Machine Learning for Additive Manufacturing of Functionally Graded Materials

Abstract

:1. Introduction

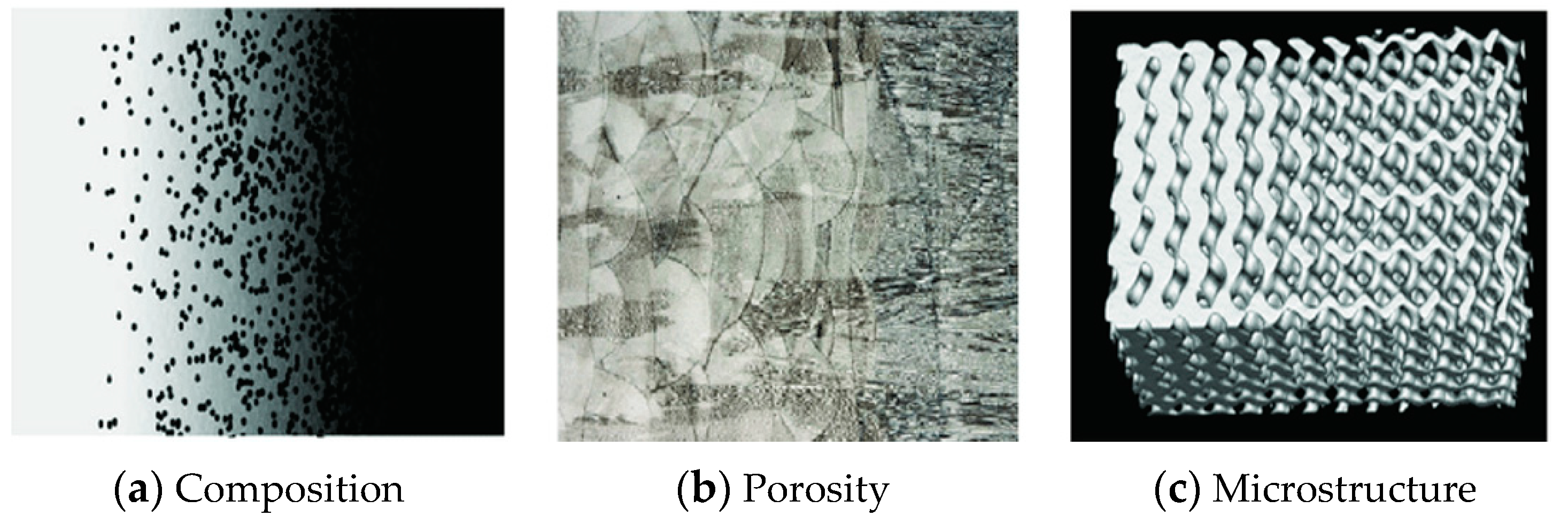

2. Additive Manufacturing for FGMs Fabrication

3. Machine Learning Methods in Additive Manufacturing

4. Overview of Machine Learning Methods

4.1. Unsupervised Learning Algorithms

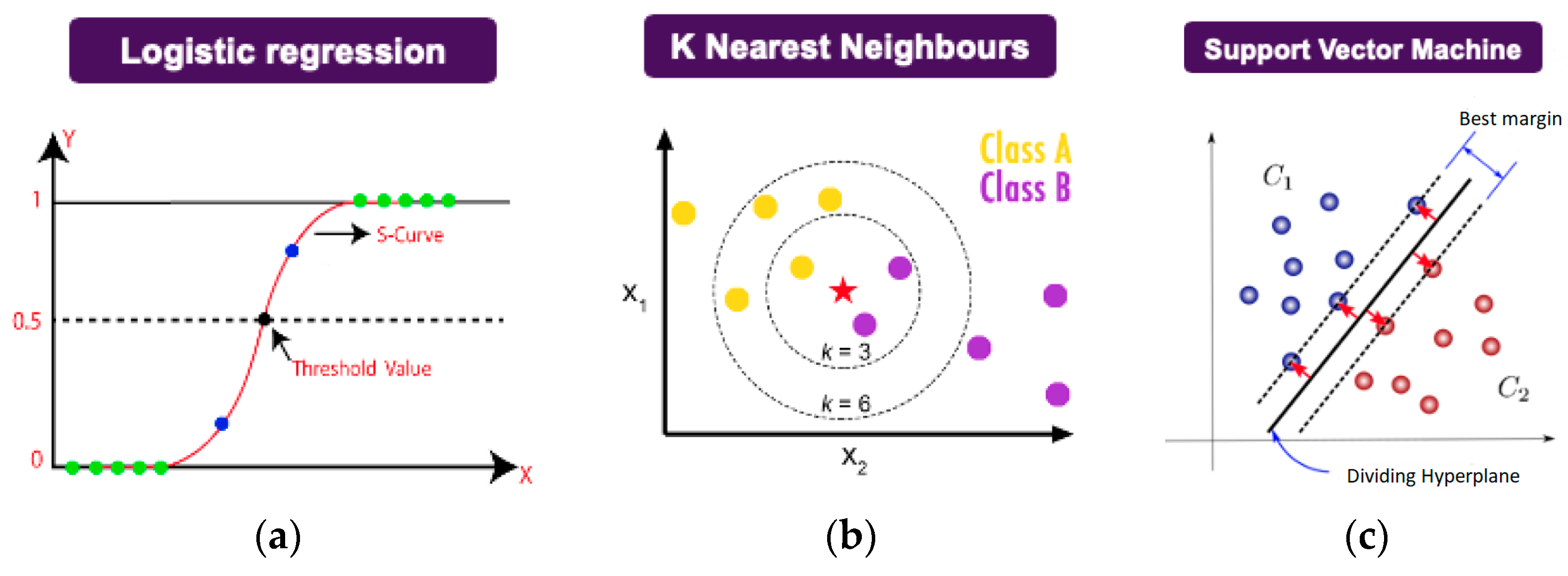

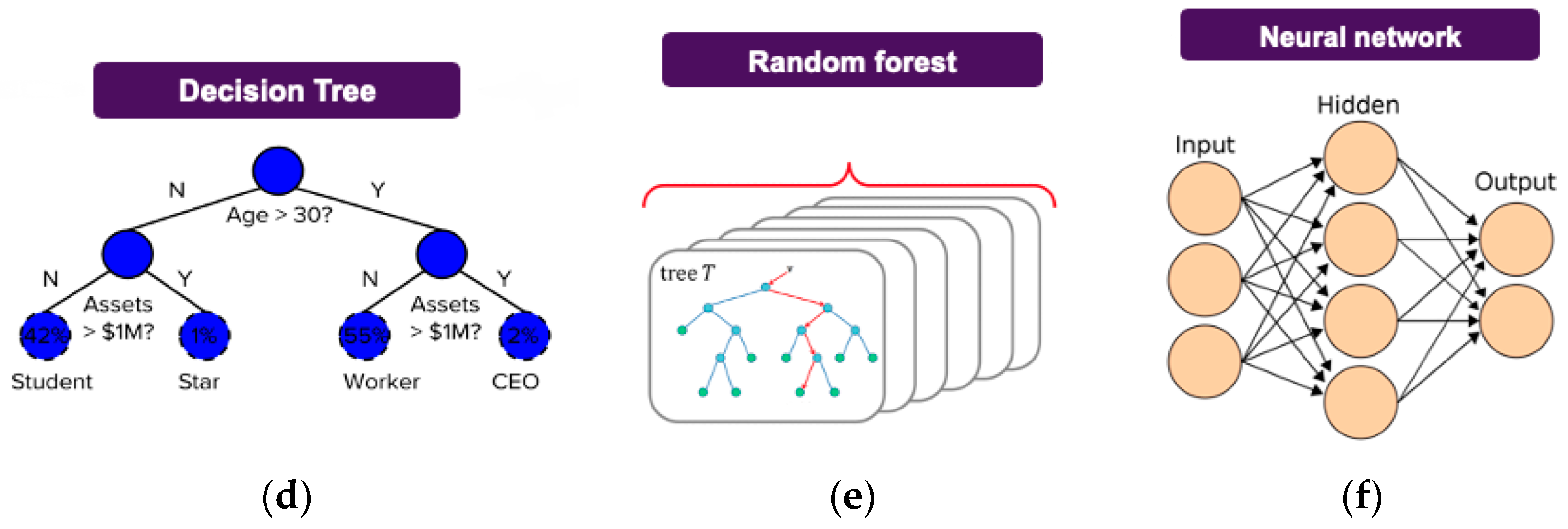

4.2. Supervised Learning Algorithms

4.3. Artificial Neural Networks

4.4. Reinforcement Learning

5. Machine Learning Methods for FGMs Fabrication

5.1. Parameters Optimization and Prediction of Material Properties

5.2. Classification of Phases in Microstructure

5.3. Detection of Defects

5.4. Discovery of New Materials

5.5. Summary of Used ML Methods for FGMs Fabrication

6. Future Directions in ML for FGMs

7. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- ISO/ASTM52900-15; Standard Terminology for Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2015.

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 978-3-030-56127-7. [Google Scholar]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, Opportunities, Considerations, and Constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Hespeler, S.; Dehghan-Niri, E.; Juhasz, M.; Luo, K.; Halliday, H.S. Deep Learning for In-Situ Layer Quality Monitoring during Laser-Based Directed Energy Deposition (LB-DED) Additive Manufacturing Process. Appl. Sci. 2022, 12, 8974. [Google Scholar] [CrossRef]

- Jin, L.; Zhai, X.; Wang, K.; Zhang, K.; Wu, D.; Nazir, A.; Jiang, J.; Liao, W.-H. Big data, machine learning, and digital twin assisted additive manufacturing: A review. Mater. Des. 2024, 244, 113086. [Google Scholar] [CrossRef]

- Dowling, L.; Kennedy, J.; O’Shaughnessy, S.; Trimble, D. A Review of Critical Repeatability and Reproducibility Issues in Powder Bed Fusion. Mater. Des. 2020, 186, 108346. [Google Scholar] [CrossRef]

- Dharmadhikari, S.; Menon, N.; Basak, A. A Reinforcement Learning Approach for Process Parameter Optimization in Additive Manufacturing. Addit. Manuf. 2023, 71, 103556. [Google Scholar] [CrossRef]

- Akbari, P.; Ogoke, F.; Kao, N.-Y.; Meidani, K.; Yeh, C.-Y.; Lee, W.; Farimani, A.B. MeltpoolNet: Melt Pool Characteristic Prediction in Metal Additive Manufacturing Using Machine Learning. Addit. Manuf. 2022, 55, 102817. [Google Scholar] [CrossRef]

- Markl, M.; Körner, C. Multiscale Modeling of Powder Bed–Based Additive Manufacturing. Annu. Rev. Mater. Res. 2016, 46, 93–123. [Google Scholar] [CrossRef]

- Narayana, P.L.; Kim, J.H.; Lee, J.; Choi, S.-W.; Lee, S.; Park, C.H.; Yeom, J.-T.; Reddy, N.G.S.; Hong, J.-K. Optimization of Process Parameters for Direct Energy Deposited Ti-6Al-4V Alloy Using Neural Networks. Int. J. Adv. Manuf. Technol. 2021, 114, 3269–3283. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.; Tor, S.; Lim, C. Machine Learning in Additive Manufacturing: State-of-the-Art and Perspectives. Addit. Manuf. 2020, 40, 101538. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Kaysser, W.A.; Rabin, B.H.; Kawasaki, A.; Ford, R.G. Functionally Graded Materials: Design, Processing and Applications; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Mohammadi, M.; Rajabi, M.; Ghadiri, M. Functionally Graded Materials (FGMs): A Review of Classifications, Fabrication Methods and Their Applications. Process. Appl. Ceram. 2021, 15, 319–343. [Google Scholar] [CrossRef]

- Kereiakes, D.J.; A Cox, D.; Hermiller, J.B.; Midei, M.G.; Bachinsky, W.B.; Nukta, E.; Leon, M.B.; Fink, S.; Marin, L.; Lansky, A.J. Usefulness of a Cobalt Chromium Coronary Stent Alloy. Am. J. Cardiol. 2003, 92, 463–466. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Kishore, M.N.; Zhang, R.; Bian, N.; Lu, H.; Li, Y.; Qian, D.; Zhang, X. Comprehensive Studies of SS316L/IN718 Functionally Gradient Material Fabricated with Directed Energy Deposition: Multi-Physics & Multi-Materials Modelling and Experimental Validation. Addit. Manuf. 2023, 61, 103358. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, T. Selective laser melting of tungsten-copper functionally graded material. Mater. Lett. 2019, 237, 328–331. [Google Scholar] [CrossRef]

- Jamaludin, S.N.S.; Latiff, M.I.A.; Nuruzzaman, D.M.; Ismail, N.M.; Basri, S. Investigation on microstructure and hardness of nickel-alumina functionally graded material. Mater. Today Proc. 2020, 29, 127–132. [Google Scholar] [CrossRef]

- Ghodsi, M.Z.; Khademzadeh, S.; Marzbanrad, E.; Razmpoosh, M.H.; De Marchi, N.; Toyserkani, E. Development of Yttria-stabilized zirconia reinforced Inconel 625 metal matrix composite by laser powder bed fusion. Mater. Sci. Eng. A 2021, 827, 142037. [Google Scholar] [CrossRef]

- Vasiraja, N.; Saravana Sathiya Prabhahar, R.; Joseph Daniel, S. Tensile and flexural characteristic of functionally graded carbon fiber reinforced composites with alumina and yttria stabilized zirconia fillers for bone implant. Mater. Today Proc. 2022, 62, 3197–3202. [Google Scholar] [CrossRef]

- Zhang, X.; Li, W.; Liou, F. Additive Manufacturing of Cobalt-Based Alloy on Tool Steel by Directed Energy Deposition. Opt. Laser Technol. 2022, 148, 107738. [Google Scholar] [CrossRef]

- Grierson, D.; Rennie, A.E.W.; Quayle, S.D. Machine Learning for Additive Manufacturing. Encyclopedia 2021, 1, 576–588. [Google Scholar] [CrossRef]

- Pan, G.; Wang, F.; Shang, C.; Wu, H.; Wu, G.; Gao, J.; Wang, S.; Gao, Z.; Zhou, X.; Mao, X. Advances in Machine Learning- and Artificial Intelligence-Assisted Material Design of Steels. Int. J. Miner. Metall. Mater. 2023, 30, 1003–1024. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with Artificial Intelligence in Additive Manufacturing: A Systematic Review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 303. [Google Scholar] [CrossRef]

- Fu, Y.; Downey, A.; Yuan, L.; Zhang, T.; Pratt, A.; Balogun, Y. Machine Learning Algorithms for Defect Detection in Metal Laser-Based Additive Manufacturing: A Review. J. Manuf. Process. 2022, 75, 693–710. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef] [PubMed]

- Priyadarshi, A.; Shahrani, S.B.; Choma, T.; Zrodowski, L.; Qin, L.; Leung, C.L.A.; Clark, S.J.; Fezzaa, K.; Mi, J.; Lee, P.D.; et al. New insights into the mechanism of ultrasonic atomization for the production of metal powders in additive manufacturing. Addit. Manuf. 2024, 83, 104033. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Bian, L.; Thompson, S.M.; Shamsaei, N. Mechanical Properties and Microstructural Features of Direct Laser-Deposited Ti-6Al-4V. JOM 2015, 67, 629–638. [Google Scholar] [CrossRef]

- Li, W.; Karnati, S.; Zhang, Y.; Liou, F. Investigating and eliminating powder separation in pre-mixed powder supply for laser metal deposition process. J. Mater. Process. Tech. 2018, 254, 294–301. [Google Scholar] [CrossRef]

- Mahmoud, D.; Elbestawi, M.A. Lattice Structures and Functionally Graded Materials Applications in Additive Manufacturing of Orthopedic Implants: A Review. J. Manuf. Mater. Process. 2017, 1, 13. [Google Scholar] [CrossRef]

- Meng, L.; McWilliams, B.; Jarosinski, W.; Park, H.-Y.; Jung, Y.-G.; Lee, J.; Zhang, J. Machine Learning in Additive Manufacturing: A Review. JOM 2020, 72, 2363–2377. [Google Scholar] [CrossRef]

- Carroll, B.E.; Otis, R.A.; Paul, J.; Suh, J.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.; Beese, A.M. Functionally Graded Material of 304L Stainless Steel and Inconel 625 Fabricated by Directed Energy Deposition: Characterization and Thermodynamic Modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef]

- Amine, T.; Newkirk, J.W.; Liou, F. An Investigation of the Effect of Laser Deposition Parameters on Characteristics of Multi-Layered 316 L Deposits. Int. J. Adv. Manuf. Technol. 2014, 73, 1739–1749. [Google Scholar] [CrossRef]

- Kar, J.; Roy, S.K.; Roy, G.G. Effect of Beam Oscillation on Electron Beam Welding of Copper with AISI-304 Stainless Steel. J. Mater. Process. Technol. 2016, 233, 174–185. [Google Scholar] [CrossRef]

- Zhang, X.; Li, L.; Liou, F. Additive Manufacturing of Stainless Steel–Copper Functionally Graded Materials via Inconel 718 Interlayer. J. Mater. Res. Technol. 2021, 15, 2045–2058. [Google Scholar] [CrossRef]

- Li, K.; Zhan, J.; Zhang, M.; Ma, R.; Tang, Q.; Zhang, D.Z.; Murr, L.E.; Cao, H. A Functionally Graded Material Design from Stainless Steel to Ni-Based Superalloy by Laser Metal Deposition Coupled with Thermodynamic Prediction. Mater. Des. 2022, 217, 110612. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: New York, NY, USA, 2006. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Pearson, K. On lines and planes of closest fit to systems of points in space. Philos. Mag. 1901, 2, 559–572. [Google Scholar] [CrossRef]

- Fisher, R.A. The use of multiple measurements in taxonomic problems. Ann. Eugen. 1936, 7, 179–188. [Google Scholar] [CrossRef]

- van der Maaten, L.; Hinton, G. Visualizing Data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. Available online: http://www.jmlr.org/papers/v9/vandermaaten08a.html (accessed on 15 May 2024).

- MacQueen, J. Some methods for classification and analysis of multivariate observations. In Proceedings of the Fifth Berkeley Symposium on Mathematical Statistics and Probability; University of California Press: Berkeley, CA, USA, 1967; Volume 1, pp. 281–297. [Google Scholar]

- Comaniciu, D.; Meer, P. Mean shift: A robust approach toward feature space analysis. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 603–619. [Google Scholar] [CrossRef]

- Ester, M.; Kriegel, H.-P.; Sander, J.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the Second International Conference on Knowledge Discovery and Data Mining (KDD-96); AAAI Press: Portland, OR, USA, 1996; pp. 226–231. [Google Scholar]

- Johnson, S.C. Hierarchical clustering schemes. Psychometrika 1967, 32, 241–254. [Google Scholar] [CrossRef] [PubMed]

- Reynolds, D.A. Gaussian Mixture Models. Encycl. Biom. 2009, 741, 659–663. [Google Scholar] [CrossRef]

- Parzen, E. On Estimation of a Probability Density Function and Mode. Ann. Math. Stat. 1962, 33, 1065–1076. [Google Scholar] [CrossRef]

- Koller, D.; Friedman, N. Probabilistic Graphical Models: Principles and Techniques; MIT Press: Cambridge, MA, USA, 2009. [Google Scholar]

- Cox, D.R. The regression analysis of binary sequences. J. R. Stat. Soc. Ser. B Methodol. 1958, 20, 215–232. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Elements of Statistical Learning: Data Mining, Inference, and Prediction; Springer: New York, NY, USA, 2009. [Google Scholar] [CrossRef]

- Rosenblatt, F. The perceptron: A probabilistic model for information storage and organization in the brain. Psychol. Rev. 1958, 65, 386–408. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- McCallum, A.; Nigam, K. A comparison of event models for Naive Bayes text classification. In Proceedings of the AAAI-98 Workshop on Learning for Text Categorization; AAAI Press: Madison, WI, USA, 1998; pp. 41–48. [Google Scholar]

- Rabiner, L.R. A tutorial on hidden Markov models and selected applications in speech recognition. Proc. IEEE 1989, 77, 257–286. [Google Scholar] [CrossRef]

- Cover, T.M.; Hart, P.E. Nearest neighbor pattern classification. IEEE Trans. Inf. Theory 1967, 13, 21–27. [Google Scholar] [CrossRef]

- Quinlan, J.R. Induction of decision trees. Mach. Learn. 1986, 1, 81–106. [Google Scholar] [CrossRef]

- Breiman, L.; Friedman, J.H.; Olshen, R.A.; Stone, C.J. Classification and Regression Trees; Wadsworth International Group: Belmont, CA, USA, 1984. [Google Scholar]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy function approximation: A gradient boosting machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A scalable tree boosting system. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining (KDD ′16), San Francisco, CA, USA, 13–17 August 2016; ACM: San Francisco, CA, USA, 2016; pp. 785–794. [Google Scholar] [CrossRef]

- Breiman, L. Bagging predictors. Mach. Learn. 1996, 24, 123–140. [Google Scholar] [CrossRef]

- Legendre, P.; Legendre, L. Numerical Ecology; Elsevier: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Smola, A.J.; Schölkopf, B. A tutorial on support vector regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar] [CrossRef]

- Nadaraya, E.A. On estimating regression. Theory Probab. Appl. 1964, 9, 141–142. [Google Scholar] [CrossRef]

- Cleveland, W.S.; Devlin, S.J. Locally weighted regression: An approach to regression analysis by local fitting. J. Am. Stat. Assoc. 1988, 83, 596–610. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. In Proceedings of the 25th International Conference on Neural Information Processing Systems (NIPS ′12); Curran Associates Inc.: Lake Tahoe, NV, USA, 2012; pp. 1097–1105. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł.; Polosukhin, I. Attention is all you need. In Proceedings of the 31st International Conference on Neural Information Processing Systems (NIPS ′17); Curran Associates Inc.: Long Beach, CA, USA, 2017; pp. 6000–6010. [Google Scholar] [CrossRef]

- Song, Y.; Ermon, S. Generative Modeling by Estimating Gradients of the Data Distribution. In Proceedings of the 33rd International Conference on Neural Information Processing Systems (NeurIPS ′19); Curran Associates Inc.: Vancouver, BC, Canada, 2019; pp. 11918–11930. [Google Scholar]

- Kipf, T.N.; Welling, M. Semi-Supervised Classification with Graph Convolutional Networks. In Proceedings of the 5th International Conference on Learning Representations (ICLR ′17), Toulon, France, 24–26 April 2017. [Google Scholar]

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative Adversarial Nets. In Proceedings of the 27th International Conference on Neural Information Processing Systems (NIPS ′14); MIT Press: Montreal, QC, Canada, 2014; pp. 2672–2680. [Google Scholar] [CrossRef]

- Sutton, R.S.; Barto, A.G. Reinforcement Learning: An Introduction; MIT Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Watkins, C.J.C.H.; Dayan, P. Q-learning. Mach. Learn. 1992, 8, 279–292. [Google Scholar] [CrossRef]

- Mnih, V.; Kavukcuoglu, K.; Silver, D.; Rusu, A.A.; Veness, J.; Bellemare, M.G.; Graves, A.; Riedmiller, M.; Fidjeland, A.K.; Ostrovski, G.; et al. Human-level control through deep reinforcement learning. Nature 2015, 518, 529–533. [Google Scholar] [CrossRef] [PubMed]

- Sutton, R.S.; McAllester, D.; Singh, S.; Mansour, Y. Policy gradient methods for reinforcement learning with function approximation. In Proceedings of the 12th International Conference on Neural Information Processing Systems (NeurIPS 1999); MIT Press: Cambridge, MA, USA, 2000; pp. 1057–1063. [Google Scholar]

- Schulman, J.; Wolski, F.; Dhariwal, P.; Radford, A.; Klimov, O. Proximal Policy Optimization Algorithms. arXiv 2017, arXiv:1707.06347. [Google Scholar]

- Konda, V.R.; Tsitsiklis, J.N. Actor-critic algorithms. In Proceedings of the 12th International Conference on Neural Information Processing Systems (NeurIPS 1999); MIT Press: Cambridge, MA, USA, 2000; pp. 1008–1014. [Google Scholar]

- Belle, V.; Papantonis, I. Principles and Practice of Explainable Machine Learning. Front. Big Data. 2021, 4, 688969. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.; Lee, J.; Yoo, J. Machine Learning-Combined Topology Optimization for Functionally Graded Composite Structure Design. Comput. Methods Appl. Mech. Eng. 2021, 387, 114158. [Google Scholar] [CrossRef]

- Srinivasan, S.; Swick, B.; Groeber, M.A. Laser Powder Bed Fusion Parameter Selection via Machine-Learning-Augmented Process Modeling. JOM 2020, 72, 4393–4403. [Google Scholar] [CrossRef]

- Alcunte, S.; Fidan, I. Machine Learning-Based Fatigue Life Prediction of Functionally Graded Materials Using Material Extrusion Technology. J. Compos. Sci. 2023, 7, 420. [Google Scholar] [CrossRef]

- Raturi, H.P.; Kushari, S.; Karsh, P.K.; Dey, S. Evaluating Stochastic Fundamental Natural Frequencies of Porous Functionally Graded Material Plate with Even Porosity Effect: A Multi Machine Learning Approach. J. Vib. Eng. Technol. 2024, 12, 1931–1942. [Google Scholar] [CrossRef]

- Sulaiman, M.; Khalaf, O.I.; Khan, N.A.; Alshammari, F.S.; Algburi, S.; Hamam, H. Machine Learning-Based Prediction of Heat Transfer Performance in Annular Fins with Functionally Graded Materials. Sci. Rep. 2024, 14, 8801. [Google Scholar] [CrossRef] [PubMed]

- Wasmer, K.; Wüst, M.; Cui, D.; Masinelli, G.; Pandiyan, V.; Shevchik, S. Monitoring of Functionally Graded Material during Laser Directed Energy Deposition by Acoustic Emission and Optical Emission Spectroscopy Using Artificial Intelligence. Virtual Phys. Prototyp. 2023, 18, e2189599. [Google Scholar] [CrossRef]

- Eliseeva, O.V.; Kirk, T.; Samimi, P.; Malak, R.; Arróyave, R.; Elwany, A.; Karaman, I. Functionally Graded Materials through Robotics-Inspired Path Planning. Mater. Des. 2019, 182, 107975. [Google Scholar] [CrossRef]

- Galvan, E.; Malak, R.; Gibbons, S.; Arróyave, R. A Constraint Satisfaction Algorithm for the Generalized Inverse Phase Stability Problem. J. Mech. Des. 2016, 139, 011401. [Google Scholar] [CrossRef]

- Kirk, T.; Malak, R.; Arroyave, R. Computational Design of Compositionally Graded Alloys for Property Monotonicity. ASME J. Mech. Des. 2021, 143, 031704. [Google Scholar] [CrossRef]

- Mojumder, S.; Gan, Z.; Li, Y.; Amin, A.A.; Liu, W.K. Linking Process Parameters with Lack-of-Fusion Porosity for Laser Powder Bed Fusion Metal Additive Manufacturing. Addit. Manuf. 2023, 68, 103500. [Google Scholar] [CrossRef]

- Van Houtum, G.J.J.; Vlasea, M.L. Active Learning via Adaptive Weighted Uncertainty Sampling Applied to Additive Manufacturing. Addit. Manuf. 2021, 48, 102411. [Google Scholar] [CrossRef]

- Eliseeva, O.V. Utilizing the Structure-Property Relationship of Porosity and Composition in Additively Manufactured Metallic Systems. Ph.D. Thesis, Texas A&M University, Dallas, TX, USA, 2021. Available online: https://hdl.handle.net/1969.1/193109 (accessed on 20 May 2024).

- Veloso, F.; Gomes-Fonseca, J.; Morais, P.; Correia-Pinto, J.; Pinho, A.C.M.; Vilaça, J.L. Overview of Methods and Software for the Design of Functionally Graded Lattice Structures. Adv. Eng. Mater. 2022, 24, 2200483. [Google Scholar] [CrossRef]

- Li, J.; Yin, J.; Li, S.; Zhang, Z.; Liu, X. Inverse Design of Nano-Sized FGM Phononic Crystals with Anticipated Band Gaps Using Probabilistic Generation Based Deep-Learning Network. Eng. Struct. 2024, 312, 118222. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Functionally Graded Material: An Overview. In Proceedings of the World Congress on Engineering 2012 Vol III (WCE 2012), London, UK, 4–6 July 2012. [Google Scholar]

- Qin, J.; Hu, F.; Liu, Y.; Witherell, P.; Wang, C.C.L.; Rosen, D.W.; Simpson, T.W.; Lu, Y.; Tang, Q. Research and Application of Machine Learning for Additive Manufacturing. Addit. Manuf. 2022, 52, 102691. [Google Scholar] [CrossRef]

- Li, L.; Chang, J.; Vakanski, A.; Wang, Y.; Yao, T.; Xian, M. Uncertainty Quantification in Multivariable Regression for Material Property Prediction with Bayesian Neural Networks. Sci. Rep. 2024, 14, 10543. Available online: https://www.nature.com/articles/s41598-024-61189-x (accessed on 20 June 2024). [CrossRef] [PubMed]

| Title | Drawback | ML Method | Data Available | Investigated Materials | Predicted Parameters/ Properties |

|---|---|---|---|---|---|

| Kim et al. [80] | N/A | ANNs | N/A | N/A | Elasticity, stiffness |

| Srinivasan et al. [81] | Not suitable for complicated geometries | PCA, DBSCAN | Yes | Ti-6Al-4V | Laser power, laser velocity, hatch spacing |

| Dharmadhikari et al. [8] | Focus on optimizing geometric tolerance and limited space action | Q-learning | Yes, upon request | N/A | Power and velocity |

| Narayana et al. [11] | N/A | ANN | Yes | Ti-6Al-4V | Scan speed, powder feed rate, and layer thickness |

| Alcunte et al. [82] | We need to improve accuracy across different stress levels | RF, SVC, ANN | Yes, upon request | PLA, TPU | Fatigue life |

| Raturi et al. [83] | N/A | LR, GPR, ANN, and SVM | Yes, upon request | SUS304, Si3N4 | Natural frequencies of porous FGMs |

| Sulaiman et al. [84] | Numerical methods implementation | ANN-BFGS | Yes, upon request | N/A | Heat transfer and temperature distribution of ring fins |

| Wasmer et al. [85] | OES Challenges, Feature Reduction Impact | LDA, LR, SVM, kNN, MLP, RF | Yes | Titanium, Niobium | Lack-of-fusion porosity, real-time monitoring |

| Title | Drawback | ML Method | Data Available | Investigated Materials |

|---|---|---|---|---|

| Eliseeva et al. [86] | N/A | Path planning | Cannot be shared | SS316L, chromium, nickel (Fe-Ni-Cr) |

| Galvan et al. [87] | Limited dimensionality | GIPSP, EDSD | Yes, ThermoCalc | Fe-Ti binary alloy compositions |

| Kirk et al. [88] | Inability to optimize multiple properties simultaneously | RRT*FN | Yes, upon request | Fe-Co-Cr system |

| Title | Drawback | ML Method | Data Available | Investigated Materials |

|---|---|---|---|---|

| Narayana et al. [11] | N/A | ANN | Yes | Ti-6Al-4V |

| Mojumder et al. [89] | Uncertainty in porosity prediction—limited to LOF porosity detection | Active learning, NN | Yes | Ti-6Al-4V |

| Akbari et al. [9] | N/A | ANN, GB, RF | Yes | N/A |

| Eliseeva et al. [91] | N/A | SVM, KNN, and Decision Tree | N/A | Ti-6Al-4V |

| Van Houtum et al. [90] | N/A | LR, SVM, RF, and NB | Yes | N/A |

| Hespeler et al. [5] | Overfitting | RF, DT, XGBoost, CNN | Not public | N/A |

| Title | Drawback | ML Method | Data Available | Investigated Materials |

|---|---|---|---|---|

| Veloso et al. [92] | ML requires large amounts of data and expertise | Reviews ML methods, Genetic algorithm | Yes | N/A |

| Li et al. [93] | Design of PnCs at nanoscale | CVAE, DDPM, DDIM, DNN, TNN, PTN | Yes, upon request | Phononic Crystals |

| ML Method | Abbreviation | Referenced Works | Advantages | Disadvantages |

|---|---|---|---|---|

| Artificial Neural Networks | ANNs | Kim et al. [80], Narayana et al. [11], Alcunte et al. [82], Raturi et al. [83], Sulaiman et al. [84], Wasmer et al. [85], Mojumder et al. [89], Akbari et al. [9], Li et al. [93] | Capture complex non-linear relationships with automatic feature extraction, can be used with various learning tasks | Require large datasets for training, are computationally expensive, and are difficult to interpret |

| Logistic Regression | LR | Wasmer et al. [85], Van Houtum et al. [90] | Simple implementation and fast training | Assume a linear relationship between data features and targets |

| Support Vector Machines | SVM | Alcunte et al. [82], Raturi et al. [83], Wasmer et al. [85], Galvan et al. [87], Van Houtum et al. [90] | Effective for high-dimensional data samples, it can use different kernel functions | Computationally expensive, requiring finetuning of kernel type and parameters |

| Naïve Bayes | NB | Van Houtum et al. [90] | Simple implementation, easy to understand | Assume independence among the data features |

| k-Nearest Neighbors | kNN | Wasmer et al. [85] | Simple implementation, easy to understand | Requires storing the entire dataset for inference |

| Decision Trees | DT | Kirk et al. [88], Hespeler et al. [5] | Capture complex relationships and make interpretable decisions | Prone to overfitting and training instability |

| Random Forest | RF | Alcunte et al. [82], Wasmer et al. [85], Akbari et al. [9], Van Houtum et al. [90] | Capture complex relationships, reduce overfitting of DT | Computationally expensive, less interpretable than DT |

| Gradient Boosting | GB | Akbari et al. [9] | High predictive accuracy for tabular data and interpretable decisions | Computationally expensive |

| Extreme Gradient Boosting | XGBoost | Hespeler et al. [5] | High predictive accuracy for tabular data, efficiency, and interpretable decisions | Computationally expensive, requires parameter finetuning |

| Principal Component Analysis | PCA | Srinivasan et al. [81] | Suitable for dimensionality reduction and feature selection | Information loss during dimensionality reduction assumes a linear relationship between features |

| Linear Discriminant Analysis | LDA | Wasmer et al. [85] | Suitable for dimensionality reduction and feature selection | Sensitive to outliers, it assumes a normal distribution of features |

| Density-Based Spatial Clustering of Applications with Noise | DBSCAN | Srinivasan et al. [81] | Can find clusters of arbitrary shape, can handle noise and outliers | Less effective for high-dimensional data, sensitive to parameter selection |

| Genetic Algorithm | GA | Veloso et al. [92] | Applicable for optimization of different problems, including non-linear functions | Computationally expensive, with no guarantee of finding an optimal solution |

| Linear Regression | LiR | Raturi et al. [83] | Simple implementation and fast training | Assumes a linear relationship between features and is sensitive to outliers |

| Gaussian Process Regression | GPR | Raturi et al. [83] | Capture complex, non-linear relationships and provides uncertainty estimates | Slow training with large datasets, requires careful parameter finetuning |

| Convolutional Neural Networks | CNNs | Hespeler et al. [5] | Suitable for image processing, robust to variations in translations | Require a large number of data samples, which is computationally expensive |

| Probabilistic Diffusion Neural Network | PDNN | Li et al. [93] | Provide probabilistic predictions and uncertainty estimates | Complex to implement and train, computationally expensive |

| Generative Adversarial Networks | GAN | Li et al. [93] | Suitable for different generative tasks, it can create realistic data samples | Difficult and unstable to train, they can suffer from mode collapse |

| Q-learning | QL | Dharmadhikari et al. [8] | Model-free RL approach, simple to implement | Struggles with large state-action spaces can be sample inefficient |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karimzadeh, M.; Basvoju, D.; Vakanski, A.; Charit, I.; Xu, F.; Zhang, X. Machine Learning for Additive Manufacturing of Functionally Graded Materials. Materials 2024, 17, 3673. https://doi.org/10.3390/ma17153673

Karimzadeh M, Basvoju D, Vakanski A, Charit I, Xu F, Zhang X. Machine Learning for Additive Manufacturing of Functionally Graded Materials. Materials. 2024; 17(15):3673. https://doi.org/10.3390/ma17153673

Chicago/Turabian StyleKarimzadeh, Mohammad, Deekshith Basvoju, Aleksandar Vakanski, Indrajit Charit, Fei Xu, and Xinchang Zhang. 2024. "Machine Learning for Additive Manufacturing of Functionally Graded Materials" Materials 17, no. 15: 3673. https://doi.org/10.3390/ma17153673