Study on Key Properties and Model Establishment of Innovative Recycled Aggregate Pervious Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Main Raw Materials and Mix Design

2.2. Experimental Design

2.2.1. Design Plan of I-RAPC Response Surface Test

2.2.2. I-RAPC Theoretical Model Construction Test Scheme

2.3. Test Methods

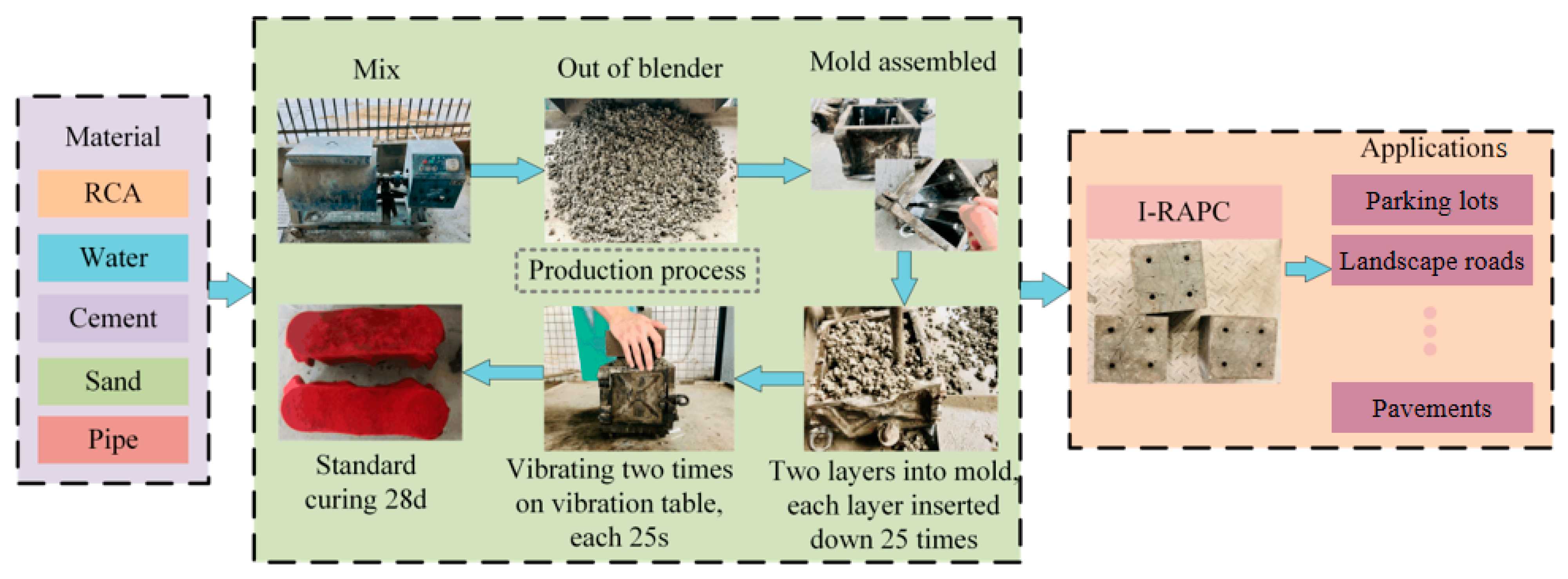

2.3.1. Preparation Process

2.3.2. Compressive Strength Test

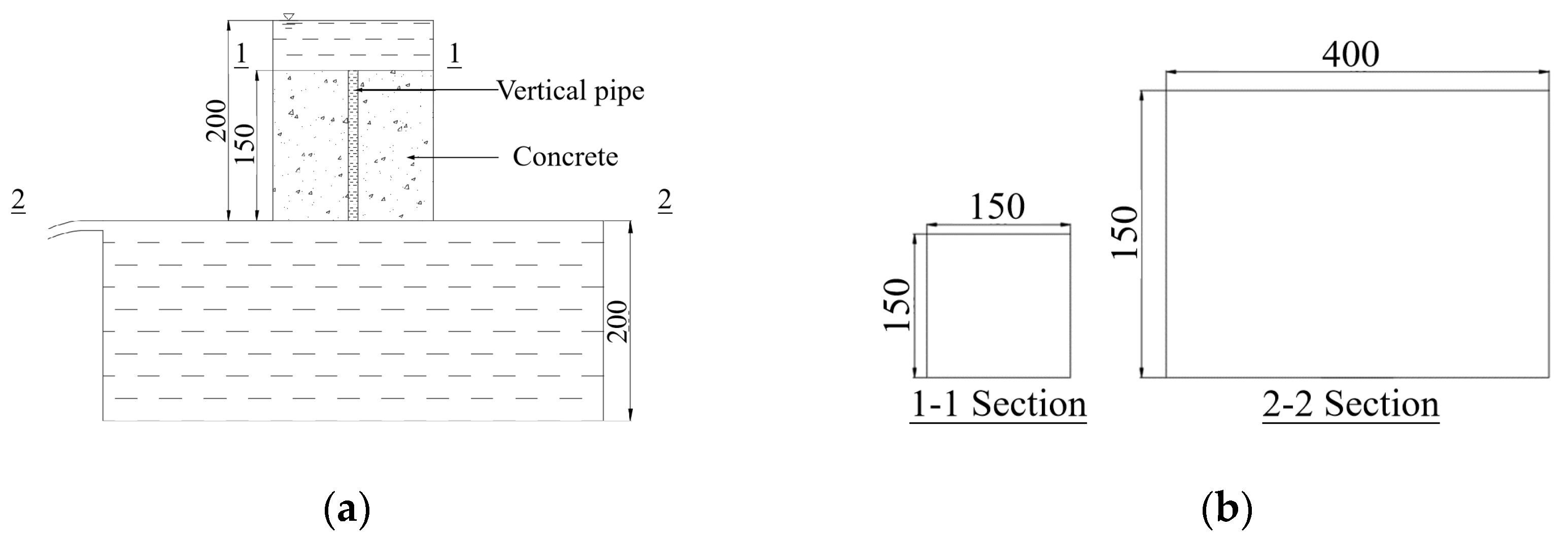

2.3.3. Permeability Test

2.3.4. Roughness Coefficient Test

3. Results and Discussion

3.1. Response Surface Methodology (RSM) Analysis

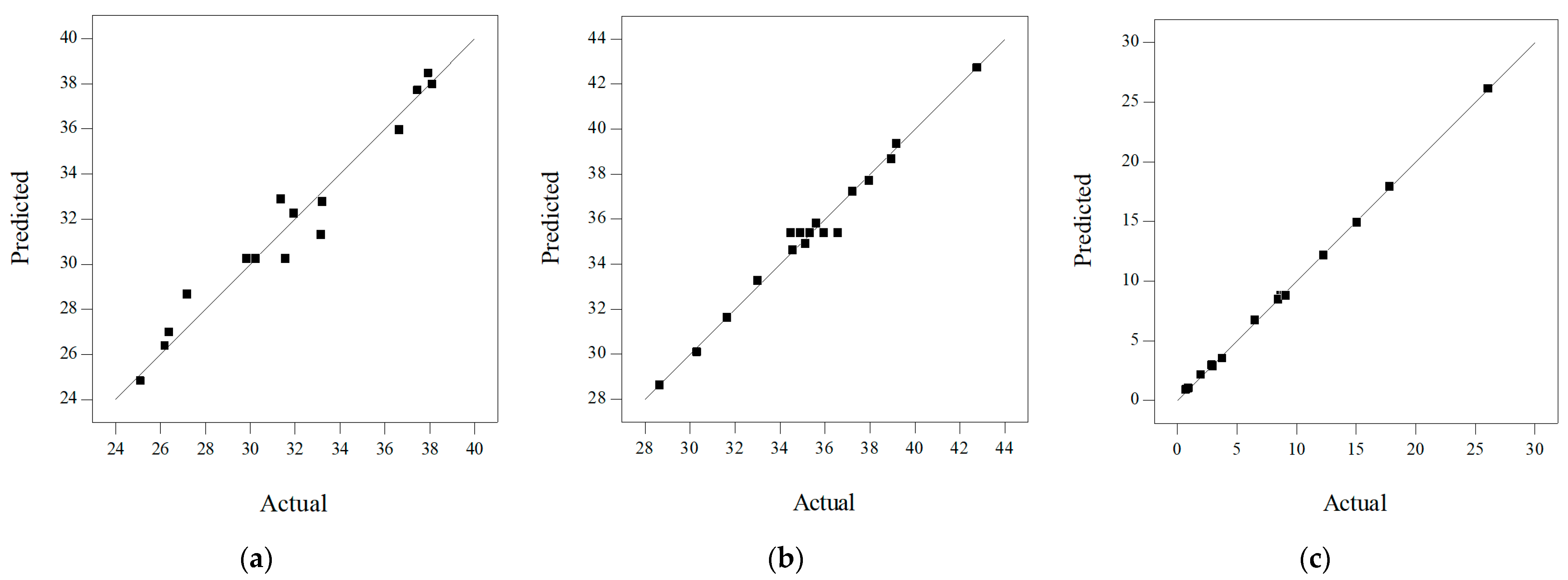

3.1.1. Response Surface Model Construction and Analysis

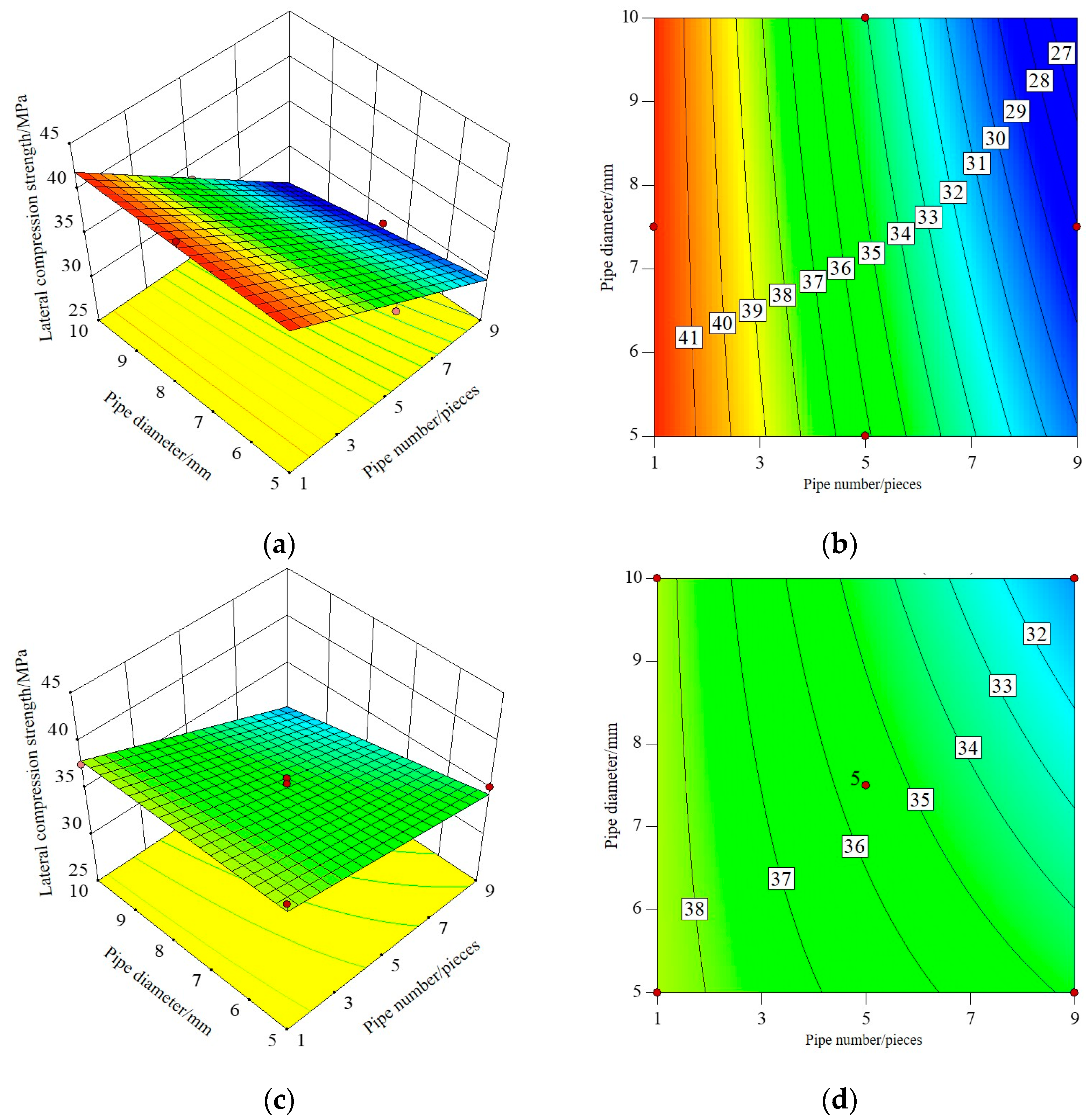

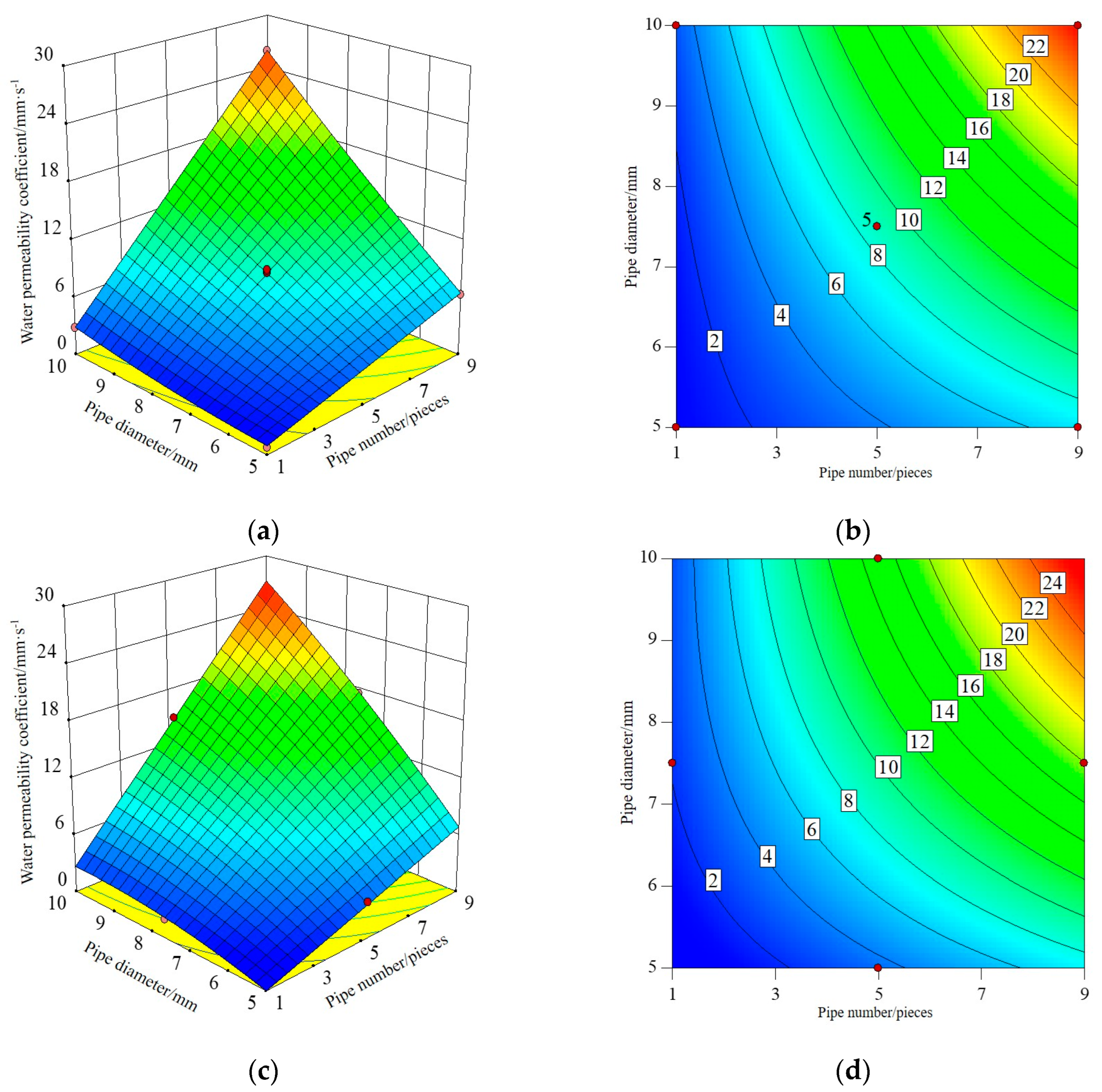

3.1.2. Response Surface and Contour Map

3.1.3. The Optimized Prediction Results Compared with the Actual Results

- (1)

- Frontal compressive strength: the number of pipes was one, the diameter of pipes was 5 mm, and the modulus of elasticity of the pipes was 3 GPa, its absolute error was 0.61 MPa, and the relative error was 1.46%;

- (2)

- Lateral compressive strength: the number of pipes was one, the diameter of the pipes was 5 mm, and the modulus of elasticity of the pipes was 3 GPa, its absolute error was 1.97 MPa, and the relative error was 4.49%;

- (3)

- Permeability coefficient: the number of pipes was nine, the diameter of the pipes was 10 mm, and the roughness of the pipes was 0.0075, its absolute error was 0.09 MPa, and the relative error was 0.33%.

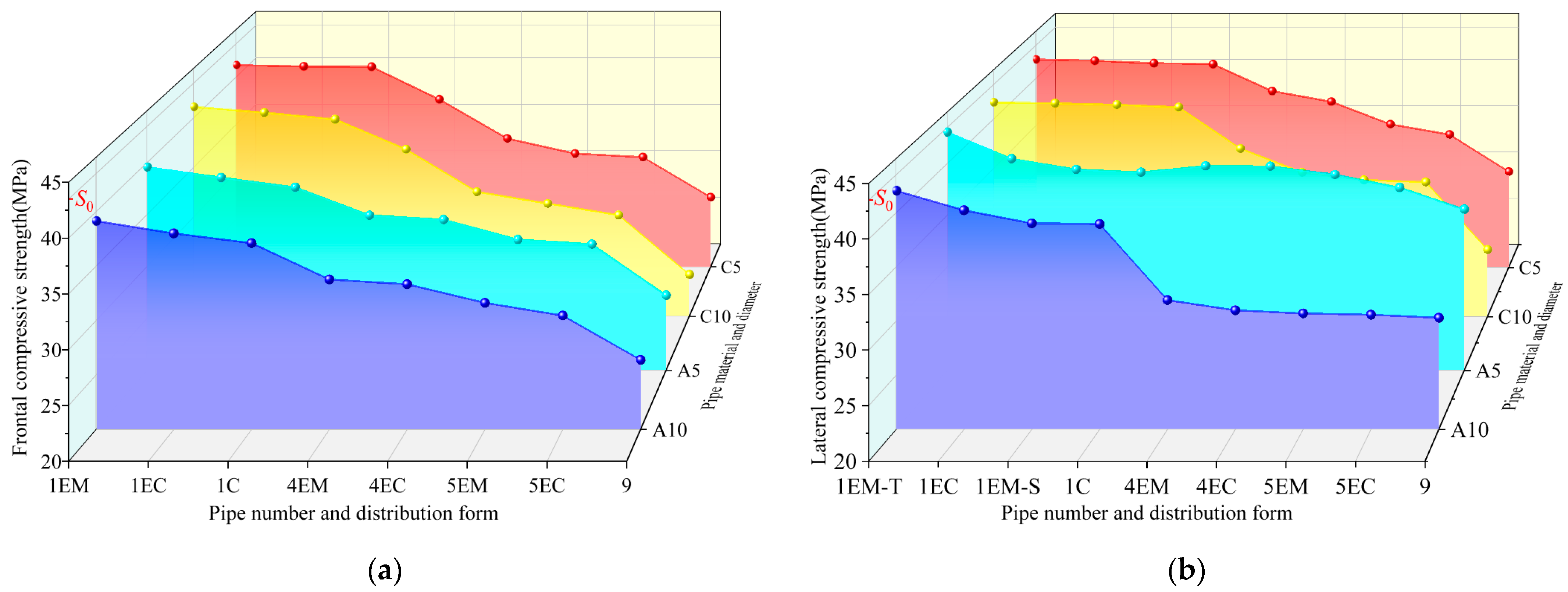

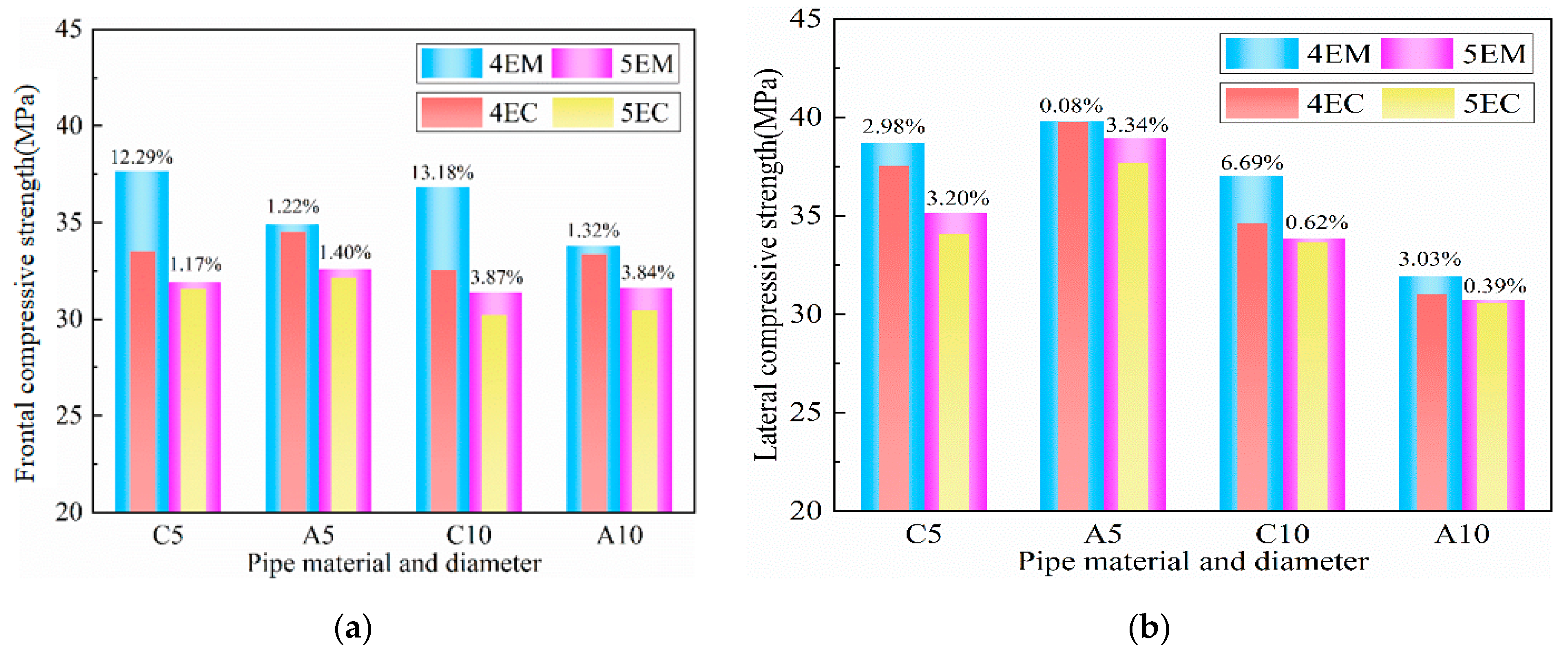

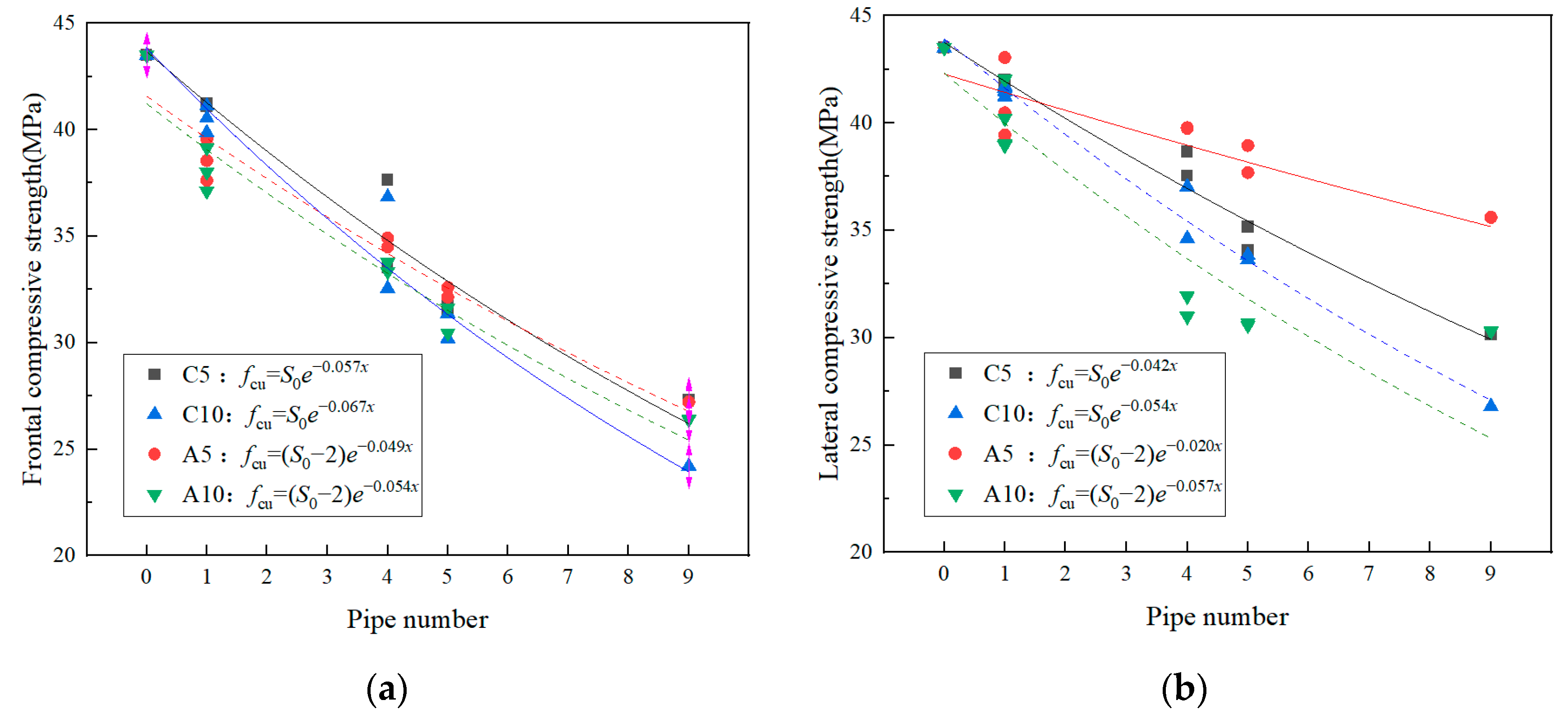

3.2. Compression Strength and Failure Morphology

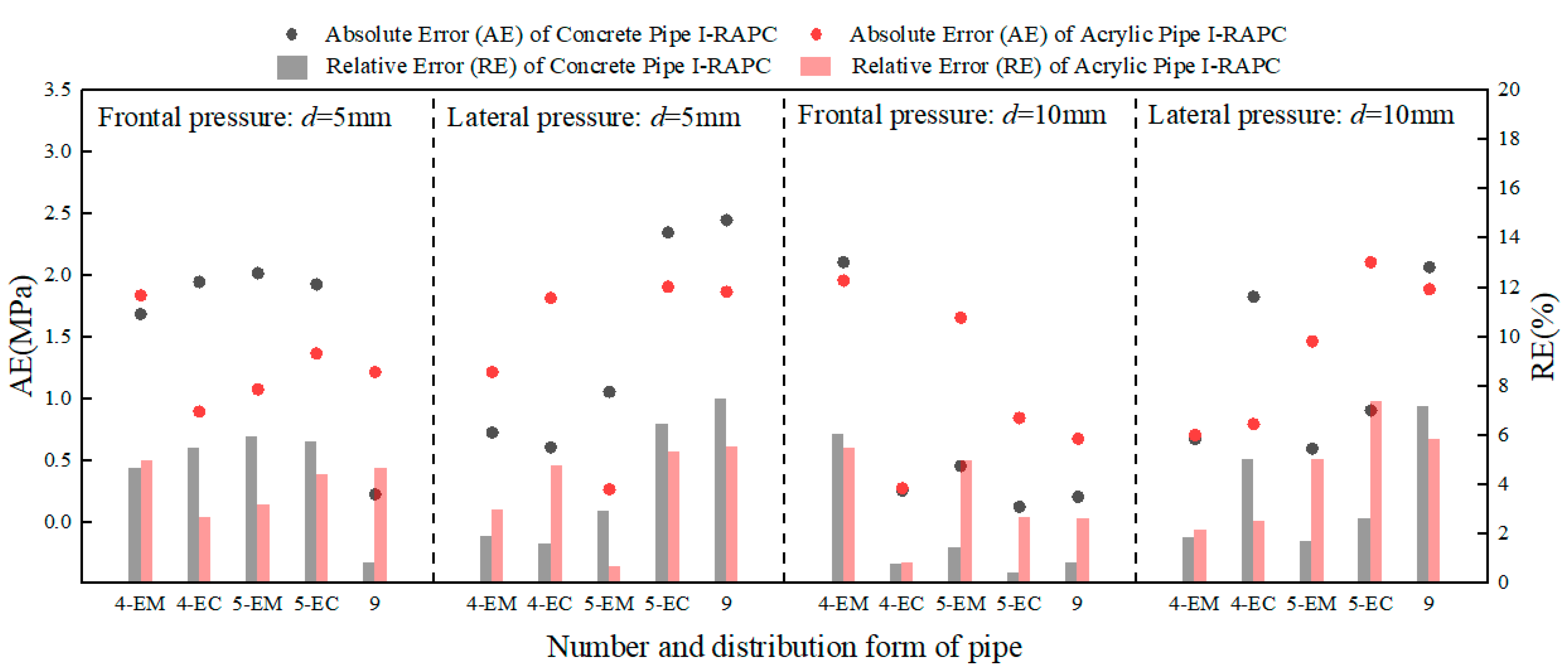

3.2.1. The Optimized Prediction Results Compared with the Actual Results

3.2.2. Theoretical Analysis

3.2.3. Permeability Coefficient

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, J.; Dai, J.; Wu, X.; Wu, S.; Zhang, Y.; Wang, F.; Gao, A.; Tan, Y. Urban rainwater utilization: A review of management modes and harvesting systems. Front. Environ. Sci. 2023, 11, 118. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Liu, Z.; Cai, C.; Peng, H.; Fan, F. Experimental study of the geopolymeric recycled aggregate concrete. J. Mater. Civil Eng. 2016, 28, 04016077. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O. Comparative analysis on costs and benefits of producing natural and recycled concrete aggregates: A south african case study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, Y.; Bie, Y. The prediction analysis of properties of recycled aggregate permeable concrete based on back-propagation neural network. J. Clean. Prod. 2020, 276, 124187. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, J.; Huang, D. Experimental study on the relationship between permeability and strength of pervious concrete. J. Mater. Civil Eng. 2017, 29, 04017217. [Google Scholar] [CrossRef]

- Ho, H.-L.; Huang, R.; Hwang, L.-C.; Lin, W.-T.; Hsu, H.-M. Waste-Based Pervious Concrete for Climate-Resilient Pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Lee, C.T.; Lin, Y. Influence of engineering properties of porous asphalt concrete on long-term performance. J. Mater. Civil Eng. 2017, 29, 04016246.1–04016246.7. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, J.; Liu, J.; Bie, Y.; Hu, Q. Sustainable ecological pervious concrete (SEPC) based on modified corn-cob coarse aggregate: Crushing morphology, strength, pore properties, and durability. Constr. Build. Mater. 2024, 426, 136194. [Google Scholar] [CrossRef]

- Bhutta, M.; Hasanah, N.; Farhayu, N.; Hussin, M.W.; Tahir, M.; Mirza, J. Properties of porous concrete from waste crushed concrete (recycled aggregate). Constr. Build. Mater. 2013, 47, 1243–1248. [Google Scholar] [CrossRef]

- Sahdeo, S.K.; Ransinchung, G.; Rahul, K.L.; Debbarma, S. Reclaimed Asphalt Pavement as a Substitution to Natural Coarse Aggregate for the Production of Sustainable Pervious Concrete Pavement Mixes. J. Mater. Civil Eng. 2021, 33, 04020469. [Google Scholar] [CrossRef]

- Zhu, H.; Wen, C.; Wang, Z.; Li, L. Study on the Permeability of Recycled Aggregate Pervious Concrete with Fibers. Materials 2020, 13, 321. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-H.; Jeong, S.-T.; Bui, Q.-T.; Yang, I.-H. Strength and Permeability Properties of Pervious Concrete Containing Coal Bottom Ash Aggregates. Materials 2022, 15, 7847. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P.; Zouaoui, S. Properties of pervious concrete incorporating recycled concrete aggregates and slag. Constr. Build. Mater. 2019, 212, 164–175. [Google Scholar] [CrossRef]

- Shi, Z.; Zhu, P.; Yan, X.; Yang, L.; Qiao, S.; Li, H. The rainstorm waterlogging resistance of a novel fiber-reinforced self-compacting recycled pervious concrete after freeze-thaw cycles. J. Build. Eng. 2024, 86, 108820. [Google Scholar] [CrossRef]

- Golewski, G.L. The Effect of the Addition of Coal Fly Ash (CFA) on the Control of Water Movement within the Structure of the Concrete. Materials 2023, 16, 5218. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Yang, X.; Zheng, K.; Chen, R. Properties and Microstructure of a Cement-Based Capillary Crystalline Waterproofing Grouting Material. Buildings 2024, 14, 1439. [Google Scholar] [CrossRef]

- Niu, Z.; Zhu, P.; Chen, C.; Wang, X.; Liu, H. Design Method of Novel Recycled Pervious Concrete for Resisting Rainstorm and Waterlogging. Bull. Chin. Ceram. Soc. 2021, 40, 106–112. [Google Scholar]

- Zhu, P.; Fan, H.; Yan, X.; Liu, H.; Wang, X.; Chen, C. Effect of Fatigue Loading on the Mechanical Properties and Resistance of High-strength Straight-hole Recycled Pervious Concrete to Rainstorm-based Waterlogging. J. Wuhan Univ. Technol.-Mater. Sci. Edit. 2023, 38, 141–148. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Liu, G.; Peng, X. Preparation and performance evaluation of an innovative pervious concrete pavement. Constr. Build. Mater. 2017, 138, 479–485. [Google Scholar] [CrossRef]

- Zhang, D.; Tang, S.; Che, J. Concurrent subspace design optimization and analysis of hypersonic vehicles based on response surface models. Aerosp. Sci. Technol. 2015, 42, 39–49. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef] [PubMed]

- Ba, D.; Boyac, S.H. Modeling and optimization i: Usability of response surface methodology. J. Food Eng. 2007, 78, 836–845. [Google Scholar]

- Güneyisi, E.; Gesoğlu, M.; Algın, Z.; Mermerdaş, K. Optimization of concrete mixture with hybrid blends of metakaolin and fly ash using response surface method. Compos. Part B-Eng. 2014, 60, 707–715. [Google Scholar] [CrossRef]

- Bowerman, B.L. Statistical Design and Analysis of Experiments With Applications to Engineering and Science. Technometrics 1991, 33, 105–106. [Google Scholar] [CrossRef]

- Tunc, E.T.; Alyamac, K.E. Determination of the relationship between the los angeles abrasion values of aggregates and concrete strength using the response surface methodology. Constr. Build. Mater. 2020, 260, 119850. [Google Scholar] [CrossRef]

- Zhang, P.; Cheng, Y.; Tao, J.; Jiao, Y. Molding process design for asphalt mixture based on response surface methodology. J. Mater. Civil Eng. 2016, 28, 04016120. [Google Scholar] [CrossRef]

- Zhang, Q.; Feng, X.; Chen, X.; Lu, K. Mix design for recycled aggregate pervious concrete based on response surface methodology. Constr. Build. Mater. 2020, 259, 119776. [Google Scholar] [CrossRef]

- JGJ/T 240-2011; Technical Specification for Application of Recycled Aggregate. Academy of Building Research: Beijing, China, 2011.

- GB/T 17431.2-2010; Lightweight Aggregates and Its Test Methods—Part 2: Test Method for Lightweight Aggregates. China Academy of Building Research: Beijing, China, 2010.

- JGJ 63-2016; Standard if Water fir Cibcreke. Academy of Building Research: Beijing, China, 2016.

- Nie, G.; Bao, Y.; Wan, D.; Yuan, T. Methods for evaluating mechanical properties of cement-based tubes. Mater. Rep. 2018, 32, 2072–2077+2084. [Google Scholar]

- DL/T 5330-2015; Academy of Building Research. Code for Mix Design of Hydraulic Concrete. Academy of Building Research: Beijing, China, 2015.

- Li, H.; Huang, F.; Yi, Z.; Wang, Z.; Zhang, Y.; Yang, Z. Investigations of Mixing Technique on the Rheological Properties of Self-Compacting Concrete. Appl. Sci. 2020, 10, 5189. [Google Scholar] [CrossRef]

- GB/T 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. Academy of Building Research: Beijing, China, 2002.

- ASTM C496/C496M; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- Li, Z.; Lu, D.; Gao, X. Optimization of mixture proportions by statistical experimental design using response surface method—A review. J. Build. Eng. 2021, 36, 102101. [Google Scholar] [CrossRef]

- Kalita, K.; Dey, P.; Haldar, S. Search for accurate RSM metamodels for structural engineering. J. Reinf. Plast. Compos. 2019, 38, 995–1013. [Google Scholar] [CrossRef]

- Ren, W.; Chen, H. Finite element model updating in structural dynamics by using the response surface method. Eng. Struct. 2010, 32, 2455–2465. [Google Scholar] [CrossRef]

- Dong, C.; Li, G.; Feng, X. Lack-of-fit tests for quantile regression models. J. R. Statist. Soc. B 2019, 81, 629–648. [Google Scholar] [CrossRef]

- Das, S.; Lee, S.H.; Kumar, P.; Kim, K.; Lee, S.S.; Bhattacharya, S.S. Solid waste management: Scope and the challenge of sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar] [CrossRef]

- Chen, K.-S.; Huang, T.-H.; Tsaur, R.-C.; Kao, W.-Y. Fuzzy Evaluation Models for Accuracy and Precision Indices. Mathematics 2022, 10, 3961. [Google Scholar] [CrossRef]

- Eleftheriou, M. A change-point model for monitoring the coefficient of variation based on squared ranks test. Comput. Ind. Eng. 2019, 136, 366–372. [Google Scholar] [CrossRef]

- Guo, Z.; Xu, L.; Lu, S.; Yan, L.; Zhu, Z.; Wang, Y. Study on the Effect of PVAc and Styrene on the Properties and Microstructure of MMA-Based Repair Material for Concrete. Materials 2023, 16, 3984. [Google Scholar] [CrossRef]

| Aggregate Type | Particle Size (mm) | Apparent Density (kg·m−3) | Bulk Density (kg·m−3) | Sediment Percentage (%) | Water Content (%) | 15 min Water Absorption (%) | Maximum Water Absorption Rate (%) | Crushing Index (%) | Numerical Tube Pressure (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| RCA | 4.75~9.5 | 2595 | 1245 | 0.25 | 2.80 | 4.70 | 5.42 | 15.54 | 1.7 |

| Water Cement Ratio | Material Consumption Per Unit Volume/(kg·m−3) | |||

|---|---|---|---|---|

| Cement | RCA (4.75~9.5 mm) | Fine Aggregate | Water | |

| 0.49 | 418 | 1164 | 613 | 205 |

| Experimental Levels | x: Number | d: Diameter | E: Elastic Modulus | n: Coefficient of Roughness | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (GPa) | |||||||||||||

| Low | 1 | 5.0 | 1.00 (B) | 0.0075 (A) | ||||||||||

| Medium | 5 | 7.5 | 2.33 (A) | 0.0100 (C) | ||||||||||

| High | 9 | 10 | 3.00 (C) | 0.0150 (B) | ||||||||||

| Experimental data points | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13~17 | |

| x | 1 | 9 | 1 | 9 | 1 | 9 | 1 | 9 | 5 | 5 | 5 | 5 | 5 | |

| fcu | d | 5 | 5 | 10 | 10 | 7.5 | 7.5 | 7.5 | 7.5 | 5 | 10 | 5 | 10 | 7.5 |

| E | 2.33 | 2.33 | 2.33 | 2.33 | 1 | 1 | 3 | 3 | 1 | 1 | 3 | 3 | 2.33 | |

| x | 1 | 9 | 1 | 9 | 1 | 9 | 1 | 9 | 5 | 5 | 5 | 5 | 5 | |

| k | d | 5 | 5 | 10 | 10 | 7.5 | 7.5 | 7.5 | 7.5 | 5 | 10 | 5 | 10 | 7.5 |

| n | 0.01 | 0.01 | 0.01 | 0.01 | 0.0075 | 0.0075 | 0.015 | 0.015 | 0.0075 | 0.0075 | 0.015 | 0.015 | 0.01 | |

| Material | Diameter | Number | Distribution Form |

|---|---|---|---|

| Concrete (C) Acrylic (A) | 5 mm 10 mm | 1 | C/EM/EC |

| 4, 5 | EM/EC | ||

| 9 | C, EM, EC |

| Category | Sum of Squares | Degrees of Freedom | Mean Square Error | F | p Value Pr > F | ||

|---|---|---|---|---|---|---|---|

| Frontal compressive strength | Model | 259.2 | 7 | 37.0 | 25.7 | <0.0001 | Significant |

| Lack of fit | 10.0 | 5 | 2.0 | 2.7 | 0.1815 | Insignificant | |

| Lateral compressive strength | Model | 162.3 | 7 | 23.2 | 28.8 | <0.0001 | Significant |

| Lack of fit | 4.7 | 5 | 0.9 | 1.5 | 0.3698 | Insignificant | |

| Permeable coefficient | Model | 701.4 | 10 | 70.1 | 917.0 | <0.0001 | Significant |

| Lack of fit | 0.3 | 2 | 0.1 | 3.4 | 0.1385 | Insignificant | |

| Statistics Project | Frontal/Lateral Compressive Strength/Permeability Coefficient | Statistics Project | Frontal/Lateral Compressive Strength/Permeability Coefficient |

|---|---|---|---|

| Std. Dev. | 1.20/0.90/0.28 | R-Squared | 0.9524/0.9573/0.9993 |

| Mean | 31.46/35.24/8.47 | Adj R-Squared | 0.9153/0.9240/0.9983 |

| C.V. % | 3.79/2.55/3.27 | Pred R-Squared | 0.7765/0.7445/0.9575 |

| PRESS | 60.82/43.32/29.86 | Adeq Precision | 16.57/22.923/113.46 |

| Coefficient Category | Pipe Material | Diameter/mm | Pipe Position | |||

|---|---|---|---|---|---|---|

| Center (C) c1 | Edge Middle (EM) c2 | Edge Corner (EC) c3 | ||||

| Edge Middle Top (EM-T) c2T | Edge Middle Side (EM-S) c2s | |||||

| Reduction coefficient of frontal compressive strength | Concrete | 5 | 0.9444 | 0.9485 | 0.9453 | |

| 10 | 0.9163 | 0.9453 | 0.9320 | |||

| Acrylic | 5 | 0.9158 | 0.9558 | 0.9375 | ||

| 10 | 0.9313 | 0.9521 | 0.9376 | |||

| Reduction coefficient of lateral compressive strength | Concrete | 5 | 0.9545 | 0.9660 | 0.9568 | 0.9628 |

| 10 | 0.9478 | 0.9589 | 0.9553 | 0.9568 | ||

| Acrylic | 5 | 0.9434 | 1.0245 | 0.9476 | 0.9663 | |

| 10 | 0.9447 | 1.0074 | 0.9407 | 0.9664 | ||

| Pipe Material | Coefficient of Roughness | Diameter/mm | Hydraulic Radius/m | Chezy’s Coefficient C | Head Loss Coefficient along the Way λ |

|---|---|---|---|---|---|

| Concrete | 0.01 | 5 | 0.00125 | 32.82 | 0.07285 |

| 10 | 0.0025 | 36.84 | 0.05782 | ||

| Acrylic | 0.0075 | 5 | 0.00125 | 43.76 | 0.04098 |

| 10 | 0.0025 | 49.12 | 0.03253 |

| Section Number | Section Form | Pipe Diameter/mm | Section Area before Change/mm2 | Section Area after Change/mm2 | Local Head Loss Coefficient |

|---|---|---|---|---|---|

| 1–1 | Sudden shrinkage | 5 | 22,500 | 19.625 | 0.4996 |

| 10 | 22,500 | 78.500 | 0.4983 | ||

| 2–2 | Sudden expansion | 5 | 19.625 | 120,000 | 0.9997 |

| 10 | 78.500 | 120,000 | 0.9987 |

| Pipe Material | Pipe Diameter (mm) | Flow Coefficient μc | Flow Q (cm3/s) | Permeability Coefficient k (mm/s) | Error | ||

|---|---|---|---|---|---|---|---|

| Calculated Value | Actual Value | Absolute Error (mm/s) | Relative Error (%) | ||||

| Concrete | 5 | 0.5276 | 20.773 | 0.692 | 0.724 | 0.032 | 4.420 |

| 10 | 0.5452 | 85.832 | 2.861 | 2.897 | 0.036 | 1.243 | |

| Acrylic | 5 | 0.5668 | 22.312 | 0.744 | 0.754 | 0.010 | 1.326 |

| 10 | 0.5763 | 90.726 | 3.024 | 3.016 | 0.008 | 0.265 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; Zhou, J.; Zhang, Z.; Chen, S. Study on Key Properties and Model Establishment of Innovative Recycled Aggregate Pervious Concrete. Materials 2024, 17, 3535. https://doi.org/10.3390/ma17143535

Zhao P, Zhou J, Zhang Z, Chen S. Study on Key Properties and Model Establishment of Innovative Recycled Aggregate Pervious Concrete. Materials. 2024; 17(14):3535. https://doi.org/10.3390/ma17143535

Chicago/Turabian StyleZhao, Panfeng, Jingfei Zhou, Zhengnan Zhang, and Shoukai Chen. 2024. "Study on Key Properties and Model Establishment of Innovative Recycled Aggregate Pervious Concrete" Materials 17, no. 14: 3535. https://doi.org/10.3390/ma17143535

APA StyleZhao, P., Zhou, J., Zhang, Z., & Chen, S. (2024). Study on Key Properties and Model Establishment of Innovative Recycled Aggregate Pervious Concrete. Materials, 17(14), 3535. https://doi.org/10.3390/ma17143535