, 1292–1296. [Google Scholar] [CrossRef]

- Yamada, T.; Yoshikawa, H.; Uetsuka, H.; Kumaragurubaran, S.; Tokuda, N.; Shikata, S.-I. Cycle of two-step etching process using ICP for diamond MEMS applications. Diam. Relat. Mater. 2007, 16, 996–999. [Google Scholar] [CrossRef]

- Challier, M.; Sonusen, S.; Barfuss, A.; Rohner, D.; Riedel, D.; Koelbl, J.; Ganzhorn, M.; Appel, P.; Maletinsky, P.; Neu, E. Advanced fabrication of single-crystal Diamond membranes for quantum technologies. Micromachines 2018, 9, 148. [Google Scholar] [CrossRef]

- Forsberg, P.; Karlsson, M. High aspect ratio optical gratings in diamond. Diam. Relat. Mater. 2013, 34, 19–24. [Google Scholar] [CrossRef]

- Wang, J.; Enlund, J.; Isberg, J.; Karlsson, M.; Nikolajeff, F.; Olsson, J.; Twitchen, D.J. Anisotropic dry etching of boron doped single crystal CVD diamond. Carbon 2005, 43, 1839–1842. [Google Scholar]

- Khanaliloo, B.; Mitchell, M.; Hryciw, A.C.; Barclay, P.E. High-Q/V monolithic Diamond microdisks fabricated with quasi-isotropic etching. Nano Lett. 2015, 15, 5131–5136. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, M.; Lake, D.P.; Barclay, P.E. Realizing Q> 300 000 in diamond microdisks for optomechanics via etch optimization. APL Photonics 2019, 4, 016101. [Google Scholar] [CrossRef]

- Leech, P.W.; Reeves, G.K.; Holland, A. Reactive ion etching of diamond in CF4, O2, O2 and Ar-based mixtures. J. Mater. Sci. 2001, 36, 3453–3459. [Google Scholar] [CrossRef]

- Ando, Y.; Nishibayashi, Y.; Kobashi, K.; Hirao, T.; Oura, K. Smooth and high-rate reactive ion etching of diamond. Diam. Relat. Mater. 2002, 11, 824–827. [Google Scholar] [CrossRef]

- Field, J.E. The mechanical and strength properties of diamond. Rep. Prog. Phys. 2012, 75, 126505. [Google Scholar] [CrossRef] [PubMed]

- Monflier, R.; Isoird, K.; Cazarre, A.; Tasselli, J.; Servel, A.; Achard, J.; Eon, D.; Birnbaum, M.J.V. Diamond Schottky diodes operating at 473 K. EPE J. 2017, 27, 118–124. [Google Scholar] [CrossRef]

- Kumaresan, R.; Umezawa, H.; Tatsumi, N.; Ikeda, K.; Shikata, S. Device processing, fabrication and analysis of diamond pseudo-vertical Schottky barrier diodes with low leak current and high blocking voltage. Diam. Relat. Mater. 2009, 18, 299–302. [Google Scholar] [CrossRef]

- Wang, J.; Shao, G.; Li, Q.; Chen, G.; Yan, X.; Song, Z.; Wang, Y.; Wang, R.; Wang, W.; Fan, S.; et al. Vertical Diamond trench MOS barrier Schottky diodes with high breakdown voltage. IEEE Trans. Electron. Devices 2022, 69, 6231–6235. [Google Scholar] [CrossRef]

- Fu, Y.; Bi, T.; Chang, Y.H.; Xu, R.M.; Xu, Y.H.; Kawarada, H. Oxidized-Silicon-Terminated Diamond p-FETs With SiO2-Filling Shallow Trench Isolation Structures. IEEE Electron. Device Lett. 2023, 44, 1899–1902. [Google Scholar] [CrossRef]

- Crawford, K.G.; Maini, I.; Macdonald, D.A.; Moran, D.A.J. Surface transfer doping of diamond: A review. Prog. Surf. Sci. 2021, 96, 100613. [Google Scholar] [CrossRef]

- Masante, C.; Pernot, J.; Letellier, J.; Eon, D.; Rouger, N. 175V, >5.4 MV/cm, 50 mΩ·cm2 at 250 °C Diamond MOSFET and its reverse conduction. In Proceedings of the 2019 31st International Symposium on Power Semiconductor Devices and ICs (ISPSD), Shanghai, China, 19–23 May 2019. [Google Scholar]

- Lagrange, J.P.; Deneuville, A.; Gheeraert, E. Activation energy in low compensated homoepitaxial boron-doped diamond films. Diam. Relat. Mater. 1998, 7, 1390–1393. [Google Scholar] [CrossRef]

- Pernot, J.; Volpe, P.N.; Omnès, F.; Muret, P.; Mortet, V.; Haenen, K.; Teraji, T. Hall hole mobility in boron-doped homoepitaxial diamond. Phys. Rev. B Condens. Matter Mater. Phys. 2010, 81, 205203. [Google Scholar] [CrossRef]

- Barjon, J.; Chikoidze, E.; Jomard, F.; Dumont, Y.; Pinault-Thaury, M.A.; Issaoui, R.; Brinza, O.; Achard, J.; Silva, F. Homoepitaxial boron-doped diamond with very low compensation: Homoepitaxial boron-doped diamond. Phys. Status Solidi (A) 2012, 209, 1750–1753. [Google Scholar] [CrossRef]

- Kitagoh, S.; Okada, R.; Kawano, A.; Watanabe, M.; Takano, Y.; Yamaguchi, T.; Chikyow, T.; Kawarada, H. Cross-sectional TEM study and film thickness dependence of Tc in heavily boron-doped superconducting diamond. Physica C 2010, 470, S610–S612. [Google Scholar] [CrossRef]

- Tsubouchi, N.; Ogura, M.; Chayahara, A.; Okushi, H. Formation of a heavily B doped diamond layer using an ion implantation technique. Diam. Relat. Mater. 2008, 17, 498–501. [Google Scholar] [CrossRef]

- Tshepe, T.; Prins, J.F.; Hoch, M.J.R. Metal–insulator transition in boron-ion implanted type IIa diamond. Diam. Relat. Mater. 1999, 8, 1508–1510. [Google Scholar] [CrossRef]

- Childress, L.; Hanson, R. Diamond NV centers for quantum computing and quantum networks. MRS Bull. 2013, 38, 134–138. [Google Scholar] [CrossRef]

- Katamune, Y.; Mori, D.; Arikawa, D.; Izumi, A.; Shimaoka, T.; Ichikawa, K.; Koizumi, S. n-Type doping of diamond by hot-filament chemical vapor deposition growth with phosphorus incorporation. Appl. Phys. A-Mater. 2020, 126, 879. [Google Scholar] [CrossRef]

- Jones, R.; Lowther, J.E.; Goss, J. Limitations to n-type doping in diamond: The phosphorus-vacancy complex. Appl. Phys. Lett. 1996, 69, 2489–2491. [Google Scholar] [CrossRef]

- Prawer, S.; Uzan-Saguy, C.; Braunstein, G.; Kalish, R. Can n-type doping of diamond be achieved by Li or Na ion implantation? Appl. Phys. Lett. 1993, 63, 2502–2504. [Google Scholar] [CrossRef]

- Zeisel, R.; Nebel, C.E.; Stutzmann, M.; Sternschulte, H.; Schreck, M.; Stritzker, B. Photoconductivity study of Li doped homoepitaxially grown CVD Diamond. Physica Status Solidi A Appl. Res. 2000, 181, 45–50. [Google Scholar] [CrossRef]

- Su, H.; Wang, J.H.; Xiong, L.W.; Liu, P.F.; Jiang, C. Semiconductor application of doped nano-crystalline diamond film. J. Wuhan Inst. Technol. 2011, 33, 68–72. [Google Scholar]

- Kawai, S.; Yamano, H.; Sonoda, T.; Kato, K.; Buendia, J.J.; Kageura, T.; Fukuda, R.; Okada, T.; Tanii, T.; Higuchi, T.; et al. Nitrogen-terminated Diamond surface for nanoscale NMR by shallow nitrogen-vacancy centers. J. Phys. Chem. C Nanomater. Interfaces 2019, 123, 3594–3604. [Google Scholar] [CrossRef]

- Strobel, P.; Riedel, M.; Ristein, J.; Ley, L. Surface transfer doping of diamond. Nature 2004, 430, 439–441. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y. Study on Hydrogen-Terminated and Silicon-Terminated Diamond MOSFET. Ph.D. Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2022. [Google Scholar]

- Lv, X.; Wang, W.; Wang, Y.; Chen, G.; He, S.; Zhang, M.; Wang, H. Hydrogen-terminated single crystal Diamond MOSFET with a bilayer dielectric of Gd2O3/Al2O3. Crystals 2023, 13, 783. [Google Scholar] [CrossRef]

- Hu, W.X.; Yu, X.X.; Tao, T.; Chen, K.; Ye, Y.C.; Zhou, J.J.; Xie, Z.L.; Yan, Y.; Liu, B.; Zhang, R. H-Terminated Diamond MOSFETs on High-Quality Diamond Film Grown by MPCVD. Crystals 2023, 13, 1221. [Google Scholar] [CrossRef]

- Yagi, I.; Notsu, H.; Kondo, T.; Tryk, D.A.; Fujishima, A. Electrochemical selectivity for redox systems at oxygen-terminated diamond electrodes. J. Electroanal. Chem. 1999, 473, 173–178. [Google Scholar] [CrossRef]

- Schenk, A.; Tadich, A.; Sear, M.; O’Donnell, K.M.; Ley, L.; Stacey, A.; Pakes, C. Formation of a silicon terminated (100) diamond surface. Appl. Phys. Lett. 2015, 106, 191603. [Google Scholar] [CrossRef]

- Fu, Y.; Chang, Y.H.; Kono, S.; Hiraiwa, A.; Kanehisa, K.; Zhu, X.H.; Xu, R.M.; Xu, Y.H.; Kawarada, H. −10 V Threshold Voltage High-Performance Normally-C-Si Diamond MOSFET Formed by p-Diamond-First and Silicon Molecular Beam Deposition Approaches. IEEE Trans. Electron. Devices 2022, 69, 2236–2242. [Google Scholar] [CrossRef]

- Qiao, P.; Liu, K.; Zhang, S.; Su, Z.; Dai, B.; Han, J.; Zhu, J. Origin of two-dimensional hole gas formation on Si-treated diamond surfaces: Surface energy band diagram perspective. Appl. Surf. Sci. 2022, 584, 152560. [Google Scholar] [CrossRef]

- Peng, B.; Li, Q.; Zhang, S.M.; Fan, S.W.; Wang, R.Z.; Wang, H.X. Research Progress of Diamond Schottky Barrier Diodes. J. Synth. Cryst. 2023, 52, 732–745. [Google Scholar]

- Koné, S.; Schneider, H.; Isoird, K.; Thion, F.; Achard, J.; Issaoui, R.; Msolli, S.; Alexis, J. An assessment of contact metallization for high power and high temperature diamond Schottky devices. Diam. Relat. Mater. 2012, 27–28, 23–28. [Google Scholar] [CrossRef]

- Mönch, W. Barrier heights of metal contacts on H-terminated Diamond: Explanation by metal-induced gap states and interface dipoles. EPL 1994, 27, 479–484. [Google Scholar] [CrossRef]

- Piñero, J.C.; Araújo, D.; Fiori, A.; Traoré, A.; Villar, M.P.; Eon, D.; Muret, P.; Pernot, J.; Teraji, T. Atomic composition of WC/ and Zr/O-terminated diamond Schottky interfaces close to ideality. Appl. Surf. Sci. 2017, 395, 200–207. [Google Scholar] [CrossRef]

- Traoré, A.; Muret, P.; Fiori, A.; Eon, D.; Gheeraert, E.; Pernot, J. Zr/oxidized diamond interface for high power Schottky diodes. Appl. Phys. Lett. 2014, 104, 052105. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, Z.; Wang, J.; Liang, Y.; Nauman, M.; Fu, J.; Wang, Y.-F.; Fan, S.; Wang, W.; Wang, H.-X. Fabrication of dual-termination Schottky barrier diode by using oxygen-/fluorine-terminated diamond. Appl. Surf. Sci. 2018, 457, 411–416. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, Z.; Wang, J.; Yi, W.; Wang, R.; Wang, K.; Wang, H. Performance improved vertical Diamond Schottky barrier diode with fluorination-termination structure. IEEE Electron. Device Lett. 2019, 40, 1229–1232. [Google Scholar] [CrossRef]

- Peng, B.; Wang, Y.Y.; Liu, X.Q.; Zhen, C.M.; Gong, H.X.; Yan, Z.J.; Yang, Y.H.; Ma, S.Y. Ohmic contacts and interface properties of Au/Ti/p-diamnond prepared by r.f. sputtering. Surf. Interface Anal. 2000, 29, 478–481. [Google Scholar]

- Hoff, H.A.; Waytena, G.L.; Vold, C.L.; Suehle, J.S.; Isaacson, I.P.; Rebbert, M.L.; Ma, D.I.; Harris, K. Ohmic contacts to semiconducting diamond using a Ti/Pt/Au trilayer metallization scheme. Diam. Relat. Mater. 1996, 5, 1450–1456. [Google Scholar] [CrossRef]

- Kono, S.; Teraji, T.; Kodama, H.; Ichikawa, K.; Ohnishi, S.; Sawabe, A. Direct determination of the barrier height of Ti-based ohmic contact on p-type diamond (001). Diam. Relat. Mater. 2015, 60, 117–122. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Shao, G.Q.; Chen, G.Q.; He, S.; Zhang, Q.W.; Zhang, S.M.; Wang, R.Z.; Fan, S.W.; Wang, H.X. Breakdown Voltage Enhancement of Vertical Diamond Schottky Barrier Diode with Annealing Method and Al2O3 Field Plate Structure. IEEE Electron. Device Lett. 2022, 43, 1937–1940. [Google Scholar] [CrossRef]

- Shao, G.; Wang, J.; Liu, Z.; Wang, Y.; Wang, W.; Wang, H.-X. Performance-improved vertical Zr/Diamond Schottky barrier diode with lanthanum hexaboride interfacial layer. IEEE Electron. Device Lett. 2021, 42, 1366–1369. [Google Scholar] [CrossRef]

- Muret, P.; Volpe, P.N.; Tran-Thi, T.N.; Pernot, J.; Hoarau, C.; Omnès, F.; Teraji, T. Schottky diode architectures on p-type diamond for fast switching, high forward current density and high breakdown field rectifiers. Diam. Relat. Mater. 2011, 20, 285–289. [Google Scholar] [CrossRef]

- Zhao, D.; Li, F.N.; Liu, Z.C.; Chen, X.D.; Wang, Y.F.; Shao, G.Q.; Zhu, T.F.; Zhang, M.H.; Zhang, J.W.; Wang, J.J.; et al. Effects of rapid thermal annealing on the contact of tungsten/p-diamond. Appl. Surf. Sci. 2018, 443, 361–366. [Google Scholar] [CrossRef]

- Li, F.; Zhang, J.; Wang, X.; Zhang, M.; Wang, H. Barrier heights of Au on Diamond with different terminations determined by X-ray photoelectron spectroscopy. Coatings 2017, 7, 88. [Google Scholar] [CrossRef]

- Kono, S.; Teraji, T.; Takeuchi, D.; Ogura, M.; Kodama, H.; Sawabe, A. Direct determination of the barrier height of Au ohmic-contact on a hydrogen-terminated diamond (001) surface. Diam. Relat. Mater. 2017, 73, 182–189. [Google Scholar] [CrossRef]

- Evans, D.A.; Roberts, O.R.; Vearey-Roberts, A.R.; Langstaff, D.P.; Twitchen, D.J.; Schwitters, M. Direct observation of Schottky to Ohmic transition in Al-diamond contacts using real-time photoelectron spectroscopy. Appl. Phys. Lett. 2007, 91, 132114. [Google Scholar] [CrossRef]

- Woo, K.; Malakoutian, M.; Saraswat, D.; Bian, Z.; Hardy, A.; Muehle, M.; Grotjohn, T.A.; Chowdhury, S. Control of Schottky barrier height in diamond using UV-generated ozone and its effect on barrier inhomogeneity and temperature dependent properties. Diam. Relat. Mater. 2024, 145, 111059. [Google Scholar] [CrossRef]

- Volpe, P.-N.; Muret, P.; Pernot, J.; Omnès, F.; Teraji, T.; Jomard, F.; Planson, D.; Brosselard, P.; Dheilly, N.; Vergne, B.; et al. High breakdown voltage Schottky diodes synthesized on p-type CVD diamond layer. Phys. Status Solidi (A) 2010, 207, 2088–2092. [Google Scholar] [CrossRef]

- Volpe, P.-N.; Muret, P.; Pernot, J.; Omnès, F.; Teraji, T.; Koide, Y.; Jomard, F.; Planson, D.; Brosselard, P.; Dheilly, N.; et al. Extreme dielectric strength in boron doped homoepitaxial diamond. Appl. Phys. Lett. 2010, 97, 223501. [Google Scholar] [CrossRef]

- Bormashov, V.S.; Terentiev, S.A.; Buga, S.G.; Tarelkin, S.A.; Volkov, A.P.; Teteruk, D.V.; Kornilov, N.V.; Kuznetsov, M.S.; Blank, V.D. Thin large area vertical Schottky barrier diamond diodes with low on-resistance made by ion-beam assisted lift-off technique. Diam. Relat. Mater. 2017, 75, 78–84. [Google Scholar] [CrossRef]

- Zhao, D.; Hu, C.; Liu, Z.; Wang, H.-X.; Wang, W.; Zhang, J. Diamond MIP structure Schottky diode with different drift layer thickness. Diam. Relat. Mater. 2017, 73, 15–18. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, D.; Shao, G.; Liu, Z.; Chang, X.; Chen, G.; Wang, W.; Yi, W.; Wang, K.; Wang, H. Fabrication of dual-barrier planar structure Diamond Schottky diodes by rapid thermal annealing. IEEE Trans. Electron. Devices 2021, 68, 1176–1180. [Google Scholar] [CrossRef]

- Baliga, B.J. The pinch rectifier: A low-forward-drop high-speed power diode. IEEE Electron. Device Lett. 1984, 5, 194–196. [Google Scholar] [CrossRef]

- Umezawa, H.; Nagase, M.; Kato, Y.; Shikata, S. Diamond vertical Schottky barrier diode with Al2O3 field plate. Mater. Sci. For. 2012, 717–720, 1319–1321. [Google Scholar]

- Driche, K.; Rugen, S.; Kaminski, N.; Umezawa, H.; Okumura, H.; Gheeraert, E. Electric field distribution using floating metal guard rings edge-termination for Schottky diodes. Diam. Relat. Mater. 2018, 82, 160–164. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, D.; Wang, W.; Zhang, X.; Wang, Y.; Chang, X.; Liu, Z.; Fu, J.; Wang, K.; Wang, H.-X. Diamond Schottky barrier diodes with floating metal rings for high breakdown voltage. Mater. Sci. Semicond. Process. 2019, 97, 101–105. [Google Scholar] [CrossRef]

- Koizumi, S.; Umezawa, H.; Pernot, J.; Suzuki, M. (Eds.) Power Electronics Device Applications of Diamond Semiconductors; Woodhead Publishing: Cambridge, UK, 2018; ISBN 9780081021835. [Google Scholar]

- Hazdra, P.; Laposa, A.; Soban, Z.; Taylor, A.; Lambert, N.; Povolny, V.; Kroutil, J.; Gedeonov, Z.; Hubik, P.; Mortet, V. Pseudo-vertical Mo/Au Schottky diodes on {113} oriented boron doped homoepitaxial diamond layers. Diam. Relat. Mater. 2022, 126, 109088. [Google Scholar] [CrossRef]

- Hanada, T.; Ohmagari, S.; Kaneko, J.H.; Umezawa, H. High yield uniformity in pseudo-vertical diamond Schottky barrier diodes fabricated on half-inch single-crystal wafers. Appl. Phys. Lett. 2020, 117, 262107. [Google Scholar] [CrossRef]

- Mortet, V.; Taylor, A.; Lambert, N.; Gedeonová, Z.; Fekete, L.; Lorinčik, J.; Klimša, L.; Kopeček, J.; Hubík, P.; Šobáň, Z.; et al. Properties of boron-doped (113) oriented homoepitaxial diamond layers. Diam. Relat. Mater. 2021, 111, 108223. [Google Scholar] [CrossRef]

- Mehrotra, M.; Baliga, B.J. Trench MOS Barrier Schottky (TMBS) rectifier: A Schottky rectifier with higher than parallel plane breakdown voltage. Solid State Electron. 1995, 38, 801–806. [Google Scholar] [CrossRef]

- Zhu, L.; Chow, T.P.; Jones, K.A.; Agarwal, A. Design, fabrication, and characterization of low forward drop, low leakage, 1-kV 4H-SiC JBS rectifiers. IEEE Trans. Electron. Devices 2006, 53, 363–368. [Google Scholar]

- Khemka, V.; Ananthan, V.; Chow, T.P. A fully planarized 4H-SiC trench MOS barrier Schottky (TMBS) rectifier. IEEE Electron. Device Lett. 2000, 21, 286–288. [Google Scholar] [CrossRef]

- Hasegawa, K.; Nishio, G.; Yasunishi, K.; Tanaka, N.; Murakami, N.; Oka, T. Vertical GaN trench MOS barrier Schottky rectifier maintaining low leakage current at 200 °C with blocking voltage of 750 V. Appl. Phys. Express 2017, 10, 121002. [Google Scholar] [CrossRef]

- Sasaki, K.; Wakimoto, D.; Thieu, Q.T.; Koishikawa, Y.; Kuramata, A.; Higashiwaki, M.; Yamakoshi, S. Demonstration of Ga2O3 Trench MOS-Type Schottky Barrier Diodes. In Proceedings of the 2017 75th Annual Device Research Conference (DRC), South Bend, IN, USA, 25–28 June 2017; pp. 1–2. [Google Scholar]

- Li, W.; Nomoto, K.; Hu, Z.; Tanen, N.; Sasaki, K.; Kuramata, A.; Jena, D.; Xing, H.G. 1.5 kV Vertical Ga2O3 Trench-MIS Schottky Barrier Diodes. In Proceedings of the 2018 76th Device Research Conference (DRC), Santa Barbara, CA, USA, 24–27 June 2018; pp. 1–2. [Google Scholar]

- Lin, W.; Wang, Q.; Lv, X.; Li, L.; Zou, G. Design of trench Schottky barrier diode on diamond for obtaining high performance. Diam. Relat. Mater. 2023, 133, 109755. [Google Scholar] [CrossRef]

- Teraji, T.; Koizumi, S.; Koide, Y.; Ito, T. Electric field breakdown of lateral Schottky diodes of Diamond. Jpn. J. Appl. Phys. 2007, 46, L196–L198. [Google Scholar] [CrossRef]

- Koizumi, S.; Umezawa, H.; Pernot, J.; Suzuki, M. (Eds.) Key technologies for device fabrications and materials characterizations. In Power Electronics Device Applications of Diamond Semiconductors; Woodhead Publishing: Cambridge, UK, 2018; pp. 219–294. [Google Scholar]

- Han, Z.; Bayram, C. Diamond p-type lateral Schottky barrier diodes with high breakdown voltage (4612 V at 0.01 mA/mm). IEEE Electron. Device Lett. 2023, 44, 1692–1695. [Google Scholar] [CrossRef]

- Makino, T.; Kato, H.; Tokuda, N.; Ogura, M.; Takeuchi, D.; Oyama, K.; Tanimoto, S.; Okushi, H.; Yamasaki, S. Diamond Schottky-pn diode without trade-off relationship between on-resistance and blocking voltage. Phys. Status Solidi (A) 2010, 207, 2105–2109. [Google Scholar] [CrossRef]

- Kubovic, M.; El-Hajj, H.; Butler, J.E.; Kohn, E. Diamond merged diode. Diam. Relat. Mater. 2007, 16, 1033–1037. [Google Scholar] [CrossRef]

- Hitchcock, C.; Chow, T.P. Degradation of forward current density with increasing blocking voltage in diamond Schottky-pn diodes. Diam. Relat. Mater. 2020, 104, 107736. [Google Scholar] [CrossRef]

- Suzuki, M.; Sakai, T.; Makino, T.; Kato, H.; Takeuchi, D.; Ogura, M.; Okushi, H.; Yamasaki, S. Electrical characterization of diamond PiN diodes for high voltage applications: Electrical characterization of diamond PiN diodes. Phys. Status Solidi (A) 2013, 210, 2035–2039. [Google Scholar] [CrossRef]

- Saremi, M.; Hathwar, R.; Dutta, M.; Koeck, F.A.M.; Nemanich, R.J.; Chowdhury, S.; Goodnick, S.M. Analysis of the reverse I-V characteristics of diamond-based PIN diodes. Appl. Phys. Lett. 2017, 111, 043507. [Google Scholar] [CrossRef]

- Makino, T.; Tanimoto, S.; Kato, H.; Tokuda, N.; Ogura, M.; Takeuchi, D.; Oyama, K.; Ohashi, H.; Okushi, H.; Yamasaki, S. Diamond Schottky p-n diode with high forward current density. Phys. Status Solidi (A) 2009, 206, 2086–2090. [Google Scholar] [CrossRef]

- Makino, T.; Oyama, K.; Kato, H.; Takeuchi, D.; Ogura, M.; Okushi, H.; Yamasaki, S. Diamond electronic devices fabricated using heavily doped hopping p+ and n+ layers. Jpn. J. Appl. Phys. 2014, 53, 05FA12. [Google Scholar] [CrossRef]

- Kato, H.; Yamasaki, S.; Okushi, H. N -type doping of (001)-oriented single-crystalline diamond by phosphorus. Appl. Phys. Lett. 2005, 86, 6189–6200. [Google Scholar] [CrossRef]

- Koizumi, S.; Kamo, M.; Sato, Y.; Ozaki, H.; Inuzuka, T. Growth and characterization of phosphorous doped 111 homoepitaxial diamond thin films. Appl. Phys. Lett. 1997, 71, 1065–1067. [Google Scholar] [CrossRef]

- Donato, N.; Rouger, N.; Pernot, J.; Longobardi, G.; Udrea, F. Diamond power devices: State of the art, modelling, figures of merit and future perspective. J. Phys. D Appl. Phys. 2020, 53, 093001. [Google Scholar] [CrossRef]

- Matsumae, T.; Kurashima, Y.; Umezawa, H.; Tanaka, K.; Ito, T.; Watanabe, H.; Takagi, H. Low-temperature direct bonding of β-Ga2O3 and diamond substrates under atmospheric conditions. Appl. Phys. Lett. 2020, 116, 141602. [Google Scholar] [CrossRef]

- Sittimart, P.; Ohmagari, S.; Matsumae, T.; Umezawa, H.; Yoshitake, T. Diamond/β-Ga2O3 pn heterojunction diodes fabricated by low-temperature direct-bonding. AIP Adv. 2021, 11, 105114. [Google Scholar] [CrossRef]

- Kumaresan, R.; Umezawa, H.; Shikata, S. Vertical structure Schottky barrier diode fabrication using insulating diamond substrate. Diam. Relat. Mater. 2010, 19, 1324–1329. [Google Scholar] [CrossRef]

- Saha, N.C.; Irie, Y.; Seki, Y.; Hoshino, Y.; Nakata, J.; Kim, S.-W.; Oishi, T.; Kasu, M. 1651-V all-ion-implanted Schottky barrier diode on heteroepitaxial Diamond with 3.6 × 10⁵ on/off ratio. IEEE Electron Device Lett. 2023, 44, 293–296. [Google Scholar] [CrossRef]

- Dutta, M.; Koeck, F.A.M.; Hathwar, R.; Goodnick, S.M.; Nemanich, R.J.; Chowdhury, S. Demonstration of Diamond-based Schottky p-i-n diode with blocking voltage >500 V. IEEE Electron. Device Lett. 2016, 37, 1170–1173. [Google Scholar] [CrossRef]

- Kawashima, H.; Noguchi, H.; Matsumoto, T.; Kato, H.; Ogura, M.; Makino, T.; Shirai, S.; Takeuchi, D.; Yamasaki, S. Electronic properties of diamond Schottky barrier diodes fabricated on silicon-based heteroepitaxially grown diamond substrates. Appl. Phys. Express 2015, 8, 104103. [Google Scholar] [CrossRef]

- Shao, G.; Wang, J.; Zhang, S.; Wang, Y.; Wang, W.; Wang, H.-X. Effect of rapid thermal annealing on performances of vertical boron-doped diamond Schottky diode with LaB6 interlayer. Diam. Relat. Mater. 2023, 132, 109678. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Chen, G.; He, S.; Zhang, Q.; Zhang, S.; Wang, R.; Fan, S.; Wang, H.-X. Breakdown voltage enhancement of vertical diamond Schottky barrier diodes by selective growth nitrogen-doped diamond field plate. Diam. Relat. Mater. 2023, 134, 109799. [Google Scholar] [CrossRef]

- Matsumoto, T.; Mukose, T.; Makino, T.; Takeuchi, D.; Yamasaki, S.; Inokuma, T.; Tokuda, N. Diamond Schottky-pn diode using lightly nitrogen-doped layer. Diam. Relat. Mater. 2017, 75, 152–154. [Google Scholar] [CrossRef]

- Chakrapani, V.; Angus, J.C.; Anderson, A.B.; Wolter, S.D.; Stoner, B.R.; Sumanasekera, G.U. Charge transfer equilibria between diamond and an aqueous oxygen electrochemical redox couple. Science 2007, 318, 1424–1430. [Google Scholar] [CrossRef]

- Sato, H.; Kasu, M. Electronic properties of H-terminated diamond during NO2 and O adsorption and desorption. Diam. Relat. Mater. 2012, 24, 99–103. [Google Scholar] [CrossRef]

- Gi, R.; Kazuhiro Tashiro, K.T.; Seiichi Tanaka, S.T.; Takao Fujisawa, T.F.; Hideki Kimura, H.K.; Tateki Kurosu, T.K.; Masamori Iida, M.I. Hall effect measurements of surface conductive layer on undoped Diamond films in NO2 and NH3 atmospheres. Jpn. J. Appl. Phys. 1999, 38, 3492. [Google Scholar] [CrossRef]

- Sque, S.J.; Jones, R.; Öberg, S.; Briddon, P.R. Transfer doping of diamond: The use of and to effect p-type surface conductivity. Phys. B Condens. Matter 2006, 376–377, 268–271. [Google Scholar] [CrossRef]

- Russell, S.A.O.; Cao, L.; Qi, D.; Tallaire, A.; Crawford, K.G.; Wee, A.T.S.; Moran, D.A.J. Surface transfer doping of diamond by MoO3: A combined spectroscopic and Hall measurement study. Appl. Phys. Lett. 2013, 103, 202112. [Google Scholar] [CrossRef]

- Crawford, K.G.; Cao, L.; Qi, D.; Tallaire, A.; Limiti, E.; Verona, C.; Wee, A.T.S.; Moran, D.A.J. Enhanced surface transfer doping of diamond by V2O5 with improved thermal stability. Appl. Phys. Lett. 2016, 108, 042103. [Google Scholar] [CrossRef]

- Kawarada, H.; Aoki, M.; Ito, M. Enhancement mode metal-semiconductor field effect transistors using homoepitaxial diamonds. Appl. Phys. Lett. 1994, 65, 1563–1565. [Google Scholar] [CrossRef]

- Gluche, P.; Aleksov, A.; Vescan, A.; Ebert, W.; Kohn, E. Diamond surface-channel FET structure with 200 V breakdown voltage. IEEE Electron. Device Lett. 1997, 18, 547–549. [Google Scholar] [CrossRef]

- Kawarada, H.; Wild, C.; Herres, N.; Koidl, P.; Mizuochi, Y.; Hokazono, A.; Nagasawa, H. Surface morphology and surface p-channel field effect transistor on the heteroepitaxial diamond deposited on inclined β-SiC(001) surfaces. Appl. Phys. Lett. 1998, 72, 1878–1880. [Google Scholar] [CrossRef]

- Hokazono, A.; Tsugawa, K.; Umezana, H.; Kitatani, K.; Kawarada, H. Surface p-channel metal-oxide-semiconductor field effect transistors fabricated on hydrogen terminated (001) surfaces of diamond. Solid State Electron. 1999, 43, 1465–1471. [Google Scholar] [CrossRef]

- Kasu, M. Influence of epitaxy on the surface conduction of diamond film. Diam. Relat. Mater. 2004, 13, 226–232. [Google Scholar] [CrossRef]

- Hirama, K.; Takayanagi, H.; Yamauchi, S.; Jingu, Y.; Umezawa, H.; Kawarada, H. High-performance p-channel diamond MOSFETs with alumina gate insulator. In Proceedings of the 2007 IEEE International Electron Devices Meeting, Washington, DC, USA, 10–12 December 2007; pp. 873–876. [Google Scholar]

- Hiraiwa, A.; Daicho, A.; Kurihara, S.; Yokoyama, Y.; Kawarada, H. Refractory two-dimensional hole gas on hydrogenated diamond surface. J. Appl. Phys. 2012, 112, 124504. [Google Scholar] [CrossRef]

- Kawarada, H.; Yamada, T.; Xu, D.; Tsuboi, H.; Saito, T.; Hiraiwa, A. Wide temperature (10 K–700 K) and high voltage (~1000 V) operation of C-H diamond MOSFETs for power electronics application. In Proceedings of the 2014 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014; pp. 1–4. [Google Scholar]

- Kawarada, H.; Yamada, T.; Xu, D.; Tsuboi, H.; Kitabayashi, Y.; Matsumura, D.; Shibata, M.; Kudo, T.; Inaba, M.; Hiraiwa, A. Durability-enhanced two-dimensional hole gas of C-H diamond surface for complementary power inverter applications. Sci. Rep. 2017, 7, 42368. [Google Scholar] [CrossRef] [PubMed]

- Saha, N.C.; Kim, S.-W.; Koyama, K.; Oishi, T.; Kasu, M. 3659-V NO2 p-Type Doped Diamond MOSFETs on Misoriented Heteroepitaxial Diamond Substrates. IEEE Electron Device Lett. 2023, 44, 112–115. [Google Scholar] [CrossRef]

- Kudara, K.; Imanishi, S.; Hiraiwa, A.; Komatsuzaki, Y.; Yamaguchi, Y.; Kawamura, Y.; Shinjo, S.; Kawarada, H. High output power density of 2DHG Diamond MOSFETs with thick ALD-Al2O3. IEEE Trans. Electron. Devices 2021, 68, 3942–3949. [Google Scholar] [CrossRef]

- Wade, T.; Geis, M.W.; Fedynyshyn, T.H.; Vitale, S.A.; Varghese, J.O.; Lennon, D.M.; Grotjohn, T.A.; Nemanich, R.J.; Hollis, M.A. Effect of surface roughness and H-termination chemistry on diamond’s semiconducting surface conductance. Diam. Relat. Mater. 2017, 76, 79–85. [Google Scholar] [CrossRef]

- Kubovic, M.; Kasu, M.; Kageshima, H.; Maeda, F. Electronic and surface properties of H-terminated diamond surface affected by NO2 gas. Diam. Relat. Mater. 2010, 19, 889–893. [Google Scholar] [CrossRef]

- Liu, J.; Ohsato, H.; Liao, M.; Imura, M.; Watanabe, E.; Koide, Y. Logic circuits with hydrogenated Diamond field-effect transistors. IEEE Electron. Device Lett. 2017, 38, 922–925. [Google Scholar] [CrossRef]

- Macdonald, D.A.; Crawford, K.G.; Tallaire, A.; Issaoui, R.; Moran, D.A.J. Performance enhancement of Al2O3/H-Diamond MOSFETs utilizing vacuum annealing and V2O5 as a surface electron acceptor. IEEE Electron. Device Lett. 2018, 39, 1354–1357. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Zhang, M.; Wang, R.; Chen, G.; Chang, X.; Lin, F.; Wen, F.; Jia, K.; Wang, H.-X. An enhancement-mode hydrogen-terminated Diamond field-effect transistor with lanthanum hexaboride gate material. IEEE Electron. Device Lett. 2020, 41, 585–588. [Google Scholar] [CrossRef]

- Liu, J.W.; Liao, M.Y.; Imura, M.; Matsumoto, T.; Shibata, N.; Ikuhara, Y.; Koide, Y. Control of normally on/off characteristics in hydrogenated diamond metal-insulator-semiconductor field-effect transistors. J. Appl. Phys. 2015, 118, 115704. [Google Scholar] [CrossRef]

- Liu, J.W.; Oosato, H.; Liao, M.Y.; Koide, Y. Enhancement-mode hydrogenated diamond metal-oxide-semiconductor field-effect transistors with Y2O3 oxide insulator grown by electron beam evaporator. Appl. Phys. Lett. 2017, 110, 203502. [Google Scholar] [CrossRef]

- Ren, Z.; Zhang, J.; Zhang, J.; Zhang, C.; Xu, S.; Li, Y.; Hao, Y. Diamond field effect transistors with MoO3Gate dielectric. IEEE Electron. Device Lett. 2017, 38, 786–789. [Google Scholar] [CrossRef]

- Ren, Z.; Zhang, J.; Zhang, J.; Zhang, C.; Chen, D.; Yang, P.; Li, Y.; Hao, Y. Polycrystalline Diamond MOSFET with MoO3 Gate Dielectric and Passivation Layer. IEEE Electron. Device Lett. 2017, 38, 1302–1304. [Google Scholar] [CrossRef]

- Tordjman, M.; Weinfeld, K.; Kalish, R. Boosting surface charge-transfer doping efficiency and robustness of diamond with WO3 and ReO3. Appl. Phys. Lett. 2017, 111, 111601. [Google Scholar] [CrossRef]

- Liu, J.W.; Liao, M.Y.; Imura, M.; Koide, Y. Normally-off HfO2-gated diamond field effect transistors. Appl. Phys. Lett. 2013, 103, 092905. [Google Scholar] [CrossRef]

- Ren, Z.; Lv, D.; Xu, J.; Su, K.; Zhang, J.; Wang, D.; Wu, Y.; Zhang, J.; Hao, Y. Performance of H-diamond MOSFETs with high temperature ALD grown HfO2 dielectric. Diam. Relat. Mater. 2020, 106, 107846. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, X.; Mao, S.; Zhou, J.; Kong, Y.; Chen, T.; Xu, R.; Yan, B.; Xu, Y. Hydrogen-terminated Diamond field-effect transistors with 1011 ON/ OFF ratio using an Al2O3/HfO2 stacked passivation layer. IEEE Trans. Electron Devices 2024, 71, 940–943. [Google Scholar] [CrossRef]

- Wang, F.; Chen, G.; Shao, G.; Wang, W.; Zhang, M.; Wang, Y.; Zhang, Q.; He, S.; Hu, W.; Wang, H. Electrical Characteristics of H-Diamond Transistors With ZrO2/Zr Stacked Dielectrics Deposited by Electron Beam Evaporation. IEEE Trans. Electron. Devices 2024, 71, 1567–1571. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, J.; Sang, L.; Liao, M.; Coathup, D.; Imura, M.; Shi, B.; Gu, C.; Koide, Y.; Ye, H. Assembly of a high-dielectric constant thin TiOx layer directly on H-terminated semiconductor diamond. Appl. Phys. Lett. 2016, 108, 012105. [Google Scholar] [CrossRef]

- Daligou, G.; Pernot, J. 2D hole gas mobility at diamond/insulator interface. Appl. Phys. Lett. 2020, 116, 162105. [Google Scholar] [CrossRef]

- Sasama, Y.; Kageura, T.; Imura, M.; Watanabe, K.; Taniguchi, T.; Uchihashi, T.; Takahide, Y. High-mobility p-channel wide-bandgap transistors based on hydrogen-terminated diamond/hexagonal boron nitride heterostructures. Nat. Electron. 2021, 5, 37–44. [Google Scholar] [CrossRef]

- Mirabedini, P.S.; Debnath, B.; Neupane, M.R.; Alex Greaney, P.; Glen Birdwell, A.; Ruzmetov, D.; Crawford, K.G.; Shah, P.; Weil, J.; Ivanov, T.G. Structural and electronic properties of 2D (graphene, hBN)/H-terminated diamond (100) heterostructures. Appl. Phys. Lett. 2020, 117, 121901. [Google Scholar] [CrossRef]

- Liu, J.W.; Liao, M.Y.; Imura, M.; Banal, R.G.; Koide, Y. Deposition of TiO2/Al2O3 bilayer on hydrogenated diamond for electronic devices: Capacitors, field-effect transistors, and logic inverters. J. Appl. Phys. 2017, 121, 224502. [Google Scholar] [CrossRef]

- Kitabayashi, Y.; Kudo, T.; Tsuboi, H.; Yamada, T.; Xu, D.; Shibata, M.; Matsumura, D.; Hayashi, Y.; Syamsul, M.; Inaba, M.; et al. Normally-off C–H Diamond MOSFETs with partial C–O channel achieving 2-kV breakdown voltage. IEEE Electron. Device Lett. 2017, 38, 363–366. [Google Scholar] [CrossRef]

- Fei, W.; Inaba, M.; Hoshino, H.; Tsuyusaki, I.; Kawai, S.; Iwataki, M.; Kawarada, H. Point-arc remote plasma chemical vapor deposition for high-quality single-crystal Diamond selective growth. Phys. Status Solidi (A) 2019, 216, 1900227. [Google Scholar] [CrossRef]

- Fei, W.; Bi, T.; Iwataki, M.; Imanishi, S.; Kawarada, H. Oxidized Si terminated diamond and its MOSFET operation with SiO2 gate insulator. Appl. Phys. Lett. 2020, 116, 212103. [Google Scholar] [CrossRef]

- Geis, M.W.; Gregory, J.A.; Pate, B.B. Capacitance-voltage measurements on metal-SiO2-diamond structures fabricated with (100)- and (111)-oriented substrates. IEEE Trans. Electron. Devices 1991, 38, 619–626. [Google Scholar] [CrossRef]

- Liu, J.; Ohsato, H.; Wang, X.; Liao, M.; Koide, Y. Design and fabrication of high-performance diamond triple-gate field-effect transistors. Sci. Rep. 2016, 6, 34757. [Google Scholar] [CrossRef]

- Saha, N.C.; Kasu, M. Heterointerface properties of diamond MOS structures studied using capacitance–voltage and conductance–frequency measurements. Diam. Relat. Mater. 2019, 91, 219–224. [Google Scholar] [CrossRef]

- Schenk, A.K.; Sear, M.J.; Dontschuk, N.; Tsai, A.; Rietwyk, K.J.; Tadich, A.; Cowie, B.C.C.; Ley, L.; Stacey, A.; Pakes, C.I. Development of a silicon–diamond interface on (111) diamond. Appl. Phys. Lett. 2020, 116, 071602. [Google Scholar] [CrossRef]

- Bi, T.; Niu, J.; Oi, N.; Inaba, M.; Sasaki, T.; Kawarada, H. Application of 2DHG Diamond p-FET in cascode with normally-OFF operation and a breakdown voltage of over 1.7 kV. IEEE Trans. Electron. Devices 2020, 67, 4006–4009. [Google Scholar] [CrossRef]

- Zhu, X.H.; Bi, T.; Yuan, X.L.; Chang, Y.H.; Zhang, R.M.; Fu, Y.; Tu, J.P.; Huang, Y.B.; Liu, J.L.; Li, C.M.; et al. C-Si interface on SiO2/(111) diamond p-MOSFETs with high mobility and excellent normally-off operation. Appl. Surf. Sci. 2022, 593, 153368. [Google Scholar] [CrossRef]

- Bi, T.; Chang, Y.; Fei, W.; Iwataki, M.; Morishita, A.; Fu, Y.; Niikura, N.; Kawarada, H. C–Si bonded two-dimensional hole gas diamond MOSFET with normally-off operation and wide temperature range stability. Carbon 2021, 175, 525–533. [Google Scholar] [CrossRef]

- Fu, Y.; Kono, S.; Kawarada, H.; Hiraiwa, A. Electrical Characterization of Metal/Al2O3/SiO2/Oxidized-Si-Terminated (C-Si-O) Diamond Capacitors. IEEE Trans. Electron. Devices 2022, 69, 3604–3610. [Google Scholar] [CrossRef]

- Kawarada, H.; Ota, K.; Fu, Y.; Narita, A.; Zhu, X.; Hiraiwa, A.; Fujishima, T. Oxidized Silicon Terminated Diamond p-MOSFETs with Channel Mobility >150 cm2V−1s−1 and |VTH| > 3V Normally-off for Complementary Power Circuits. In Proceedings of the 2023 International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 9–13 December 2023; pp. 1–4. [Google Scholar]

- Sun, S.C.; Plummer, J.D. Modeling of the on-resistance of LDMOS, VDMOS, and VMOS power transistors. IEEE Trans. Electron. Devices 1980, 27, 356–367. [Google Scholar] [CrossRef]

- Prins, J.F. Bipolar transistor action in ion implanted diamond. Appl. Phys. Lett. 1982, 41, 950–952. [Google Scholar] [CrossRef]

- Kato, H.; Makino, T.; Ogura, M.; Takeuchi, D.; Yamasaki, S. Fabrication of bipolar junction transistor on (001)-oriented diamond by utilizing phosphorus-doped n-type diamond base. Diam. Relat. Mater. 2013, 34, 41–44. [Google Scholar] [CrossRef]

- Cho, S.J.; Liu, D.; Hardy, A.; Kim, J.; Gong, J.; Herrera-Rodriguez, C.J.; Swinnich, E.; Konstantinou, X.; Oh, G.-Y.; Kim, D.G.; et al. Fabrication of AlGaAs/GaAs/diamond heterojunctions for diamond-collector HBTs. AIP Adv. 2020, 10, 125226. [Google Scholar] [CrossRef]

- Hoshino, Y.; Kato, H.; Makino, T.; Ogura, M.; Iwasaki, T.; Hatano, M.; Yamasaki, S. Electrical properties of lateral p–n junction diodes fabricated by selective growth of n+ diamond. Phys. Status Solidi (A) 2012, 209, 1761–1764. [Google Scholar] [CrossRef]

- Suwa, T.; Iwasaki, T.; Sato, K.; Kato, H.; Makino, T.; Ogura, M.; Takeuchi, D.; Yamasaki, S.; Hatano, M. Normally-off Diamond junction field-effect transistors with submicrometer channel. IEEE Electron. Device Lett. 2016, 37, 209–211. [Google Scholar] [CrossRef]

- Shimada, Y.; Kato, K.; Ikeda, S.; Yoshida, H. Low input capacitance and low loss VD-MOSFET rectifier element. IEEE Trans. Electron. Devices 1982, 29, 1332–1334. [Google Scholar] [CrossRef]

- Chen, X.B.; Huang, M.M. A Vertical Power MOSFET with an Interdigitated Drift Region Using High-Insulator. IEEE Trans. Electron. Devices 2012, 59, 2430–2437. [Google Scholar] [CrossRef]

- Chang, H.R.; Holroyd, F.W. High voltage power MOSFETs with a trench-gate structure. Solid State Electron. 1990, 33, 381–386. [Google Scholar] [CrossRef]

- Inaba, M.; Muta, T.; Kobayashi, M.; Saito, T.; Shibata, M.; Matsumura, D.; Kudo, T.; Hiraiwa, A.; Kawarada, H. Hydrogen-terminated diamond vertical-type metal oxide semiconductor field-effect transistors with a trench gate. Appl. Phys. Lett. 2016, 109, 033503. [Google Scholar] [CrossRef]

- Oi, N.; Inaba, M.; Okubo, S.; Tsuyuzaki, I.; Kageura, T.; Onoda, S.; Hiraiwa, A.; Kawarada, H. Vertical-type two-dimensional hole gas diamond metal oxide semiconductor field-effect transistors. Sci. Rep. 2018, 8, 10660. [Google Scholar] [CrossRef] [PubMed]

- Iwataki, M.; Oi, N.; Horikawa, K.; Amano, S.; Nishimura, J.; Kageura, T.; Inaba, M.; Hiraiwa, A.; Kawarada, H. Over 12000 A/cm2 and 3.2 m Ω cm2 Miniaturized Vertical-Type Two-Dimensional Hole Gas Diamond MOSFET. IEEE Electron. Device Lett. 2020, 41, 111–114. [Google Scholar] [CrossRef]

- Aleksov, A.; Vescan, A.; Kunze, M.; Gluche, P.; Ebert, W.; Kohn, E.; Bergmeier, A.; Dollinger, G. Diamond junction FETs based on δ-doped channels. Diam. Relat. Mater. 1999, 8, 941–945. [Google Scholar] [CrossRef]

- Iwasaki, T.; Yaita, J.; Kato, H.; Makino, T.; Ogura, M.; Takeuchi, D.; Okushi, H.; Yamasaki, S.; Hatano, M. 600 V Diamond Junction Field-Effect Transistors Operated at 200 °C. IEEE Electron. Device Lett. 2014, 35, 241–243. [Google Scholar] [CrossRef]

- Iwasaki, T.; Kato, H.; Yaita, J.; Makino, T.; Ogura, M.; Takeuchi, D.; Okushi, H.; Yamasaki, S.; Hatano, M. Current enhancement by conductivity modulation in diamond JFETs for next generation low-loss power devices. In Proceedings of the 2015 IEEE 27th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Hong Kong, China, 14–15 May 2015; pp. 77–80. [Google Scholar]

- Iwasaki, T.; Kato, H.; Makino, T.; Ogura, M.; Takeuchi, D.; Yamasaki, S.; Hatano, M. High-temperature bipolar-mode operation of normally-off Diamond JFET. IEEE J. Electron. Devices Soc. 2017, 5, 95–99. [Google Scholar] [CrossRef]

- Pham, T.T.; Pernot, J.; Masante, C.; Eon, D.; Gheeraert, E.; Chicot, G.; Udrea, F.; Rouger, N. 200V, 4MV/cm Lateral Diamond MOSFET. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; pp. 25.4.1–25.4.4. [Google Scholar] [CrossRef]

- Guo, Z.B.; Chow, T.P. Performance projection of high-voltage, quasi-lateral diamond MOSFET for power electronics applications. Diam. Relat. Mater. 2020, 104, 107741. [Google Scholar] [CrossRef]

- Oi, N.; Kudo, T.; Inaba, M.; Okubo, S.; Onoda, S.; Hiraiwa, A.; Kawarada, H. Normally-OFF Two-Dimensional Hole Gas Diamond MOSFETs Through Nitrogen-Ion Implantation. IEEE Electron. Device Lett. 2019, 40, 933–936. [Google Scholar] [CrossRef]

- Liu, B.; Bi, T.; Fu, Y.; Kudara, K.; Imanishi, S.; Liu, K.; Dai, B.; Zhu, J.; Kawarada, H. MOSFETs on (110) C–H Diamond: ALD Al2O3/Diamond interface analysis and high performance normally-OFF operation realization. IEEE Trans. Electron. Devices 2022, 69, 949–955. [Google Scholar] [CrossRef]

- Fu, Y.; Chang, Y.; Zhu, X.; Xu, R.; Xu, Y.; Kawarada, H. Normally-off oxidized Si-terminated (111) Diamond MOSFETs via ALD-Al2O3 gate insulator with drain current density over 300 mA/mm. IEEE Trans. Electron. Devices 2022, 69, 4144–4152. [Google Scholar] [CrossRef]

- Tsunoda, J.; Niikura, N.; Ota, K.; Morishita, A.; Hiraiwa, A.; Kawarada, H. 580 V Breakdown Voltage in Vertical Diamond Trench MOSFETs with a P Drift Layer. IEEE Electron. Device Lett. 2022, 43, 88–91. [Google Scholar] [CrossRef]

- Kato, H.; Oyama, K.; Makino, T.; Ogura, M.; Takeuchi, D.; Yamasaki, S. Diamond bipolar junction transistor device with phosphorus-doped diamond base layer. Diam. Relat. Mater. 2012, 27–28, 19–22. [Google Scholar] [CrossRef]

- Perez, G.; Lefranc, P.; Jeannin, P.-O.; Eon, D.; Rouger, N. Parallel and interleaved structures for diamond Schottky diodes. In Proceedings of the 2017 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017; pp. 1–10. [Google Scholar]

- Perez, G.; Letellier, J.; Maréchal, A.; Eon, D.; Chicot, G.; Jeannin, P.O.; Rouger, N.; Schanen, J.L. Diamond Schottky barrier diodes for power electronics applications. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 1956–1963. [Google Scholar] [CrossRef]

- Ren, C.; Malakoutian, M.; Li, S.; Ercan, B.; Chowdhury, S. Demonstration of monolithic polycrystalline Diamond-GaN complementary FET technology for high-temperature applications. ACS Appl. Electron. Mater. 2021, 3, 4418–4423. [Google Scholar] [CrossRef]

- Nagase, M.; Umezawa, H.; Shikata, S. Vertical Diamond Schottky Barrier Diode Fabricated on Insulating Diamond Substrate Using Deep Etching Technique. IEEE Trans. Electron. Devices 2013, 60, 1416–1420. [Google Scholar] [CrossRef]

- Liu, L.; Wang, J.; Ren, N.; Guo, Q.; Sheng, K. 1.43 kV 4H-SiC Lateral Junction Barrier Schottky Diode with High BFOM (390 MW/cm2). IEEE Electron. Device Lett. 2024; early access. [Google Scholar] [CrossRef]

- Wang, Q.; Hua, H.; Zheng, L.; Feng, J.H.; Zhang, C.; Gao, M.Y.; Qiu, K.; Luo, J.; Cheng, X.H. Simultaneous improvement of high-frequency and Baliga figures of merit of 1.7 kV 4H-SiC MOSFET with retrograded JFET doping. J. Phys. D Appl. Phys. 2024, 57, 255105. [Google Scholar] [CrossRef]

- Liu, X.K.; Lin, F.; Li, J.; Lin, Y.H.; Wu, J.Y.; Wang, H.F.; Li, X.H.; Huang, S.W.; Wang, Q.; Chiu, H.C.; et al. 1.7-kV Vertical GaN-on-GaN Schottky Barrier Diodes With Helium-Implanted Edge Termination. IEEE Trans. Electron. Devices 2022, 69, 1938–1944. [Google Scholar] [CrossRef]

- Wang, C.L.; Yan, Q.L.; Su, C.X.; Alghamdi, S.; Ghandourah, E.; Liu, Z.H.; Feng, X.; Zhang, W.H.; Dang, K.; Wang, Y.M.; et al. Demonstration of the β-Ga2O3 MOS-JFETs with Suppressed Gate Leakage Current and Large Gate Swing. IEEE Electron. Device Lett. 2023, 44, 380–383. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, P.; Dang, K.; Zhang, Y.; Yan, Q.; Xiang, H.; Su, J.; Liu, Z.; Si, M.; Gao, J.; et al. Ultra-wide bandgap semiconductor Ga2O3 power diodes. Nat. Commun. 2022, 13, 3900. [Google Scholar] [CrossRef]

- Wang, H.C.; Lumbantoruan, F.J.; Hsieh, T.E.; Wu, C.H.; Lin, Y.C.; Chang, E.Y. High-Performance LPCVD-SiN/InAlGaN/GaN MIS-HEMTs with 850-V 0.98-mΩ·cm for Power Device Applications. IEEE J. Electron. Devices 2018, 6, 1136–1141. [Google Scholar] [CrossRef]

- Eon, D. Diamonds in the Current: Navigating Challenges for the Integration of Diamond in Power Electronics. Phys. Status Solidi A 2024, 221, 2400085. [Google Scholar] [CrossRef]

- Benipal, M.K.; Brown, J.; Koeck, F.; Zaniewski, A.; Ahmad, M.F.; Nemanich, R. Commercialization of Diamond Semiconductor Devices. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 5585–5589. [Google Scholar]

- Global Diamond Semiconductor Substrates Market Research Report—Segmentation by Type of Diamond Material (Synthetic Diamond, Natural Diamond); By Application (Diamond Detectors, Optical Systems, Power Electronics, Heat Spreaders, Others); By Manufacturing Process (Chemical Vapor Deposition (CVD), High-Pressure High Temperature (HPHT)); By Diamond Grade (Single Crystal Diamond, Polycrystalline Diamond); By End-User Industry (Consumer Electronics, Automotive, Industrial, Energy Sector, Telecommunications, Aerospace & Defense, Healthcare, Others); Region–Forecast (2024–2030). Available online: https://virtuemarketresearch.com/report/diamond-semiconductor-substrates-market (accessed on 30 July 2023).

- Diamfab Announces €8.7M Round of Funding from Asterion Ventures, Bpifrance and FondsRégional Avenir Industrie Auvergne-Rhône-Alpes. Available online: https://diamfab.com/wp-content/uploads/2024/03/20240328-PR-Diamfab-announced-a-E8.7M-round-of-funding.pdf (accessed on 28 March 2024).

- Diamond Quanta to Announce Findings on Novel Diamond Semiconductor Fabrication and Doping Techniques. Available online: https://thequantuminsider.com/2024/06/10/diamond-quanta-to-announce-findings-on-novel-diamond-semiconductor-fabrication-and-doping-techniques/ (accessed on 10 June 2024).

| Terminal Type | H | O | F | Si | N |

|---|---|---|---|---|---|

| Symbol | C-H | C-O | C-F | C-Si | C-N |

| Electron affinity (eV) | −1.0 | 1.7 | 2.56 | −0.86 | 3.46 |

| Metal | Barrier Height (eV) | Contact Type |

|---|---|---|

| W [115] (annealing at 773 K) | 0.45 ± 0.12 | Schottky |

| Al [118] (at T = 294 K) | 1.05 | Schottky |

| Ni [103] | 1.57 | Schottky |

| Mo [119] (with O-Diamond) | 1.61 ± 0.03~1.98 ± 0.02 | Schottky |

| Cr [103] | 0.73 | Schottky |

| Zr [105] (with O-Diamond) | 1.97 | Schottky |

| Ti [112] | −0.63 | Ohmic |

| Au (with H-Diamond) [116] | −0.19 | Ohmic |

| Au (with O-Diamond) [116] | 1.71 | Schottky |

| Device | LSBDs | pVSBDs | VSBDs | SPND/SPIND |

|---|---|---|---|---|

| Current density | 5.39 mA/mm at V = 40 V with T = 473 K [142] | 1000 A/cm2 at V = 6 V with T = 300 K [104] | 2980 A/cm2 at V = 8 V with T = 300 K [155] | >60 kA/cm2 at V = 6 V with T = 300 K [143] |

| Breakdown voltage | 1651 V at T = 300 K [156] | 1600 V at T = 300 K [76] | ~10 kV under vacuum [121] | >50 V at T = 300 K [157] |

| Rectifying ratios | 1012 at ±4 V with T = 300 K [158] | 1010 at T = 300 K [130] | >1010 at ±10 V with T = 350 K [159] 1011 at ±10 V with T = 300 K [160] | >1013 at ±8 V with T = 300 K [161] |

| Device | Structural Characteristics | VTH (V) | |ID_MAX| (mA/mm) | Ion/Ioff | |BV|(V) | Ron (mΩ·cm2) | BFOM (MW/cm2) | Ref. |

|---|---|---|---|---|---|---|---|---|

| H-terminated MOSFETs | NO2 p-type doping | 4.1 | 372 | >107 | 3659 | 13.48 | 173 | [177] |

| ALD-Al2O3 (10 nm @ 450 °C) | 1.36 | 388 | ~2 × 107 | >50V | — | — | [229] | |

| NO2 p-type doping | 3.9–4.1 | 680 | ~107 | 2568 | 7.54 | 874.6 | [39] | |

| V2O5 gate dielectric layer (10 nm) | 1.7 | 375 | ~107 | — | 16.8 | — | [182] | |

| N-implanted region in channel | −2.5 | 5.4/2.7 | >107 | 531/1600 | — | — | [228] | |

| ALD-Al2O3 (200 nm @ 450 °C with partial C-O channel) | −2.5~−4.0 | 5.2~18.2 | 108 | 2021 | — | — | [198] | |

| Si-terminated MOSFETs | ALD-Al2O3 (100 nm @ 450 °C) | −5.6 | 311 | >107 | 150.2 | — | — | [230] |

| Trench MOSFETs | Vertical U-trench | 17.8 | 210 | ~106 | 580 | 23 | 14.6 | [231] |

| Vertical V-trench | 20.2~20.5 | 12,800 | ~107 | 340 | 3.2 | 31.0 | [221] | |

| Vertical U-trench with n-implanted/n-doped epitaxial layer | 23.2/23.0 | 234/191 | ~108 | 249/359 | 31/41 | 2/3.1 | [220] | |

| JFETs | Lateral p-n junctions | — | 1.2 | — | 608 | 3.7 | 99.91 | [223] |

| BJTs | On (001) | αT = 0.44, β = 0.79, diffusion length = 4.2 × 10−5 cm3 αT = 0.91, β = 10.1, diffusion length = 4.3 × 10−5 cm3 | [212] | |||||

| On (111) | [232] | |||||||

| HBTs | p-n-p:lGaAs/GaAs/Diamond (e-b-c) | e-b:AlGaAs/GaAs n = 1.09, Ion/Ioff = 1.53 × 107 at ±1.5 V | β ≈ 1 | [213] | ||||

| b-c:GaAs/diamond n = 3.67, Ion/Ioff = 3.74 × 1010 at ±5.2V | ||||||||

| Diodes | FETs/HEMTs | |||||||

|---|---|---|---|---|---|---|---|---|

| BV (kV) | Ron (mΩ·cm2) | BFOM (MW/cm2) | Ref. | BV (kV) | Ron (mΩ·cm2) | BFOM (MW/cm2) | Ref. | |

| SiC | 1.43 | 5.25 | 390 | [235] | 1.83 | 11 | 304.4 | [236] |

| GaN | 0.995 | 1.2 | 825 | [237] | 0.850 | 0.98 | 737 | [238] |

| β-Ga2O3 | 8.32 | 5.24 | 1320 | [239] | 1.32 | 4.4 | 405 | [240] |

| Diamond | 0.7 | 5.89 | 332 | [241] | 2.57 | 7.54 | 874.6 | [39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, F.; He, Y.; Huang, B.; Zhang, T.; Zhu, H. A Review of Diamond Materials and Applications in Power Semiconductor Devices. Materials 2024, 17, 3437. https://doi.org/10.3390/ma17143437

Zhao F, He Y, Huang B, Zhang T, Zhu H. A Review of Diamond Materials and Applications in Power Semiconductor Devices. Materials. 2024; 17(14):3437. https://doi.org/10.3390/ma17143437

Chicago/Turabian StyleZhao, Feiyang, Yongjie He, Bin Huang, Tianyi Zhang, and Hao Zhu. 2024. "A Review of Diamond Materials and Applications in Power Semiconductor Devices" Materials 17, no. 14: 3437. https://doi.org/10.3390/ma17143437

APA StyleZhao, F., He, Y., Huang, B., Zhang, T., & Zhu, H. (2024). A Review of Diamond Materials and Applications in Power Semiconductor Devices. Materials, 17(14), 3437. https://doi.org/10.3390/ma17143437