A Review of Gene–Property Mapping of Cementitious Materials from the Perspective of Material Genome Approach

Abstract

1. Introduction

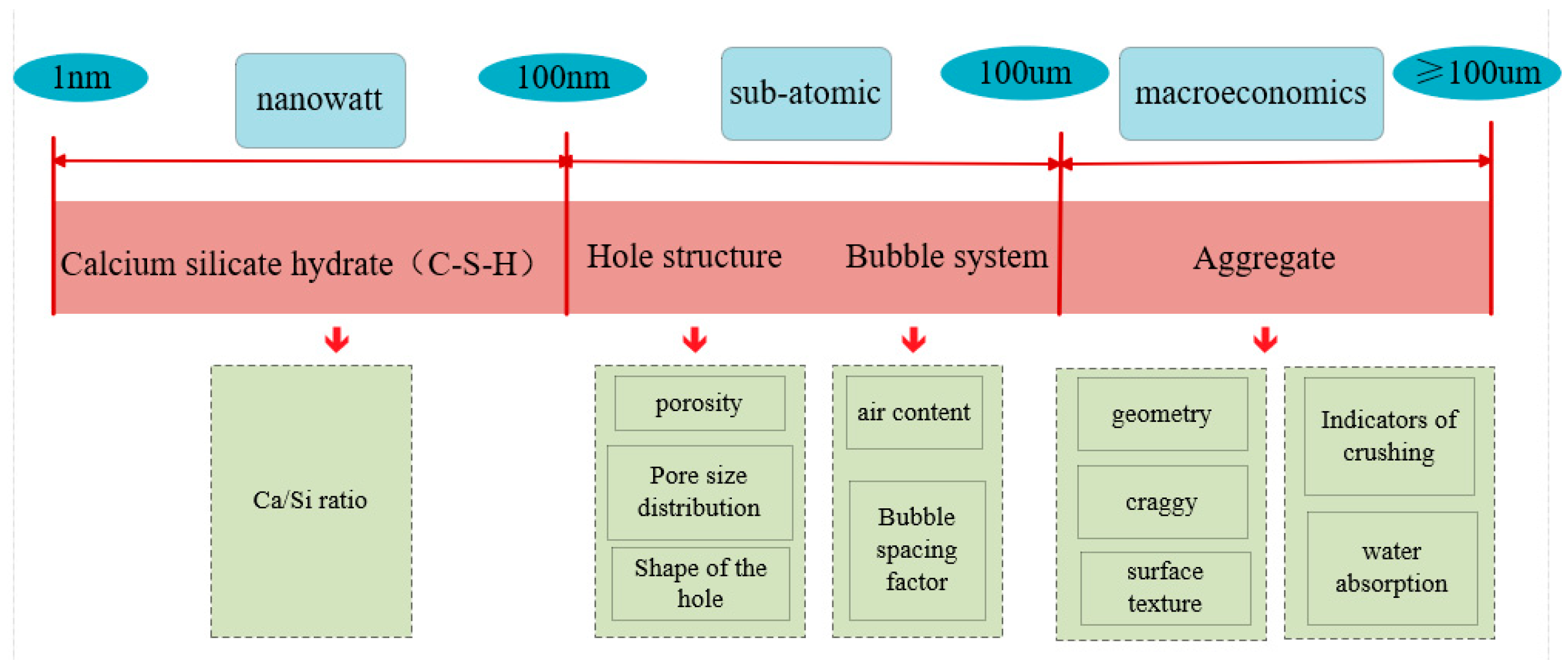

2. Main Characteristic Genes of Cementitious Materials

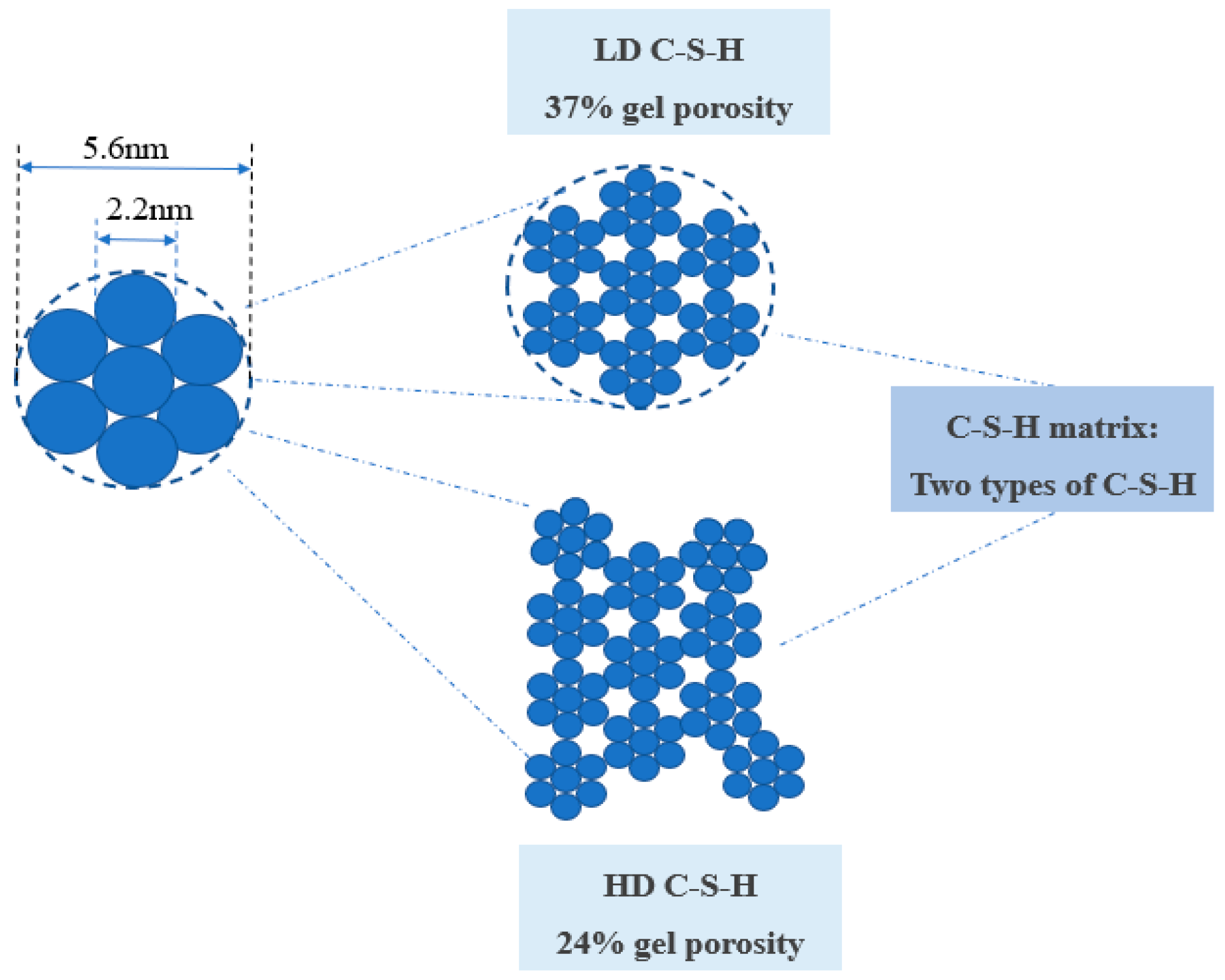

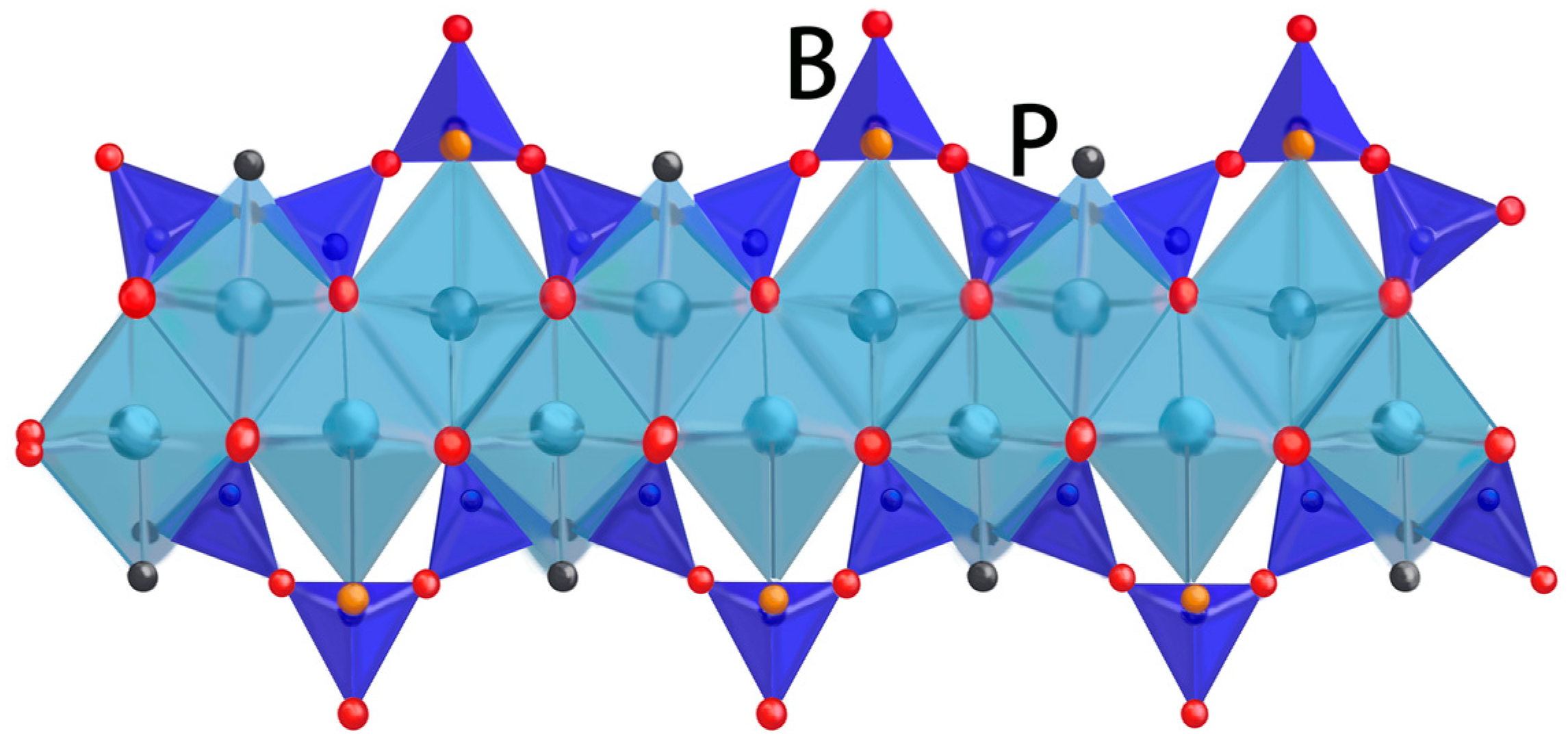

2.1. Nano View: Hydrated Calcium Silicate

2.2. Microscopic: Pore Structure and Bubble Systems

2.2.1. Hole Structure

2.2.2. Bubble System

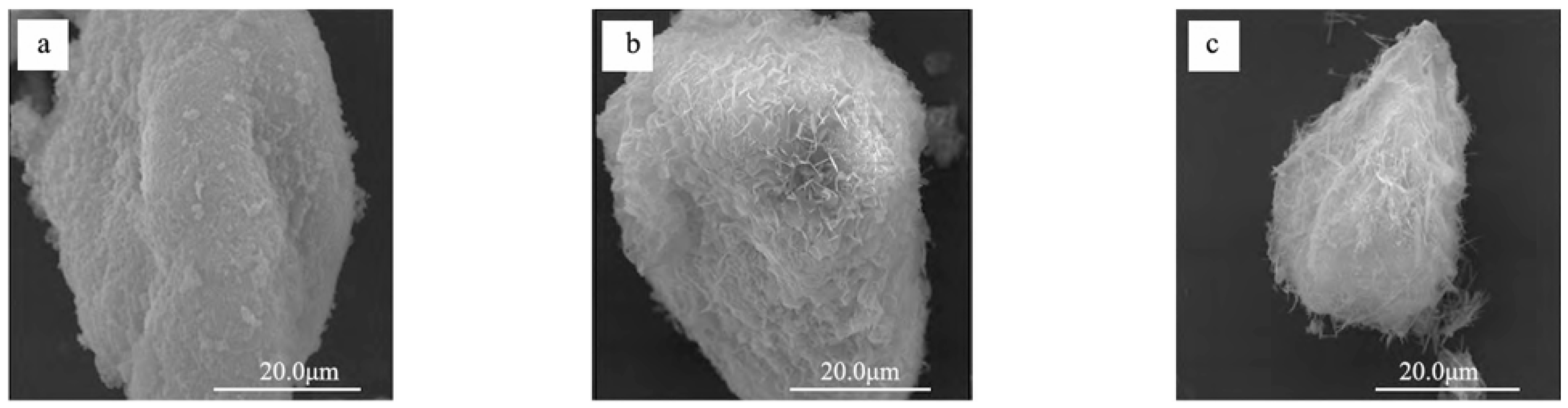

2.3. Macro: Aggregates

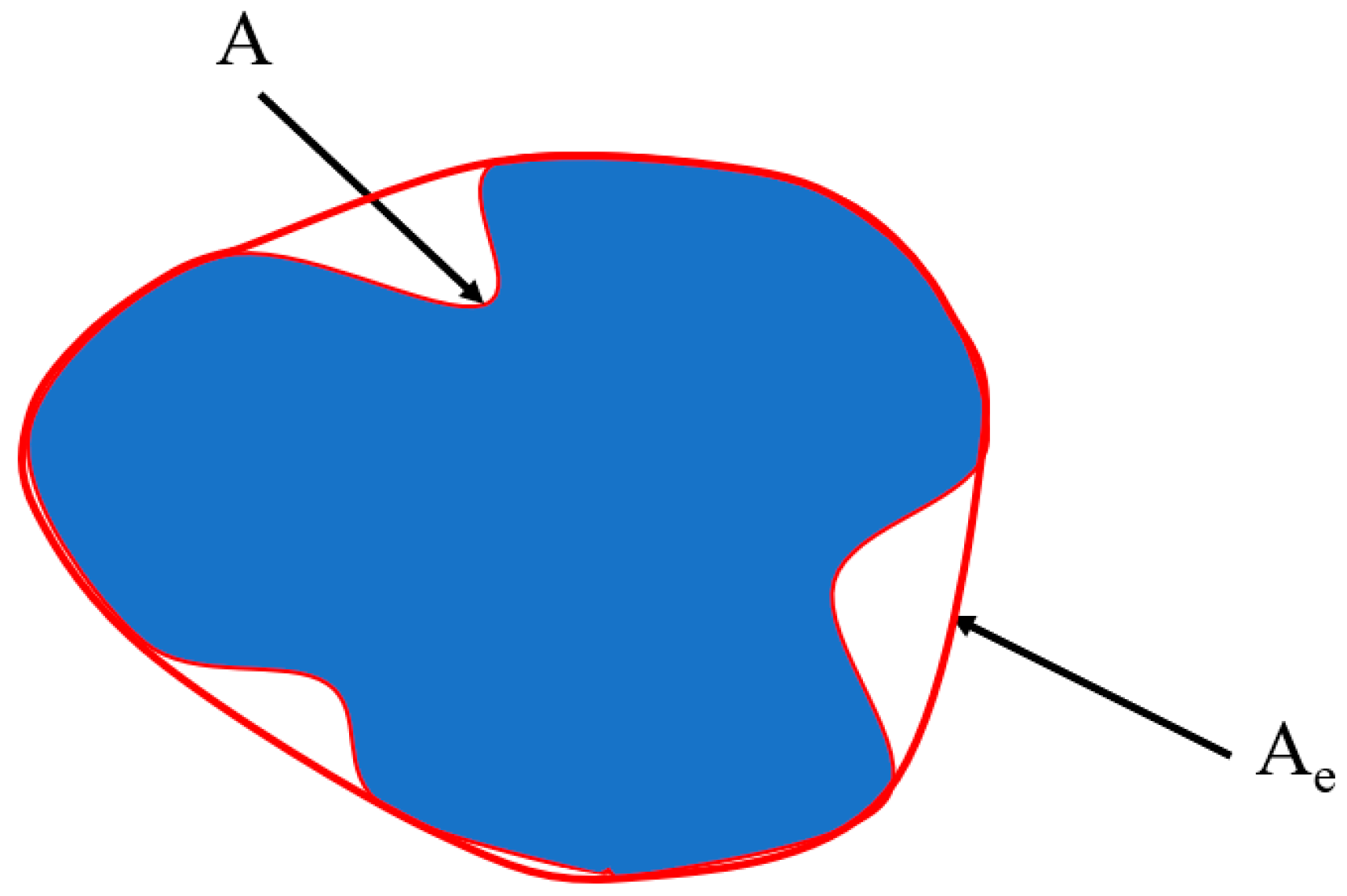

2.3.1. Aggregate Shape

2.3.2. Aggregate Angles

2.3.3. Surface Texture

2.3.4. Crushing Indicators

- The encapsulation of secondary aggregates within cement mortar, which, due to its relatively lower strength, yields a higher crushing index for recycled aggregates.

- The formation of cracks within the stone during the crushing process, which diminishes the strength of the recycled aggregate. Table 4 compiles a comprehensive overview of the crushing index data for both natural and recycled aggregates, as documented by a multitude of scholars.

2.3.5. Water Absorption

- The process of stone crushing generates cracks both on the surface and within the natural aggregate, facilitating the penetration of cement mortar into these fissures, thereby augmenting the water absorption and rate of the aggregate.

- The reduction in particle size due to stone crushing increases the specific surface area of recycled aggregates, enhancing their contact area with cement mortar and, in turn, their water adsorption capacity.

3. Relationship between the Main Characteristic Genes of Cementitious Materials and Performance Mapping

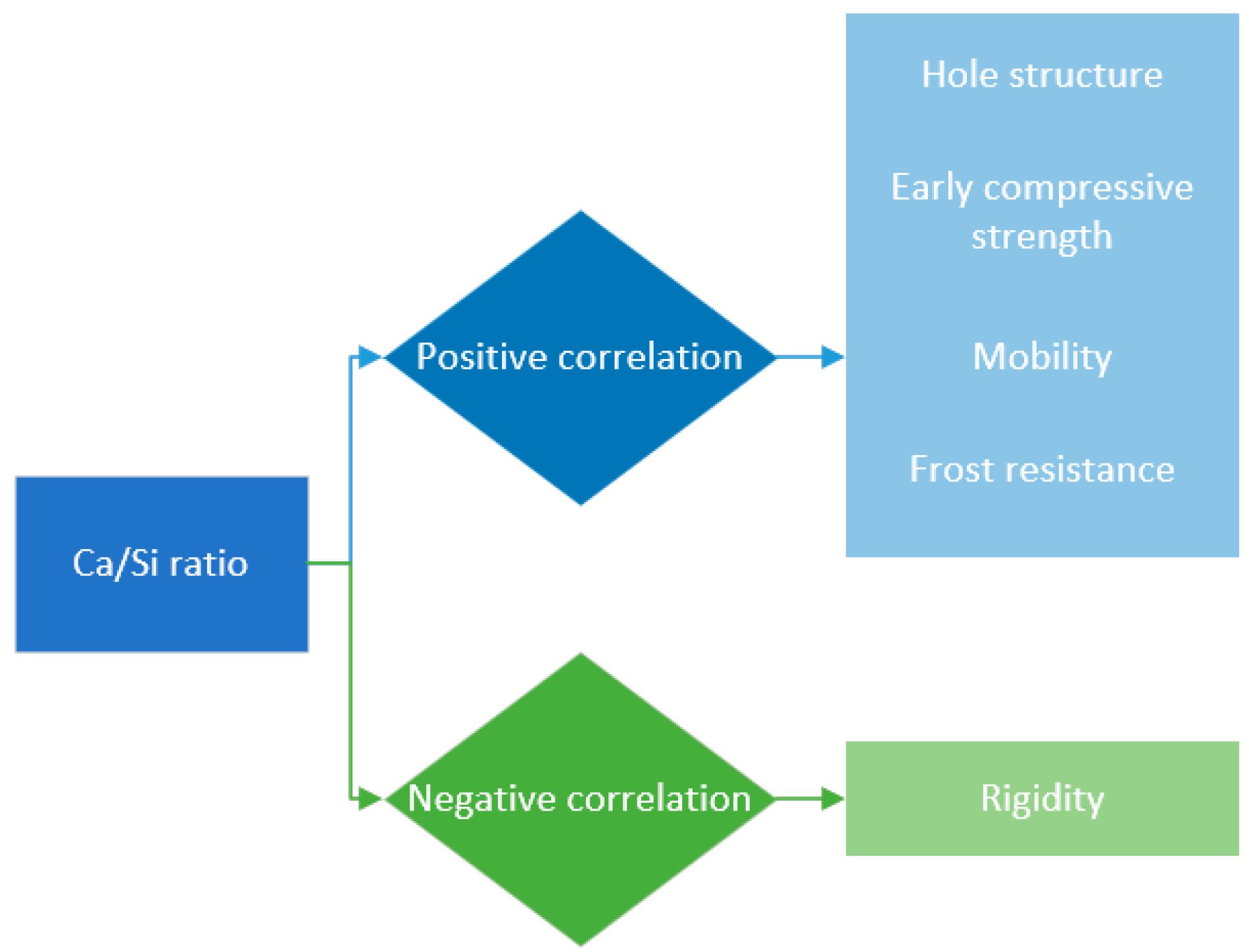

3.1. Mapping of Hydrated Calcium Silicate to Properties

3.2. Pore Structure and Performance Mapping Relationship

3.3. Bubble System and Performance Mapping Relationship

3.4. Aggregate–Property Mapping Relationships

3.4.1. Aggregate Shape

3.4.2. Aggregate Angles

3.4.3. Surface Texture

3.4.4. Crushing Indicators

3.4.5. Water Absorption

4. Summary

- From a nano-scale perspective, hydrated calcium silicate (C-S-H) emerges as the most critical characteristic component of cementitious materials. It is the calcium-to-silicon ratio that serves as the pivotal parameter in describing the structure of C-S-H. This ratio influences the material’s categorization into two distinct forms based on stacking density: OPC, characterized by its low density and substantial porosity of 37%, and IPC, known for its high density and reduced porosity of 24%. As the calcium-to-silicon ratio escalates, the morphological characteristics of C-S-H undergo a transformation, shifting from dense agglomerates to more elongated, needle-like rods, and then to loose, network-like fibrous structures. This transition is accompanied by an increase in early compressive strength, a decrease in fluidity, and a decline in frost resistance.

- From a microscopic perspective, the pore structure and the bubble system are key characteristics of cementitious materials. These features, including porosity, the distribution of pore sizes, the configuration of pores, the volume of entrained air, and the bubble spacing factor, are critical indicators of the material’s properties. They significantly influence the freeze–thaw resistance, permeability, and compressive strength of cementitious materials.

- ①

- Porosity: When porosity is below 20%, the permeability of cementitious materials remains minimal. Conversely, when porosity exceeds 25%, permeability notably escalates.

- ②

- Pore size distribution: The more superior the frost resistance and the greater the compressive strength of cementitious materials, the more numerous the pores under 50 nm and the fewer the pores above 100 nm.

- ③

- Shape of holes: Maintaining uniform porosity, cementitious materials with circular pores display enhanced strength relative to those with square pores.

- ④

- Air content: Typically, the air content within cementitious materials is confined to a range of 3% to 5%. An air content of approximately 4.3% is associated with the optimal balance of frost resistance and mechanical properties in these materials.

- From a macroscopic perspective, the aggregate is a defining characteristic of cementitious materials. The properties of the aggregate, such as its shape, angularity, surface texture, crushing strength index, and water absorption capacity, are fundamental in determining the performance of these materials. Notably, these attributes substantially influence the chloride ion penetration resistance, rheological properties, including viscosity and fluidity, as well as the mechanical strength of cementitious materials.

- ①

- Shape: Aggregates with higher sphericity and cubic shapes are conducive to enhanced performance in cementitious materials.

- ②

- Angularity: An angularity coefficient above 1.5 adversely affects the mechanical and operational properties of cementitious materials. The performance is optimized with spherical shapes, slightly reduced with near-spherical shapes, and is minimal with angular shapes.

- ③

- Surface texture: Low surface texture correlates with reduced slip resistance, while a higher texture enhances durability and anti-slip characteristics of cementitious materials.

- ④

- Crushing index: An elevated crushing index is associated with reduced compressive strength and modulus of elasticity. Cementitious materials with crushing indices of 25%, 18%, and 10% demonstrate a gradient in elastic modulus, with the highest index showing a decrease of approximately 2 × 104 GPa compared to the lowest. Correspondingly, an increased permeability coefficient is observed, with the highest index having a coefficient approximately 2.06 × 10−9 cm·s−1 greater than the lowest.

- ⑤

- Water absorption: Typically, the water absorption rate should not exceed 1%. Exceeding this threshold can significantly reduce the slump and fluidity of the material and may result in a compressive strength reduction within the range of 15% to 42%.

5. Research Outlook

- The establishment of a standardized, extensive database is essential for the accuracy of performance forecasts. A challenge arises from the utilization of databases compiled from a multitude of previous experimental studies: the inconsistency in test materials and environments, the breadth of data sources, and the suboptimal standardization. Therefore, it is imperative to address the issues of standardization and precision in the creation of subsequent databases for cementitious materials.

- For performance prediction, machine learning algorithms have become highly sophisticated. Leveraging high-throughput algorithms enables the integration of artificial intelligence with extensive databases, facilitating the establishment of correlations between the characteristic properties and performance of cementitious materials. This approach can identify the optimal material composition and structure to meet specific property requirements in complex cementitious materials. Bidirectional optimization of material properties and their genetic factors is pursued.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qian, Z. Study on Ionic Conduction Problem of Inorganic Solid Electrolyte Based on Material Genome. Doctoral Dissertation, Donghua University, Shanghai, China, 2021. [Google Scholar]

- Xing, C.; Tan, Y.; Zhang, K.; Shan, L.-Y.; Xu, H.-N. A Review and Prospect of Genetic Characterization of Asphalt Mixtures Based on Material Genome Approach. Chin. J. Highw. 2020, 33, 76–90. [Google Scholar]

- Tan, Y.-Q.; Lv, H.-J.; Xu, H.-N. Prospects for the application of material gene ideas in the field of asphalt pavement materials. Transp. Res. 2020, 6, 2–12+11. [Google Scholar]

- Wang, H.; Xiang, Y.; Xiang, X.-D.; Chen, L.-Q. Material genome—A new paradigm for material research and development. Sci. Technol. Her. 2015, 33, 13–19. [Google Scholar]

- Ding, S.; Zhang, J.; Wang, Q. Chloride ion permeation resistance of low-shrinkage ductile fiber-reinforced cementitious composites. J. Build. Mater. 2017, 20, 827–834. [Google Scholar]

- Liu, J.-F.; Zhang, X.-Y.; Chen, L.; Wang, J.; Liu, J. Properties and applications of low pH cementitious materials. J. Silic. 2023, 51, 2992–3004. [Google Scholar]

- Zhao, X. Application of X-ray tomography in the study of cementitious materials. Sichuan Build. Mater. 2023, 49, 21–23. [Google Scholar]

- Zhu, Y.; Yang, R.; Peng, Y.; Pan, W.-H.; Zeng, Q. Characterization of interfacial transition zone of cementitious materials by pressed mercury method combined with X-ray tomography. J. Silic. 2022, 50, 2136–2144. [Google Scholar]

- Lorenzoni, R.; Lima, V.N.; Figueiredo, T.C.S.P.; Hering, M.; Paciornik, S.; Curbach, M.; Mechtcherine, V.; de Andrade, S.F. Macro and meso analysis of cement-based materials subjected to triaxial and uniaxial loading using X-ray microtomography and digital volume correlation. Constr. Build. Mater. 2022, 323, 126558. [Google Scholar] [CrossRef]

- Ding, Y.-Q.; Ma, J.; Rao, J.-Y.; Zhu, C.-L.; Cai, Y.-H. 2023 Review on the management of the National Natural Science Foundation of China (NSFC) in the field of organic polymers and the recent progress of important research in related fields. Polym. Bull. 2024, 37, 419–429. [Google Scholar]

- Lei, D.-Y.; Li, M.-A.; Zhang, P.; Yi, B.-B.; Li, A. Progress in the study of multiscale crack-resistant toughening mechanism of cement-based materials. J. Silic. 2023, 51, 2876–2889. [Google Scholar]

- Bahraq, A.A.; Al-Osta, M.A.; Al-Amoudi, O.S.B.; Obot, I.B.; Maslehuddin, M. Molecular Simulation of Cement-Based Materials and Their Properties. Engineering 2022, 15, 165–178. [Google Scholar] [CrossRef]

- Jie, X.; Xi, C.; Guang, Y.; Xianli, N.; Fujie, C. Review of research on micromechanical properties of cement-based materials based on molecular dynamics simulation. Constr. Build. Mater. 2021, 312, 125389. [Google Scholar]

- Zhou, Y. Research on the Microstructure and Properties of Hydrated Calcium Silicate Based on Molecular Dynamics. Doctoral Dissertation, Southeast University, Nanjing, China, 2018. [Google Scholar]

- Merlino, S.; Bonaccorsi, E.; Armbruster, T. The real structures of clinotobermorite and tobermorite 9 Å: OD character, polytypes, and structural relationships. Eur. J. Mineral. 2000, 12, 411–429. [Google Scholar] [CrossRef]

- Hamid, S.A. The crystal structure of the 11 Ä natural tobermorite Ca2.25[Si3O7.5(OH)1.5]-1H2O. Z. Für Krist.-Cryst. Mater. 2014, 154, 189–198. [Google Scholar] [CrossRef]

- Ma, X. X-ray Scattering Study of the Microstructure of Hydrated Calcium Silicate(C-S-H). Master’s Thesis, Jinan University, Guangzhou, China, 2013. [Google Scholar]

- Liu, X.; Feng, P.; Shen, X.-Y.; Wang, H.-C.; Zhao, L.-X. Progress in the study of calcium silicate hydrate (C-S-H), a product of cement hydration. Mater. Her. 2021, 35, 9157–9167. [Google Scholar]

- Haojing, B.; Jiajie, L.; Wen, N.; Ying, L.; Yongjian, J. Effect of calcium to silicon ratio on the microstructure of hydrated calcium silicate gels prepared under medium alkalinity. Constr. Build. Mater. 2023, 379, 131240. [Google Scholar]

- Lothenbach, B.; Nonat, A. Calcium silicate hydrates: Solid and liquid phase composition. Cem. Concr. Res. 2015, 78, 57–70. [Google Scholar] [CrossRef]

- Wolfgang, K.; Sergio, F.; Jørgen, S. Influence of the Ca/Si ratio on the compressive strength of cementitious calcium-silicate-hydrate binders. J. Mater. Chem. A 2017, 5, 17401–17412. [Google Scholar]

- Xu, W.; Wu, X. Study on the effect of calcium-silicon ratio on experimental hydrothermal synthesis of hydrated calcium silicate. Silic. Bull. 2018, 37, 1294–1298. [Google Scholar]

- Lv, L.-L.; Zhao, X.-G.; He, Y.-J.; Hu, S.-G. Effect of calcium-silicon ratio on the morphology and structure of hydrated calcium silicate. In Proceedings of the First Annual Academic Conference of the Cement Branch of the China Silicate Society, Jiaozuo, China, 22–25 August 2009. [Google Scholar]

- Zhao, X. Synthesis of Hydrated Calcium Silicate and Its Composition, Structure and Morphology. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2010. [Google Scholar]

- Foley, E.M.; Kim, J.J.; Taha, M.R. Synthesis and nano-mechanical characterization of calcium-silicate-hydrate (C-S-H) made with 1.5 CaO/SiO2 mixture. Cem. Concr. Res. 2012, 42, 1225–1232. [Google Scholar] [CrossRef]

- Yongjia, H.; Linnu, L.; Struble, L.J.; Rapp, J.L.; Mondal, P. Effect of calcium-silicon ratio on microstructure and nanostructure of calcium silicate hydratesynthesized by reaction of fumed silica and calcium oxide at room temperature. Mater. Struct. 2014, 47, 311–322. [Google Scholar]

- Lin, W.F. Molecular Dynamics Simulation of Mechanical Properties of Hydrated Calcium Silicate. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2017. [Google Scholar]

- Lin, W.-H.; Fu, J.; Wang, Z.-H.; Xin, H. Molecular dynamics simulation of mechanical properties of hydrated calcium silicate with different calcium to silicon ratios. Mater. Her. 2017, 31, 158–163+169. [Google Scholar]

- Xu, X.; Tang, S.; He, Z. Molecular dynamics simulation study oneffect of calcium-silicon molar ratio on the structure and mechanical properties of hydrated calcium silicate. Silic. Bull. 2021, 40, 3903–3909. [Google Scholar]

- Yang, H.-X.; Liu, Q.; Zhai, J.; Zhan, J.-N. Calculation study on mechanical properties of cement hydration C-S-H. Sichuan Cem. 2019, 1, 3. [Google Scholar]

- Li, T. Molecular Dynamics Simulation Study of The Structure and Mechanical Properties of the Major Components of Cement. Master’s Thesis, Shenzhen University, Shenzhen, China, 2019. [Google Scholar]

- Sun, T. Preparation of Hydrated Calcium Silicate and Its Improvement of Micromechanical Properties of Cementitious Materials. Master’s Thesis, Chung Yuan Christian Institute of Technology, Zhengzhou, China, 2021. [Google Scholar]

- Sun, T.; Sun, Y. Effect of synthetic hydrated calcium silicate on micromechanical properties of cementitious materials. J. Zhongyuan Inst. Technol. 2021, 32, 51–57. [Google Scholar]

- Wang, S. Preparation of Hydrated Calcium Silicate and Its Effect on Cement Concrete Properties. Master’s Thesis, Chongqing University, Chongqing, China, 2022. [Google Scholar]

- Wang, A. Synthesis of Hydrated Calcium Silicate and Its Effect on the Properties Of Cement-Based Mortar. Master’s Thesis, Wuhan Institute of Technology, Wuhan, China, 2018. [Google Scholar]

- Wang, Z.; Yang, Y.Z.; Li, J.H. Preparation of hydrated calcium silicate crystal species and its effect on cement strength. Mater. Sci. Technol. 2007, 6, 789–791+796. [Google Scholar]

- Wu, C.W. Some important issues in current cement concrete science and technology. Concr. Cem. Prod. 1982, 1, 1–4. [Google Scholar]

- Lv, K. Characterization and Simulation of the Microfine Structure of Cementitious Materials. Ph.D. Thesis, Southeast University, Nanjing, China, 2020. [Google Scholar]

- Yang, S.; Mao, H.-T.; Liu, C.; Wang, X.-J. Modeling of the relationship between compressive strength and porosity distribution characteristics of medium-high strength concrete. J. Chang. Acad. Sci. 2024, 41, 194–202. [Google Scholar]

- Powers, T.C.; Brownyard, T.L. Landmark Series: Studies of the Physical Properties of Hardened Portland Cement Paste. Concr. Int. 2003, 25, 59–70. [Google Scholar]

- Guo, X.; Song, M. Research progress on pore structure and characterization method of autoclaved aerated concrete. Mater. Her. 2018, 32, 440–445. [Google Scholar]

- Jiang, Z.-W.; Deng, Z.-L.; Yuan, Z.-C.; Li, W.-T.; Zhang, N. Thermal porosimetry method to characterize the pore structure of concrete at different ages. J. Build. Mater. 2013, 16, 1044–1048. [Google Scholar]

- Jiang, Z.W.; Zhang, N.; Yang, Z.H. Thermodynamic computational model for characterizing the pore structure of cementitious materials by thermal porosimetry. J. Silic. 2012, 40, 194–199. [Google Scholar]

- Pang, C.-M.; Wang, S.-H. Pore structure of foam concreteand its effect on properties. J. Build. Mater. 2017, 20, 93–98. [Google Scholar]

- Yuan, Z.Y.; Chen, B.; Chen, J.L.; Gao, Z.H. Characterization of pore structure of foam concrete and its effect on mechanical properties. J. Compos. Mater. 2023, 40, 4117–4127. [Google Scholar]

- Yan, X.Y. Research on the Influence Law of Pore Structure on the Salt Freezing Resistance of Cementitious Materials. Master’s Thesis, Southeast University, Nanjing, China, 2015. [Google Scholar]

- Jiang, L.; Guan, Y.; Zhu, W. Correlation between pore structure and strength of cementitious composites. J. Hohai Univ. 2003, 6, 666–668. [Google Scholar]

- Kong, J. Influence of pore structure parameter characteristics on the frost resistance of high-performance concrete. North. Transp. 2023, 2, 29–32. [Google Scholar]

- Zhang, J.J.; Yuan, J.; Liu, W.B.; Wu, Y. Analysis of concrete bubble structure and salt-freezing resistance based on industrial scanning. J. Tongji Univ. 2018, 46, 53–59. [Google Scholar]

- Lin, H.; Chen, W.C.; Lan, C.L.; Cao, Y.; Gao, C.Y. Study on the effect of bubble spacing coefficient of hardened concrete on its properties. In Proceedings of the 2013 Concrete and Cement Products Symposium, Wuhan, China, 22–24 October 2013. [Google Scholar]

- Guo, B.-L. Correlation analysis of hardened concrete bubble characteristic parameters and freeze-thaw durability. Highw. Transp. Sci. Technol. 2013, 30, 80–85. [Google Scholar]

- Yang, L. Study on Air Bubble Parameters of Fresh and Hardened Concrete. Master’s Thesis, Chongqing University, Chongqing, China, 2012. [Google Scholar]

- Liu, Q. Research on the Formation Mechanism and Influencing Factors of Air-Entraining Concrete Pore Structure. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2021. [Google Scholar]

- Li, J.X.; Wang, Q.C.; Li, S.; Li, W.L.; Ma, L. Effect of air content on frost durability of cement mortar. Silic. Bull. 2014, 33, 1781–1787. [Google Scholar]

- Xu, W.Y.; Zhang, L.J.; Zhang, R.; Wang, B.; Wu, J.Y. Study on the effect of air content and bubble parameterson concrete properties. Concr. World 2022, 12, 26–29. [Google Scholar]

- Chen, Z.Y.; Wang, Q.C.; Dai, J.P.; Bi, R.X.; Chu, H. Study on Strength and Pore Structure of Equal-Strength Concrete by Maintenance Temperature and Air-entraining Agent. Concrete 2023, 1, 21–24+27. [Google Scholar]

- Li, L.S. Effects of different air-entraining agents on concrete properties. Transp. World 2023, 15, 40–42. [Google Scholar]

- Yuan, X.F. Research on Preparation and Performance of Frost-Resistant Concrete. Master’s Thesis, Chongqing University, Chongqing, China, 2016. [Google Scholar]

- Gao, H.; Zhang, X.; Zhang, Y.J. Research on the effect of air-entraining agent on concrete properties. Compr. Util. Fly Ash 2013, 5, 7–9. [Google Scholar]

- Xu, C.D.; Li, Z.; Lian, H.D.; Chen, J.H.; Huang, S. Mechanical Properties and Pore Structure Fractal Characteristics of Early-Frozen Concrete with Different Admixtures of Air-entraining Agents. Hydropower Energy Sci. 2023, 41, 133–136+180. [Google Scholar]

- Liu, X. Research on the effect of air-entraining agent on the performance of cement concrete pavement. Transp. World 2022, 34, 33–35. [Google Scholar]

- Liu, H.; Fu, Z. Experimental study on the effect of air content on concrete properties. Highw. Transp. Sci. Technol. 2009, 26, 38–43. [Google Scholar]

- Nie, P. Effect of air content of concreteon its mechanical properties. Northeast Highw. 2000, 2, 30–32+81. [Google Scholar]

- Xie, J.; Tang, J.; Sun, Y. Experimental study on the effect of air-entraining agent on the frost resistance of concrete under ultra-low temperature. Silic. Bull. 2020, 39, 12–19. [Google Scholar]

- Liu, P.F.; Shao, Y.; Li, C.X.; Zhang, H. Study on the effect of bubble characteristics on the durability performance of concrete. Concr. World 2022, 2, 56–59. [Google Scholar]

- Feng, G. Study on the Effect of Lightweight Aggregate Types on Physical and Mechanical Properties of Concrete. Master’s Thesis, Henan University, Kaifeng, China, 2022. [Google Scholar]

- Guo, H. Effect of different particle grading compositions onvoid ratio of coarse aggregate. Value Eng. 2022, 41, 48–50. [Google Scholar]

- Wang, H.; Zheng, Y.J.; Wang, L.; Tan, Y.B. Yang, L. Study on the effect of coarse aggregate pin-flake particle content on concrete properties. China Build. Mater. 2020, 4, 115–118. [Google Scholar]

- Shen, H. Influence of coarse aggregate quality on concrete properties. Henan Water Conserv. South-North Water Divers. 2018, 47, 74–75. [Google Scholar]

- Sang, D. Research on the Preparation and Application Performance of Porous Low Thermal Expansion Coefficient Functional Aggregate. Master’s Thesis, Anhui University of Architecture, Hefei, China, 2016. [Google Scholar]

- Sun, P. Functional Aggregate Preparation and Its Effect on Volumetric Deformation Properties of Cementitious Materials. Master’s Thesis, Anhui University of Architecture, Hefei, China, 2014. [Google Scholar]

- Zhang, X.Q.; Ma, K.L.; Long, G.C.; Zeng, X.H.; Tang, Z. Progress in the study of characterization parameters of coarse aggregate morphology and their relationship with concrete properties. Mater. Guide 2024, 38, 118–129. [Google Scholar]

- Maroofm, A.; Eidgaheed, R.; Mahboubi, A. Particle Morphology Effect on the Soil Pore Structure. In Proceedings of the 8th International Conference on Civil Engineering (ICCE 2021), Nanchang, China, 5 December 2021. [Google Scholar]

- Zhang, Z.Q.; Zhang, Y.F.; Yan, C.G.; Liu, Y.X. Influence of crushing index on properties of recycled aggregates pervious concrete. Constr. Build. Mater. 2017, 135, 112–118. [Google Scholar] [CrossRef]

- Tao, M.; Huadong, W.; Xiufen, Y.; Bo, Z.; Yuncai, Z. Effect of Mixed Recycled Aggregate on the Mechanical Strength and Microstructure of Concrete under Different Water Cement Ratios. Materials 2021, 14, 2631. [Google Scholar] [CrossRef]

- Hu, E. Study on road performance of road recycled concrete coarse aggregate. Railw. Constr. 2009, 05, 113–115. [Google Scholar]

- Su, D.; Wu, J.; Xiao, Z.J.; Huang, C. Characterization of aggregate and recycled aggregate particle shapes based on 3D scanning and spherical harmonic analysis. J. Shenyang Univ. Archit. 2020, 36, 827–835. [Google Scholar]

- Wadell, H. Volume, Shape, and Roundness of Rock Particles. J. Geol. 1932, 40, 443–451. [Google Scholar] [CrossRef]

- Wang, C. Numerical Simulation Study on the Effect of Coarse aggregate Morphology Characteristics on the Compressive Strength of Water Stabilized Layer. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2023. [Google Scholar]

- Wei, H.-L.; Ren, W.-Y.; Zhang, A.-J.; Li, J.-S.; Liu, H.-T. Two-dimensional fine morphology of concrete coarse aggregate based on XCT scanning images. Sci. Technol. Eng. 2021, 21, 8183–8189. [Google Scholar]

- Liu, X. Concrete Coarse Aggregate Topography Recognition and Application Based on Image Processing Techniques. Master’s Thesis, Chongqing University, Chongqing, China, 2021. [Google Scholar]

- Jean, J.K.T.; Wang, Z.Y.; Wang, S.D.; Huang, S.F.; Cheng, X. The influence of different fineaggregate and cooling regimes on the engineering properties of sulphoaluminate cement mortar after heating. Case Stud. Constr. Mater. 2023, 18, e01866. [Google Scholar]

- Zhu, H. Comparative Study on Measurement Methods and Experiments of Coarse Aggregate Angularity and Surface Texture. Master’s Thesis, Huaqiao University, Xiamen, China, 2020. [Google Scholar]

- Li, K.-L.; Gong, J.-W.; Chen, A.-J.; Sun, Z.-Z.; Du, X.-M. Evaluation method of morphological characteristics of slurry-modified recycled aggregates. Mater. Herald 2023, 37, 154–160. [Google Scholar]

- Guo, F.Q.; Zhang, H.; Yang, Z.J.; Huang, Y.J.; Withers, P.J. A spherical harmonic-random field coupled method for efficient reconstruction of CT-image based 3D aggregates with controllable multiscale morphology. Comput. Methods Appl. Mech. Eng. 2023, 406, 115901. [Google Scholar] [CrossRef]

- Jing, H. Elemental Simulation of Asphalt Mixture Based on Aggregate Particle Breakage Characteristics. Master’s Thesis, South China University of Technology, Guangzhou, China, 2020. [Google Scholar]

- Li, J.; Zhang, Q.; Chen, Z. Characterization and Evaluation of Aggregate Shape Characteristics of Modified Epoxy Abrasive Layer for Cement Pavements. J. Shenyang Univ. Archit. 2017, 33, 1055–1064. [Google Scholar]

- Muldowney, G.P.; James, D.B. Characterization of CMP Pad Surface Texture and Pad-Wafer Contact. MRS Proc. 2004, 816, K5.2. [Google Scholar] [CrossRef]

- Feng, P.; Wang, H.; Ding, H.; Xiao, J.; Hassan, M. Effects of surface texture and its mineral composition on interfacial behavior between asphalt binder and coarse aggregate. Constr. Build. Mater. 2020, 262, 120869. [Google Scholar] [CrossRef]

- Wang, H.-N.; Lei, M.-Y.; Kong, Q.-X.; Wang, H.-M.; Feng, B.-N. Correlation between comprehensive morphological characteristics of coarse aggregates and anti-wear performance. Sci. Technol. Eng. 2022, 22, 8056–8063. [Google Scholar]

- Wang, F.; Xiao, Y.; Cui, P.D.; Mo, L.T.; Fang, M.J. Progress of research on the influence law of aggregate morphology characteristics on the performance of asphalt mixtures. Mater. Guide 2022, 36, 95–107. [Google Scholar]

- Zhang, P. Review of the research on physical and mechanical properties of recycled concrete and analysis of its application in road engineering. China Water Transp. 2023, 23, 127–129. [Google Scholar]

- Zhang, S.F.; Yang, K.; Guo, J.Z.; Ma, J. Experimental study on self-compacting concrete with recycled fine aggregate. Shanxi Constr. 2024, 50, 111–113. [Google Scholar]

- Yan, L.; Yang, C.; Wang, C. Influence of coarse aggregate particle shape index and grading on the workability of self-compacting concrete. Concrete 2011, 1, 75–77+80. [Google Scholar]

- Wang, J.; Zhang, G.; Sun, L. Influence of shape of coarse aggregate on strength of asphalt concrete. Highw. Transp. Sci. Technol. 2007, S1, 53–56+65. [Google Scholar]

- Chen, F.Y. Effects of recycled aggregate and fly ash admixture on concrete properties. Fujian Transp. Sci. Technol. 2023, 12, 28–32. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.B. Study on the properties of recycledcoarse aggregate from waste concrete. Eng. Constr. 2023, 37, 746–749. [Google Scholar]

- Lin, S.-Y.; Bi, X.-S.; Luo, C.-S.; Ye, J.-F. Research on the basic mechanical properties of recycled high-strength concrete. Fujian Constr. 2019, 1, 86–90. [Google Scholar]

- Lan, X.-J.; Zhang, H.; Wang, Y.-B.; Hao, Z.-Q. Research progress on physical and mechanical properties of cement stabilized recycled aggregates. Mater. Her. 2024, 38, 69–80. [Google Scholar]

- Huang, Q.Y. Effect of recycled aggregate properties on the properties of recycled concrete. Constr. Technol. Dev. 2019, 46, 129–131. [Google Scholar]

- Lv, S.-H.; Yu, C.-T.; Zhou, X.-Z.; Yang, Q.-R. Recycled Coarse Aggregate and Its Effect on the Properties of Recycled Concrete. Brick Tile 2017, 8, 20–22. [Google Scholar]

- Li, Q.; Xiong, Z. Analysis of factors affecting recycled coarse aggregate on its basic mechanical properties of recycled concrete. Zhejiang Water Conserv. Sci. Technol. 2017, 45, 42–45. [Google Scholar]

- Zhang, Y.; Zhang, X.; Liu, X. Research on the quality of recycled coarse aggregate and its evaluation method. Compr. Util. Fly Ash 2012, 04, 3–8. [Google Scholar]

- Fan, L. Research on the basic properties and pretreatment methods of recycled coarse aggregates. Residence 2021, 03, 8–9+68. [Google Scholar]

- Gu, Z. Research on the Performance and Application of Cement Stabilized Recycled Aggregate Base. Master’s Thesis, Hebei University of Technology, Shijiazhuang, China, 2019. [Google Scholar]

- Gao, L. Research on Reinforcement and Proportion Design of Cement Stabilized Crushed Stone Recycled Aggregate. Master’s Thesis, Shandong University of Technology, Zibo, China, 2018. [Google Scholar]

- Chen, X.Y.; Ai, Y.Z.; Cheng, S.K.; Xu, X. Distribution and correlation analysis of performance indexes of recycled coarse aggregates. J. Build. Sci. Eng. 2023, 40, 1–10. [Google Scholar]

- Liu, S.-H.; Qian, X.-Q.; Fu, X.; Tong, Y.-W.; Ren, Q. Discussion on the performance index of recycled coarse aggregate and its linear fitting applicability. Concrete 2017, 10, 118–122. [Google Scholar]

- Wang, L.; Liang, L.; Fan, L.-B.; Huang, L.; Deng, X.-L. Experimental study on the effect of brick and mortar content on the properties of recycled aggregates. Concrete 2023, 7, 161–164+168. [Google Scholar]

- Wang, C.; Ge, Z. Influence of Crushing Value of Coarse Aggregate on Seepage Resistance of Asphalt Concrete. Sci. Technol. Eng. 2010, 10, 4061–4064. [Google Scholar]

- Rao, Z.; Wu, X.; Hua, L. Experimental study on the effect of recycled coarse aggregate on the anti-chlorine ion penetration performance of concrete. Fly Ash 2014, 26, 18–19. [Google Scholar]

- Yuan, H. Research on the Rheology and Mechanism of Self-Compacting Concrete Based on Theinteraction Force between Particles of Cementitious Materials and Aggregate Properties. Ph.D. Thesis, Shandong University, Jinan, China, 2023. [Google Scholar]

- Liu, G.Z.; Song, Y.X.; Zhang, X.J.; Chang, M.F. Aggregate compaction performance based on aggregate geometric properties. Highw. Transp. Sci. Technol. 2013, 30, 12–17. [Google Scholar]

- Guo, P. Research on Uniform Design of Cementitious Composites Based on Recycled Aggregate Packing Compactness. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2019. [Google Scholar]

- Guo, C. Study on the Modulation of Aggregate Morphological Characteristics and GradePair Concrete Properties. Master’s Thesis, Wuhan Institute of Technology, Wuhan, China, 2020. [Google Scholar]

- Guo, C.; Shui, Z.H.; Fei, X.F.; Guo, W. Study on the effect of fine aggregate morphology on the rheological properties of C30 concrete. Concr. Cem. Prod. 2020, 7, 21–25+29. [Google Scholar]

- Bu, Y.; Wu, Z. Influence of coarse aggregate morphology on compaction performance of asphalt pavement. Transp. World 2021, 28, 133–136. [Google Scholar]

- Liang, R.; Liu, H.; Lin, L. Yue Influence of coarse aggregate particle shape on concrete properties. Guangdong Build. Mater. 2003, 8, 11–13. [Google Scholar]

- Zhang, K.Y.; Cui, S.S.; Li, S.; Zhang, B.; Xu, C. Influence of Aggregate Morphological Characteristics on Anti-skid Performance of Asphalt Pavements. J. Wuhan Univ. Technol. 2021, 43, 41–46. [Google Scholar]

- Zhou, C.; Chen, G.; Tan, Y. Fractal measurement and characterization of coarse aggregate surface texture roughness. J. Harbin Inst. Technol. 2009, 41, 85–89. [Google Scholar]

- Zhou, C.; Chen, G.; Tan, Y. Measurement of texture roughness of aggregate surface. J. Transp. Eng. 2009, 9, 50–55. [Google Scholar]

- Shen, Y. Effect of coarse aggregate strength on mechanical properties of concrete. Low Temp. Constr. Technol. 2012, 34, 37–39. [Google Scholar]

- Ma, M.C.; Zhou, Y.X.; Tian, S.; Dong, B.J.; Gao, F. Influence of crushing index of coarse aggregate on mechanical properties of concrete. Build. Mater. Dev. Orientat. 2018, 16, 109–112. [Google Scholar]

- Liu, D.; Dong, C. Influence of technical indexes of coarse aggregates on cement concrete properties. Shanxi Constr. 2012, 38, 124–125. [Google Scholar]

- Wang, D. Effects of water absorption of coarse and fine aggregates on concrete properties. Sichuan Build. Mater. 2022, 48, 9–10. [Google Scholar]

- Zhu, L.C.; Li, P.; Kou, J.S.; Ma, Z.; Yuan, M. Research progress on physical and mechanical properties of recycled coarse aggregate concrete. Sichuan Build. Mater. 2015, 41, 13–14. [Google Scholar]

- Sri Ravindrarajah, R.; Tam, C.T. Properties of concrete made with crushed concrete as coarse aggregate. Mag. Concr. Res. 1985, 37, 29–38. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Gumaste, K.S. Properties of recycled aggregate concrete. Indian Concr. J. 1998, 72, 49–53. [Google Scholar]

- Mandal, S.K.; Chakraborty, S.; Gupta, A. Some studies on durability of recycled aggregate concrete. Indian Concr. J. 2002, 76, 385–388. [Google Scholar]

- Fan, C. Influence of recycled coarse aggregate on the mechanical properties of concrete structure. Jiangxi Build. Mater. 2021, 10, 29–30. [Google Scholar]

- Lin, J.; Wu, Y.-J.; Gao, S.; Lu, L.-L.; Wang, J.-F. Study on the effect of maintenance temperature on the pore structure of activated powder concrete. Silic. Bull. 2019, 38, 2600–2605. [Google Scholar]

- Li, D.; Wu, J.-W.; Zhang, P.; Geng, W.-C.; Ding, X.-Y. Chloride ion permeability resistance of air-entraining concrete and its microporous structure. Silic. Bull. 2017, 36, 3797–3802. [Google Scholar]

| Ca/Si Ratio | C-S-H Morphological Characterization |

|---|---|

| <1.5 | Clusters, granules, flakes |

| 1.5 to 2.0 | Short thick needle-like rods, longer network fibers |

| >2.0 | Elongated needle-like rods, loose network fibers |

| Low Texture | Medial Texture | High Grain (Texture) | Extremely High Texture | |

|---|---|---|---|---|

| Range of indicators | 0 ≤ X ≤ 2100 | 2100 ≤ X ≤ 3975 | 3975 ≤ X ≤ 5400 | 5400 ≤ X ≤ 10,000 |

| Form | Class I | Class II | Class III | |

|---|---|---|---|---|

| Crushing index/% | crushed or broken rock | ≤10 | ≤20 | ≤30 |

| pebbles | ≤12 | ≤14 | ≤16 | |

| Literature Sources | Natural Aggregate Crushing Index/% | Recycled Aggregate Crushing Index/% | Recycled Aggregate/Natural Aggregate |

|---|---|---|---|

| literature [77] | 4.04 | 15.2 | 3.76 |

| literature [78] | 6.20 | 16.5 | 2.66 |

| literature [79] | 4.85 | 19.17 | 3.95 |

| literature [80] | 4.80 | 15.10 | 3.15 |

| Form | Class I | Class II | Class III |

|---|---|---|---|

| Water absorption/% | ≤1.0 | ≤2.0 | ≤2.5 |

| Literature Sources | Fit Function | Correlation Coefficient/R2 |

|---|---|---|

| literature [84] | + 1.07 | 0.972 |

| literature [85] | − 0.263 | 0.954 |

| literature [86] | + 8 | 0.97 |

| Fit a Model (Math.) | Specimen 1 | Specimen 2 | Specimen 3 | |

|---|---|---|---|---|

| 7.24 | 7.41 | 5.97 | ||

| 18.17 | 18.67 | 4.41 | ||

| 0.98 | 0.99 | 0.85 |

| Grading Criteria | Characterized Genes | Associative Properties | |||

|---|---|---|---|---|---|

| cementitious material | Constituents | Nano | C-S-H | Calcium–silica ratio | Pore structure, early compressive strength, flow properties, frost resistance, stiffness |

| Structural genes | Micro | Pore structure | Porosity, pore size distribution, pore shape | frost resistance, permeability, compressive strength | |

| Air content | Air content, bubble spacing factor | Frost resistance, durability, compression resistance | |||

| Macro | Aggregate | Shape | Chloride penetration resistance, viscosity, fluidity | ||

| Angularity | Fluidity, viscosity, strength, peak shear stress | ||||

| Surface texture | Slip resistance | ||||

| Crushing index | Compressive strength, flexural strength, modulus of elasticity, coefficient of permeability | ||||

| water absorption | Slump, fluidity, drying shrinkage capacity, compressive strength | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Zhong, Y. A Review of Gene–Property Mapping of Cementitious Materials from the Perspective of Material Genome Approach. Materials 2024, 17, 3640. https://doi.org/10.3390/ma17153640

Li F, Zhong Y. A Review of Gene–Property Mapping of Cementitious Materials from the Perspective of Material Genome Approach. Materials. 2024; 17(15):3640. https://doi.org/10.3390/ma17153640

Chicago/Turabian StyleLi, Fei, and Yan Zhong. 2024. "A Review of Gene–Property Mapping of Cementitious Materials from the Perspective of Material Genome Approach" Materials 17, no. 15: 3640. https://doi.org/10.3390/ma17153640

APA StyleLi, F., & Zhong, Y. (2024). A Review of Gene–Property Mapping of Cementitious Materials from the Perspective of Material Genome Approach. Materials, 17(15), 3640. https://doi.org/10.3390/ma17153640