Mechanical Properties and Microscopic Study of Recycled Fibre Concrete Based on Wind Turbine Blades

Abstract

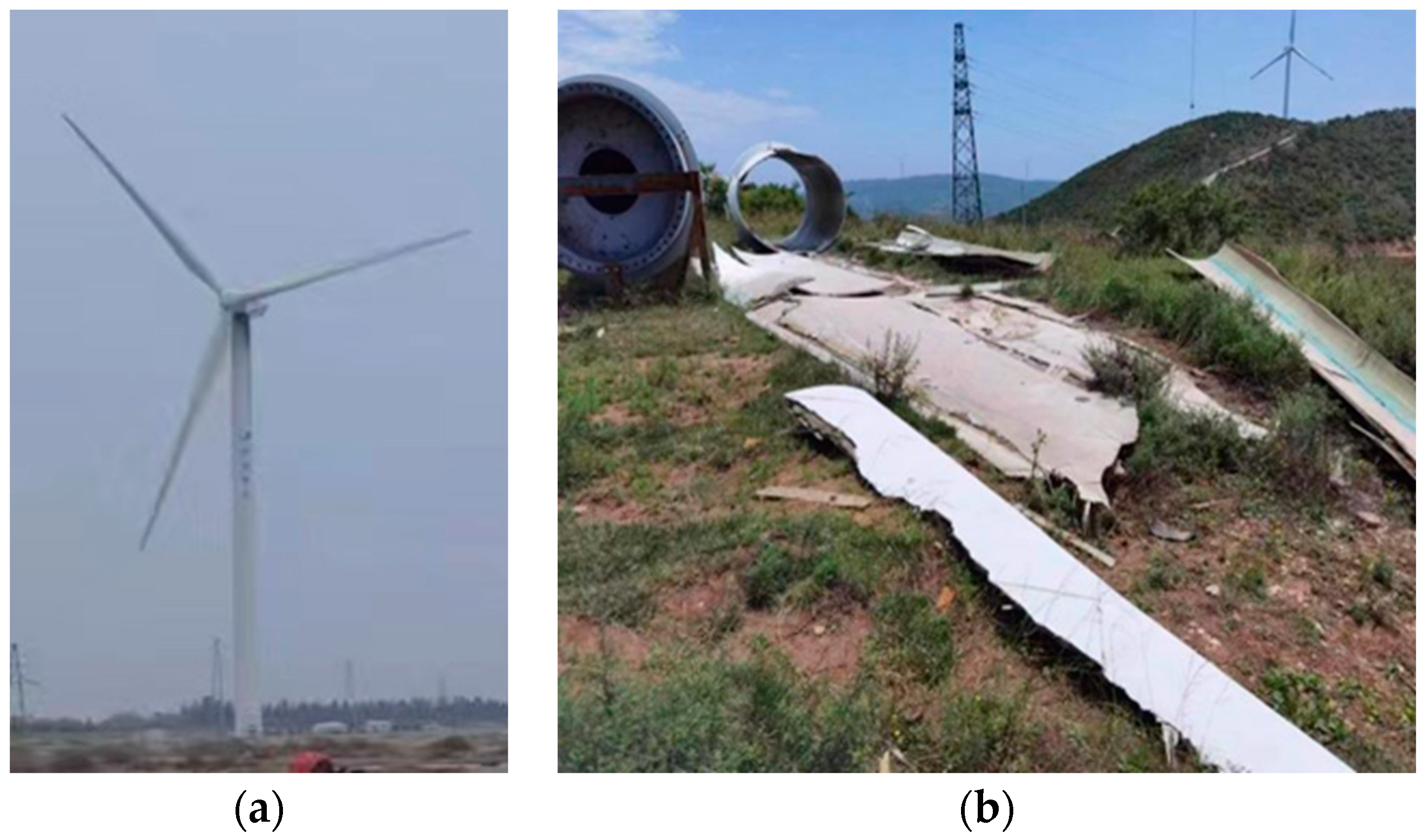

:1. Introduction

2. Materials and Methods

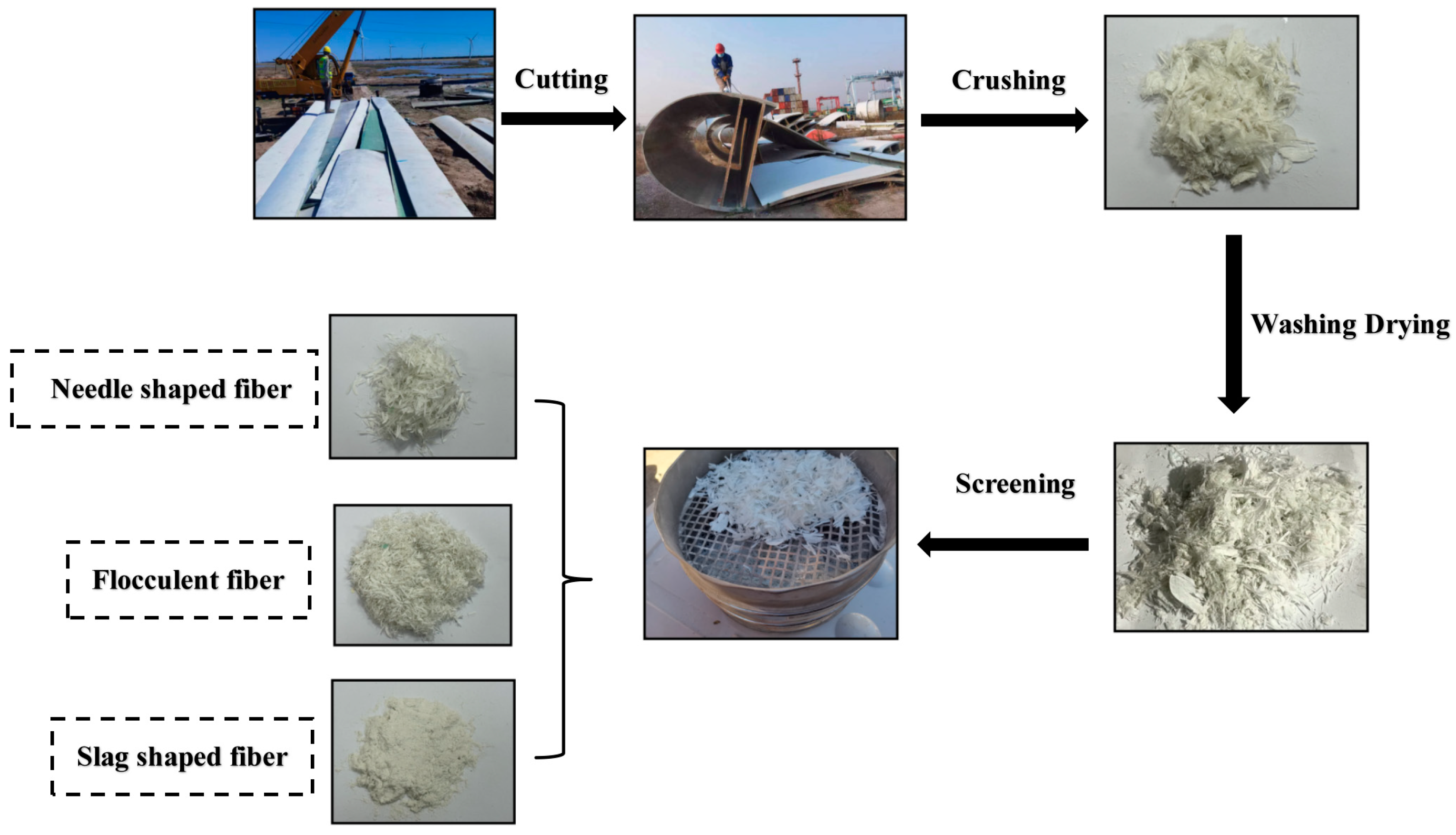

2.1. Methodology for Recovering Fibres from Wind Turbine Blades

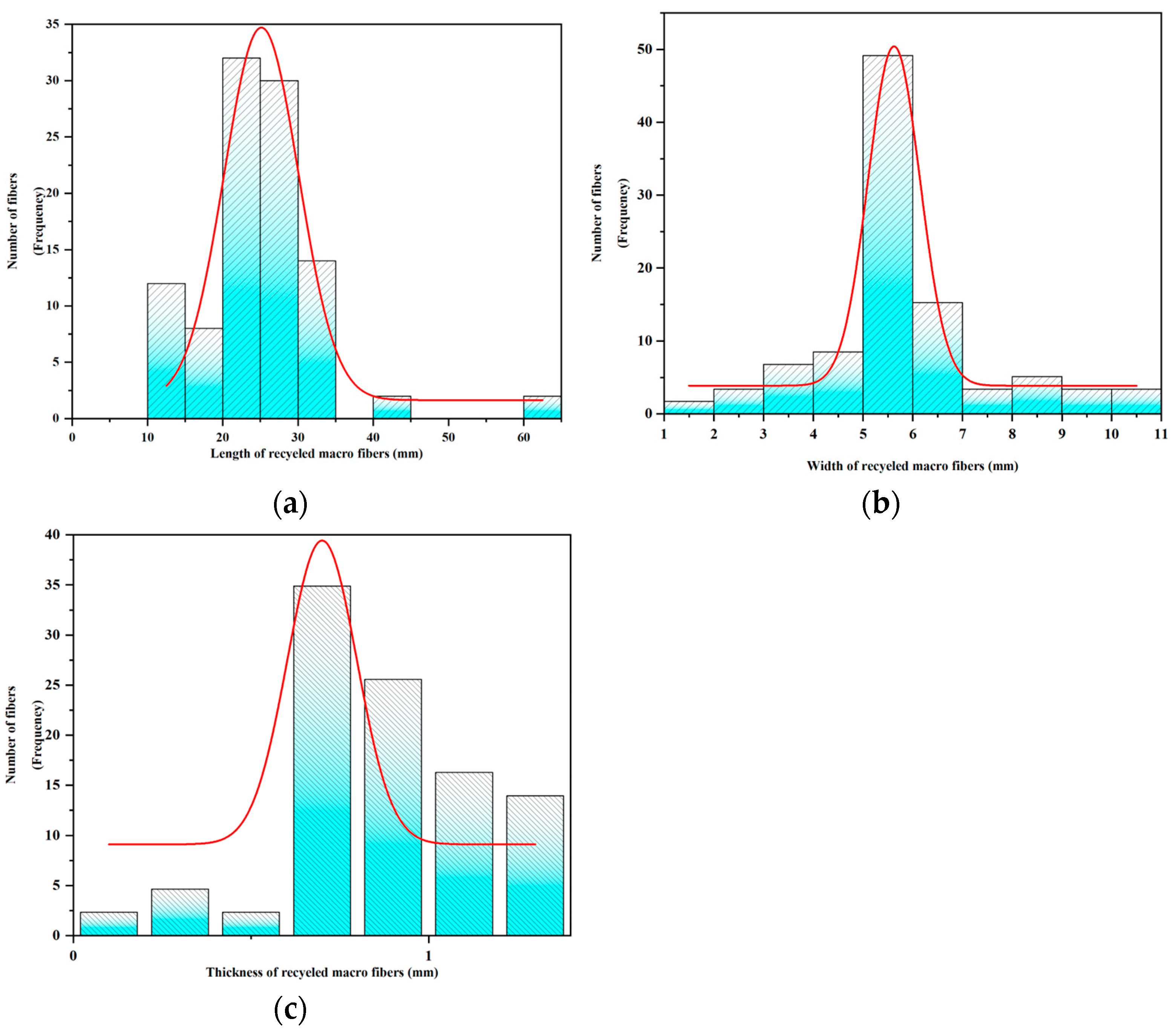

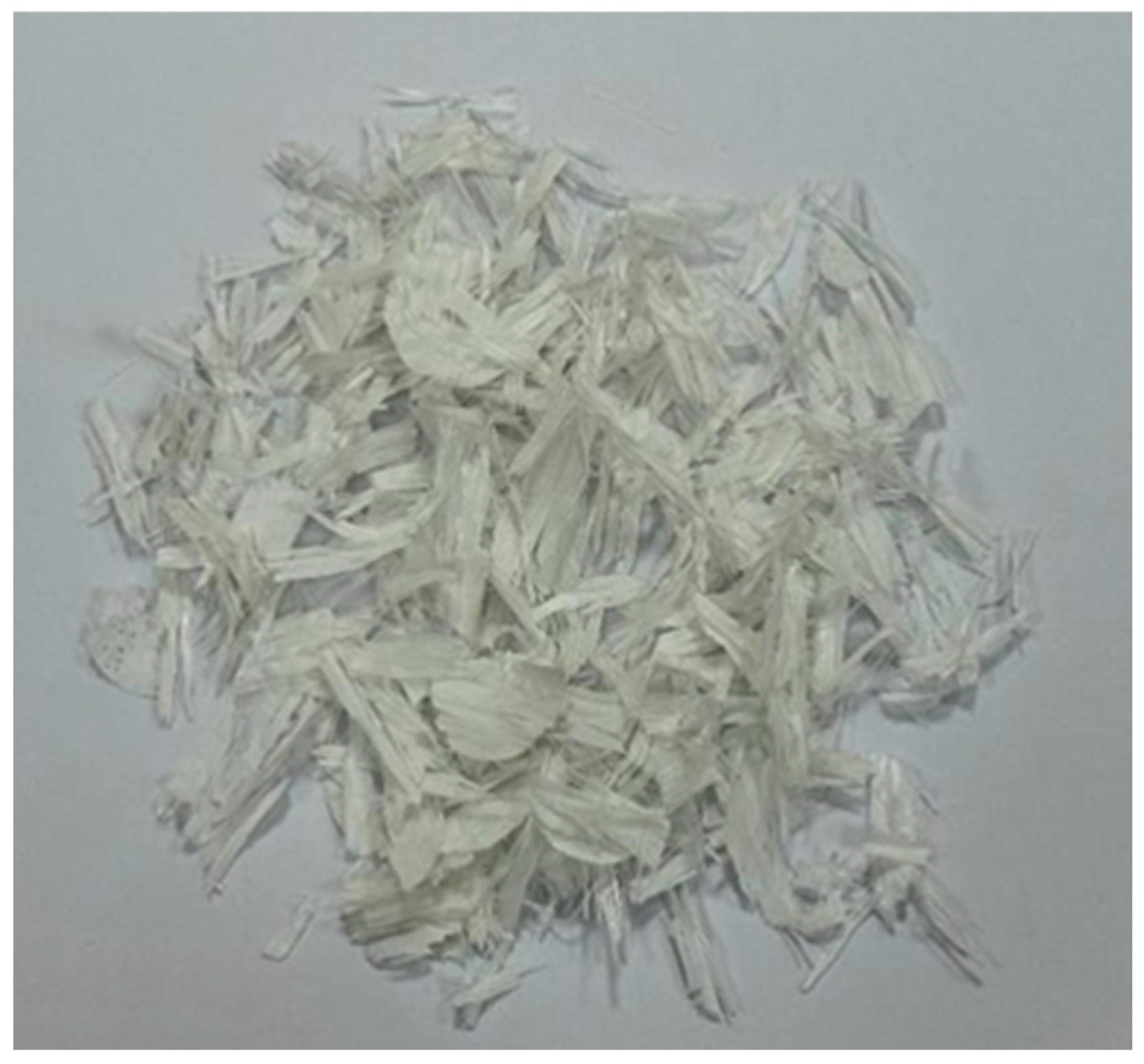

2.2. Materials and Properties

2.3. Mixing Ratio Design

2.4. Specimen Preparation

2.5. Testing Methods

2.6. Intrinsic Model

2.6.1. Recycled Fibre Concrete Intrinsic Modelling

2.6.2. Damage Factor Equation Fitting

3. Results and Discussion

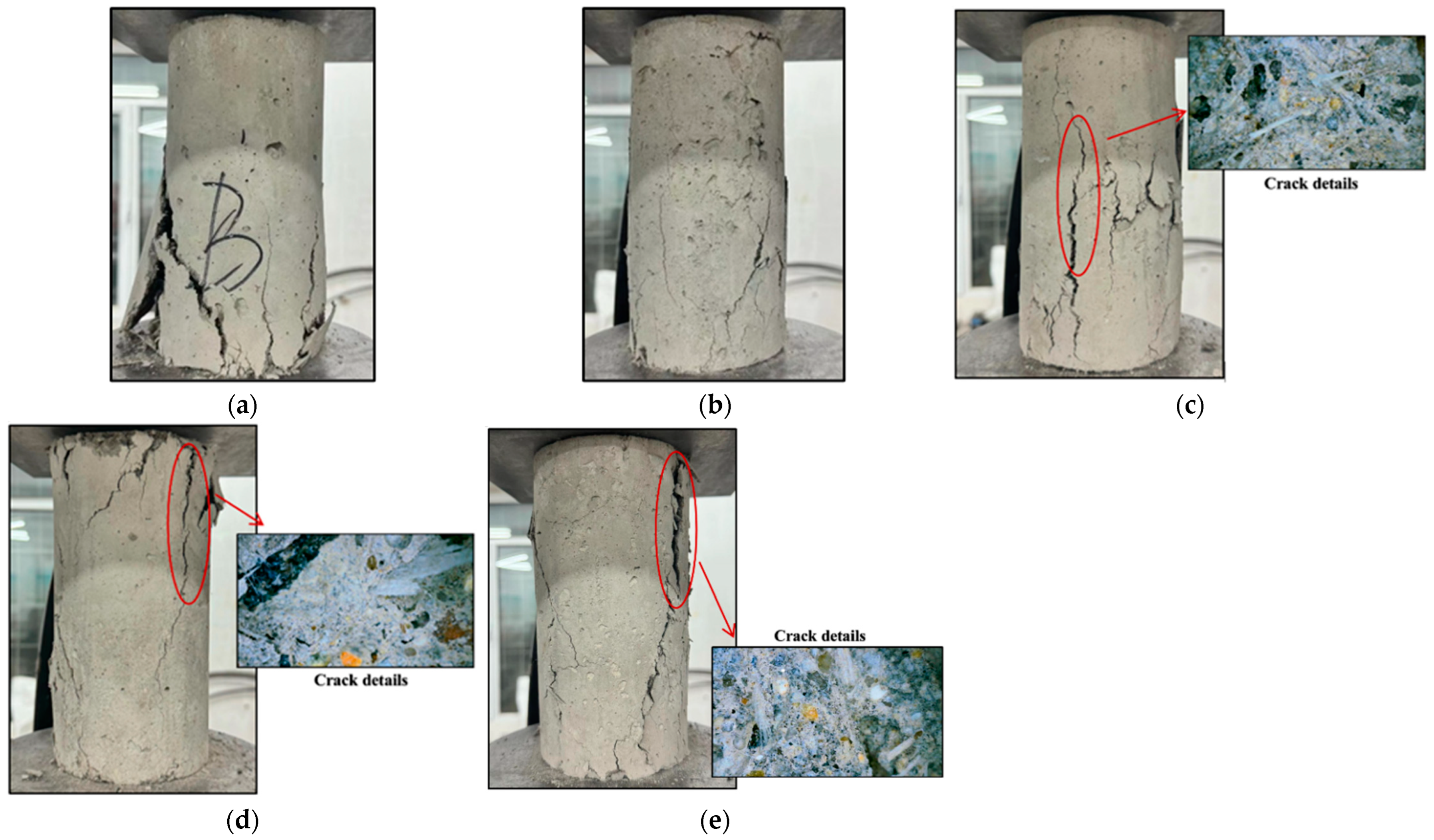

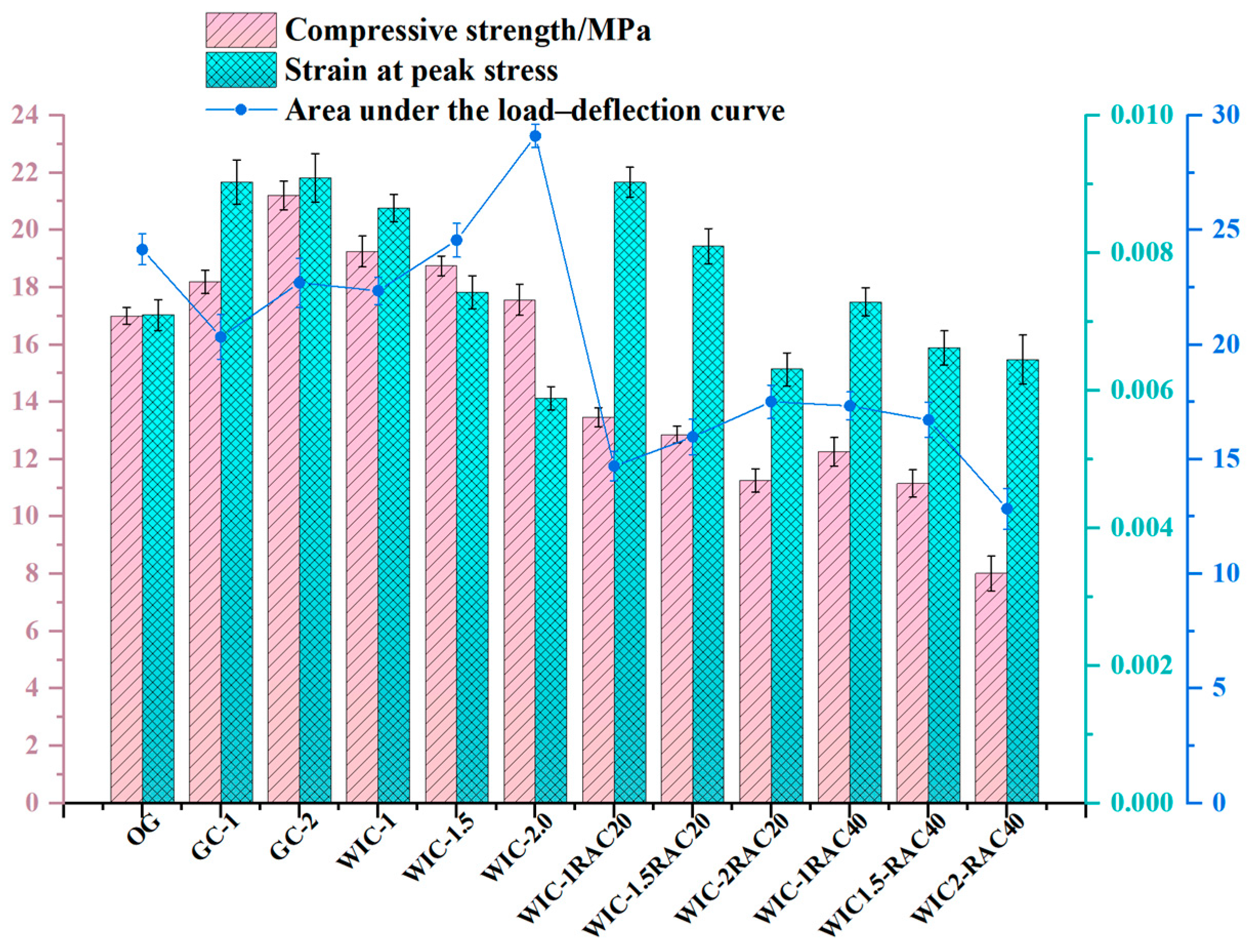

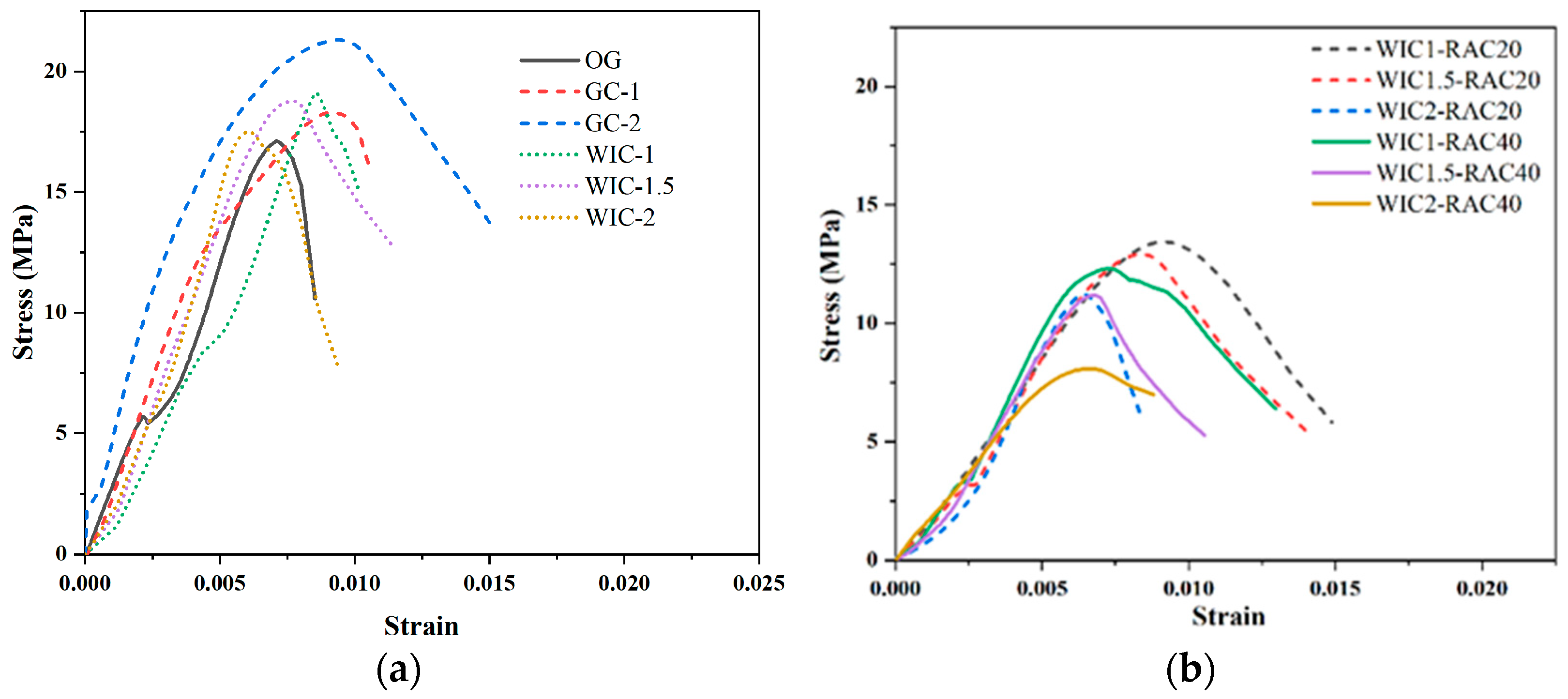

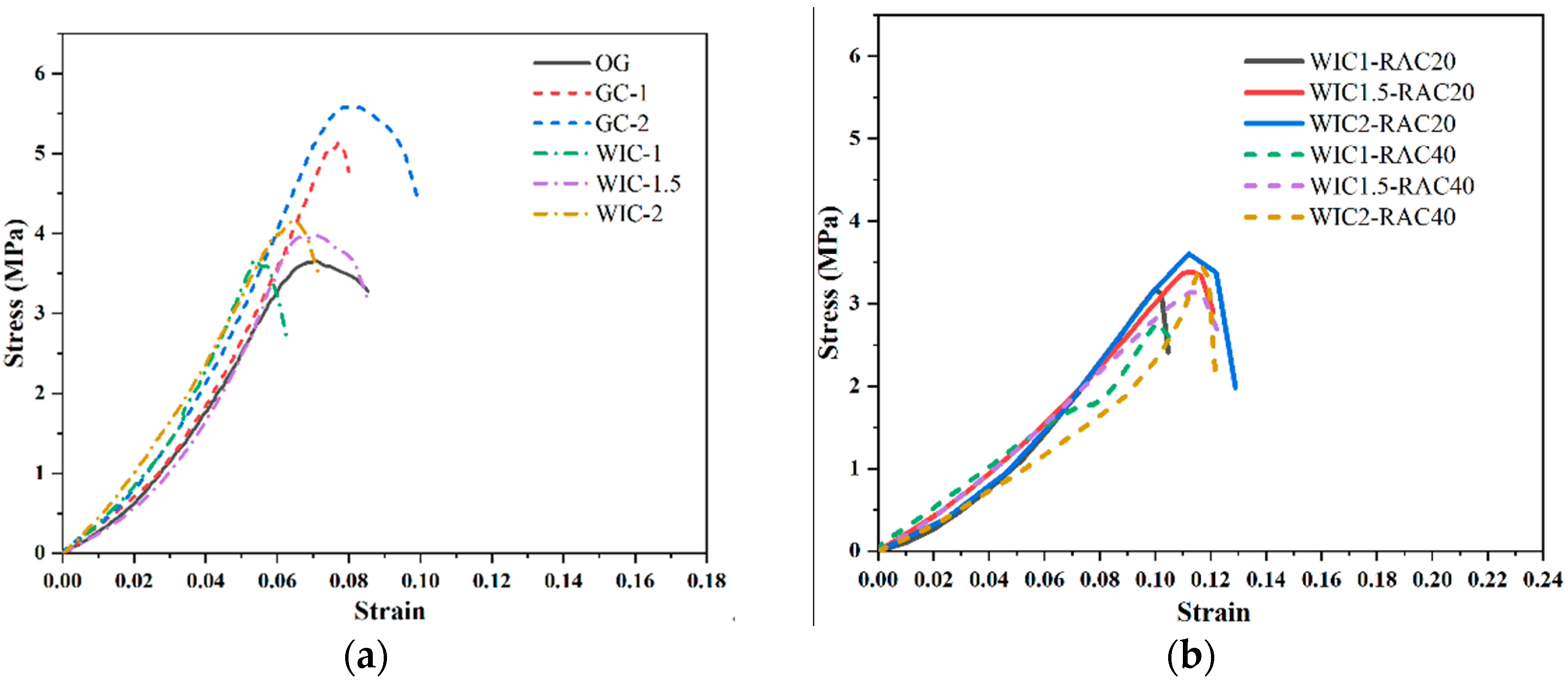

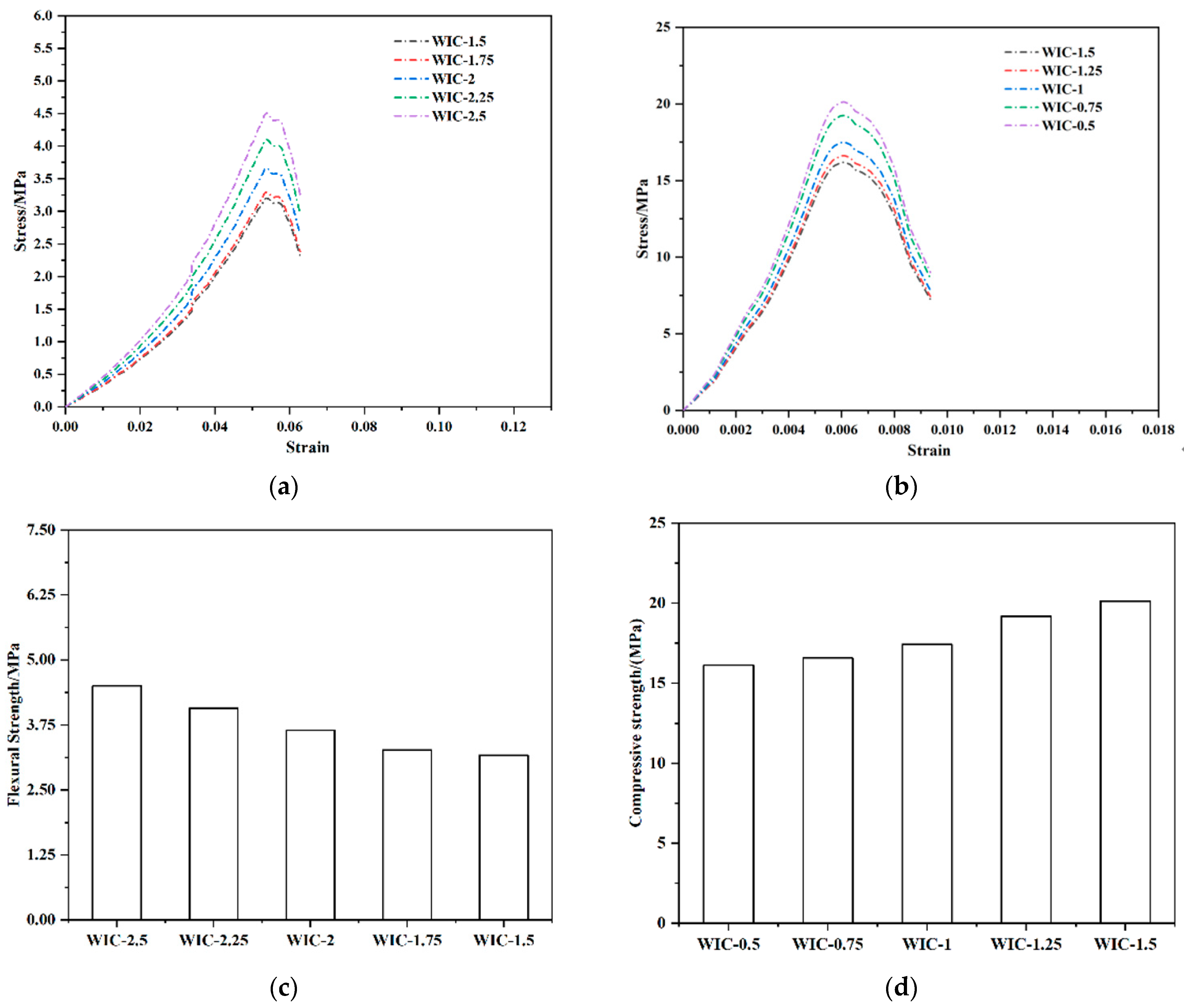

3.1. Compressive Strength

- Low admixture: Macrofibres in concrete have three roles: (1) absorption of little free water, leading to a slight reduction in the water–cement ratio; (2) to restrain the development of cracks; and (3) to introduce a weak interface between the macrofibres and the concrete [21]. In general, if the compressive strength is increased, it should be attributed to the first two effects being stronger than the third; otherwise the strength decreases. When the wind blade fibres are kept at a low admixture (1%) during the fracture process, the needle-like wind blade fibres break due to compressive stresses, and the fibres are distributed longitudinally and horizontally in the concrete, which plays the central reinforcing role. However, the reinforcing effect of wind blade fibres on concrete is also related to interfacial bonding, and the macroscopic properties are analysed from the direct interfacial bonding of the components in the composite. The wind blade fibres are firmly embedded in the cement matrix, and the strongly bonded interface can transfer the stresses to the high-tenacity glass fibres when subjected to external forces, thus increasing the overall strength of the WIC [38].

- Medium dosage: The length of the WIC fibres selected in this experiment was within a specific interval, which was graded to play the role of skeleton support and filler, a better qualitative choice. At the same time, the dosage was not higher, but better; when higher than the appropriate range, too many fibres agglomerate and gather together dramatically impacting the compressive strength [53].

- High dosage: When the dosage is too high, the fibres inside the stress surface are inevitably arranged longitudinally and transversely, and when there are almost no fibres inside the stress surface, the compressive strength is reduced due to internal defects resulting in a reduction in the compressive strength. With the increase in stress, when the direction of the fibres in the matrix is the same as the direction of crack generation, it leads to the further extension and expansion of cracks, which coupled with the doping of fibres produces more pores. The higher the porosity, the faster the decrease in the performance of the composite material, resulting in a rapid decrease in the compressive strength, and the compression curve of the machine test decreases rapidly. Thus, the specimen can be easily crushed [53].

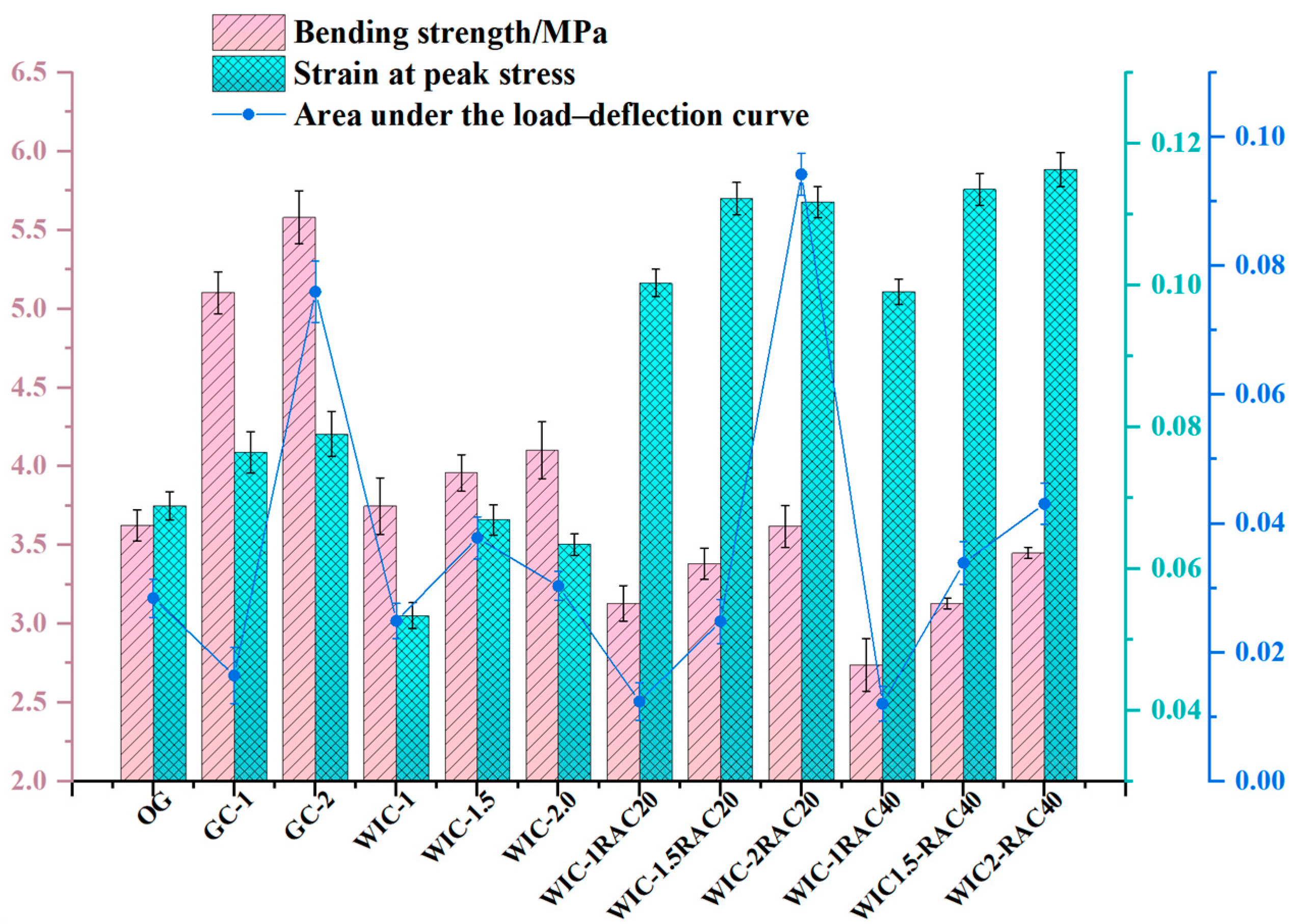

3.2. Flexural Strength

3.3. Microscopic Characterisation

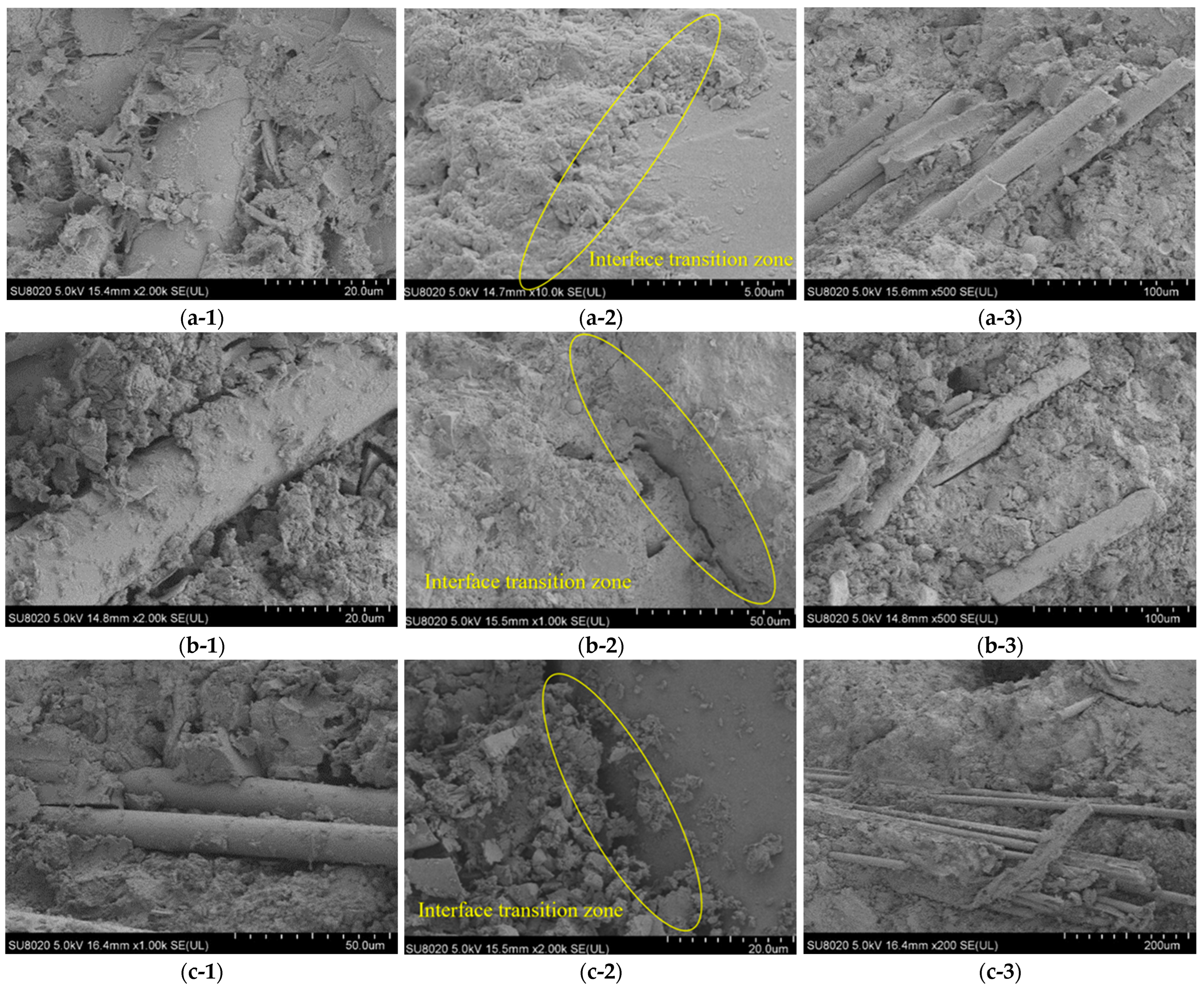

3.3.1. SEM

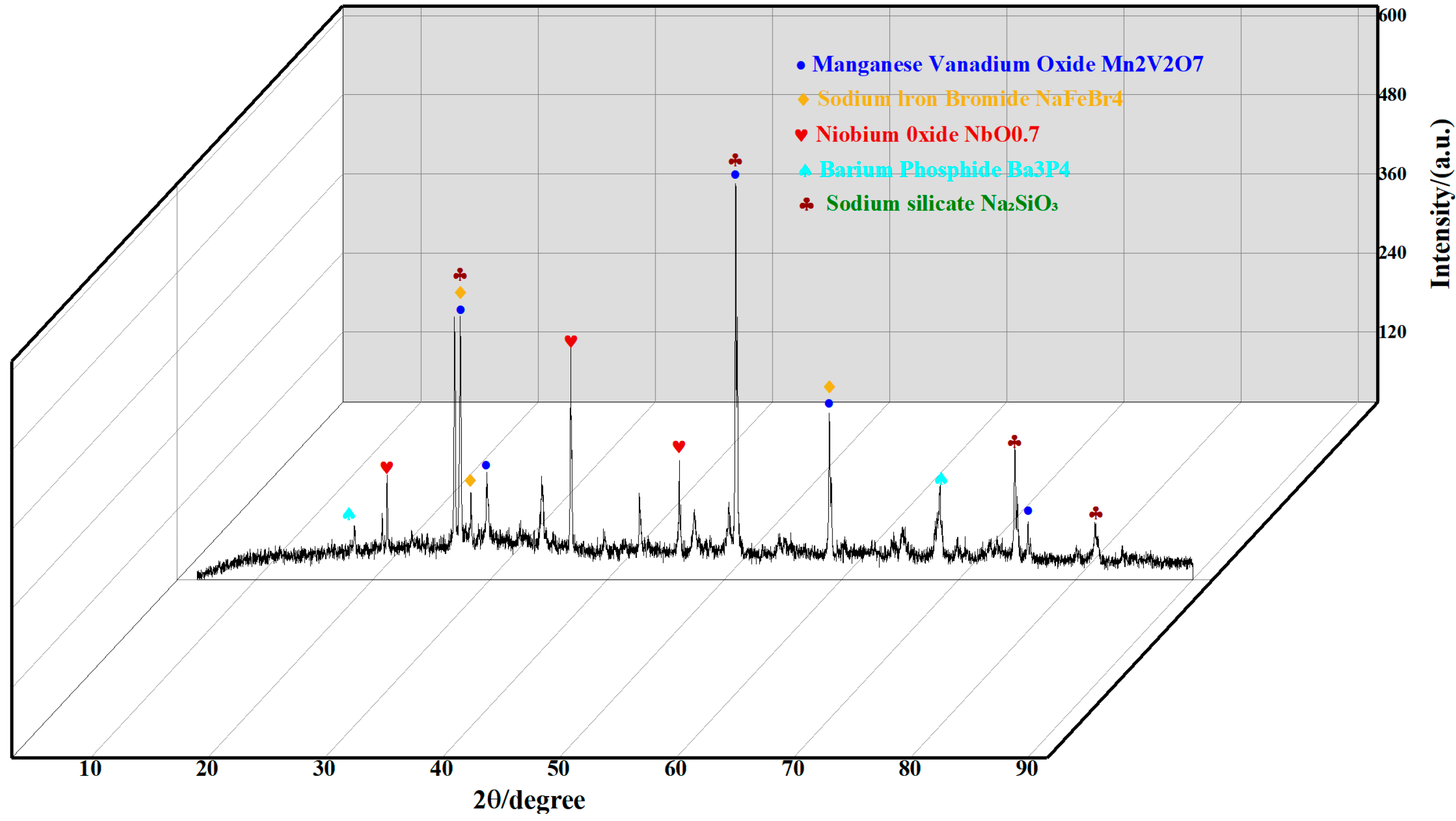

3.3.2. XRD

4. Recycled Concrete Intrinsic Model and Prediction

5. Conclusions

- The compressive strength of concrete was increased by adding an appropriate content of wind blade fibres. With the addition of wind blade fibres, the decreasing branch of the compressive stress–strain curve tends to flatten; so, the higher the addition of wind blade fibres, the higher the toughness. The specimens containing wind blade fibres have ductility compared to the glass fibre group. The compressive strength of GC was found to be higher than that of WIC at a higher admixture (2%); however, the gain in the compressive strength of WIC was better at a lower admixture (1%).

- The wind blade fibres can significantly enhance the flexural strength. The stress–strain curves of the control specimens showed a sharp decrease to zero along the linear ascending branches until the concrete cracked. In contrast, the wind blade fibre specimens showed hardened or softened branches along the linear ascending branches. This characteristic of and the enhancement in the concrete properties tends to be more significant when there is a higher content of wind blade fibres. Although the flexural strength of WIC is lower than that of GC, the strength gain for the plain concrete is up to 18.5%.

- For the peak compressive and flexural strengths, the reinforcing effect of wind blade fibres on concrete is significantly weaker than that of glass fibres. However, the surface of the recycled fibres recovered from wind turbine blades is more likely to have a resin coating, which provides additional slip resistance at the fibre–cement interface and improves the interlocking properties. Thus, the wind blade fibres also have a significant reinforcing effect on plain concrete. The strength of this effect is related to the random distribution of the fibres. This indicates that the effect of WIC fibres is comparable to or better than that of glass fibres in the appropriate dosage range, which proves the feasibility and practicality of the fibres prepared by this recycling method.

- Although recycled aggregates have been studied extensively, the combination of recycled aggregates with recycled fibres is not common. Even when recycled fibres were added to the second-generation RAC, the strength was significantly lower than that of the NAC group. The RCAs derived from the RAC reduced the strength of the concrete, and the gain effect of the fibres was lower than this reduction effect. This informs the subsequent selection of recycling methods for materials.

- The SEM results showed that the high-strength WIC presented a denser and more homogeneous ITZ, and it could be observed that the fibres were tightly bonded to the mortar matrix, with a more pronounced bridging effect; in contrast, fine cracks could be observed in the low-strength WIC, and the ITZ presented a relaxed state. In addition, the wind blade fibres are basically monofibres with a uniform distribution and large specific surface area, which increases the contact area with the matrix and facilitates the ITZ, verifying the gain effect. The XRD analysis results show that the WIC fibres are composed of glass fibres and epoxy resin, with a better alignment of the layer structure with the fibre axis.

- There are still some limitations to this experiment. For example, wind power fibres are organic materials that are usually not alkali-resistant and concrete is alkaline, which may adversely affect the performance. In subsequent studies, methods to address this issue need to be considered, such as selecting suitable reagents, improving the formulation, or chemically modifying the wind power fibres to enhance their stability and durability in alkaline environments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yazdanbakhsh, A.; Bank, L.-C.; Rieder, K.-A.; Tian, Y.; Chen, C. Concrete with discrete slender elements from mechanically recycled wind turbine blades. Resour. Conserv. Recycl. 2018, 128, 11–21. [Google Scholar] [CrossRef]

- Lichtenegger, G.; Rentizelas, A.-A.; Trivyza, N.; Siegl, S. Offshore and onshore wind turbine blade waste material forecast at a regional level in Europe until 2050. Waste Manag. 2020, 106, 120–131. [Google Scholar] [CrossRef] [PubMed]

- Glosser, D.; Santykul, E.; Fagan, E.; Suraneni, P. A thermodynamic perspective on wind turbine glass fiber waste as a supplementary cementitious material. Cement 2022, 9, 100039. [Google Scholar] [CrossRef]

- Ding, G.-K. Sustainable construction—The role of environmental assessment tools. J. Environ. Manag. 2008, 86, 451–464. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Charak, A.; Biligiri, K.-P.; Pandurangan, V. Glass and carbon fiber reinforced polymer composite wastes in pervious concrete: Material characterization and lifecycle assessment. Resour. Conserv. Recycl. 2022, 182, 106304. [Google Scholar] [CrossRef]

- Li, G.; Yin, B.-B.; Zhang, L.-W.; Liew, K.-M. Modeling microfracture evolution in heterogeneous composites: A coupled cohesive phase-field model. J. Mech. Phys. Solids 2020, 142, 103968. [Google Scholar] [CrossRef]

- Beauson, J.; Lilholt, H.; Brøndsted, P. Recycling solid residues recovered from glass fibre-reinforced composites–A review applied to wind turbine blade materials. J. Reinf. Plast. Compos. 2014, 33, 1542–1556. [Google Scholar] [CrossRef]

- Wu, H.; Gao, J.; Liu, C.; Guo, Z.; Luo, X. Reusing waste clay brick powder for low-carbon cement concrete and alkali-activated concrete: A critical review. J. Clean. Prod. 2024, 449, 141755. [Google Scholar] [CrossRef]

- Wu, H.; Gao, J.; Liu, C.; Luo, X.; Chen, G. Combine use of 100% thermoactivated recycled cement and recycled aggregate for fully recycled mortar: Properties evaluation and modification. J. Clean. Prod. 2024, 450, 141841. [Google Scholar] [CrossRef]

- Liu, M.; Hu, R.; Zhang, Y.; Wang, C.; Ma, Z. Effect of ground concrete waste as green binder on the micro-macro properties of eco-friendly metakaolin-based geopolymer mortar. J. Build. Eng. 2023, 68, 106191. [Google Scholar] [CrossRef]

- Mamanpush, S.-H.; Li, H.; Englund, K.; Tabatabaei, A.-T. Recycled wind turbine blades as a feedstock for second generation composites. Waste Manag. 2018, 76, 708–714. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural reuse of high end composite products: A design case study on wind turbine blades. Resour. Conserv. Recycl. 2021, 167, 105393. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.; Ni, A. Recycling and reuse of composite materials for wind turbine blades: An overview. J. Reinf. Plast. Compos. 2019, 38, 567–577. [Google Scholar] [CrossRef]

- Psomopoulos, C.-S.; Kalkanis, K.; Kaminaris, S.; Ioannidis, G.-C.; Pachos, P. A review of the potential for the recovery of wind turbine blade waste materials. Recycling 2019, 4, 7. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Beauson, J.; Madsen, B.; Toncelli, C.; Brøndsted, P.; Bech, J.-I. Recycling of shredded composites from wind turbine blades in new thermoset polymer composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 390–399. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Tahir, M.; Fayazbakhsh, K.; Lessard, L. Tensile properties and interfacial shear strength of recycled fibers from wind turbine waste. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105786. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Ortega-López, V.; Manso, J.-M. Raw-crushed wind-turbine blade: Waste characterization and suitability for use in concrete production. Resour. Conserv. Recycl. 2023, 198, 107160. [Google Scholar] [CrossRef]

- Baturkin, D.; Hisseine, O.-A.; Masmoudi, R.; Tagnit-Hamou, A.; Massicotte, L. Valorization of recycled FRP materials from wind turbine blades in concrete. Resour. Conserv. Recycl. 2021, 174, 105807. [Google Scholar] [CrossRef]

- Peng, K.-D.; Huang, B.-T.; Xu, L.-Y.; Hu, R.-L.; Dai, J.-G. Flexural strengthening of reinforced concrete beams using geopolymer-bonded small-diameter CFRP bars. Eng. Struct. 2022, 256, 113992. [Google Scholar] [CrossRef]

- Fu, B.; Liu, K.-C.; Chen, J.-F.; Teng, J.-G. Concrete reinforced with macro fibres recycled from waste GFRP. Constr. Build. Mater. 2021, 310, 125063. [Google Scholar] [CrossRef]

- Xu, G.-T.; Liu, M.-J.; Xiang, Y.; Fu, B. Valorization of macro fibers recycled from decommissioned turbine blades as discrete reinforcement in concrete. J. Clean. Prod. 2022, 379, 134550. [Google Scholar] [CrossRef]

- Yuan, H.; Fu, X.-H.; Fan, Y.-C.; Fu, B.; Zou, Q.-Q. Flexural performance of layered macro fiber reinforced concrete beams. Constr. Build. Mater. 2022, 357, 129314. [Google Scholar] [CrossRef]

- Akbar, A.; Liew, K.-M. Assessing recycling potential of carbon fiber reinforced plastic waste in production of eco-efficient cement-based materials. J. Clean. Prod. 2020, 274, 123001. [Google Scholar] [CrossRef]

- Lin, L.; Wu, B. Fracture and flexural behaviors of recycled lump-aggregate concrete. Constr. Build. Mater. 2023, 393, 132104. [Google Scholar] [CrossRef]

- Kim, J.; Nciri, N.; Sicakova, A.; Kim, N. Characteristics of waste concrete powders from multi-recycled coarse aggregate concrete and their effects as cement replacements. Constr. Build. Mater. 2023, 398, 132525. [Google Scholar] [CrossRef]

- Zhang, M.; Zhu, L.; Gao, S.; Dong, Y.; Yuan, H. Mechanical properties of recycled aggregate concrete prepared from waste concrete treated at high temperature. J. Build. Eng. 2023, 76, 107045. [Google Scholar] [CrossRef]

- Kim, J. Construction and demolition waste management in Korea: Recycled aggregate and its application. Clean Technol. Environ. Policy 2021, 23, 2223–2234. [Google Scholar] [CrossRef]

- Poon, C.-S.; Shui, Z.-H.; Lam, L. Strength of concretes prepared with natural and recycled aggregates at different moisture conditions. In Advances in Building Technology; Elsevier: Amsterdam, The Netherlands, 2002; pp. 1407–1414. [Google Scholar]

- Deng, Z.; Wang, Y.; Sheng, J.; Hu, X. Strength and deformation of recycled aggregate concrete under triaxial compression. Constr. Build. Mater. 2017, 156, 1043–1052. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, J.; Tang, Y.; Duan, Z.; Poon, C.-S. Long-term shrinkage and mechanical properties of fully recycled aggregate concrete: Testing and modelling. Cem. Concr. Compos. 2022, 130, 104527. [Google Scholar] [CrossRef]

- Xu, F.; Wang, S.; Li, T.; Liu, B.; Li, B.; Zhou, Y. Mechanical properties and pore structure of recycled aggregate concrete made with iron ore tailings and polypropylene fibers. J. Build. Eng. 2021, 33, 101572. [Google Scholar] [CrossRef]

- Hossain, F.-Z.; Shahjalal, M.; Islam, K.; Tiznobaik, M.; Alam, M.-S. Mechanical properties of recycled aggregate concrete containing crumb rubber and polypropylene fiber. Construct. Build. Mater. 2019, 225, 983–996. [Google Scholar] [CrossRef]

- Zhu, L.; Wen, T.; Tian, L. Size effects in compressive and splitting tensile strengths of polypropylene fiber recycled aggregate concrete. Construct. Build. Mater. 2022, 341, 127878. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, P.; Ma, M. Mechanical properties and meso-microscopic mechanism of basalt fiber-reinforced recycled aggregate concrete. J. Clean. Prod. 2022, 370, 133555. [Google Scholar] [CrossRef]

- Chen, Y.; He, Q.; Liang, X.; Chen, Z.; Li, H. Experimental investigation on mechanical properties of steel fiber reinforced recycled aggregate concrete under uniaxial cyclic compression. Constr. Build. Mater. 2023, 387, 131616. [Google Scholar] [CrossRef]

- Del Bosque, I.-S.; Zhu, W.; Howind, T.; Matías, A.; De Rojas, M.-S.; Medina, C. Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef]

- Liu, M. Research on the Application of FRP Waste Slag in Wood-Plastic Composite Materials. Master’s Thesis, University of Jinan, Jinan, China, 2022. [Google Scholar]

- Zhang, J.; Chevali, V.-S.; Wang, H.; Wang, C.-H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Tang, J.; Swolfs, Y.; Longana, M.-L.; Yu, H.; Wisnom, M.-R.; Lomov, S.-V.; Gorbatikh, L. Hybrid composites of aligned discontinuous carbon fibers and self-reinforced polypropylene under tensile loading. Compos. Part A Appl. Sci. Manuf. 2019, 123, 97–107. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard Test Methods for Physical and Mechanical Properties of Concrete. China Architecture & Building Press: Beijing, China, 2019.

- JGJ 52-2006; Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2006.

- CNS1233-1984; Test Method for Flexural Strength of Concrete (Three-Point Load Method). Taiwan Local Standards: Taipei, Taiwan, 1984.

- Dong, Z.; Wu, G.; Zhao, X.-L.; Zhu, H.; Wei, Y.; Yan, Z. Mechanical properties of discrete BFRP needles reinforced seawater sea-sand concrete-filled GFRP tubular stub columns. Constr. Build. Mater. 2020, 244, 118330. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, Y.-W.; Li, F. Dynamic mechanical properties and constitutive model of polypropylene fibre concrete under high strain rate. J. Cent. South Univ. (Nat. Sci. Ed.) 2013, 44, 3464–3473. [Google Scholar]

- Wang, Y.; Jin, H.; Demartino, C.; Chen, W.; Yu, Y. Mechanical properties of SFRC: Database construction and model prediction. Case Stud. Constr. Mater. 2022, 17, e01484. [Google Scholar] [CrossRef]

- Dong, Y.; Xie, H.; Li, S. Continuum damage mechanics constitutive model of concrete under compression. Eng. Mech. 1996, 13, 44–53. [Google Scholar]

- Ji, Y.; Wang, D. Constitutive model of waste brick concrete based on Weibull strength theory. Case Stud. Constr. Mater. 2023, 18, e01738. [Google Scholar] [CrossRef]

- Lemaitre, J. How to use damage mechanics. Nucl. Eng. Des. 1984, 80, 233–245. [Google Scholar] [CrossRef]

- Yu, S. Damage Mechanics; Tsinghua University Press: Beijing, China, 1997; pp. 26–32. [Google Scholar]

- Shen, M.-Y.; Guo, Z.-H.; Feng, W.-T. A study on the characteristics and thermal properties of modified regenerated carbon fiber reinforced thermoplastic composite recycled from waste wind turbine blade spar. Compos. Part B Eng. 2023, 264, 110878. [Google Scholar] [CrossRef]

- Senff, L.; Novais, R.-M.; Carvalheiras, J.; Labrincha, J.-A. Eco-friendly approach to enhance the mechanical performance of geopolymer foams: Using glass fibre waste coming from wind blade production. Constr. Build. Mater. 2020, 239, 117805. [Google Scholar] [CrossRef]

- Yang, L.; Wang, D.; Wang, J.; Liu, H.; Wang, D.; Wang, C. Effect of waste wind turbine blade fiber on the properties of phosphate-building gypsum. Non-Met. Mines 2021, 44, 4. [Google Scholar]

- Wang, D.; Lu, C.; Zhu, Z.; Zhang, Z.; Liu, S.; Ji, Y.; Xing, Z. Mechanical performance of recycled aggregate concrete in green civil engineering. Case Stud. Constr. Mater. 2023, 19, e02384. [Google Scholar] [CrossRef]

- You, X.-M.; Lin, L.-B.; Fu, B.; Xiang, Y. Ultra-high performance concrete reinforced with macro fibres recycled from waste GFRP composites. Case Stud. Constr. Mater. 2023, 18, e02120. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Miliket, T.-A.; Ageze, M.-B.; Tigabu, M.-T.; Zeleke, M.-A. Experimental characterizations of hybrid natural fiber-reinforced composite for wind turbine blades. Heliyon 2022, 8, e09092. [Google Scholar] [CrossRef]

- Verian, K.-P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production, Resources. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Cheng, Z. Application Research of wind power blade waste in fiber cement board. Jiangxi Build. Mater. 2023, 1, 51–53. [Google Scholar]

- Zhou, B.; Zhang, M.; Wang, L.; Ma, G. Experimental study on mechanical property and microstructure of cement mortar reinforced with elaborately recycled GFRP fiber. Cem. Concr. Compos. 2021, 117, 103908. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Zhu, H. Mechanical properties of seawater sea-sand concrete reinforced with discrete BFRP-Needles. Constr. Build. Mater. 2019, 206, 432–441. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Branner, K.; Petersen, H.-N.; Beauson, J.; McGugan, M.; Sørensen, B.-F. Materials for wind turbine blades: An overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed]

- Brydson, J.A. (Ed.) 26—Epoxide resins. In Plastics Materials, 7th ed.; Butterworth-Heinemann: Oxford, UK, 1999; pp. 744–777. [Google Scholar]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of fiberglass wind turbine blades into reinforced filaments for use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, Q.; Pacheco-Torgal, F.; Zhang, Y. Hybrid effect of basalt fiber textile and macro polypropylene fiber on flexural load-bearing capacity and toughness of two-way concrete slabs. Constr. Build. Mater. 2020, 261, 119881. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Z.-H.; Ma, W.-J.; Ma, Q.-S. Influence of heat treatment on physical–chemical properties of PAN-based carbon fiber. Ceram. Int. 2006, 32, 291–295. [Google Scholar] [CrossRef]

| Standard Consistency Water Consumption/% | Density/(g/cm3) | Heat Loss/% | Solidification Time/min | Stability | Flexural Strength/MPa | ||

|---|---|---|---|---|---|---|---|

| Initial | Final | 3 Day | 28 Day | ||||

| 28.2 | 3.11 | 3.76 | 165 | 305 | eligible | 5.5 | 8.6 |

| C3S | C2S | C4AF | C3A | f-MgO | f-CaO | Else |

|---|---|---|---|---|---|---|

| 60.3 | 19.3 | 8.6 | 7.0 | 2.0 | 0.7 | 2.1 |

| Crushed Stone Specifications/mm | Bulk Density/(kg/m3) | Apparent Density/ (kg/m3) | Crushing Value/% | Granule Content of Needle Chips/% | Porosity/% | Mud Content/% |

|---|---|---|---|---|---|---|

| 5–26.5 | 1460 | 2661 | 11.2 | 4.2 | 43 | 0.6 |

| Raw Materials | Apparent Density/(kg/m3) | Capacity/(kg/m3) | Water Absorption/% | Crush Value/% |

|---|---|---|---|---|

| Natural medium-grained Sand | 2689 | 1655 | 0.51 | / |

| RCA | 2603 | 1408 | 6.7 | 14.9 |

| Length/mm | Width/mm | Thickness/mm | Aspect Ratio |

|---|---|---|---|

| 25.6 | 5.2 | 0.65 | 5.6 |

| Density/(g·cm3) | Line Density/dtex | Calibre/μm | Length/mm | Tensile Strength/MPa | Rupture Expansion Rate/% | Tensile Modulus/GPa |

|---|---|---|---|---|---|---|

| 2.7 | 78 | 15 | 3, 6, 9, 12 | 2000 | 2.5 | 75 |

| Original Concrete | OG |

|---|---|

| Glass fibre (1%) concrete | GC-1 |

| Glass fibre (2%) concrete | GC-2 |

| Wind blade recycled fibre (1%) concrete | WIC-1 |

| Wind blade recycled fibre (1.5%) concrete | WIC-1.5 |

| Wind blade recycled fibre (2%) concrete | WIC-2 |

| Wind blade fibre (1%) recycled aggregate (20%) concrete | WIC-1RAC20 |

| Wind blade fibre (1.5%) recycled aggregate (20%) concrete | WIC-1.5RAC20 |

| Wind blade fibre (2%) recycled aggregate (20%) concrete | WIC-2RAC20 |

| Wind blade fibre (1%) recycled aggregate (40%) concrete | WIC-1RAC40 |

| Wind blade fibre (1.5%) recycled aggregate (40%) concrete | WIC-1.5RAC40 |

| Wind blade fibre (2%) recycled aggregate (40%) concrete | WIC-2RAC40 |

| Groups | Water/(kg/m3) | Cement/(kg/m3) | Coarse Aggregates (5–10 mm)/(kg/m3) | Coarse Aggregates (10–20 mm)/(kg/m3) | RCA/(kg/m3) | Natural Medium Sand/(kg/m3) | Fibre/(g) |

|---|---|---|---|---|---|---|---|

| OG | 195 | 487 | 341 | 797 | - | 613 | 0 |

| GC-1 | 195 | 487 | 341 | 797 | - | 613 | 315.33 |

| GC-2 | 195 | 487 | 341 | 797 | - | 613 | 637.27 |

| WIC-1 | 195 | 487 | 341 | 797 | - | 613 | 315.33 |

| WIC-1.5 | 195 | 487 | 341 | 797 | - | 613 | 478.13 |

| WIC-2 | 195 | 487 | 341 | 797 | - | 613 | 637.27 |

| WIC-1RAC20 | 195 | 487 | 341 | 797 | 153.5 | 613 | 315.33 |

| WIC-1.5RAC20 | 195 | 487 | 341 | 797 | 153.5 | 613 | 478.13 |

| WIC-2RAC20 | 195 | 487 | 341 | 797 | 153.5 | 613 | 637.27 |

| WIC-1RAC40 | 195 | 487 | 341 | 797 | 408.5 | 613 | 315.33 |

| WIC-1.5RAC40 | 195 | 487 | 341 | 797 | 408.5 | 613 | 478.13 |

| WIC-2RAC40 | 195 | 487 | 341 | 797 | 408.5 | 613 | 637.27 |

| Type | fc (MPa) | εc (%) | Em (GPa) |

|---|---|---|---|

| OG | 16.56 | 0.0071 | 24.15 |

| GC-1 | 18.19 | 0.00903 | 20.34 |

| GC-2 | 21.21 | 0.00909 | 22.7 |

| WIC-1 | 19.25 | 0.00865 | 22.35 |

| WIC-1.5 | 18.75 | 0.00743 | 24.56 |

| WIC-2.0 | 17.56 | 0.00589 | 29.1 |

| WIC-1RAC20 | 13.47 | 0.00903 | 14.7 |

| WIC-1.5RAC20 | 12.86 | 0.00810 | 15.98 |

| WIC-2RAC20 | 11.26 | 0.00631 | 17.51 |

| WIC-1RAC40 | 12.26 | 0.00729 | 17.33 |

| WIC-1.5RAC40 | 11.154 | 0.00662 | 16.72 |

| WIC-2RAC40 | 8.017 | 0.00645 | 12.84 |

| Type | fc (MPa) | εc (%) | Toughness (J) |

|---|---|---|---|

| OG | 3.625 | 0.0689 | 0.02842 |

| GC-1 | 5.102 | 0.0764 | 0.01641 |

| GC-2 | 5.58 | 0.0790 | 0.07599 |

| WIC-1 | 3.748 | 0.0534 | 0.0249 |

| WIC-1.5 | 3.958 | 0.0669 | 0.03778 |

| WIC-2.0 | 4.15 | 0.0634 | 0.03029 |

| WIC1-RAC20 | 3.13 | 0.1003 | 0.01241 |

| WIC1.5-RAC20 | 3.38 | 0.1122 | 0.02481 |

| WIC2-RAC20 | 3.618 | 0.1117 | 0.09423 |

| WIC1-RAC40 | 2.739 | 0.0991 | 0.01203 |

| WIC1.5-RAC40 | 3.13 | 0.1135 | 0.03388 |

| WIC2-RAC40 | 3.45 | 0.1163 | 0.04305 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, C.; Ji, Y.; Qie, R.; Wang, D.; Liu, G. Mechanical Properties and Microscopic Study of Recycled Fibre Concrete Based on Wind Turbine Blades. Materials 2024, 17, 3565. https://doi.org/10.3390/ma17143565

Wang J, Wang C, Ji Y, Qie R, Wang D, Liu G. Mechanical Properties and Microscopic Study of Recycled Fibre Concrete Based on Wind Turbine Blades. Materials. 2024; 17(14):3565. https://doi.org/10.3390/ma17143565

Chicago/Turabian StyleWang, Jiajing, Chenghao Wang, Yongcheng Ji, Ruihang Qie, Dayang Wang, and Guanxun Liu. 2024. "Mechanical Properties and Microscopic Study of Recycled Fibre Concrete Based on Wind Turbine Blades" Materials 17, no. 14: 3565. https://doi.org/10.3390/ma17143565