In Situ Prediction of Microstructure and Mechanical Properties in Laser-Remelted Al-Si Alloys: Towards Enhanced Additive Manufacturing

Abstract

1. Introduction

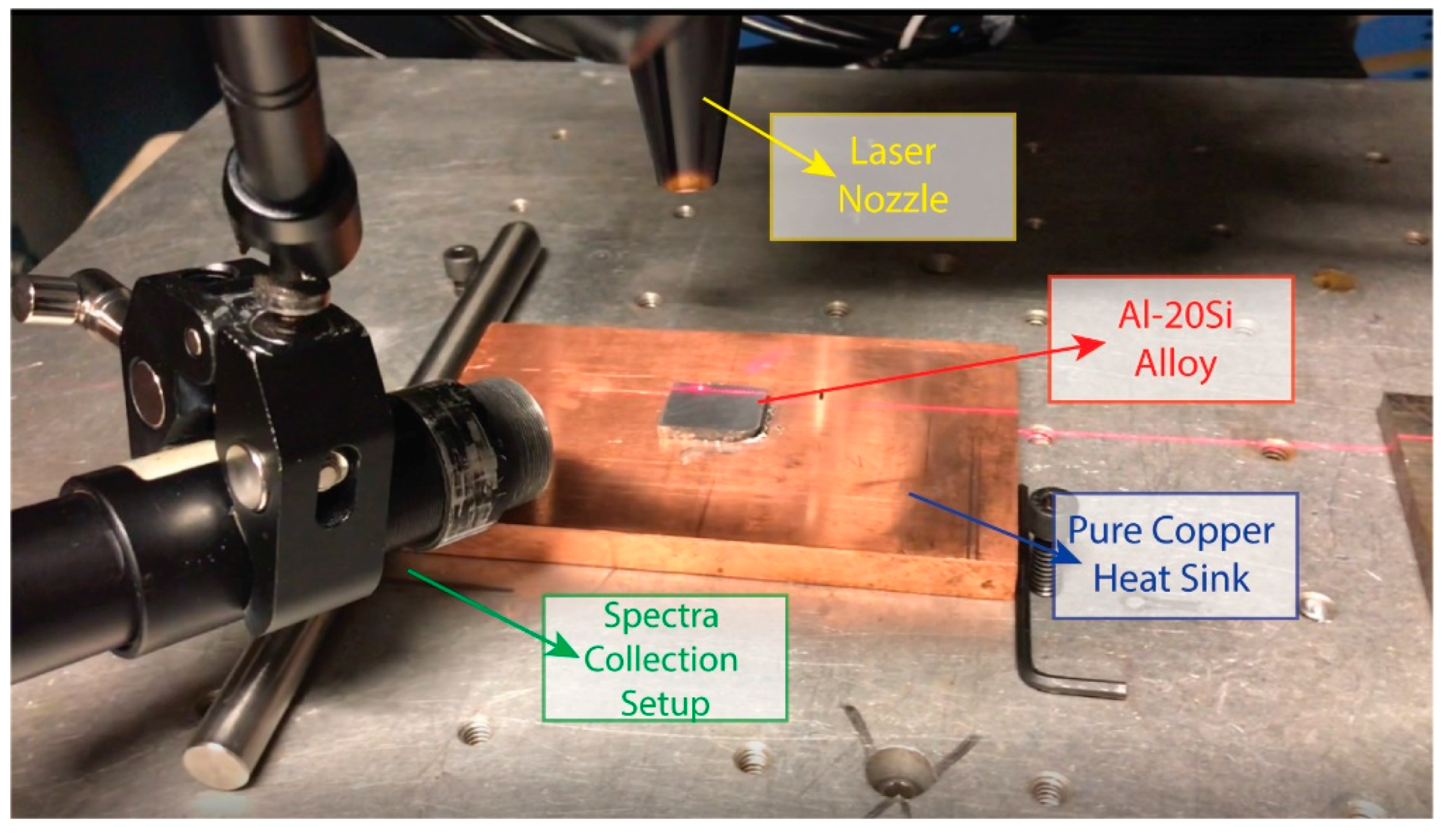

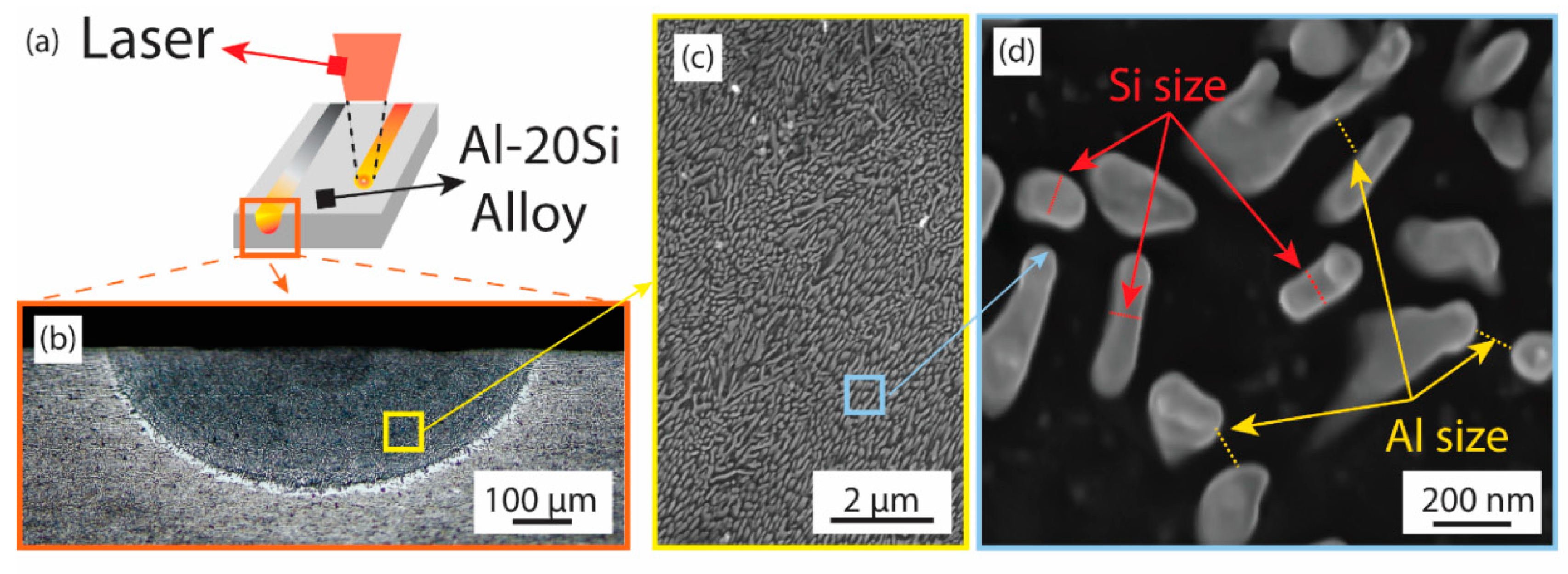

2. Materials and Experimental Setup

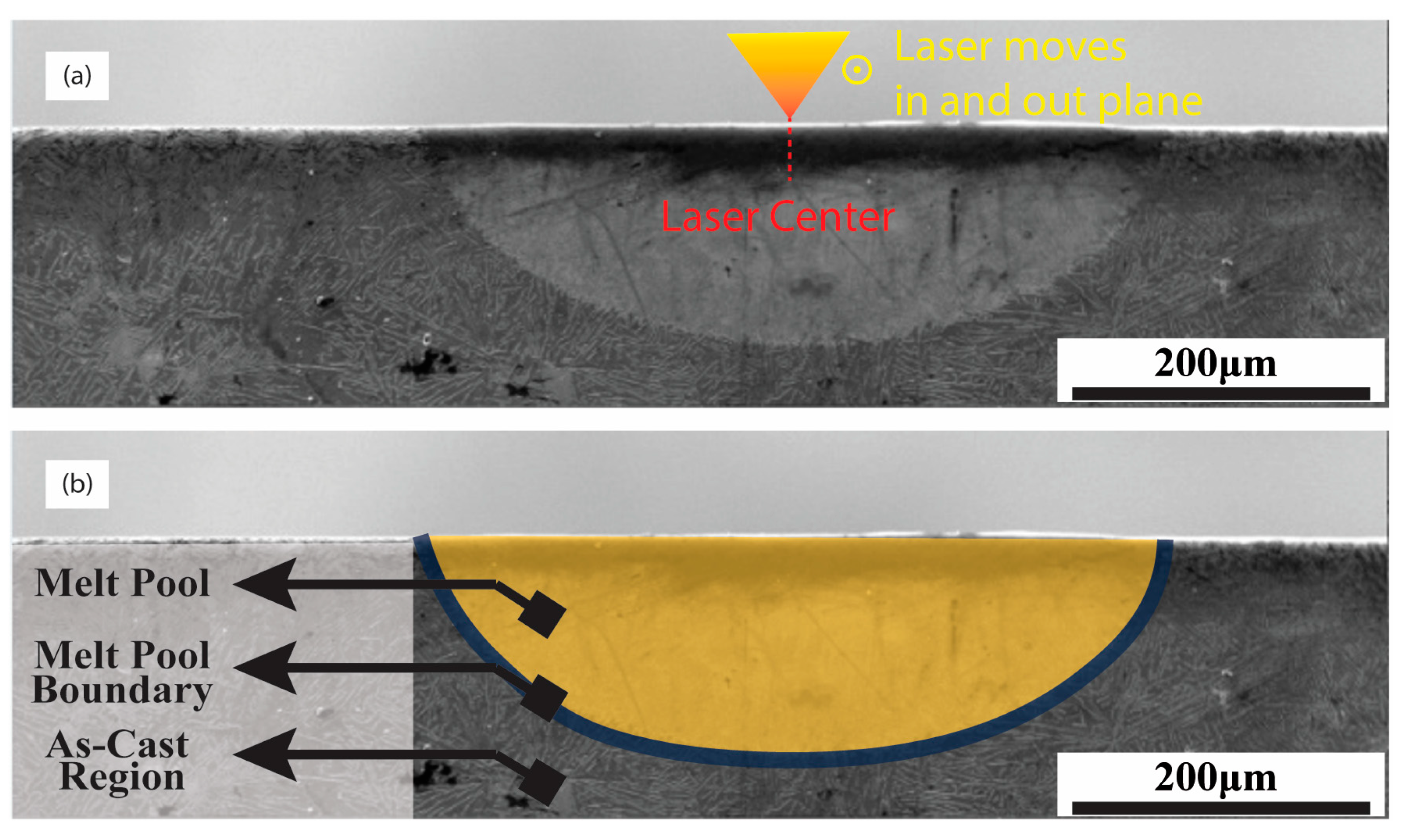

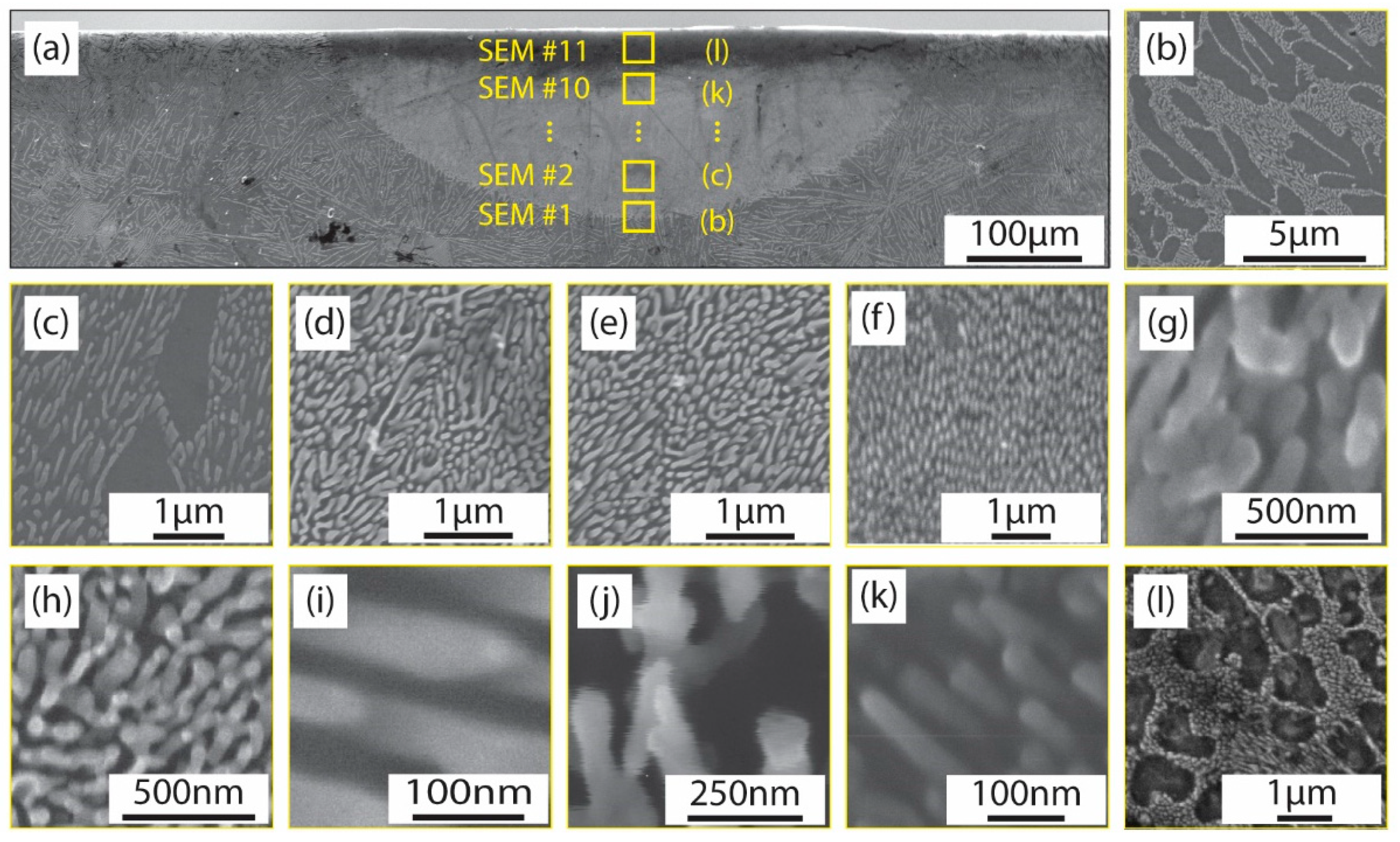

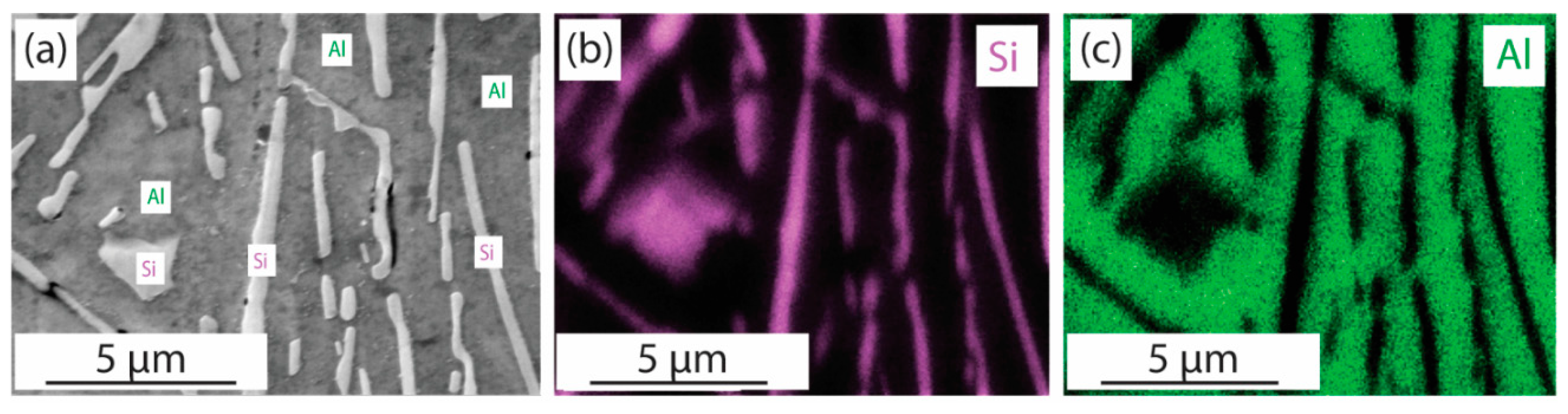

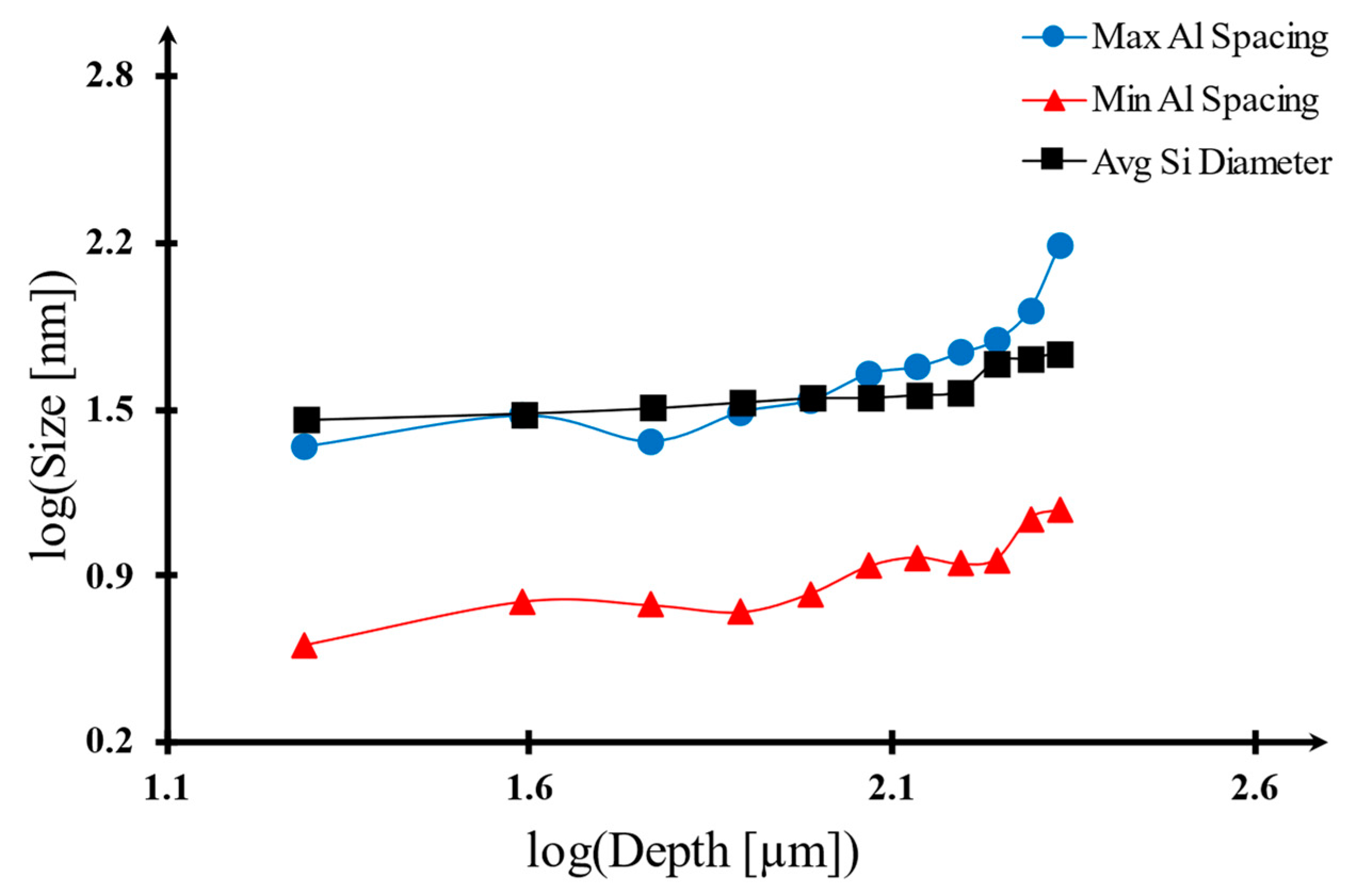

3. Analysis of the Melt Pool Shapes and Grain Refinement

4. Dimensional Analysis and Predictions

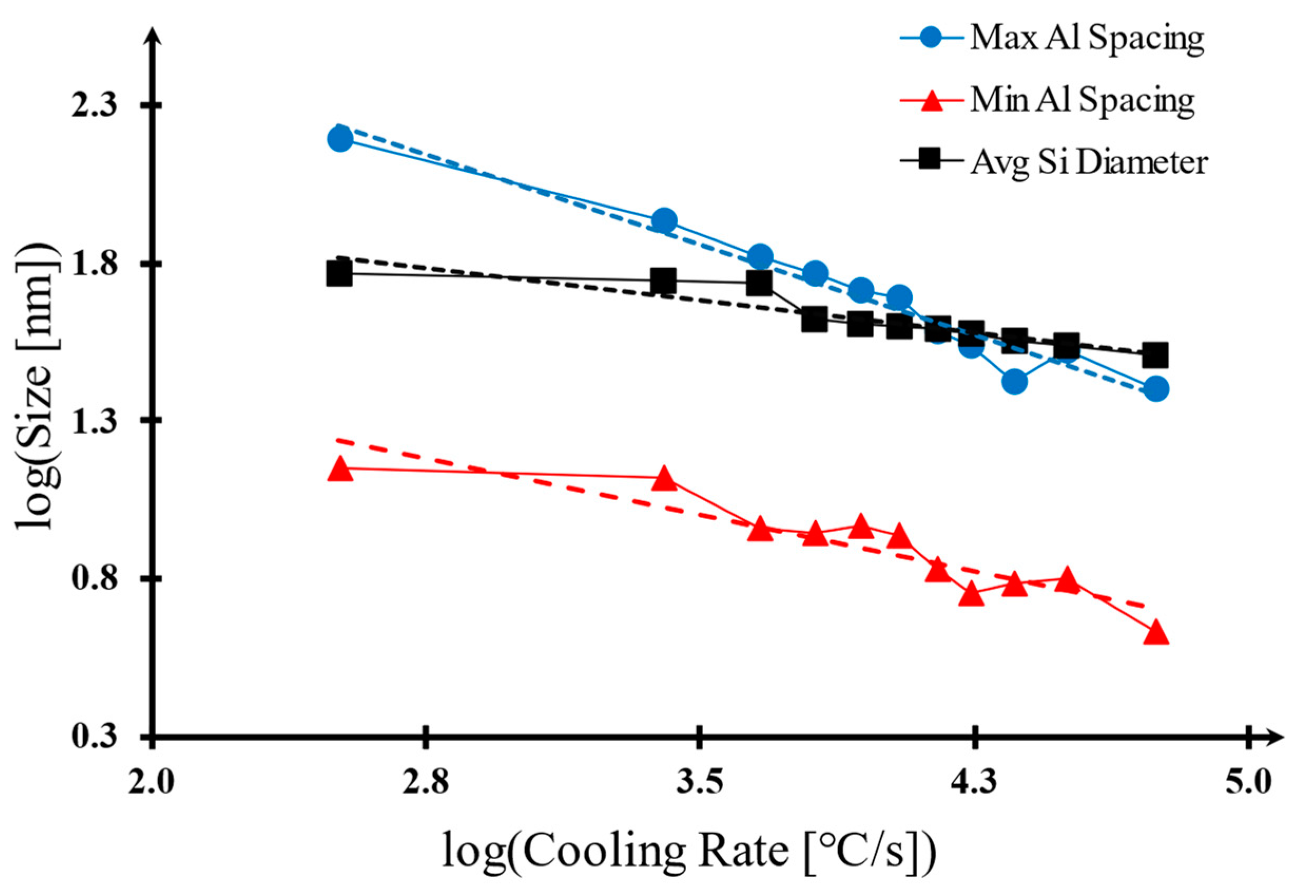

4.1. Correlation of the Microstructure Refinement and Cooling Rate

- : 0.613x + 0.426 (R2 = 0.71)

- : 0.439x − 0.018 (R2 = 0.82)

- : 0.231x + 1.116 (R2 = 0.74)

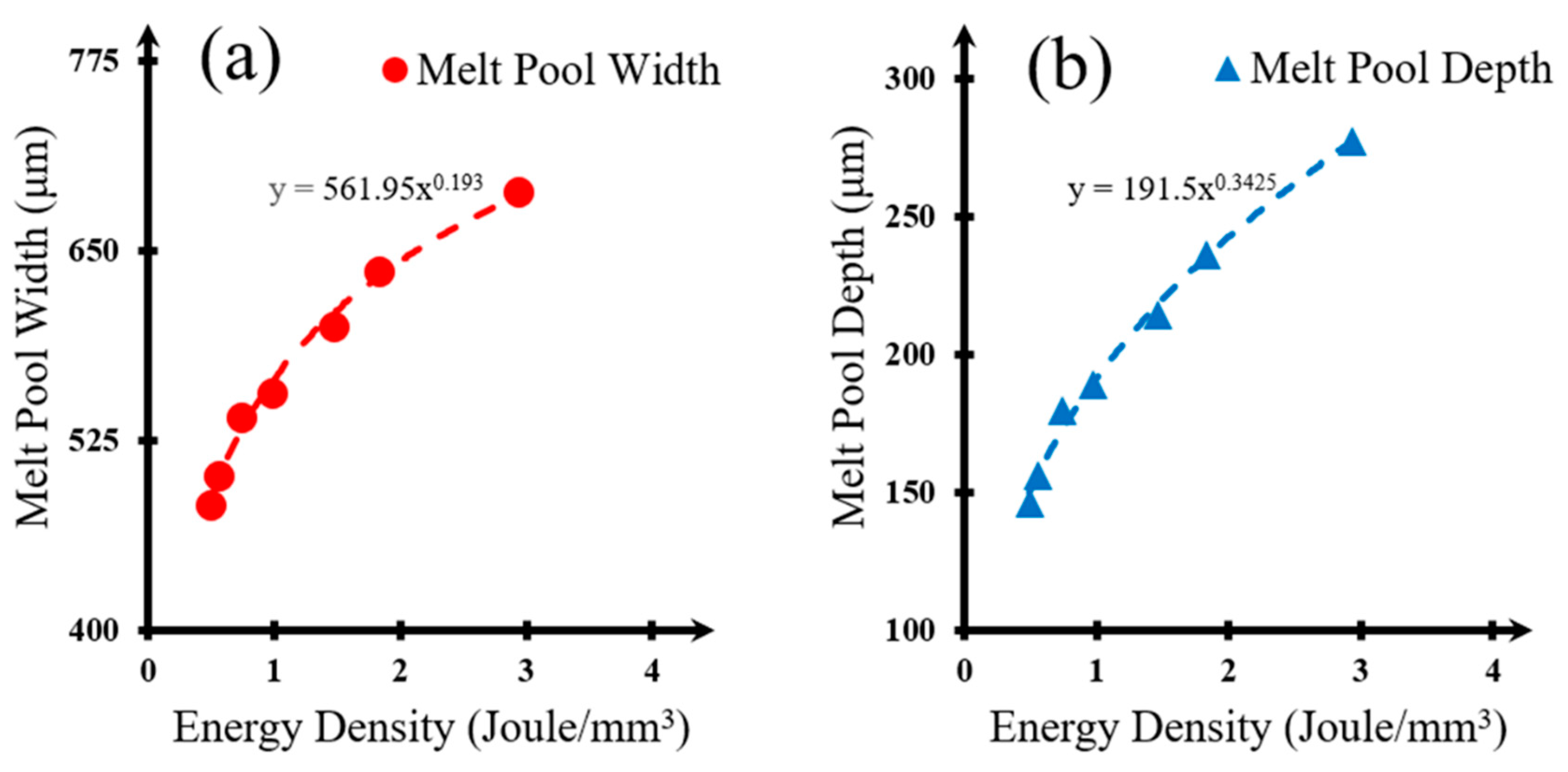

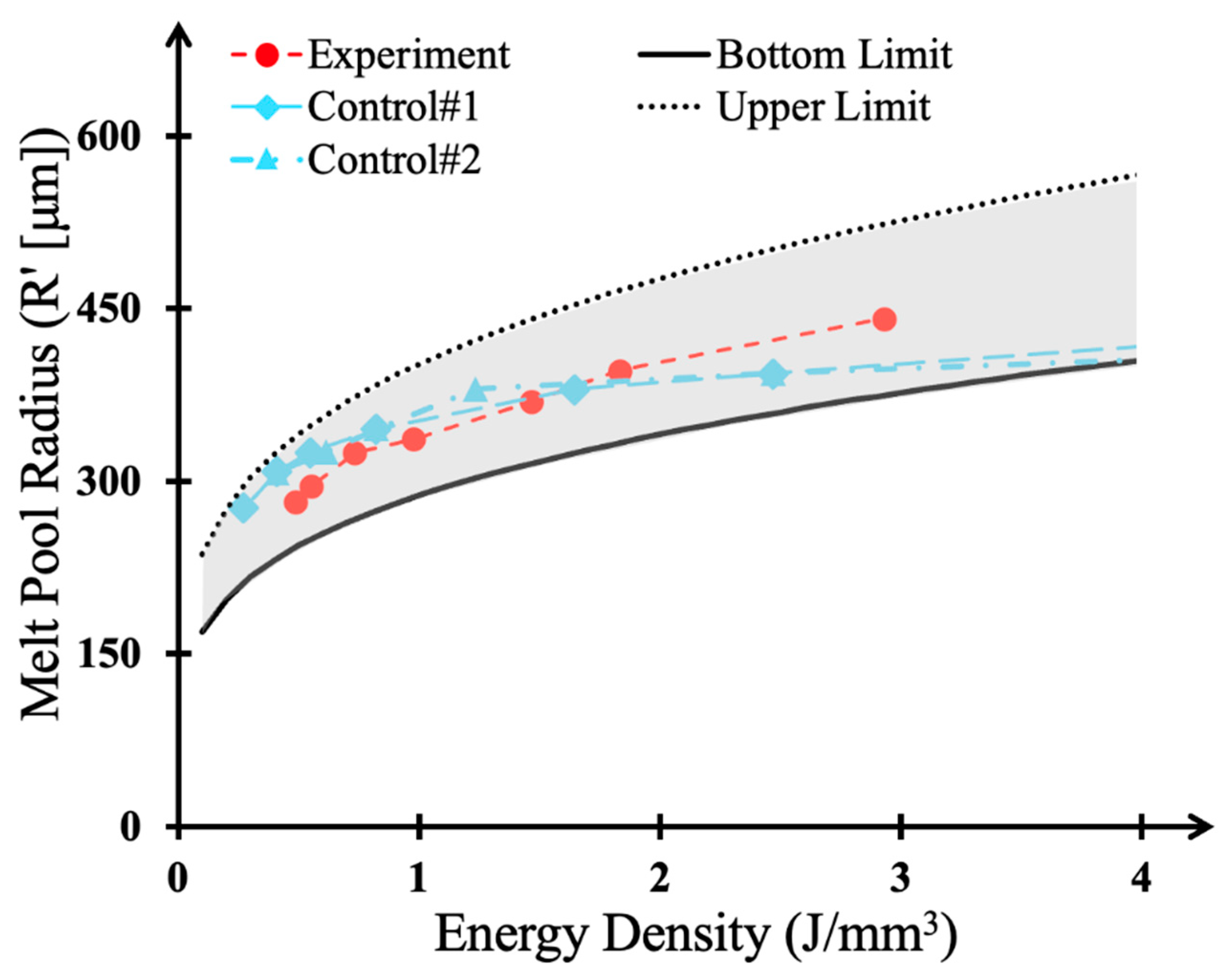

4.2. Correlation of the Melt Pool Dimensions and Energy Density

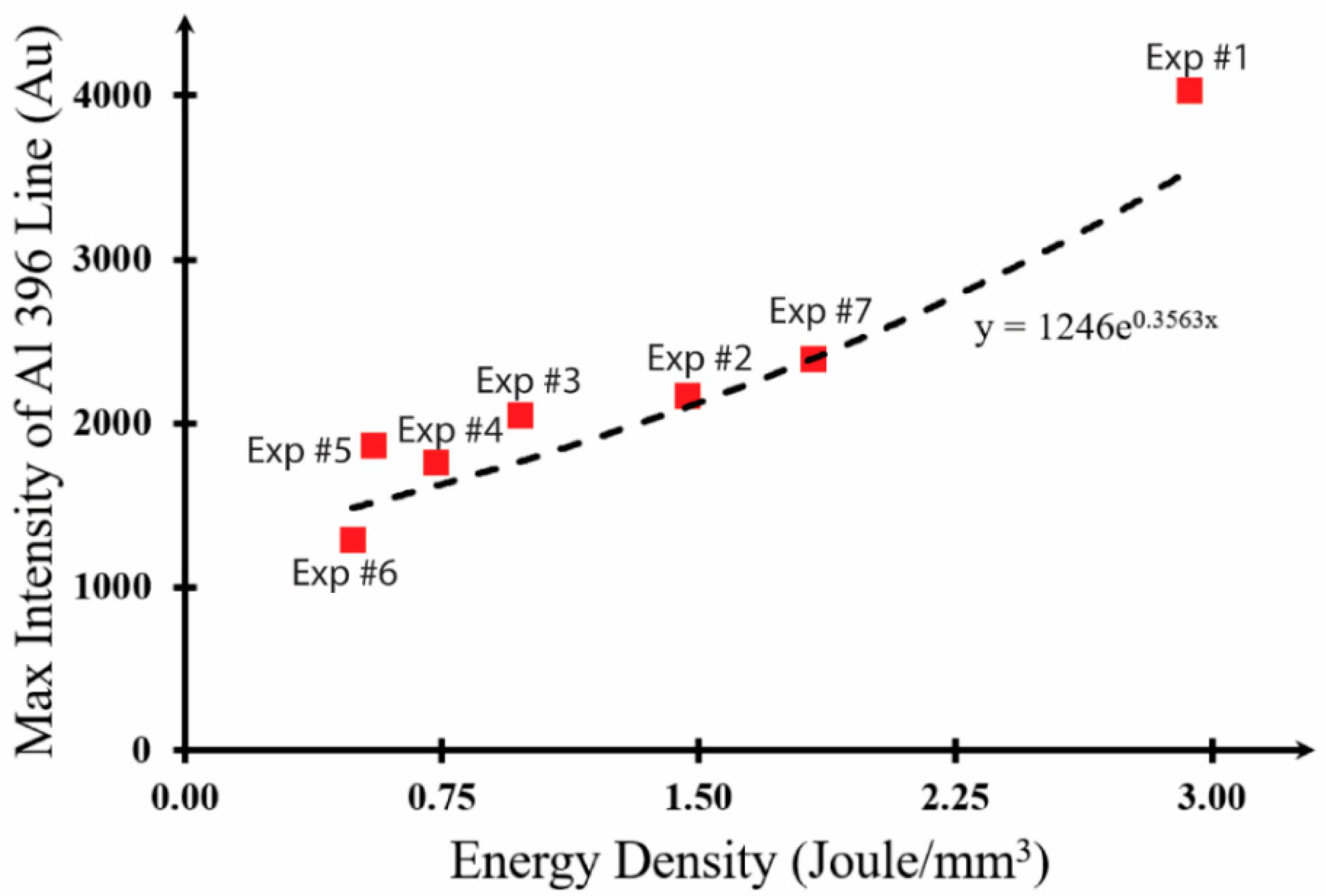

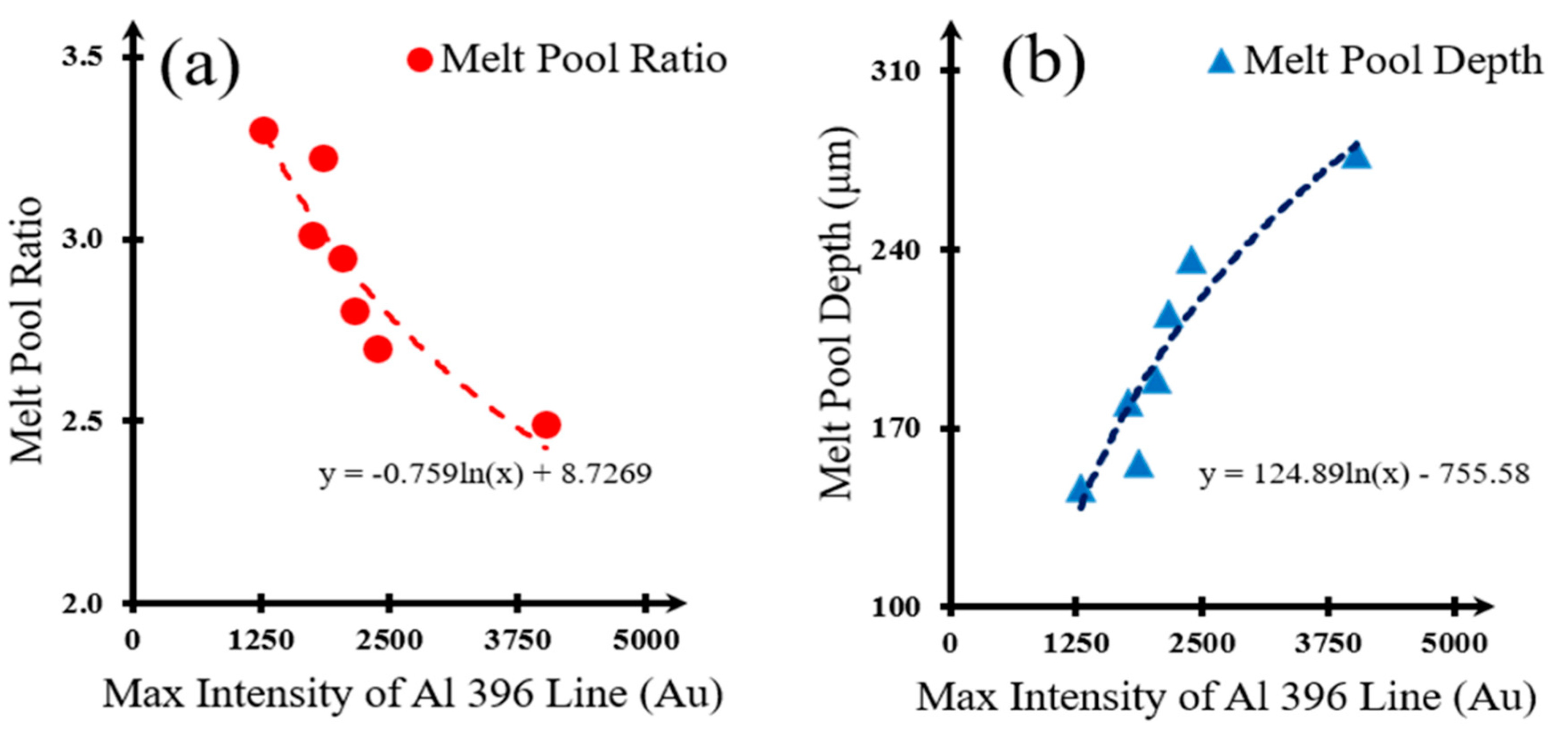

4.3. Prediction of the Melt Pool Dimensions Based on Plasma Signals

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Meaning |

| T | Temperature (°C) |

| T0 | Initial Temperature (°C) |

| ξ | Location of the T Temperature (x − vt) (m) |

| α | Thermal Diffusivity (m2/s) |

| ɛ | Laser Absorb Efficiency |

| K | Thermal Conductivity (W/mK) |

| R | Melt Pool Radius [ξ2 + x2 + y2]1/2 |

| v | Laser Speed (m/s) |

| Q | Laser Power (W) |

| A | Laser Spot Area (mm2) |

References

- Sahu, H.; Dave, R.; Chauhan, S.; Dwivedi, R. Review on Laser Welding of High Strength Aluminium Alloy for Automotive Applications. SAE Tech. Pap. Ser. 2024, 1. [Google Scholar] [CrossRef]

- Li, S.S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Fan, J.; Shu, S.L.; Qiu, F.; et al. Development and Applications of Aluminum Alloys for Aerospace Industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Stemper, L.; Tunes, M.A.; Tosone, R.; Uggowitzer, P.J.; Pogatscher, S. On the Potential of Aluminum Crossover Alloys. Prog. Mater. Sci. 2022, 124, 100873. [Google Scholar] [CrossRef]

- Kamarska, K.; Dimova, D.; Dochev, B.; Dubaradjieva, M.; Peeva, N.; Demirev, T. Investigation of the Corrosion Resistance of Complex Alloyed Hypereutectic Aluminium-Silicon Alloys. AIP Conf. Proc. 2024, 3129, 040002. [Google Scholar] [CrossRef]

- Dinesh Kumar, P.K.; Darius Gnanaraj, S. Studies on Al-Si Based Hybrid Aluminium Metal Matrix Nanocomposites. Mater. Today Commun. 2024, 38, 108132. [Google Scholar] [CrossRef]

- Tenekedjiev, N.; Gruzleski, J.E. Hypereutectic Aluminium-Silicon Casting Alloys—A Review. Cast Metals 2016, 3, 96–105. [Google Scholar] [CrossRef]

- Kayitmazbatir, M.; Lien, H.H.; Mazumder, J.; Wang, J.; Misra, A. Effect of Cooling Rate on Nano-Eutectic Formation in Laser Surface Remelted and Rare Earth Modified Hypereutectic Al-20Si Alloys. Crystals 2022, 12, 750. [Google Scholar] [CrossRef]

- Lei, Q.; Ramakrishnan, B.P.; Wang, S.; Wang, Y.; Mazumder, J.; Misra, A. Structural Refinement and Nanomechanical Response of Laser Remelted Al-Al2Cu Lamellar Eutectic. Mater. Sci. Eng. A 2017, 706, 115–125. [Google Scholar] [CrossRef]

- Wei, B.; Wu, W.; Ghosh, A.; Kayitmazbatir, M.; Misra, A.; Wang, J. In Situ SEM Characterization of Tensile Behavior of Nano-Fibrous Al–Si and Al–Si–Sr Eutectics. J. Mater. Sci. 2023, 59, 5233–5246. [Google Scholar] [CrossRef]

- Song, L.; Mazumder, J. In-Situ Spectroscopic Analysis of Laser Induced Plasma for Monitoring of Composition during Direct Metal Deposition Process. In Proceedings of the 29th International Congress on Applications of Lasers and Electro-Optics, ICALEO 2010—Congress Proceedings 2010, Anaheim, CA, USA, 26–30 September 2010; Volume 103, pp. 166–171. [Google Scholar]

- Choi, J.; Wooldridge, M.; Mazumder, J. Spectroscopy-Based Smart Optical Monitoring System in the Applications of Laser Additive Manufacturing. J. Laser Appl. 2023, 35, 012030. [Google Scholar] [CrossRef]

- Choi, J.; Mazumder, J.; Rice, A. Innovative Additive Manufacturing Process for Successful Production of 7000 Series Aluminum Alloy Components Using Smart Optical Monitoring System. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2020; Volume 2020. [Google Scholar] [CrossRef]

- Song, L.; Wang, C.; Mazumder, J. Identification of Phase Transformation Using Optical Emission Spectroscopy for Direct Metal Deposition Process. In High Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications; SPIE: Bellingham, WA, USA, 2012; Volume 8239, p. 82390G. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Z.; Ren, W.; Mazumder, J.; Jin, J.J. In Situ Monitoring of Optical Emission Spectra for Microscopic Pores in Metal Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2022, 144, 011006. [Google Scholar] [CrossRef]

- Lu, Y.; Sun, G.; Xiao, X.; Ren, W.; Sprague, E.; Ni, Z.; Mazumder, J. In Suit Monitoring of Solidification Mode, Porosity and Clad Height during Laser Metal Deposition of AISI 316 Stainless Steel. J. Manuf. Process 2021, 68, 1705–1713. [Google Scholar] [CrossRef]

- Ren, W.; Mazumder, J. In-Situ Porosity Recognition for Laser Additive Manufacturing of 7075-Al Alloy Using Plasma Emission Spectroscopy. Sci. Rep. 2020, 10, 19493. [Google Scholar] [CrossRef] [PubMed]

- Abboud, J.; Mazumder, J. Developing of nano sized fibrous eutectic silicon in hypereutectic Al–Si alloy by laser remelting. Sci. Rep. 2020, 10, 12090. [Google Scholar] [CrossRef] [PubMed]

- Lien, H.H.; Mazumder, J.; Wang, J.; Misra, A. Microstructure Evolution and High Density of Nanotwinned Ultrafine Si in Hypereutectic Al-Si Alloy by Laser Surface Remelting. Mater. Charact. 2020, 161, 110147. [Google Scholar] [CrossRef]

- Wei, B.; Wu, W.; Xie, D.; Lien, H.H.; Kayitmazbatir, M.; Misra, A.; Wang, J. In Situ Characterization of Tensile Behavior of Laser Rapid Solidified Al–Si Heterogeneous Microstructures. Mater. Res. Lett. 2021, 9, 507–515. [Google Scholar] [CrossRef]

- Rosenthal, D. The Theory of Moving Sources of Heat and Its Application to Metal Treatments. J. Fluids Eng. 1946, 68, 849–865. [Google Scholar] [CrossRef]

- Shin, J.; Mazumder, J. Plasma Diagnostics Using Optical Emission Spectroscopy in Laser Drilling Process. J. Laser Appl. 2016, 28, 022008. [Google Scholar] [CrossRef]

| Experiment Number | Laser Power (W) | Laser Scanning Speed (mm/s) |

|---|---|---|

| #1 | 1200 | 30 |

| #2 | 1200 | 60 |

| #3 | 1200 | 90 |

| #4 | 1200 | 120 |

| #5 | 1200 | 160 |

| #6 | 1200 | 180 |

| #7 | 1500 | 60 |

| Control #1 | 1200 | 10–300 |

| Control #2 | 1800 | 10–300 |

| Depth (μm) | SEM Image Number | Min. (nm) | Max. (nm) | Mean (nm) |

|---|---|---|---|---|

| 213.95 | 1 | 12.73 | 139.39 | 36.29 |

| 194.50 | 2 | 11.80 | 77.32 | 23.78 |

| 175.05 | 3 | 8.21 | 59.09 | 22.13 |

| 155.60 | 4 | 7.87 | 52.34 | 15.70 |

| 136.15 | 5 | 8.34 | 46.36 | 15.30 |

| 116.70 | 6 | 7.70 | 43.50 | 16.76 |

| 97.25 | 7 | 6.05 | 34.30 | 15.34 |

| 77.80 | 8 | 5.12 | 30.73 | 14.36 |

| 58.35 | 9 | 5.45 | 23.61 | 12.65 |

| 38.90 | 10 | 5.62 | 29.83 | 22.55 |

| 19.45 | 11 | 3.82 | 22.47 | 10.94 |

| Depth (μm) | SEM Image Number | Min. (nm) | Max. (nm) | Mean (nm) |

|---|---|---|---|---|

| 213.95 | 1 | 18.55 | 105.09 | 52.39 |

| 194.50 | 2 | 17.97 | 82.66 | 49.60 |

| 175.05 | 3 | 23.70 | 96.38 | 48.37 |

| 155.60 | 4 | 20.03 | 71.02 | 37.32 |

| 136.15 | 5 | 17.92 | 80.66 | 36.05 |

| 116.70 | 6 | 18.26 | 62.08 | 35.19 |

| 97.25 | 7 | 14.18 | 109.35 | 35.03 |

| 77.80 | 8 | 17.05 | 56.26 | 33.75 |

| 58.35 | 9 | 15.93 | 47.80 | 32.09 |

| 38.90 | 10 | 10.02 | 68.48 | 30.65 |

| 19.45 | 11 | 15.95 | 77.08 | 29.00 |

| Exp. No. | Energy Density (J/mm3) | Melt Pool Width (μm) | Melt Pool Depth (μm) | Melt Pool Ratio (Width/Depth) |

|---|---|---|---|---|

| 1 | 2.934 | 689.07 | 277.15 | 2.49 |

| 2 | 1.467 | 600.27 | 214.52 | 2.80 |

| 3 | 0.978 | 556.59 | 189.19 | 2.94 |

| 4 | 0.734 | 540.78 | 179.77 | 3.01 |

| 5 | 0.550 | 501.90 | 156.03 | 3.22 |

| 6 | 0.489 | 482.44 | 146.33 | 3.30 |

| 7 | 1.834 | 636.75 | 236.34 | 2.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kayitmazbatir, M.; Banu, M. In Situ Prediction of Microstructure and Mechanical Properties in Laser-Remelted Al-Si Alloys: Towards Enhanced Additive Manufacturing. Materials 2024, 17, 3622. https://doi.org/10.3390/ma17143622

Kayitmazbatir M, Banu M. In Situ Prediction of Microstructure and Mechanical Properties in Laser-Remelted Al-Si Alloys: Towards Enhanced Additive Manufacturing. Materials. 2024; 17(14):3622. https://doi.org/10.3390/ma17143622

Chicago/Turabian StyleKayitmazbatir, Metin, and Mihaela Banu. 2024. "In Situ Prediction of Microstructure and Mechanical Properties in Laser-Remelted Al-Si Alloys: Towards Enhanced Additive Manufacturing" Materials 17, no. 14: 3622. https://doi.org/10.3390/ma17143622

APA StyleKayitmazbatir, M., & Banu, M. (2024). In Situ Prediction of Microstructure and Mechanical Properties in Laser-Remelted Al-Si Alloys: Towards Enhanced Additive Manufacturing. Materials, 17(14), 3622. https://doi.org/10.3390/ma17143622