Interface Structures on Mechanically Polished Surface of Spinel Ferrite and Its Effect on the Magnetic Domains

Abstract

:1. Introduction

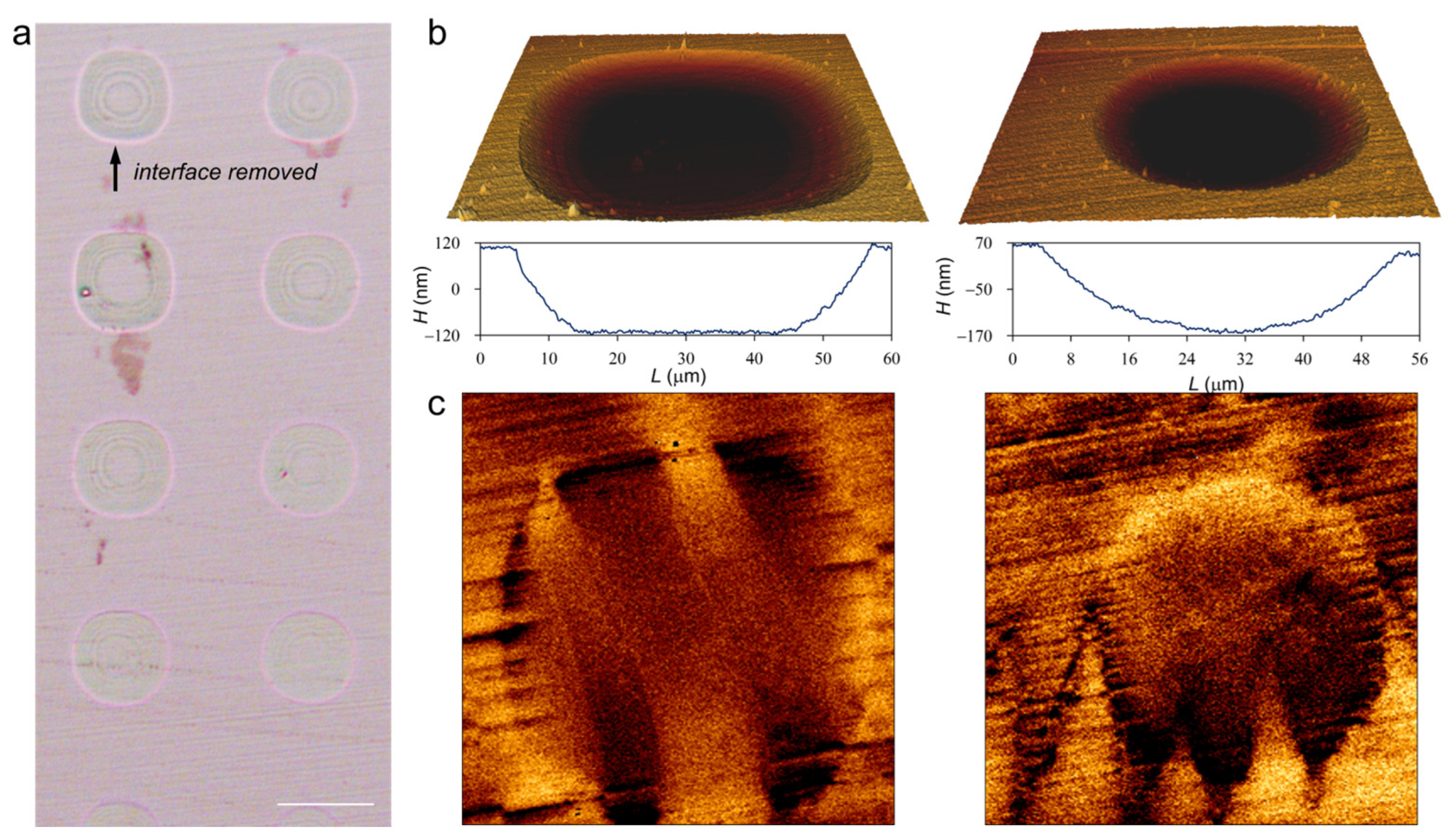

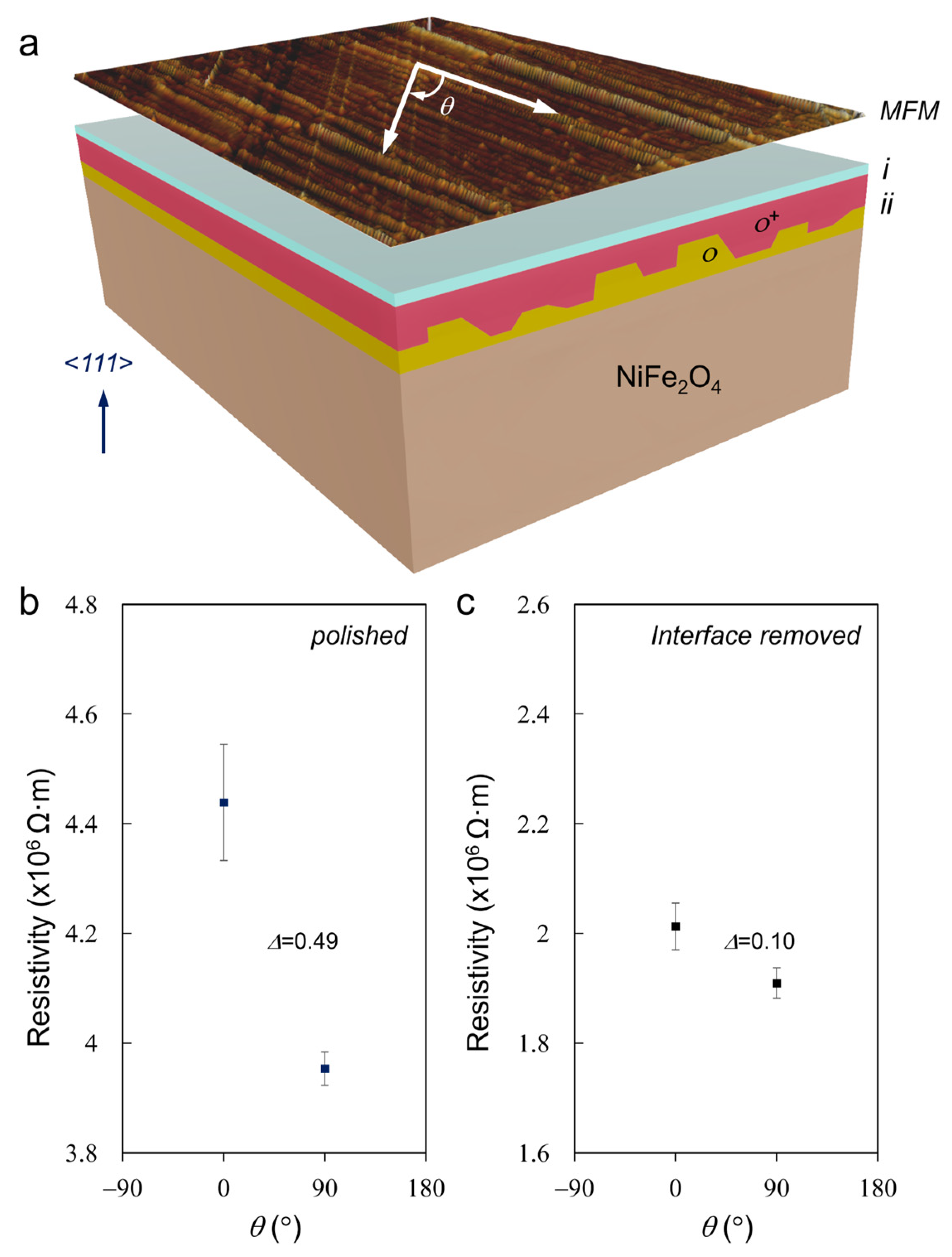

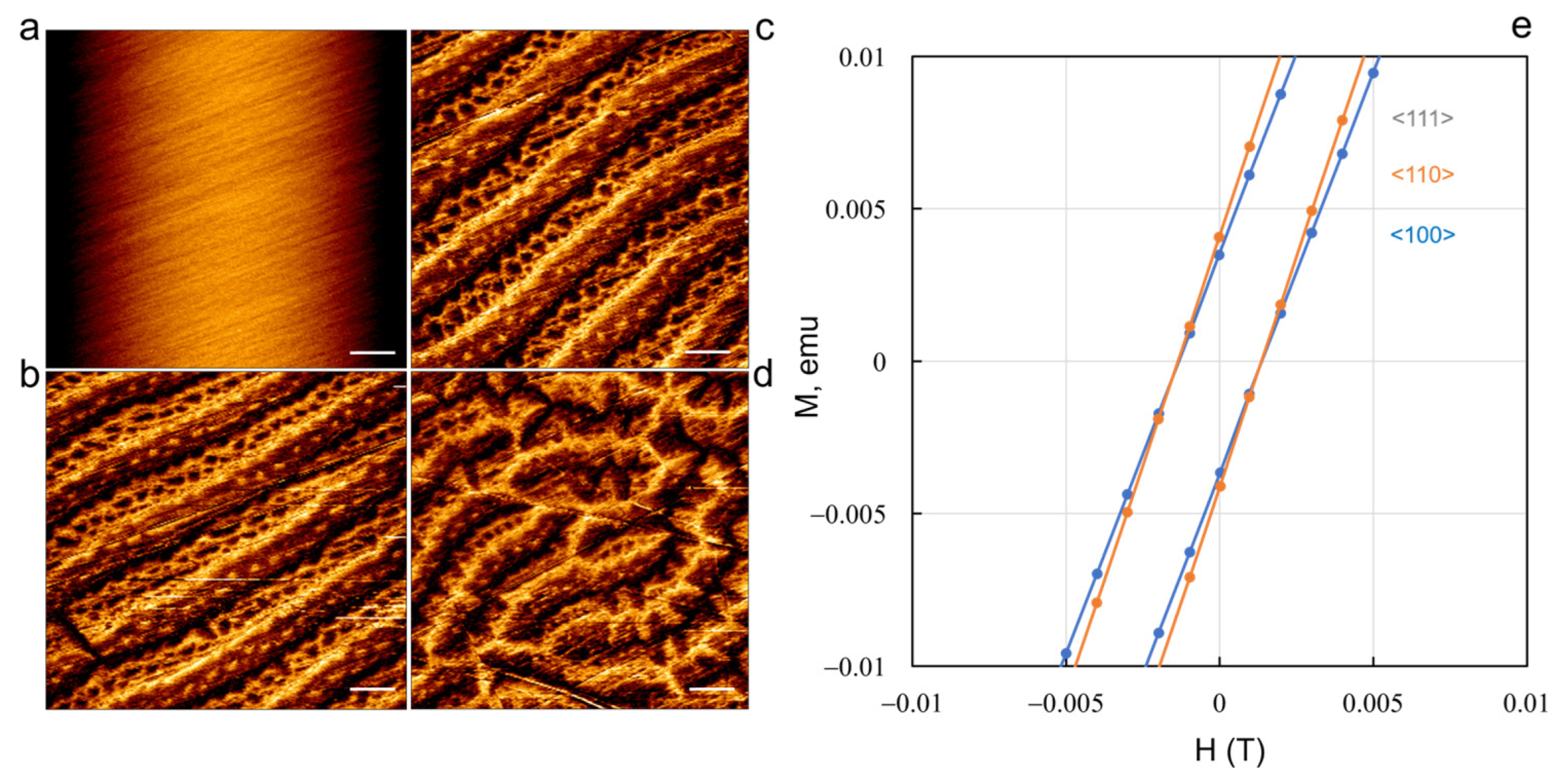

2. Experimental Methods

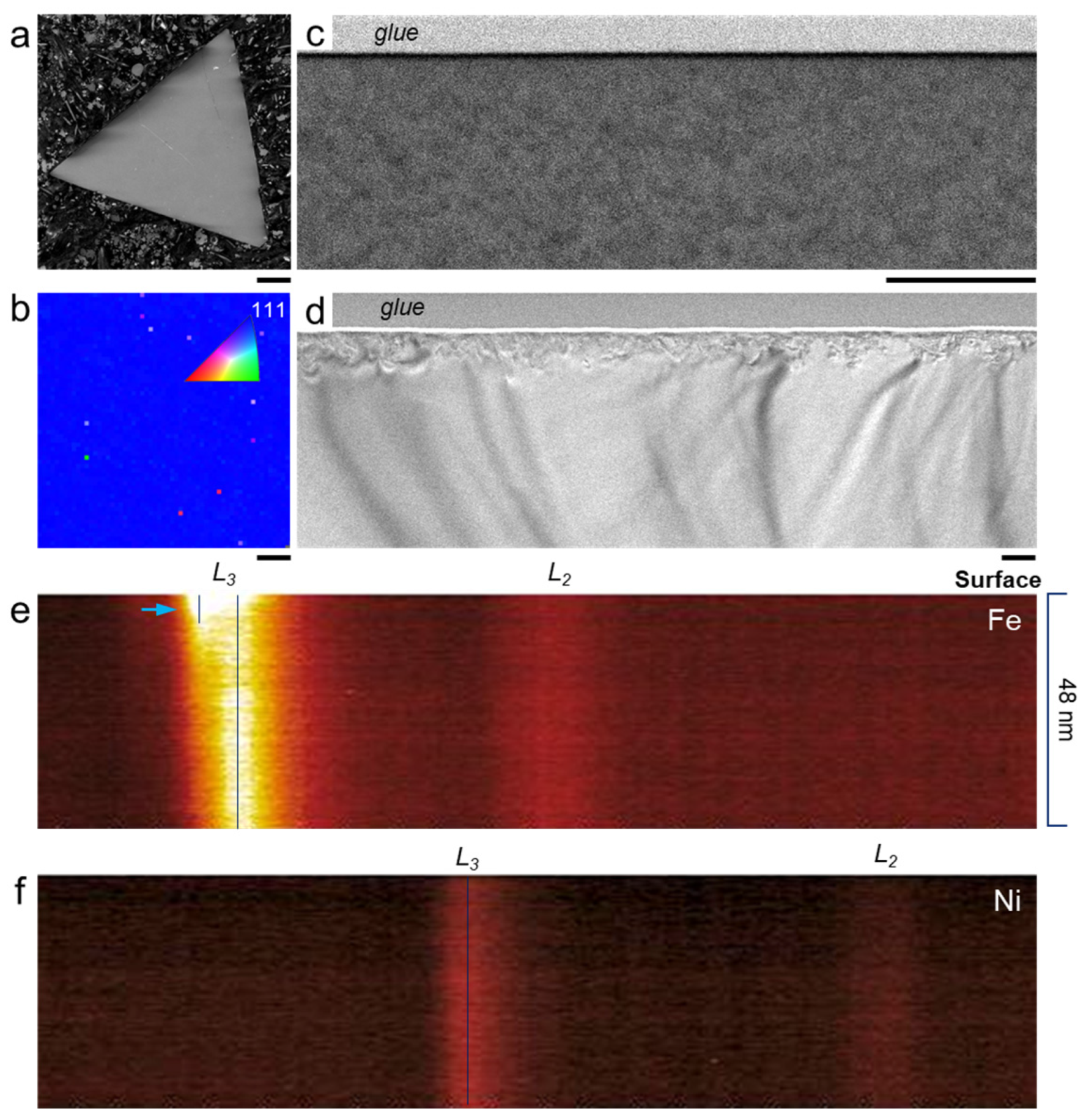

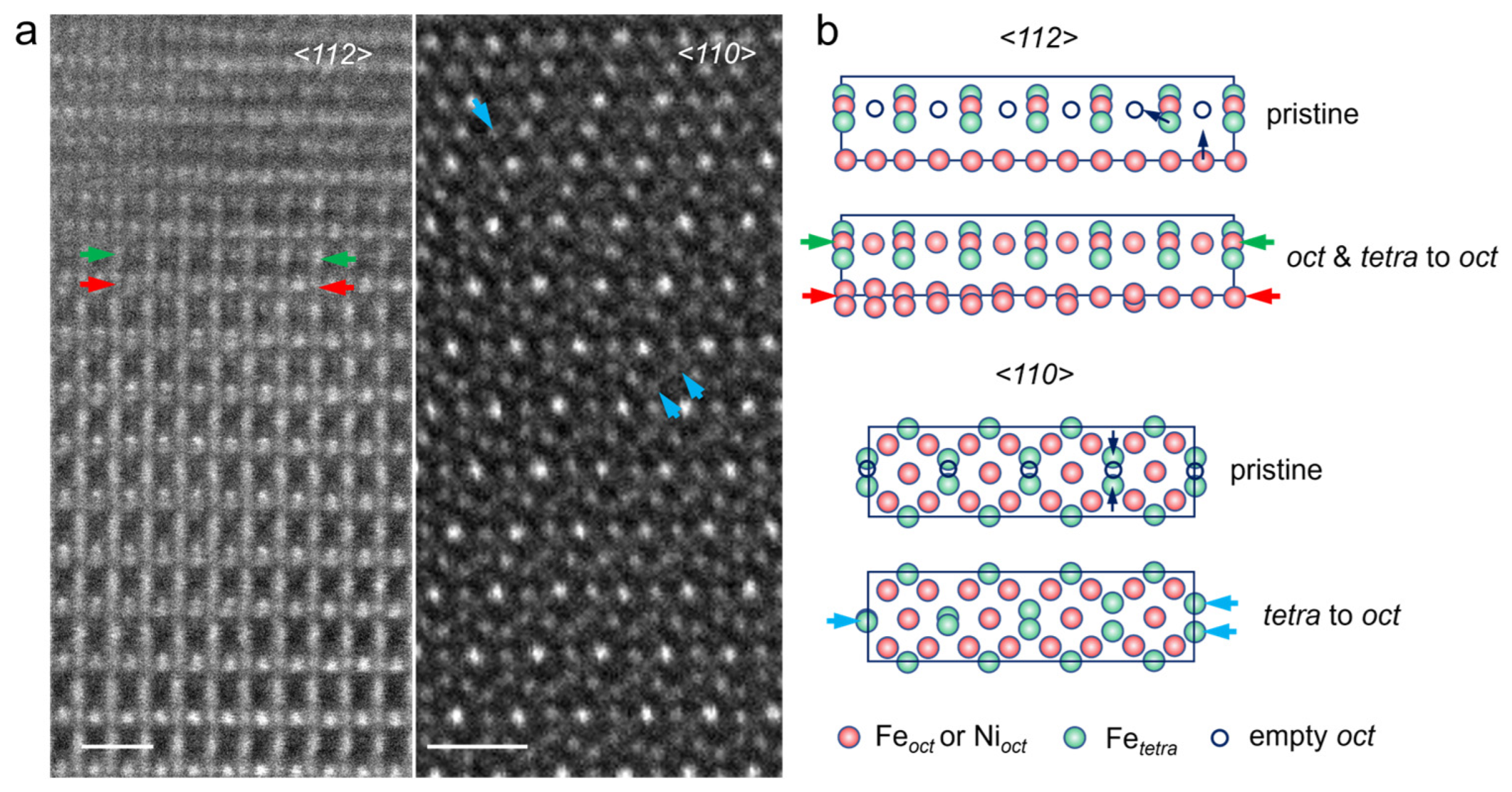

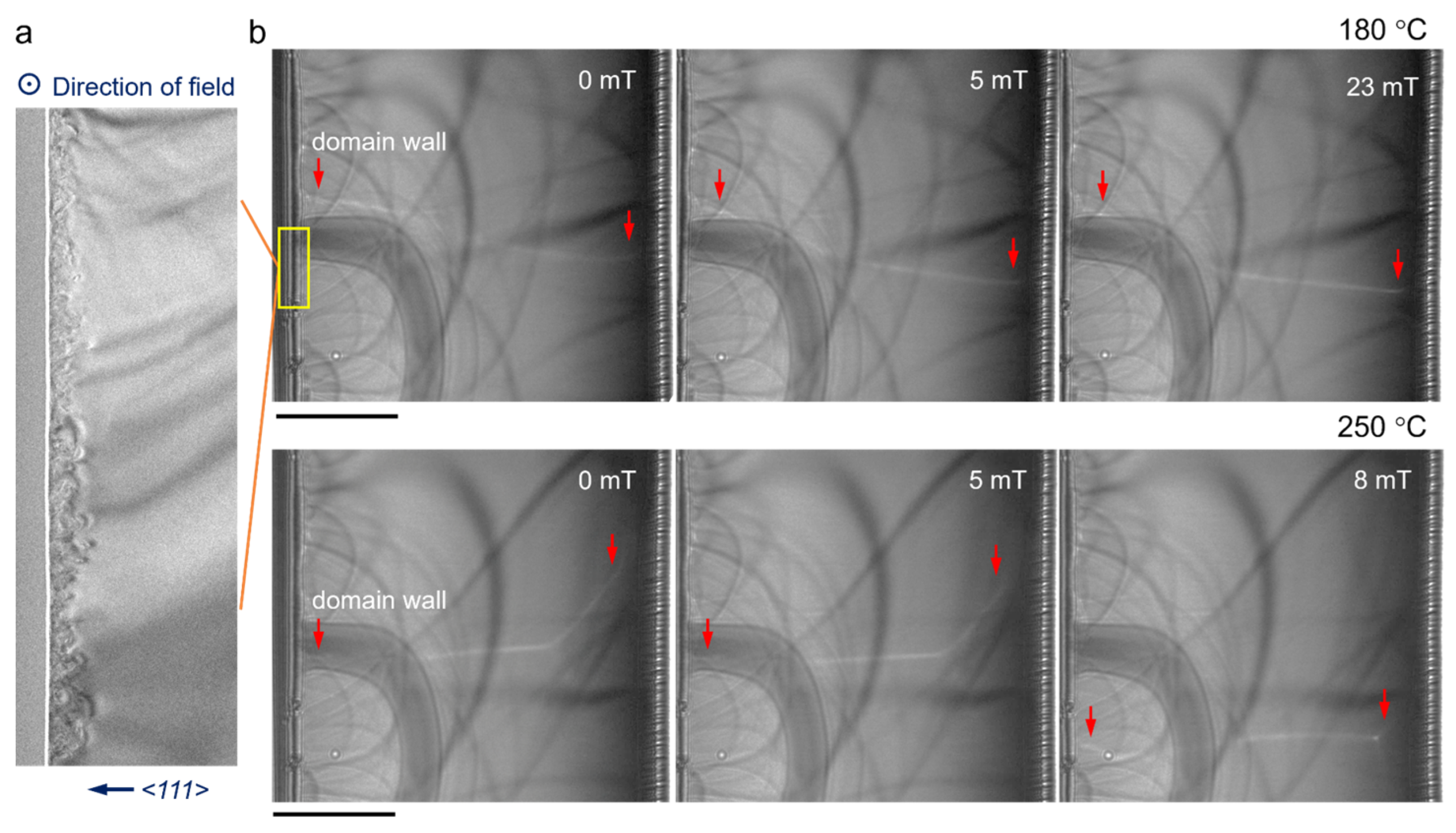

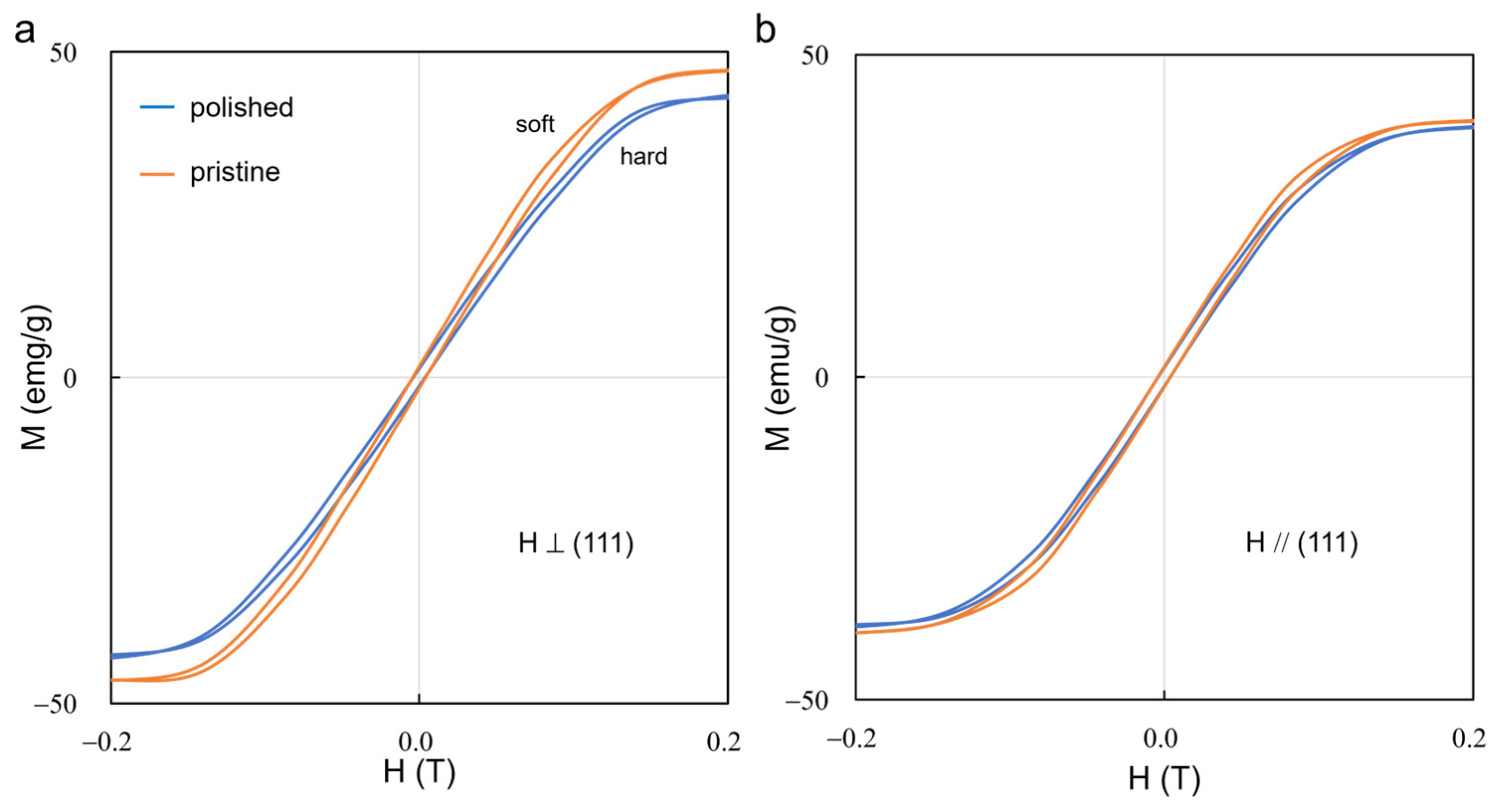

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andalib, P.; Harris, V.G. Grain boundary engineering of power inductor cores for MHz applications. J. Alloys Compd. 2020, 832, 153131. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, eaao0195. [Google Scholar] [CrossRef] [PubMed]

- Yan, M.; Yi, S.; Fan, X.; Zhang, Z.; Jin, J.; Bai, G. High-frequency MnZn soft magnetic ferrite by engineering grain boundaries with multiple-ion doping. J. Mater. Sci. Technol. 2021, 79, 165–170. [Google Scholar] [CrossRef]

- Fan, X.; Bai, G.; Zhang, Z.; Liu, X.; Jin, J.; Xu, J.; Yan, M. Correlating the microstructure with magnetic properties of Ti-doped high-frequency MnZn ferrite. J. Eur. Ceram. Soc. 2023, 43, 5540–5547. [Google Scholar] [CrossRef]

- Lu, Y.; Takai, M. Surface damage in a Mn-Zn ferrite induced by laser chemical etching. J. Appl. Phys. 1993, 73, 158–162. [Google Scholar] [CrossRef]

- Harris, V.G.; Geiler, A.; Chen, Y.; Yoon, S.D.; Wu, M.; Yang, A.; Chen, Z.; He, P.; Parimi, P.V.; Zuo, X. Recent advances in processing and applications of microwave ferrites. J. Magn. Magn. Mater. 2009, 321, 2035–2047. [Google Scholar] [CrossRef]

- Kalantari, A.R.; Zarei-Hanzaki, A.; Abedi, H.; Hassanpour-Esfahani, M.; Park, S.J.; Park, J.Y. Microstructure evolution and room temperature mechanical properties of a thermomechanically processed ferrite-based low density steel. Mater. Sci. Eng. A 2019, 754, 57–67. [Google Scholar] [CrossRef]

- Jin, T.; Ma, M.; Li, B.; Gao, Y.; Zhao, Q.; Zhao, Z.; Chen, J.; Tian, Y. Mechanical polishing of ultrahard nanotwinned diamond via transition into hard sp2-sp3 amorphous carbon. Carbon 2020, 161, 1–6. [Google Scholar] [CrossRef]

- Bilovol, V.; Pampillo, L.G.; Meier, D.; Wolff, U.; Saccone, F. Cobalt Ferrite Films: Nanopolishing and Magnetic Properties. IEEE Trans. Magn. 2014, 50, 1–5. [Google Scholar] [CrossRef]

- Sakaki, Y.; Matsuoka, T. Effect of Surface Layer on the Magnetic Characteristics of Mn-Zn Ferrite. IEEE Transl. J. Magn. Jpn. 1985, 1, 772–774. [Google Scholar] [CrossRef]

- Swerts, J.; Temst, K.; Van Bael, M.J.; Van Haesendonck, C.; Bruynseraede, Y. Magnetic domain wall trapping by in-plane surface roughness modulation. Appl. Phys. Lett. 2003, 82, 1239–1241. [Google Scholar] [CrossRef]

- Billington, D.; Toyoki, K.; Okazaki, H.; Kotani, Y.; Fukagawa, T.; Nishiuchi, T.; Hirosawa, S.; Nakamura, T. Unmasking the interior magnetic domain structure and evolution in Nd-Fe-B sintered magnets through high-field magnetic imaging of the fractured surface. Phys. Rev. Mater. 2018, 2, 104413. [Google Scholar] [CrossRef]

- Samuels, L.E. Metallographic Polishing by Mechanical Methods; ASM International: Almere, The Netherlands, 2003. [Google Scholar]

- Yamashita, O.; Ikeda, T. Effect of polishing stress on Raman spectra of the Mn-Zn ferrite. J. Appl. Phys. 2004, 95, 1743–1748. [Google Scholar] [CrossRef]

- Kawai, Y.; Ogawa, T. Domain Wall Motions Due to External Stresses in a Mn-Zn Ferrite Single Crystal. Phys. Status Solidi 1983, 77, K103–K106. [Google Scholar] [CrossRef]

- Jiang, S.D.; Eggers, T.; Thiabgoh, O.; Xing, D.W.; Fei, W.D.; Shen, H.X.; Liu, J.S.; Zhang, J.R.; Fang, W.B.; Sun, J.F.; et al. Relating surface roughness and magnetic domain structure to giant magneto-impedance of Co-rich melt-extracted microwires. Sci. Rep. 2017, 7, 46253. [Google Scholar] [CrossRef] [PubMed]

- Kuch, W.; Chelaru, L.I.; Offi, F.; Wang, J.; Kotsugi, M.; Kirschner, J. Tuning the magnetic coupling across ultrathin antiferromagnetic films by controlling atomic-scale roughness. Nat. Mater. 2006, 5, 128–133. [Google Scholar] [CrossRef] [PubMed]

- Kudrnovsk, J.; Drchal, V.; Turek, I.; Sob, M.; Weinberger, P. Interlayer magnetic coupling: Effect of interface roughness. Phys. Rev. B Condens. Matter 1996, 53, 5125–5128. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.P.; Gamache, R.M.; Wang, G.C.; Lu, T.M.; Palasantzas, G.; De Hosson, J.T.M. Effect of surface roughness on magnetic domain wall thickness. domain size, and coercivity. J. Appl. Phys. 2001, 89, 1325–1330. [Google Scholar] [CrossRef]

- Brabers, V. Progress in spinel ferrite research. Handb. Magn. Mater. 1995, 8, 189–324. [Google Scholar]

- Bai, G.; Zhong, W.; Zhang, Z.; Bandaru, S.; Fan, X.; Liu, X.; Zhang, X. Atomic-scale observation of calcium occupation in spinel cobalt ferrite towards the regulation of intrinsic magnetic properties. Nanoscale 2023, 15, 19586–19597. [Google Scholar] [CrossRef]

- Anderson, P.W. Antiferromagnetism. Theory of superexchange interaction. Phys. Rev. 1950, 79, 350. [Google Scholar] [CrossRef]

- Skoropata, E.; Su, T.T.; Ouyang, H.; Freeland, J.W.; van Lierop, J. Intermixing enables strong exchange coupling in nanocomposites: Magnetism through the interfacial ferrite in γ−Fe2O3/NiO. Phys. Rev. B 2017, 96, 024447. [Google Scholar] [CrossRef]

- Mathew, D.S.; Juang, R.S. An overview of the structure and magnetism of spinel ferrite nanoparticles and their synthesis in microemulsions. Chem. Eng. J. 2007, 129, 51–65. [Google Scholar] [CrossRef]

- Tatarchuk, T.; Bououdina, M.; Vijaya, J.J.; Kennedy, L.J. Spinel Ferrite Nanoparticles: Synthesis, Crystal Structure, Properties, and Perspective Applications, Nanophysics, Nanomaterials, Interface Studies, and Applications; Springer International Publishing: Cham, Switzerland, 2017; pp. 305–325. [Google Scholar]

- Li, Z.; Lu, J.; Jin, L.; Rusz, J.; Kocevski, V.; Yanagihara, H.; Kita, E.; Mayer, J.; Dunin-Borkowski, R.E.; Xiang, H.; et al. Atomic Structure and Electron Magnetic Circular Dichroism of Individual Rock Salt Structure Antiphase Boundaries in Spinel Ferrites. Adv. Funct. Mater. 2021, 31, 2008306. [Google Scholar] [CrossRef]

- Wang, H.; Gao, W.; Altman, E.I.; Henrich, V.E. Studies of the electronic structure at the Fe3O4–NiO interface. J. Vac. Sci. Technol. A Vac. Surf. Films 2004, 22, 1675–1681. [Google Scholar] [CrossRef]

- Kuschel, O.; Buß, R.; Spiess, W.; Schemme, T.; Wöllermann, J.; Balinski, K.; N’Diaye, A.T.; Kuschel, T.; Wollschläger, J.; Kuepper, K. From Fe3O4/NiO bilayers to NiFe2O4-like thin films through Ni interdiffusion. Phys. Rev. B 2016, 94, 094423. [Google Scholar] [CrossRef]

- Boeglin, C.; Ersen, O.; Pilard, M.; Speisser, V.; Kronast, F. Temperature dependence of magnetic coupling in ultrathin NiO/Fe3O4 (001) films. Phys. Rev. B 2009, 80, 035409. [Google Scholar] [CrossRef]

- Lavorato, G.; Winkler, E.; Rivas-Murias, B.; Rivadulla, F. Thickness dependence of exchange coupling in epitaxial Fe3O4/CoFe2O4 soft/hard magnetic bilayers. Phys. Rev. B 2016, 94, 054405. [Google Scholar] [CrossRef]

- Krug, I.P.; Hillebrecht, F.U.; Haverkort, M.W.; Tanaka, A.; Tjeng, L.H.; Gomonay, H.; Fraile-Rodríguez, A.; Nolting, F.; Cramm, S.; Schneider, C.M. Impact of interface orientation on magnetic coupling in highly ordered systems: A case study of the low-indexed Fe3O4/NiO interfaces. Phys. Rev. B 2008, 78, 064427. [Google Scholar] [CrossRef]

- Pohlmann, T.; Bertram, F.; Thien, J.; Rodewald, J.; Ruwisch, K.; Kuschel, T.; Weschke, E.; Küpper, K.; Wollschläger, J. Structural and magnetic investigation of the interfaces of Fe3O4/MgO (001) with and without NiO interlayer. Phys. Rev. B 2022, 105, 235436. [Google Scholar] [CrossRef]

- Chen, B.; Gauquelin, N.; Green, R.J.; Verbeeck, J.; Rijnders, G.; Koster, G. Asymmetric Interfacial Intermixing Associated Magnetic Coupling in LaMnO3/LaFeO3 Heterostructures. Front. Phys. 2021, 9, 698154. [Google Scholar] [CrossRef]

- Lama, B.; Tsymbal, E.Y.; Paudel, T.R. Effects of intermixing and oxygen vacancies on a two-dimensional electron gas at the polar (TbScO3/KTaO3) (001) interface. Phys. Rev. Mater. 2023, 7, 026201. [Google Scholar] [CrossRef]

- Pilard, M.; Ersen, O.; Cherifi, S.; Carvello, B.; Roiban, L.; Muller, B.; Scheurer, F.; Ranno, L.; Boeglin, C. Magnetic properties of coupled ultrathin NiO/Fe3O4 films. Phys. Rev. B 2007, 76, 214436. [Google Scholar] [CrossRef]

- Tabis, W.; Lorenzo, J.E.; Kozlowski, A.; Kolodziej, T.; Tarnawski, Z.; Kakol, Z.; Mazzoli, C.; Walker, H.C.; Jaouen, N.; Mannix, D.; et al. Effect of surface polishing and oxidization induced strain on electronic order at the Verwey transition in Fe3O4. J. Phys. Condens. Matter 2013, 25, 055603. [Google Scholar] [CrossRef] [PubMed]

- Husain, N.A.; Camilleri, J.; Özcan, M. Effect of polishing instruments and polishing regimens on surface topography and phase transformation of monolithic zirconia: An evaluation with XPS and XRD analysis. J. Mech. Behav. Biomed. Mater. 2016, 64, 104–112. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Yasui, A.; Kotani, Y.; Tsuji, N.; Nakamura, T.; Hirosawa, S. Magnetic domain evolution in Nd–Fe–B: Cu sintered magnet visualized by scanning hard X-ray microprobe. Acta Mater. 2016, 106, 155–161. [Google Scholar] [CrossRef]

- Kohashi, T.; Motai, K.; Nishiuchi, T.; Hirosawa, S. Magnetism in grain-boundary phase of a NdFeB sintered magnet studied by spin-polarized scanning electron microscopy. Appl. Phys. Lett. 2014, 104, 232408. [Google Scholar] [CrossRef]

- Kobayashi, K.; Nakamura, M.; Urushibata, K. Magnetic properties of the surface layer and its magnetic interaction with the interior of Nd-Fe-B sintered magnets. J. Appl. Phys. 2015, 117, 173909. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Zhang, Z.; Fan, X.; Wang, J.; Bandaru, S.; Bai, G. Interface Structures on Mechanically Polished Surface of Spinel Ferrite and Its Effect on the Magnetic Domains. Materials 2024, 17, 3509. https://doi.org/10.3390/ma17143509

Xu S, Zhang Z, Fan X, Wang J, Bandaru S, Bai G. Interface Structures on Mechanically Polished Surface of Spinel Ferrite and Its Effect on the Magnetic Domains. Materials. 2024; 17(14):3509. https://doi.org/10.3390/ma17143509

Chicago/Turabian StyleXu, Siyuan, Zhenhua Zhang, Xiuyuan Fan, Jinhu Wang, Sateesh Bandaru, and Guohua Bai. 2024. "Interface Structures on Mechanically Polished Surface of Spinel Ferrite and Its Effect on the Magnetic Domains" Materials 17, no. 14: 3509. https://doi.org/10.3390/ma17143509