Simulation and Algorithmic Optimization of the Cutting Process for the Green Machining of PM Green Compacts

Abstract

:1. Introduction

- Investigate deformation characteristics—to investigate the deformation characteristics of PM green compacts during the cutting process and evaluate the influence of various machining parameters on cutting forces.

- Develop a simulation model—to develop a cutting process model for PM green compacts using Abaqus (2022) software for simulation.

- Assess parameter significance—to use orthogonal test ANOVA methods to assess the significance of different machining parameters on cutting forces.

- Optimize machining parameters—to optimize machining parameters through the application of a genetic algorithm for neural network optimization.

- Validate the model—to validate the developed cutting model with experimental procedures.

- Analyze cutting force variations—to analyze the variations in cutting forces under different machining parameters to determine the optimal cutting conditions.

2. Finite Element Modeling

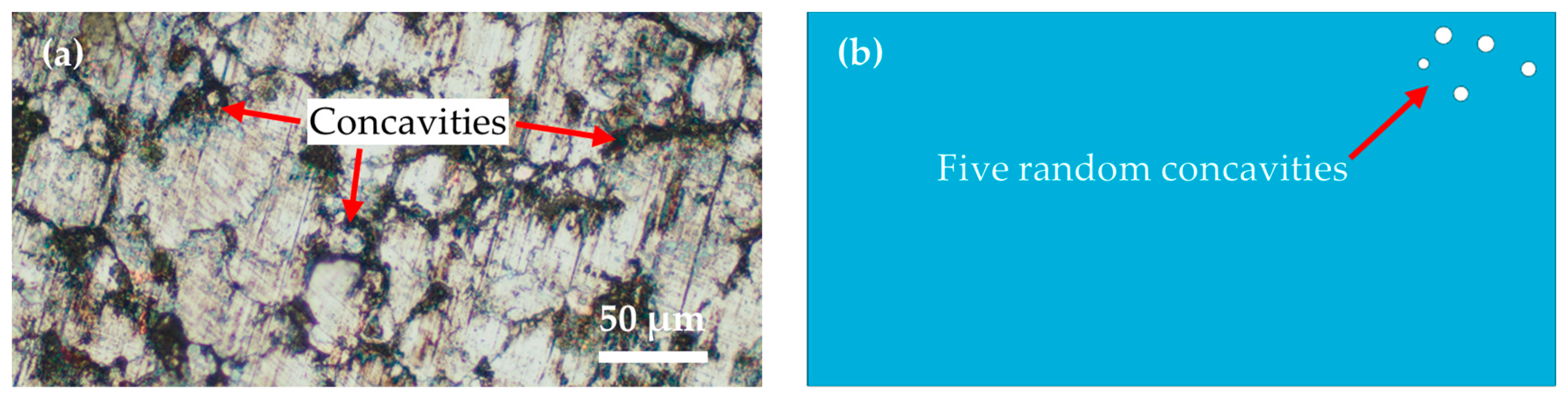

2.1. Microstructure of Materials

2.2. Model Parameters

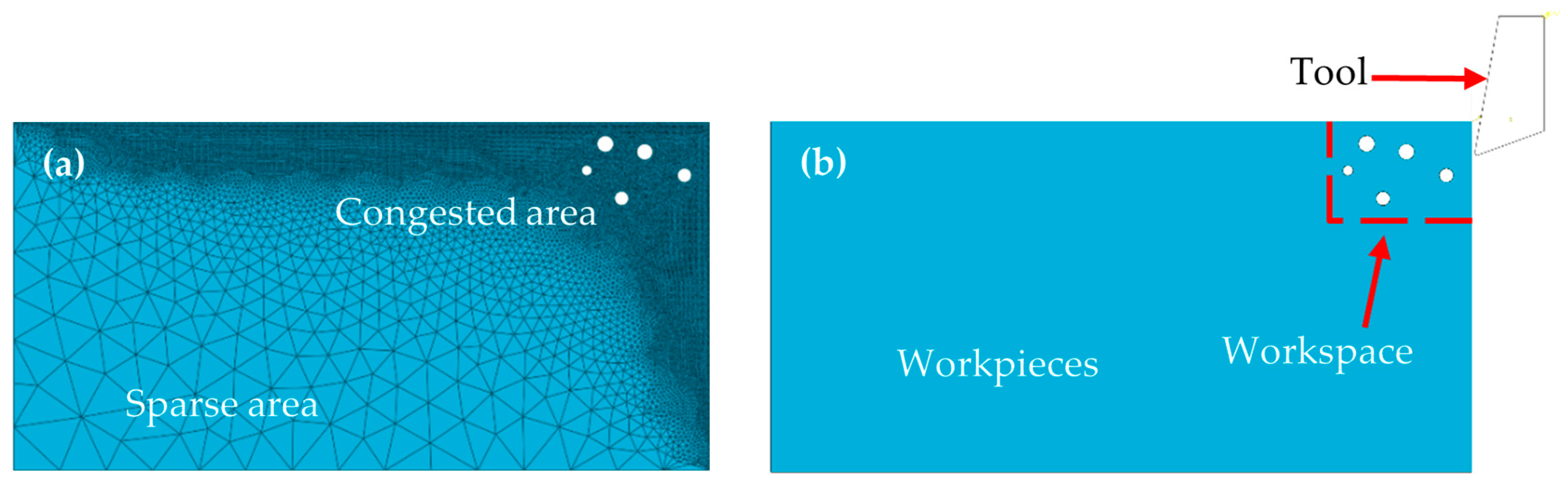

2.3. Meshing and Assembly

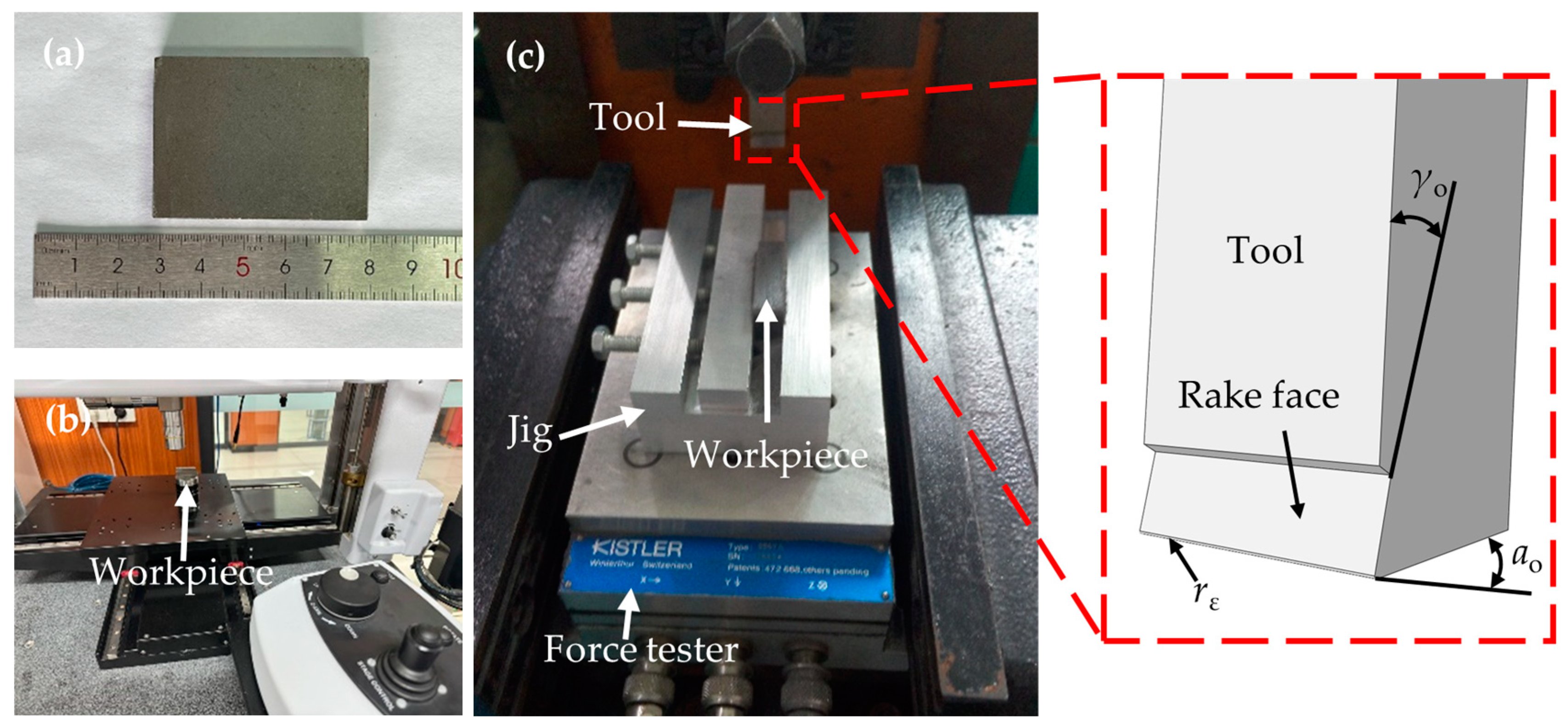

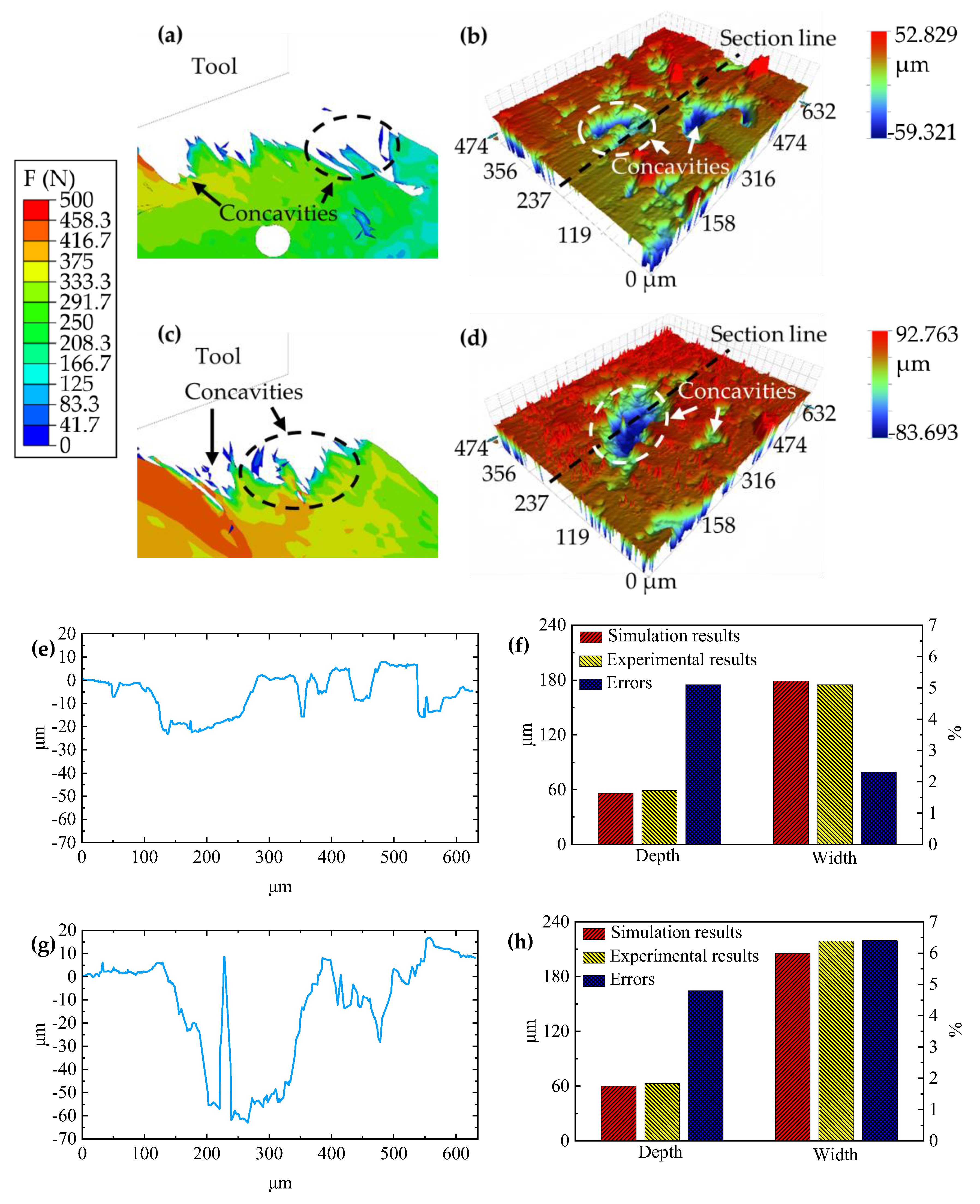

2.4. Experimental Validation and Data Analysis

3. Results and Discussion

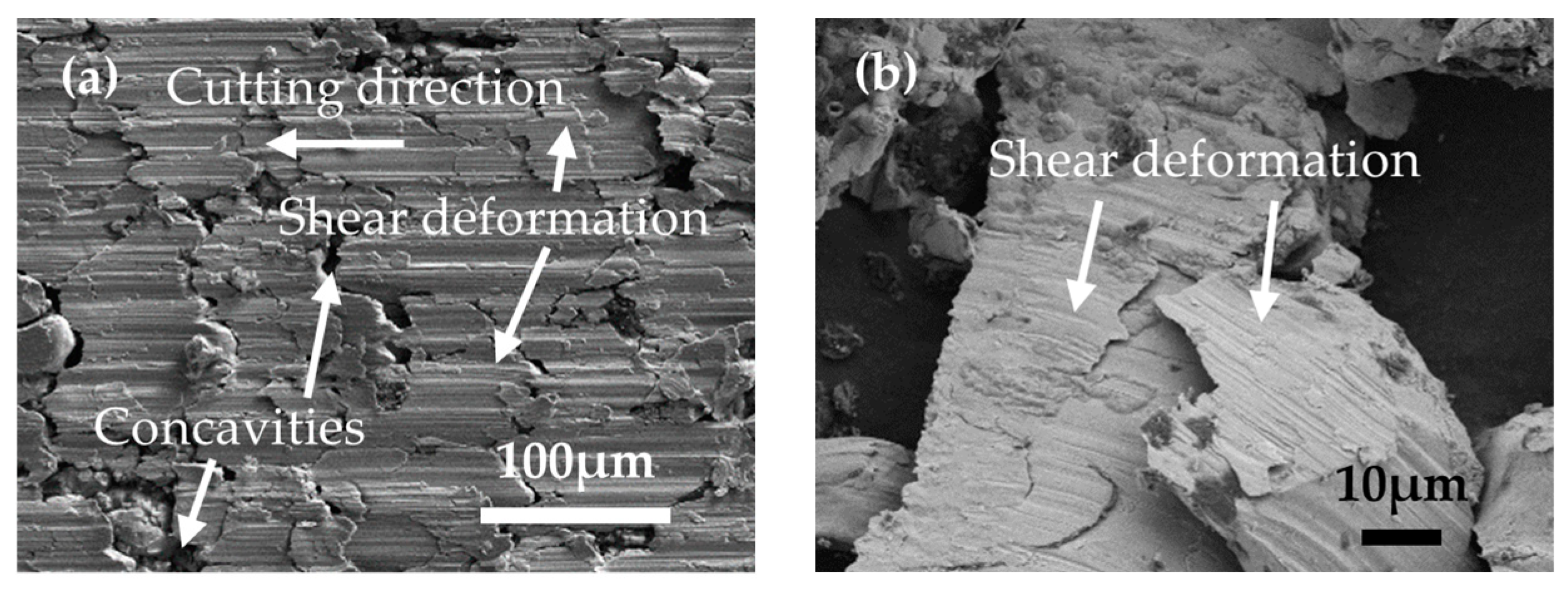

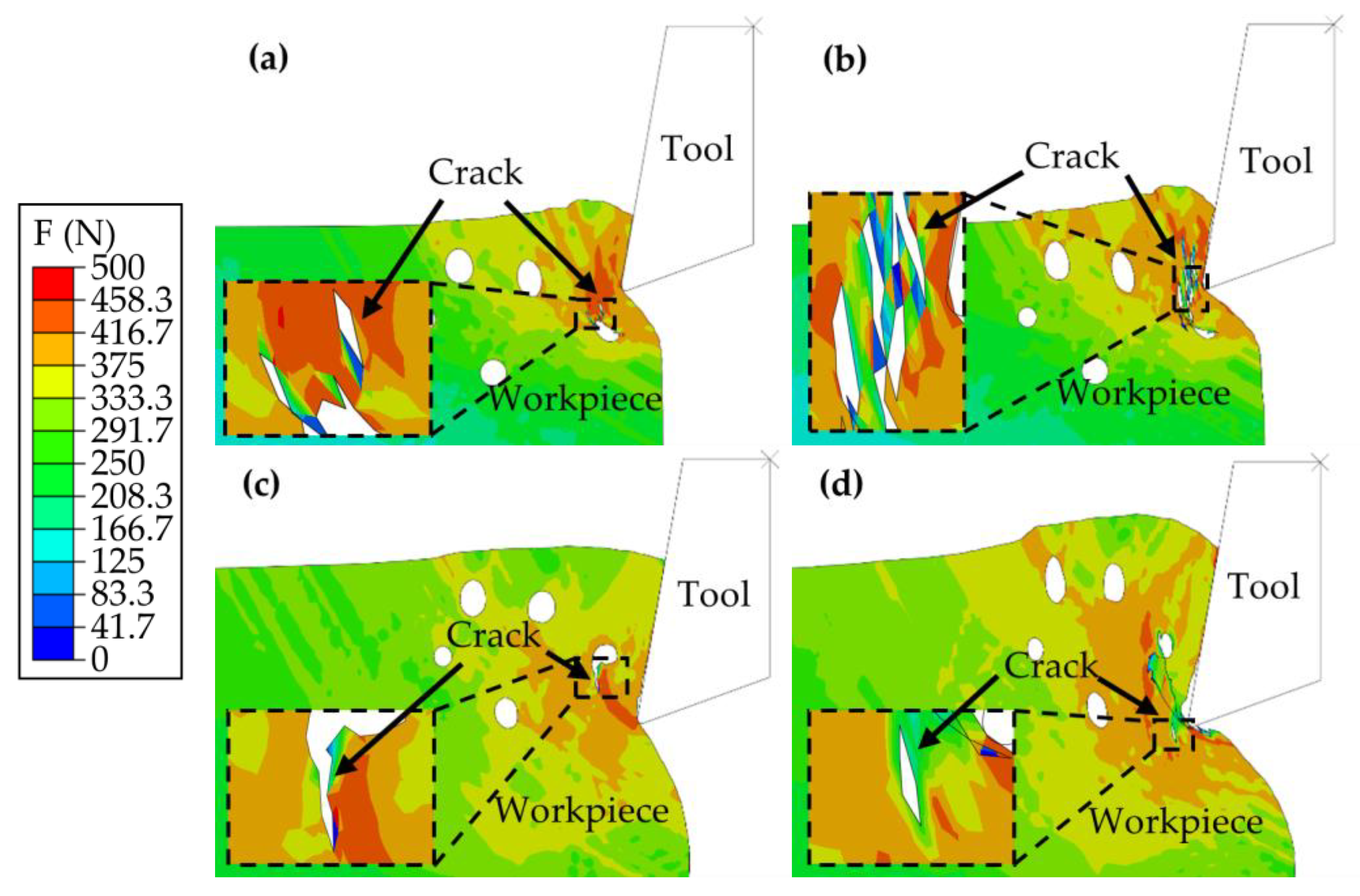

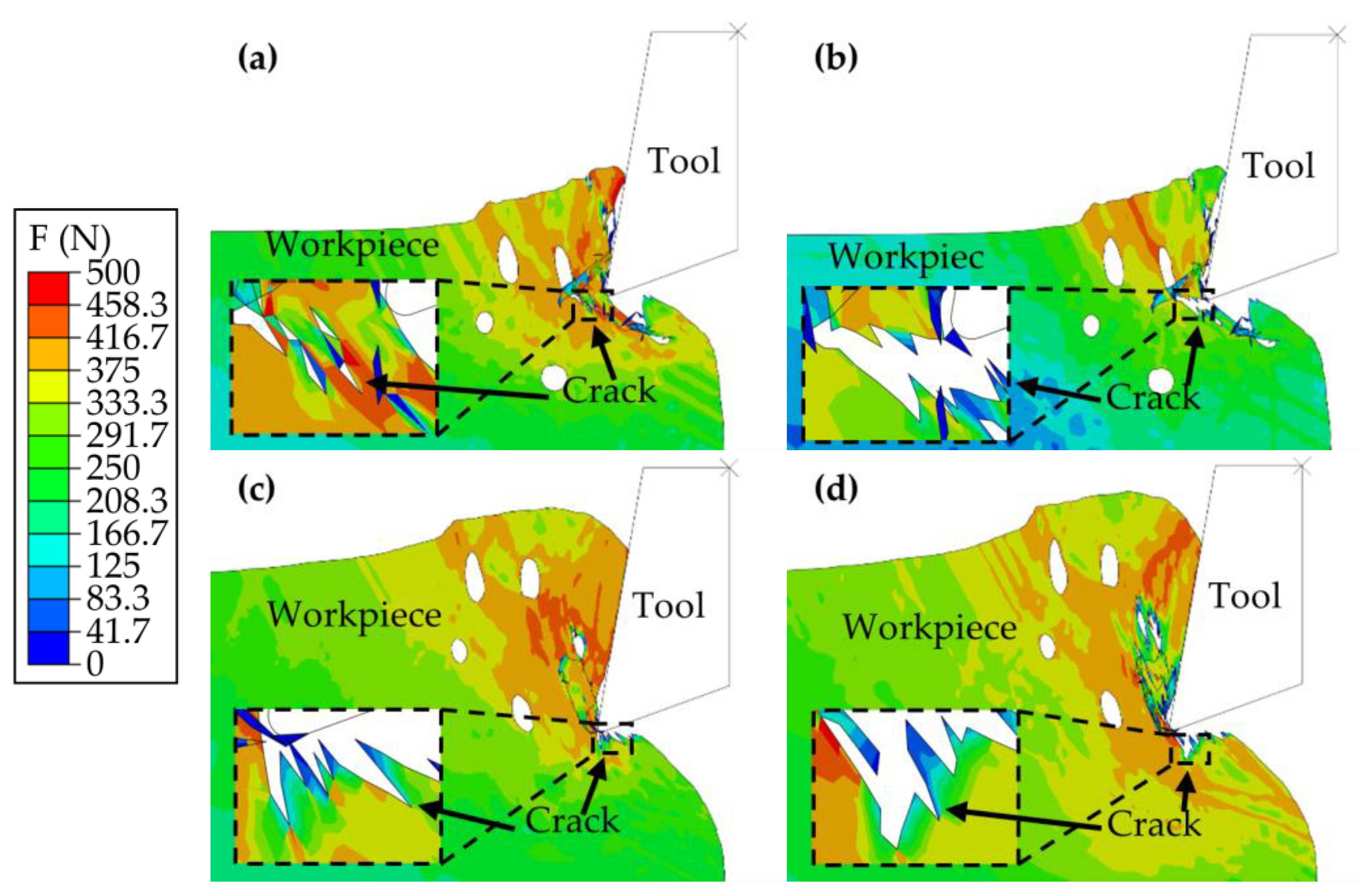

3.1. Analysis of the Cutting Process

3.2. Significance Analysis of the Cutting Force Factors

3.3. Optimization of the Cutting Force Parameters

4. Conclusions

- (1)

- A refined model of PM compacts was developed, yielding an average cutting force error of 3.8% within a cutting thickness range of 0.12–0.20 mm. Additionally, the average errors for the concavity depth and width on the machined surface were 5.0% and 4.4%, respectively.

- (2)

- PM green compacts, characterized as brittle materials, exhibit plastic deformation during cutting, deviating from the traditional cutting model for brittle materials. This observation offers fresh perspectives on cutting PM green compacts, thus improving the understanding of their machining dynamics.

- (3)

- The cutting thickness has the most substantial impact on the cutting force, while the speed of cutting, the tool rake angle, and the radius of the rounded edge have minimal effects. This finding underscores the importance of cutting thickness control in PM green compact machining to prevent damage due to excessive cutting force.

- (4)

- The optimization of the neural network using genetic algorithms determined the ideal parameter set for cutting PM green compacts, as follows: a cutting thickness of 0.15 mm, a cutting speed of 20 m/min, a tool rake angle of 10°, and a radius of the rounded edge of 25 μm. This parameter set led to a cutting force of 174.998 N with a 4.05% deviation from the actual measurement, which provides a valuable reference for machining PM green compacts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, K.; Wu, X.; Jiang, F.; Shen, J.Y.; Zhu, L.F.; Li, L. A comprehensive review on the cutting and abrasive machining of cemented carbide materials. J. Manuf. Process. 2023, 108, 335–358. [Google Scholar] [CrossRef]

- Du, J.G.; Tian, B.; Duan, L.Y.; Ming, W.Y.; Liu, K.; He, W.B. Traditional and non-traditional machining technology of metallic glass. Int. J. Adv. Manuf. Technol. 2022, 120, 2879–2902. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.H.; Hao, J.Y.; Huang, Q.B. The impact of green technology innovation on global value chain upgrading in China’s equipment manufacturing industry. Front. Environ. Sci. 2022, 10, 1044583. [Google Scholar] [CrossRef]

- Zhu, J.H.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.Q.; Zhang, W.H. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Erdem, M.; Cinici, H.; Gokmen, U.; Karakoc, H.; Turker, M. Mechanical and ballistic properties of powder metal 7039 aluminium alloy joined by friction stir welding. Trans. Nonferrous Met. Soc. China 2016, 26, 74–84. [Google Scholar] [CrossRef]

- Tijo, D.; Kumari, S.; Masanta, M. Hard and wear resistance TiC-composite coating on AISI 1020 steel using powder metallurgy tool by electro-discharge coating process. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 4719–4734. [Google Scholar] [CrossRef]

- Zharov, M.V. Comparative Analysis of Features of Technologies for Obtaining Quality Spherical Powder of Nickel Aluminide NiAl. Metallurgist 2023, 66, 1401–1411. [Google Scholar] [CrossRef]

- Boujelbene, M.; Ezeddini, S.; Ben Said, L.; Bayraktar, E.; Alhadri, M.; Aich, W.; Ghachem, K.; Kolsi, L. Analysis of surface integrity of intermetallic composite based on titanium-aluminum machined by laser cutting. Opt. Laser Technol. 2023, 161, 109187. [Google Scholar] [CrossRef]

- Egorov, M.S.; Egorova, R.V. Characteristics of the Formation of Structure and Properties of Dispersed-Hardened Charges at the Hot Stamping of Complex Shape Products. Metallurgist 2023, 66, 1436–1441. [Google Scholar] [CrossRef]

- Zhong, B.; Wang, Y.R.; Wei, D.S.; Zhang, K.S.; Wang, J.L. Multiaxial fatigue life prediction for powder metallurgy superalloy FGH96 based on stress gradient effect. Int. J. Fatigue 2018, 109, 26–36. [Google Scholar] [CrossRef]

- Sun, F.J.; Qu, S.G.; Li, G.; Pan, Y.X.; Li, X.Q. Comparison of the machinability of titanium alloy forging and powder metallurgy materials. Int. J. Adv. Des. Manuf. Technol. 2016, 85, 1529–1538. [Google Scholar] [CrossRef]

- da Silva, G.C.; Saraiva, Q.M.; Carneiro, J.R.G.; Santos, I.A.; José, A.S. New milling methodology for sealing planes in AlSi9Cu3(Fe) alloy machined with PCD tool. Int. J. Adv. Manuf. Technol. 2021, 113, 3211–3223. [Google Scholar] [CrossRef]

- Dong, X.J.; Wu, J.Q.; Yu, H.L.; Zhou, Q.; Wang, W.Q.; Zhang, X.Q.; Zhang, L.; Li, L.; He, R.J. Additive manufacturing of silicon nitride ceramics: A review of advances and perspectives. Int. J. Appl. Ceram. Technol. 2022, 19, 2929–2949. [Google Scholar] [CrossRef]

- Yin, Y.K.; Xu, J.Y.; Ji, M.; Li, L.F.; Chen, M. A critical review on sintering and mechanical processing of 3Y-TZP ceramics. Ceram. Int. 2023, 49, 1549–1571. [Google Scholar] [CrossRef]

- Attia, U.M. Cold-isostatic pressing of metal powders: A review of the technology and recent developments. Crit. Rev. Solid State Mater. Sci. 2021, 46, 587–610. [Google Scholar] [CrossRef]

- Kulkarni, H.; Dabhade, V. Green machining of powder-metallurgy-steels (PMS): An overview. J. Manuf. Process. 2019, 44, 1–18. [Google Scholar] [CrossRef]

- Chen, C.; Huang, B.Y.; Liu, Z.M.; Li, Y.X.; Zou, D.; Liu, T.; Chang, Y.M.; Chen, L. Additive manufacturing of WC-Co cemented carbides: Process, microstructure, and mechanical properties. Addit. Manuf. 2023, 63, 103410. [Google Scholar] [CrossRef]

- Parvizi, S.; Hashemi, S.M.; Asgarinia, F.; Nematollahi, M.; Elahinia, M. Effective parameters on the final properties of NiTi-based alloys manufactured by powder metallurgy methods: A review. Prog. Mater. Sci. 2021, 117, 100739. [Google Scholar] [CrossRef]

- Bram, M.; Ebel, T.; Wolff, M.; Cysne Barbosa, A.P.; Tuncer, N. Applications of Powder Metallurgy in Biomaterials. In Advances in Powder Metallurgy; Woodhead Publishing: Cambridge, UK, 2013; pp. 520–554. [Google Scholar]

- Paradis, L.; Waryoba, D.; Robertson, K.; Ndayishimiye, A.; Fan, Z.M.; Rajagopalan, R.; Randall, C.A. Densification and Strengthening of Ferrous-Based Powder Compacts Through Cold Sintering Aided Warm Compaction. Adv. Eng. Mater. 2022, 24, 2200714. [Google Scholar] [CrossRef]

- Robert-Perron, E.; Blais, C.; Pelletier, S. Tensile properties of sinter hardened powder metallurgy components machined in their green state. Powder Metall. 2009, 52, 80–83. [Google Scholar] [CrossRef]

- Yang, D.Y.; Lu, L.S.; Wan, Z.P. Material Removal Mechanism of Green Machining on Powder Metallurgy Parts during Orthogonal Cutting. Adv. Mater. Sci. Eng. 2020, 2020, 1962602. [Google Scholar] [CrossRef]

- Shi, Q.L.; Chen, D.; Pan, Q.Q.; Peng, J.G. Study on the Influence of Warm Die Compaction Behavior on the Mechanical Properties of Iron-Based Powder Materials. J. Mater. Eng. Perform. 2023, 33, 5655–5666. [Google Scholar] [CrossRef]

- Kulkarni, H.; Dabhade, V.V.; Blais, C. Analysis of machining green compacts of a sinter-hardenable powder metallurgy steel: A perspective of material removal mechanism. CIRP J. Manuf. Sci. Technol. 2023, 41, 430–445. [Google Scholar] [CrossRef]

- Goncalves, M.; Sanchez, L.E.D.; Franca, T.V.; Fortulan, C.A.; da Silva, R.H.L.; Foschini, C.R. Analysis of the tool nose radius influence in the machining of a green ceramic material. Int. J. Adv. Manuf. Technol. 2019, 105, 3117–3125. [Google Scholar] [CrossRef]

- Kumar, P.; Karsh, P.K.; Misra, J.P.; Kumar, J. Multi-objective optimization of machining parameters during green machining of aerospace grade titanium alloy using Grey-Taguchi approach. Proc. Inst. Mech. Eng. Part E 2021. [Google Scholar] [CrossRef]

- Yang, D.Y.; Zhang, Y.C.; Wang, R.; Wei, F.R.; Zeng, L.X.; Liu, M. Finite Element Modeling and Optimization Analysis of Cutting Force in Powder Metallurgy Green Compacts. Processes 2023, 22, 3186. [Google Scholar] [CrossRef]

- Bidulska, J.; Bidulsky, R.; Grande, M.A.; Kvackaj, T. Different Formation Routes of Pore Structure in Aluminum Powder Metallurgy Alloy. Materials 2019, 12, 3724. [Google Scholar] [CrossRef]

- Shokry, A. On the constitutive modeling of a powder metallurgy nanoquasicrystalline Al93Fe3Cr2Ti2 alloy at elevated temperatures. J. Braz. Soc. Mech. Sci. 2019, 41, 118. [Google Scholar] [CrossRef]

- Sun, Y.; Li, G.H.; He, Z.; Kong, X.C. The advance of research on constitutive model used in finite element simulation of metal cutting. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2022, 236, 4921–4945. [Google Scholar] [CrossRef]

- Hüseyin, G.; Yunus, E.G. Optimization and evaluation of dry and minimum quantity lubricating methods on machinability of AISI 4140 using Taguchi design and ANOVA. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 235, 1211–1227. [Google Scholar]

- Naik, A.B.; Reddy, A.C. Optimization of Tensile Strength in TIG Welding Using Taguchi Method and Analysis of Variance (ANOVA). Therm. Sci. Eng. Prog. 2018, 8, 327–339. [Google Scholar] [CrossRef]

- Savković, B.; Kovăc, P.; Stoić, A.; Dudić, B. Optimization of Machining Parameters Using the Taguchi and ANOVA Analysis in the Face Milling of Aluminum Alloys AL7075. Teh. Vjesn. 2020, 27, 1221–1228. [Google Scholar]

- Deng, C.S.; Hsia, K.L. Analysis of the optimisation of parameters for the laser machining of timber. Int. J. Adv. Manuf. Technol. 2017, 89, 3721–3729. [Google Scholar] [CrossRef]

- Kruzel, R.; Dembiczak, T.; Wachowicz, J. Optimization of Spark Plasma Sintering Technology by Taguchi Method in the Production of a Wide Range of Materials: Review. Materials 2023, 16, 5539. [Google Scholar] [CrossRef] [PubMed]

- Elkatatny, S.; Alsharekh, M.F.; Alateyah, A.I.; El-Sanabary, S.; Nassef, A.; Alawad, M.O.; Kamel, M.; BaQais, A.; El-Garaihy, W.H.; Kouta, H. Optimizing the Powder Metallurgy Parameters to Enhance the Mechanical Properties of Al-4Cu/xAl2O3 Composites Using Machine Learning and Response Surface Approaches. Appl. Sci. 2023, 13, 7483. [Google Scholar] [CrossRef]

- Wen, H.N.; Jin, J.S.; Tang, X.F.; Wang, X.Y.; Yang, H.Y.; Zhang, Y.D.; Zhang, M.; Deng, L.; Wei, Q.S.; Chen, J.Z.; et al. Machine learning-assisted constitutive modeling of a novel powder metallurgy superalloy. Int. J. Mech. Sci. 2023, 260, 108654. [Google Scholar] [CrossRef]

- Dreano, A.; Favre, J.; Desrayaud, C.; Chanin-Lambert, P.; Wimmer, A.; Zaeh, M.F. Computational design of a crack-free aluminum alloy for additive manufacturing br. Addit. Manuf. 2022, 55, 102876. [Google Scholar]

| Performance | Density (g/cm3) | Vickers Hardness (HV) | Tensile Strength (MPa) | Compressive Strength (MPa) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| Parameter | 7.1 | 87 | 3.9 | 98 | 210 | 0.018 |

| Chemical Composition | Fe | C | O | S | Mn | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| Proportion (%) | 96.0586 | 0.002 | 0.07 | 0.0074 | 0.136 | 0.506 | 1.75 | 1.47 |

| Parameter | A (MPa) | B (MPa) | C | m | n | Tm (°C) | Tr (°C) |

|---|---|---|---|---|---|---|---|

| Value | 101 | 91 | 0.127 | 1.46 | 0.213 | 1861 | 25 |

| Test Number (i) | Four Factors | FH (yi) | |||

|---|---|---|---|---|---|

| ap (mm) | vc (m/min) | γo (°) | rε (μm) | ||

| 1 | 0.15 | 5 | 0 | 10 | 183.564 |

| 2 | 0.15 | 20 | 10 | 25 | 184.028 |

| 3 | 0.15 | 35 | 20 | 15 | 186.512 |

| 4 | 0.15 | 50 | 5 | 30 | 189.603 |

| 5 | 0.15 | 65 | 15 | 20 | 186.964 |

| 6 | 0.2 | 5 | 20 | 25 | 212.920 |

| 7 | 0.2 | 20 | 5 | 15 | 230.748 |

| 8 | 0.2 | 35 | 15 | 30 | 212.350 |

| 9 | 0.2 | 50 | 0 | 20 | 237.716 |

| 10 | 0.2 | 65 | 10 | 10 | 245.292 |

| 11 | 0.25 | 5 | 15 | 15 | 263.694 |

| 12 | 0.25 | 20 | 0 | 30 | 275.158 |

| 13 | 0.25 | 35 | 10 | 20 | 273.018 |

| 14 | 0.25 | 50 | 20 | 10 | 280.353 |

| 15 | 0.25 | 65 | 5 | 25 | 284.094 |

| 16 | 0.3 | 5 | 10 | 30 | 308.031 |

| 17 | 0.3 | 20 | 20 | 20 | 296.932 |

| 18 | 0.3 | 35 | 5 | 10 | 330.820 |

| 19 | 0.3 | 50 | 15 | 25 | 312.766 |

| 20 | 0.3 | 65 | 0 | 15 | 340.883 |

| 21 | 0.35 | 5 | 5 | 20 | 443.402 |

| 22 | 0.35 | 20 | 15 | 10 | 432.286 |

| 23 | 0.35 | 35 | 0 | 25 | 433.532 |

| 24 | 0.35 | 50 | 10 | 15 | 420.143 |

| 25 | 0.35 | 65 | 20 | 30 | 371.171 |

| Variation Source | Square of Deviance | Degree of Freedom | Sum of Mean Squares | F | Significance | F0.05 | F0.01 |

|---|---|---|---|---|---|---|---|

| ap (mm) | 162,374.456 | 4 | 40,593.614 | 177.781 | ** | 3.84 | 7.01 |

| vc (m/min) | 113.973 | 4 | 28.493 | 0.125 | ns | ||

| γo (°) | 2244.428 | 4 | 561.107 | 2.457 | ns | ||

| rε (μm) | 1479.226 | 4 | 369.807 | 1.620 | ns | ||

| Error | 1826.676 | 8 | 228.335 | / | / | ||

| Summation | 168,038.759 | 24 | / | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yang, D.; Zeng, L.; Zhang, Z.; Li, S. Simulation and Algorithmic Optimization of the Cutting Process for the Green Machining of PM Green Compacts. Materials 2024, 17, 3963. https://doi.org/10.3390/ma17163963

Zhang Y, Yang D, Zeng L, Zhang Z, Li S. Simulation and Algorithmic Optimization of the Cutting Process for the Green Machining of PM Green Compacts. Materials. 2024; 17(16):3963. https://doi.org/10.3390/ma17163963

Chicago/Turabian StyleZhang, Yuchen, Dayong Yang, Lingxin Zeng, Zhiyang Zhang, and Shuping Li. 2024. "Simulation and Algorithmic Optimization of the Cutting Process for the Green Machining of PM Green Compacts" Materials 17, no. 16: 3963. https://doi.org/10.3390/ma17163963

APA StyleZhang, Y., Yang, D., Zeng, L., Zhang, Z., & Li, S. (2024). Simulation and Algorithmic Optimization of the Cutting Process for the Green Machining of PM Green Compacts. Materials, 17(16), 3963. https://doi.org/10.3390/ma17163963