Crystal Lattice Recovery and Optical Activation of Yb Implanted into β-Ga2O3

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

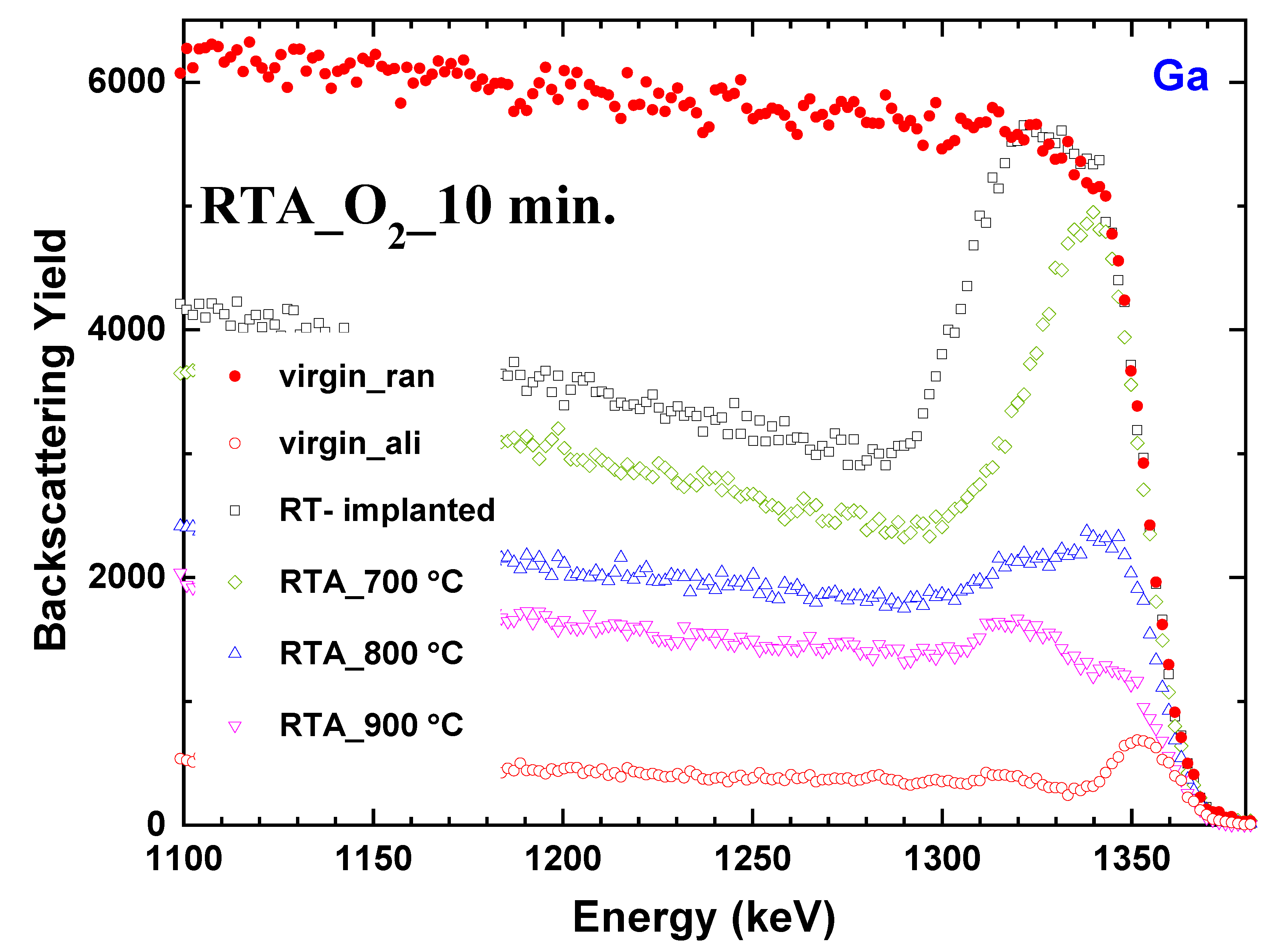

3.1. Crystal Lattice Recovery

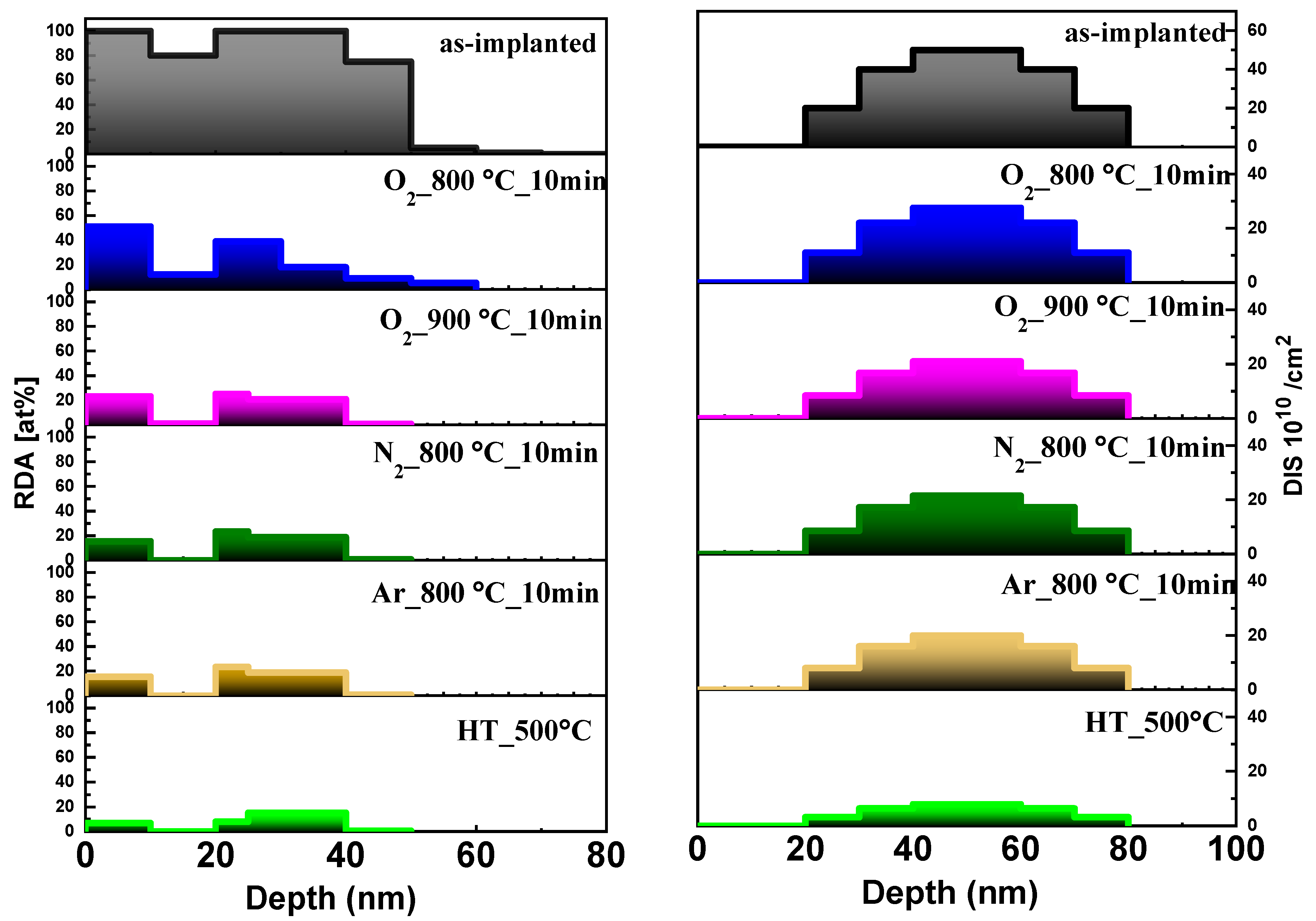

3.2. Yb Ion Location

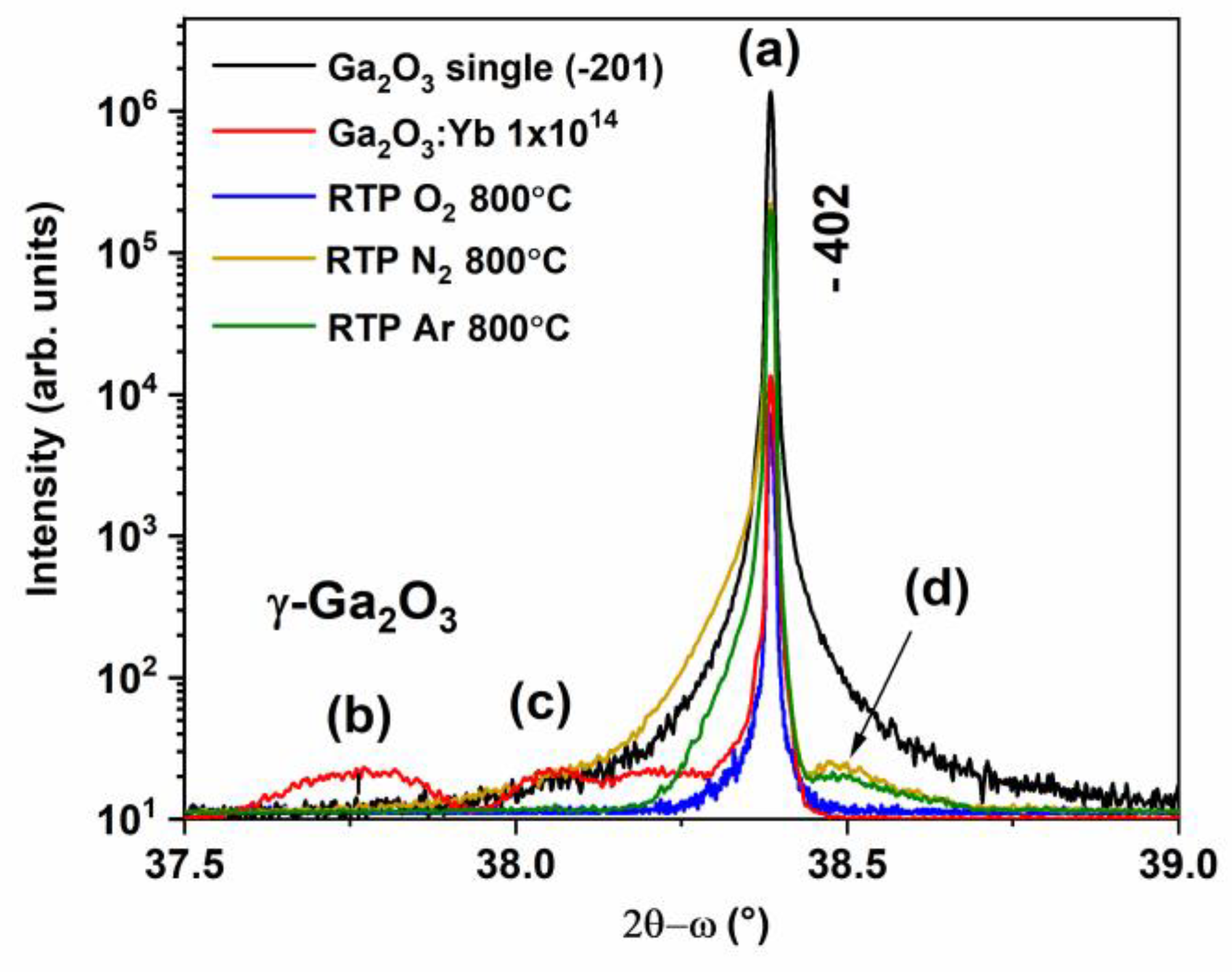

3.3. High-Resolution X-ray Diffraction

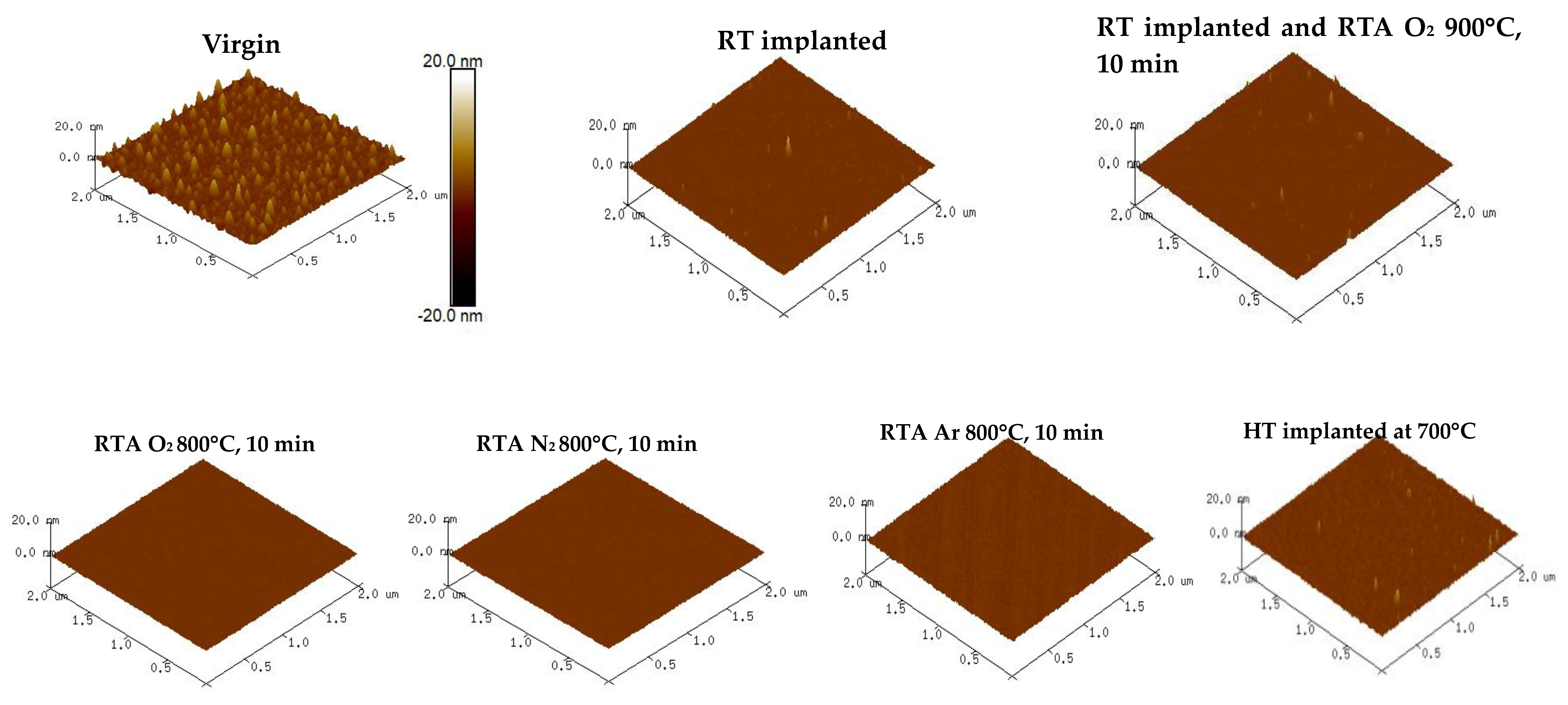

3.4. Surface Morphology

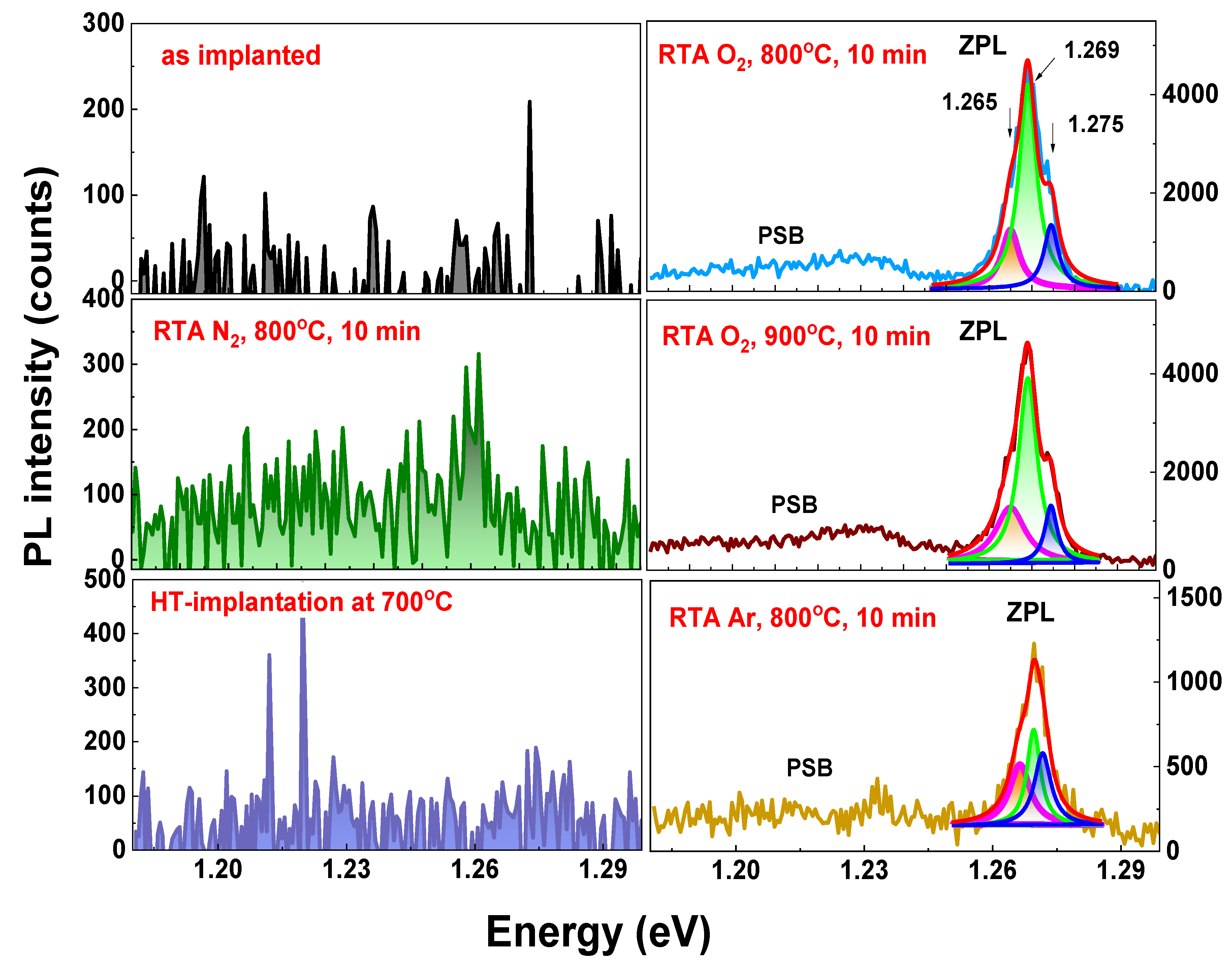

3.5. Room-Temperature Photoluminescence

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuramata, A.; Koshi, K.; Watanabe, S.; Yamaoka, Y.; Masui, T.; Yamakoshi, S. High-quality β-Ga2O3 single crystals grown by edge-defined film-fed growth. Jpn. J. Appl. Phys. 2016, 55, 1202A2. [Google Scholar] [CrossRef]

- Tsao, J.Y.; Chowdhury, S.; Hollis, M.A.; Jena, D.; Johnson, N.M.; Jones, K.A.; Kaplar, R.J.; Rajan, S.; Van de Walle, C.G.; Bellotti, E.; et al. Ultrawide-Bandgap Semiconductors: Research Opportunities and Challenges. Adv. Electron. Mater. 2018, 4, 1. [Google Scholar] [CrossRef]

- Davis, K.; Yarbrough, R.; Froeschle, M.; Whitea, J.; Rathnayake, H. Band gap engineered zinc oxide nanostructures via a sol–gel synthesis of solvent driven shape-controlled crystal growth. RSC Adv. 2019, 9, 14638. [Google Scholar] [CrossRef] [PubMed]

- Mastro, M.A.; Kuramata, A.; Calkins, J.; Kim, J.; Ren, F.; Pearton, S.J. Perspective—Opportunities and Future Directions for Ga2O3. ECS J. Solid State Sci. Technol. 2017, 6, 5. [Google Scholar] [CrossRef]

- Pearton, S.J.; Yang, J.; Cary, P.H., IV; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A review of Ga2O3 materials, processing, and devices. Appl. Phys. Rev. 2018, 5, 1. [Google Scholar] [CrossRef]

- Kim, J.; Pearton, S.J.; Fares, C.; Yang, J.; Ren, F.; Kim, S.; Polyakov, A.Y. Radiation damage effects in Ga2O3 materials and devices. J. Mater. Chem. C 2019, 7, 10–24. [Google Scholar] [CrossRef]

- Xu, J.; Zheng, W.; Huang, F. Gallium oxide solar-blind ultraviolet photodetectors: A review. J. Mater. Chem. C 2019, 7, 8753–8770. [Google Scholar] [CrossRef]

- Ghose, S.; Rahman, S.; Hong, L.; Rojas-Ramirez, J.S.; Jin, H.; Park, K.; Klie, R.; Droopad, R. Growth and characterization of β-Ga2O3 thin films by molecular beam epitaxy for deep-UV photodetectors. J. Appl. Phys. 2017, 122, 9. [Google Scholar] [CrossRef]

- Pearton, S.J.; Ren, F.; Tadjer, M.; Kim, J. Perspective: Ga2O3 for ultra-high power rectifiers and MOSFETS. J. Appl. Phys. 2018, 124, 22. [Google Scholar] [CrossRef]

- Zhang, J.; Willis, J.; Yang, Z.; Lian, X.; Chen, W.; Wang, L.-S.; Xu, X.; Lee, T.-L.; Chen, L.; Scanlon, D.O.; et al. Deep UV transparent conductive oxide thin films realized through degenerately doped wide-bandgap gallium oxide. Cell Rep. Phys. Sci. 2022, 3, 100801. [Google Scholar] [CrossRef]

- Miyata, T.; Nakatani, T.; Minami, T. Gallium oxide as host material for multicolor emitting phosphors. J. Lumin. 2000, 87–89, 1183–1185. [Google Scholar] [CrossRef]

- Onuma, T.; Nakata, Y.; Sasaki, K.; Masui, T.; Yamaguchi, T.; Honda, T.; Kuramata, A.; Yamakoshi, S.; Higashiwaki, M. Modeling and interpretation of UV and blue luminescence intensity in β-Ga2O3 by silicon and nitrogen doping. J. Appl. Phys. 2018, 124, 075103. [Google Scholar] [CrossRef]

- Ratajczak, R.; Guziewicz, E.; Prucnal, S.; Mieszczynski, C.; Jozwik, P.; Barlak, M.; Romaniuk, S.; Gieraltowska, S.; Wozniak, W.; Heller, R.; et al. Enhanced Luminescence of Yb3+ Ions Implanted to ZnO through the Selection of Optimal Implantation and Annealing Conditions. Materials 2023, 16, 1756. [Google Scholar] [CrossRef] [PubMed]

- Williams, J.S. Ion implantation of semiconductors. Mater. Sci. Eng. A 1998, 253, 8–15. [Google Scholar] [CrossRef]

- Polyakov, A.Y.; Kochkova, A.I.; Azarov, A.; Venkatachalapathy, V.; Miakonkikh, A.V.; Vasilev, A.A.; Chernykh, A.V.; Shchemerov, I.V.; Romanov, A.A.; Kuznetsov, A.; et al. Tuning electrical properties in Ga2O3 polymorphs induced with ion beams. J. Appl. Phys. 2023, 133, 9. [Google Scholar] [CrossRef]

- Azarov, A.; Venkatachalapathy, V.; Lee, I.-H.; Kuznetsov, A. Thermal versus radiation-assisted defect annealing in β-Ga2O3. J. Vac. Sci. Technol. A 2023, 41, 2. [Google Scholar] [CrossRef]

- Kjeldby, S.B.; Azarov, A.; Nguyen, P.; Venkatachalapathy, V.; Mikšová, R.; Macková, A.; Kuznetsov, A.; Prytz, Ø.; Vines, L. Radiation-induced defect accumulation and annealing in Si-implanted gallium oxide. J. Appl. Phys. 2022, 131, 125701. [Google Scholar] [CrossRef]

- Lorenz, K.; Peres, M.; Felizardo, M.; Correia, J.G.; Alves, L.C.; Alves, E.; López, I.; Nogales, E.; Méndez, B.; Piqueras, J.; et al. Doping of Ga2O3 bulk crystals and NWs by ion implantation. In Oxide-Based Materials and Devices V; SPIE: Bellingham, WA, USA, 2014; p. 89870M. [Google Scholar]

- Wendler, E.; Treiber, E.; Baldauf, J.; Wolf, S.; Ronning, C. High-level damage saturation below amorphisation in ion implanted β-Ga2O3. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2016, 379, 85–90. [Google Scholar] [CrossRef]

- Sarwar, M.; Ratajczak, R.; Mieszczynski, C.; Wierzbicka, A.; Gieraltowska, S.; Heller, R.; Eisenwinder, S.; Wozniak, W.; Guziewicz, E. Defect accumulation in β-Ga2O3 implanted with Yb. Acta Mater. 2024, 268, 119760. [Google Scholar] [CrossRef]

- Koleśnik-Gray, M.M.; Sorger, C.; Biswas, S.; Holmes, J.D.; Weber, H.B.; Krstić, V. In operandi observation of dynamic annealing: A case study of boron in germanium nanowire devices. Appl. Phys. Lett. 2015, 106, 23. [Google Scholar] [CrossRef]

- Wallace, J.B.; Aji, L.B.B.; Martin, A.A.; Shin, S.J.; Shao, L.; Kucheyev, S.O. The role of Frenkel defect diffusion in dynamic annealing in ion-irradiated Si. Sci. Rep. 2017, 7, 39754. [Google Scholar] [CrossRef] [PubMed]

- Williams, J.S.; Poate, J.M. Ion Implantation and Beam Processing; Academic Press: Sydney, Australia, 1984. [Google Scholar]

- Peres, M.; Lorenz, K.; Alves, E.; Nogales, E.; Mendez, B.; Biquard, X.; Daudin, B.; Víllora, E.; Shimamura, K. Doping β-Ga2O3 with Europium: Influence of the Implantation and Annealing Temperature. J. Phys. D Appl. Phys. 2017, 50, 325101. [Google Scholar] [CrossRef]

- Feldman, L.C.; Mayer, J.W.; Picraux, S.T. INTRODUCTION. In Materials Analysis by Ion Channeling; Feldman, L.C., Mayer, J.W., Picraux, S.T., Eds.; Academic Press: San Diego, CA, USA, 1982; pp. 1–11. [Google Scholar]

- Jóźwik, P.; Caçador, A.; Lorenz, K.; Ratajczak, R.; Mieszczyński, C. Monte Carlo simulations of ion channeling in the presence of dislocation loops: New development in the McChasy code. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2023, 538, 198–204. [Google Scholar] [CrossRef]

- Jozwik, P.; Nowicki, L.; Ratajczak, R.; Stonert, A.; Mieszczynski, C.; Turos, A.; Morawiec, K.; Lorenz, K.; Alves, E. Monte Carlo simulations of ion channeling in crystals containing dislocations and randomly displaced atoms. J. Appl. Phys. 2019, 126, 195107. [Google Scholar] [CrossRef]

- Ratajczak, R.; Guziewicz, E.; Prucnal, S.; Łuka, G.; Böttger, R.; Heller, R.; Mieszczynski, C.; Wozniak, W.; Turos, A. Luminescence in the Visible Region from Annealed Thin ALD-ZnO Films Implanted with Different Rare Earth Ions. Phys. Status Solidi (A) 2018, 215, 1700889. [Google Scholar] [CrossRef]

- Azarov, A.; Wendler, E.; Kuznetsov, Y.; Svensson, B. Crucial role of implanted atoms on dynamic defect annealing in ZnO. Appl. Phys. Lett. 2014, 104, 052101. [Google Scholar] [CrossRef]

- Myers, M.T.; Charnvanichborikarn, S.; Shao, L.; Kucheyev, S. Effect of the surface on ion-beam damage build-up in ZnO. Scr. Mater. 2012, 67, 65–68. [Google Scholar] [CrossRef]

- Kucheyev, S.O.; Williams, J.S.; Jagadish, C.; Zou, J.; Evans, C.; Nelson, A.J.; Hamza, A.V. Ion-beam-produced structural defects in ZnO. Phys. Rev. B 2003, 67, 094115. [Google Scholar] [CrossRef]

- Turos, A.; Jozwik, P.; Wójcik, M.; Gaca, J.; Ratajczak, R.; Stonert, A. Mechanism of damage buildup in ion bombarded ZnO. Acta Mater. 2017, 134, 249–256. [Google Scholar] [CrossRef]

- Ratajczak, R.; Prucnal, S.; Guziewicz, E.; Mieszczynski, C.; Snigurenko, D.; Stachowicz, M.; Skorupa, W.; Turos, A. The photoluminescence response to structural changes of Yb implanted ZnO crystals subjected to non-equilibrium processing. J. Appl. Phys. 2017, 121, 075101. [Google Scholar] [CrossRef]

- Maitiniyazi, T.; Matniyaz, T. Power Scaling of Single-Mode Ytterbium and Erbium High-Power Fiber Lasers. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2020. [Google Scholar]

- Prucnal, S.; Rebohle, L.; Skorupa, W. Blue electroluminescence of ytterbium clusters in SiO2 by co-operative up-conversion. Appl. Phys. B 2010, 98, 451–454. [Google Scholar] [CrossRef]

- Otieno, F.; Airo, M.; Njoroge, E.G.; Erasmus, R.; Ganetsos, T.; Quandt, A.; Wamwangi, D.; Billing, D.G. Effect of implantation of Sm+ ions into RF sputtered ZnO thin film. AIP Adv. 2019, 9, 4. [Google Scholar] [CrossRef]

- Klochkov, A.N.; Yskakov, A.; Vinichenko, A.N.; Safonov, D.A.; Kargin, N.I.; Bulavin, M.V.; Galushko, A.V.; Yamurzin, V.R.; Vasil’evskii, I.S. Effect of Neutron Irradiation on the Electronic and Optical Properties of AlGaAs/InGaAs-Based Quantum Well Structures. Materials 2023, 16, 6750. [Google Scholar] [CrossRef]

- Kanemitsu, Y.; Tanaka, H.; Kushida, T.; Min, K.S.; Atwater, H.A. Luminescence properties of GaAs nanocrystals fabricated by sequential ion implantation. J. Lumin. 2000, 87–89, 432–434. [Google Scholar] [CrossRef]

- Hughes, M.; Federenko, Y.; Lee, T.; Yao, J.; Gholipour, B.; Gwilliam, R.; Homewood, K.; Hewak, D.; Elliott, S.; Curry, R. Optical and Electronic Properties of Bismuth-Implanted Glasses; SPIE: Bellingham, WA, USA, 2014; Volume 8982, pp. 274–281. [Google Scholar]

| Different RTA Temperatures | Different RTA Time | Different RTA Atmospheres | HT Implantation | ||||

|---|---|---|---|---|---|---|---|

| Sample | RMS (nm) | Sample | RMS (nm) | Sample | RMS (nm) | Sample | RMS (nm) |

| Virgin | 1.3 | O2 800 °C, 1 min | 0.7 | N2 800 °C, 10 min | 0.2 | 500 °C | 0.2 |

| RT implanted | 0.7 | O2 800 °C, 5 min | 0.6 | Ar 800 °C, 10 min | 0.3 | 700 °C | 1.0 |

| O2 700 °C, 10 min | 0.2 | O2 800 °C, 10 min | 0.6 | O2 800 °C, 10 min | 0.6 | 900 °C | 0.3 |

| O2 800 °C, 10 min | 0.6 | O2 800 °C, 20 min | 0.3 | - | - | - | - |

| O2 900 °C, 10 min | 1.3 | - | - | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarwar, M.; Ratajczak, R.; Ivanov, V.Y.; Gieraltowska, S.; Wierzbicka, A.; Wozniak, W.; Heller, R.; Eisenwinder, S.; Guziewicz, E. Crystal Lattice Recovery and Optical Activation of Yb Implanted into β-Ga2O3. Materials 2024, 17, 3979. https://doi.org/10.3390/ma17163979

Sarwar M, Ratajczak R, Ivanov VY, Gieraltowska S, Wierzbicka A, Wozniak W, Heller R, Eisenwinder S, Guziewicz E. Crystal Lattice Recovery and Optical Activation of Yb Implanted into β-Ga2O3. Materials. 2024; 17(16):3979. https://doi.org/10.3390/ma17163979

Chicago/Turabian StyleSarwar, Mahwish, Renata Ratajczak, Vitalii Yu. Ivanov, Sylwia Gieraltowska, Aleksandra Wierzbicka, Wojciech Wozniak, René Heller, Stefan Eisenwinder, and Elżbieta Guziewicz. 2024. "Crystal Lattice Recovery and Optical Activation of Yb Implanted into β-Ga2O3" Materials 17, no. 16: 3979. https://doi.org/10.3390/ma17163979