Examining the Workability, Mechanical, and Thermal Characteristics of Eco-Friendly, Structural Self-Compacting Lightweight Concrete Enhanced with Fly Ash and Silica Fume

Abstract

:1. Introduction

2. Experimental Program

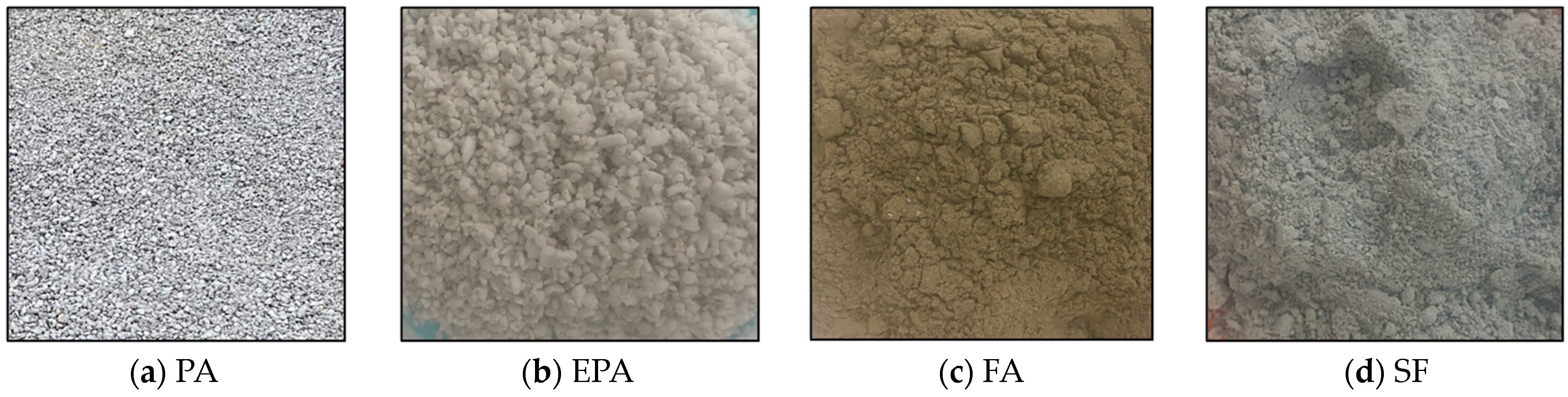

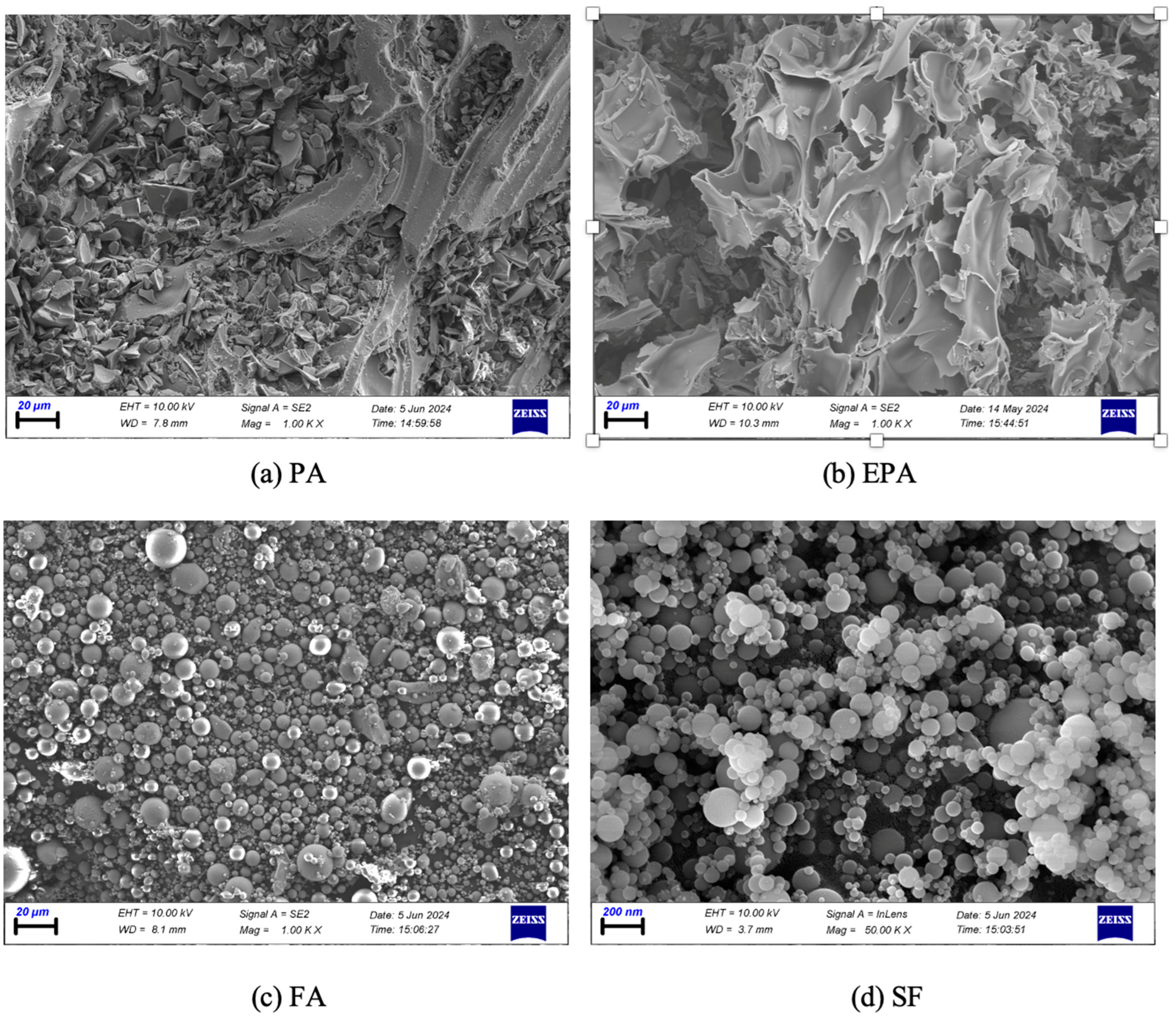

2.1. Materials Used in the SCLWC Mixtures

2.2. Mixing Phases of SCLWC Mixtures

2.3. Fresh and Hardened Tests of SCLWC Mixtures

3. Results and Discussion

3.1. Workability of SCLWC Mixtures

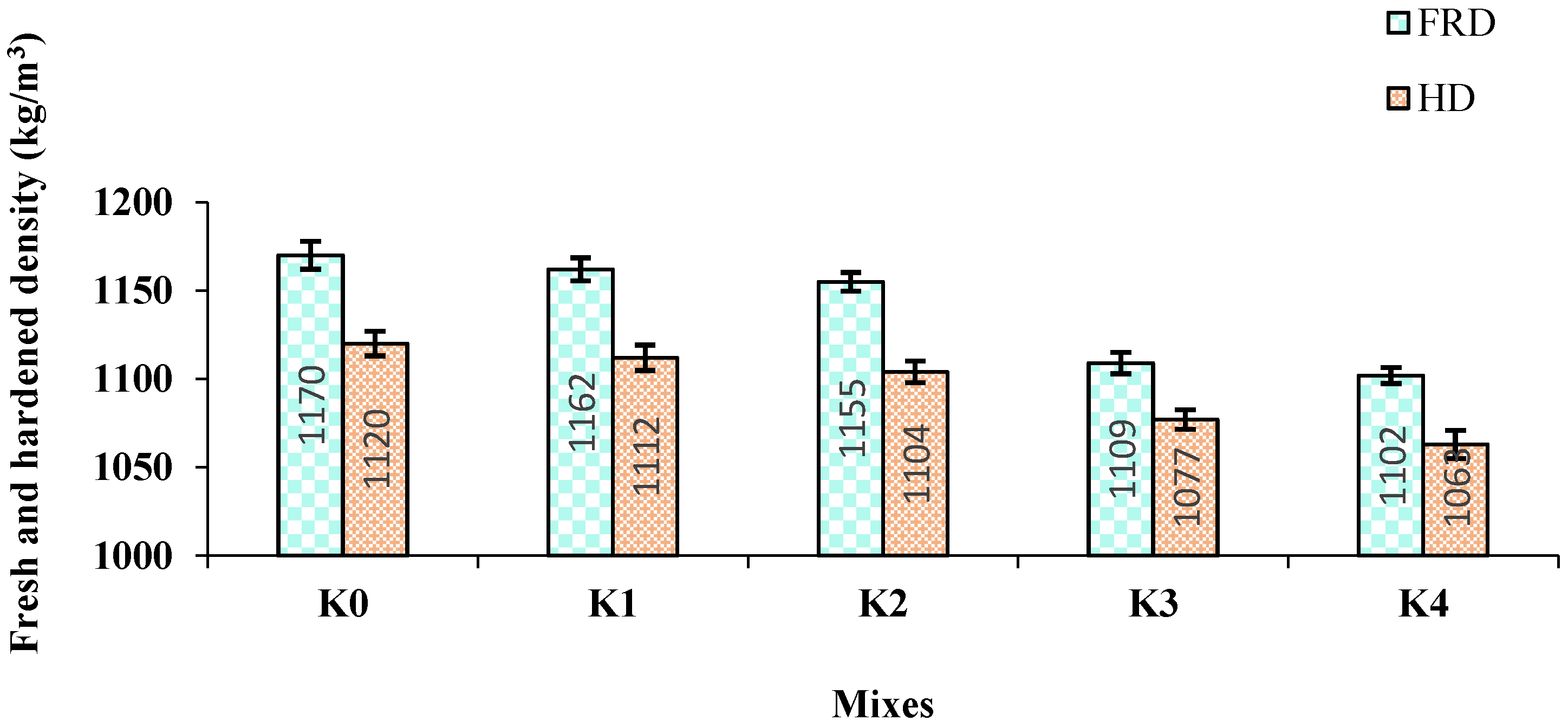

3.1.1. Density and Slump Flow of SCLWC Mixtures

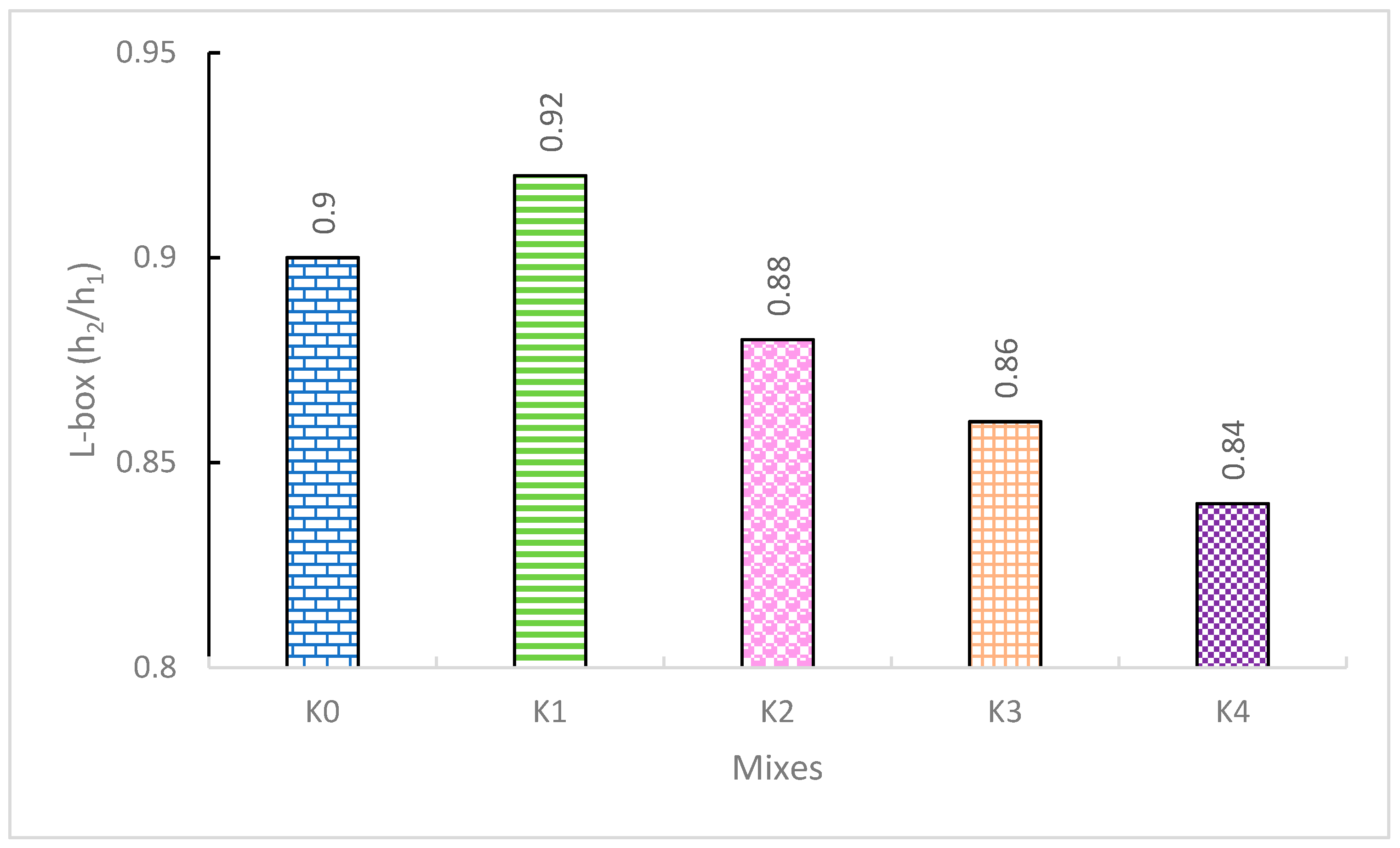

3.1.2. L-Box of SCLWC Mixtures

3.1.3. V-Funnel of SCLWC Mixtures

3.1.4. Thermal Conductivity Coefficient

3.1.5. Compressive Strength

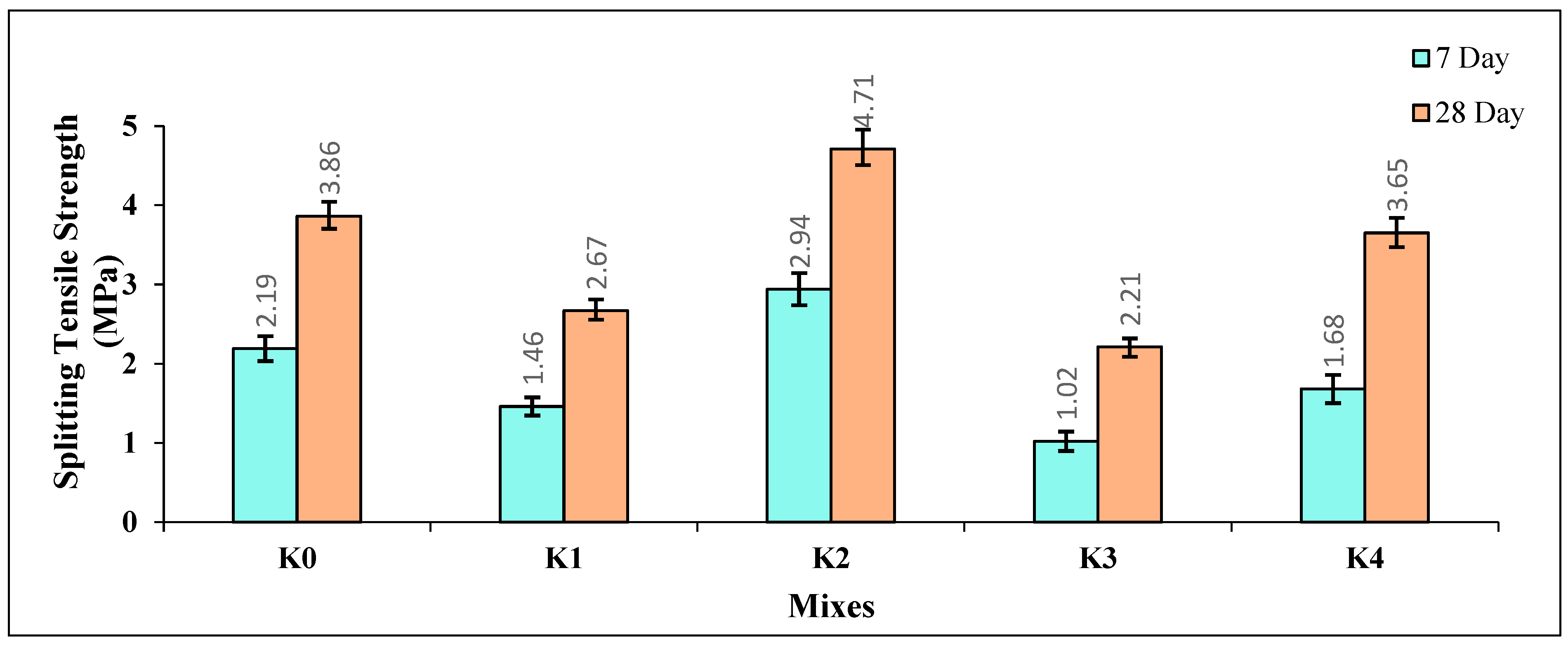

3.1.6. Splitting Tensile Strength

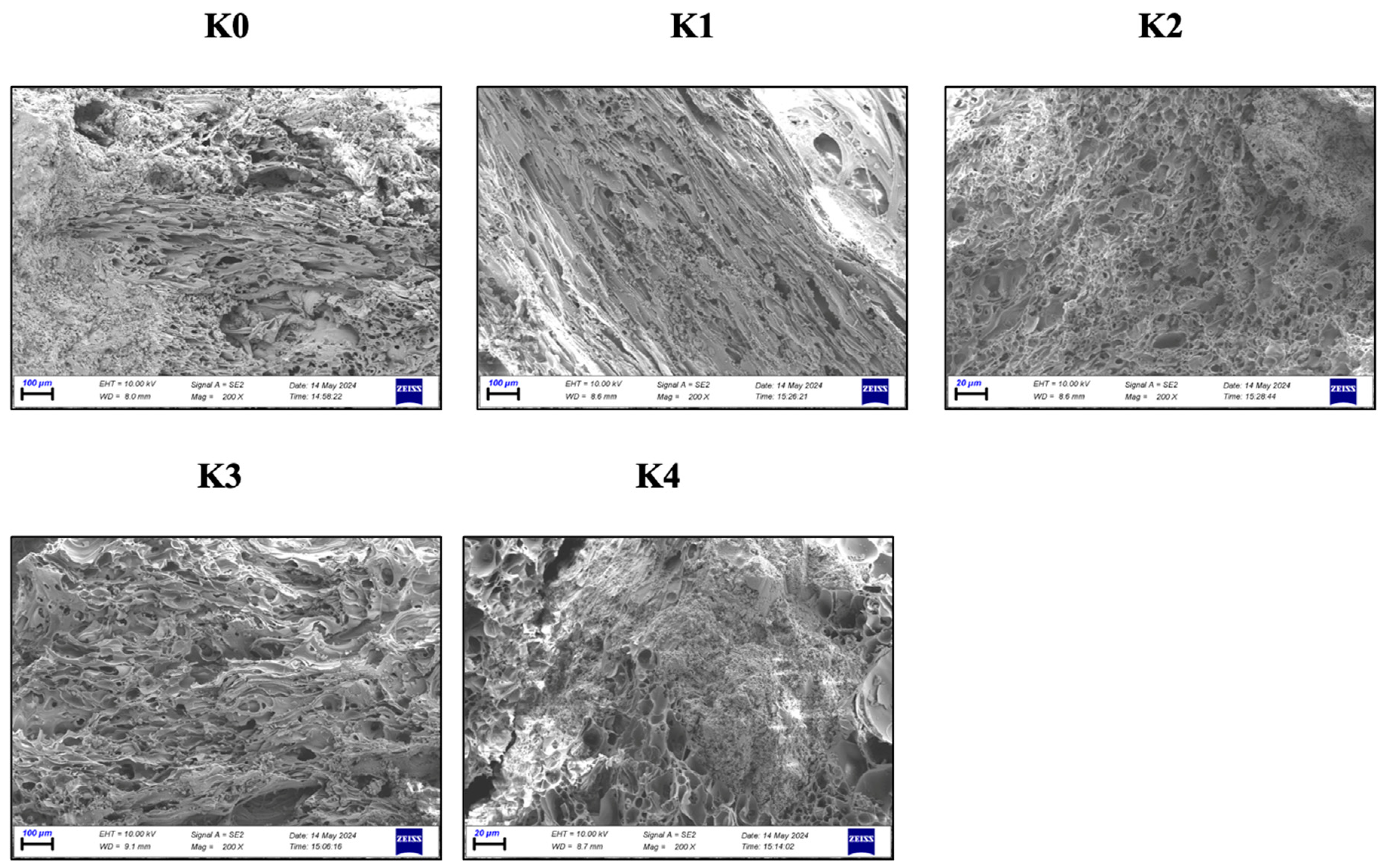

3.1.7. SEM Analysis

4. Conclusions

- The incorporation of fly ash (FA) and silica fume (SF) into structural self-compacting lightweight concrete (SCLWC) showed significant effects on both its workability and mechanical properties. Fly ash was observed to enhance workability, whereas silica fume, while decreasing workability, was found to improve the compressive strength (CS) and splitting tensile strength (STS) of the SCLWC samples.

- Pumice aggregate (PA) and expanded perlite aggregate (EPA) demonstrated distinct effects on the properties of the SCLWC mixtures. PA, utilized in different sizes across various mixtures, enhanced overall structural integrity. Conversely, EPA, especially when used in conjunction with PA, reduced the workability, compressive strength (CS), and splitting tensile strength (STS) of the SCLWC samples.

- Workability parameters such as the slump flow diameter, the flow time in the V-funnel, and the height ratio in the L-box were influenced differently by the composition of the SCLWC mixtures. Fly ash (FA) improved workability, whereas silica fume (SF) had a detrimental effect, highlighting the importance of the precise selection and proportioning of supplementary materials.

- The selection of aggregates and supplementary materials had a substantial impact on the thermal properties of the SCLWC samples. Expanded perlite aggregate (EPA) notably decreased the thermal conductivity coefficient (TCC), suggesting its potential to enhance thermal insulation properties in construction applications.

- This study emphasizes the significance of understanding material interactions for developing optimized SCLWC mixtures. Achieving a balance between workability, mechanical strength, and thermal performance necessitates careful consideration of aggregate types, supplementary materials, and their proportions.

- In terms of sustainability, this study makes significant contributions towards reducing environmental impacts. Lightweight aggregates like pumice (PA) and expanded perlite (EPA) can minimize natural resource consumption and lower the carbon footprint of building material production. Additionally, the utilization of by-products such as fly ash (FA) and silica fume (SF) represents a crucial step towards recycling waste materials and reducing environmental burdens. Therefore, the findings of this study provide valuable insights for developing sustainable building materials and promoting environmentally friendly practices in the construction sector.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development, and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef] [PubMed]

- Asim, M.; Uddin, G.M.; Jamshaid, H.; Raza, A.; Hussain, U.; Satti, A.N.; Hayat, N.; Arafat, S.M. Comparative experimental investigation of natural fibers reinforced light weight concrete as thermally efficient building materials. J. Build. Eng. 2020, 31, 101411. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current sustainable trends of using waste materials in concrete—A decade review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Jouzdani, B.E.; Reisi, M. Effect of magnetized water characteristics on fresh and hardened properties of self-compacting concrete. Constr. Build. Mater. 2020, 242, 118196. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Saradar, A.; Jabbari, M.; Moein, M.M. Evaluation of fresh and hardened properties of self-compacting concrete containing different percentages of waste tiles. J. Build. Pathol. Rehabil. 2023, 8, 81. [Google Scholar] [CrossRef]

- Chakravarthy, P.K.; Namratha, K. Strength and durability properties of high strength self compacting concrete. Mater. Today Proc. 2022, 69, 896–900. [Google Scholar] [CrossRef]

- Promsawat, P.; Chatveera, B.; Sua-iam, G.; Makul, N. Properties of self-compacting concrete prepared with ternary Portland cement-high volume fly ash-calcium carbonate blends. Case Stud. Constr. Mater. 2020, 13, e00426. [Google Scholar] [CrossRef]

- Karthika, R.B.; Vidyapriya, V.; Sri, K.N.; Beaula, K.M.G.; Harini, R.; Sriram, M. Experimental study on lightweight concrete using pumice aggregate. Mater. Today Proc. 2021, 43, 1606–1613. [Google Scholar] [CrossRef]

- Sifan, M.; Nagaratnam, B.; Thamboo, J.; Poologanathan, K.; Corradi, M. Development and prospectives of lightweight high strength concrete using lightweight aggregates. Constr. Build. Mater. 2023, 362, 129628. [Google Scholar] [CrossRef]

- Aygun, Z.; Aygun, M. A study on usability of Ahlat ignimbrites and pumice as radiation shielding materials, by using EpiXS code. Int. J. Environ. Sci. Technol. 2022, 19, 5675–5688. [Google Scholar] [CrossRef]

- Çelik, D.N.; Durmuş, G. The development of ultralightweight expanded perlite-based thermal insulation panel using alkali activator solution. Front. Struct. Civ. Eng. 2022, 16, 1486–1499. [Google Scholar] [CrossRef]

- Siamardi, K. Optimization of fresh and hardened properties of structural light weight self-compacting concrete mix design using response surface methodology. Constr. Build. Mater. 2022, 317, 125928. [Google Scholar] [CrossRef]

- Mohamed, S.H.; Asran, A.G.; Noman, M.T.; Azim, M.A. Properties of structural lightweight high strength self-compacting concrete. GEOMATE J. 2022, 23, 50–60. [Google Scholar] [CrossRef]

- Chen, X.; Gruyaert, E.; Li, J. Modelling the effect of coarse recycled concrete aggregate on compressive strength of Portland cement concrete using volume fraction-based approach. Constr. Build. Mater. 2021, 309, 125159. [Google Scholar] [CrossRef]

- Yehia, S.; Abdelfatah, A.; Mansour, D. Effect of aggregate type and specimen configuration on concrete compressive strength. Crystals 2020, 10, 625. [Google Scholar] [CrossRef]

- Agrawal, Y.; Gupta, T.; Sharma, R.; Panwar, N.L.; Siddique, S. A comprehensive review on the performance of structural lightweight aggregate concrete for sustainable construction. Constr. Mater. 2021, 1, 39–62. [Google Scholar] [CrossRef]

- Evangelista, A.C.J.; Tam, V.W. Properties of high-strength lightweight concrete using manufactured aggregate. Proc. Inst. Civ. Eng. Constr. Mater. 2020, 173, 157–169. [Google Scholar] [CrossRef]

- Sahoo, S.; Lakavath, C.; Prakash, S.S. Experimental and analytical studies on fracture behavior of fiber-reinforced structural lightweight aggregate concrete. J. Mater. Civ. Eng. 2021, 33, 04021074. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ahmad, A.; Barry, M.S.; Alhems, L.M.; Mohamed Suhoothi, A.C. Durability of structural lightweight concrete containing expanded perlite aggregate. Int. J. Concr. Struct. Mater. 2020, 14, 1–15. [Google Scholar] [CrossRef]

- Türkmen, İ.; Gavgalı, M. Influence of mineral admixtures on the some properties and corrosion of steel embedded in sodium sulfate solution of concrete. Mater. Lett. 2003, 57, 3222–3233. [Google Scholar] [CrossRef]

- Liu, W.V.; Apel, D.B.; Bindiganavile, V.S. Thermal properties of lightweight dry-mix shotcrete containing expanded perlite aggregate. Cem. Concr. Compos. 2014, 53, 44–51. [Google Scholar] [CrossRef]

- TS EN 197-1; Cement-Part 1: General Cements-Composition, Features and Eligibility Criteria. TSE (Turkish Standards Institute): Ankara, Turkey, 2012.

- EFNARC; Specification and Guidelines for Self-Compacting Concrete. European Federation for Specialist Construction Chemicals and Concrete Systems, Association House: London, UK, 2002.

- TS EN 1745; Masonry and Masonry Products—Determination Methods of Thermal Properties. Turkish Standards Institute: Ankara, Turkey, 2020.

- TS EN 12390-3; Concrete—Hardened Concrete Tests—Part 3: Determination of Compressive Strength of Test Samples Determination. Turkish Standards Institute: Ankara, Turkey, 2019.

- TS EN 12390-6; Concrete—Hardened Concrete Tests—Part 6: Determination of Splitting Tensile Strength of Test Specimens. Turkish Standards Institute: Ankara, Turkey, 2010.

- Alterary, S.S.; Marei, N.H. Fly ash properties, characterization, and applications: A review. J. King Saud. Univ. Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Nasr, M.S.; Hussain, T.; Kubba, H.; Shubbar, A.A.F. Influence of using high volume fraction of silica fume on mechanical and durability properties of cement mixtures. J. Eng. Sci. Technol. 2020, 15, 2494–2506. [Google Scholar]

- Stratoura, M.C.; Lazari, G.E.D.; Badogiannis, E.G.; Papadakis, V.G. Perlite and Rice Husk Ash Re-Use As Fine Aggregates in Lightweight Aggregate Structural Concrete—Durability Assessment. Sustainability 2023, 15, 4217. [Google Scholar] [CrossRef]

- Saba, A.M.; Khan, A.H.; Akhtar, M.N.; Khan, N.A.; Koloor, S.S.R.; Petrů, M.; Radwan, N. Strength and flexural behavior of steel fiber and silica fume incorporated self-compacting concrete. J. Mater. Res. Technol. 2021, 12, 1380–1390. [Google Scholar] [CrossRef]

- Nahhab, A.H.; Ketab, A.K. Influence of content and maximum size of light expanded clay aggregate on the fresh, strength, and durability properties of self-compacting lightweight concrete reinforced with micro steel fibers. Constr. Build. Mater. 2020, 233, 117922. [Google Scholar] [CrossRef]

- Joshaghani, A.; Balapour, M.; Mashhadian, M.; Ozbakkaloglu, T. Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): An experimental study. Constr. Build. Mater. 2020, 245, 118444. [Google Scholar] [CrossRef]

- Dong, D.; Huang, Y.; Pei, Y.; Zhang, X.; Cui, N.; Zhao, P.; Lu, L. Effect of spherical silica fume and fly ash on the rheological property, fluidity, setting time, compressive strength, water resistance and drying shrinkage of magnesium ammonium phosphate cement. J. Build. Eng. 2023, 63, 105484. [Google Scholar] [CrossRef]

- Mahalakshmi, S.H.V.; Khed, V.C. Experimental study on M-sand in self-compacting concrete with and without silica fume. Mater. Today Proc. 2020, 27, 1061–1065. [Google Scholar] [CrossRef]

- Hilal, N.; Tawfik, T.A.; Edan, H.H.; Hamah Sor, N. The mechanical and durability behaviour of sustainable self-compacting concrete partially contained waste plastic as fine aggregate. Aust. J. Civ. Eng. 2023, 21, 151–166. [Google Scholar] [CrossRef]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Benjeddou, O.; Ravindran, G.; Abdelzaher, M.A. Thermal and acoustic features of lightweight concrete based on marble wastes and expanded perlite aggregate. Buildings 2023, 13, 992. [Google Scholar] [CrossRef]

- Suarez, L.; Abu-Lebdeh, T.M.; Picornell, M.; Hamoush, S.A. Investigating the role of fly ash and silica fume in the cement hydration process. Am. J. Eng. Appl. Sci. 2016, 9, 134–145. [Google Scholar] [CrossRef]

- Singh, A.; Mehta, P.K.; Kumar, R. Performance of binary admixtures (Fly ash and Silica fume) on self-compacting concrete. Mater. Today Proc. 2022, 58, 970–977. [Google Scholar] [CrossRef]

- Tangpagasit, J.; Cheerarot, R.; Jaturapitakkul, C.; Kiattikomol, K. Packing effect and pozzolanic reaction of fly ash in mixtures. Cem. Concr. Res. 2005, 35, 1145–1151. [Google Scholar] [CrossRef]

- Qureshi, L.A.; Ali, B.; Ali, A. Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete. Constr. Build. Mater. 2020, 263, 120636. [Google Scholar] [CrossRef]

- Zhou, H.; Brooks, A.L. Thermal and mechanical properties of structural lightweight concrete containing lightweight aggregates and fly-ash cenospheres. Constr. Build. Mater. 2019, 198, 512–526. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Tahmouresi, B.; Kohani Khoshkbijari, R. Effect of fly ash and silica fume on transition zone, pore structure and permeability of concrete. Mag. Concr. Res. 2018, 70, 519–532. [Google Scholar] [CrossRef]

- Angelopoulos, P.M. Insights in the Physicochemical and Mechanical Properties and Characterization Methodology of Perlites. Minerals 2024, 14, 113. [Google Scholar] [CrossRef]

| Chemical Properties | PC | FA | SF | PA | EPA |

|---|---|---|---|---|---|

| (Component) | (%) | (%) | (%) | (%) | (%) |

| SiO2 | 20.23 | 60.32 | 91.44 | 75.2 | 70.64 |

| Al2O3 | 5.33 | 23.87 | 1.78 | 14.1 | 13.01 |

| Fe2O3 | 4.01 | 7.62 | 0.45 | 2.47 | 1.02 |

| CaO | 62.55 | 2.03 | 0.28 | 1.30 | 2.01 |

| MgO | 2.81 | 2.05 | 0.08 | 0.03 | 1.74 |

| Na2O | 0.22 | 0.26 | 1.97 | 0.2 | 3.57 |

| K2O | 0.91 | 0.37 | 0.22 | 5.25 | 4.37 |

| Loss of ignition (%) | 2.94 | - | - | 3.30 | - |

| Density (g/cm3) | 2.95 | 2.04 | 2.32 | - | 0.08 |

| Mixes | Mix Code | Cement | FA | SF | (0–4 mm) (PA) | (4–8 mm) (PA) | (8–16 mm) (PA) | (0–4 mm) (EPA) | SP (%) | w/c |

|---|---|---|---|---|---|---|---|---|---|---|

| Control | K0 | 400 | - | - | 450 | 150 | 130 | - | 0.1 | 0.55 |

| FA_10% | K1 | 360 | 40 | - | 450 | 150 | 130 | - | 0.1 | 0.55 |

| SF_10% | K2 | 360 | - | 40 | 450 | 150 | 130 | - | 0.2 | 0.55 |

| FA_10% | K3 | 360 | 40 | - | - | 150 | 130 | 450 | 0.1 | 0.55 |

| SF_10% | K4 | 360 | - | 40 | - | 150 | 130 | 450 | 0.2 | 0.55 |

| Experiment | Classification | Range of Values |

|---|---|---|

| Slump flow | SF1 | 55–65 cm |

| SF2 | 66–75 cm | |

| SF3 | 76–85 cm | |

| T500 time | VS1 | ≤2 s |

| VS2 | >2 s | |

| L-box | PA1 | ≥0.8 (two and three bars) |

| V-funnel | VF1 | ≤8 s |

| VF2 | 9–25 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akbulut, Z.F.; Yavuz, D.; Tawfik, T.A.; Smarzewski, P.; Guler, S. Examining the Workability, Mechanical, and Thermal Characteristics of Eco-Friendly, Structural Self-Compacting Lightweight Concrete Enhanced with Fly Ash and Silica Fume. Materials 2024, 17, 3504. https://doi.org/10.3390/ma17143504

Akbulut ZF, Yavuz D, Tawfik TA, Smarzewski P, Guler S. Examining the Workability, Mechanical, and Thermal Characteristics of Eco-Friendly, Structural Self-Compacting Lightweight Concrete Enhanced with Fly Ash and Silica Fume. Materials. 2024; 17(14):3504. https://doi.org/10.3390/ma17143504

Chicago/Turabian StyleAkbulut, Zehra Funda, Demet Yavuz, Taher A. Tawfik, Piotr Smarzewski, and Soner Guler. 2024. "Examining the Workability, Mechanical, and Thermal Characteristics of Eco-Friendly, Structural Self-Compacting Lightweight Concrete Enhanced with Fly Ash and Silica Fume" Materials 17, no. 14: 3504. https://doi.org/10.3390/ma17143504