Temperature–Stress Coupling Fatigue Behavior of Film-Cooling Holes in Complex Temperature Fields

Abstract

1. Introduction

2. Drilling Experiment and Real Hole Modeling

2.1. Experimental Materials and Drilling Process

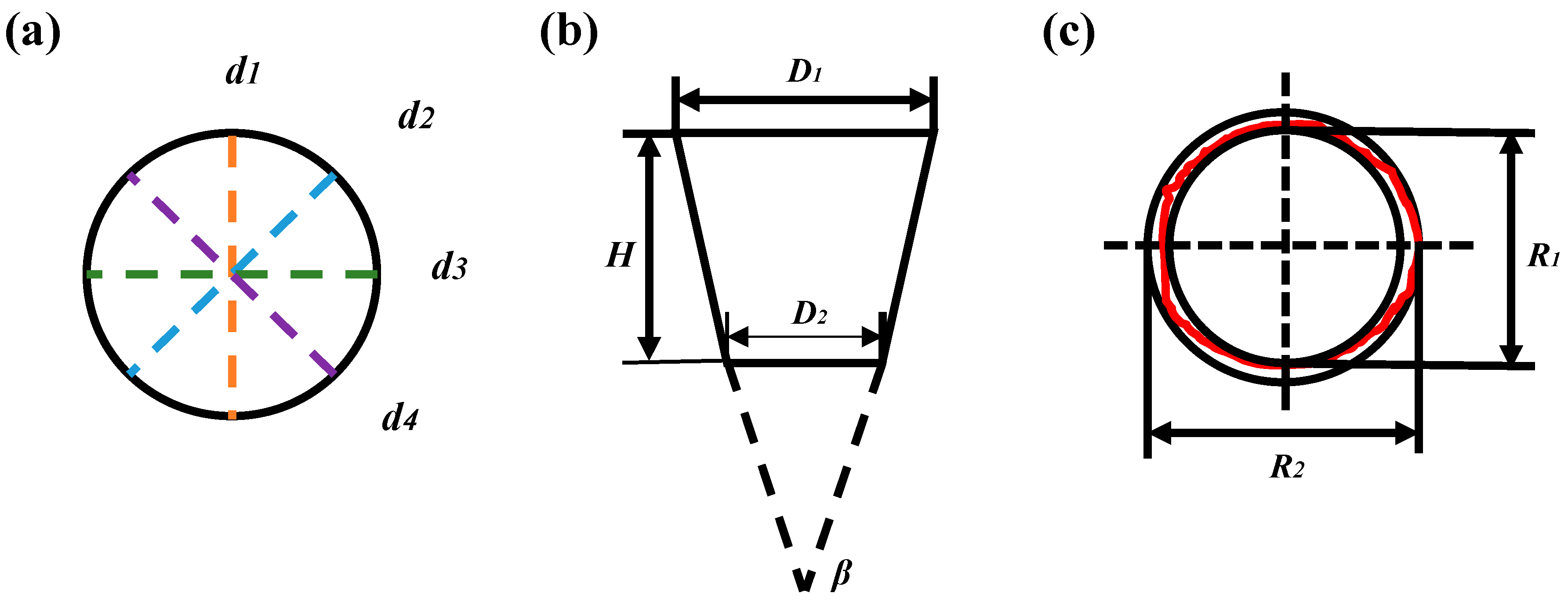

2.2. Geometric Accuracy Evaluation of Film-Cooling Holes

2.3. Real Geometric Modeling of Film-Cooling Holes

3. Nickel-Based Single-Crystal Fatigue Constitutive Model

3.1. Fatigue Constitutive Model

- (1)

- Assuming that , , , , and are all equal to zero, Young’s modulus E, Poisson’s ratio v, the shear modulus G, , and are determined from the stress–strain curves at different temperatures. For nickel-based single-crystal DD6, and are highly temperature sensitive. Thus, they are calculated using the following equation:

- (2)

- Through experiments, the trial-and-error method is used to determine , , , , , , , and , as shown in Table 3.

- (3)

- For , obtained by fitting through low-cycle fatigue experiments..

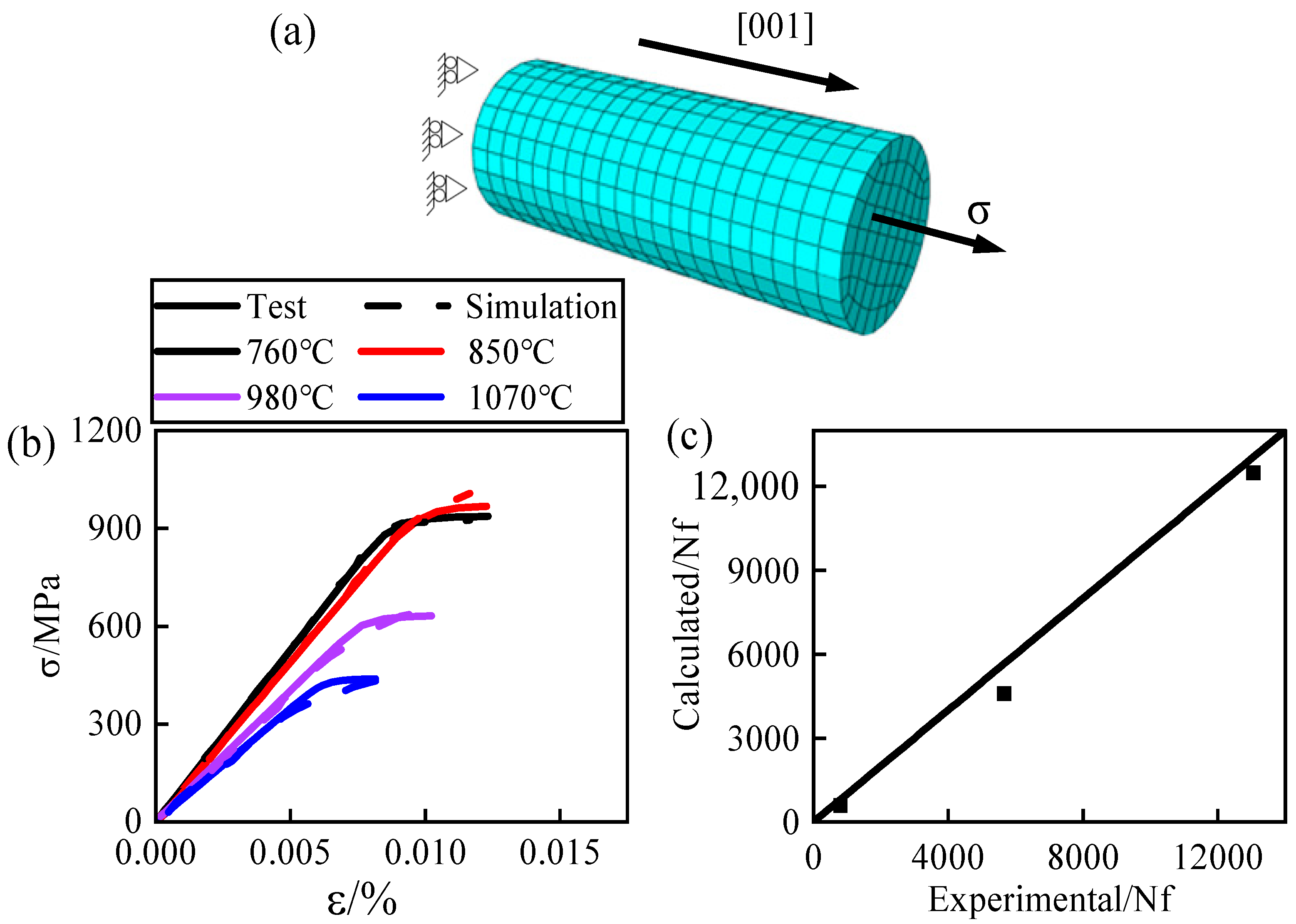

3.2. Validation of Constitutive Models

3.3. Numerical Simulation Methods and Models

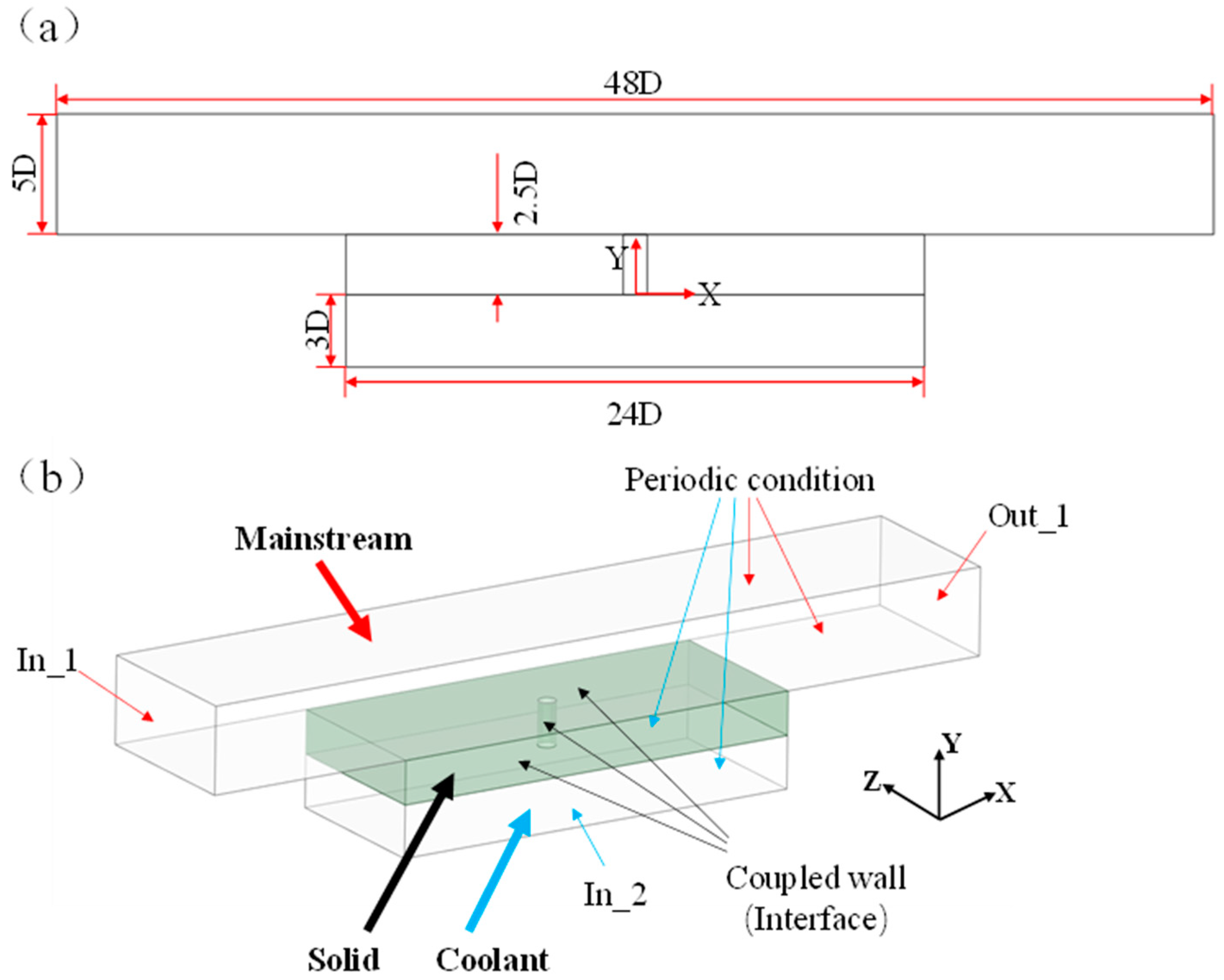

3.3.1. Domain Model and Boundary Conditions

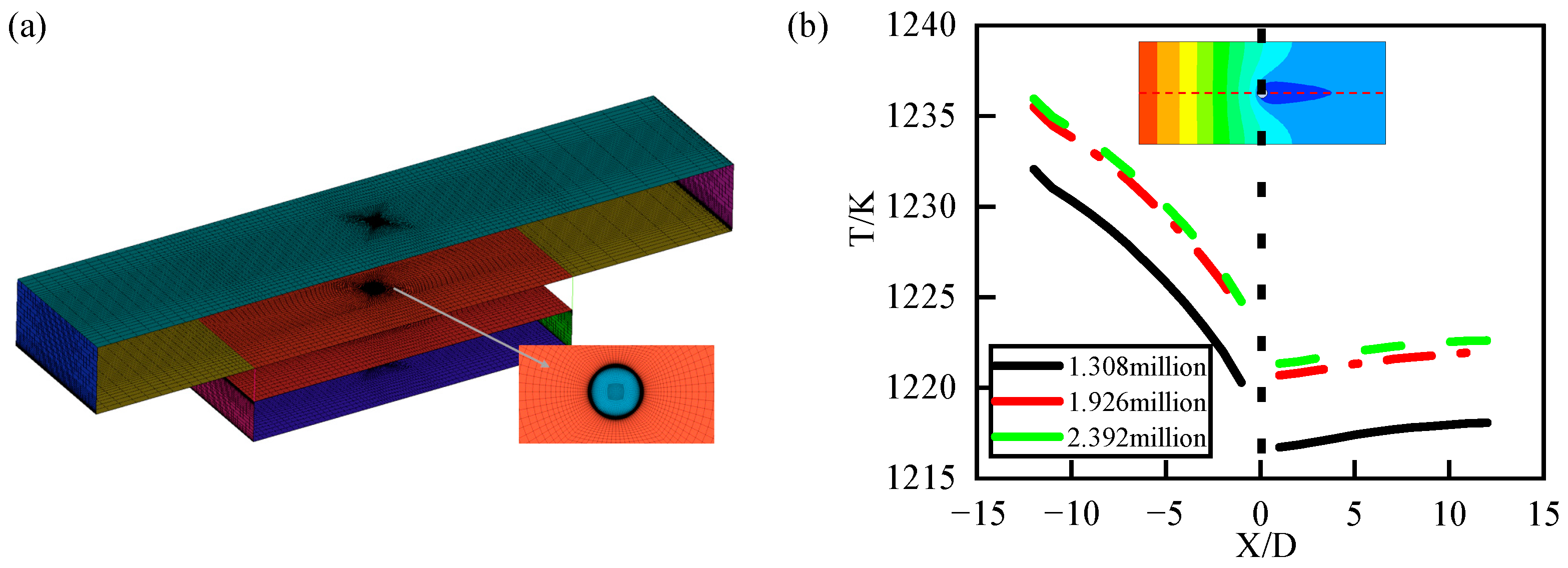

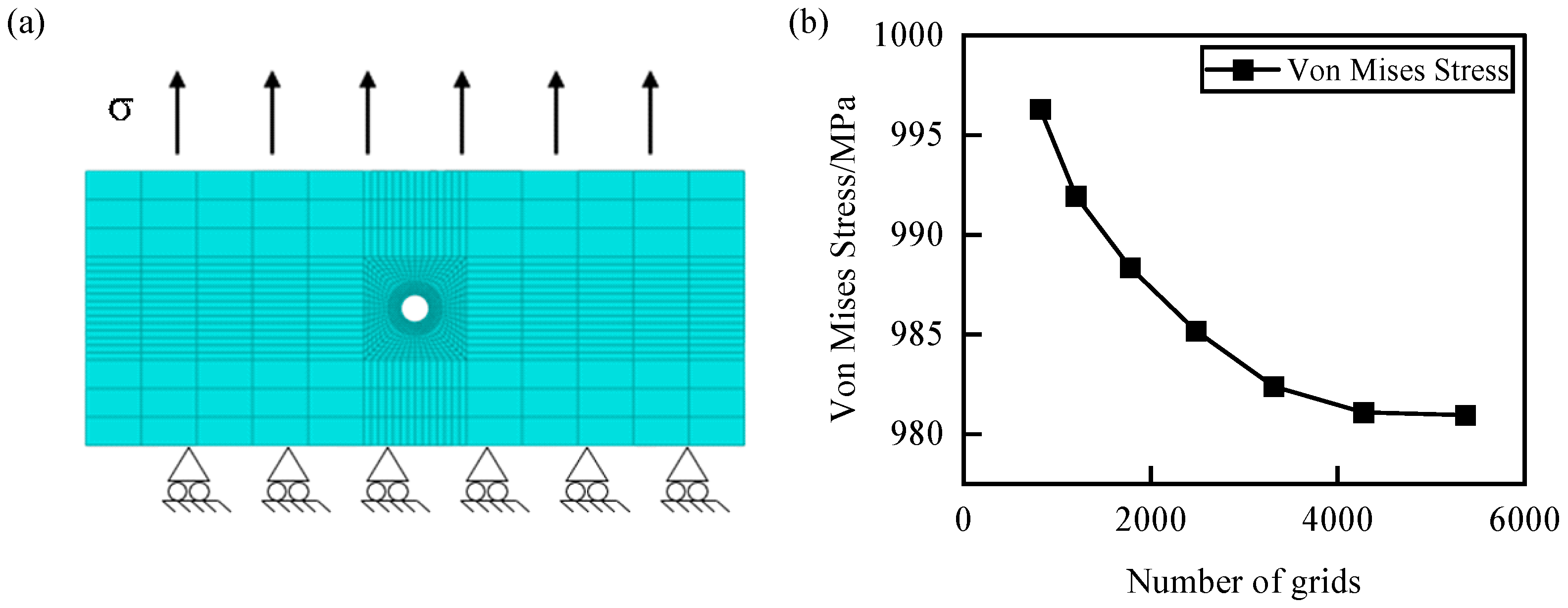

3.3.2. Mesh Partitioning and Mesh Independence Validation

4. Conjugate Heat Transfer Analysis

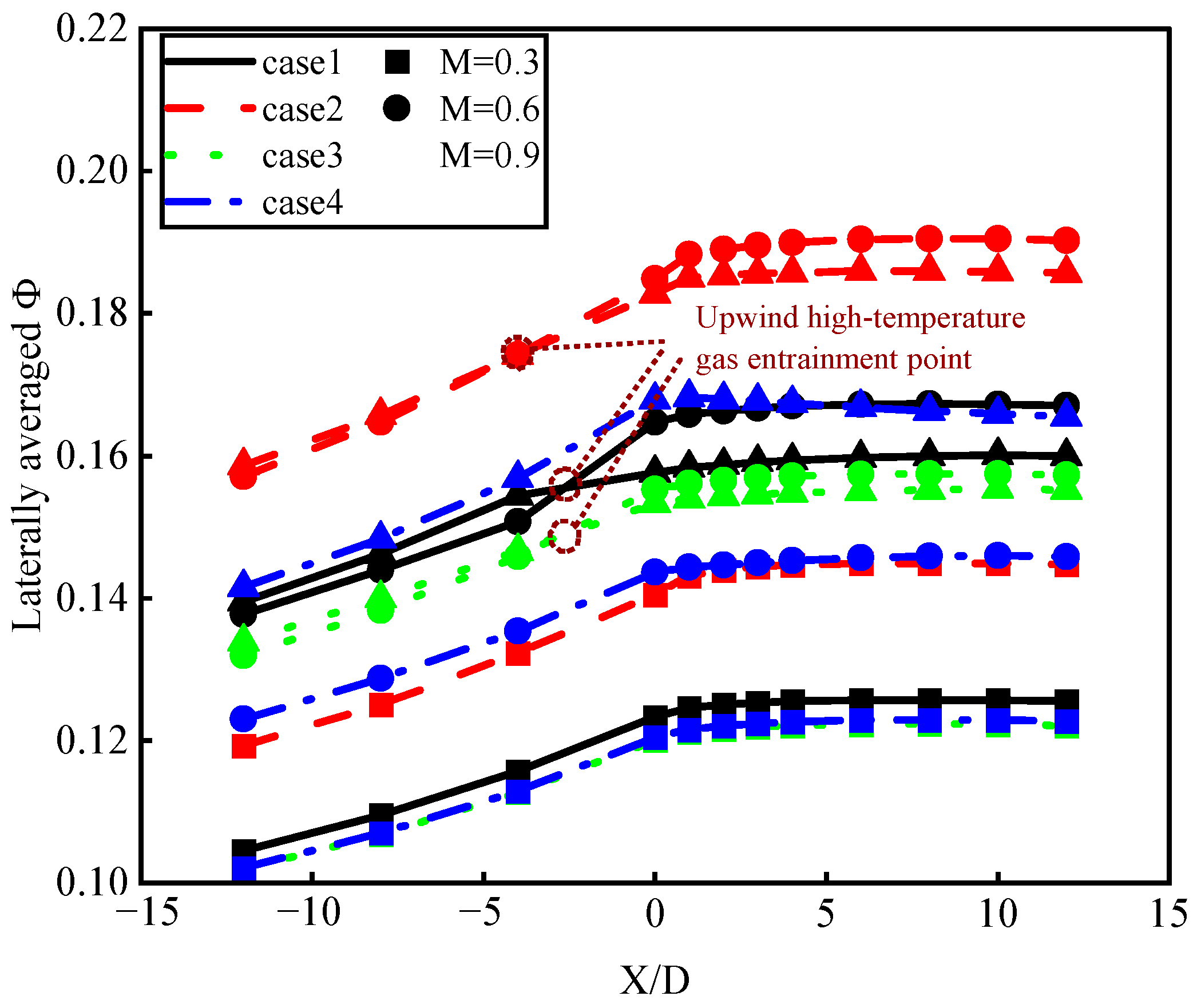

4.1. Analysis of Overall Cooling Effect of Film-Cooling Holes

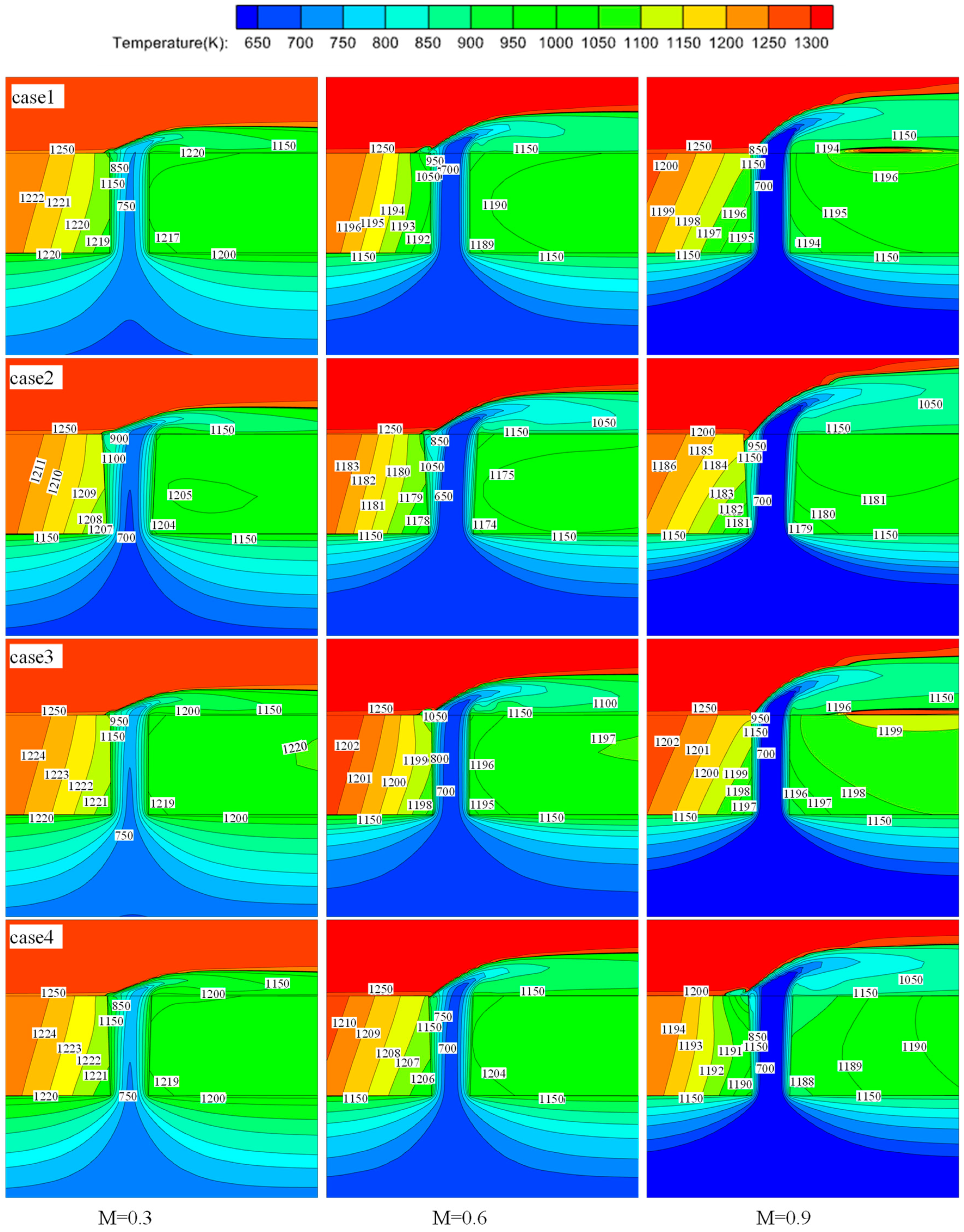

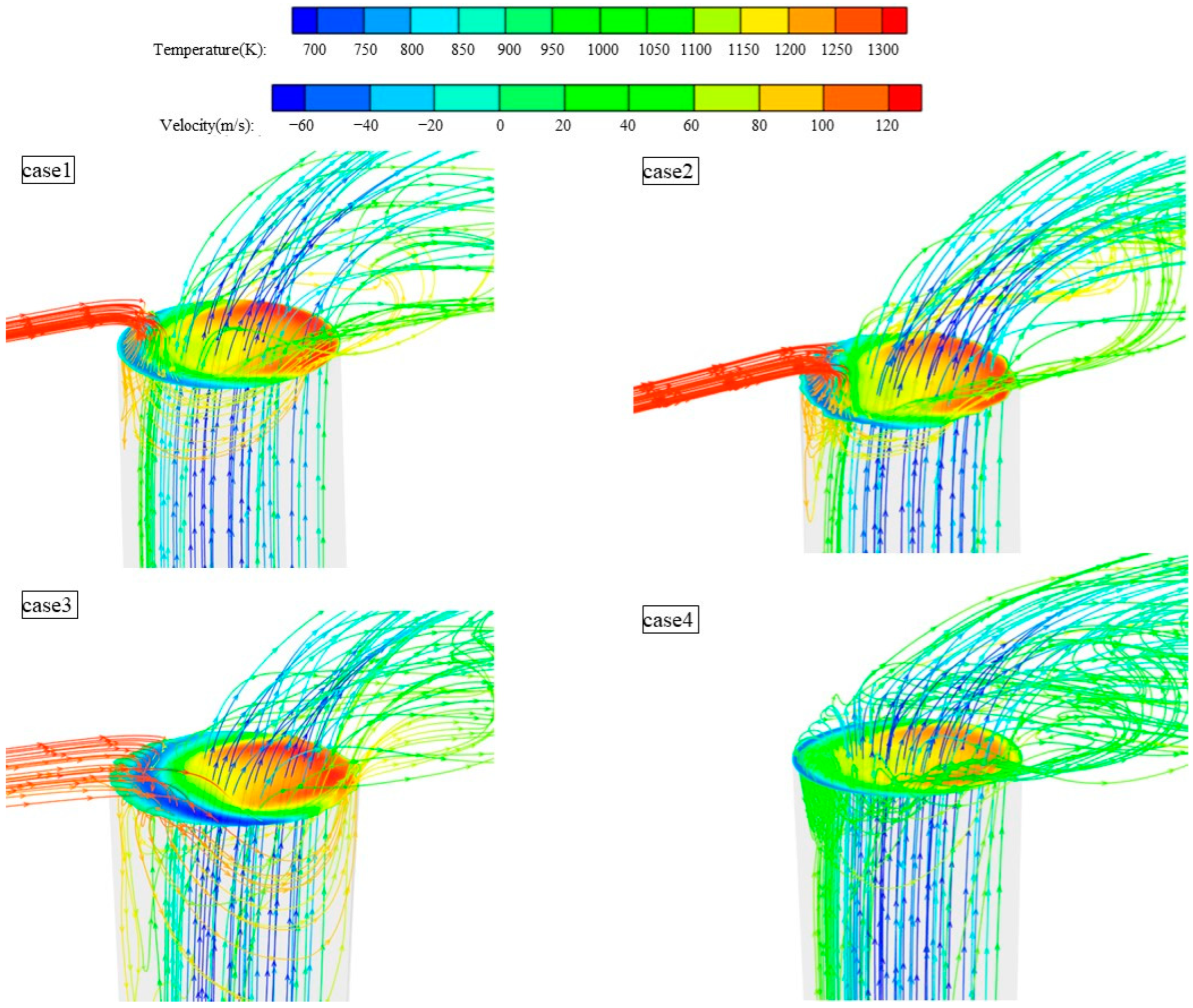

4.2. Behavior of Temperature Field of Film-Cooling Holes

5. Fatigue Damage Analysis

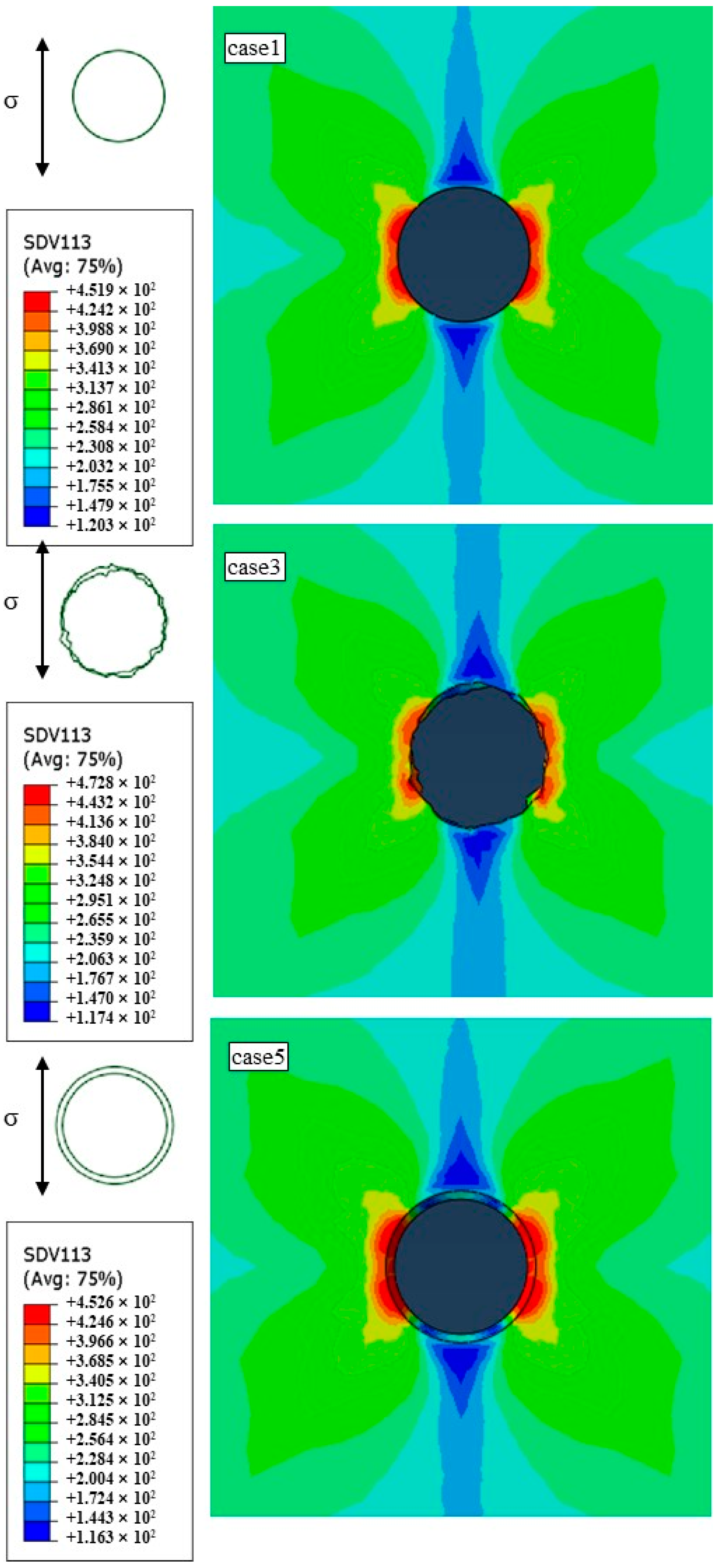

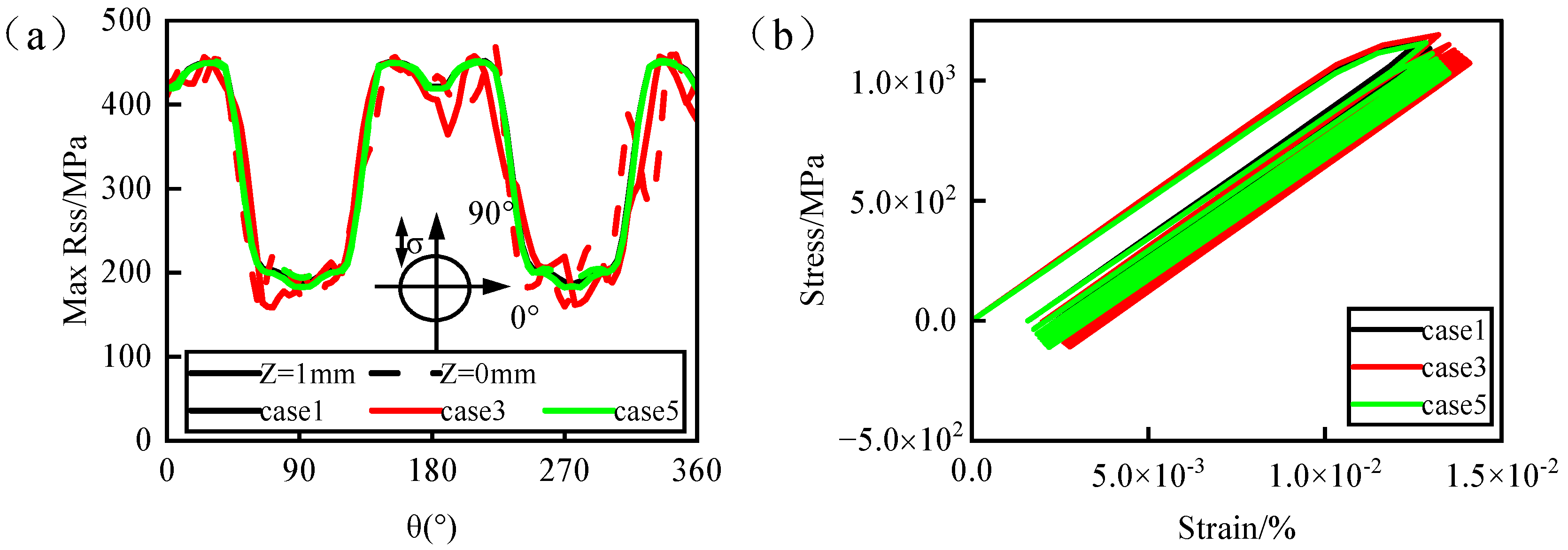

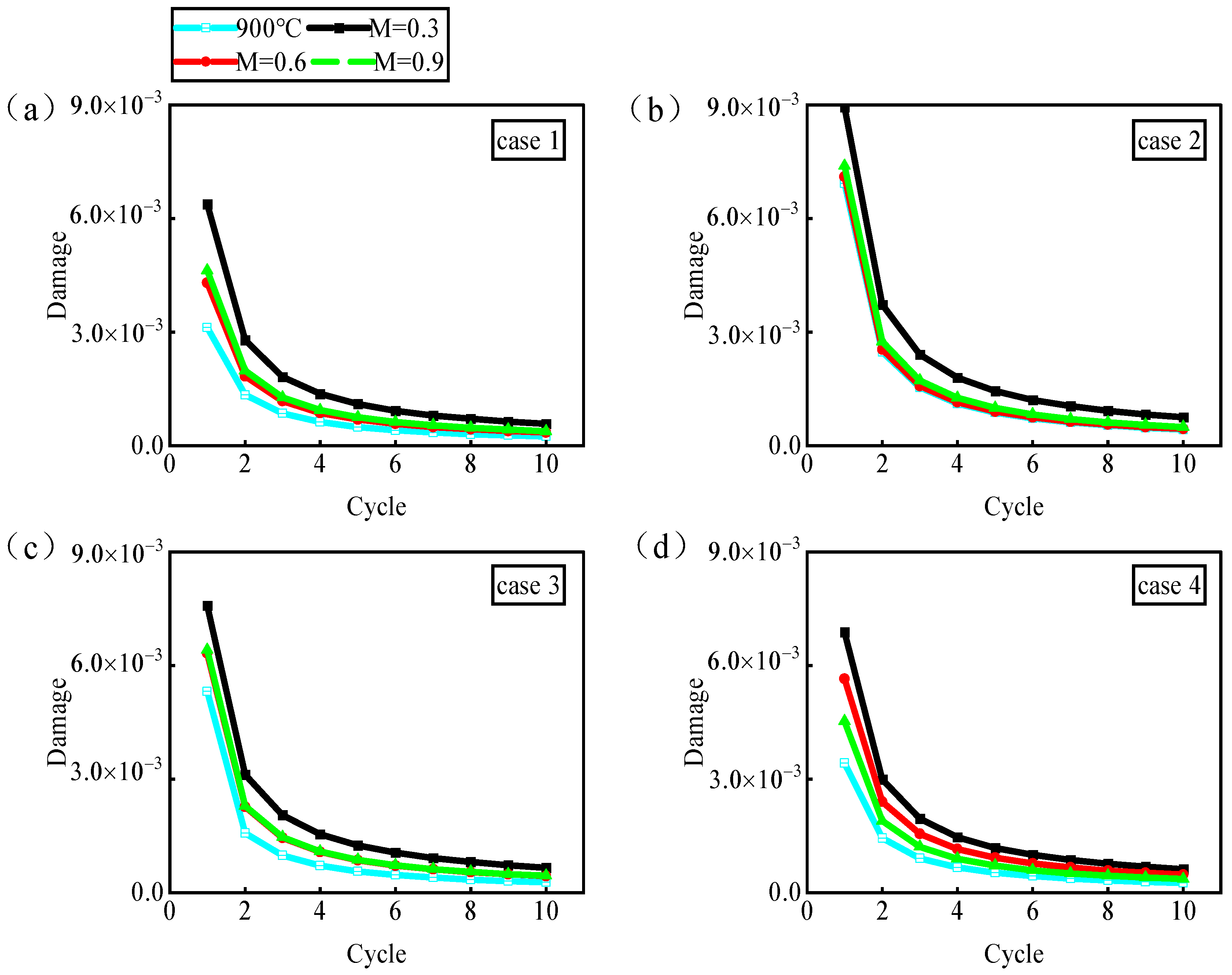

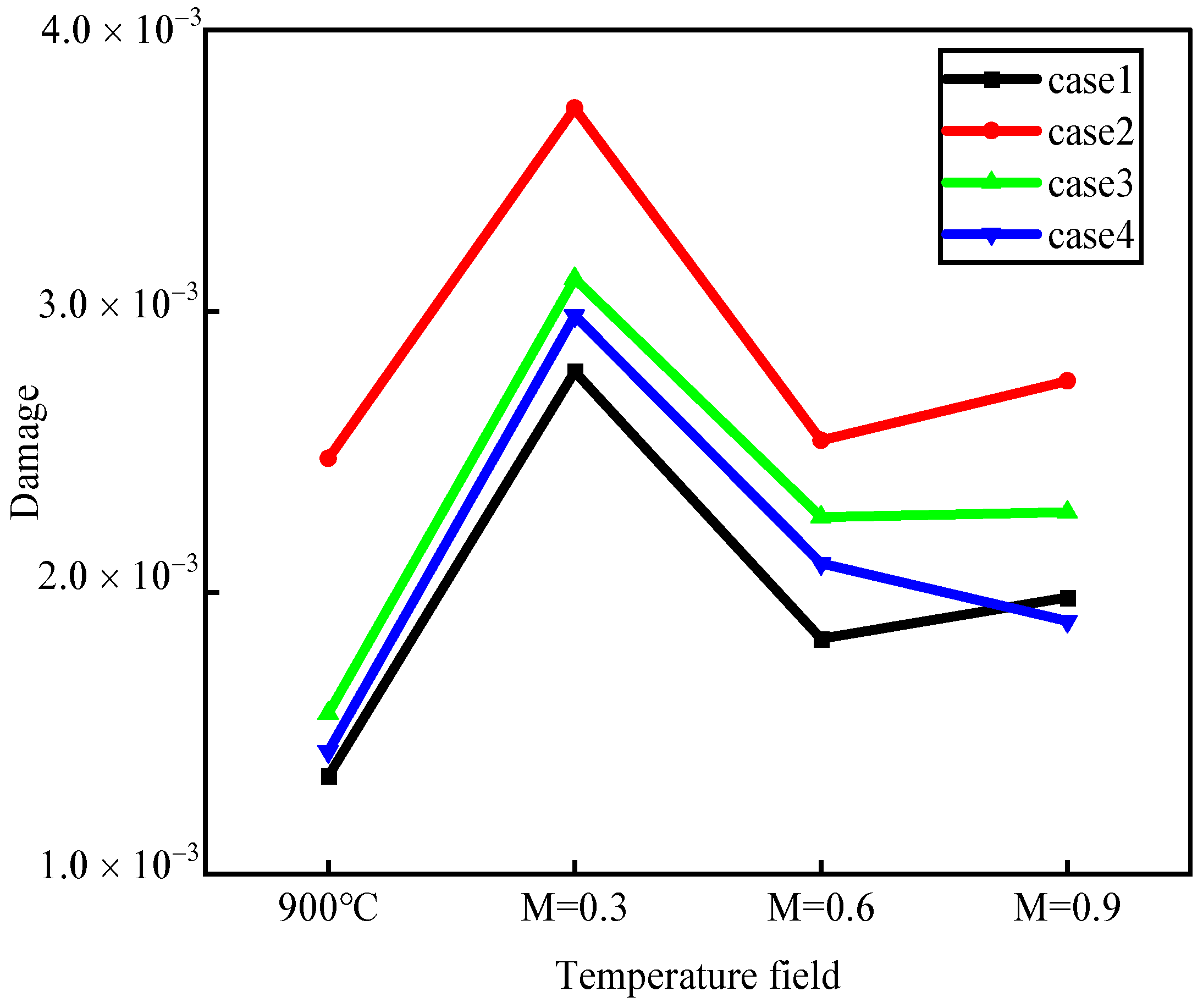

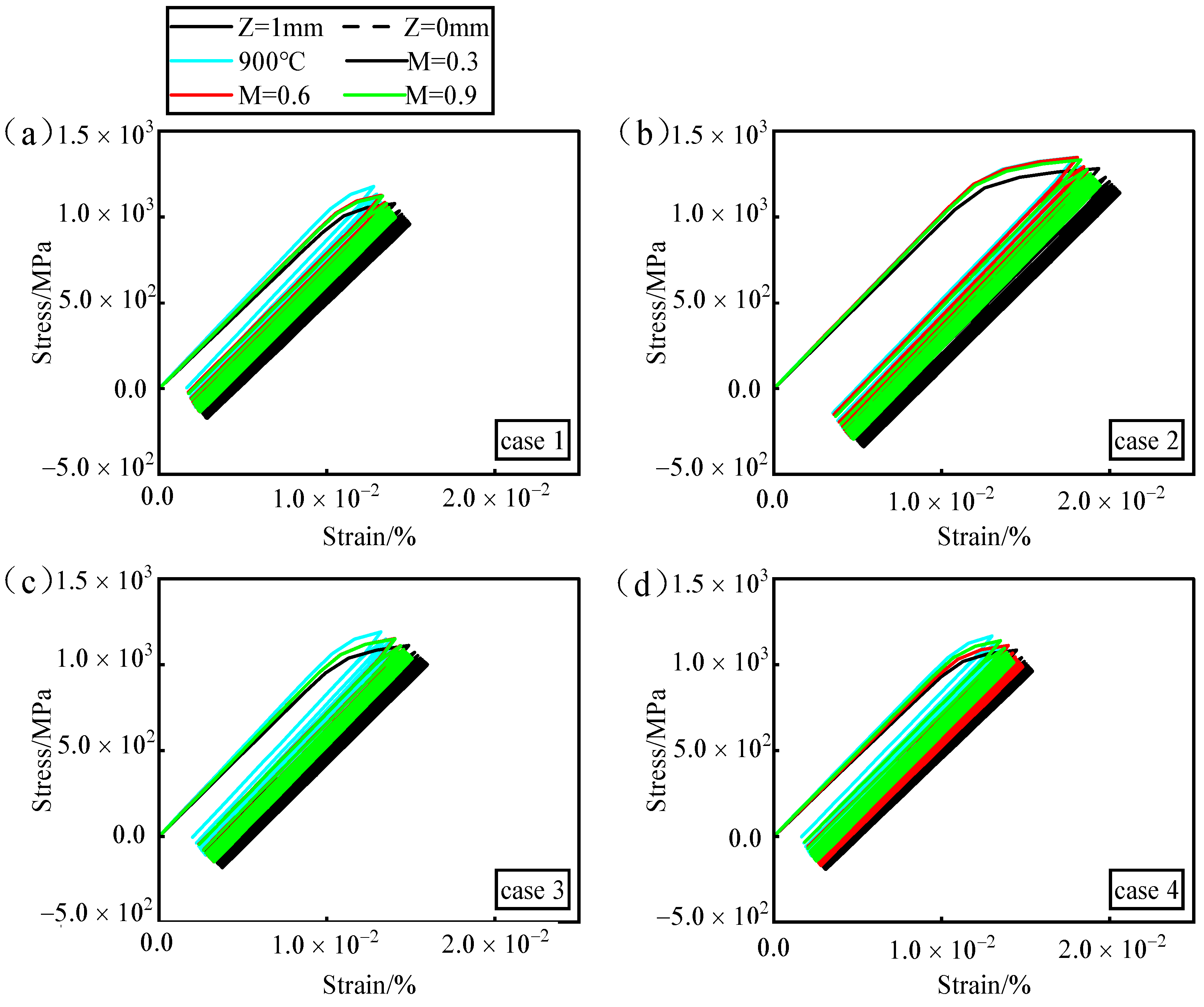

5.1. Fatigue Behavior of Film-Cooling Hole Structures in Isothermal Fields

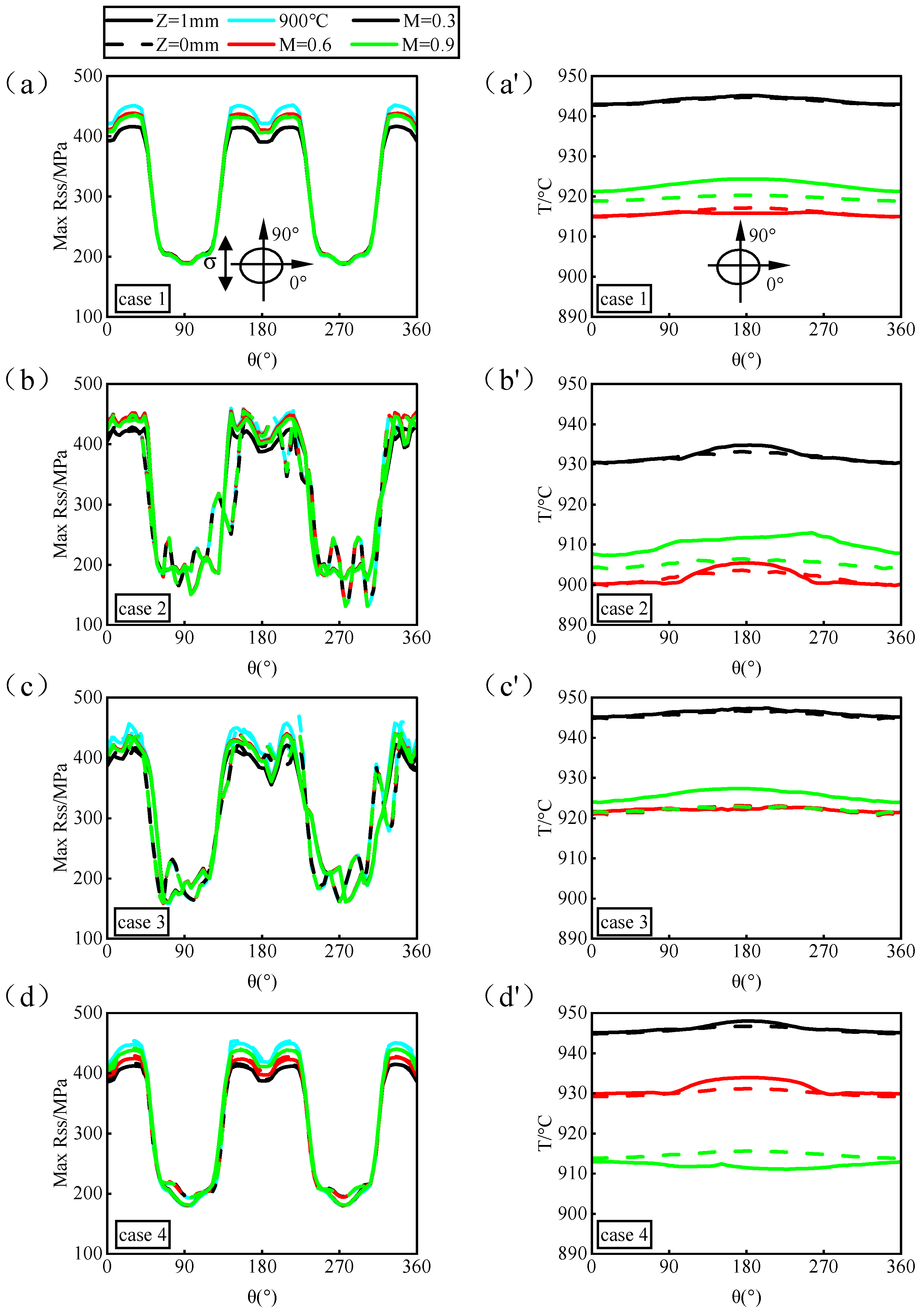

5.2. Fatigue Behavior of Film-Cooling Hole Structures under Real Flow-Field Temperature Conditions

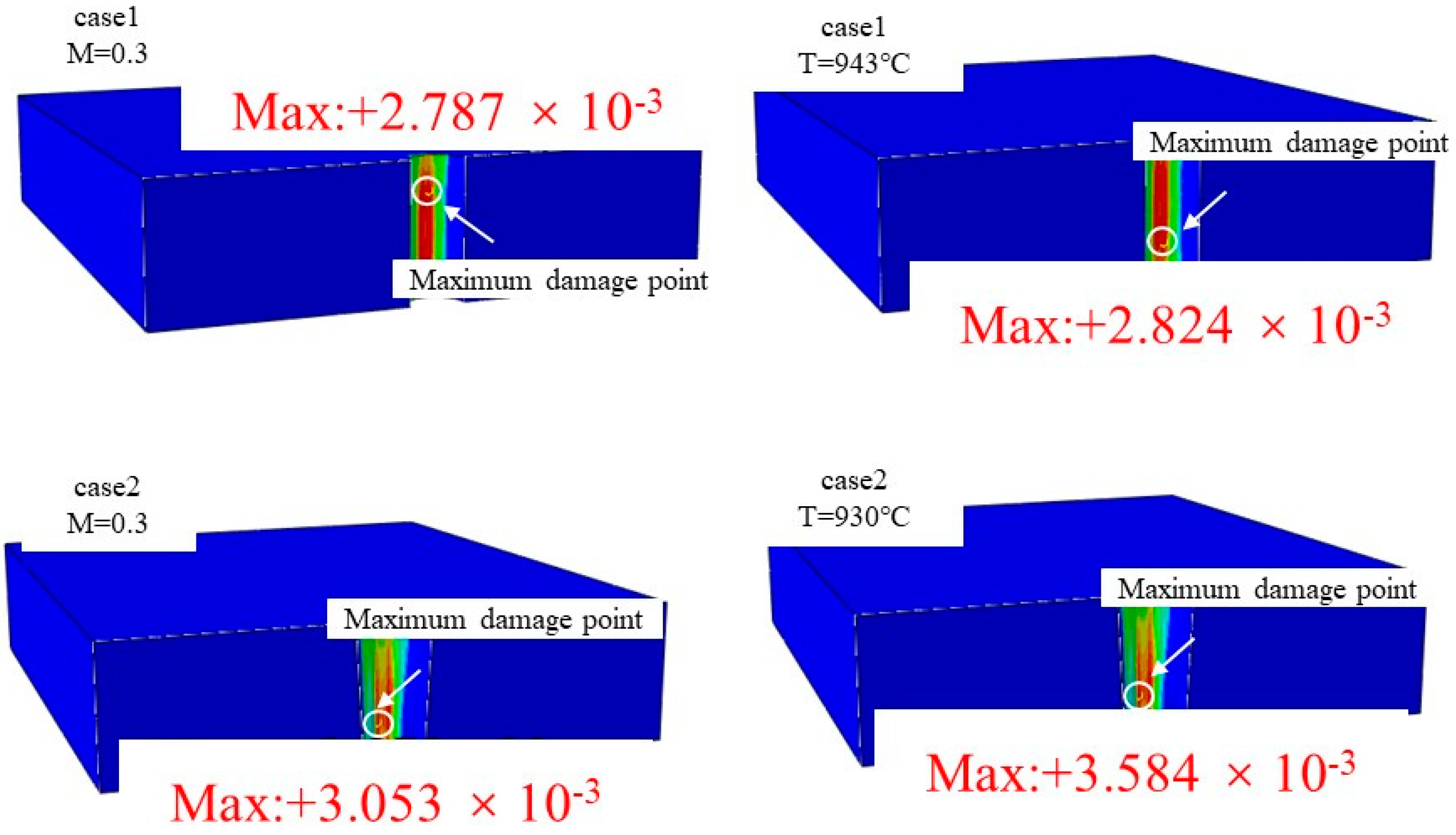

5.3. Analysis of Fatigue Behavior of Individual Film-Cooling Holes Manufactured Using Lasers with Different Pulse Widths

6. Conclusions

- (1)

- The diameter and taper of film-cooling holes significantly influence their aerodynamic and heat transfer characteristics, while roundness has no impact. However, roundness errors notably affect the fatigue behavior of film-cooling holes and exhibit a negative correlation. Conversely, the diameter and taper hardly alter their fatigue behavior. The influence of the structure on fatigue behavior is greater than the influence of temperature. Therefore, in design, it is a priority to optimize the structure while maximizing cooling performance as much as possible.

- (2)

- In a real flow field, a single film-cooling hole exhibits second-order thermal distribution characteristics. The first order is dominated by film cooling, evident in the temperature gradient along the downstream hot wall surface of the hole. The second order is controlled by heat conduction between the gas and solid, manifested as the lowest temperature around the hole perimeter, with temperature gradients extending outward and increasing. Based on the conclusions of this study, further equivalent research using real flow-field temperature tests can be conducted. Establishing a quantitative conversion relationship between equivalent boundaries and real boundaries can be used to guide mechanical testing.

- (3)

- Changes in the blowing ratio do not affect the temperature or stress distribution around the hole perimeter; they only alter the temperature peak values. An increase in temperature peaks leads to a decrease in stress peak values. According to crystal plasticity theory, DD6 exhibits a positive correlation between fatigue damage and temperature above 850 °C. This phenomenon results in the occurrence of low damage with high stress at low temperatures and high damage with low stress at high temperatures. This has practical application value for material selection and thermal management strategies in high-temperature environments.

- (4)

- The fatigue damage of a single film-cooling hole is jointly determined by structural defects in the hole and changes in material performance due to temperatures around the hole, with structural factors exerting a greater influence. Nanosecond laser processing exhibits significant machining errors, resulting in oversized apertures, roundness issues, and excessive taper. While its cooling effect is optimal, the roundness error notably decreases fatigue behavior. Picosecond laser drilling follows next in preference. On the other hand, femtosecond laser processing, due to its smaller roundness error, demonstrates superior fatigue behavior.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, K.; Lü, J.; Zhao, Y.; Tao, J.; Qin, Y.; Chen, Y.; Wang, W.; Sun, Q.; Wang, C.; Liang, J. Turbine Blade Three-Wavelength Radiation Temperature Measurement Method Based on Reflection Error Correction. Appl. Sci. 2021, 11, 3913. [Google Scholar] [CrossRef]

- Yanling, Y.A.O.; Jun, D.A.I.; Chunfeng, H. Develop-Ment for Temperature Measurement Technology in Modern Aeroengine. Aeronaut. Manuf. Technol. 2015, 58, 103–107. [Google Scholar]

- Garg, S. Aircraft Turbine Engine Control Research at NASA Glenn Research Center. J. Aerosp. Eng. 2013, 26, 422–438. [Google Scholar] [CrossRef]

- Bahr, D.W. Technology for the Design of High Temperature Rise Combustors. J. Propuls. Power 1987, 3, 179–186. [Google Scholar] [CrossRef]

- Sturgess, G.J. Combustor Design Trends for Aircraft Gas Turbine Engines; American Society of Mechanical Engineers: New York, NY, USA, 1996; Volume 78774, ISBN 0-7918-7877-5. [Google Scholar]

- Chin, J.; Dang, J. New Generation Aero Combustor. In Renewable Energy-Technologies and Applications; IntechOpen: London, UK, 2020; pp. 1–19. ISBN 1-83881-001-3. [Google Scholar]

- Al-Zurfi, N.; Turan, A.; Nasser, A.; Alhusseny, A. A Numerical Study of Anti-Vortex Film cooling holes Designs in a 1-1/2 Turbine Stage Using LES. Propuls. Power Res. 2019, 8, 275–299. [Google Scholar] [CrossRef]

- He, W.; Deng, Q.; Zhou, W.; Gao, T.; Feng, Z. Film Cooling and Aerodynamic Performances of a Turbine Nozzle Guide Vane with Trenched Cooling Holes. Appl. Therm. Eng. 2019, 150, 150–163. [Google Scholar] [CrossRef]

- Zhang, Y.; Wen, Z.; Pei, H.; Wang, J.; Li, Z.; Yue, Z. Equivalent Method of Evaluating Mechanical Properties of Perforated Ni-Based Single Crystal Plates Using Artificial Neural Networks. Comput. Methods Appl. Mech. Eng. 2020, 360, 112725. [Google Scholar] [CrossRef]

- Wen, Z.; Pei, H.; Yang, H.; Wu, Y.; Yue, Z. A Combined CP Theory and TCD for Predicting Fatigue Lifetime in Single-Crystal Superalloy Plates with Film Cooling Holes. Int. J. Fatigue 2018, 111, 243–255. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Z.; Zhu, Y.; Zhu, D. Machining of a Film-Cooling Hole in a Single-Crystal Superalloy by High-Speed Electrochemical Discharge Drilling. Chin. J. Aeronaut. 2016, 29, 560–570. [Google Scholar] [CrossRef]

- Li, F.; Wen, Z.; Wu, Z.; Liu, S.; Li, Z.; Pei, H.; Yue, Z. Evaluation of Different Drilling Quality and Fatigue Life Prediction of Nickel-Based Superalloy Using Equivalent Initial Flaw Size. Eng. Fract. Mech. 2021, 253, 107908. [Google Scholar] [CrossRef]

- Wen, Z.; Huang, S.; Gao, H.; Yue, Z. Experimental Investigation on Low Cycle Fatigue Properties of GH3536 Alloy with Film Cooling Holes in Different Drilling Processes. Eng. Fail. Anal. 2017, 82, 190–197. [Google Scholar] [CrossRef]

- Zhang, T.; Sun, J.; Yuan, H. Cyclic Plasticity Modeling and Fatigue Life Assessment of the Recasting Material of a Nickel-Based Superalloy Induced by Laser Manufacturing. Int. J. Fatigue 2021, 147, 106154. [Google Scholar] [CrossRef]

- Jiang, J.; Ma, X.; Wang, B. Stress Analysis of the Thermal Barrier Coating System near a Cooling Hole Considering the Free-Edge Effect. Ceram. Int. 2020, 46, 331–342. [Google Scholar] [CrossRef]

- Wen, Z.; Zhang, D.; Li, S.; Yue, Z.; Gao, J. Anisotropic Creep Damage and Fracture Mechanism of Nickel-Base Single Crystal Superalloy under Multiaxial Stress. J. Alloys Compd. 2017, 692, 301–312. [Google Scholar] [CrossRef]

- Kudla, L.A. Fracture Phenomena of Microdrills in Static and Dynamic Conditions. Eng. Fract. Mech. 2011, 78, 1–12. [Google Scholar] [CrossRef]

- Fu, L.; Ling, S.-F.; Tseng, C.-H. On-Line Breakage Monitoring of Small Drills with Input Impedance of Driving Motor. Mech. Syst. Signal Process. 2007, 21, 457–465. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, J. Laser Drilling Assisted with Jet Electrochemical Machining for the Minimization of Recast and Spatter. Int. J. Adv. Manuf. Technol. 2012, 62, 1055–1062. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, W.; Xi, X. A Study on Pulse Control for Small-Hole Electrical Discharge Machining. J. Mater. Process. Technol. 2012, 212, 1463–1471. [Google Scholar] [CrossRef]

- Burger, M.; Koll, L.; Werner, E.A.; Platz, A. Electrochemical Machining Characteristics and Resulting Surface Quality of the Nickel-Base Single-Crystalline Material LEK94. J. Manuf. Process. 2012, 14, 62–70. [Google Scholar] [CrossRef]

- Singh, T.; Dvivedi, A. Developments in Electrochemical Discharge Machining: A Review on Electrochemical Discharge Machining, Process Variants and Their Hybrid Methods. Int. J. Mach. Tools Manuf. 2016, 105, 1–13. [Google Scholar] [CrossRef]

- Bharatish, A.; Murthy, H.N.; Anand, B.; Madhusoodana, C.D.; Praveena, G.S.; Krishna, M. Characterization of Hole Circularity and Heat Affected Zone in Pulsed CO2 Laser Drilling of Alumina Ceramics. Opt. Laser Technol. 2013, 53, 22–32. [Google Scholar] [CrossRef]

- Döring, S.; Richter, S.; Tünnermann, A.; Nolte, S. Evolution of Hole Depth and Shape in Ultrashort Pulse Deep Drilling in Silicon. Appl. Phys. A 2011, 105, 69–74. [Google Scholar] [CrossRef]

- Chen, L.; Hu, W.B.; Wen, Z.X.; Yue, Z.F.; Gao, Y.F. Effects of Roundness of Laser Formed Film Cooling Holes on Fatigue Life of Nickel Based Single Crystal. Mater. High Temp. 2014, 31, 18–26. [Google Scholar] [CrossRef]

- Li, F.; Zhang, Y.; Wu, Z.; Ren, X.; Yue, X.; Pei, H.; Yue, Z. Fatigue Crack Initiation and Propagation Behavior of Nickel-Based Single Crystal DD6 under Different Drilling Processes. Mater. Sci. Eng. A 2022, 831, 142246. [Google Scholar] [CrossRef]

- Ren, X.; Lu, J.; Zhou, J.; Liu, X.; Jiang, W.; Wang, J.; Zhang, Y.; Zhang, Z. In-Situ Fatigue Behavior Study of a Nickel-Based Single-Crystal Superalloy with Different Orientations. Mater. Sci. Eng. A 2022, 855, 143913. [Google Scholar] [CrossRef]

- Yin, Q.; Lian, Y.; Wen, Z.; Pei, H.; Wang, J.; Yue, Z. Atomic Simulation of the Effect of Orientation on Tensile/Compressive Properties in Nickel-Based Single Crystal Superalloys. J. Alloys Compd. 2022, 893, 162210. [Google Scholar] [CrossRef]

- Hou, N.X.; Wen, Z.X.; Yue, Z.F. Tensile and Fatigue Behavior of Thin-Walled Cylindrical Specimens under Temperature Gradient Condition. J. Mater. Sci. 2008, 43, 1933–1938. [Google Scholar] [CrossRef]

- Hou, N.X.; Yu, Q.M.; Wen, Z.X.; Yue, Z.F. Low Cycle Fatigue Behavior of Single Crystal Superalloy with Temperature Gradient. Eur. J. Mech.-A/Solids 2010, 29, 611–618. [Google Scholar] [CrossRef]

- Skamniotis, C.; Cocks, A.C. Designing against Severe Stresses at Compound Cooling Holes of Double Wall Transpiration Cooled Engine Components. Aerosp. Sci. Technol. 2021, 116, 106856. [Google Scholar] [CrossRef]

- Skamniotis, C.; Cocks, A.C. 2D and 3D Thermoelastic Phenomena in Double Wall Transpiration Cooling Systems for Gas Turbine Blades and Hypersonic Flight. Aerosp. Sci. Technol. 2021, 113, 106610. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, J.; Liang, J.; Jia, J. The Creep Rupture Behavior of Thin-Walled Plates with a Single Film Cooling Hole at Different Inclination Angles in a Real Flow Field. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, W.; Wang, Z.; Tong, Z. Conjugate Heat Transfer Simulation of Overall Cooling Performance for Cratered Film Cooling Holes. Machines 2022, 10, 395. [Google Scholar] [CrossRef]

- Ramesh, S.; Ramirez, D.G.; Ekkad, S.V.; Alvin, M.A. Analysis of Film Cooling Performance of Advanced Tripod Hole Geometries with and without Manufacturing Features. Int. J. Heat Mass Transf. 2016, 94, 9–19. [Google Scholar] [CrossRef]

- Taylor, G.I. Plastic Strain in Metals. J Inst. Met. 1938, 62, 307–324. [Google Scholar]

- Hill, R.; Rice, J. Constitutive Analysis of Elastic-Plastic Crystals at Arbitrary Strain. J. Mech. Phys. Solids 1972, 20, 401–413. [Google Scholar] [CrossRef]

- Asaro, R.J.; Rice, J. Strain Localization in Ductile Single Crystals. J. Mech. Phys. Solids 1977, 25, 309–338. [Google Scholar] [CrossRef]

- Taylor, G.I. The Mechanism of Plastic Deformation of Crystals. Part I.—Theoretical. Proc. R. Soc. London Ser. A Contain. Pap. A Math. Phys. Character 1934, 145, 362–387. [Google Scholar]

- Taylor, G.I. The Mechanism of Plastic Deformation of Crystals. Part II.—Comparison with Observations. Proc. R. Soc. London Ser. A Contain. Pap. A Math. Phys. Character 1934, 145, 388–404. [Google Scholar]

- Yaguchi, M.; Yamamoto, M.; Ogata, T. A Viscoplastic Constitutive Model for Nickel-Base Superalloy, Part 1: Kinematic Hardening Rule of Anisotropic Dynamic Recovery. Int. J. Plast. 2002, 18, 1083–1109. [Google Scholar] [CrossRef]

- Tinga, T.; Brekelmans, W.A.M.; Geers, M.G.D. Time-Incremental Creep–Fatigue Damage Rule for Single Crystal Ni-Base Superalloys. Mater. Sci. Eng. A 2009, 508, 200–208. [Google Scholar] [CrossRef]

- Shi, C.X.; Zhong, Z.Y.; Feng, D. China Superalloys Handbook; China Zhijian Publishing House and Standard Press: Beijing, China, 2012. [Google Scholar]

- Jiang, J.; Jiang, L.; Cai, Z.; Wang, W.; Zhao, X.; Liu, Y.; Cao, Z. Numerical Stress Analysis of the TBC-Film Cooling System under Operating Conditions Considering the Effects of Thermal Gradient and TGO Growth. Surf. Coat. Technol. 2019, 357, 433–444. [Google Scholar] [CrossRef]

- Zhou, W.; Deng, Q.; He, W.; He, J.; Feng, Z. Conjugate Heat Transfer Analysis for Composite Cooling Structure Using a Decoupled Method. Int. J. Heat Mass Transf. 2020, 149, 119200. [Google Scholar] [CrossRef]

- Liu, Y.; Rao, Y.; Yang, L.; Xu, Y.; Terzis, A. Flow and Heat Transfer Characteristics of Double-Wall Cooling with Multi-Row Short Film Cooling Hole Arrangements. Int. J. Therm. Sci. 2021, 165, 106878. [Google Scholar] [CrossRef]

- Zhang, D.; He, J.; Liang, J.; He, Z. Surface Slip Deformation Characteristics of Nickel-Base Single Crystal Thin Plates with Film Cooling Holes. IEEE Access 2020, 8, 75145–75153. [Google Scholar] [CrossRef]

- Wen, Z.; Zhang, Y.; Li, Y.; Yue, Z. Effects of Blade Curvature on Fatigue Life of Nickel-Based Single Crystal Structures with Film cooling holes. In Mechanical and Creep Behavior of Advanced Materials: A SMD Symposium Honoring Professor K. Linga Murty; Springer: Berlin, Germany, 2017; pp. 207–215. [Google Scholar]

- Mao, H.Z.; Wen, Z.X.; Yue, Z.F.; Wang, B.Z. The Evolution of Plasticity for Nickel-Base Single Crystal Cooled Blade with Film Cooling Holes. Mater. Sci. Eng. A 2013, 587, 79–84. [Google Scholar] [CrossRef]

| Element | Co | W | Ta | Al | Cr | Re | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| Content | 8.5~9.5 | 7.0~9.0 | 6.0~8.5 | 5.2~6.2 | 3.8~4.8 | 1.6~2.4 | 1.5~2.5 | Bal |

| Number | Laser Type | Upper Hole Diameter (µm) | Lower Hole Diameter (µm) | Upper Hole Diameter Error | Lower Hole Diameter Error | Upper Hole Roundness (µm) | Lower Hole Roundness (µm) | Taper (°) |

|---|---|---|---|---|---|---|---|---|

| Case 1 | Ideal hole | 400.0 | 400.0 | 0 | 0 | 0 | 0 | 0 |

| Case 2 | Nanosecond | 539.2 | 448.6 | 34.80% | 12.15% | 0.0318 | 0.0357 | 7.41 |

| Case 3 | Picosecond | 396.4 | 385.2 | −0.90% | −3.70% | 0.0246 | 0.0346 | 0.92 |

| Case 4 | Femtosecond | 450.2 | 382.8 | 12.50% | −4.30% | 0.0047 | 0.0131 | 5.50 |

| 6.0 | 150.0 | 4.5 × 10–7 | 85.0 | 8.31 | 1.6 × 10–7 | 4.275 | 5.0 |

| Temperature (°C) | E (MPa) | v | G (MPa) | |||

|---|---|---|---|---|---|---|

| 25 | 131.50 | 0.344 | 155.07 | 382.6 | 366.9 | 0.61 |

| 760 | 105.50 | 0.377 | 115.43 | 376.0 | 408.0 | 0.65 |

| 850 | 91.46 | 0.383 | 105.85 | 357.2 | 410.5 | 0.71 |

| 980 | 80.50 | 0.390 | 85.60 | 240.0 | 275.0 | 0.37 |

| 1070 | 69.50 | 0.399 | 72.50 | 200.0 | 206.5 | 0.24 |

| Temperature (K) | Heat Transfer Coefficient (W (m·K)) | Specific Heat Capacity (J (kg·K)) |

|---|---|---|

| 773.15 | 15.35 | 496 |

| 973.15 | 20.20 | 566 |

| 1173.15 | 24.55 | 635 |

| 1273.15 | 26.80 | 669 |

| 1373.15 | 28.95 | 704 |

| 1473.15 | 33.20 | 773 |

| Number | Laser Type | Upper Hole Diameter (µm) | Lower Hole Diameter (µm) | Upper Hole Roundness (µm) | Lower Hole Roundness (µm) | Taper (°) |

|---|---|---|---|---|---|---|

| Case 1 | Ideal hole | 400.0 | 400.0 | 0 | 0 | 0 |

| Case 3 | Picosecond | 385.2 | 380.9 | 24.6 | 34.6 | 0.35 |

| Case 5 | Tapered hole | 450.0 | 400.0 | 0 | 0 | 4.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Xin, Z.; Luo, Z. Temperature–Stress Coupling Fatigue Behavior of Film-Cooling Holes in Complex Temperature Fields. Materials 2024, 17, 3785. https://doi.org/10.3390/ma17153785

Zhang D, Xin Z, Luo Z. Temperature–Stress Coupling Fatigue Behavior of Film-Cooling Holes in Complex Temperature Fields. Materials. 2024; 17(15):3785. https://doi.org/10.3390/ma17153785

Chicago/Turabian StyleZhang, Dongxu, Zhenyu Xin, and Zhuang Luo. 2024. "Temperature–Stress Coupling Fatigue Behavior of Film-Cooling Holes in Complex Temperature Fields" Materials 17, no. 15: 3785. https://doi.org/10.3390/ma17153785

APA StyleZhang, D., Xin, Z., & Luo, Z. (2024). Temperature–Stress Coupling Fatigue Behavior of Film-Cooling Holes in Complex Temperature Fields. Materials, 17(15), 3785. https://doi.org/10.3390/ma17153785