Evaluation of Shear Strength and Stiffness of a Loess–Sand Mixture in Triaxial and Unconfined Compression Tests

Abstract

:1. Introduction

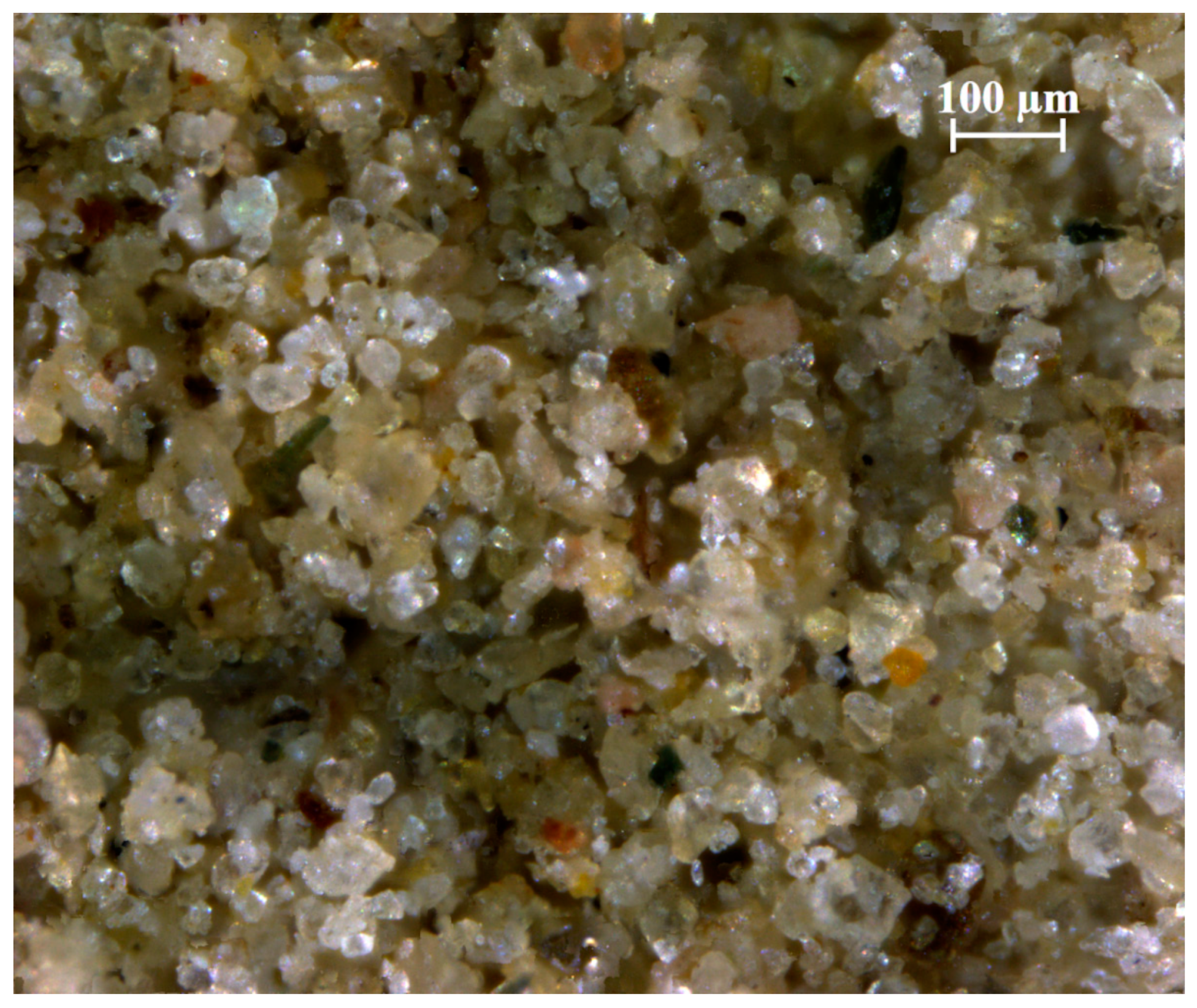

2. Mechanical Parameters Interpretation

3. Materials and Sample Preparation

4. Methodology

5. Results and Discussion

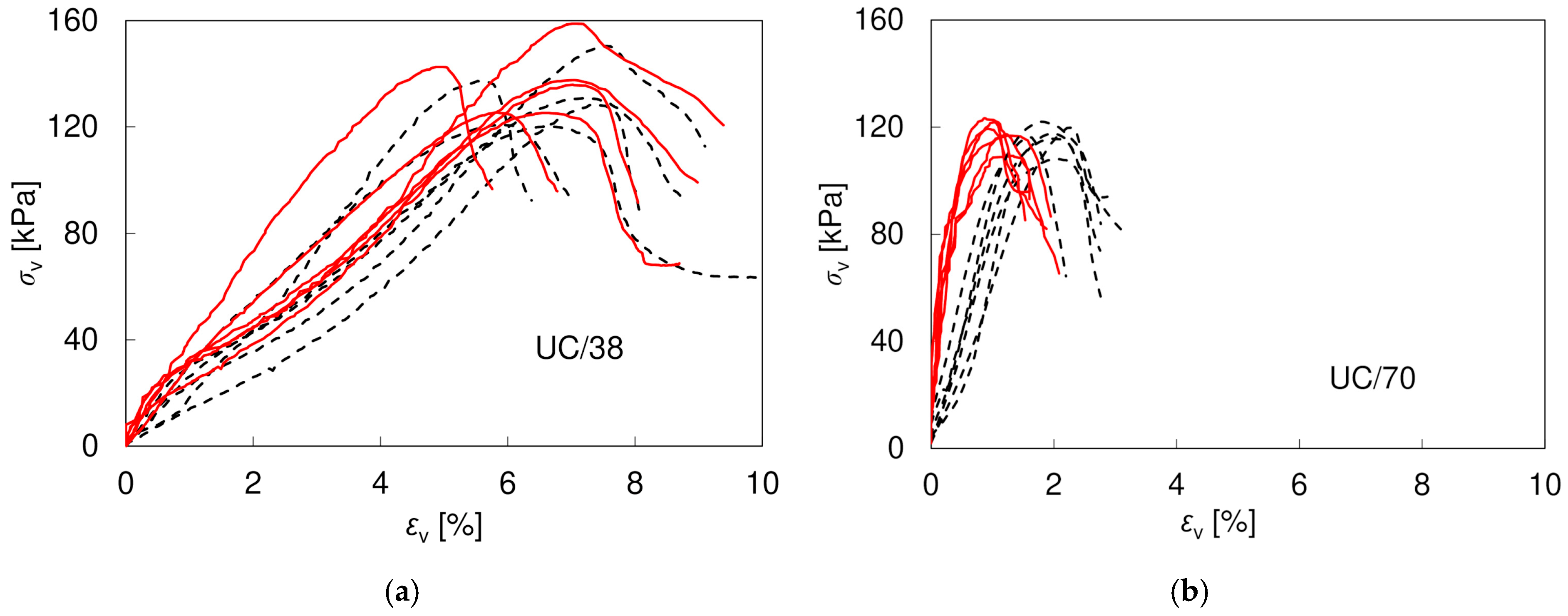

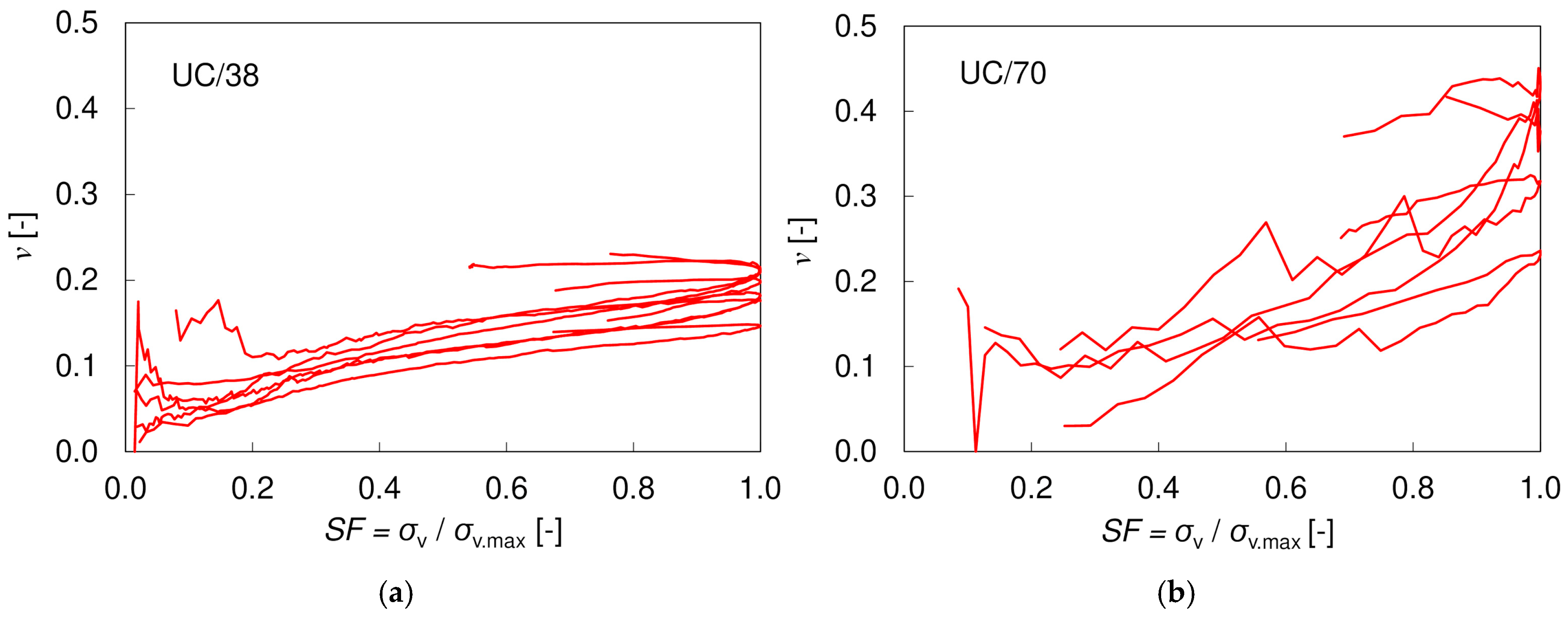

5.1. Strength and Stiffness in Unconfined Compression

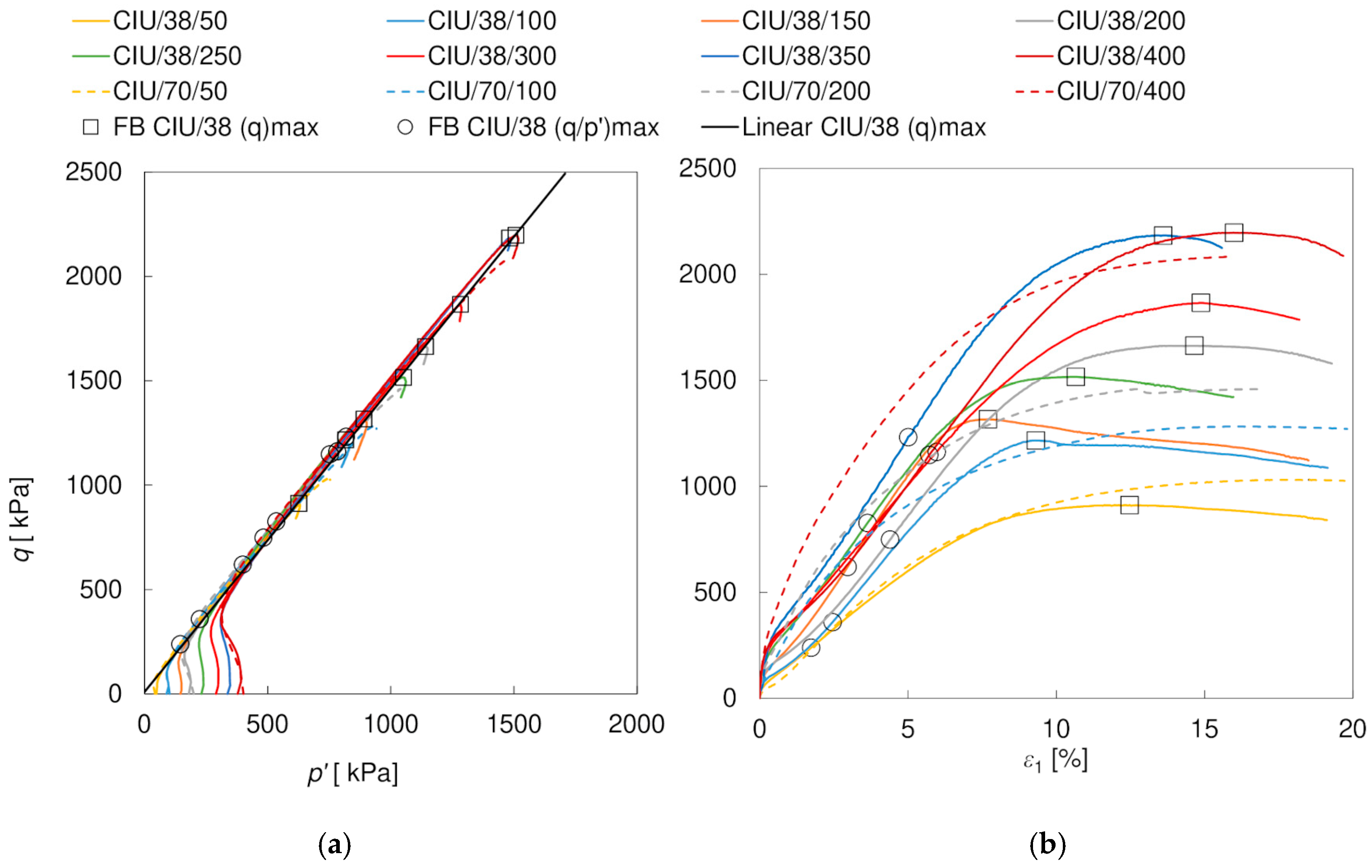

5.2. Shear Strength in Triaxial Compression

5.3. Stiffness in Triaxial Compression

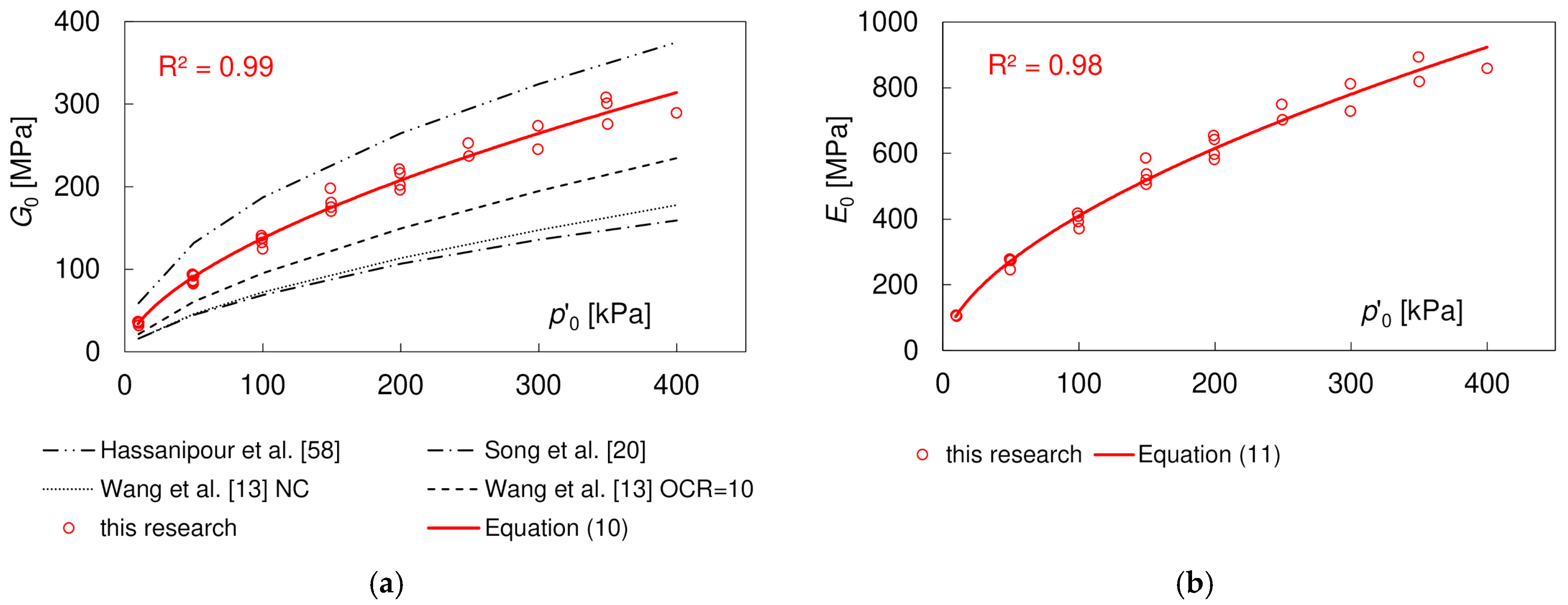

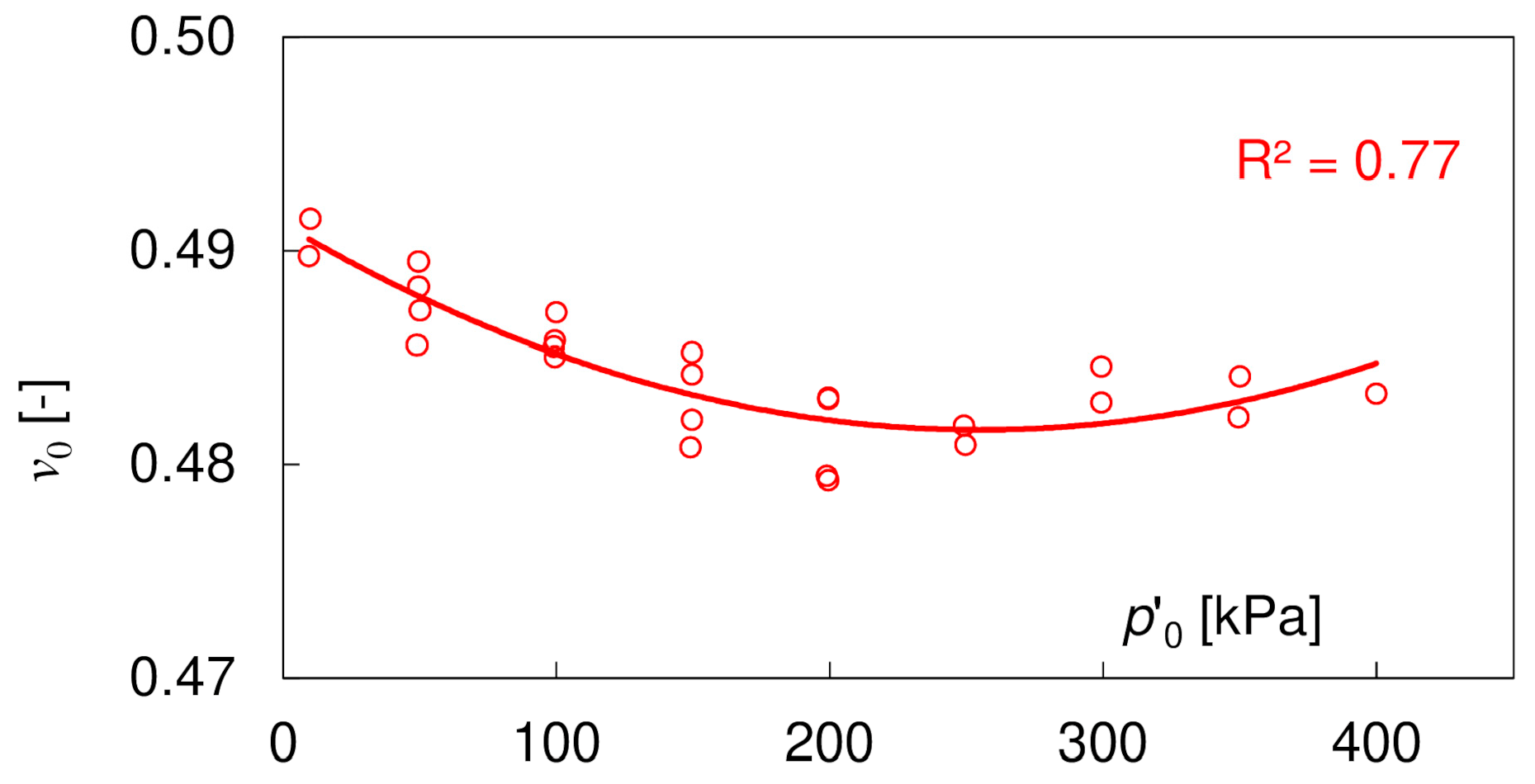

5.3.1. Initial Shear Modulus G0, Poisson’s Ratio ν0, and Young’s Modulus E0

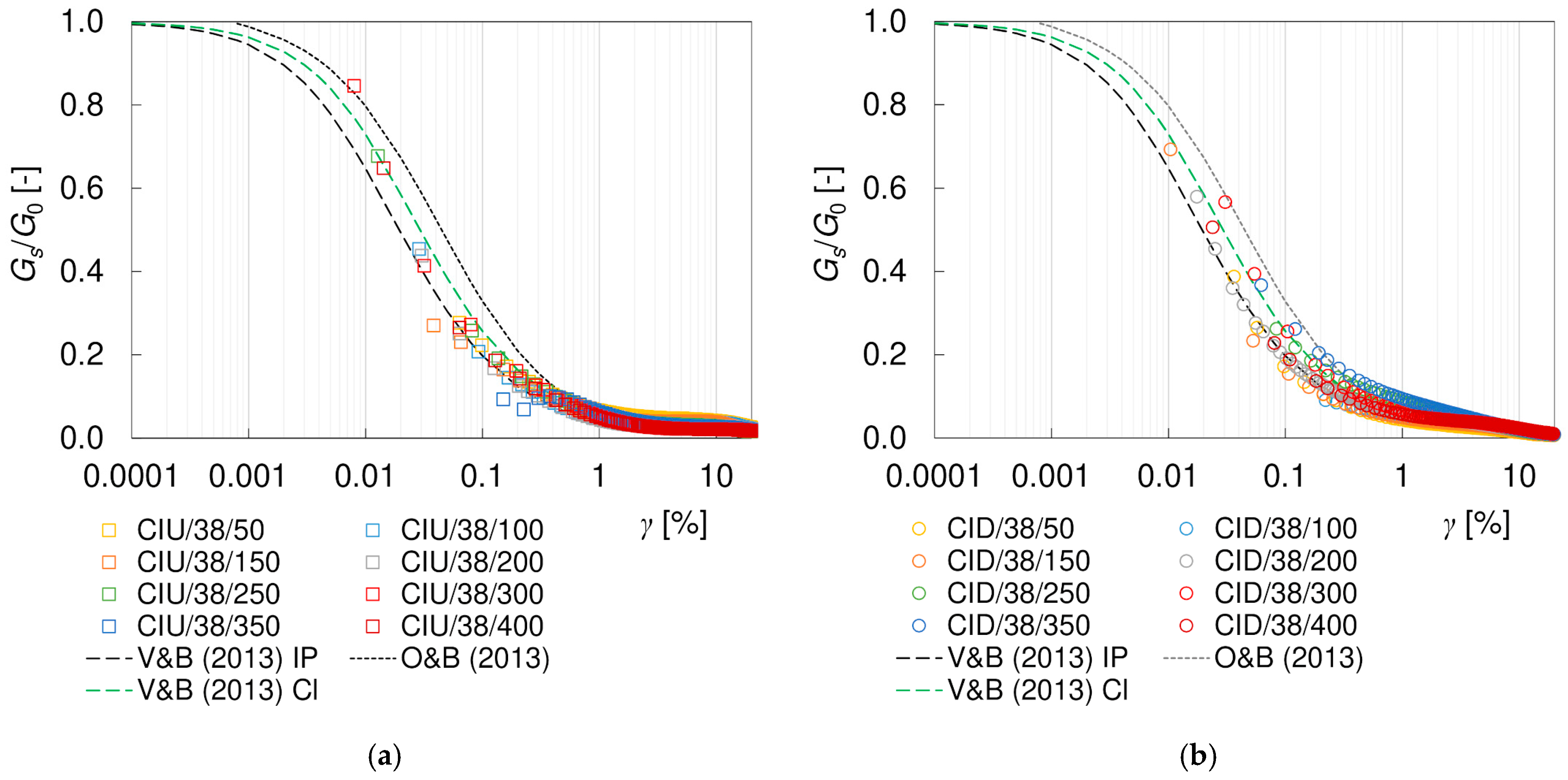

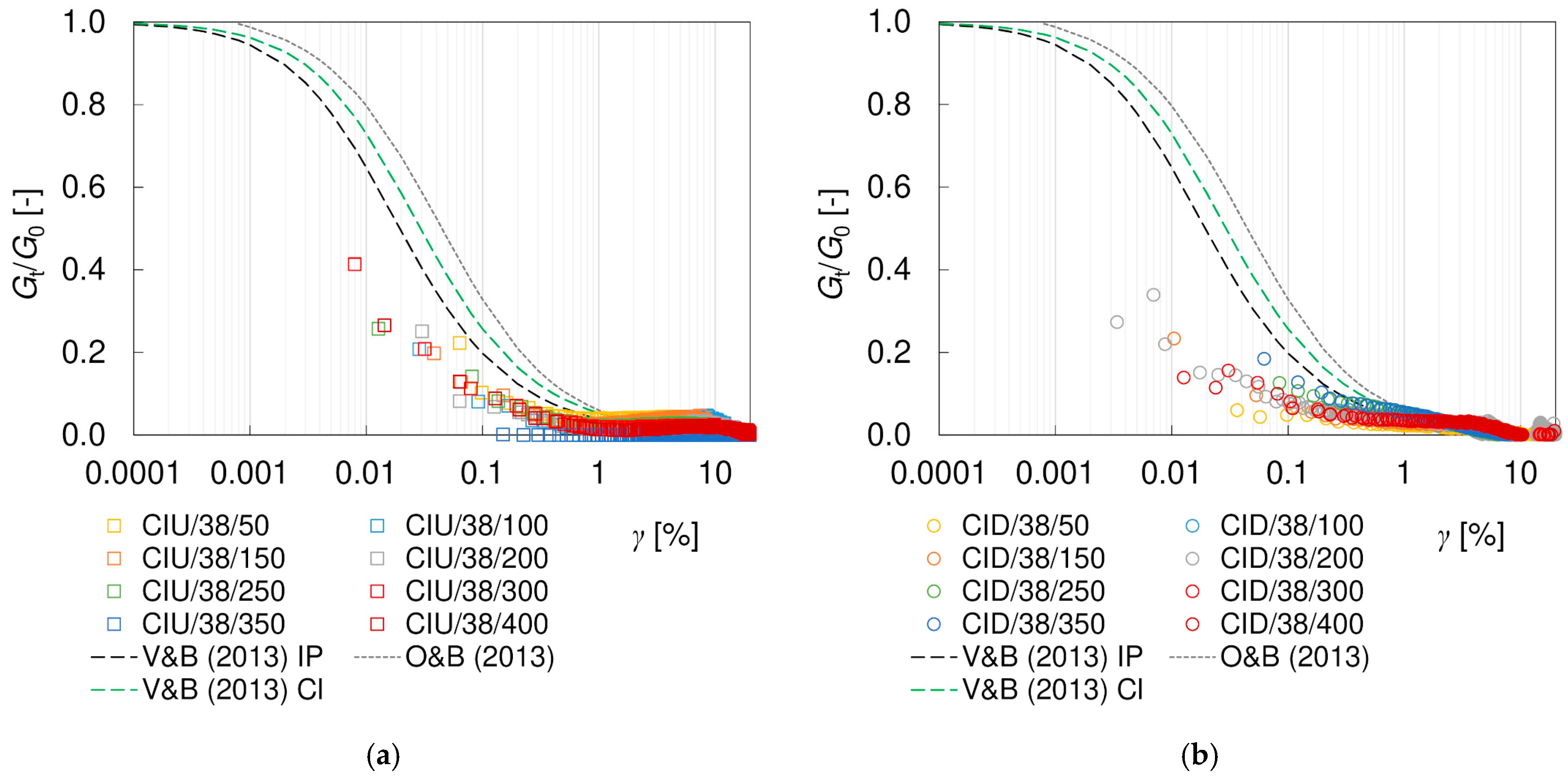

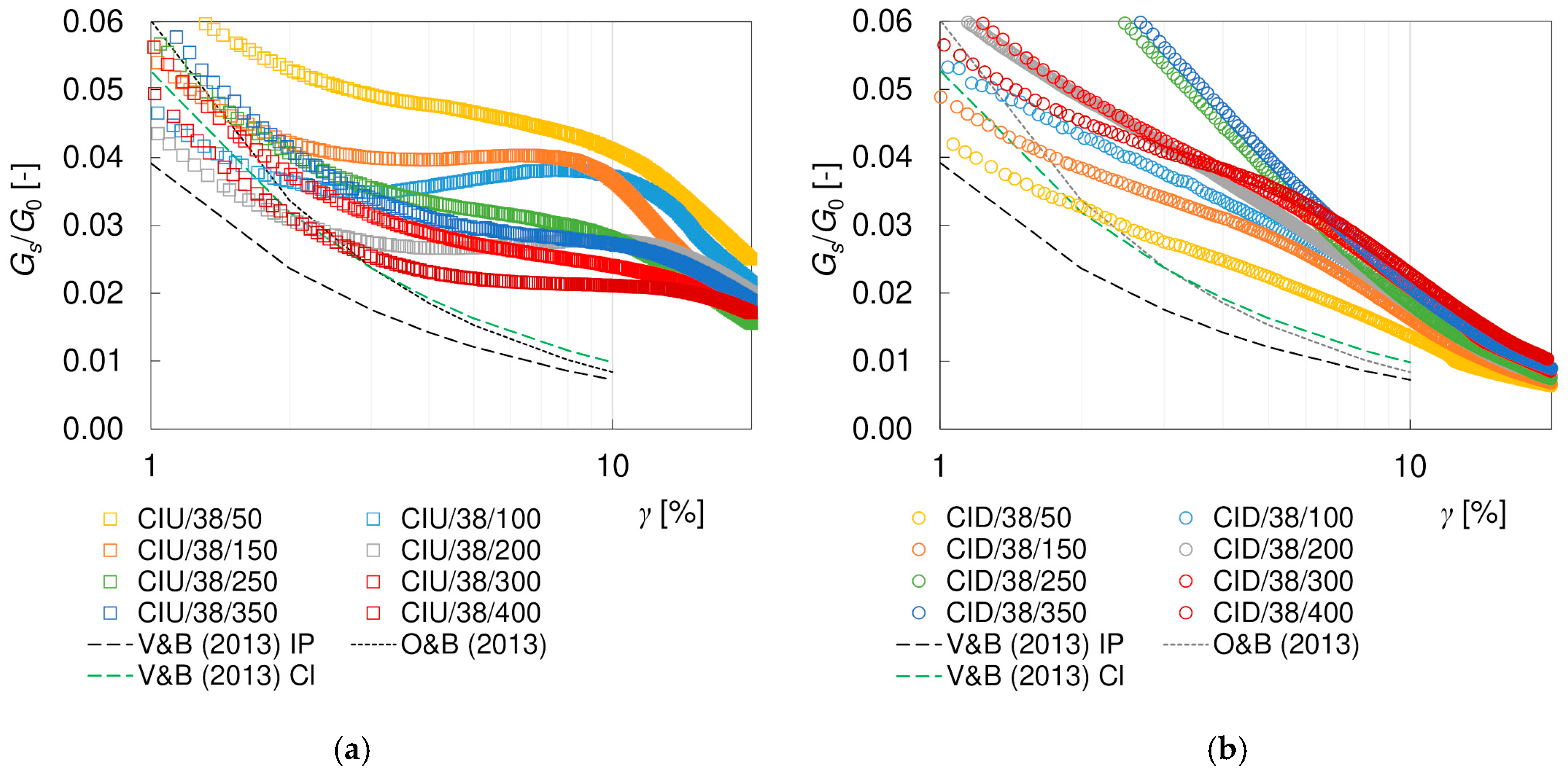

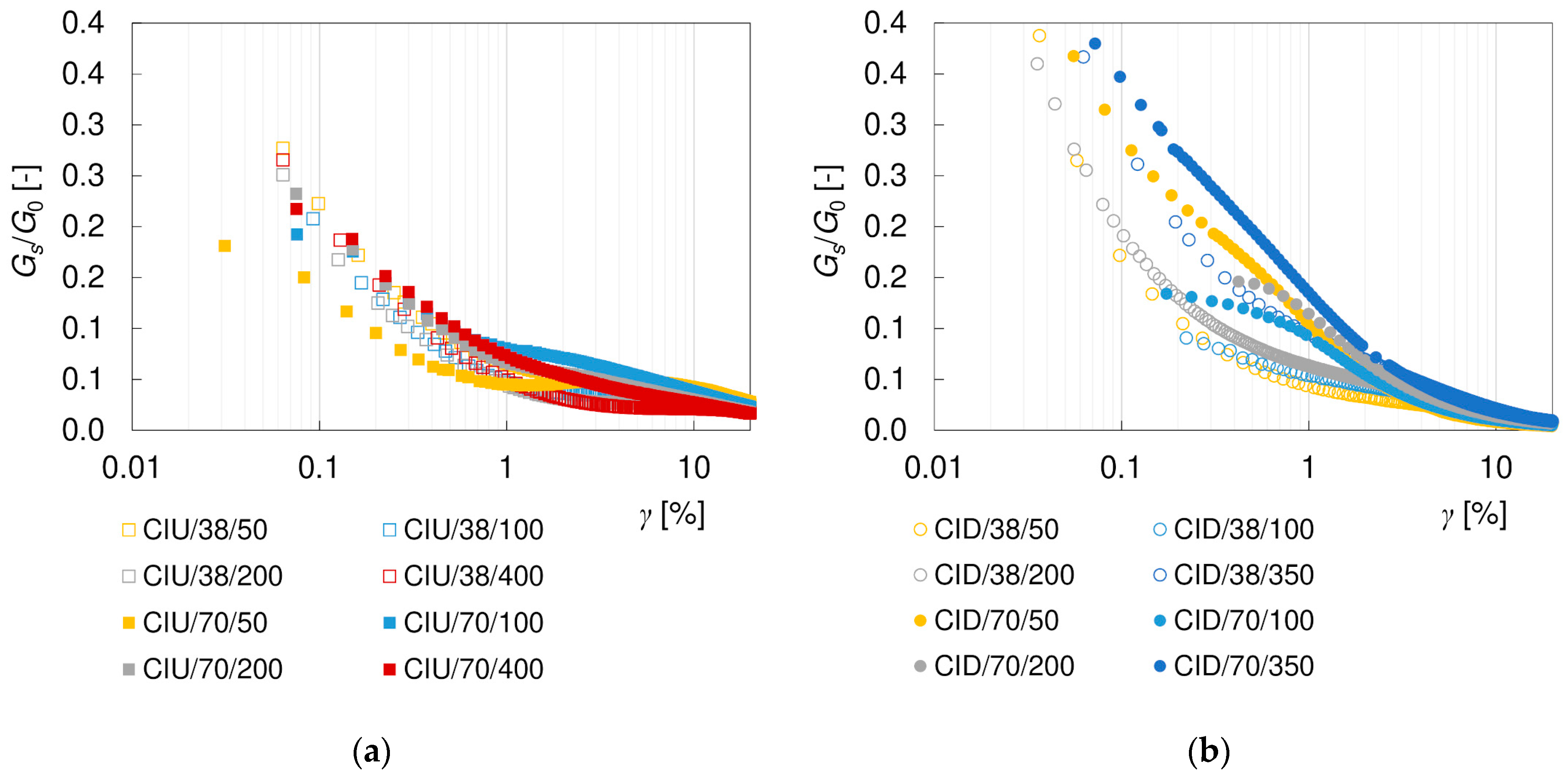

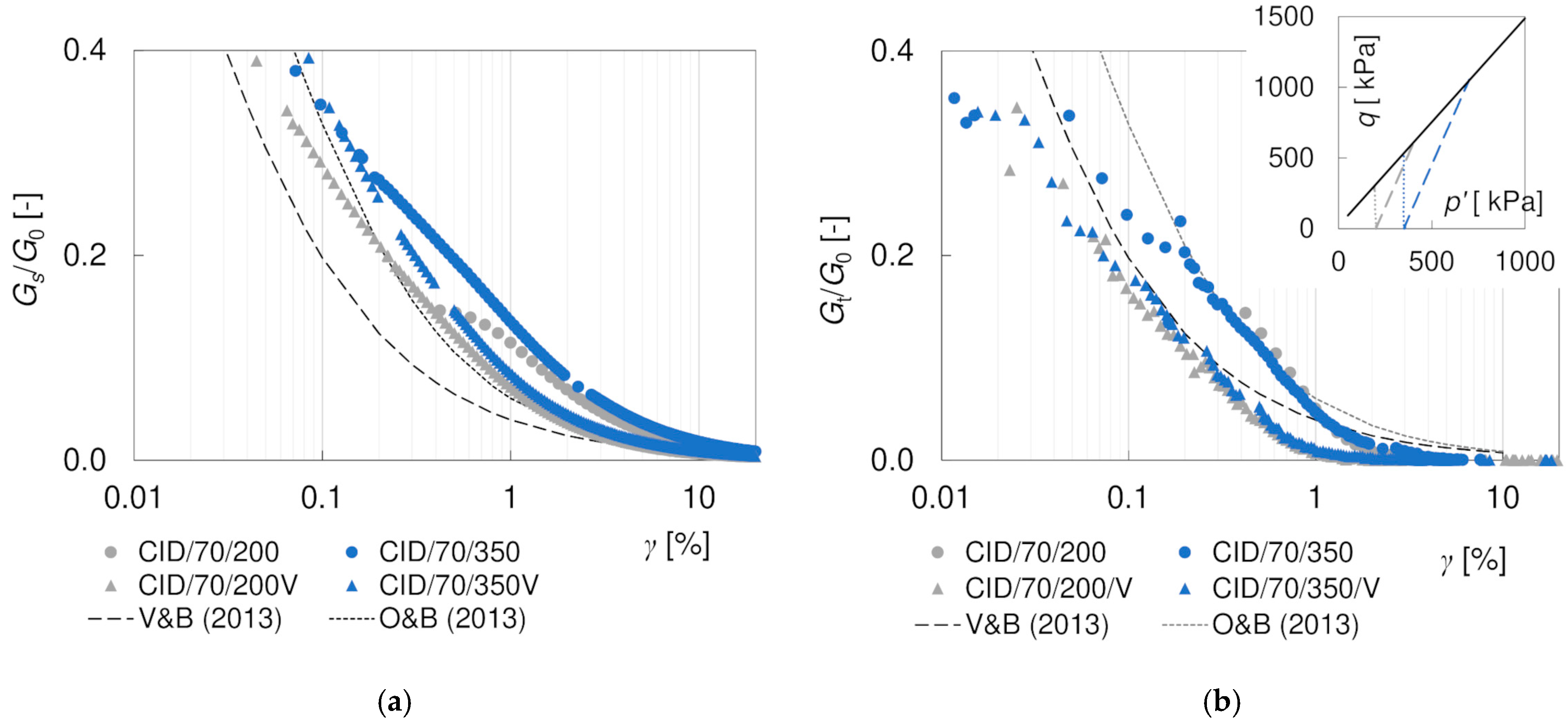

5.3.2. Shear Modulus G

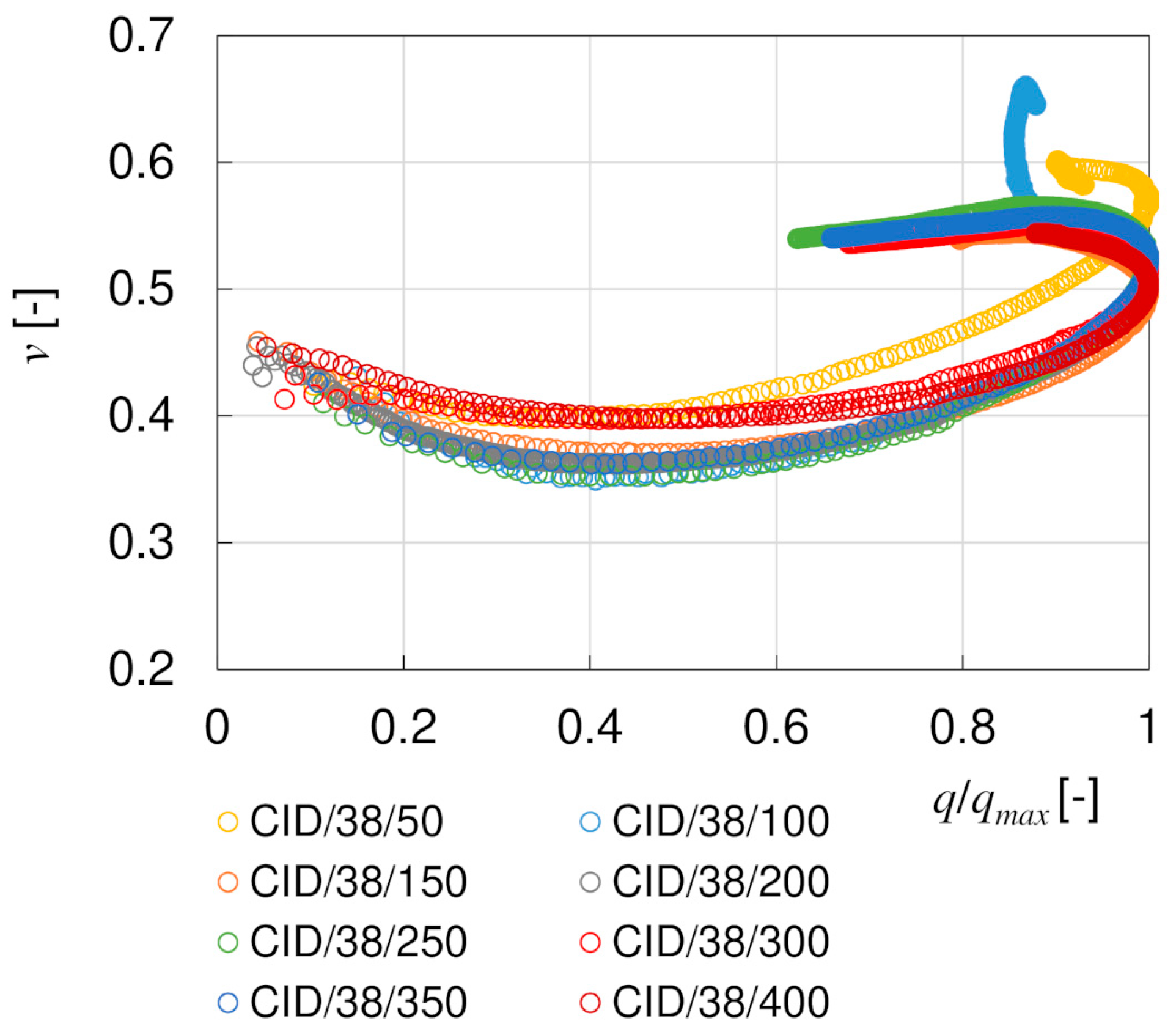

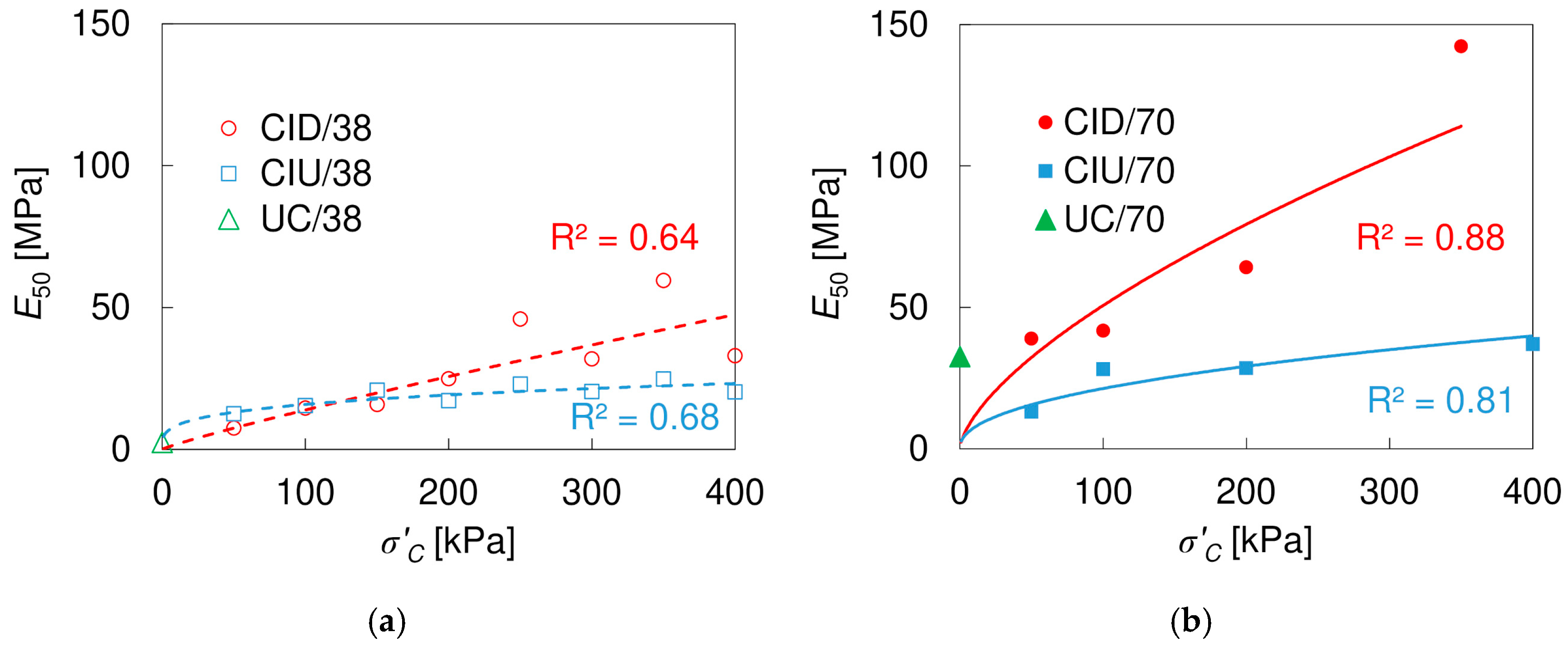

5.3.3. Poisson’s Ratio ν and Young’s Moduli E and E50

6. Summary and Conclusions

- The UCS values of the loess–sand mixture were not much influenced by the size of the specimen. They were smaller than reported by other researchers for naturally compacted loess, which is due to the higher sand content and, possibly, the lower CaCO3 content.

- The choice of the shear strength criterion ((q)max or (q/p)max), the specimen size and drainage conditions had little influence on the value of effective angle of internal friction φ’, which was slightly larger than that of typical natural loess. On the other hand, the values of cohesion c’ depended on both the criterion used and the size of the specimens.

- The initial moduli G0 and E0 increase with consolidation pressure, and the dependency can be described with a classical power function. The values obtained for the loess–sand mixture are higher than those published for natural loess, due to the higher density and sand content, confirming the positive influence of compaction and sand admixture on loess stiffness.

- Tangent stiffness moduli show higher variability, as they are very sensitive to any changes in the slope of the stress–strain curve. Their values are smaller than the secant moduli, and after achieving maximum stress intensity, they fall below zero. There is no obvious relationship between the secant and tangent moduli.

- The larger specimens have usually been found to be stiffer. The shape of the stress path also influences the soil stiffness, which is related to the current stress level. The specimens sheared along vertical effective p’–q stress paths show faster degradation of stiffness with strain.

- The clay content is more representative for loess than IP for the theoretical description of stiffness degradation.

- The Poisson’s ratio ν depends on the degree of saturation and is not constant during drained shearing. No dependency on the size of the specimen was identified.

- The Young’s modulus E shows behavior similar to that of the shear modulus. The E50 values are greater in larger specimens, regardless of the confining stress. They are also greater in drained than in undrained triaxial tests, which is mainly due to the much smaller strain at which 50% ultimate stress intensity is achieved. Due to the high sensitivity of E50 to the testing conditions, it is not recommended as a valuable parameter in numerical analyses.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kowalska, M. Influence of loading history and boundary conditions on parameters of soil constitutive models. Stud. Geotech. Mech. 2012, 34, 15–33. [Google Scholar] [CrossRef]

- Lade, P. Overview of constitutive models for soils. In Soil Constitutive Models: Evaluation, Selection, and Calibration; ASCE: Reston, VA, USA, 2005; pp. 1–34. [Google Scholar] [CrossRef]

- Młynarek, Z.; Wierzbicki, J.; Mańka, M. Geotechnical Parameters of Loess Soils from CPTU and SDMT. In Proceedings of the International Conference on the Flat Dilatometer DMT, Rome, Italy, 14–16 June 2015; Volume 15, pp. 481–489. [Google Scholar]

- Ng, C.W.W.; Baghbanrezvan, S.; Sadeghi, H.; Zhou, C.; Jafarzadeh, F. Effect of specimen preparation techniques on dynamic properties of unsaturated fine-grained soil at high suctions. Can. Geotech. J. 2017, 54, 1310–1319. [Google Scholar] [CrossRef]

- Rinaldi, V.; Rocca, R.J.; Zeballos, M. Geotechnical characterization and behaviour of Argentinean collapsible loess. Characterisation Eng. Prop. Nat. Soils 2007, 3, 2259–2286. [Google Scholar]

- Rinaldi, V.; Claria, J.J.; Santamarina, J.C. The small-strain shear modulus (Gmax) of Argentinean loess. In Proceedings of the International Conference on Soil Mechanics and Geotechnical Engineering, Istanbul, Turkey, 27–31 August 2001; Volume 1, pp. 495–498. [Google Scholar]

- Song, B.; Tsinaris, A.; Anastasiadis, A.; Pitilakis, K.; Chen, W. Small-strain stiffness and damping of Lanzhou loess. Soil Dyn. Earthq. Eng. 2017, 95, 96–105. [Google Scholar] [CrossRef]

- Wang, Z.; Luo, Y.; Guo, H.; Tian, H. Effects of initial deviatoric stress ratios on dynamic shear modulus and damping ratio of undisturbed loess in China. Eng. Geol. 2012, 143, 43–50. [Google Scholar] [CrossRef]

- Zhong, Z.; Liu, X. Mechanical characteristics of intact Middle Pleistocene Epoch loess in northwestern China. J. Cent. South Univ. 2012, 19, 1163–1168. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Sriyoratch, A.; Arngbunta, A.; Chetchotisak, P.; Jitsangiam, P.; Kampala, A. Estimation of modulus of elasticity of compacted loess soil and lateritic-loess soil from laboratory plate bearing test. Case Stud. Constr. Mater. 2022, 16, e00837. [Google Scholar] [CrossRef]

- Kim, D.; Kang, S.S. Engineering properties of compacted loesses as construction materials. KSCE J. Civ. Eng. 2013, 17, 335–341. [Google Scholar] [CrossRef]

- Ma, J.; Zhong, X.; Wang, P.; Ye, S.; Liu, F.; Xu, X. Shear strength and meso-pore characteristic of saturated compacted loess. Open Geosci. 2022, 14, 1393–1408. [Google Scholar] [CrossRef]

- Wang, F.; Li, D.; Du, W.; Zarei, C.; Liu, Y. Bender Element Measurement for Small-Strain Shear Modulus of Compacted Loess. Int. J. Geomech. 2021, 21, 04021063. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Z.; Ren, X.; Li, F.; Zhang, F. Dynamic modulus and damping ratio of compacted loess under long-term traffic loading. Road Mater. Pavement Des. 2022, 23, 1731–1745. [Google Scholar] [CrossRef]

- Xu, J.; Wei, W.; Bao, H.; Zhang, K.; Lan, H.; Yan, C.; Sun, W.; Wu, F. Study on shear strength characteristics of loess dam materials under saturated conditions. Environ. Earth Sci. 2020, 79, 346. [Google Scholar] [CrossRef]

- Ghadakpour, M.; Choobbasti, A.J.; Kutanaei, S.S. Experimental study of impact of cement treatment on the shear behavior of loess and clay. Arab. J. Geosci. 2020, 13, 184. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B. Loess stabilization using cement, waste phosphogypsum, fly ash and quicklime for self-compacting rammed earth construction. Constr. Build. Mater. 2020, 231, 117195. [Google Scholar] [CrossRef]

- Sokolovich, V.E.; Semkin, V.V. Chemical stabilization of loess soils. Soil Mech. Found Eng. 1984, 21, 149–154. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, G.; Su, L.; Zhou, G. Effect of cement on the stabilization of loess. J. Mt. Sci. 2017, 14, 2325–2336. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, N.; Lan, H. Effects of sand and water contents on the small-strain shear modulus of loess. Eng. Geol. 2019, 260, 105202. [Google Scholar] [CrossRef]

- Tankiewicz, M.; Kowalska, M. Stiffness moduli in triaxial tests on a loess-sand mixture. In Proceedings of the 8th International Symposium on Deformation Characteristics of Geomaterials, Porto, Portugal, 3–6 September 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Ma, H.; Ma, Q. Experimental studies on the mechanical properties of loess stabilized with sodium carboxymethyl cellulose. Adv. Mater. Sci. Eng. 2019, 2019, e9375685. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Yan, R.; Zheng, W.; Shao, S. Characteristics of structural loess strength and preliminary framework for joint strength formula. Water Sci. Eng. 2014, 7, 319–330. [Google Scholar] [CrossRef]

- Bowers, C.R. Measurement of Poisson’s Ratio and Tangent Modulus of a Loess. Master’s Thesis, University of Missouri, Columbia, MO, USA, 1978. [Google Scholar]

- Atkinson, J.H.; Sallfors, G. Experimental determination of stress–strain–time characteristics in laboratory and in situ tests. In Proceedings of the 10th European Conference on Soil Mechanics & Foundation Engineering, Florence, Italy, 26–30 May 1991; Volume 3, pp. 915–956. [Google Scholar]

- Holtz, R.D.; Kovacs, W.D.; Sheahan, T.C. An Introduction to Geotechnical Engineering; Prentice-Hall: Hoboken, NJ, USA, 1981. [Google Scholar]

- Santamarina, J.C. “Cohesive Soil”: A Dangerous Oxymoron. 1997. Available online: https://egel.kaust.edu.sa/docs/default-source/publications-files/santamarina_1997nn.pdf (accessed on 29 July 2024).

- Schofield, A.N. The “Mohr-Coulomb” Error; Cambridge University Engineering Department, Division D Soil Mechanics Group: Cambridge, UK, 1998. [Google Scholar]

- Lambe, T.W.; Whitman, R.V. Soil Mechanics; John Wiley & Sons: New York, NY, USA, 1969. [Google Scholar]

- Muir Wood, D. Soil Behaviour and Critical State Soil Mechanics; Cambridge University Press: New York, NY, USA, 1990. [Google Scholar]

- Chang, W.J.; Phantachang, T.; Ieong, W.M. Evaluation of size and boundary effects in simple shear tests with distinct element method. J. GeoEngin. 2014, 11, 133–142. [Google Scholar] [CrossRef]

- Burland, J.B. Ninth Laurits Bjerrum Memorial Lecture: “Small is beautiful”—The stiffness of soils at small strains. Can. Geotech. J. 1989, 26, 499–516. [Google Scholar] [CrossRef]

- Viggiani, G.; Atkinson, J.H. Stiffness of fine-grained soil at very small strains. Géotechnique 1995, 45, 249–265. [Google Scholar] [CrossRef]

- Atkinson, J.H. Non-linear soil stiffness in routine design. Géotechnique 2000, 50, 487–508. [Google Scholar] [CrossRef]

- Dyvik, R.; Madshus, C. Lab Measurements of Gmax Using Bender Elements; ASCE Geotechnical Engineering Division; ASCE: Reston, VA, USA, 1985; pp. 186–196. [Google Scholar]

- Richart, F.E.; Hall, J.R.; Woods, R. Vibrations of Soils and Foundations; Prentice-Hall: Hoboken, NJ, USA, 1970. [Google Scholar]

- Haase, D.; Fink, J.; Haase, G.; Ruske, R.; Pécsi, M.; Richter, H.; Altermann, M.; Jäger, K.D. Loess in Europe—Its spatial distribution based on a European Loess Map, scale 1:2,500,000. Quat. Sci. Rev. 2007, 26, 1301–1312. [Google Scholar] [CrossRef]

- Krawczyk, M.; Ryzner, K.; Skurzyński, J.; Jary, Z. Lithological indicators of loess sedimentation of SW Poland. Contemp. Trends Geosci. 2017, 6, 94–111. [Google Scholar] [CrossRef]

- Jary, Z.; Ciszek, D. Late Pleistocene loess–palaeosol sequences in Poland and western Ukraine. Quat. Int. 2013, 296, 37–50. [Google Scholar] [CrossRef]

- Jary, Z.; Krzyszkowski, D. Stratigraphy, genesis and properties of loess in Trzebnica brickyard, Southwestern Poland. Acta Univ. Wratislav. 1994, 1702, 63–83. [Google Scholar]

- ISO 17892-4; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. ISO: Geneva, Switzerland, 2016.

- ISO 17892-12; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 12: Determination of Liquid and Plastic Limits. ISO: Geneva, Switzerland, 2018.

- PN-88/B-04481; Building Soils. Laboratory Tests. PKNMiJ: Warsaw, Poland, 1988. (In Polish)

- ISO 17892-3; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 3: Determination of Particle Density. International Organization for Standardization: Geneva, Switzerland, 2015.

- EN 13286-2; Unbound and Hydraulically Bound Mixtures—Part 2: Test Methods for Laboratory Reference Density and Water Content-Proctor Compaction. CEN: Brussels, Belgium, 2010.

- ISO 17892-7; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 7: Unconfined Compression Test. ISO: Geneva, Switzerland, 2017.

- ISO 17892-9; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 9: Consolidated Triaxial Compression Tests on Water Saturated Soils. ISO: Geneva, Switzerland, 2018.

- Lo Presti, D.C.F.; Pallara, O.; Impavido, M. Small strain measurements during triaxial tests: Many problems, some solutions. Prefailure Deform. Geomaterials 1994, 1, 11–16. [Google Scholar]

- Scholey, G.K.; Frost, J.D.; Lo Presti, D.C.F.; Jamiolkowski, M.B. A Review of Instrumentation for Measuring Small Strains During Triaxial Testing of Soil Specimens. Geotech. Test. J. 1995, 18, 137–156. [Google Scholar] [CrossRef]

- Oh, W.T.; Vanapalli, S.K. Relationship between Poisson’s ratio and soil suction for unsaturated soils. In Proceedings of the 5th Asia-Pacific Conference on Unsaturated Soils, Pattaya, Thailand, 14–16 November 2011; pp. 239–245. [Google Scholar]

- Lee, J.S.; Santamarina, J.C. Bender Elements: Performance and signal interpretation. J. Geotech. Geoenviron. Eng. 2005, 131, 1063–1070. [Google Scholar] [CrossRef]

- Hu, W.; Dano, C.; Hicher, P.Y.; Le Touzo, J.Y.; Derkx, F.; Merliot, E. Effect of sample size on the behavior of granular materials. Geotech. Test. J. 2011, 34, 103095. [Google Scholar] [CrossRef]

- Omar, T.; Sadrekarimi, A. Effect of triaxial specimen size on engineering design and analysis. Int. J. Geo-Eng. 2015, 6, 5. [Google Scholar] [CrossRef]

- Poulos, S.J. The steady state of deformation. J. Geotech. Geoenviron. Eng. 1981, 107, 553–562. [Google Scholar] [CrossRef]

- Sheeler, J.B. Summarization and comparison of engineering properties of loess in the United States. Highw. Res. Rec. 1968, 212, 1–9. [Google Scholar]

- Capdevila, J.; Rinaldi, V. Stress-strain behavior of a heterogeneous and lightly cemented soil under triaxial compression test. Electron. J. Geotech. Eng. 2015, 20, 6745–6760. [Google Scholar]

- Nuntasarn, R.; Wannakul, W. Drained shear strength of compacted khon kaen loess. Int. J. Geomate 2017, 13, 28–33. [Google Scholar] [CrossRef]

- Hassanipour, A.; Shafiee, A.; Jafari, M.K. Low-amplitude dynamic properties for compacted sand-clay mixtures. Int. J. Civ. Eng. 2011, 9, 255–264. [Google Scholar]

- Kumar Thota, S.; Duc Cao, T.; Vahedifard, F. Poisson’s ratio characteristic curve of unsaturated soils. J. Geotech. Geoenviron. Eng. 2021, 147, 04020149. [Google Scholar] [CrossRef]

- Soból, E.; Gabryś, K.; Zabłocka, K.; Šadzevičius, R.; Skominas, R.; Sas, W. Laboratory studies of small strain stiffness and modulus degradation of Warsaw mineral cohesive soils. Minerals 2020, 10, 1127. [Google Scholar] [CrossRef]

- Hardin, B.O.; Drnevich, V.P. Shear modulus and damping in soils: Design equations and curves. J. Soil Mech. Found Div. 1972, 98, 667–692. [Google Scholar] [CrossRef]

- Darendeli, M.B. Development of a New Family of Normalized Modulus Reduction and Material Damping Curves. Ph.D. Thesis, The University of Texas, Austin, TX, USA, 2001. [Google Scholar]

- Amir-Faryar, B.; Aggour, M.S.; McCuen, R.H. Universal model forms for predicting the shear modulus and material damping of soils. Geomech. Geoengin. 2017, 12, 60–71. [Google Scholar] [CrossRef]

- Oztoprak, S.; Bolton, M.D. Stiffness of sands through a laboratory test database. Géotechnique 2015, 63, 54–70. [Google Scholar] [CrossRef]

- Zhang, J.; Andrus, R.D.; Juang, C.H. Normalized shear modulus and material damping ratio relationships. J. Geotech. Geoenviron. Eng. 2005, 131, 453–464. [Google Scholar] [CrossRef]

- Vardanega, P.J.; Bolton, M.D. Stiffness of clays and silts: Normalizing shear modulus and shear strain. J. Geotech. Geoenviron. Eng. 2013, 139, 1575–1589. [Google Scholar] [CrossRef]

- Gasparre, A.; Hight, D.W.; Coop, M.R.; Jardine, R.J. The laboratory measurement and interpretation of the small-strain stiffness of stiff clays. Géotechnique 2014, 64, 942–953. [Google Scholar] [CrossRef]

- Lee, J.; Salgado, R.; Carraro, J.H. Stiffness degradation and shear strength of silty sands. Can. Geotech. J. 2011, 41, 831–843. [Google Scholar] [CrossRef]

- Hight, D.W.; Gasparre, A.; Nishimura, S.; Minh, N.A.; Jardine, R.J.; Coop, M.R. Characteristics of the London Clay from the Terminal 5 site at Heathrow Airport. Géotechnique 2007, 57, 3–18. [Google Scholar] [CrossRef]

- Puzrin, A.M.; Burland, J.B. A logarithmic stress–strain function for rocks and soils. Géotechnique 1996, 46, 157–164. [Google Scholar] [CrossRef]

- Rios, S.; Cristelo, N.; Viana da Fonseca, A.; Ferreira, C. Stiffness behavior of soil stabilized with alkali-activated fly ash from small to large strains. Int. J. Geomech. 2017, 17, 04016087. [Google Scholar] [CrossRef]

- Clayton, C.R.I. Stiffness at small strain: Research and practice. Géotechnique 2011, 61, 5–37. [Google Scholar] [CrossRef]

- Zarei, C.; Wang, F.; Qiu, P.; Fang, P.; Liu, Y. Laboratory Investigations on Geotechnical Characteristics of Albumen Treated Loess Soil. KSCE J. Civ. Eng. 2022, 26, 539–549. [Google Scholar] [CrossRef]

| Sa [%] | Si [%] | Cl [%] | d50 [mm] | CU [-] | CC [-] | wP [%] | wL [%] | IP [%] | A [%] | LOI [%] | ρs [g/cm3] | ρd.max [g/cm3] | wopt [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 22.9 | 68.6 | 8.5 | 0.36 | 15.0 | 3.4 | 19.9 | 25.5 | 5.64 | 0.66 | 1.9 | 2.66 | 1.86 | 11.0 |

| Symbol | Diameter [mm] | ρ0 [g/cm3] | e0 [-] |

|---|---|---|---|

| UC/38 | 38 | 2.069 ± 0.016 | 0.428 ± 0.011 |

| UC/70 | 70 | 2.084 ± 0.006 | 0.417 ± 0.004 |

| No. | Symbol | Stress Path | Diameter [mm] | Drainage | LD | PETs | σ’C [kPa] | ρ0 [g/cm3] | e0 [-] |

|---|---|---|---|---|---|---|---|---|---|

| 1 | CIU/38/50 | Conventional | 38 | U | LVDT | NO | 50 | 2.041 | 0.447 |

| 2 | CIU/38/100 | Conventional | 38 | U | LVDT | NO | 100 | 2.044 | 0.445 |

| 3 | CIU/38/150 | Conventional | 38 | U | LVDT | NO | 150 | 2.079 | 0.420 |

| 4 | CIU/38/200 | Conventional | 38 | U | LVDT | NO | 200 | 2.056 | 0.430 |

| 5 | CIU/38/250 | Conventional | 38 | U | LVDT | NO | 250 | 2.068 | 0.428 |

| 6 | CIU/38/300 | Conventional | 38 | U | LVDT | NO | 300 | 2.084 | 0.417 |

| 7 | CIU/38/350 | Conventional | 38 | U | - | NO | 350 | 2.103 | 0.404 |

| 8 | CIU/38/400 | Conventional | 38 | U | LVDT | NO | 400 | 2.064 | 0.430 |

| 9 | CIU/70/50 | Conventional | 70 | U | - | NO | 50 | 2.090 | 0.413 |

| 10 | CIU/70/100 | Conventional | 70 | U | - | NO | 100 | 2.064 | 0.430 |

| 11 | CIU/70/200 | Conventional | 70 | U | - | NO | 200 | 2.057 | 0.436 |

| 12 | CIU/70/400 | Conventional | 70 | U | - | NO | 400 | 2.081 | 0.419 |

| 13 | CID/38/50 | Conventional | 38 | D | LVDT | NO | 50 | 2.051 | 0.439 |

| 14 | CID/38/100 | Conventional | 38 | D | LVDT | NO | 100 | 2.046 | 0.443 |

| 15 | CID/38/150 | Conventional | 38 | D | LVDT | NO | 150 | 2.076 | 0.422 |

| 16 | CID/38/200 | Conventional | 38 | D | LVDT | NO | 200 | 2.105 | 0.403 |

| 17 | CID/38/250 | Conventional | 38 | D | LVDT | NO | 250 | 2.058 | 0.435 |

| 18 | CID/38/300 | Conventional | 38 | D | LVDT | NO | 300 | 2.072 | 0.425 |

| 19 | CID/38/350 | Conventional | 38 | D | - | NO | 350 | 2.085 | 0.416 |

| 20 | CID/38/400 | Conventional | 38 | D | LVDT | NO | 400 | 2.086 | 0.415 |

| 21 | CID/70/50 | Conventional | 70 | D | Hall-effect | YES | 50 | 2.027 | 0.456 |

| 22 | CID/70/100 | Conventional | 70 | D | - | YES | 100 | 2.034 | 0.452 |

| 23 | CID/70/200 | Conventional | 70 | D | - | YES | 200 | 2.054 | 0.438 |

| 24 | CID/70/350 | Conventional | 70 | D | Hall-effect | YES | 350 | 2.070 | 0.427 |

| 25 | CID/70/200/V | Vertical | 70 | D | Hall-effect | YES | 200 | 2.022 | 0.456 |

| 26 | CID/70/350/V | Vertical | 70 | D | Hall-effect | YES | 350 | 2.032 | 0.448 |

| Specimen Diameter | UCS [kPa] | E50 [MPa] | ν50 [-] | ||

|---|---|---|---|---|---|

| ex | loc | ex | loc | loc | |

| 38 mm | 131.3 ± 11.3 | 137.6 ± 12.5 | 2.0 ± 0.4 | 2.4 ± 0.7 | 0.13 ± 0.02 |

| 70 mm | 116.5 ± 4.8 | 118.0 ± 4.9 | 7.4 ± 1.5 | 32.5 ± 8.9 | 0.16 ± 0.03 * |

| Criterion | (q/p’)max | (q)max | ||

|---|---|---|---|---|

| φ’ [°] | c’ [kPa] | φ’ [°] | c’ [kPa] | |

| CIU/38 | 36.2 | 16.1 | 36.0 | 0.0 * |

| CIU/70 | 38.0 | 10.0 | 34.6 | 0.0 * |

| CID/38 | 38.5 | 22.8 | 38.5 | 22.7 |

| CID/70 | 36.1 | 10.1 | 36.1 | 10.0 |

| Ref. | Method a | Source | Sa [%] | Cl [%] | wP [%] | wL [%] | wopt [%] | ρd [kPa] | crit. b | φ’ [°] | c’ [kPa] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [11] | DS/63.5 | Southwestern Indiana loess (USA) | 10 | 20 | 9.3 | 32.2 | 16.2 | 1.71 | P | 33.4 | 33.2 |

| [56] | CID/50 | Córdoba (Argentina) | 0 | n.d. | 21.1 | 24.5 | 43.2 c | 1.24 | 6%/Y | 24/6 | 0/3 |

| [57] | CID/50 | Khon Kaen (Thailand) | 53 | 20 | 12 | 13 | 8.5 d | 1.95 | 20% | 31 | 44 |

| [16] | DS/150 | Beshahr (Iran) | 20 | 25 | 21 | 26 | 15 | 1.71 | P | 26.1 | 39.0 |

| CID/52 | P | 23.6 | 17.9 | ||||||||

| [15] | CIU/39 | Shaanxi Province (China) | 12 | 6 | n.d. | n.d. | 15.0 c | 1.4–1.7 | P | 28.5–38 | 2–5 |

| [12] | CIU/50 | Gansu Province (China) | 16 | 6 | 19.4 | 28.6 | 17.2 e | 1.65 | P | 38.5 | 25.3 |

| Specimen Size | 38 mm | 70 mm | ||||||

|---|---|---|---|---|---|---|---|---|

| σ’C [kPa] | E’50 [MPa] | ν’50 [-] | Eu50 [MPa] | νu50 [-] | E’50 [MPa] | ν’50 [-] | Eu50 [MPa] | νu50 [-] |

| 50 | 7.5 | 0.41 | 12.5 | 0.5 | 39.0 | 0.31 | 13.1 | 0.5 |

| 100 | 14.5 | 0.36 | 15.4 | 41.7 | 0.41 | 28.2 | ||

| 150 | 15.8 | 0.37 | 20.8 | - | - | - | ||

| 200 | 24.8 | 0.36 | 17.2 | 64.1 | 0.41 | 28.5 | ||

| 250 | 45.9 | 0.35 | 23.0 | - | - | - | ||

| 300 | 31.9 | 0.40 | 20.4 | - | - | - | ||

| 350 | 59.5 | 0.37 | 24.8 | 142.3 | 0.38 | - | ||

| 400 | 33.0 | 0.40 | 20.2 | - | - | 36.9 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tankiewicz, M.; Kowalska, M.; Mońka, J. Evaluation of Shear Strength and Stiffness of a Loess–Sand Mixture in Triaxial and Unconfined Compression Tests. Materials 2024, 17, 3831. https://doi.org/10.3390/ma17153831

Tankiewicz M, Kowalska M, Mońka J. Evaluation of Shear Strength and Stiffness of a Loess–Sand Mixture in Triaxial and Unconfined Compression Tests. Materials. 2024; 17(15):3831. https://doi.org/10.3390/ma17153831

Chicago/Turabian StyleTankiewicz, Matylda, Magdalena Kowalska, and Jakub Mońka. 2024. "Evaluation of Shear Strength and Stiffness of a Loess–Sand Mixture in Triaxial and Unconfined Compression Tests" Materials 17, no. 15: 3831. https://doi.org/10.3390/ma17153831