The Diatomite Grinding Technology Concept for the Protection of Diatomite Shells and the Control of Product Grading

Abstract

1. Introduction

2. Materials and Methods

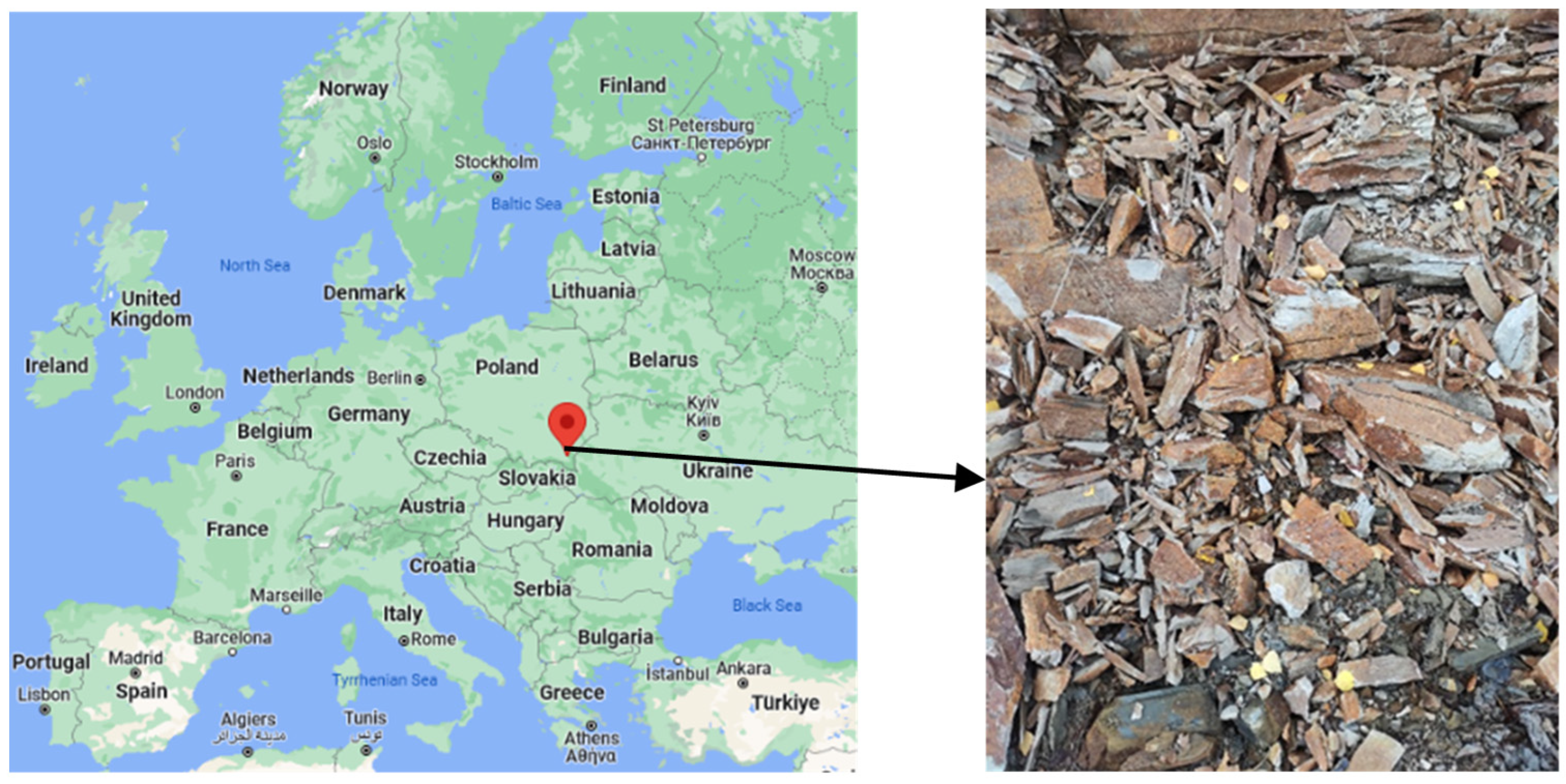

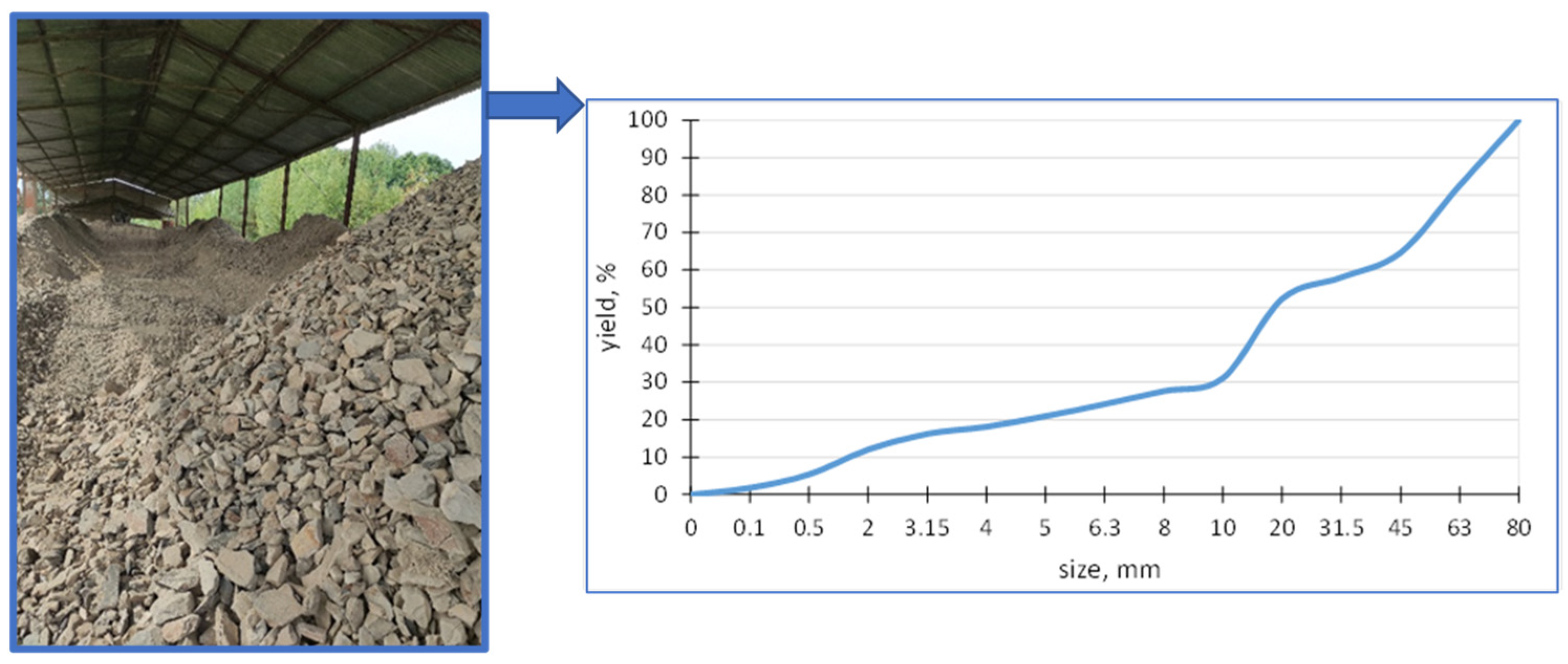

2.1. Basic Physical Parameters, XRF Chemical Analysis, XRD Phase Composition Assessment, and Microscopic Images of the Feed

2.2. Characteristics of the Grinding and Screening Machines Used in This Study

- -

- System A with a jaw crusher and a hammer crusher;

- -

- System B with a jaw crusher and a high-pressure grinding roll (HPGR);

- -

- System C with a jaw crusher and a ball mill;

- -

- System D with a jaw crusher, a hammer crusher and high-pressure grinding rolls (HPGR);

- -

- System E with a jaw crusher, a high-pressure grinding rolls (HPGR) and a hammer crusher.

| Crusher, System | Operating Parameters |

|---|---|

| A1 #12 mm, jaw crusher, open circuit | outlet gap 12 mm |

| A2 #10 mm, hammer crusher, open circuit | grid 10 mm, rate 3000 1/min |

| A2 #15 mm, hammer crusher, open circuit | grid 15 mm, rate 3000 1/min |

| A2 #20 mm, hammer crusher, open circuit | grid 20 mm, rate 3000 1/min |

| A3 #20 mm, hammer crusher, closed circuit | grid 20 mm, rate 3000 1/min |

| B2 10 kN, HPGR, open circuit | roll pressure force, 10 kN, gap 3 mm, speed 0.5 m/s |

| B2 15 kN, HPGR, open circuit | roll pressure force, 15 kN, gap 3 mm, speed 0.5 m/s |

| B3 15 kN, HPGR, closed circuit | roll pressure force, 15 kN, gap 3 mm, speed 0.5 m/s |

| C2 2 min, ball mill, open circuit | milling time 2 min, Bond’s standards |

| C3 4 min, ball mill, open circuit | milling time 4 min, Bond’s standards |

| D2 + D3 #20 mm, hammer crusher + HPGR, closed circuit | grid 20 mm, roll pressure force, 15 kN |

| E2 + E3 #10 mm, HPGR + hammer crusher, closed circuit | roll pressure force, 15 kN, grid 10 mm |

3. Results

3.1. Grinding Rates for All Systems

3.2. Analysis of Grain Shape in Comminution Products

- The smallest dimension,

- Intermediate dimension, and

- The largest dimension.

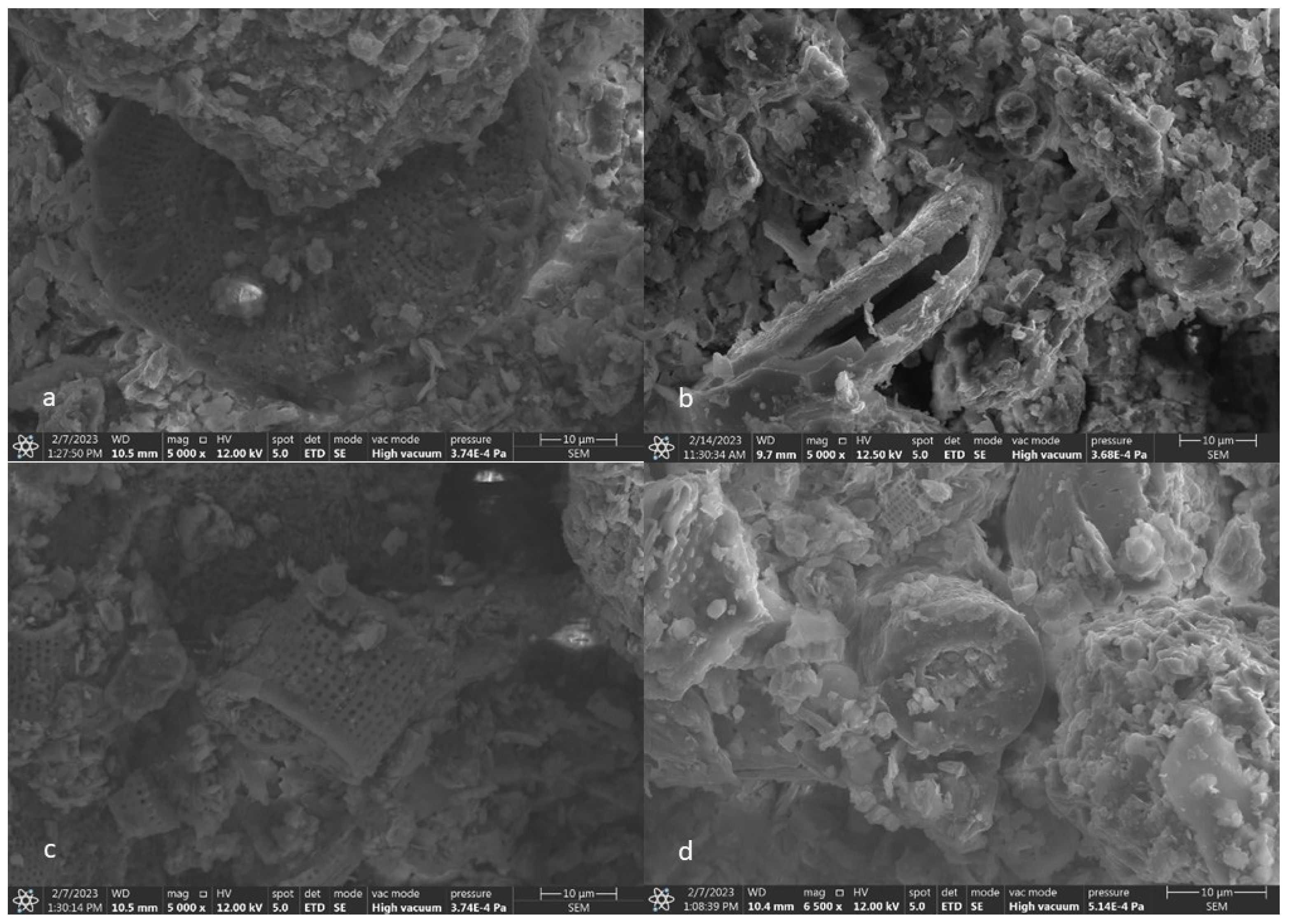

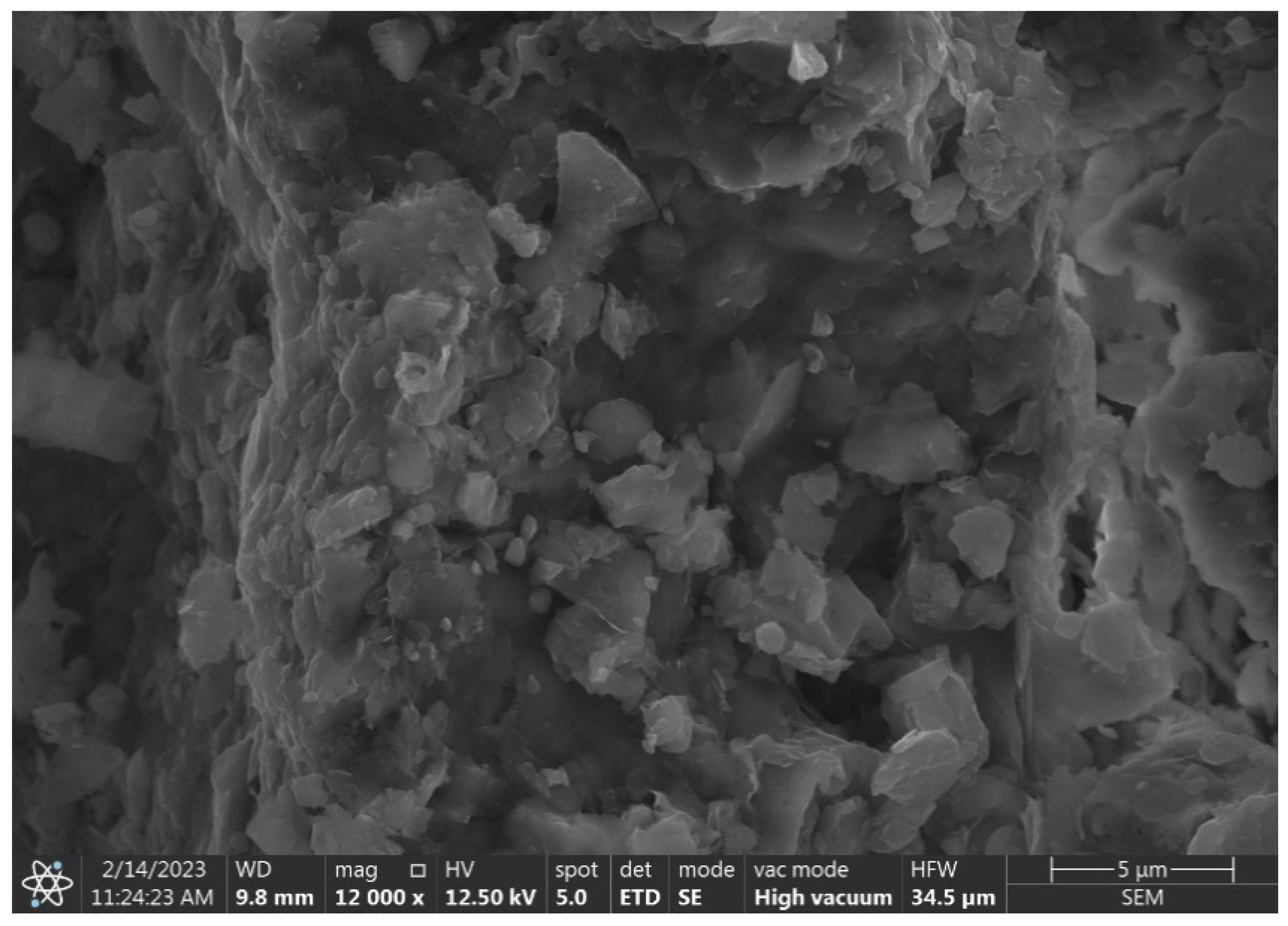

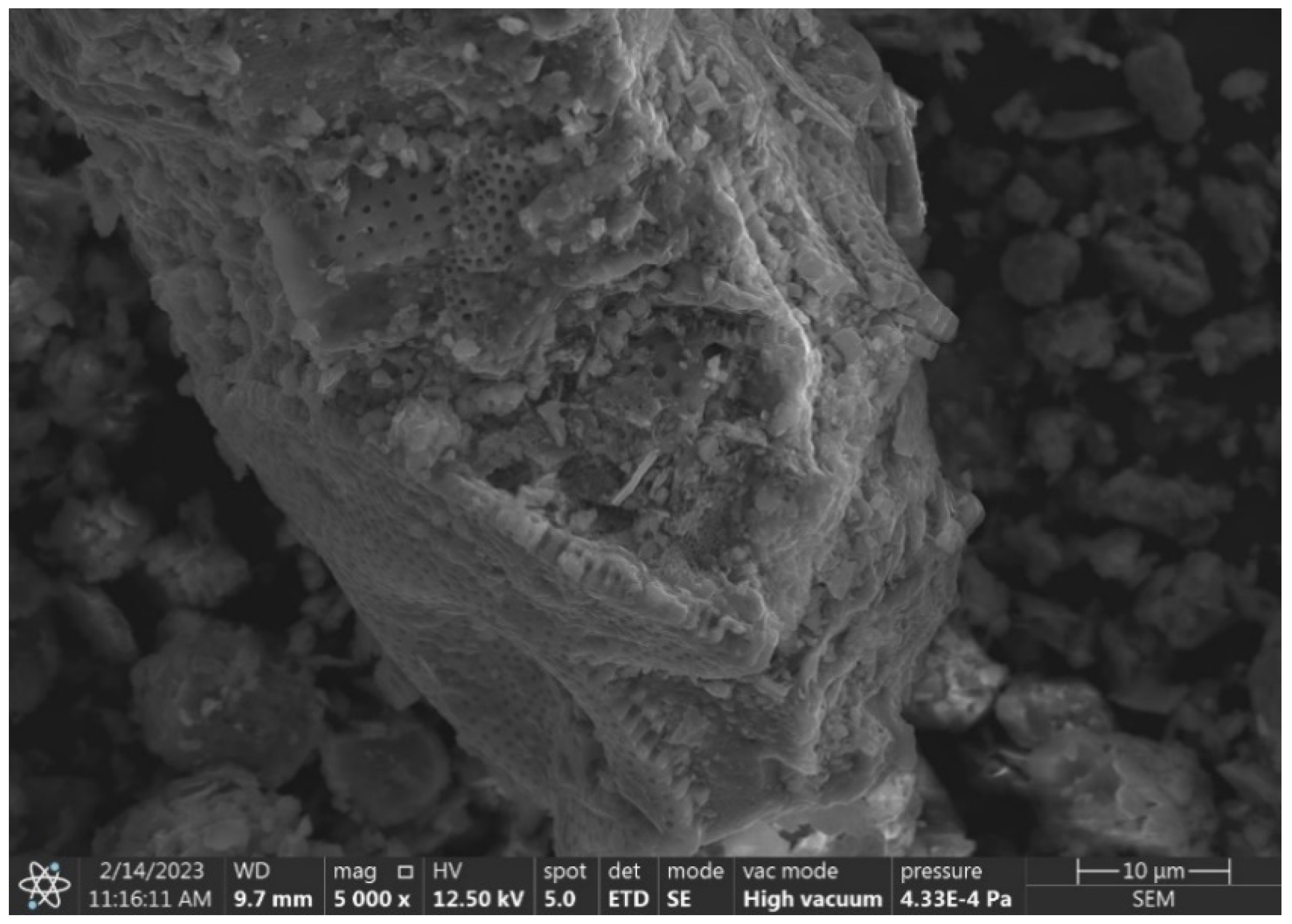

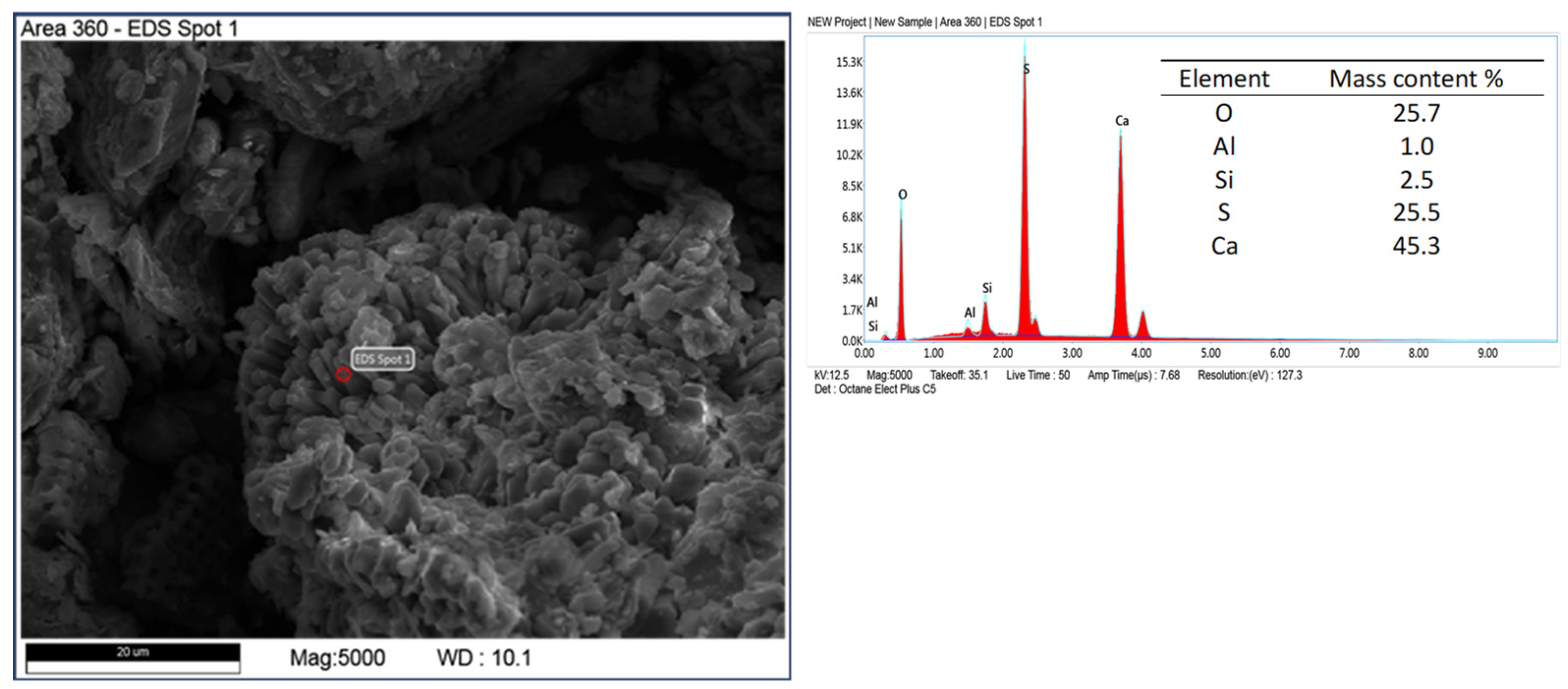

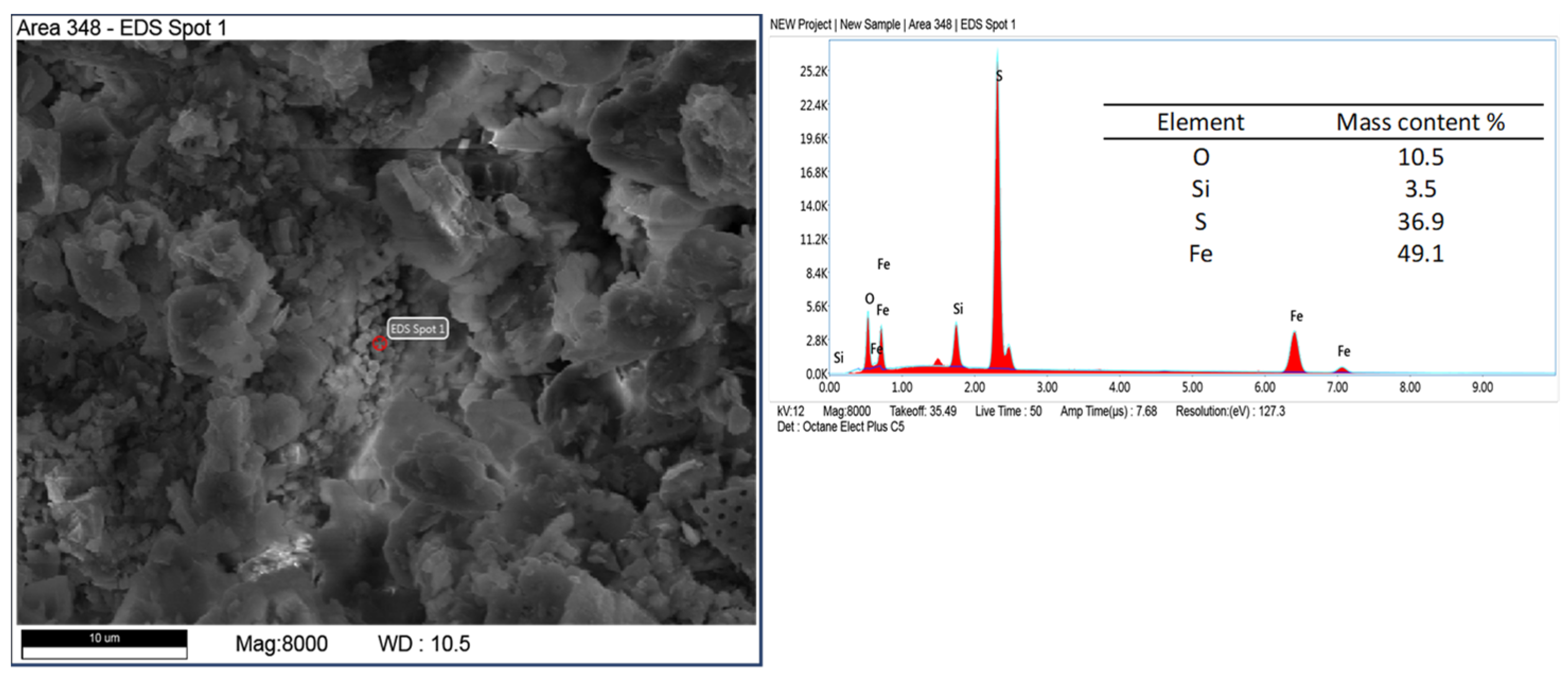

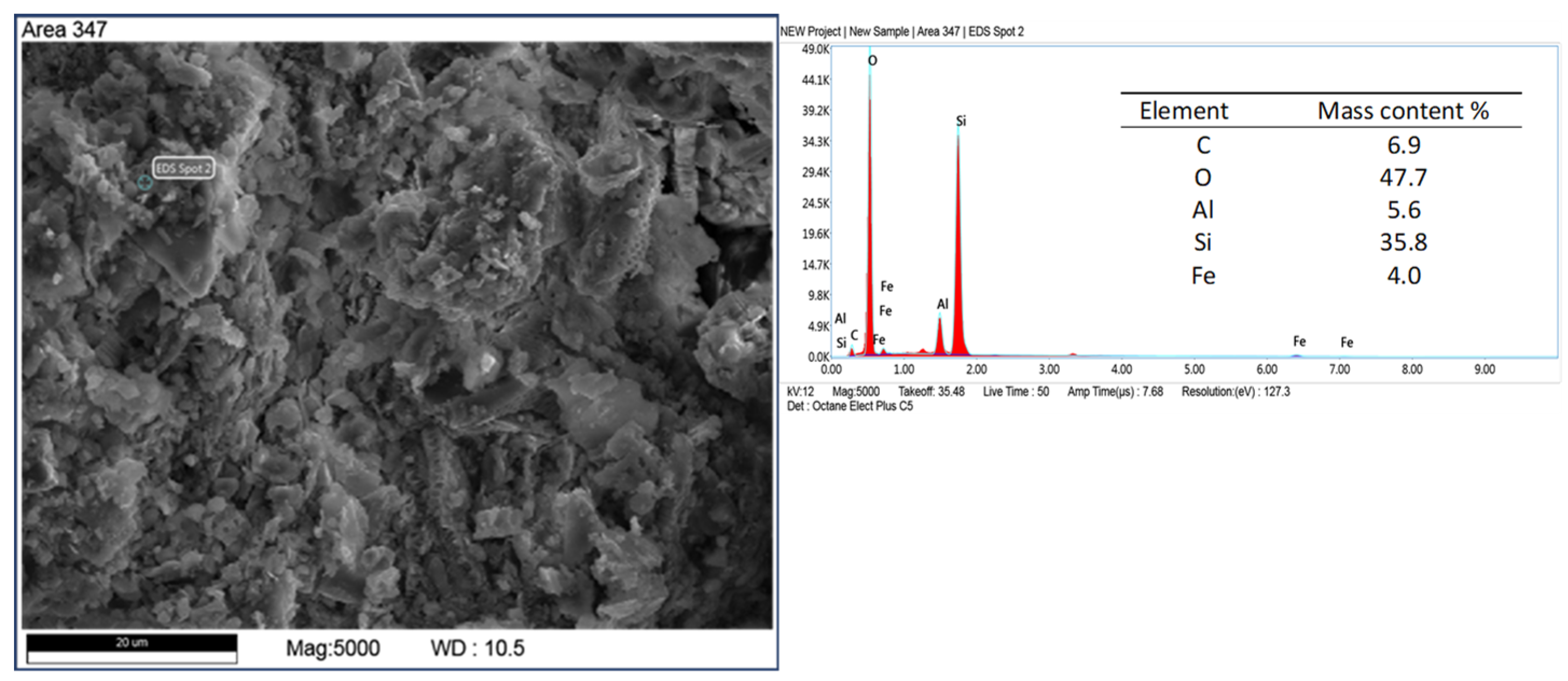

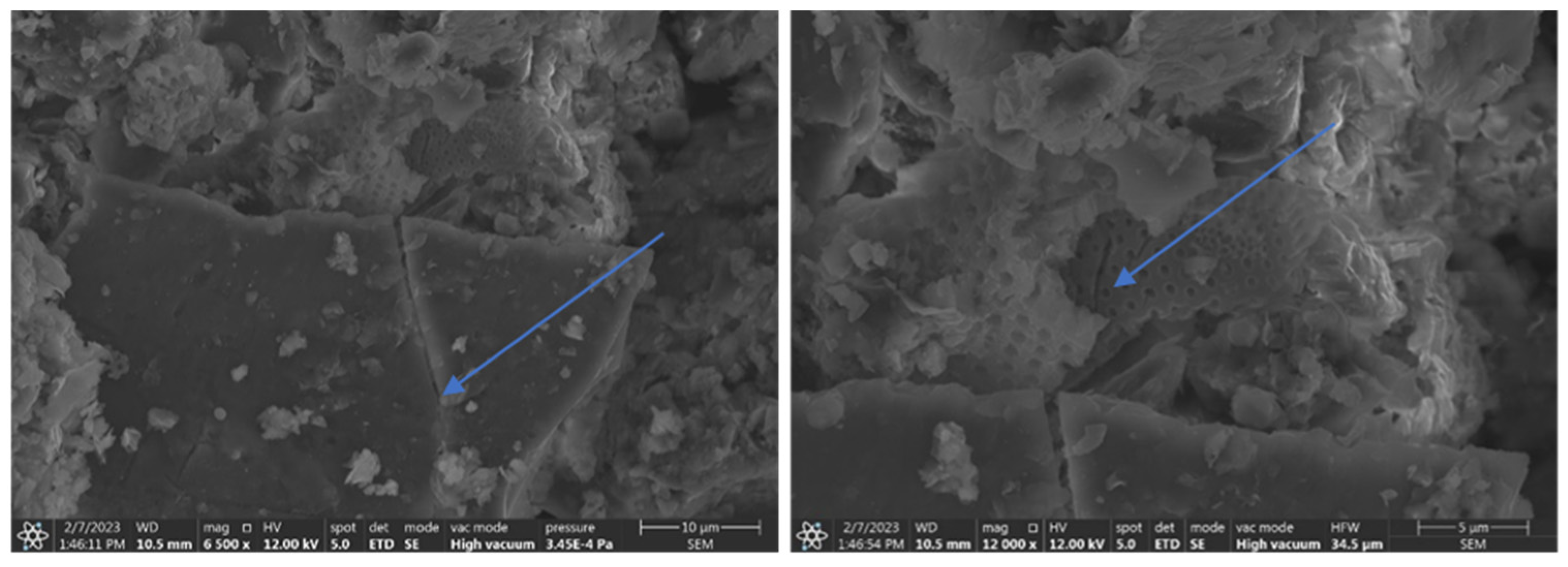

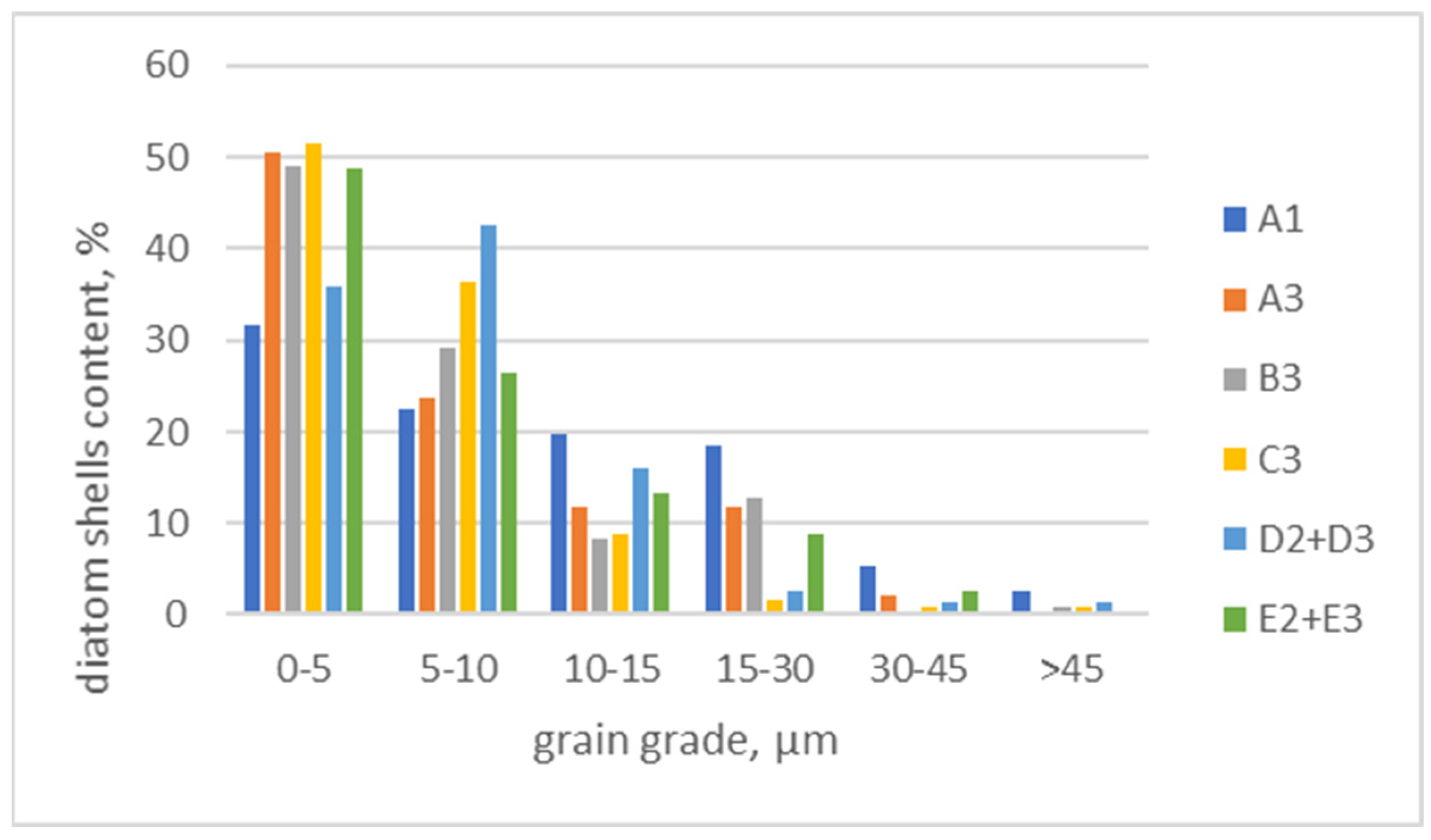

3.3. SEM and EDS Microscopic and Chemical Analysis of Grinding Products and Evaluation of Diatom Shell Destruction

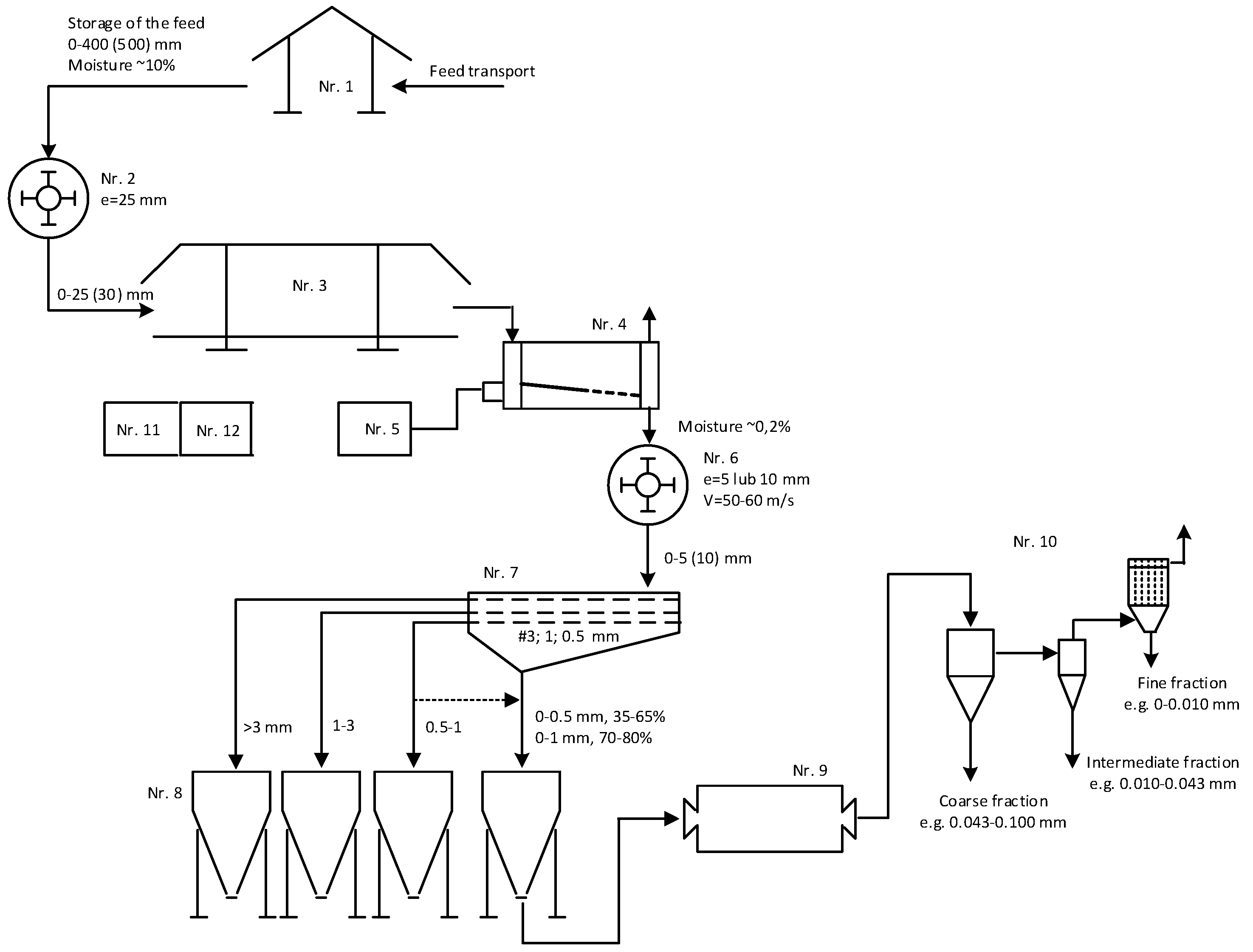

3.4. The Concept of the Technological System

- Stone storage and transport facility for the crushing plant.

- 2.

- Crushing facility with a hammer crusher with a 25 mm grid.

- 3.

- Raw material pre-drying facility with roofing.

- 4.

- Raw material drying facility in a rotary dryer with loading system.

- 5.

- A fuel oil or gas tank facility with a heat burner in the drying system.

- 6.

- Crushing facility with a hammer crusher, 5 or 10 mm grate (interchangeable), and variable linear speed 50–60 m/s.

- 7.

- Screen classification facility with multideck staggered motion screen with production dust collection system.

- 8.

- Silos collection and product packaging facility.

- 9.

- Ball mill grinding facility with dust extraction system.

- 10.

- Pneumatic classification facility in an open-circuit air cyclone separator with dust extraction system in the filters.

- 11.

- Energy facility—power, supply, control.

- 12.

- Land development.

4. Summary and Conclusions

- The highest comminution ratios were characterized by the roller press and the hammer crusher operating in the closed system with a crusher grate of 10 mm. It can be concluded that the crushers operating in closed systems produce the output of more than 83%, these are: a hammer crusher in the A3 closed system and a hammer crusher with HPGR in the D2 + D3 system.

- The yields of fractions below 0.01 mm in crushers are low, with the highest output of 0.25% achievable in a C3 system with a ball mill. The ball mill shows great potential, and the system should be terminated at the third crushing stage. It has a dominant function for the finer feed and should work in an open system with the dried material. In addition, it will have a beneficial effect on the shape of the grains and the release of diatom shells, which has been confirmed by studies presented in this article. It should be noted that the damp material fed into the mill will cause the raw material to cling to the roller and grinders.

- Crushing with high-pressure grinding rolls will be problematic. The grains obtained after HPGR are weak and tend to self-crumb. This is a feature of the product caused by acquired microcracking of grains as a result of high-pressure forces between the rollers in the press chamber on the material being shredded. This was visualized in photos taken in SEM.

- The shape analysis according to the Zingg classification in the grain size range of 0–0.1 mm shows that system B3 with a roller press had the lowest spherical grain production (almost 87%) and system E2 + E3 with an HPGR and a hammer crusher had the highest spherical grain production of spherical grains (91.5%).

- Samples of crushed materials were analyzed under an electron microscope in different crushers and machine systems. It was observed that, as the grain size of the diatomite decreased, the content of well-preserved diatomite carapaces increased. This can be explained by their release from other rock-forming minerals and their accumulation in the finest fractions as a result of the crushing process.

- A conceptual scheme of a technological system for dual stage grinding and classification together with diatomite drying, was proposed for the production of sand, grit, and silt fractions in various grain size ranges with a capacity of up to 20 mg/h. The technological system consists of 12 facilities.

- Appropriate processing of diatomite increases its potential for use in filtration, adsorption, and concrete additives and eliminates the challenges and limitations that can be encountered in these applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gondek, K.; Micek, P.; Baran, A.; Bajda, T.; Kowal, J.; Lis, M.; Wyrobisz-Papiewska, A.; Wojtysiak, D.; Smoroń, K. Modified Natural Diatomite with Various Additives and Its Environmental Potential. Materials 2023, 16, 4494. [Google Scholar] [CrossRef] [PubMed]

- Bońda, R. Skała diatomitowa. In Bilans Zasobów Złóz Kopalin W Polsce Wg Stanu Na 31 XII 2020 r; Szuflicki, M., Malon, A., Tymiński, M., Eds.; Państwowy Instytut Geologiczny—Państwowy Instytut Badawczy: Warszawa, Poland, 2021; pp. 78–79. [Google Scholar]

- Ye, X.; Kang, S.; Wang, H.; Li, H.; Zhang, Y.; Wang, G.; Zhao, H. Modified natural diatomite and its enhanced immobilization of lead, copper and cadmium in simulated contaminated soil. J. Hazard. Mater. 2015, 289, 210–218. [Google Scholar] [CrossRef]

- Aksakal, E.L.; Angin, I.; Oztas, T. Effects of diatomite on soil physical properties. Catena 2012, 88, 1–5. [Google Scholar] [CrossRef]

- Grela, A.; Łach, M.; Korniejenko, K.; Mierzwiński, D.; Bajda, T.; Hebda, M.; Figiela, B. Management of mining wastes through their transformation into useful sorbent. IOP Conf. Ser. Earth Environ. Sci. 2021, 942, 012007. [Google Scholar] [CrossRef]

- Grela, A.; Łach, M.; Mikuła, J.; Hebda, M. Thermal analysis of the products of alkali activation of fly ash from CFB boilers. J. Therm. Anal. Calorim. 2016, 124, 1609–1621. [Google Scholar] [CrossRef]

- Łach, M.; Grela, A.; Komar, N.; Mikuła, J.; Hebda, M. Calcined post-production waste as Materials Suitable for the Hydrothermal Synthesis of Zeolites. Materials 2019, 12, 2742. [Google Scholar] [CrossRef]

- Łach, M.; Grela, A.; Pławecka, K.; Guigou, M.D.; Mikuła, J.; Komar, N.; Bajda, T.; Korniejenko, K. Surface modification of synthetic zeolites with Ca and HDTMA compounds with determination of their phytoavailability and comparison of CEC and AEC parameters. Materials 2022, 15, 4083. [Google Scholar] [CrossRef] [PubMed]

- Garcia, G.; Cardenas, E.; Cabrera, S.; Hedlund, J.; Mouzon, J. Synthesis of zeolite Y from diatomite as silica source. Microporous Mesoporous Mater. 2016, 219, 29–37. [Google Scholar] [CrossRef]

- Stafin, G.; Grzebielucka, E.C.; Antunes, S.R.M.; Borges, C.P.F.; de Andrade, A.V.C.; Alves, S.A.; de Souza, É.C.F. Synthesis of zeolites from residual diatomite using a microwave-assisted hydrothermal method. Waste Manag. 2021, 126, 853–860. [Google Scholar] [CrossRef]

- Reka, A.A.; Pavlovski, B.; Ademi, E.; Jashari, A.; Boev, B.; Boev, I.; Makreski, P. Effect of thermal treatment of clayey diatomite at temperature range 800–1200 °C. In Prime Archives in Chemistry; Ayuk, E.L., Ed.; Vide Leaf: Telangana, India, 2020; pp. 1–18. [Google Scholar]

- Reka, A.A.; Pavlovski, B.; Fazlija, E.; Berisha, A.; Pacarizi, M.; Daghmehchi, M.; Sacalis, C.; Jovanovski, G.; Makreski, P.; Oral, A. Diatomaceous Earth: Characterization, thermal modification, and application. Open Chem. 2021, 19, 451–461. [Google Scholar] [CrossRef]

- Kashin, A.D.; Sedelnikova, M.B.; Chebodaeva, V.V.; Uvarkin, P.V.; Luginin, N.A.; Dvilis, E.S.; Kazmina, O.V.; Sharkeev, Y.P.; Khlusov, I.A.; Miller, A.A.; et al. Diatomite-based ceramic biocoating for magnesium implants. Ceram. Int. 2022, 48 Pt A, 28059–28071. [Google Scholar] [CrossRef]

- Ha, J.H.; Oh, E.; Song, I.H. The fabrication and characterization of sintered diatomite for potential microfiltration applications. Ceram. Int. 2013, 39, 7641–7648. [Google Scholar] [CrossRef]

- Kuzminchuk, A.; Burmak, A.; Litynska, M.; Dontsova, T. New diatomaceous earth and kaolinite ceramic membranes for turbidity reduction in water. Appl. Nanosci. 2023, 13, 5335–5343. [Google Scholar] [CrossRef]

- Łach, M.; Pławecka, K.; Marczyk, J.; Ziejewska, C.; Hebdowska-Krupa, M.; Nykiel, M.; Hebda, M.; Miernik, K.; Mierzwiński, D.; Korniejenko, K.; et al. Use of diatomite from Polish fields in sustainable development as a sorbent for petroleum substances. J. Clean. Prod. 2023, 389, 136100. [Google Scholar] [CrossRef]

- Dong, L. Study on building energy—Saving performance of diatomite materials. Chem. Eng. Trans. 2017, 62, 535–540. [Google Scholar] [CrossRef]

- Karaman, S.; Karaipekli, A.; Sar, A.; Biçer, A. Polyethylene glycol (PEG)/diatomite composite as a novel form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2011, 95, 1647–1653. [Google Scholar] [CrossRef]

- Xu, B.; Li, Z. Paraffin/diatomite composite phase change material incorporated cement-based composite for thermal energy storage. Appl. Energy 2013, 105, 229–237. [Google Scholar] [CrossRef]

- Benayache, S.; Alleg, S.; Mebrek, A.; Sunol, J.J. Thermal and microstructural properties of paraffin/diatomite composite. Vacuum 2018, 157, 136–144. [Google Scholar] [CrossRef]

- Jeong, S.G.; Jeon, J.; Lee, J.H.; Kim, S. Optimal preparation of PCM/diatomite composites for enhancing thermal properties. Int. J. Heat Mass Tran. 2013, 62, 711–717. [Google Scholar] [CrossRef]

- Ergün, A. Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Construct. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- Lv, Z.; Jiang, A.; Liang, B. Development of eco-efficiency concrete containing diatomite and iron ore tailings: Mechanical properties and strength prediction using deep learning. Construct. Build. Mater. 2022, 327, 126930. [Google Scholar] [CrossRef]

- Sun, M.; Zou, C.; Xin, D. Pore structure evolution mechanism of cement mortar containing diatomite subjected to freeze-thaw cycles by multifractal analysis. Cem. Concr. Compos. 2020, 114, 103731. [Google Scholar] [CrossRef]

- Kapeluszna, E.; Szudek, W.; Wolka, P.; Zieliński, A. Implementation of alternative mineral additives in low-emission sustainable cement composites. Materials 2021, 14, 6423. [Google Scholar] [CrossRef] [PubMed]

- Stempkowska, A.; Gawenda, T.; Chajec, A.; Sadowski, Ł. Effect of Granite Powder Grain Size and Grinding Time of the Properties of Cementitious Composites. Materials 2022, 15, 8837. [Google Scholar] [CrossRef] [PubMed]

- Degirmenci, N.; Arin Yilmaz, A. Use of diatomite as partial replacement for Portland cement in cement mortars, Construction and Building. Materials 2009, 23, 284–288. [Google Scholar] [CrossRef]

- Vedat, D. Comparison with Some Porous Materials and the Effects of Powder Filling on Breakage Parameters of Diatomite in Dry Ball Milling. Part. Sci. Technol. 2011, 29, 428–440. [Google Scholar] [CrossRef]

- Cui, T.S.; Wu, H.H.; Zhou, Z.G. Research on mineral processing technology of low gradediatomite of Shuangjiang in Yunnan. J. Guilin Inst. Technol. 1996, 16, 313–316. [Google Scholar]

- Yang, X.; Sun, Z.; Zheng, S. Physical purification of diatomite based on laminar-flow centrifugal separation, Physicochem. Probl. Miner. Process. 2014, 50, 705–718. [Google Scholar]

- Gawenda, T.; Stempkowska, A.; Saramak, D.; Foszcz, D.; Krawczykowska, A.; Surowiak, A. Assessment of Operational Effectiveness of Innovative Circuit for Production of Crushed Regular Aggregates in Particle Size Fraction 8–16 mm. Minerals 2022, 12, 634. [Google Scholar] [CrossRef]

- Gawenda, T.; Surowiak, A.; Krawczykowska, A.; Stempkowska, A.; Niedoba, T. Analysis of the Aggregate Production Process with Different Geometric Properties in the Light Fraction Separator. Materials 2022, 15, 4046. [Google Scholar] [CrossRef] [PubMed]

- Bembenek, M.; Krawczyk, J.; Pańcikiewicz, K. The wear mechanism of mill beaters for coal grinding made-up from high manganese cast steel. Eng. Fail. Anal. 2022, 142, 106843. [Google Scholar] [CrossRef]

- Bembenek, M.; Wdaniec, P. Effect of crusher type and its parameters on the dry granulation of powders. Przemysl Chem. 2019, 98, 310–313. [Google Scholar] [CrossRef]

- Gawenda, T. Production Methods for Regular Aggregates and Innovative Developments in Poland. Minerals 2021, 11, 1429. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J.A. FRSC, FCIM, P.Eng. In Wills’ Mineral Processing Technology, 8th ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- PN-EN 933-1; Badania Geometrycznych Właściwości Kruszyw. Oznaczanie Składu Ziarnowego. Metoda Przesiewania. Polish Committee for Standardization: Warsaw, Poland, 2000.

- PN-EN 1097-5; Testing the Mechanical and Physical Properties of Aggregates. Polish Committee for Standardization: Warsaw, Poland, 2013.

- De Namor, A.F.D.; El Gamouz, A.; Frangie, S.; Martinez, V.; Valiente, L.; Oliver, A.; Webb, O.A. Turning the volume down on heavy metals using tuned diatomite. A review of diatomite and modified diatomite for the extraction of heavy metals from water. J. Hazard. Mater. 2012, 241–242, 14–31. [Google Scholar] [CrossRef] [PubMed]

- Flower, R.J. Diatom Methods, Diatomites: Their Formation, Distribution, and Uses. In Encyclopedia of Quaternary Science, 2nd ed.; Elias, S.A., Mock, C.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 501–506. [Google Scholar]

- Costa, C.; Velosa, A.; Cerqueira, A.; Caetano, P.; Rocha, F. Characterization of Portuguese diatomites in order to assess potential applications. Acta Geodyn. Geomater. 2018, 15, 47–56. [Google Scholar] [CrossRef]

- Marczyk, J.; Pławecka, K.; Hebdowska-Krupa, M.; Nykiel, M.; Łach, M. Research on diatomite from Polish deposits and the possibilities of its use. J. Achiev. Mater. Manuf. 2022, 115, 5–15. [Google Scholar] [CrossRef]

- Avramenko, A.S.; Cherepanova, M.V.; Pushkar, V.S.; Yarusova, S.B. Diatom characteristics of the Far East siliceous organogenic deposits. Russ. Geol. Geophys. 2015, 56, 947–958. [Google Scholar] [CrossRef]

- Lutyński, M.; Sakiewicz, P.; Lutyńska, S. Characterization of Diatomaceous Earth and Halloysite Resources of Poland. Minerals 2019, 9, 670. [Google Scholar] [CrossRef]

- De Jonghe, A.; Hart, M.B.; Grimes, S.T.; Mitlehner, A.G.; Price, G.D.; Smart, C.W. Eocene diatoms from Whitecliff Bay, Isle of Wight, England: Stratigraphy and preservation. Proc. Geol. Assoc. 2011, 122, 472–483. [Google Scholar] [CrossRef]

- He, Q.; An, Y.; Sun, F.; Lai, C. Genesis of Pyrite Concretions: Constraints from Mineral and Geochemical Features of Longtan Formation in Anhui Province, Eastern China. Minerals 2019, 9, 467. [Google Scholar] [CrossRef]

- PN-EN 933-3; Badania Geometrycznych Właściwości Kruszyw. Oznaczanie Kształtu Ziarn za Pomocą Wskaźnika Płaskości. Polish Committee for Standardization: Warsaw, Poland, 1999.

- Kamiński, S.; Kamińska, D. Badanie uziarnienia materiałów mineralnych 0.5 μm–100 mm. Pr. Nauk. Inst. Gór. Politech. Wroc. Stud. Mater. 2009, 125, 113–120. [Google Scholar]

- Hubao, A.; Yang, Z.; Hu, R.; Chen, Y.-F. Molecular Origin of Wetting Characteristics on Mineral Surfaces. Langmuir 2023, 39, 2932–2942. [Google Scholar]

- Jin, J.; Wang, X.; Wic, C.D.; Dang, L.X.; Miller, J.D. Silica surface states and their wetting characteristics. Surf. Innov. 2020, 8, 145–157. [Google Scholar] [CrossRef]

| Component | Concentration [%wt.] |

|---|---|

| Na2O | 1.19 |

| MgO | 1.44 |

| Al2O3 | 21.86 |

| SiO2 | 60.49 |

| P2O5 | 0.47 |

| SO2 | 1.37 |

| K2O | 6.25 |

| CaO | 1.47 |

| TiO2 | 1.10 |

| Cr2O3 | 0.09 |

| MnO2 | 0.21 |

| Fe2O3 | 3.80 |

| CuO | 0.04 |

| ZnO | 0.04 |

| Rb2O | 0.07 |

| SrO | 0.03 |

| ZrO2 | 0.07 |

| Identified Mineral Phase | Estimated Amount of Mineral Phase in the Sample [%wt.] | |||||

|---|---|---|---|---|---|---|

| A1, A2 | A3 | B2, B3 | C2, C3 | D2, D3 | E2, E3 | |

| Quartz | 35 | 27 | 38 | 56 | 29 | 25 |

| Muscovite | 51 | 50 | 50 | 25 | 59 | 57 |

| Clinochlore | 4 | 6 | 2 | 4 | 3 | 4 |

| Orthoclase | 5 | 11 | - | 6 | 3 | 4 |

| Albite | 5 | 6 | 11 | 11 | 9 | 10 |

| Crusher, System | Smax | S80 | FI [%] |

|---|---|---|---|

| A1 #12 mm, jaw crusher, open circuit | 2.5 | 3.3 | 28.5 |

| A2 #10 mm, hammer crusher, open circuit | 3.2 | 3.8 | 29.8 |

| A2 #15 mm, hammer crusher, open circuit | 2.1 | 2.6 | 29.1 |

| A2 #20 mm, hammer crusher, open circuit | 1.6 | 2.3 | 27.9 |

| A3 #20 mm, hammer crusher, closed circuit | 3.2 | 2.9 | 29.3 |

| B2 10 kN, HPGR, open circuit | 1.0 | 1.5 | 16.8 |

| B2 15 kN, HPGR, open circuit | 1.0 | 1.4 | 17.1 |

| B3 15 kN, HPGR, closed circuit | 3.2 | 4.1 | 23.3 |

| C2 2 min, ball mill, open circuit | 1.0 | 1.2 | 11.2 |

| C3 4 min, ball mill, open circuit | 1.0 | 1.5 | 7.2 |

| D2 + D3 #20 mm, hammer crusher + HPGR, closed circuit | 3.2 | 3.7 | 22.4 |

| E2 + E3 #10 mm, HPGR + hammer crusher, closed circuit | 3.2 | 4.4 | 23.8 |

| Crusher, System | γ0–0.01 [%] | γ0–0.043 [%] | γ0–0.1 [%] | γ0.5–10 [%] |

|---|---|---|---|---|

| A1 #12 mm, jaw crusher, open circuit | 0.04 | 1.1 | 2.6 | 48.9 |

| A2 #10 mm, hammer crusher, open circuit | - | - | 6.8 | 79.3 |

| A2 #15 mm, hammer crusher, open circuit | - | - | 4.1 | 82.2 |

| A2 #20 mm, hammer crusher, open circuit | - | - | 4.2 | 73.6 |

| A3 #20 mm, hammer crusher, closed circuit | 0.08 | 2.4 | 5.0 | 83.2 |

| B2 10 kN, HPGR, open circuit | - | - | 3.9 | 63.5 |

| B2 15 kN, HPGR, open circuit | - | - | 3.4 | 64.9 |

| B3 15 kN, HPGR, closed circuit | 0.12 | 3.0 | 5.9 | 80.4 |

| C2 2 min, ball mill, open circuit | - | - | 8.0 | 24.5 |

| C3 4 min, ball mill, open circuit | 0.25 | 4.8 | 8.5 | 31.5 |

| D2 + D3 #20 mm, hammer crusher + HPGR, closed circuit | 0.09 | 2.2 | 4.6 | 83.2 |

| E2 + E3 #10 mm, HPGR + hammer crusher, closed circuit | 0.05 | 2.4 | 5.4 | 79.0 |

| Crusher, System | Spheres | Cylinders | Plates | Discs |

|---|---|---|---|---|

| A1 #12 mm, jaw crusher, open circuit | 90.0 | 0.0 | 6.0 | 4.0 |

| A3 #20 mm, hammer crusher, closed circuit | 88.0 | 0.0 | 6.8 | 5.2 |

| B3 15 kN, HPGR, closed circuit | 86.8 | 0.0 | 7.7 | 5.6 |

| C3 4 min, ball mill, open circuit | 90.1 | 0.0 | 5.1 | 4.8 |

| D2 + D3 #20 mm, hammer crusher + HPGR, closed circuit | 89.5 | 0.0 | 5.7 | 4.9 |

| E2 + E3 #10 mm, HPGR + hammer crusher, closed circuit | 91.5 | 0.0 | 4.0 | 4.5 |

| Crusher, System | Spheres | Cylinders | Plates | Discs |

|---|---|---|---|---|

| A1 #12 mm, jaw crusher, open circuit | 52.5 | 0.0 | 26.0 | 21.6 |

| A3 #20 mm, hammer crusher, closed circuit | 51.0 | 0.0 | 21.1 | 27.9 |

| B3 15 kN, HPGR, closed circuit | 51.7 | 0.0 | 27.3 | 21.0 |

| C3 4 min, ball mill, open circuit | 54.0 | 0.0 | 20.4 | 25.7 |

| D2 + D3 #20 mm, hammer crusher + HPGR, closed circuit | 52.5 | 0.0 | 24.3 | 23.2 |

| E2 + E3 #10 mm, HPGR + hammer crusher, closed circuit | 71.1 | 0.0 | 0.8 | 28.0 |

| Crusher, System | Spheres | Cylinders | Plates | Discs |

|---|---|---|---|---|

| A1 #12 mm, jaw crusher, open circuit | 58.0 | 22.2 | 4.6 | 15.2 |

| A3 #20 mm, hammer crusher, closed circuit | 56.0 | 21.0 | 8.1 | 14.9 |

| B3 15 kN, HPGR, closed circuit | 62.8 | 22.1 | 2.9 | 12.3 |

| C3 4 min, ball mill, open circuit | 49.6 | 28.2 | 7.9 | 14.3 |

| D2 + D3 #20 mm, hammer crusher + HPGR, closed circuit | 51.2 | 19.9 | 9.0 | 19.9 |

| E2 + E3 #10 mm, HPGR + hammer crusher, closed circuit | 61.0 | 20.5 | 4.3 | 14.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stempkowska, A.; Gawenda, T.; Smoroń, K. The Diatomite Grinding Technology Concept for the Protection of Diatomite Shells and the Control of Product Grading. Materials 2024, 17, 3662. https://doi.org/10.3390/ma17153662

Stempkowska A, Gawenda T, Smoroń K. The Diatomite Grinding Technology Concept for the Protection of Diatomite Shells and the Control of Product Grading. Materials. 2024; 17(15):3662. https://doi.org/10.3390/ma17153662

Chicago/Turabian StyleStempkowska, Agata, Tomasz Gawenda, and Krzysztof Smoroń. 2024. "The Diatomite Grinding Technology Concept for the Protection of Diatomite Shells and the Control of Product Grading" Materials 17, no. 15: 3662. https://doi.org/10.3390/ma17153662

APA StyleStempkowska, A., Gawenda, T., & Smoroń, K. (2024). The Diatomite Grinding Technology Concept for the Protection of Diatomite Shells and the Control of Product Grading. Materials, 17(15), 3662. https://doi.org/10.3390/ma17153662