Comparative Analysis of Surface Roughness and Plastic Deformation of Reciprocating Instruments after Clinical Use

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Size Calculation

2.2. NiTi Instruments Used

2.3. Clinical Procedure

2.4. Analysis of the Instruments

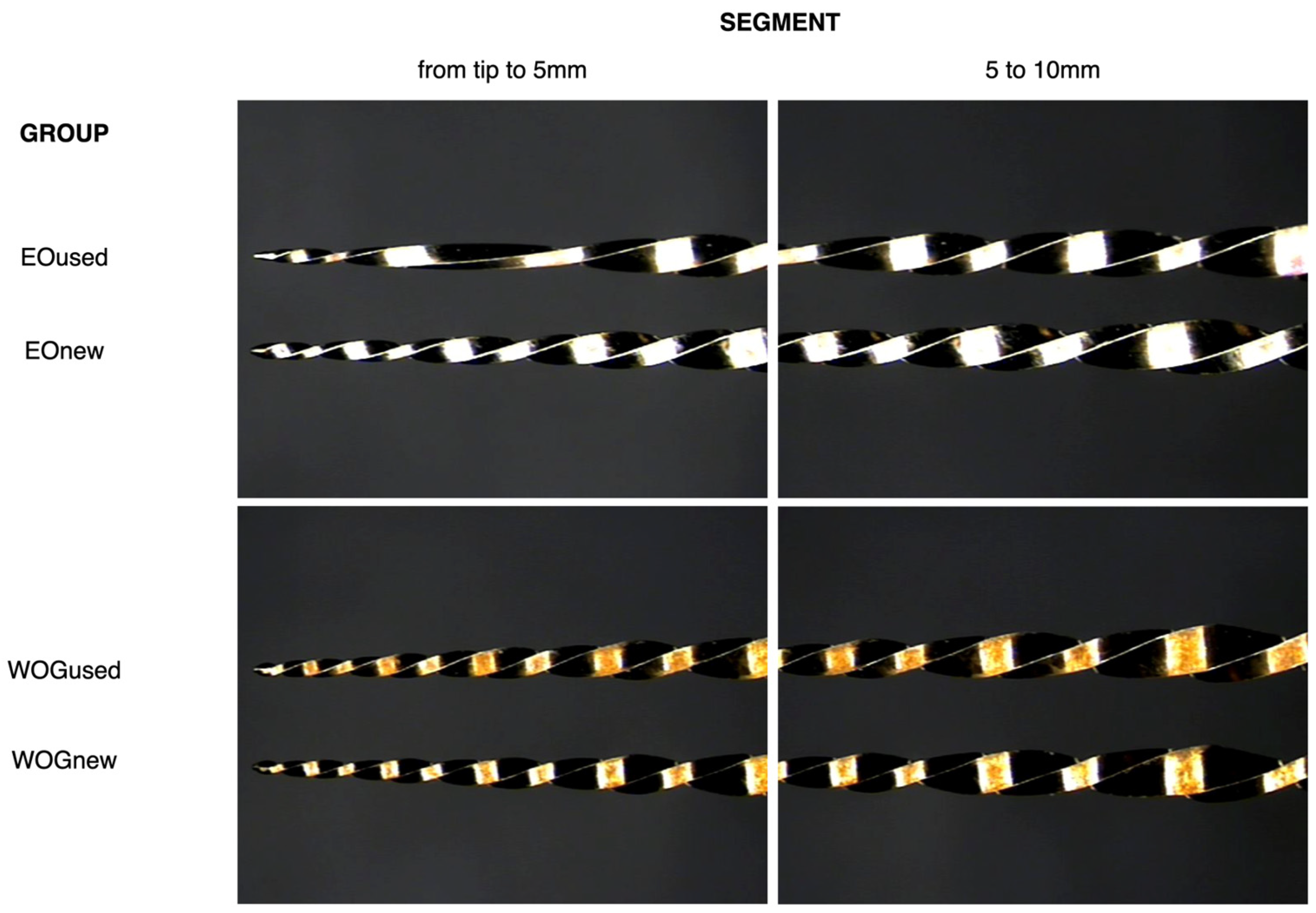

2.4.1. Analysis via Stereoscopic Microscopy

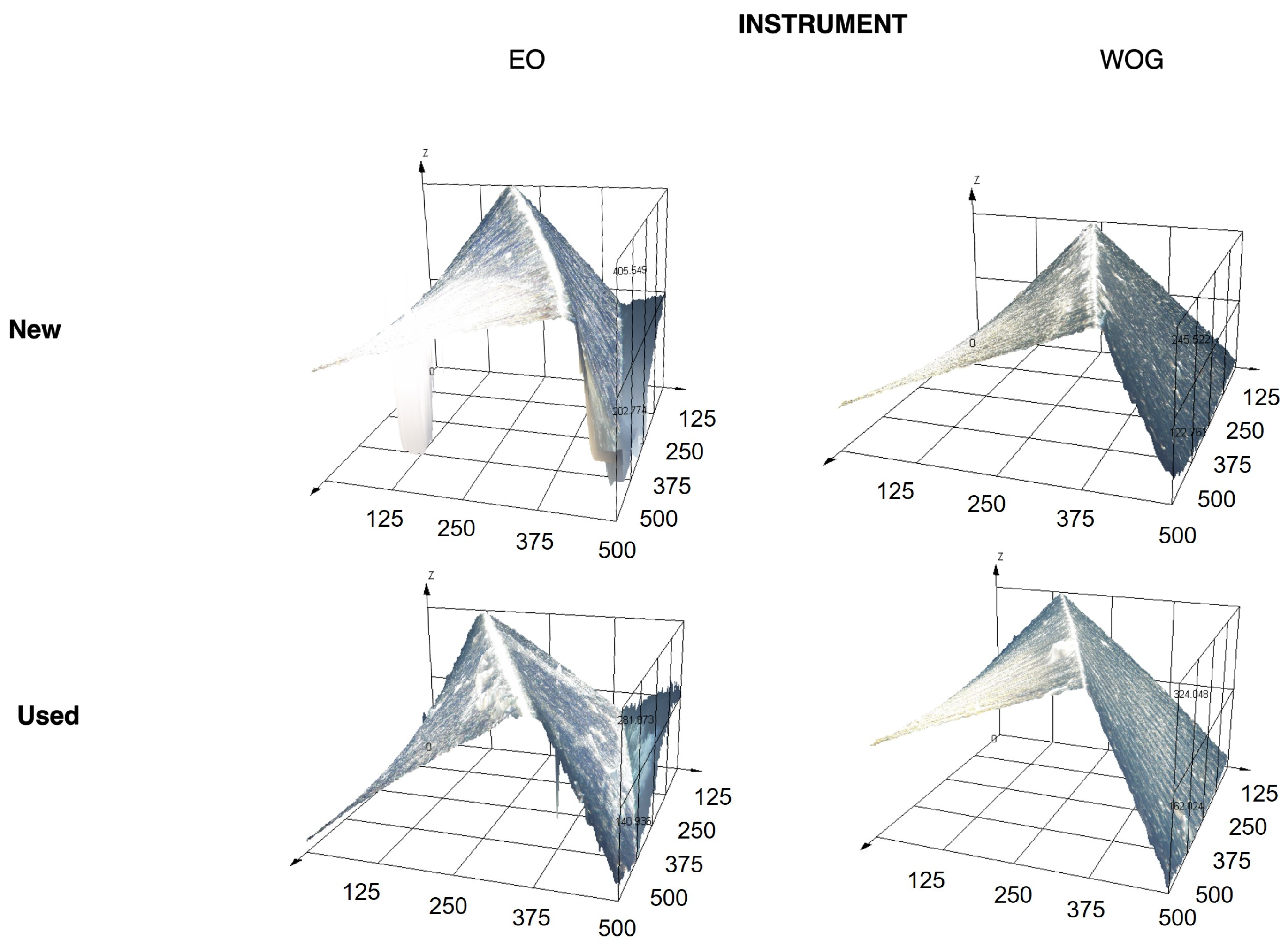

2.4.2. Analysis via Non-Contact 3D Profilometry

2.4.3. Data Analysis

3. Results

3.1. Plastic Deformation

3.2. Surface Roughness

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Walia, H.; Brantley, W.A.; Gerstein, H. An initial investigation of the bending and torsional properties of nitinol root canal files. J. Endod. 1988, 14, 346–351. [Google Scholar] [CrossRef] [PubMed]

- Thompson, S.A. An overview of NiTi alloys used in dentistry. Int. Endod. J. 2000, 33, 297–310. [Google Scholar] [CrossRef]

- Peters, O.A. Current challenges and concepts in the preparation of root canal systems: A review. J. Endod. 2004, 30, 559–567. [Google Scholar] [CrossRef]

- Parashos, P.; Messer, H.H. Rotary NiTi Instrument Fracture and its Consequences. J. Endod. 2006, 32, 1031–1043. [Google Scholar] [CrossRef] [PubMed]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef]

- Grande, N.M.; Ahmed, H.M.A.; Cohen, S.; Bukiet, F.; Plotino, G. Current Assessment of Reciprocation in Endodontic Preparation: A Comprehensive Review—Part I: Historic Perspectives and Current Applications. J. Endod. 2015, 41, 1778–1783. [Google Scholar] [CrossRef] [PubMed]

- Bürklein, S.; Hinschitza, K.; Dammaschke, T.; Schäfer, E. Shaping ability and cleaning effectiveness of two single-file systems in severely curved root canals of extracted teeth: Reciproc and WaveOne versus Mtwo and ProTaper. Int. Endod. J. 2012, 45, 449–461. [Google Scholar] [CrossRef]

- Yared, G. Canal preparation using only one Ni-Ti rotary instrument: Preliminary observations. Int. Endod. J. 2008, 41, 339–344. [Google Scholar] [CrossRef]

- Webber, J.; Machtou, P.; Pertot, W.; Kuttler, S.; West, J. The WaveOne single-file reciprocating system. Roots 2011, 1, 28–33. [Google Scholar]

- Alapati, S.B.; Brantley, W.A.; Iijima, M.; Clark, W.A.; Kovarik, L.; Buie, C.; Liu, J.; Johnson, W.B. Metallurgical Characterization of a New Nickel-Titanium Wire for Rotary Endodontic Instruments. J. Endod. 2009, 35, 1589–1593. [Google Scholar] [CrossRef]

- Pereira, E.S.; Peixoto, I.F.; Viana, A.C.; Oliveira, I.I.; Gonzalez, B.M.; Buono, V.T.; Bahia, M.G. Physical and mechanical properties of a thermomechanically treated NiTi wire used in the manufacture of rotary endodontic instruments. Int. Endod. J. 2012, 45, 469–474. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, F.; Adeodato, C.; Barbosa, I.; Aboud, L.; Scelza, P.; Zaccaro Scelza, M. Movement kinematics and cyclic fatigue of NiTi rotary instruments: A systematic review. Int. Endod. J. 2017, 50, 143–152. [Google Scholar] [CrossRef] [PubMed]

- Prados-Privado, M.; Rojo, R.; Ivorra, C.; Prados-Frutos, J.C. Finite element analysis comparing WaveOne, WaveOne Gold, Reciproc and Reciproc Blue responses with bending and torsion tests. J. Mech. Behav. Biomed. Mater. 2019, 90, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Arias, A.; Peters, O.A. Present status and future directions: Canal shaping. Int. Endod. J. 2022, 55, 637–655. [Google Scholar] [CrossRef]

- Logsdon, J.; Dunlap, C.; Arias, A.; Scott, R.; Peters, O.A. Current Trends in Use and Reuse of Nickel-Titanium Engine-driven Instruments: A Survey of Endodontists in the United States. J. Endod. 2020, 46, 391–396. [Google Scholar] [CrossRef]

- Scott, R.; Arias, A.; Macorra, J.C.; Govindjee, S.; Peters, O.A. Resistance to cyclic fatigue of reciprocating instruments determined at body temperature and phase transformation analysis. Aust. Endod. J. 2019, 45, 400–406. [Google Scholar] [CrossRef] [PubMed]

- EdgeEndo. EdgeOne™ Fire. Twice as Good. Half the Cost. Available online: https://www.edgeendo.es/edgeonefire/ (accessed on 23 September 2023).

- Ebrahimi, M.; Attarilar, S.; Gode, C.; Kandavalli, S.R.; Shamsborhan, M.; Wang, Q. Conceptual Analysis on Severe Plastic Deformation Processes of Shape Memory Alloys: Mechanical Properties and Microstructure Characterization. Metals 2023, 13, 447. [Google Scholar] [CrossRef]

- AlRahabi, A.M.K.; Atta, R.M. Surface nanoscale profile of WaveOne, WaveOne Gold, Reciproc, and Reciproc blue, before and after root canal preparation. Odontology 2019, 107, 500–506. [Google Scholar] [CrossRef]

- Van Pham, K.; Vo, C.Q. A new method for assessment of nickel-titanium endodontic instrument surface roughness using field emission scanning electronic microscope. BMC Oral Health 2020, 20, 240. [Google Scholar] [CrossRef]

- Ferreira, F.; Barbosa, I.; Scelza, P.; Russano, D.; Neff, J.; Montagnana, M.; Scelza, M.Z. A new method for the assessment of the surface topography of NiTi rotary instruments. Int. Endod. J. 2017, 50, 902–909. [Google Scholar] [CrossRef]

- Lopes, H.P.; Elias, C.N.; Vieira, M.V.; Vieira, V.T.; de Souza, L.C.; Santos, A.L.D. Influence of Surface Roughness on the Fatigue Life of Nickel-Titanium Rotary Endodontic Instruments. J. Endod. 2016, 42, 965–968. [Google Scholar] [CrossRef] [PubMed]

- Merima, B.; Ivona, B.; Dubravka, M.; Gianluca, P.; Ivica, A. Surface roughness and cyclic fatigue resistance of reciprocating and novel rotary instruments after use in curved root canals. Aust. Endod. J. 2023, 49, 117–123. [Google Scholar] [CrossRef] [PubMed]

- Nair, A.S.; Tilakchand, M.; Naik, B.D. The effect of multiple autoclave cycles on the surface of rotary nickel-titanium endodontic files: An in vitro atomic force microscopy investigation. J. Conserv. Dent. 2015, 18, 218–222. [Google Scholar] [CrossRef] [PubMed]

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.; Messer, H.H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000, 26, 161–165. [Google Scholar] [CrossRef] [PubMed]

- Moreira, E.J.L.; dos Santos Antunes, H.; Vieira, V.T.L.; Cavalcante, D.M.; Oliveira, H.E.; da Silva Oliveira, D.; De-Deus, G.; da Silva, E.J.N.L. Effects of clinical use of NiTi reciprocating instruments on cyclic and torsional resistance, and on roughness. Braz. Oral Res. 2021, 35, e021. [Google Scholar] [CrossRef] [PubMed]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 25178-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- Uslu, G.; Özyürek, T.; Yılmaz, K. Comparison of Alterations in the Surface Topographies of HyFlex CM and HyFlex EDM Nickel-titanium Files after Root Canal Preparation: A Three-dimensional Optical Profilometry Study. J. Endod. 2018, 44, 115–119. [Google Scholar] [CrossRef] [PubMed]

- Schindler, W.G. The stereo microscope: An aid to evaluate root canal debridement and obturation. J. Endod. 1986, 12, 359–362. [Google Scholar] [CrossRef] [PubMed]

- Inan, U.; Gonulol, N. Deformation and Fracture of Mtwo Rotary Nickel-Titanium Instruments After Clinical Use. J. Endod. 2009, 35, 1396–1399. [Google Scholar] [CrossRef] [PubMed]

- Martins, J.N.R.; Silva, E.J.N.L.; Marques, D.; Pinto, R.; Francisco, H.; Ajuz, N.; Rito Pereira, M.; Fernandes, F.M.B.; Versiani, M.A. Characterization of four heat-treated reciprocating instruments: Design, metallurgy, mechanical performance, and irrigation flow patterns. Int. Endod. J. 2023, 56, 1412–1428. [Google Scholar] [CrossRef]

- Alapati, S.B.; Brantley, W.A.; Svec, T.A.; Powers, J.M.; Mitchell, J.C. Scanning electron microscope observations of new and used nickel-titanium rotary files. J. Endod. 2003, 29, 667–669. [Google Scholar] [CrossRef]

- Hanan, A.R.; Meireles, D.A.; Sponchiado Júnior, E.C.; Hanan, S.; Kuga, M.C.; Bonetti Filho, I. Surface characteristics of reciprocating instruments before and after use—A SEM analysis. Braz. Dent. J. 2015, 26, 121–127. [Google Scholar] [CrossRef] [PubMed]

- Field, J.; Waterhouse, P.; German, M. Quantifying and qualifying surface changes on dental hard tissues in vitro. J. Dent. 2010, 38, 182–190. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, F.G.; Nouer, D.F.; Silva, N.P.; Garbui, I.U.; Correr-Sobrinho, L.; Nouer, P.R.A. Qualitative and quantitative evaluation of human dental enamel after bracket debonding: A noncontact three-dimensional optical profilometry analysis. Clin. Oral Investig. 2014, 18, 1853–1864. [Google Scholar] [CrossRef]

- Cehreli, Z.C.; Lakshmipathy, M.; Yazici, R. Effect of different splint removal techniques on the surface roughness of human enamel: A three-dimensional optical profilometry analysis. Dent. Traumatol. 2008, 24, 177–182. [Google Scholar] [CrossRef] [PubMed]

- Zafar, M.S. Impact of Endodontic Instrumentation on Surface Roughness of Various Nickel-Titanium Rotary Files. Eur. J. Dent. 2021, 15, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Cordaro, M.; Testarelli, L.; Gambarini, G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J. Endod. 2009, 35, 1469–1476. [Google Scholar] [CrossRef] [PubMed]

- Keskin, C.; Inan, U.; Demiral, M.; Keleş, A. Cyclic Fatigue Resistance of Reciproc Blue, Reciproc, and WaveOne Gold Reciprocating Instruments. J. Endod. 2017, 43, 1360–1363. [Google Scholar] [CrossRef] [PubMed]

- Gündoğar, M.; Özyürek, T. Cyclic Fatigue Resistance of OneShape, HyFlex EDM, WaveOne Gold, and Reciproc Blue Nickel-titanium Instruments. J. Endod. 2017, 43, 1192–1196. [Google Scholar] [CrossRef] [PubMed]

- Keskin, C.; İnan, U.; Demiral, M.; Keleş, A. Cyclic fatigue resistance of R-Pilot, WaveOne Gold Glider, and ProGlider glide path instruments. Clin. Oral Investig. 2018, 22, 3007–3012. [Google Scholar] [CrossRef]

- Özyürek, T. Cyclic Fatigue Resistance of Reciproc, WaveOne, and WaveOne Gold Nickel-Titanium Instruments. J. Endod. 2016, 42, 1536–1539. [Google Scholar] [CrossRef]

- Seracchiani, M.; Reda, R.; Zanza, A.; D’Angelo, M.; Russo, P.; Luca, T. Mechanical Performance and Metallurgical Characteristics of 5 Different Single-file Reciprocating Instruments: A Comparative In Vitro and Laboratory Study. J. Endod. 2022, 48, 1073–1080. [Google Scholar] [CrossRef] [PubMed]

- Bhandi, S.; Seracchiani, M.; Donfrancesco, O.; Reda, R.; Mazzoni, A.; Nottola, S.; Familiari, G.; Testarelli, L.; Gambarini, G. Nickel–Titanium Rotary Instruments: An In Vitro Comparison (Torsional Resistance of Two Heat-treated Reciprocating Files). J. Contemp. Dent. Pract. 2021, 22, 361–364. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhou, H.M.; Zheng, Y.F.; Peng, B.; Haapasalo, M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J. Endod. 2013, 39, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Arias, A.; Macorra, J.C.; Govindjee, S.; Peters, O.A. Correlation between Temperature-dependent Fatigue Resistance and Differential Scanning Calorimetry Analysis for 2 Contemporary Rotary Instruments. J. Endod. 2018, 44, 630–634. [Google Scholar] [CrossRef] [PubMed]

- Arias, A.; Hejlawy, S.; Murphy, S.; de la Macorra, J.C.; Govindjee, S.; Peters, O.A. Variable impact by ambient temperature on fatigue resistance of heat-treated nickel titanium instruments. Clin. Oral Investig. 2019, 23, 1101–1108. [Google Scholar] [CrossRef]

- Rodrigues, C.S.; Vieira, V.T.; Antunes, H.S.; De-Deus, G.; Elias, C.N.; Moreira, E.J.; Silva, E. Mechanical characteristics of counterfeit Reciproc instruments: A call for attention. Int. Endod. J. 2018, 51, 556–563. [Google Scholar] [CrossRef] [PubMed]

- Madytianos, B.; Liu, E.; Marshall, A.; Mahony, E.; Liu, K.; Manogaran, J.; Liu, H.H.; Parashos, P.; Evans, M. A critical evaluation of physical and manufacturing properties of genuine and counterfeit rotary nickel–titanium endodontic instruments. Aust. Dent. J. 2023, 68, 179–185. [Google Scholar] [CrossRef]

- Özyürek, T.; Yılmaz, K.; Uslu, G.; Plotino, G. The effect of root canal preparation on the surface roughness of WaveOne and WaveOne Gold files: Atomic force microscopy study. Restor. Dent. Endod. 2018, 43, e10. [Google Scholar] [CrossRef]

| Flute | Blade | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average Roughness (Sa) | Quadratic Avarage (Sq) | Height (Sz) | Average Roughness (Ra) | Quadratic Avarage (Rq) | Height (Rz) | ||||||||||||||

| Instrument | Portion | New | Used | Ratio | New | Used | Ratio | New | Used | Ratio | New | Used | Ratio | New | Used | Ratio | New | Used | Ratio |

| WOG | Apical (3 mm) | 1.2 (0.48) | 1.4 (0.08) | 1.17 | 1.53 (0.52) | 1.82 (0.81) | 1.18 | 9.4 (2.86) | 12.05 (1.5) | 1.28 | 3.29 (0,27) | 3.14 (0.29) | 0.95 | 3.99 (0.28) | 3.91 (0.3) | 0.98 | 16.56 (0.72) | 17.86 (0.91) | 1.08 |

| EO | 0.84 (0.19) | 1.18 (0.61) | 1.40 | 1.11 (0.21) | 1.58 (0.04) | 1.42 | 8.27 (0.2) | 10.56 (1.32) | 1.28 | 2.68 (0.12) | 3.63 (0.3) | 1.35 | 3.28 (0.19) | 4.32 (0.41) | 1.32 | 13.23 (0.51) | 15.98 (1.2) | 1.21 | |

| WOG | Middle (5 mm) | 1.25 (0.57) | 1.26 (0.1) | 1.01 | 1.57 (0.63) | 1.63 (0.22) | 1.03 | 9.21 (2.5) | 10.86 (3.19) | 1.18 | 2.78 (0.34) | 3.86 (0.84) | 1.39 | 3.45 (0.4) | 4.67 (0.88) | 1.35 | 15.5 (0.98) | 19.96 (3.01) | 1.29 |

| EO | 0.97 (0.1) | 1.06 (0.15) | 1.09 | 1.27 (0.14) | 1.41 (0.16) | 1.11 | 8.69 (1.83) | 9.94 (1.16) | 1.14 | 2.12 (0.3) | 2.71 (0.5) | 1.28 | 2.55 (0.38) | 3.2 (0.49) | 1.25 | 10.44 (1.76) | 12.94 (1.51) | 1.24 | |

| WOG | Coronal (12 mm) | 0.84 (0.12) | 1.07 (0.12) | 1.28 | 1.07 (0.1) | 1.44 (0.21) | 1.34 | 7.49 (0.72) | 11.38 (3.65) | 1.52 | 3.9 (1.67) | 3.36 (0.38) | 1.39 | 4.9 (2.24) | 4.24 (0.41) | 0.86 | 23.37 (11.4) | 18.92 (1.32) | 0.80 |

| EO | 0.9 (0.11) | 1.16 (0.1) | 1.29 | 1.12 (0.15) | 1.43 (0.11) | 1.28 | 7.46 (0.57) | 9.97 (0.97) | 1.34 | 1.9 (0.73) | 2.24 (0.53) | 1.17 | 2.45 (1.05) | 2.68 (0.6) | 1.09 | 11.16 (4.82) | 11.06 (2.56) | 0.99 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrera, Á.; Azabal, M.; Jimenez-Octavio, J.R.; del Real-Romero, J.C.; López de Armentia, S.; Asensio-Gil, J.M.; Arias, A. Comparative Analysis of Surface Roughness and Plastic Deformation of Reciprocating Instruments after Clinical Use. Materials 2024, 17, 3978. https://doi.org/10.3390/ma17163978

Herrera Á, Azabal M, Jimenez-Octavio JR, del Real-Romero JC, López de Armentia S, Asensio-Gil JM, Arias A. Comparative Analysis of Surface Roughness and Plastic Deformation of Reciprocating Instruments after Clinical Use. Materials. 2024; 17(16):3978. https://doi.org/10.3390/ma17163978

Chicago/Turabian StyleHerrera, Ángel, Magdalena Azabal, Jesús R. Jimenez-Octavio, Juan C. del Real-Romero, Sara López de Armentia, Juan M. Asensio-Gil, and Ana Arias. 2024. "Comparative Analysis of Surface Roughness and Plastic Deformation of Reciprocating Instruments after Clinical Use" Materials 17, no. 16: 3978. https://doi.org/10.3390/ma17163978