Effects of Impurities and Ageing on the Functional and Rheological Properties of Asphalts with Additives from Recovered and Pyrolysis-Processed Plastics

Abstract

:1. Introduction

2. Selection of Additives for Extended Functional and Rheological Testing

- Materials other than PE, PP, PET, and PS are rejected from the unwashed municipal waste stream;

- A mixture with the specified mass proportions is prepared from the segregated materials;

- The mixture prepared in this way constitutes 80% by weight of the pyrolysis feedstock;

- The remaining 20% is a non-segregated mix of the typical municipal waste stream.

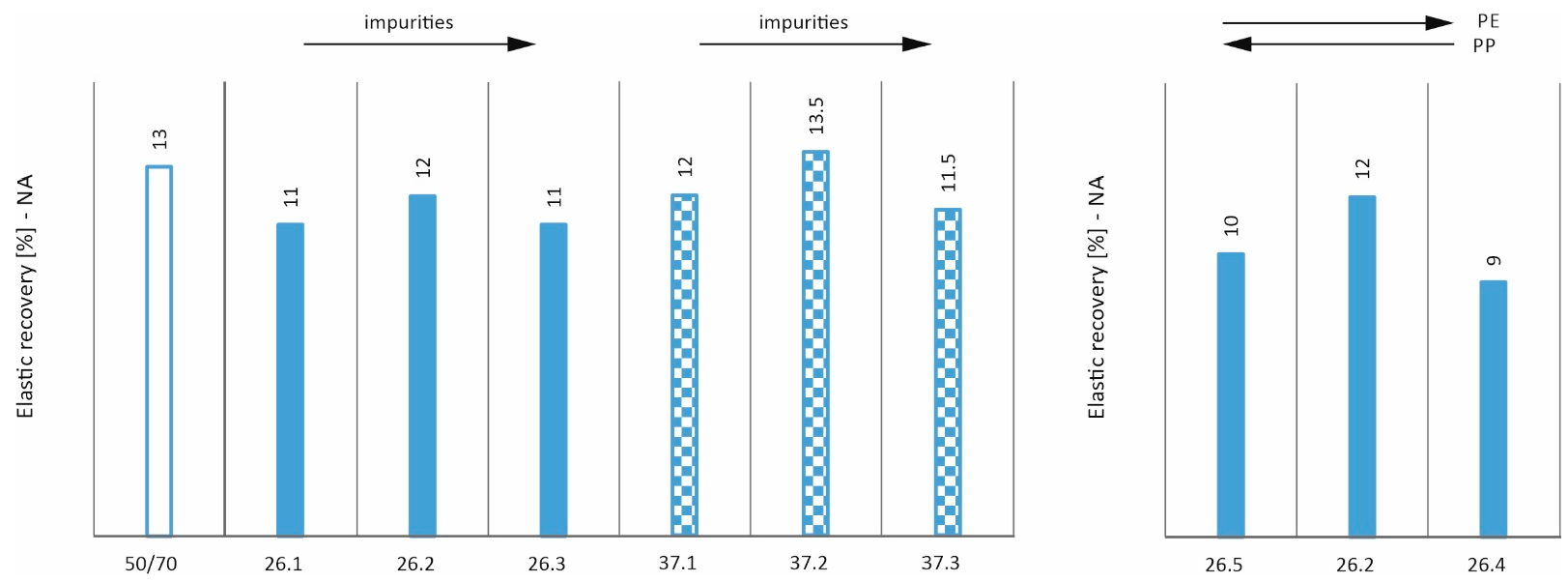

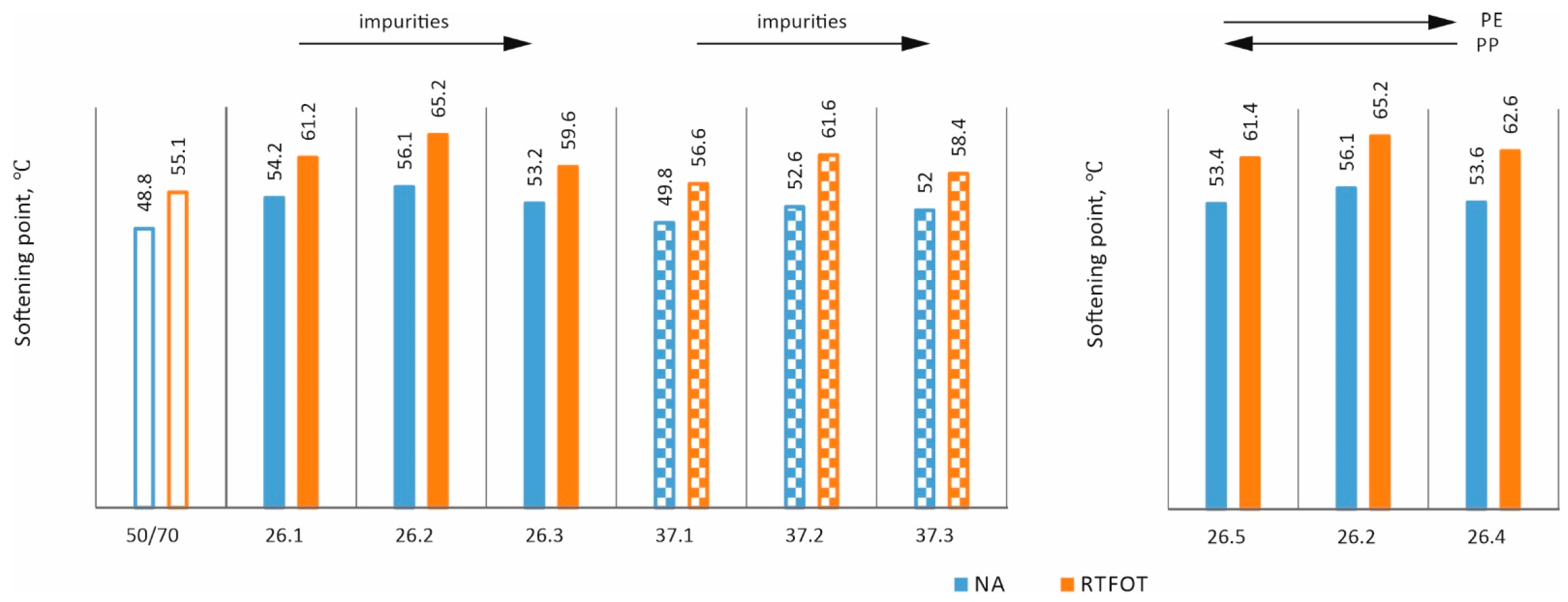

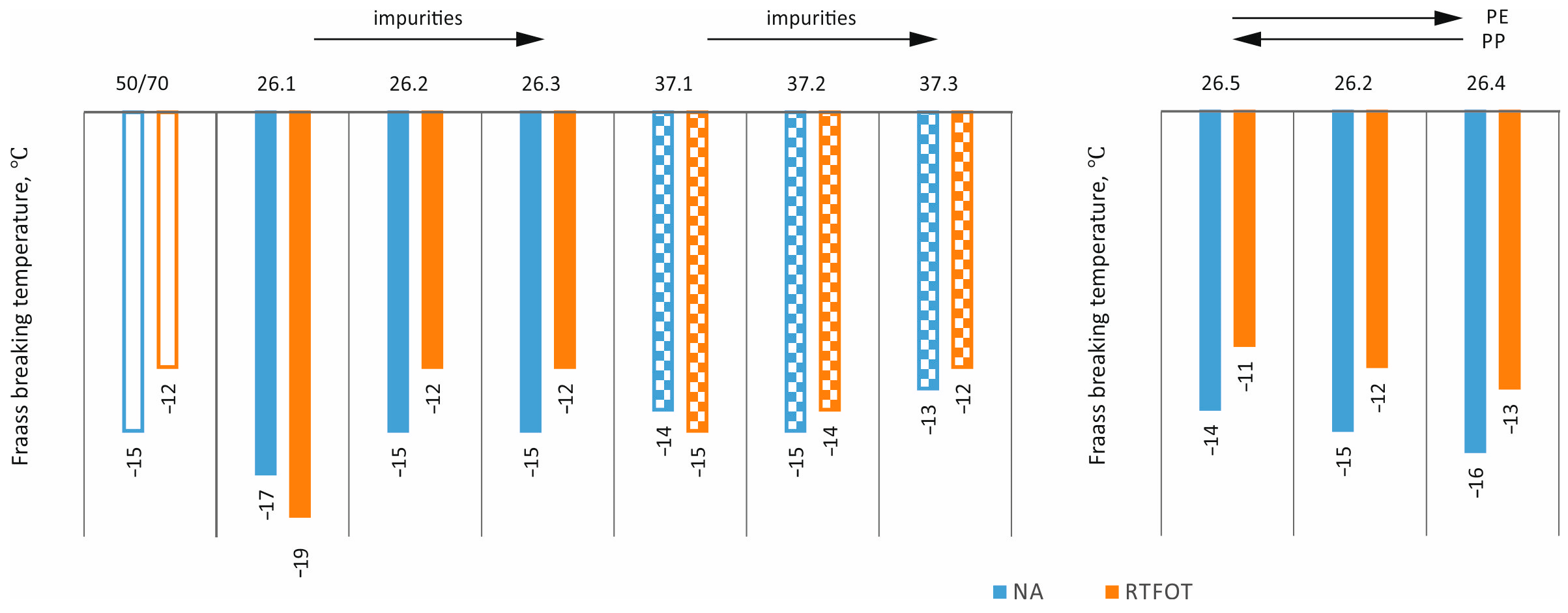

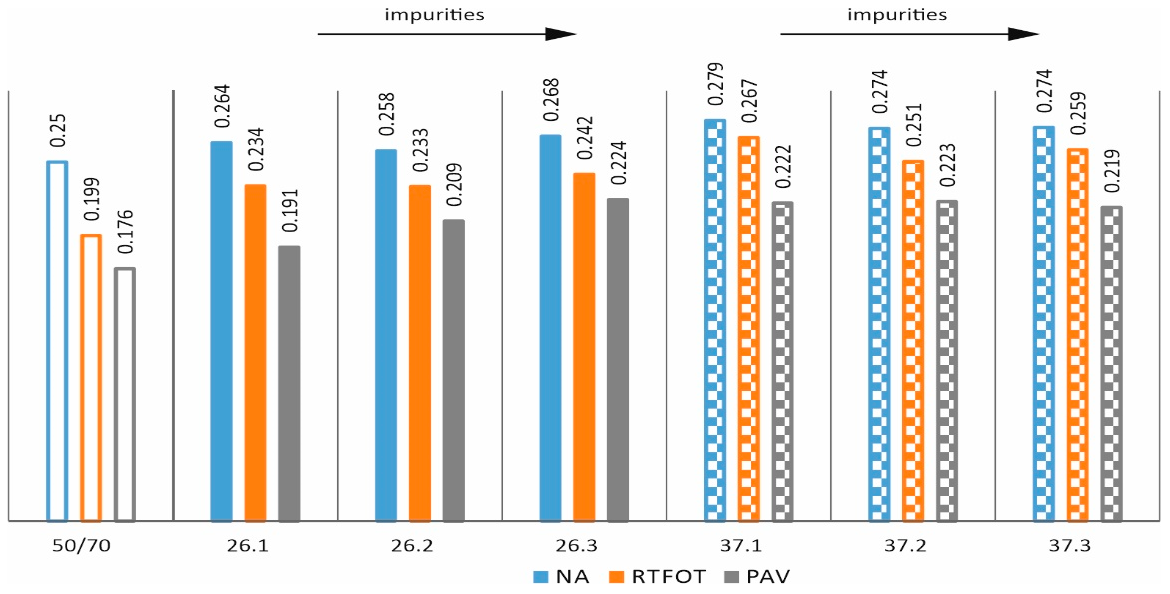

3. Evaluation of Stability, Elastic Recovery, and Adhesion to Aggregates, Taking into Account the Share of Impurities and the PE/PP Ratio

4. Effect of Technological Ageing on Basic Functional Parameters

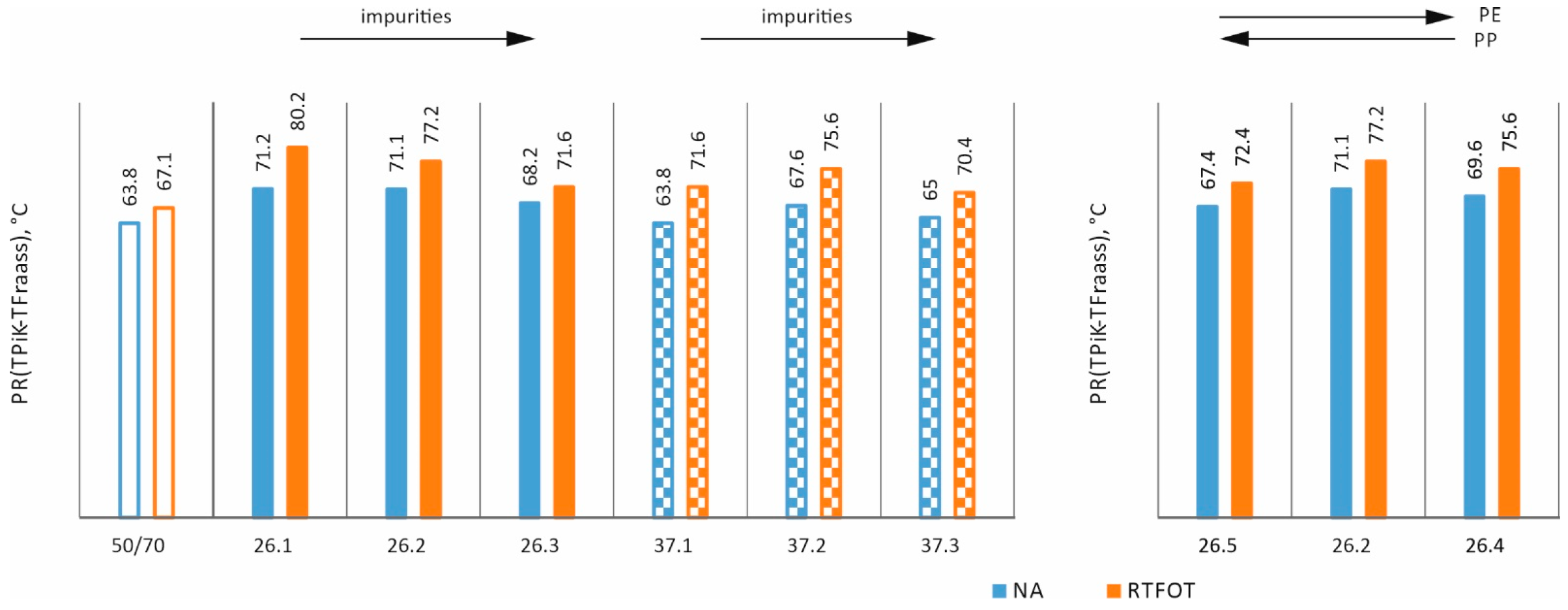

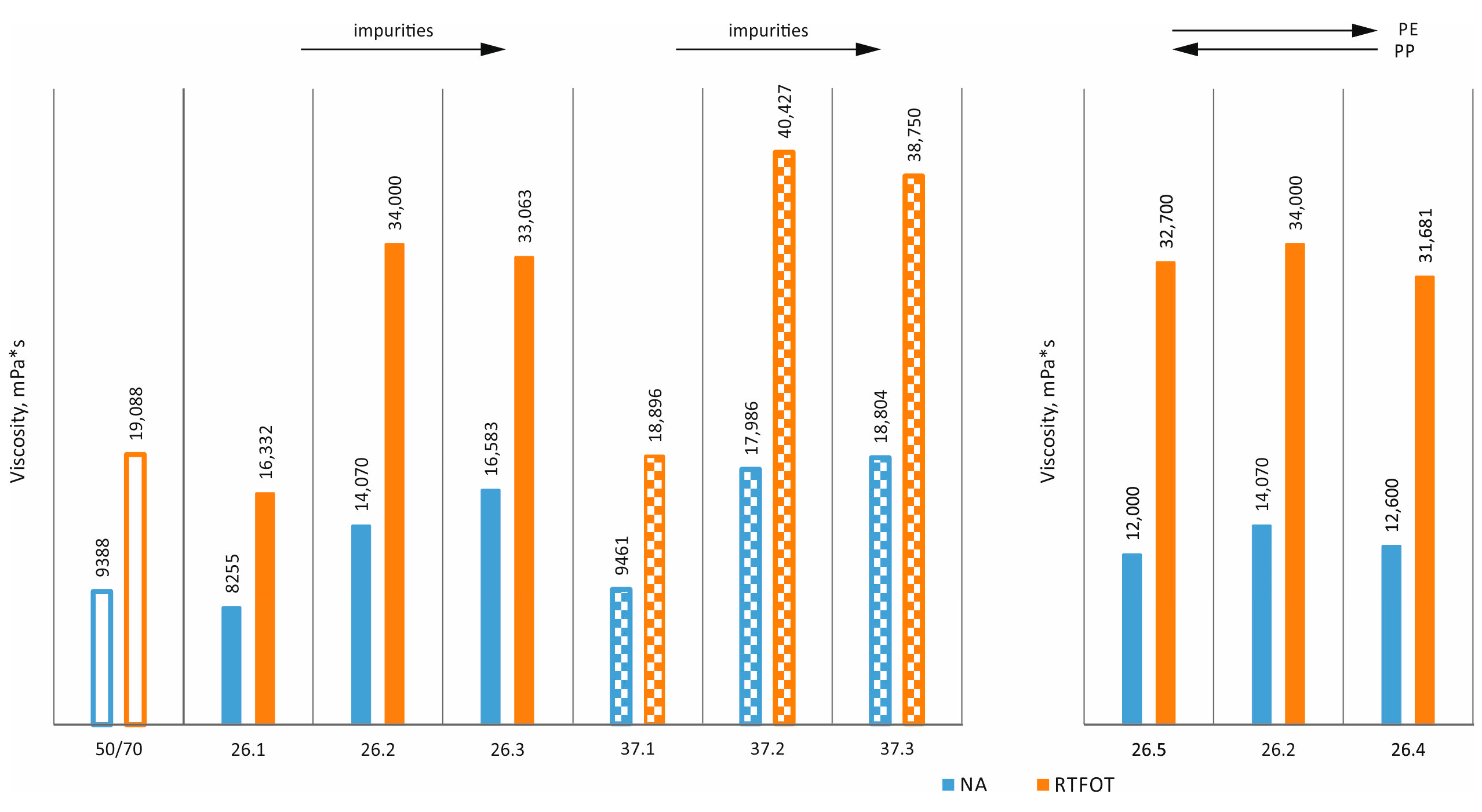

5. Effect of Technological Ageing on Basic Functional Parameters

5.1. High Temperature Range

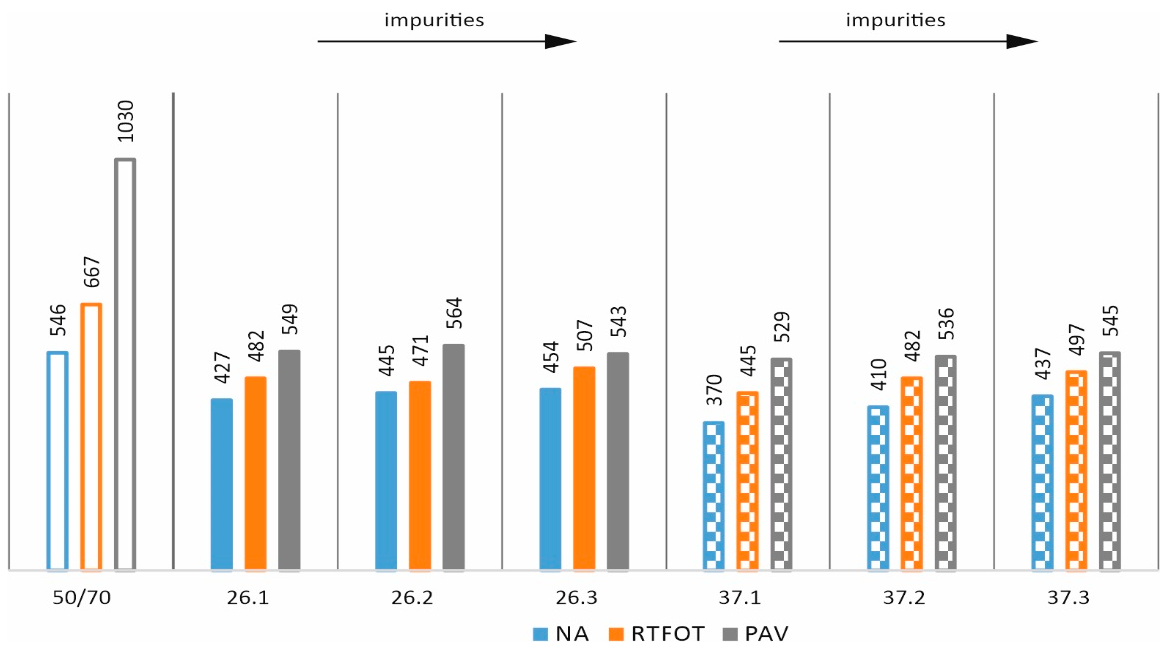

5.2. Medium Temperature Range

5.3. Low Temperature Range (Negative Temperature Values, Solid)—BBR Rheometer

6. Conclusions and Summary

- The addition of impurities in limited amount not only does not worsen but, in the case of several of the parameters, even improves the properties of the mixtures. Unfortunately, excess impurities lead to deterioration of their properties.

- When analysing the influence of the mass share of PE and PP, it can be seen that there is certainly an optimum value for the PE/PP ratio. In this study, only three mixtures were tested with values of this ratio of 48/52, 58/42, and 68/32, respectively. The results obtained indicate that the 58/42 ratio is the best; however, this research direction can be taken in further work to identify the optimum PE/PP ratio.

- Mixtures with additives undergo an ageing process analogous to road asphalts or modified asphalts. The results obtained with the BBR rheometer even show that the degree of ageing, especially operational ageing, is much lower (lower increase in modulus of stiffness) for mixtures with the additives tested than for the base asphalt.

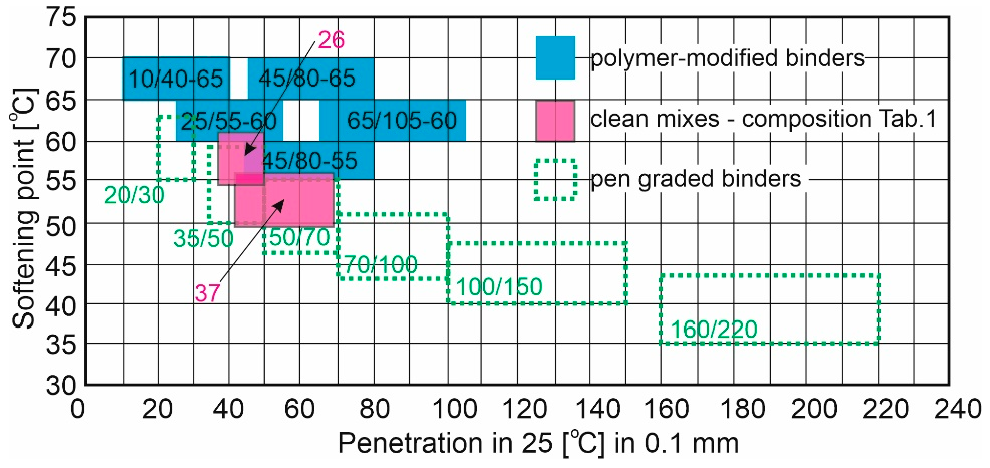

- Treating the tested mixtures as a market product, it can be concluded that they rank between the 35/50 and 50/70 road asphalts and the PMB 25/55-60 and PMB 65/105-60 polymer asphalts, with some overlap with the PMB 45/80-55 asphalt. Unfortunately, the elastic recoveries obtained (elastic recovery test and MSCR test) are not as high as for asphalts modified with SBS copolymer.

- Comparing the results of the mixtures and the base asphalt, it can be concluded that, despite the lack of elastic recovery at the polymer asphalt level, features can be identified that are in comparison with the base asphalt. The effect of additives can be particularly beneficial under high-temperature conditions, providing higher resistance to permanent deformation. This was demonstrated for a number of mixture variants by softening temperature tests, shear modulus at 70 °C and MSCR results under post-ageing conditions at 64 °C and a stress of 3.2 kPa. On the other hand, and advantageously, no deterioration of the low-temperature properties was observed in Fraass breaking temperature and BBR rheometer tests, and in some cases, they were even better than for the base asphalt. In addition, basic research has indicated a beneficial increase in the plasticity interval.

- It is difficult to prejudge whether the presence of oil condensate in the production process (i.e., whether additive 26 or additive 37 is better) has a positive or negative effect on the properties of the resulting mixtures. The results obtained slightly distinguish one or the other additive depending on the study/parameter. On the other hand, it is clear that processing the oil condensate into additives has a positive environmental effect (there is no need to manage the remaining oil after additive production).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, B.; Wang, T.; Hao, G. Review on the Development of Plastic Road. Adv. Transdiscipl. Eng. 2022, 23, 536–544. [Google Scholar] [CrossRef]

- Heydari, S.; Hajimohammadi, A.; Haji Seyed Javadi, N.; Khalili, N. The use of plastic waste in asphalt: A critical review on asphalt mix design and Marshall properties. Constr. Build. Mater. 2021, 309, 125185. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Rezagholilou, A.; Nikraz, H. Waste Plastic as Additive in Asphalt Pavement Reinforcement: A review. In Proceedings of the 18th AAPA International Flexible Pavements Conference & Exhibition, Sydney, NSW, Australia, 18–21 August 2019; pp. 1–9. [Google Scholar]

- Jwaida, Z.; Dulaimi, A.; Mydin, M.A.O.; Özkılıç, Y.O.; Jaya, R.P.; Ameen, A. The Use of Waste Polymers in Asphalt Mixtures: Bibliometric Analysis and Systematic Review. J. Compos. Sci. 2023, 7, 415. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2022, 15, 110. [Google Scholar] [CrossRef]

- Enfrin, M.; Myszka, R.; Giustozzi, F. Paving roads with recycled plastics: Microplastic pollution or eco-friendly solution? J. Hazard. Mater. 2022, 437, 129334. [Google Scholar] [CrossRef] [PubMed]

- Visscher, J.; Vanelstraete, A. Ravelling by traffic: Performance testing and field validation. Int. J. Pavement Res. Technol. 2017, 10, 54–61. [Google Scholar] [CrossRef]

- Vargas, C.A.; Lu, H.R.; El Hanandeh, A. Environmental impact of pavements formulated with bitumen modified with PE pyrolytic wax: A comparative life cycle assessment study. J. Clean. Prod. 2023, 419, 138070. [Google Scholar] [CrossRef]

- Tušar, M.; Poulikakos, L.D.; Kakar, M.R.; Pasquini, E.; Pasetto, M.; Porot, L.; Wang, D.; Cannone Falchetto, A.; Carter, A.; Orozco, G.; et al. Bituminous Binder and Bituminous Mixture Modified with Waste Polyethylene; RILEM State-of-the-Art Reports; Springer International Publishing: Cham, Switzerland, 2023; Volume 38, pp. 7–35. [Google Scholar]

- Saadeh, S.; Katawal, P.; Kabir, S.F.; Fini, E.H.; Titi, H.H. Performance of reclaimed asphalt pavements containing recycled waste plastics. J. Clean. Prod. 2024, 442, 140935. [Google Scholar] [CrossRef]

- Shah, M.M.; Yousaf, J.; Khalid, U.; Li, H.; Yee, J.J.; Naqvi, S.A.Z. Plastic roads: Asphalt mix design and performance. Discov. Appl. Sci. 2024, 6, 195. [Google Scholar] [CrossRef]

- Bueno, I.M.; Teixeira, J.E.S.L. Waste Plastic in Asphalt Mixtures via the Dry Method: A Bibliometric Analysis. Sustainability 2024, 16, 4675. [Google Scholar] [CrossRef]

- White, G.; Hall, F. Comparing Wet Mixed and Dry Mixed Binder Modification with Recycled Waste Plastic. In Proceedings of the RILEM International Symposium on Bituminous Materials; Di Benedetto, H., Baaj, H., Chailleux, E., Tebaldi, G., Sauzéat, C., Mangiafico, S., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 435–441. [Google Scholar]

- Xiao, R.; Polaczyk, P.; Huang, B. Mitigating Stripping in Asphalt Mixtures: Pretreatment of Aggregate by Thermoplastic Polyethylene Powder Coating. Transp. Res. Rec. 2024, 2678, 776–787. [Google Scholar] [CrossRef]

- Xiao, R.; Zhang, M.; Zhong, J.; Baumgardner, G.L.; Huang, B. Waste Plastic Powder Coating on Acidic Aggregates: A New Hydrophobic Coating Technology to Build Moisture-Resistant Asphalt Mixtures. Transp. Res. Rec. 2023. [Google Scholar] [CrossRef]

- Xiao, R.; Shen, Z.; Polaczyk, P.; Huang, B. Thermodynamic Properties of Aggregate Coated by Different Types of Waste Plastic: Adhesion and Moisture Resistance of Asphalt-Aggregate Systems. J. Mater. Civ. Eng. 2023, 35, 4023261. [Google Scholar] [CrossRef]

- Gajewski, M.; Horodecka, R.; Bańkowski, W.; Grzegórska, A.; Kłopociński, M. Evaluation of the Effect of Processed Plastic Additives on the Properties of Paving Grade Bitumen. Roads Bridg.-Drog. Most. 2023, 22, 287–307. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, A.; Miljković, M. Intermediate- and high-temperature damage of bitumen modified by HDPE from various sources. Road Mater. Pavement Des. 2023, 24, 640–653. [Google Scholar] [CrossRef]

- Abdy, C.; Zhang, Y.; Wang, J.; Yang, Y.; Artamendi, I.; Allen, B. Pyrolysis of polyolefin plastic waste and potential applications in asphalt road construction: A technical review. Resour. Conserv. Recycl. 2022, 180, 106213. [Google Scholar] [CrossRef]

- Huang, G.; Yang, T.; He, Z.; Yu, L.; Xiao, H. Polyurethane as a modifier for road asphalt: A literature review. Constr. Build. Mater. 2022, 356, 129058. [Google Scholar] [CrossRef]

- Filonzi, A.; Komaragiri, S.; Lakshmi Roja, K.; Sreeram, A.; Bhasin, A.; Masad, E. A comprehensive evaluation of mixture and binder properties to explore the use of low-density polyethylene (LDPE) as an asphalt modifier and co-modifier. Int. J. Pavement Eng. 2022, 24, 2120988. [Google Scholar] [CrossRef]

- Mehta, D.; Saboo, N.; Mariam, S.; Utkarsh, A. A review on the use of waste plastics in hot mix asphalt. Mech. Time-Dependent Mater. 2023. in print. [Google Scholar] [CrossRef]

- Lu, D.X.; Enfrin, M.; Boom, Y.J.; Giustozzi, F. Future recyclability of hot mix asphalt containing recycled plastics. Constr. Build. Mater. 2023, 368, 130396. [Google Scholar] [CrossRef]

- Nasr, D.; Pakshir, A.H. Rheology and storage stability of modified binders with waste polymers composites. Road Mater. Pavement Des. 2019, 20, 773–792. [Google Scholar] [CrossRef]

- Kakar, M.R.; Mikhailenko, P.; Piao, Z.; Bueno, M.; Poulikakos, L. Analysis of waste polyethylene (PE) and its by-products in asphalt binder. Constr. Build. Mater. 2021, 280, 122492. [Google Scholar] [CrossRef]

- Cong, P.; Wang, J.; Li, K.; Chen, S. Physical and rheological properties of asphalt binders containing various antiaging agents. Fuel 2012, 97, 678–684. [Google Scholar] [CrossRef]

- Pérez, I.; Pasandín, A.R.; Pais, J.C.; Pereira, P.A.A. Feasibility of Using a Lignin-Containing Waste in Asphalt Binders. Waste Biomass Valorization 2020, 11, 3021–3034. [Google Scholar] [CrossRef]

- Naskar, M.; Chaki, T.K.; Reddy, K.S. Effect of waste plastic as modifier on thermal stability and degradation kinetics of bitumen/waste plastics blend. Thermochim. Acta 2010, 509, 128–134. [Google Scholar] [CrossRef]

- Xue, H.; Cao, Y.; Liu, Q.; Zhang, H.; Zhang, M. Stability Evaluation and Mechanism of Asphalts Modified with Various Rubber Powder Contents. Front. Mater. 2021, 7, 622479. [Google Scholar] [CrossRef]

- Al-Abdul Wahhab, H.I.; Dalhat, M.A.; Habib, M.A. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2017, 18, 1117–1134. [Google Scholar] [CrossRef]

- Joohari, I.B.; Maniam, S.; Giustozzi, F. Enhancing the Storage Stability of SBS-Plastic Waste Modified Bitumen Using Reactive Elastomeric Terpolymer. Int. J. Pavement Res. Technol. 2023, 16, 304–318. [Google Scholar] [CrossRef]

- Xu, N.; Wang, H.; Chen, Y.; Miljković, M.; Feng, P.; Ding, H. Thermal storage stability and rheological properties of multi-component styrene-butadiene-styrene composite modified bitumen. Constr. Build. Mater. 2022, 322, 126494. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- White, G.; Hall, F. Comparing asphalt modified with recycled plastic polymers to conventional polymer modified asphalt. In Proceedings of the Eleventh International Conference on the Bearing Capacity of Roads, Railways and Airfields; CRC Press: Boca Raton, FL, USA, 2021; Volume 1, pp. 3–17. [Google Scholar] [CrossRef]

- Fang, C.; Zhang, M.; Yu, R.; Liu, X. Effect of Preparation Temperature on the Aging Properties of Waste Polyethylene Modified Asphalt. J. Mater. Sci. Technol. 2015, 31, 320–324. [Google Scholar] [CrossRef]

- Błażejowski, K.; Olszacki, J.; Peciakowski, H. Poradnik Asfaltowy; Orlen Asfalt sp. z o.o.: Płock, Poland, 2014. [Google Scholar]

- Błażejowski, K.; Baranowska, W.; Ostrowski, P.; Wójcik-Wiśniewska, M. Bitumen Handbook; Orlen Asfalt sp. z o.o.: Płock, Poland, 2021. [Google Scholar]

- Sybilski, D.; Soenen, H.; Gajewski, M.; Chailleux, E.; Bankowski, W. Binder testing. In Advances in Interlaboratory Testing and Evaluation of Bituminous Materials; RILEM State-of-the-Art Reports; Partl, M.N., Bahia, H.U., Canestrari, F., de la Roche, C., Di Benedetto, H., Piber, H., Sybilski, D., Eds.; Springer Science & Business Media: Berlin, Germany, 2013; Volume 9, pp. 15–83. ISBN 978-94-007-5103-3. [Google Scholar]

- Bastos, J.B.S.; Babadopulos, L.F.A.L.; Soares, J.B. Relationship between multiple stress creep recovery (MSCR) binder test results and asphalt concrete rutting resistance in Brazilian roadways. Constr. Build. Mater. 2017, 145, 20–27. [Google Scholar] [CrossRef]

| Additive Number | PE | PP | PET | PS | Oil Condensate |

|---|---|---|---|---|---|

| 26 | 57 | 41 | 1.5 | 0.5 | none |

| 37 | 57 | 41 | 1.5 | 0.5 | current |

| 26.1 | 26.2 | 26.3 | 26.4 | 26.5 | 37.1 | 37.2 | 37.3 | |

|---|---|---|---|---|---|---|---|---|

| Percentage share of impurities | 0 | 20 | 40 | 20 | 20 | 0 | 20 | 40 |

| Mass ratio PE/PP | 58/42 | 58/42 | 58/42 | 68/32 | 48/52 | 58/42 | 58/42 | 58/42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gajewski, M.D.; Horodecka, R.; Bańkowski, W.; Mirski, K.; Grzegórska, A.; Kłopociński, M. Effects of Impurities and Ageing on the Functional and Rheological Properties of Asphalts with Additives from Recovered and Pyrolysis-Processed Plastics. Materials 2024, 17, 3451. https://doi.org/10.3390/ma17143451

Gajewski MD, Horodecka R, Bańkowski W, Mirski K, Grzegórska A, Kłopociński M. Effects of Impurities and Ageing on the Functional and Rheological Properties of Asphalts with Additives from Recovered and Pyrolysis-Processed Plastics. Materials. 2024; 17(14):3451. https://doi.org/10.3390/ma17143451

Chicago/Turabian StyleGajewski, Marcin Daniel, Renata Horodecka, Wojciech Bańkowski, Krzysztof Mirski, Aleksandra Grzegórska, and Maciej Kłopociński. 2024. "Effects of Impurities and Ageing on the Functional and Rheological Properties of Asphalts with Additives from Recovered and Pyrolysis-Processed Plastics" Materials 17, no. 14: 3451. https://doi.org/10.3390/ma17143451