Spark Plasma Sintering of Pure Titanium: Microstructure and Mechanical Characteristics

Abstract

1. Introduction

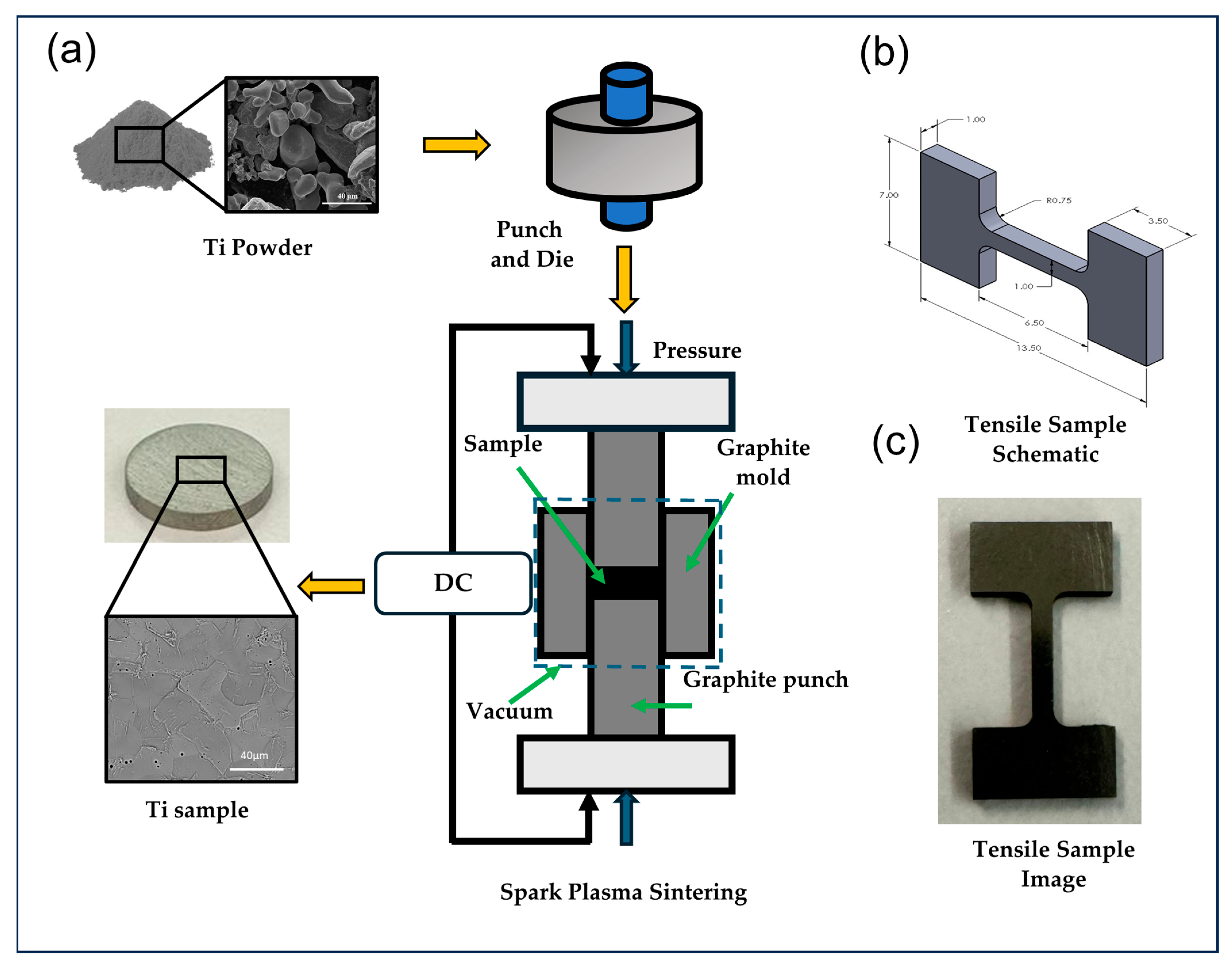

2. Materials and Methods

3. Results and Discussion

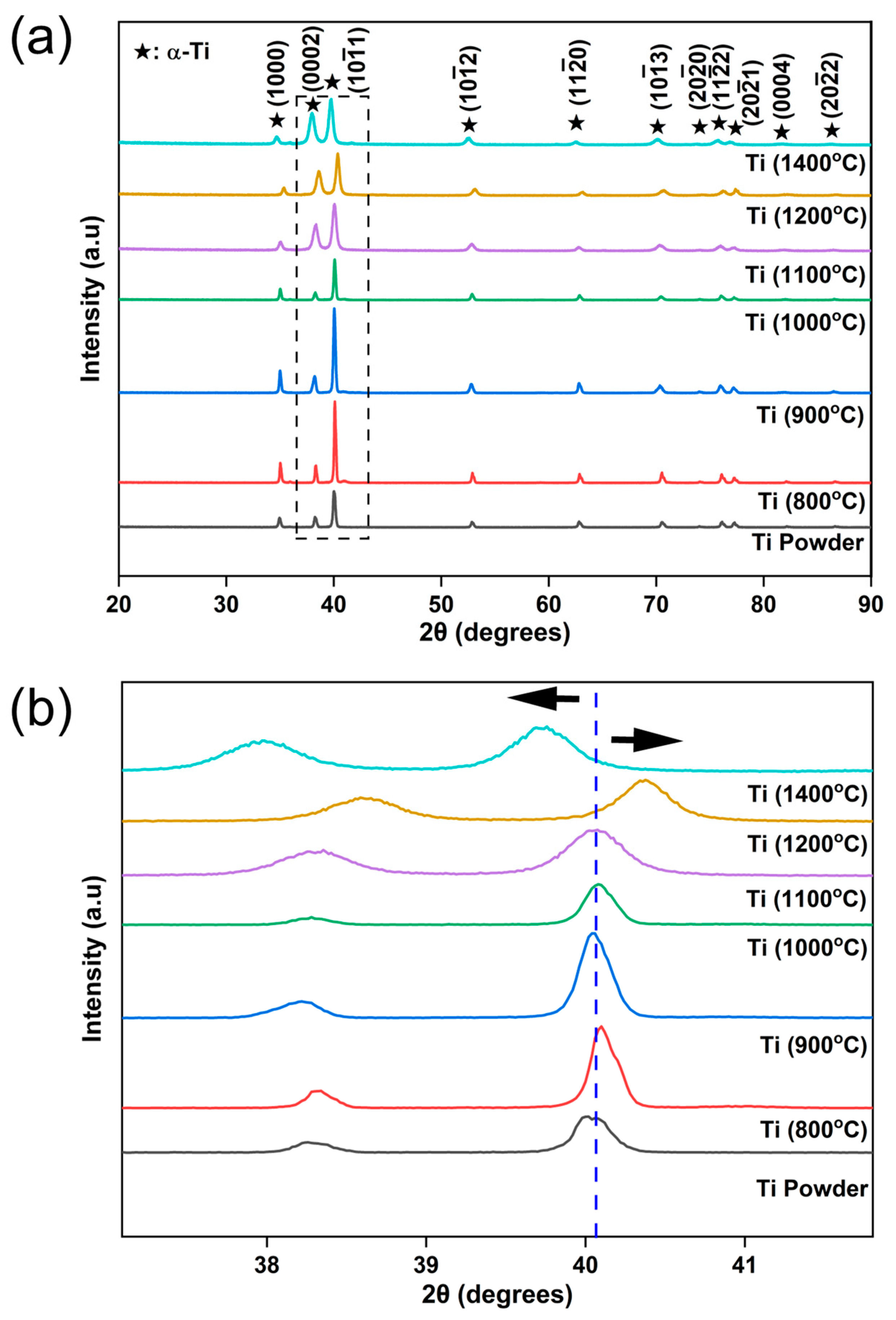

3.1. Structural Analysis

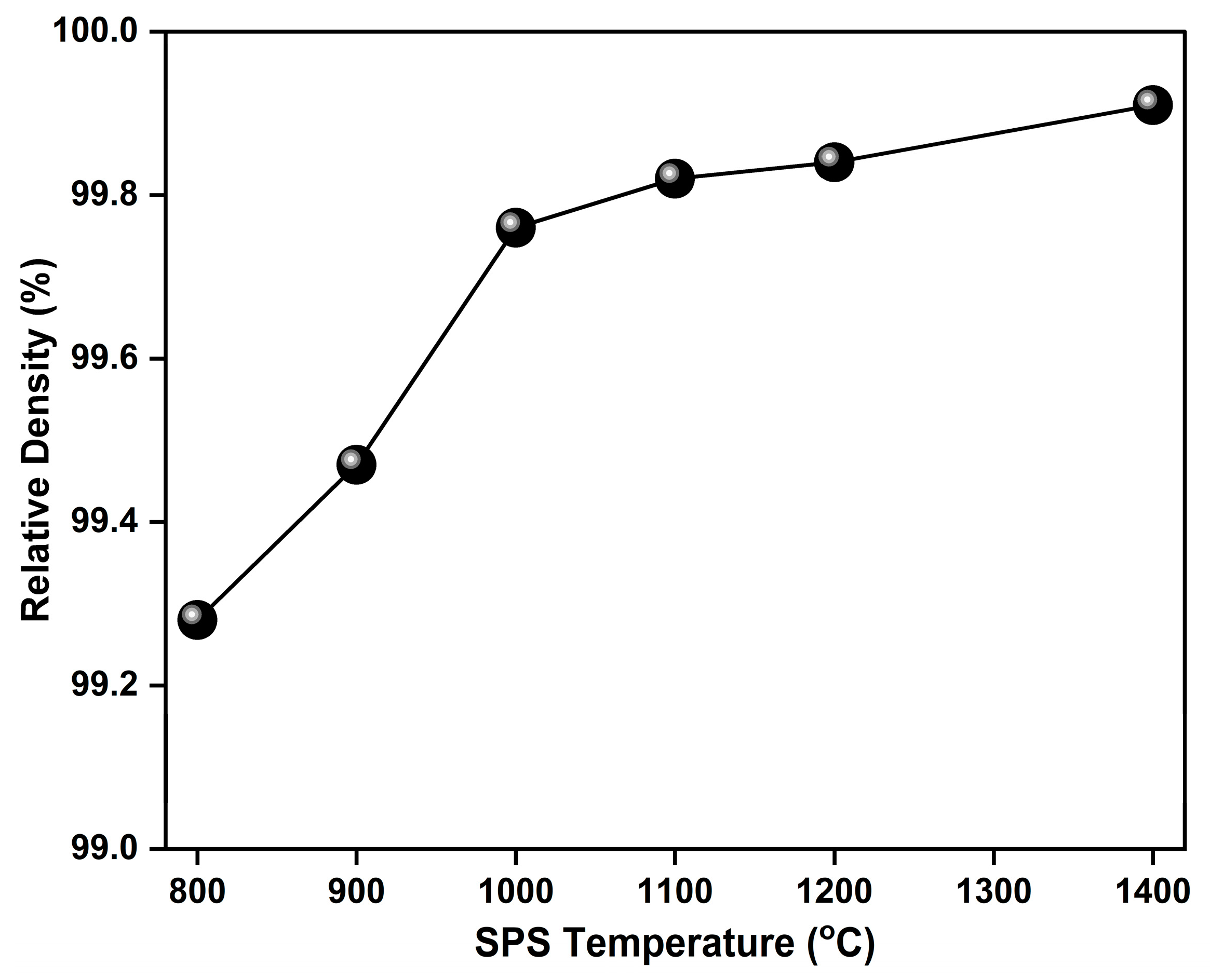

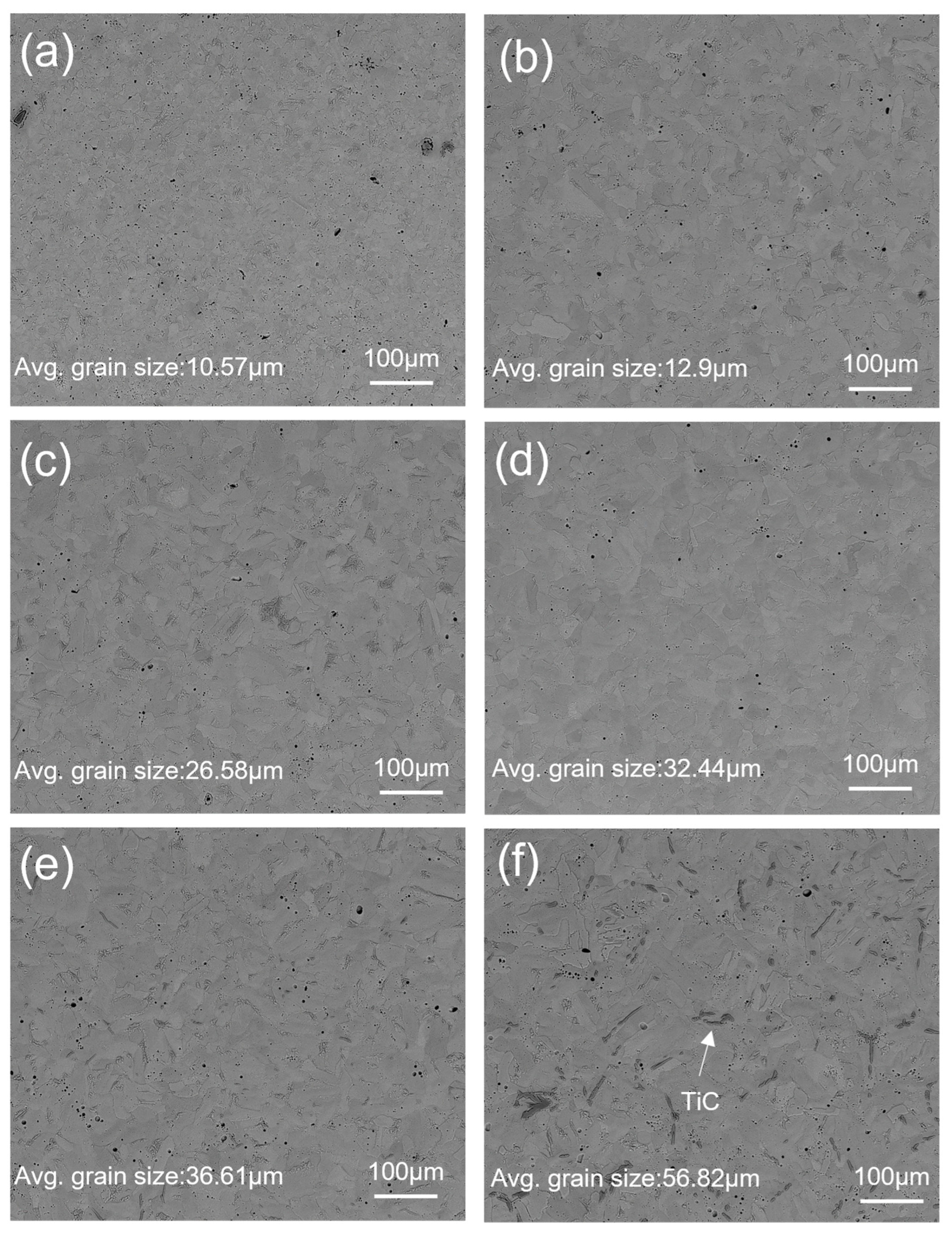

3.2. Microstructure and Densification Analysis

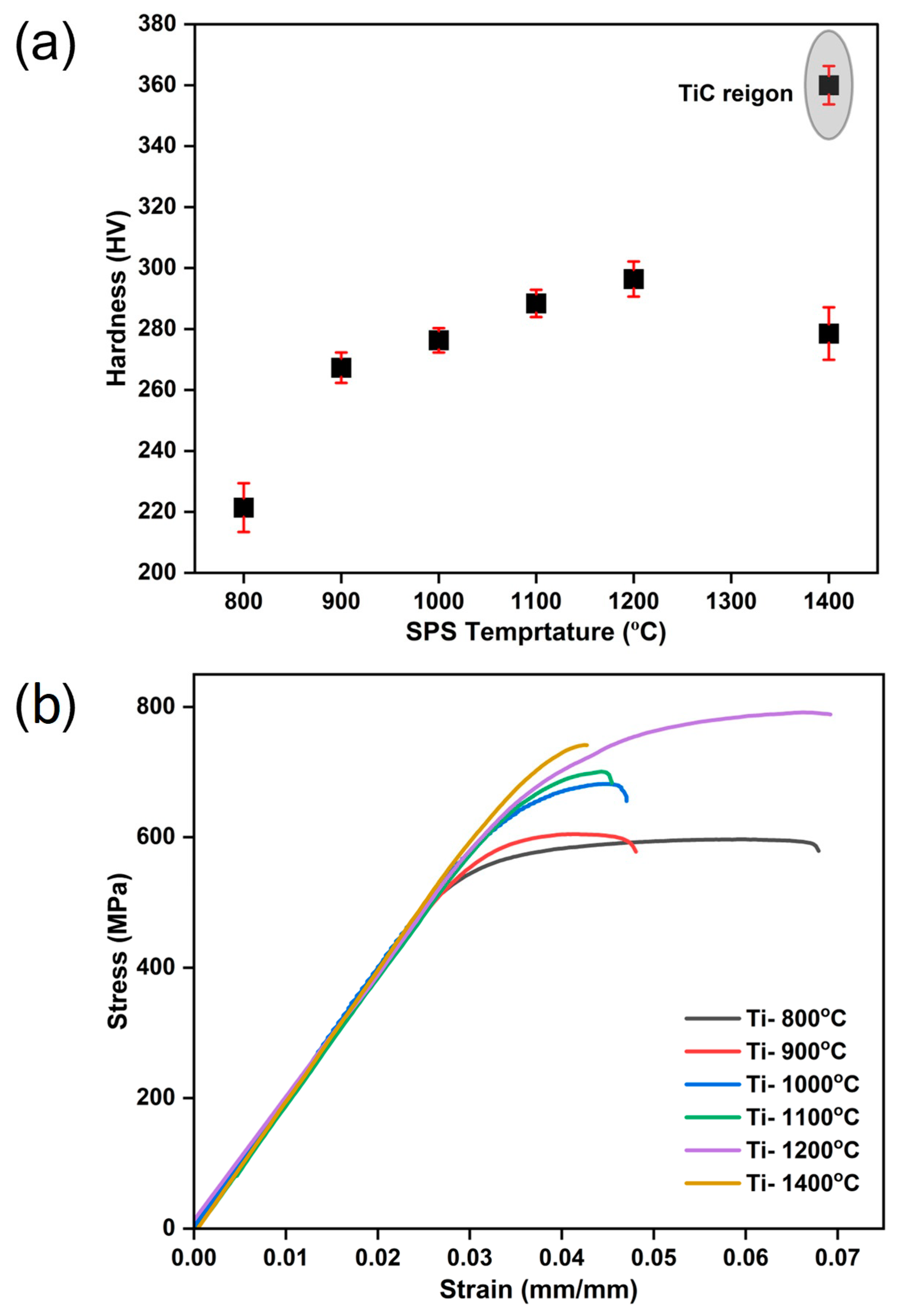

3.3. Hardness and Tensile Property

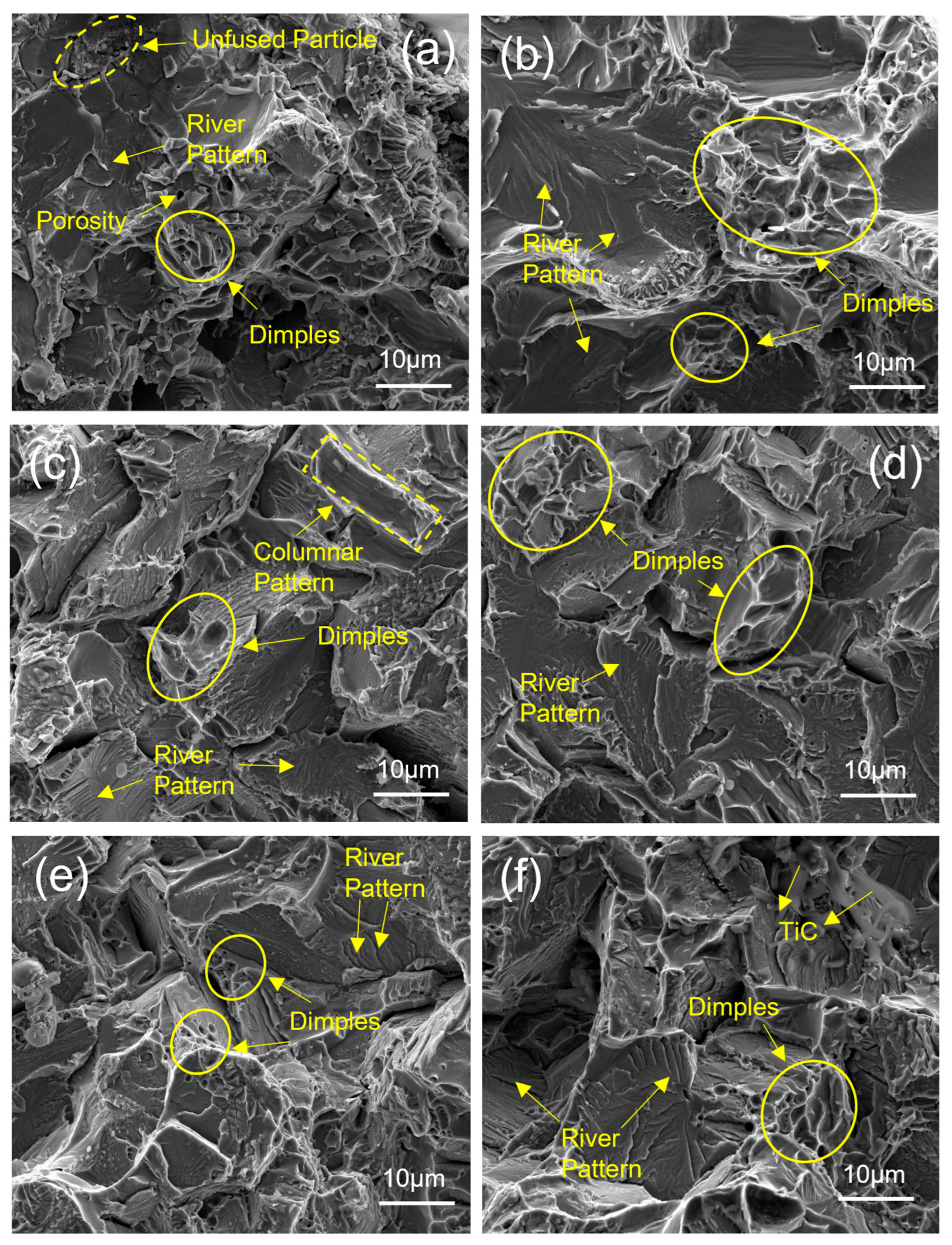

3.4. Fractography Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Siengchin, S. A review on lightweight materials for defence applications: A present and future developments. Def. Technol. 2023, 24, 1–17. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Dai, J.; Zhu, J.; Chen, C.; Weng, F. High temperature oxidation behavior and research status of modifications on improving high temperature oxidation resistance of titanium alloys and titanium aluminides: A review. J. Alloys Compd. 2016, 685, 784–798. [Google Scholar] [CrossRef]

- Nicholson, W.J. Titanium Alloys for Dental Implants: A Review. Prosthesis 2020, 2, 100–116. [Google Scholar] [CrossRef]

- Shao, L.; Du, Y.; Dai, K.; Wu, H.; Wang, Q.; Liu, J.; Tang, Y.; Wang, L. β-Ti Alloys for Orthopedic and Dental Applications: A Review of Progress on Improvement of Properties through Surface Modification. Coatings 2021, 11, 1446. [Google Scholar] [CrossRef]

- Bairagi, D.; Mandal, S. A comprehensive review on biocompatible Mg-based alloys as temporary orthopaedic implants: Current status, challenges, and future prospects. J. Magnes. Alloy. 2022, 10, 627–669. [Google Scholar] [CrossRef]

- Al-Shalawi, F.D.; Mohamed Ariff, A.H.; Jung, D.-W.; Mohd Ariffin, M.K.A.; Seng Kim, C.L.; Brabazon, D.; Al-Osaimi, M.O. Biomaterials as Implants in the Orthopedic Field for Regenerative Medicine: Metal versus Synthetic Polymers. Polymers 2023, 15, 2601. [Google Scholar] [CrossRef] [PubMed]

- Baltatu, I.; Sandu, A.V.; Vlad, M.D.; Spataru, M.C.; Vizureanu, P.; Baltatu, M.S. Mechanical Characterization and In Vitro Assay of Biocompatible Titanium Alloys. Micromachines 2022, 13, 430. [Google Scholar] [CrossRef]

- Spataru, M.C.; Butnaru, M.; Sandu, A.V.; Vulpe, V.; Vlad, M.D.; Baltatu, M.S.; Geanta, V.; Voiculescu, I.; Vizureanue, P.; Solcan, C. In-depth assessment of new Ti-based biocompatible materials. Mater. Chem. Phys. 2021, 258, 123959. [Google Scholar] [CrossRef]

- Digole, S.; Desai, J.; Christopher, C.; Bohara, S.; Witharamage, C.S.; Kothapalli, C.; Gupta, R.K.; Borkar, T. Improved Tribological Performance of Nitride-Reinforced Biocompatible Titanium–Niobium–Zirconium–Tantalum (TNZT) Alloys for Advanced Orthopedic Applications. Metals 2024, 14, 122. [Google Scholar] [CrossRef]

- Sarraf, M.; Rezvani, G.E.; Alipour, S.; Ramakrishna, S.; Liana, S.N. A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications. Bio Des. Manuf. 2021, 5, 371–395. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A. Biomedical Applications of Titanium Alloys: A Comprehensive Review. Materials 2024, 17, 114. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.Z.; Paramore, J.D.; Sun, P.; Chandran, K.R.; Zhang, Y.; Xia, Y.; Cao, F.; Koopman, M.; Free, M. Powder metallurgy of titanium–past, present, and future. Int. Mater. Rev. 2018, 63, 407–459. [Google Scholar] [CrossRef]

- Rodriguez-Contreras, A.; Punset, M.; Calero, J.A.; Gil, F.J.; Ruperez, E.; Manero, J.M. Powder metallurgy with space holder for porous titanium implants: A review. J. Mater. Sci. Technol. 2021, 76, 129–149. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, Y.; Li, N. Powder metallurgy of titanium alloys: A brief review. J. Alloys Compd. 2023, 965, 171030. [Google Scholar] [CrossRef]

- Munir, K.; Biesiekierski, A.; Wen, C.; Li, Y. Powder metallurgy in manufacturing of medical devices. In Metallic Biomaterials Processing and Medical Device Manufacturing; Woodhead Publishing: Sawston, UK, 2020; pp. 159–190. [Google Scholar] [CrossRef]

- Bolzoni, L.; Ruiz-Navas, E.M.; Neubauer, E.; Gordo, E. Inductive hot-pressing of titanium and titanium alloy powders. Mater. Chem. Phys. 2012, 131, 672–679. [Google Scholar] [CrossRef]

- Weston, N.S.; Derguti, F.; Tudball, A.; Jackson, M. Spark plasma sintering of commercial and development titanium alloy powders. J. Mater. Sci. 2015, 50, 4860–4878. [Google Scholar] [CrossRef]

- Groza, J.R.; Zavaliangos, A. Sintering activation by external electrical field. Mater. Sci. Eng. A 2000, 287, 171–177. [Google Scholar] [CrossRef]

- Dudina, D.V.; Bokhonov, B.B. Elimination of oxide films during Spark Plasma Sintering of metallic powders: A case study using partially oxidized nickel. Adv. Powder Technol. 2017, 28, 641–647. [Google Scholar] [CrossRef]

- Tokita, M. Progress of Spark Plasma Sintering (SPS) Method, Systems, Ceramics Applications and Industrialization. Ceramics 2021, 4, 160–198. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Zhang, Z.H.; Cheng, X.W.; Wang, F.C.; Zhang, Y.F.; Li, S.L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Stuer, M.; Bowen, P.; Zhao, Z. Spark Plasma Sintering of Ceramics: From Modeling to Practice. Ceramics 2020, 3, 476–493. [Google Scholar] [CrossRef]

- Asl, M.S.; Namini, A.S.; Motallebzadeh, A.; Azadbeh, M. Effects of sintering temperature on microstructure and mechanical properties of spark plasma sintered titanium. Mater. Chem. Phys. 2018, 203, 266–273. [Google Scholar] [CrossRef]

- Miklaszewski, A.; Garbiec, D.; Niespodziana, K. Sintering behavior and microstructure evolution in cp-titanium processed by spark plasma sintering. Adv. Powder Technol. 2018, 29, 50–57. [Google Scholar] [CrossRef]

- Chaudhari, R.; Bauri, R. Microstructure and mechanical properties of titanium processed by spark plasma sintering (SPS). Metallogr. Microstruct. Anal. 2014, 3, 30–35. [Google Scholar] [CrossRef]

- Zadra, M.; Casari, F.; Girardini, L.; Molinari, A. Microstructure and mechanical properties of cp-titanium produced by spark plasma sintering. Powder Metall. 2008, 51, 59–65. [Google Scholar] [CrossRef]

- Motsi, G.T.; Guillemet-Fritsch, S.; Chevallier, G.; Shongwe, M.B.; Olubambi, P.A.; Estournes, C. Microstructural evolution and mechanical properties of pure titanium powders processed by spark plasma sintering. Powder Technol. 2019, 345, 415–424. [Google Scholar] [CrossRef]

- Vander, V.G. Metallographic preparation of titanium and its alloys. Buehler Tech. Notes 1999, 3, 4. [Google Scholar]

- Liu, J.; Wu, M.; Yang, Y.; Yang, G.; Yan, H.; Jiang, K. Preparation and mechanical performance of graphene platelet reinforced titanium nanocomposites for high temperature applications. J. Alloys Compd. 2018, 765, 1111–1118. [Google Scholar] [CrossRef]

- Shon, J.H.; Song, I.B.; Cho, K.S.; Park, Y.I.; Hong, J.K.; Park, N.K.; Oh, M.H. Effect of particle size distribution on microstructure and mechanical properties of spark-plasma-sintered titanium from CP-Ti powders. Int. J. Precis. Eng. Manuf. 2014, 15, 643–647. [Google Scholar] [CrossRef]

- Diouf, S.; Molinari, A. Densification mechanisms in spark plasma sintering: Effect of particle size and pressure. Powder Technol. 2012, 221, 220–227. [Google Scholar] [CrossRef]

- Gil, F.J.; Aparicio, C.; Planell, J.A. Effect of oxygen content on grain growth kinetics of titanium. J. Mater. Synth. Process. 2002, 10, 263–266. [Google Scholar] [CrossRef]

- Motyka, M.; Kubiak, K.; Sieniawski, J.; Ziaja, W. Phase transformations and characterization of α + β titanium alloys. Compr. Mater. Process. 2014, 2, 7–36. [Google Scholar] [CrossRef]

- Motyka, M. Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys—An Overview. Metals 2021, 11, 481. [Google Scholar] [CrossRef]

- Lee, S.; Park, C.; Hong, J.; Yeom, J.T. The role of nano-domains in {1–011} twinned martensite in metastable titanium alloys. Sci. Rep. 2018, 8, 11914. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Ma, G.; Yu, C.; Tang, B.; Li, Y.; Niu, F.; Wu, D.; Bi, G.; Liu, S. High-mass-proportion TiCp/Ti6Al4V titanium matrix composites prepared by directed energy deposition. Addit. Manuf. 2020, 35, 101323. [Google Scholar] [CrossRef]

- Choudhari, A.; Elder, J.; Mugale, M.; Karki, S.; Digole, S.; Omeike, S.; Borkar, T. Enhancing Quality Control: Image-Based Quan-tification of Carbides and Defect Remediation in Binder Jetting Additive Manufacturing. Materials 2024, 17, 2174. [Google Scholar] [CrossRef]

- Joshi, V.A. Titanium Alloys: An Atlas of Structures and Fracture Features; Chemical Rubber Company Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

| SPS Temperature | Relative Density (%) | Avg. Grain Size (µm) | Hardness (HV) | YS (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|---|---|

| 800 °C | 99.28 | 10.57 | 221.4 ± 8.2 | 488 ± 10 | 597 ± 12 | 6.8 ± 0.2 |

| 900 °C | 99.47 | 12.9 | 267.3 ± 5.4 | 518 ± 6 | 608 ± 10 | 4.8 ± 0.5 |

| 1000 °C | 99.76 | 26.58 | 276.3 ± 4.3 | 592 ± 15 | 683 ± 8 | 4.7 ± 0.3 |

| 1100 °C | 99.82 | 32.44 | 288.4 ± 4.5 | 610 ± 9 | 702 ± 13 | 4.5 ± 0.5 |

| 1200 °C | 99.84 | 36.61 | 296.4 ± 5.7 | 642 ± 5 | 792 ± 11 | 7 ± 0.5 |

| 1400 °C | 99.91 | 56.82 | 278.5 ± 8.6 | 700 ± 15 | 742 ± 7 | 4.2 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Digole, S.; Karki, S.; Mugale, M.; Choudhari, A.; Gupta, R.K.; Borkar, T. Spark Plasma Sintering of Pure Titanium: Microstructure and Mechanical Characteristics. Materials 2024, 17, 3469. https://doi.org/10.3390/ma17143469

Digole S, Karki S, Mugale M, Choudhari A, Gupta RK, Borkar T. Spark Plasma Sintering of Pure Titanium: Microstructure and Mechanical Characteristics. Materials. 2024; 17(14):3469. https://doi.org/10.3390/ma17143469

Chicago/Turabian StyleDigole, Satyavan, Sanoj Karki, Manoj Mugale, Amit Choudhari, Rajeev Kumar Gupta, and Tushar Borkar. 2024. "Spark Plasma Sintering of Pure Titanium: Microstructure and Mechanical Characteristics" Materials 17, no. 14: 3469. https://doi.org/10.3390/ma17143469

APA StyleDigole, S., Karki, S., Mugale, M., Choudhari, A., Gupta, R. K., & Borkar, T. (2024). Spark Plasma Sintering of Pure Titanium: Microstructure and Mechanical Characteristics. Materials, 17(14), 3469. https://doi.org/10.3390/ma17143469