Enhanced Multifaceted Properties of Nanoscale Metallic Multilayer Composites

Abstract

1. Introduction

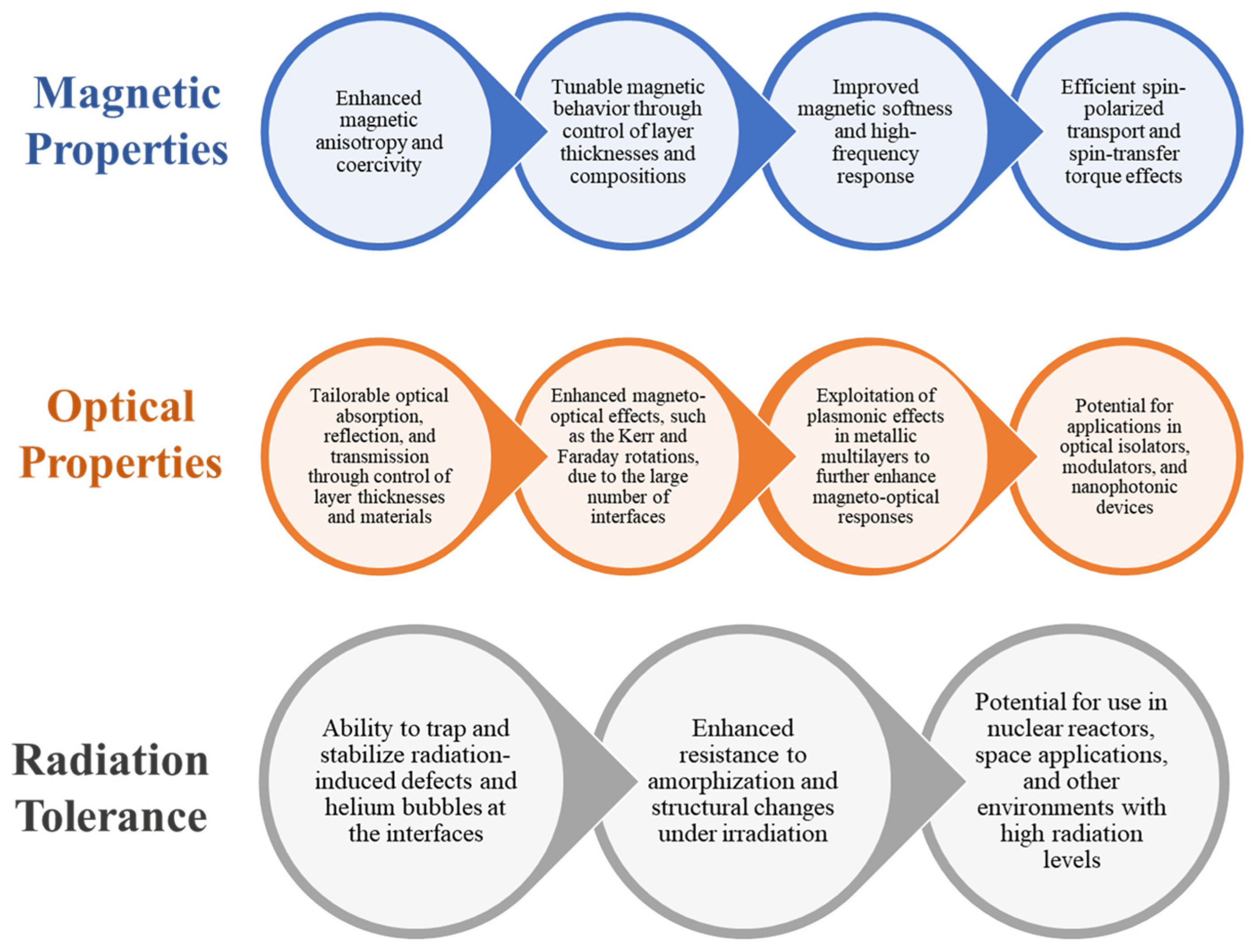

1.1. Outline of Multifunctional Properties

- (i)

- Reducing the repeat layer spacing to the nanoscale results in an extremely high density of heterophase interfaces, enhancing radiation resistance and facilitating the development of ultra-high-strength V-graphene nanolayers for nuclear structural applications [15];

- (ii)

- NMMCs can also be engineered to reduce radiation-induced crystalline defects, which leads to improved radiation tolerance, and they can be used in the production of amorphous/crystalline composites with greatly improved radiation tolerance [15];

- (iii)

- In the case of thermal properties:

- (i)

- Thermal barrier coatings, heat exchangers, and other high-temperature components have been developed using NMMCs due to their excellent thermal stability [18].

- (ii)

- NMMCs have a high thermal conductivity, which makes them attractive for thermal management applications. They are used to produce thermal interface materials, heat sinks, and other thermal management devices [19].

- Regarding the electrical properties of NMMCs:

- (i)

- The development of electrical contacts, interconnects, and other electrical components can utilize their high electrical conductivity [1].

- (ii)

- NMMCs can be tailored to manifest specific electrical resistance values, which makes them ideal for various electrical applications, such as resistors, strain gauges, and other electrical components [1].

- (i)

- It provides a comprehensive review of the existing literature on NMMCs, summarizing findings related to their magnetic, optical, radiation tolerance, thermal, and electrical properties.

- (ii)

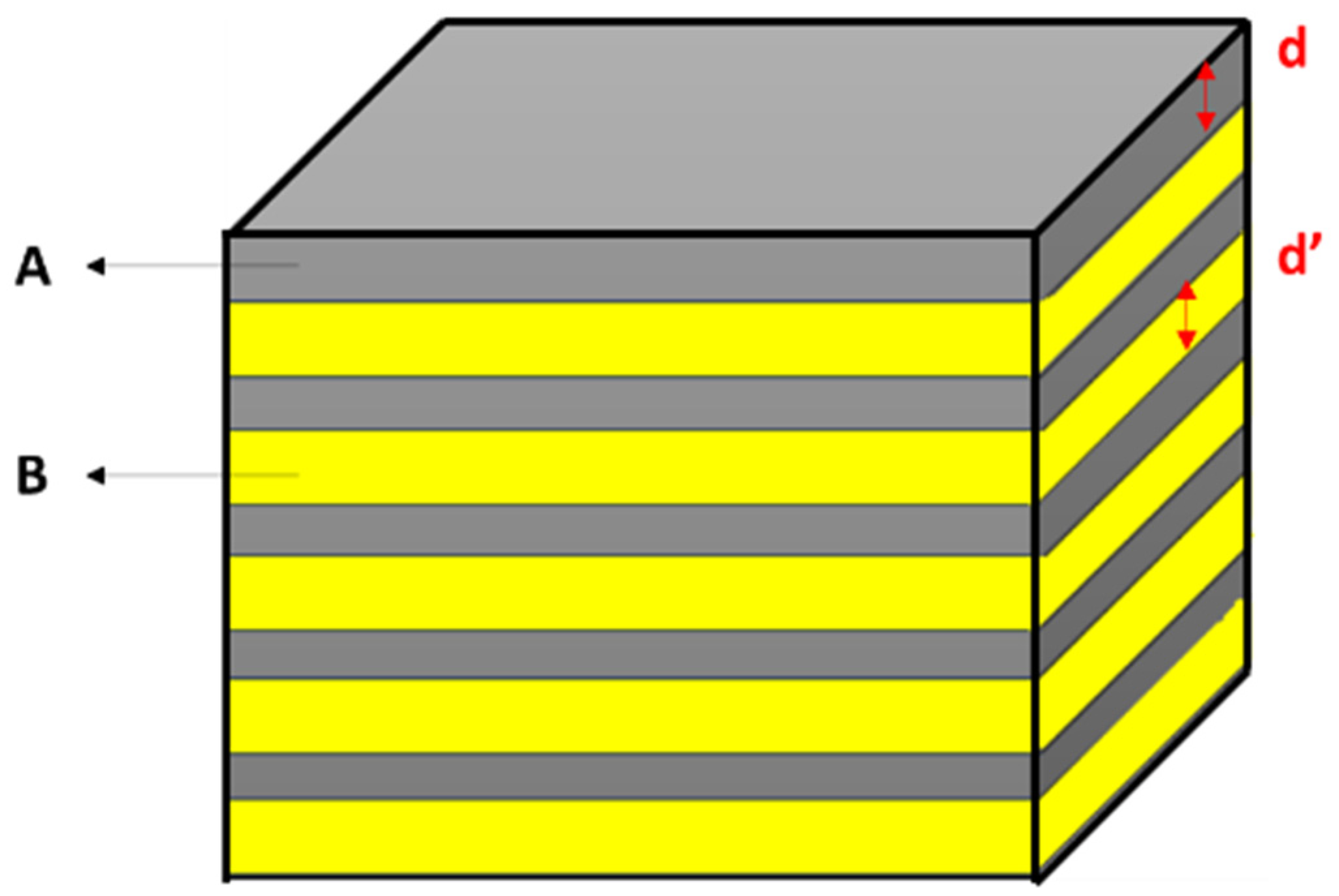

- The paper emphasizes how precisely controlling layer thicknesses and interfaces in these composites can achieve remarkable performance enhancements. This level of control allows for tuning their properties to a great extent.

- (iii)

- It discusses the underlying mechanisms responsible for the exceptional properties of NMMCs, providing insights into future research directions in this rapidly evolving field.

- (iv)

- This study covers other phenomena of interest, such as thermal stability studies, self-propagating reactions, and the progression from nanomultilayers to amorphous and/or crystalline alloys.

- (v)

- It discusses challenges and future perspectives relating to the design and implementation of nanomaterials for advanced technological applications.

| Properties | Material | Method | Key Results | Ref. |

|---|---|---|---|---|

| Magnetic | Epitaxial symmetric (Fe/Ni)fcc001 multilayers | Sputter deposited | Enhanced magnetic coercivity by 30% compared to bulk materials | [20] |

| Fe/Cu multilayers | Prepared under high vacuum conditions | Enhanced magnetic properties due to exchange coupling between layers | [21] | |

| Fe/Fe-N multilayered films | Sputter deposited | Improved soft magnetic properties | [22] | |

| Fe/Cu-N multilayered films | Sputter deposited | The oscillations of the in-plane saturation field, coercive force, and remanence ratio | [22] | |

| Cu/Fe multilayers | DC-magnetron sputtering | Change in magnetic behavior with the evolution from multilayer to island structures rather than the formation of a nonmagnetic FCC-Fe phase | [23] | |

| Fe-Ni/Cu | DC-magnetron sputtering | Fe-Ni/Cu multilayers exhibit alternate ferromagnetic and antiferromagnetic coupling | [24] | |

| Optical | Au/Ag nanocomposite clusters | Thermal annealing | Tunable plasmonic response in the visible spectrum with high reflectance efficiency | [25] |

| Ag/Au bilayer thin films | Electron beam deposition | By adjusting the mass–thickness ratio between Au and Ag, bilayer films’ spectral dispersion of the effective refractive index can be tuned | [26] | |

| A multilayer stack composite of alternating layers of Ag and TiO2 | Sputtering | The transmission decreases as the number of multilayer pairs increases due to metal absorption | [27] | |

| Radiation tolerance | Bulk nanolayered Cu/Nb composites | Accumulative roll bonding | Improved resistance to radiation-induced damage with minimal structural degradation | [28] |

| Nanometric Cr/Ta multilayer | Physical vapor deposition | This coating showed an extremely high radiation tolerance | [29] | |

| Cu/V, Cu/Mo, Fe/W, and Al/Nb nanostructured metallic multilayers | Sputtering | He can be stored in extremely high concentrations in nanolayer composites; by encouraging the recombination of point defects of the opposite type, layer interfaces lessen lattice distortion, swelling, and accumulative defect density; interfaces also significantly reduce radiation hardening | [30] | |

| Thermal | Al/Cu multilayer composite | Repeated hydrostatic extrusion process | High thermal conductivity and low coefficient of thermal expansion for efficient heat dissipation applications | [31] |

| Multilayered Cu mesh/AZ31 Mg foil composites | Diffusion bonding | The α-Mg region and intermetallic compounds form a continuous film-like structure that contributes significantly to heat conduction, making it useful for designing and creating Mg matrix composites with high thermal conductivity | [32] | |

| Al/Cu laminated multilayered metal composites | Explosion welding and heat treatment | The thermal resistance of multilayered Al/Cu composites is enhanced by thin Cu layers and a high-volume fraction of intermetallics | [33] | |

| Multilayered Al/Cu metal matrix composite | Cold roll bonding and accumulative roll bonding | The thermal conductivity from the Al layer to the Cu layer increased with an increase in copper content, demonstrating the good conductance of the Al/Cu interface and copper’s constituent parts | [34] | |

| Electrical | Cu/Nb multilayer | Sputtering | Enhanced electrical conductivity attributed to electron scattering at interfaces | [35] |

| Multilayered metallic thin films | Sputtering | Electrical conductivity due to their enhanced interactions at the interfaces between different metals | [36] | |

| Ni/Pt and Co/Au25Cu75 multilayered system | Sputtering | These multilayers show a similar type of anomaly in electrical resistivity near a certain temperature, with a deep minimum in dρ/dT, reversible under temperature cycling | [37] | |

| Cu/Nb composites with continuous laminated structure | Accumulative roll bonding | The nanolaminated Cu/Nb composites retained excellent electrical conductivity | [38] |

1.2. Motivation

2. Magnetic NMMCs

2.1. Magnetism at the Nanoscale

2.2. Magnetic Multilayer Composites

3. Optical NMMCs

- (i)

- Promote the adhesion of metal layers to their substrates;

- (ii)

- Increase the mechanical hardness of soft plasmonic metal layers;

- (iii)

- Improve the morphology of metal layers by “filling the pores” between the ultrathin metal nanoislands;

- (iv)

- Potentially smoothing the interface roughness of the ultrathin metal layers [86].

3.1. Light–Matter Interaction at the Nanoscale

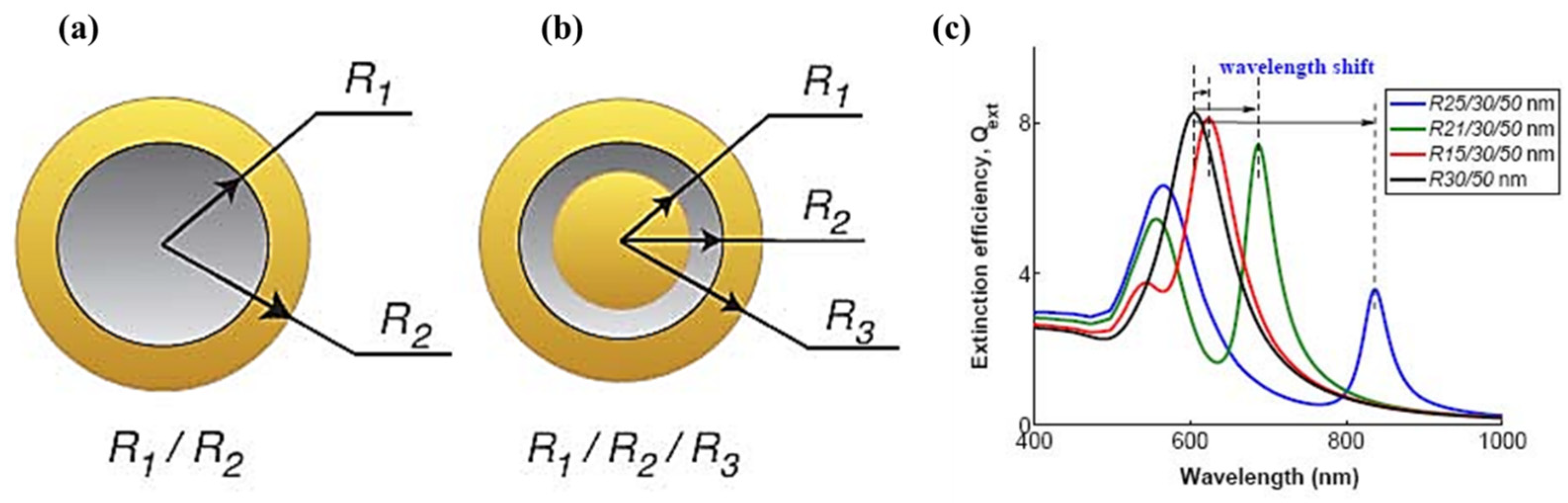

3.2. Plasmonic Effects in Multilayer Composites

- (i)

- (ii)

- (iii)

- Fano resonance and giant field enhancement [96];

- (iv)

- (v)

4. Thermal NMMCs

4.1. Thermal Conductivity in Multilayer Composites

4.2. Transport Mechanisms of Phonon

5. Electrical NMMCs

5.1. Conductivity in Multilayer Composites

- (i)

- Increasing the number of interfaces: the large number of interfaces in NMMCs can lead to enhanced electron scattering and improved electrical conductivity;

- (ii)

- Controlling the layer thickness: the thickness of the individual layers in NMMs can be precisely controlled, which can lead to improved electrical conductivity [1];

- (iii)

- Using conductive nanomaterials: conductive nanomaterials, such as silver nanowires, can be incorporated into NMMCs to enhance their electrical conductivity [117];

- (iv)

- Fine-tuning the sheet resistance: the electrical conductivity of NMMCs can be fine-tuned by adjusting the number of deposition cycles [118].

5.2. Quantum Size Effects on Electrical Conductivity

6. Radiation Tolerance NMMCs

- (i)

- Enhanced durability: coatings with high radiation tolerance can protect underlying materials and components from degradation and damage caused by radiation exposure, thereby extending their operational lifespan [29];

- (ii)

- Improved reliability: by withstanding radiation, multilayer coatings can contribute to the reliability and stability of critical components, reducing the need for frequent maintenance and replacement;

- (iii)

- Radiation shielding: high radiation-tolerant coatings can serve as effective barriers against harmful radiation, safeguarding sensitive instruments and equipment from its detrimental effects [30];

- (iv)

- Versatile applications: these coatings can find applications in diverse fields, including aerospace, nuclear technology, medical devices, and particle accelerators, where exposure to radiation is a concern [30].

6.1. Radiation Tolerance in Multilayer Composites

6.2. Potential Applications of Radiation Tolerance in Nanoscale Multilayer Composites

- (i)

- Radiation shielding: NMMCs can serve as effective barriers against harmful radiation, safeguarding sensitive instruments and equipment from its detrimental effects [30];

- (ii)

- Nuclear technology: radiation-tolerant NMMCs can be used in nuclear reactors and other nuclear technology applications to enhance the durability and reliability of critical components [30];

- (iii)

- Space: the ability of radiation-tolerant NMMCs to withstand and mitigate the effects of radiation exposure is crucial for ensuring the longevity and performance of sensitive equipment and components in space;

- (iv)

- High-energy physics facilities: radiation-tolerant NMMCs can be used in high-energy physics facilities to protect sensitive detectors and other equipment from radiation damage.

7. Conclusions

Future Directions

- (i)

- Advanced synthesis methods: continued research and development of advanced synthesis methods, such as physical vapor deposition technologies like magnetron sputtering, will enable the precise control and fabrication of metallic-based structures with nanoscaled layer dimensions.

- (ii)

- Enhanced material behaviors: further exploration of the enhanced material behaviors exhibited by NMMCs, with a focus on tailoring their properties to meet specific application requirements in diverse fields.

- (iii)

- Multifunctional coatings: advancement in the development of multifunctional coatings, particularly in the optical domain, leveraging the promising attributes of NMMCs for durable and transparent multifunctional coatings.

- (iv)

- Radiation tolerance studies: continued research into the radiation tolerance properties of NMMCs, with a focus on understanding and enhancing their ability to withstand radiation damage, particularly in applications related to nuclear technology, space, and high-energy physics facilities.

- (v)

- Mechanical and thermal properties: further investigations into the mechanical, thermal conductivity, and thermal stability properties of NMMCs are needed to expand their potential applications in areas requiring high-strength and thermally stable materials.

- (vi)

- Characterization techniques: advancements in characterization techniques, such as X-rays, enable comprehensive analysis and understanding of the properties and behaviors of NMMCs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sáenz-Trevizo, A.; Hodge, A.M. Nanomaterials by Design: A Review of Nanoscale Metallic Multilayers. Nanotechnology 2020, 31, 292002. [Google Scholar] [CrossRef]

- Zhou, Q.; Ren, Y.; Du, Y.; Hua, D.; Han, W. Cracking and Toughening Mechanisms in Nanoscale Metallic Multilayer Films: A Brief Review. Appl. Sci. 2018, 8, 1821. [Google Scholar] [CrossRef]

- Nasim, M.; Li, Y.; Wen, M.; Wen, C. A Review of High-Strength Nanolaminates and Evaluation of Their Properties. J. Mater. Sci. Technol. 2020, 50, 215–244. [Google Scholar] [CrossRef]

- Péter, L.; Bakonyi, I. Electrodeposition and Properties of Nanoscale Magnetic/Non-Magnetic Metallic Multilayer Films. In Electrocrystallization in Nanotechnology; Wiley: Hoboken, NJ, USA, 2007; pp. 242–260. [Google Scholar]

- Antón, R.L.; González, J.A.; Andrés, J.P.; Svalov, A.V.; Kurlyandskaya, G.V. Structural and Magnetic Properties of Ni0.8Fe0.2/Ti Nanoscale Multilayers. Nanomaterials 2018, 8, 780. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Wang, Q.; Attarilar, S. A Comprehensive Review of Magnesium-Based Alloys and Composites Processed by Cyclic Extrusion Compression and the Related Techniques. Prog. Mater. Sci. 2023, 131, 101016. [Google Scholar] [CrossRef]

- Armstrong, S.R.; Du, J.; Baer, E. Co-Extruded Multilayer Shape Memory Materials: Nano-Scale Phenomena. Polymer 2014, 55, 626–631. [Google Scholar] [CrossRef]

- Lega, P.; Koledov, V.; Orlov, A.; Kuchin, D.; Frolov, A.; Shavrov, V.; Martynova, A.; Irzhak, A.; Shelyakov, A.; Sampath, V.; et al. Composite Materials Based on Shape-Memory Ti 2 NiCu Alloy for Frontier Micro- and Nanomechanical Applications. Adv. Eng. Mater. 2017, 19, 1700154. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Wang, Q. Accumulative Roll-Bonding of Aluminum Alloys and Composites: An Overview of Properties and Performance. J. Mater. Res. Technol. 2022, 19, 4381–4403. [Google Scholar] [CrossRef]

- Kelly, K.L.; Coronado, E.; Zhao, L.L.; Schatz, G.C. The Optical Properties of Metal Nanoparticles: The Influence of Size, Shape, and Dielectric Environment. J. Phys. Chem. B 2003, 107, 668–677. [Google Scholar] [CrossRef]

- Chen, Y.-A.; Naidu, S.V.; Luo, Z.; Chang, C.-H. Enhancing Optical Transmission of Multilayer Composites Using Interfacial Nanostructures. J. Appl. Phys. 2019, 126, 063101. [Google Scholar] [CrossRef]

- Abazari, A.M.; Safavi, S.M.; Rezazadeh, G.; Villanueva, L.G. Size Effects on Mechanical Properties of Micro/Nano Structures. arXiv 2015, arXiv:1508.01322. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, M.; Luo, B.; Wang, Q.; Attarilar, S. High-Performance Nanoscale Metallic Multilayer Composites: Techniques, Mechanical Properties and Applications. Materials 2024, 17, 2124. [Google Scholar] [CrossRef] [PubMed]

- Subedi, S.; Beyerlein, I.J.; LeSar, R.; Rollett, A.D. Strength of Nanoscale Metallic Multilayers. Scr. Mater. 2018, 145, 132–136. [Google Scholar] [CrossRef]

- Kim, Y.; Baek, J.; Kim, S.; Kim, S.; Ryu, S.; Jeon, S.; Han, S.M. Radiation Resistant Vanadium-Graphene Nanolayered Composite. Sci. Rep. 2016, 6, 24785. [Google Scholar] [CrossRef] [PubMed]

- Thibeault, S.A.; Kang, J.H.; Sauti, G.; Park, C.; Fay, C.C.; King, G.C. Nanomaterials for Radiation Shielding. MRS Bull. 2015, 40, 836–841. [Google Scholar] [CrossRef]

- Amini, M.; Azadegan, B.; Akbarzadeh, H.; Gharaei, R. Analysis of MoS2 and WS2 Nano-Layers Role on the Radiation Resistance of Various Cu/MS2/Cu and Cu/MS2@Cu@MS2/Cu Nanocomposites. Materialia 2022, 21, 101281. [Google Scholar] [CrossRef]

- You, C.; Xie, W.; Miao, S.; Liang, T.; Zeng, L.; Zhang, X.; Wang, H. High Strength, High Electrical Conductivity and Thermally Stable Bulk Cu/Ag Nanolayered Composites Prepared by Cross Accumulative Roll Bonding. Mater. Des. 2021, 200, 109455. [Google Scholar] [CrossRef]

- Aryal, A.; Bradicich, A.; Iverson, E.T.; Long, C.T.; Chiang, H.-C.; Grunlan, J.C.; Shamberger, P.J. Thermal Conductivity of Multilayer Polymer-Nanocomposite Thin Films. J. Appl. Phys. 2022, 132, 195104. [Google Scholar] [CrossRef]

- Frisk, A.; Ali, H.; Svedlindh, P.; Leifer, K.; Andersson, G.; Nyberg, T. Composition, Structure and Magnetic Properties of Ultra-Thin Fe/Ni Multilayers Sputter Deposited on Epitaxial Cu/Si(001). Thin Solid Films 2018, 646, 117–125. [Google Scholar] [CrossRef]

- Badia, F.; Fratucello, G.; Martinez, B.; Fiorani, D.; Labarta, A.; Tejada, J. Magnetic Properties of Fe/Cu Multilayers. J. Magn. Magn. Mater. 1991, 93, 425–428. [Google Scholar] [CrossRef]

- Ono, H.; Fujinaga, M.; Yonemoto, T.; Miyagawa, T.; Yamamoto, H. Magnetic Properties of Fe/Fe-N and Fe/Cu-N Multilayered Films Having Intermediate Layers Containing Nitrogen. IEEE Trans. Magn. 1995, 31, 795–799. [Google Scholar] [CrossRef]

- Lee, D.W.; Ryan, D.H.; Altounian, Z.; Kuprin, A. Structural and Magnetic Properties of Cu/Fe Multilayers. Phys. Rev. B 1999, 59, 7001–7009. [Google Scholar] [CrossRef]

- Zhou, S.M.; Zhai, H.R.; Hu, A.; Liu, Y.H.; Lu, M.; Xu, Y.B. Magnetic Properties of Fe-Ni/Cu Multilayers. J. Magn. Magn. Mater. 1993, 126, 298–299. [Google Scholar] [CrossRef]

- Ji, J.; Li, Z. Tunable Surface Plasmon Resonance Wavelengths Response from Au/Ag Nanocomposite System. Thin Solid Films 2023, 764, 139602. [Google Scholar] [CrossRef]

- Hsu, J.; Fuentes-Hernandez, C.; Ernst, A.R.; Hales, J.M.; Perry, J.W.; Kippelen, B. Linear and Nonlinear Optical Properties of Ag/Au Bilayer Thin Films. Opt. Express 2012, 20, 8629. [Google Scholar] [CrossRef]

- Subramania, G.; Fischer, A.J.; Luk, T.S. Optical Properties of Metal-Dielectric Based Epsilon near Zero Metamaterials. Appl. Phys. Lett. 2012, 101, 241107. [Google Scholar] [CrossRef]

- Han, W.; Demkowicz, M.J.; Mara, N.A.; Fu, E.; Sinha, S.; Rollett, A.D.; Wang, Y.; Carpenter, J.S.; Beyerlein, I.J.; Misra, A. Design of Radiation Tolerant Materials Via Interface Engineering. Adv. Mater. 2013, 25, 6975–6979. [Google Scholar] [CrossRef]

- Khodja, H.; Sall, M.; Loyer-Prost, M.; Cabet, C.; Billard, A.; Monnet, I. Radiation Tolerance of Multilayer Coating Revealed by IBA. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2019, 450, 215–219. [Google Scholar] [CrossRef]

- Zhang, X.; Fu, E.G.; Li, N.; Misra, A.; Wang, Y.-Q.; Shao, L.; Wang, H. Design of Radiation Tolerant Nanostructured Metallic Multilayers. J. Eng. Mater. Technol. 2012, 134, 041010. [Google Scholar] [CrossRef]

- Lee, T.-H.; Lee, Y.-J.; Park, K.-T.; Jeong, H.-G.; Lee, J.-H. Mechanical and Asymmetrical Thermal Properties of Al/Cu Composite Fabricated by Repeated Hydrostatic Extrusion Process. Met. Mater. Int. 2015, 21, 402–407. [Google Scholar] [CrossRef]

- Yao, F.; You, G.; Zeng, S.; Zhou, K.; Peng, L.; Ming, Y. Fabrication, Microstructure, and Thermal Conductivity of Multilayered Cu Mesh/AZ31 Mg Foil Composites. J. Mater. Res. Technol. 2021, 14, 1539–1550. [Google Scholar] [CrossRef]

- Trykov, Y.; Gurevich, L.; Pronichev, D.; Trunov, M. Influence of Strain-Hardened Zones and Intermetallic Layers of Explosion Welded and Heat Treated Al/Cu Laminated Metal Composites on the Evolution of Thermal Conductivity Coefficient. Mater. Sci. 2014, 20, 267–270. [Google Scholar] [CrossRef]

- Tayyebi, M.; Alizadeh, M. Thermal and Wear Properties of Al/Cu Functionally Graded Metal Matrix Composite Produced by Severe Plastic Deformation Method. J. Manuf. Process. 2023, 85, 515–526. [Google Scholar] [CrossRef]

- Fenn, M.; Petford-Long, A.; Donovan, P. Electrical Resistivity of Cu and Nb Thin Films and Multilayers. J. Magn. Magn. Mater. 1999, 198–199, 231–232. [Google Scholar] [CrossRef]

- Chen, C.X. Electrical Conductivity of Multi-Layered Metallic Thin Films. Appl. Phys. A Solids Surfaces 1986, 40, 37–40. [Google Scholar] [CrossRef]

- de Azevedo, M.M.P.; Almeida, B.G.; Amaral, V.S.; Sousa, J.B.; Freitas, P.P.; Krishnan, R. Anomalous Electrical Resistivity in Metallic Multilayer Systems and Interfacial Structural Changes. J. Magn. Magn. Mater. 1996, 156, 357–358. [Google Scholar] [CrossRef]

- Ding, C.; Xu, J.; Shan, D.; Guo, B.; Langdon, T.G. Sustainable Fabrication of Cu/Nb Composites with Continuous Laminated Structure to Achieve Ultrahigh Strength and Excellent Electrical Conductivity. Compos. Part B Eng. 2021, 211, 108662. [Google Scholar] [CrossRef]

- Chen, M.; Hao, Y.; Zhu, C.; Liu, S.; Liu, S.; Hu, X.; Li, X.; Wu, H.; Lu, X.; Qu, J. Efficient Exfoliation and Dispersion of Expanded Graphite through Dry Ice Explosion Synergized Shear Flow Field for High-Thermal Conductive NR/EG Composite Preparation in Large-Scale. Polymer 2024, 297, 126854. [Google Scholar] [CrossRef]

- Xue, N.; Li, W.; Shao, L.; Tu, Z.; Chen, Y.; Dai, S.; Ye, N.; Zhang, J.; Liu, Q.; Wang, J.; et al. Comparison of Cold-Sprayed Coatings of Copper-Based Composite Deposited on AZ31B Magnesium Alloy and 6061 T6 Aluminum Alloy Substrates. Materials 2023, 16, 5120. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Shaeri, M.H.; Gode, C.; Armoon, H.; Shamsborhan, M. The Synergistic Effect of Dilute Alloying and Nanostructuring of Copper on the Improvement of Mechanical and Tribological Response. Compos. Part B Eng. 2019, 164, 508–516. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Zhang, L.; Wang, Q.; Zhou, H.; Li, W. Damping Characterization and Its Underlying Mechanisms in CNTs/AZ91D Composite Processed by Cyclic Extrusion and Compression. Mater. Sci. Eng. A 2021, 821, 141605. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Zhang, L.; Wang, Q.; Zhou, H.; Li, W. Damping Performance of SiC Nanoparticles Reinforced Magnesium Matrix Composites Processed by Cyclic Extrusion and Compression. J. Magnes. Alloys 2021, 11, 1608–1617. [Google Scholar] [CrossRef]

- Li, M.; Guo, Q.; Chen, L.; Li, L.; Hou, H.; Zhao, Y. Microstructure and Properties of Graphene Nanoplatelets Reinforced AZ91D Matrix Composites Prepared by Electromagnetic Stirring Casting. J. Mater. Res. Technol. 2022, 21, 4138–4150. [Google Scholar] [CrossRef]

- Yin, S.; Du, Y.; Liang, X.; Xie, Y.; Xie, D.; Mei, Y. Surface Coating of Biomass-Modified Black Phosphorus Enhances Flame Retardancy of Rigid Polyurethane Foam and Its Synergistic Mechanism. Appl. Surf. Sci. 2023, 637, 157961. [Google Scholar] [CrossRef]

- Antony, R.; Jacob, J.A.E.; Fan, H.-X.; Li, W.; Li, W.-Y. 00215 Designing Composite Materials for Oxidative Desulfurization. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Zhang, C.; Khorshidi, H.; Najafi, E.; Ghasemi, M. Fresh, Mechanical and Microstructural Properties of Alkali-Activated Composites Incorporating Nanomaterials: A Comprehensive Review. J. Clean. Prod. 2023, 384, 135390. [Google Scholar] [CrossRef]

- Bakonyi, I.; Péter, L. Electrodeposited Multilayer Films with Giant Magnetoresistance (GMR): Progress and Problems. Prog. Mater. Sci. 2010, 55, 107–245. [Google Scholar] [CrossRef]

- Ennen, I.; Kappe, D.; Rempel, T.; Glenske, C.; Hütten, A. Giant Magnetoresistance: Basic Concepts, Microstructure, Magnetic Interactions and Applications. Sensors 2016, 16, 904. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Shen, Z.; Long, X.; Chen, C.; Qi, L.; Chao, X. Gaussian Filtering Method of Evaluating the Elastic/Elasto-Plastic Properties of Sintered Nanocomposites with Quasi-Continuous Volume Distribution. Mater. Sci. Eng. A 2023, 872, 145001. [Google Scholar] [CrossRef]

- Tang, X.; Zhu, S.; Wei, R.; Hu, L.; Yang, J.; Song, W.; Dai, J.; Zhu, X.; Sun, Y. Exchange Coupling and Improved Properties of the Multilayer CoFe2O4/La0.7Sr0.3MnO3 Thin Films. Compos. Part B Eng. 2020, 186, 107801. [Google Scholar] [CrossRef]

- Kurichenko, V.L.; Karpenkov, D.Y.; Degtyarenko, A.Y. Experimental and Micromagnetic Investigation of Texture Influence on Magnetic Properties of Anisotropic Co/Co3O4 Exchange-Bias Composites. J. Magn. Magn. Mater. 2023, 565, 170232. [Google Scholar] [CrossRef]

- Nandwana, V.; Zhou, R.; Mohapatra, J.; Kim, S.; Prasad, P.V.; Liu, J.P.; Dravid, V.P. Exchange Coupling in Soft Magnetic Nanostructures and Its Direct Effect on Their Theranostic Properties. ACS Appl. Mater. Interfaces 2018, 10, 27233–27243. [Google Scholar] [CrossRef] [PubMed]

- Dahal, J.N.; Neupane, D.; Mishra, S.R. Exchange-Coupling Behavior in SrFe12O19/La0.7Sr0.3MnO3 Nanocomposites. Ceramics 2019, 2, 100–111. [Google Scholar] [CrossRef]

- Slimani, Y.; Algarou, N.A.; Almessiere, M.A.; Sadaqat, A.; Vakhitov, M.G.; Klygach, D.S.; Tishkevich, D.I.; Trukhanov, A.V.; Güner, S.; Hakeem, A.S.; et al. Fabrication of Exchange Coupled Hard/Soft Magnetic Nanocomposites: Correlation between Composition, Magnetic, Optical and Microwave Properties. Arab. J. Chem. 2021, 14, 102992. [Google Scholar] [CrossRef]

- Li, Y.T.; Jiang, X.; Wang, X.T.; Leng, Y.X. Integration of Hardness and Toughness in (CuNiTiNbCr)Nx High Entropy Films through Nitrogen-Induced Nanocomposite Structure. Scr. Mater. 2024, 238, 115763. [Google Scholar] [CrossRef]

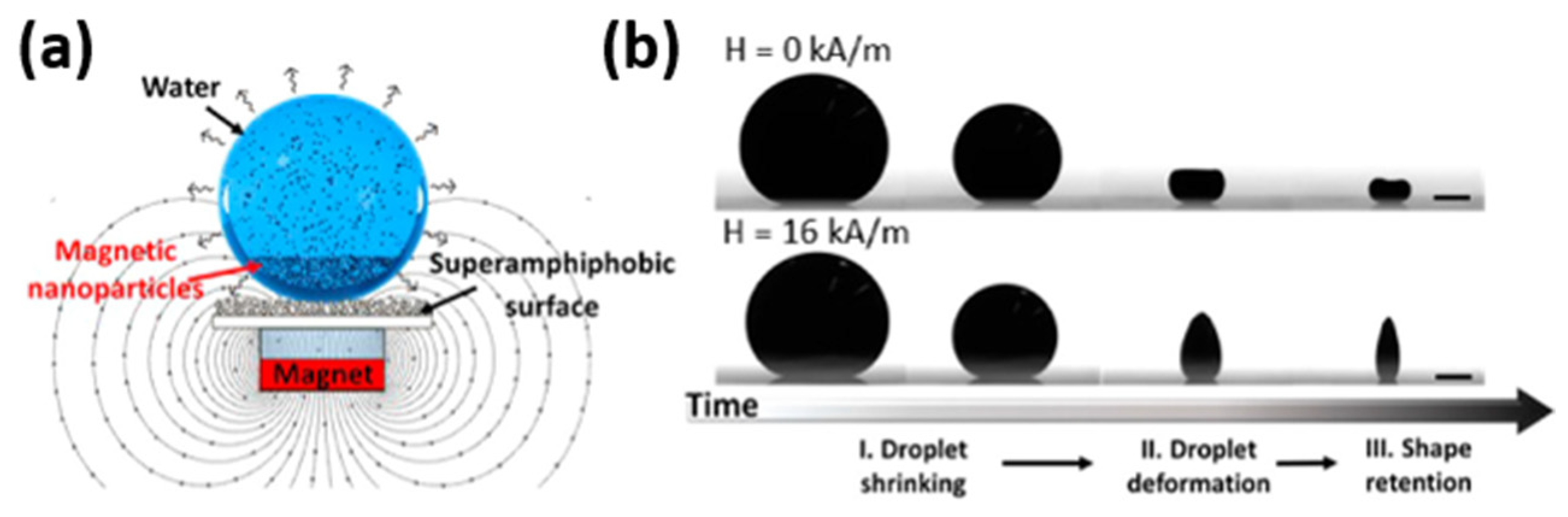

- Hu, M.; Butt, H.-J.; Landfester, K.; Bannwarth, M.B.; Wooh, S.; Thérien-Aubin, H. Shaping the Assembly of Superparamagnetic Nanoparticles. ACS Nano 2019, 13, 3015–3022. [Google Scholar] [CrossRef]

- Tartaj, P. Superparamagnetic Composites: Magnetism with No Memory. Eur. J. Inorg. Chem. 2009, 2009, 333–343. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Liu, G.; Wang, Q.; Jiang, H.; Ding, W.; Shang, Z.; Luo, L. Evaluation of Interface Structure and High-Temperature Tensile Behavior in Cu/Al8011/Al5052 Trilayered Composite. Mater. Sci. Eng. A 2020, 798, 140129. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Shaeri, M.H.; Taghiabadi, R.; Mozaffari, F.; Ebrahimi, M. Investigating the Combination Effect of Warm Extrusion and Multi-Directional Forging on Microstructure and Mechanical Properties of Al–Mg2Si Composites. Arch. Civ. Mech. Eng. 2020, 20, 33. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Liu, G.; Li, C.; Wang, Q.; Jiang, H.; Ding, W.; Su, F. Experimental and Numerical Analysis of Cu/Al8011/Al1060 Trilayered Composite: A Comprehensive Study. J. Mater. Res. Technol. 2020, 9, 14695–14707. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Liu, G.; Li, C.; Wang, Q.; Jiang, H.; Ding, W.; Su, F.; Shang, Z. Characteristic Investigation of Trilayered Cu/Al8011/Al1060 Composite: Interface Morphology, Microstructure, and in-Situ Tensile Deformation. Prog. Nat. Sci. Mater. Int. 2021, 31, 679–687. [Google Scholar] [CrossRef]

- Li, Y.T.; Chen, X.M.; Zeng, X.K.; Liu, M.; Jiang, X.; Leng, Y.X. Hard yet Tough and Self-Lubricating (CuNiTiNbCr)C High-Entropy Nanocomposite Films: Effects of Carbon Content on Structure and Properties. J. Mater. Sci. Technol. 2024, 173, 20–30. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, G.; Liu, F.; Xiang, T.; Zhou, J.; Li, L. Realizing Dendrite-Free Lithium Deposition with Three-Dimensional Soft-Rigid Nanofiber Interlayers. J. Colloid Interface Sci. 2024, 666, 131–140. [Google Scholar] [CrossRef]

- Qiu, J.; Xu, C.; Xu, X.; Zhao, Y.; Zhao, Y.; Zhao, Y.; Wang, J. Porous Covalent Organic Framework Based Hydrogen-Bond Nanotrap for the Precise Recognition and Separation of Gold. Angew. Chemie Int. Ed. 2023, 62, e202300459. [Google Scholar] [CrossRef]

- Zhao, C.; Kang, J.; Li, Y.; Wang, Y.; Tang, X.; Jiang, Z. Carbon-Based Stimuli-Responsive Nanomaterials: Classification and Application. Cyborg Bionic Syst. 2023, 4, 22. [Google Scholar] [CrossRef]

- Kang, J.; Liu, G.; Hu, Q.; Huang, Y.; Liu, L.-M.; Dong, L.; Teobaldi, G.; Guo, L. Parallel Nanosheet Arrays for Industrial Oxygen Production. J. Am. Chem. Soc. 2023, 145, 25143–25149. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.-M.; Yang, T.N.; Chen, L.Q.; Nan, C.W. Engineering Domain Structures in Nanoscale Magnetic Thin Films via Strain. J. Appl. Phys. 2013, 114, 164303. [Google Scholar] [CrossRef]

- Takamura, Y.; Chopdekar, R.V.; Scholl, A.; Doran, A.; Liddle, J.A.; Harteneck, B.; Suzuki, Y. Tuning Magnetic Domain Structure in Nanoscale La0.7Sr0.3MnO3 Islands. Nano Lett. 2006, 6, 1287–1291. [Google Scholar] [CrossRef] [PubMed]

- Bettinger, J.S.; Chopdekar, R.V.; Mesler, B.; Chain, D.; Doran, A.; Anderson, E.; Scholl, A.; Suzuki, Y. Tuning the Magnetic Domain Structure of Spin-Polarized Complex Oxide Nanostructures. MRS Proc. 2010, 1256, 1303. [Google Scholar] [CrossRef]

- Thi-Xuan Dang, D.; Barik, R.K.; Phan, M.-H.; Woods, L.M. Enhanced Magnetism in Heterostructures with Transition-Metal Dichalcogenide Monolayers. J. Phys. Chem. Lett. 2022, 13, 8879–8887. [Google Scholar] [CrossRef]

- Fang, K.Y.; Gong, L.H.; Jing, W.Q.; Fang, F. Nanoscale Domain Structure Evolution and Magnetoelectric Coupling for PMN-33PT/Terfenol-D Multiferroic Composite. Mater. Today Commun. 2019, 21, 100650. [Google Scholar] [CrossRef]

- Fang, F.; Jing, W.Q. Magnetic Field-Induced Ferroelectric Domain Structure Evolution and Magnetoelectric Coupling for [110]-Oriented PMN-PT/Terfenol-D Multiferroic Composites. AIP Adv. 2016, 6, 015008. [Google Scholar] [CrossRef]

- Fang, F.; Jing, W.; Zhou, Y.; Yang, W. In Situ Domain Structure Observation and Giant Magnetoelectric Coupling for PMN—PT /Terfenol-D Multiferroic Composites. J. Am. Ceram. Soc. 2014, 97, 2511–2516. [Google Scholar] [CrossRef]

- Nisticò, R.; Cesano, F.; Garello, F. Magnetic Materials and Systems: Domain Structure Visualization and Other Characterization Techniques for the Application in the Materials Science and Biomedicine. Inorganics 2020, 8, 6. [Google Scholar] [CrossRef]

- Soler, M.A.G. Hybrid Nanoscale Magnetic Composites. In Proceedings of the 8th Pacific Rim International Congress on Advanced Materials and Processing, Waikoloa, HI, USA, 4–9 August 2013; Springer: Cham, Switzerland, 2013; Volume 2, pp. 1709–1721. [Google Scholar] [CrossRef]

- Shukla, V. Observation of Critical Magnetic Behavior in 2D Carbon Based Composites. Nanoscale Adv. 2020, 2, 962–990. [Google Scholar] [CrossRef] [PubMed]

- Barman, A.; Mondal, S.; Sahoo, S.; De, A. Magnetization Dynamics of Nanoscale Magnetic Materials: A Perspective. J. Appl. Phys. 2020, 128, 170901. [Google Scholar] [CrossRef]

- Behrens, S. Preparation of Functional Magnetic Nanocomposites and Hybrid Materials: Recent Progress and Future Directions. Nanoscale 2011, 3, 877–892. [Google Scholar] [CrossRef] [PubMed]

- Inoue, J. GMR, TMR and BMR. In Nanomagnetism and Spintronics; Elsevier: Amsterdam, The Netherlands, 2009; pp. 15–92. [Google Scholar]

- Falub, C.V.; Bless, M.; Hida, R.; Meduňa, M.; Ammann, A. Innovative Soft Magnetic Multilayers with Enhanced In-Plane Anisotropy and Ferromagnetic Resonance Frequency for Integrated RF Passive Devices. AIP Adv. 2018, 8, 048002. [Google Scholar] [CrossRef]

- Makarova, L.A.; Alekhina, I.A.; Khairullin, M.F.; Makarin, R.A.; Perov, N.S. Dynamic Magnetoelectric Effect of Soft Layered Composites with a Magnetic Elastomer. Polymers 2023, 15, 2262. [Google Scholar] [CrossRef]

- Jan Kusinski, G.; Thomas, G. Microstructural Design of Nanomultilayers (from Steel to Magnetics). In Nano and Microstructural Design of Advanced Materials; Elsevier: Amsterdam, The Netherlands, 2003; pp. 81–91. [Google Scholar]

- Moruzzi, V.L.; Marcus, P.M. Giant Magnetoresistance in FeRh: A Natural Magnetic Multilayer. Phys. Rev. B 1992, 46, 14198–14200. [Google Scholar] [CrossRef]

- Hu, Y.; Fleming, R.C.; Drezek, R.A. Optical Properties of Gold-Silica-Gold Multilayer Nanoshells. Opt. Express 2008, 16, 19579. [Google Scholar] [CrossRef]

- Nur-E-Alam, M.; Rahman, M.M.; Basher, M.K.; Vasiliev, M.; Alameh, K. Optical and Chromaticity Properties of Metal-Dielectric Composite-Based Multilayer Thin-Film Structures Prepared by RF Magnetron Sputtering. Coatings 2020, 10, 251. [Google Scholar] [CrossRef]

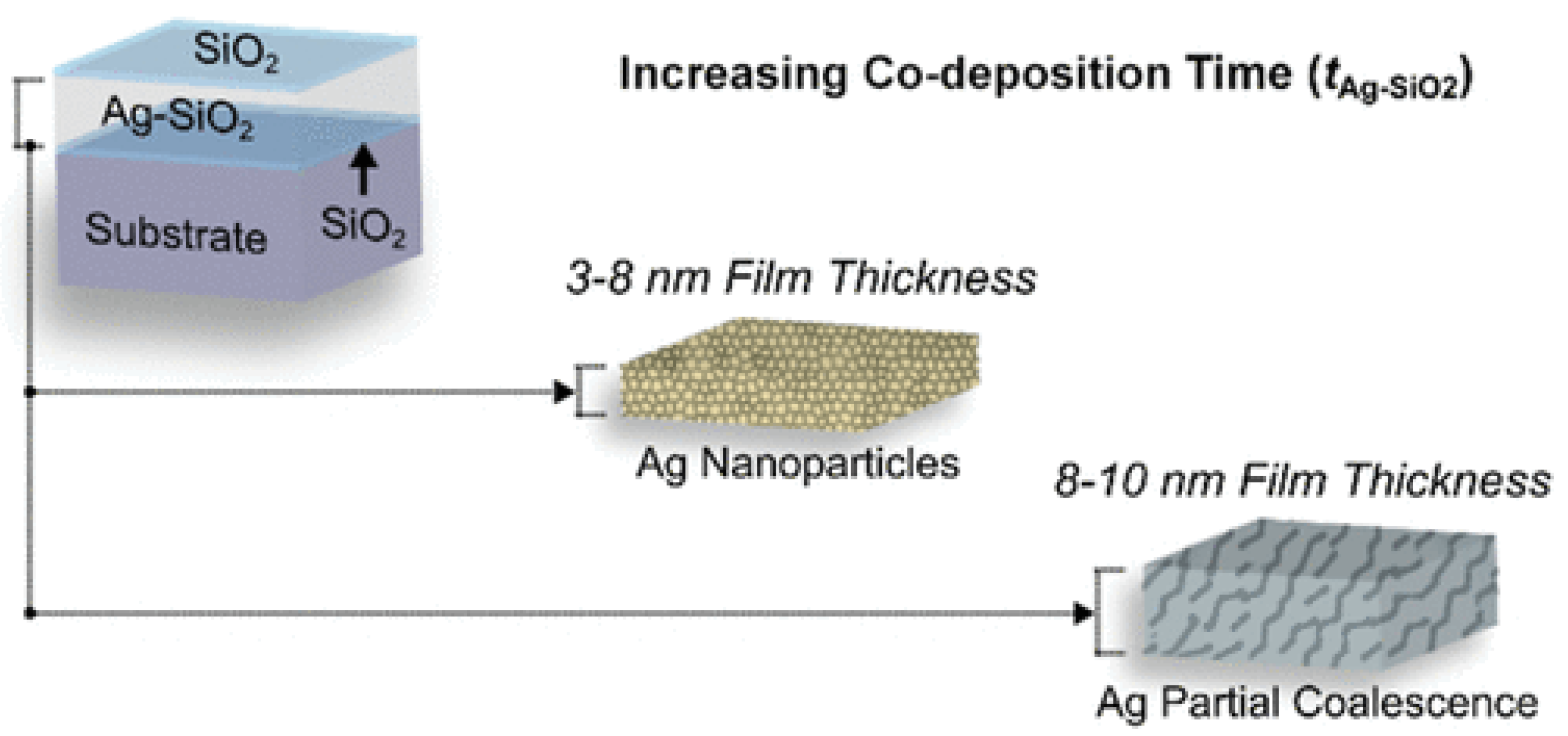

- Sun, L.; Grant, J.T.; Jones, J.G.; Murphy, N.R.; Vernon, J.P.; Stevenson, P.R. Tailoring the Optical Properties of Nanoscale-Thick Metal–Dielectric Ag–SiO2 Nanocomposite Films for Precision Optical Coating Integration. ACS Appl. Nano Mater. 2023, 6, 7704–7714. [Google Scholar] [CrossRef]

- Ramos, M.; Gadea, M.; Mañas-Valero, S.; Boix-Constant, C.; Henríquez-Guerra, E.; Díaz-García, M.A.; Coronado, E.; Calvo, M.R. Tunable, Multifunctional Opto-Electrical Response in Multilayer FePS3 /Single-Layer MoS2 van Der Waals p–n Heterojunctions. Nanoscale Adv. 2024, 6, 1909–1916. [Google Scholar] [CrossRef]

- Lienau, C.; Noginov, M.A.; Lončar, M. Light–Matter Interactions at the Nanoscale. J. Opt. 2014, 16, 110201. [Google Scholar] [CrossRef][Green Version]

- Rahmani, M.; Jagadish, C. Light–Matter Interactions on the Nanoscale. Beilstein J. Nanotechnol. 2018, 9, 2125–2127. [Google Scholar] [CrossRef]

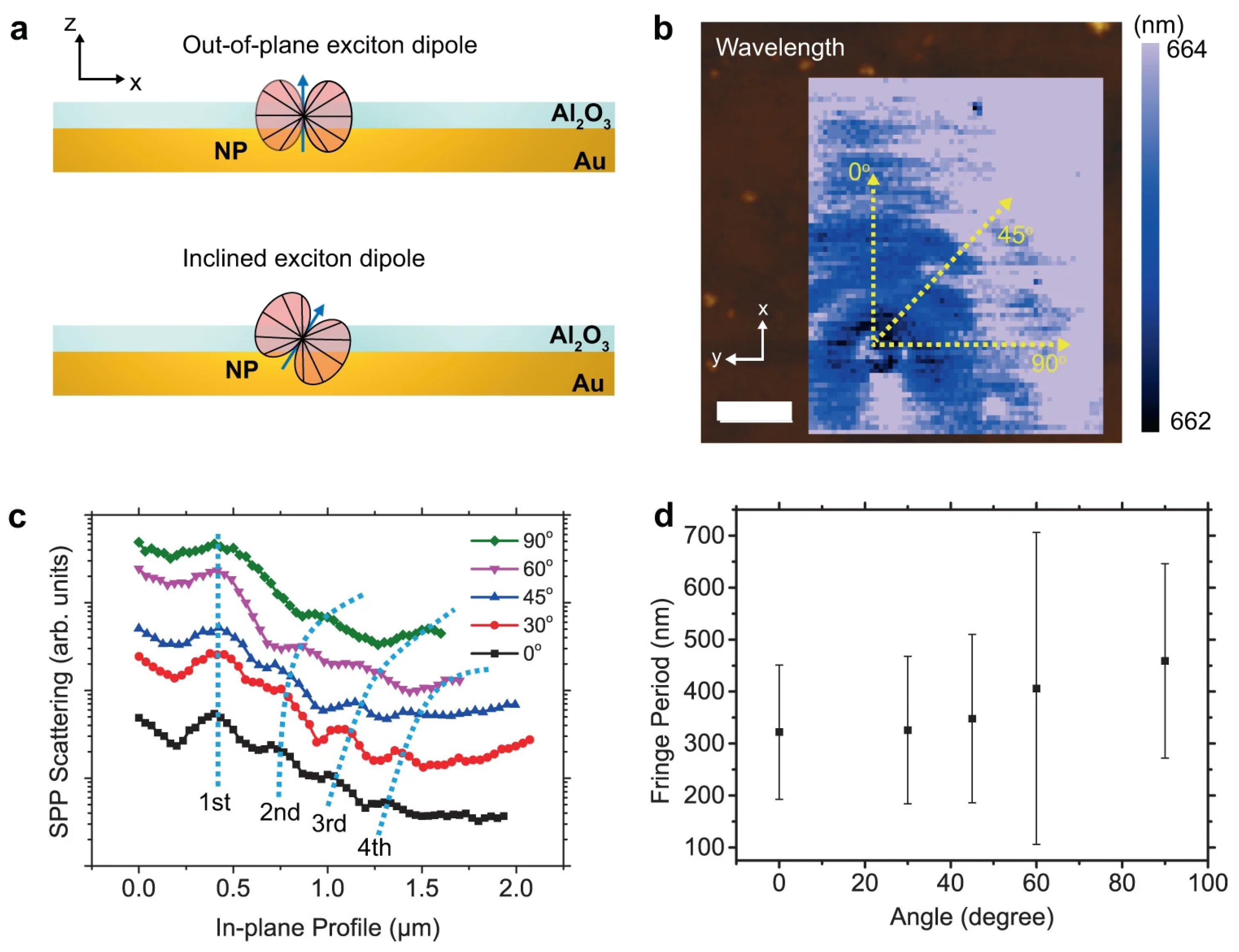

- Jo, K.; Marino, E.; Lynch, J.; Jiang, Z.; Gogotsi, N.; Darlington, T.P.; Soroush, M.; Schuck, P.J.; Borys, N.J.; Murray, C.B.; et al. Direct Nano-Imaging of Light-Matter Interactions in Nanoscale Excitonic Emitters. Nat. Commun. 2023, 14, 2649. [Google Scholar] [CrossRef]

- Neyer, T.; Schattschneider, P.; Bolton, J.P.R.; Botton, G.A. Plasmon Coupling and Finite Size Effects in Metallic Multilayers. J. Microsc. 1997, 187, 184–192. [Google Scholar] [CrossRef]

- Halas, N.J.; Lal, S.; Chang, W.-S.; Link, S.; Nordlander, P. Plasmons in Strongly Coupled Metallic Nanostructures. Chem. Rev. 2011, 111, 3913–3961. [Google Scholar] [CrossRef]

- Okamoto, K.; Tanaka, D.; Degawa, R.; Li, X.; Wang, P.; Ryuzaki, S.; Tamada, K. Electromagnetically Induced Transparency of a Plasmonic Metamaterial Light Absorber Based on Multilayered Metallic Nanoparticle Sheets. Sci. Rep. 2016, 6, 36165. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Gao, C.; Zeng, L.; Zhang, D.; Zhang, H. Investigating on the Electromagnetically Induced Absorption Metamaterial in the Terahertz Region Realized by the Multilayer Structure. Phys. B Condens. Matter 2022, 639, 413936. [Google Scholar] [CrossRef]

- Sekkat, Z.; Hayashi, S.; Nesterenko, D.V.; Rahmouni, A.; Refki, S.; Ishitobi, H.; Inouye, Y.; Kawata, S. Plasmonic Coupled Modes in Metal-Dielectric Multilayer Structures: Fano Resonance and Giant Field Enhancement. Opt. Express 2016, 24, 20080. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Peng, Y.; Yang, Y.; Li, Z.-Y. Plasmon-Enhanced Light–Matter Interactions and Applications. Npj Comput. Mater. 2019, 5, 45. [Google Scholar] [CrossRef]

- Mukherjee, S.; Chowdhury, R.K.; Karmakar, D.; Wan, M.; Jacob, C.; Das, S.; Ray, S.K. Plasmon Triggered, Enhanced Light–Matter Interactions in Au–MoS2 Coupled System with Superior Photosensitivity. J. Phys. Chem. C 2021, 125, 11023–11034. [Google Scholar] [CrossRef]

- Lo Sciuto, G.; Napoli, C.; Kowol, P.; Capizzi, G.; Brociek, R.; Wajda, A.; Słota, D. Multilayer Plasmonic Nanostructures for Improved Sensing Activities Using a FEM and Neurocomputing-Based Approach. Sensors 2022, 22, 7486. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, T.; Yuan, X.; Wang, Y.; Yue, X.; Wang, L.; Zhang, J.; Wang, J. Plasmonic Nanostructure Biosensors: A Review. Sensors 2023, 23, 8156. [Google Scholar] [CrossRef] [PubMed]

- Päivänranta, B.; Merbold, H.; Giannini, R.; Büchi, L.; Gorelick, S.; David, C.; Löffler, J.F.; Feurer, T.; Ekinci, Y. High Aspect Ratio Plasmonic Nanostructures for Sensing Applications. ACS Nano 2011, 5, 6374–6382. [Google Scholar] [CrossRef] [PubMed]

- Sui, M.; Kunwar, S.; Pandey, P.; Lee, J. Strongly Confined Localized Surface Plasmon Resonance (LSPR) Bands of Pt, AgPt, AgAuPt Nanoparticles. Sci. Rep. 2019, 9, 16582. [Google Scholar] [CrossRef] [PubMed]

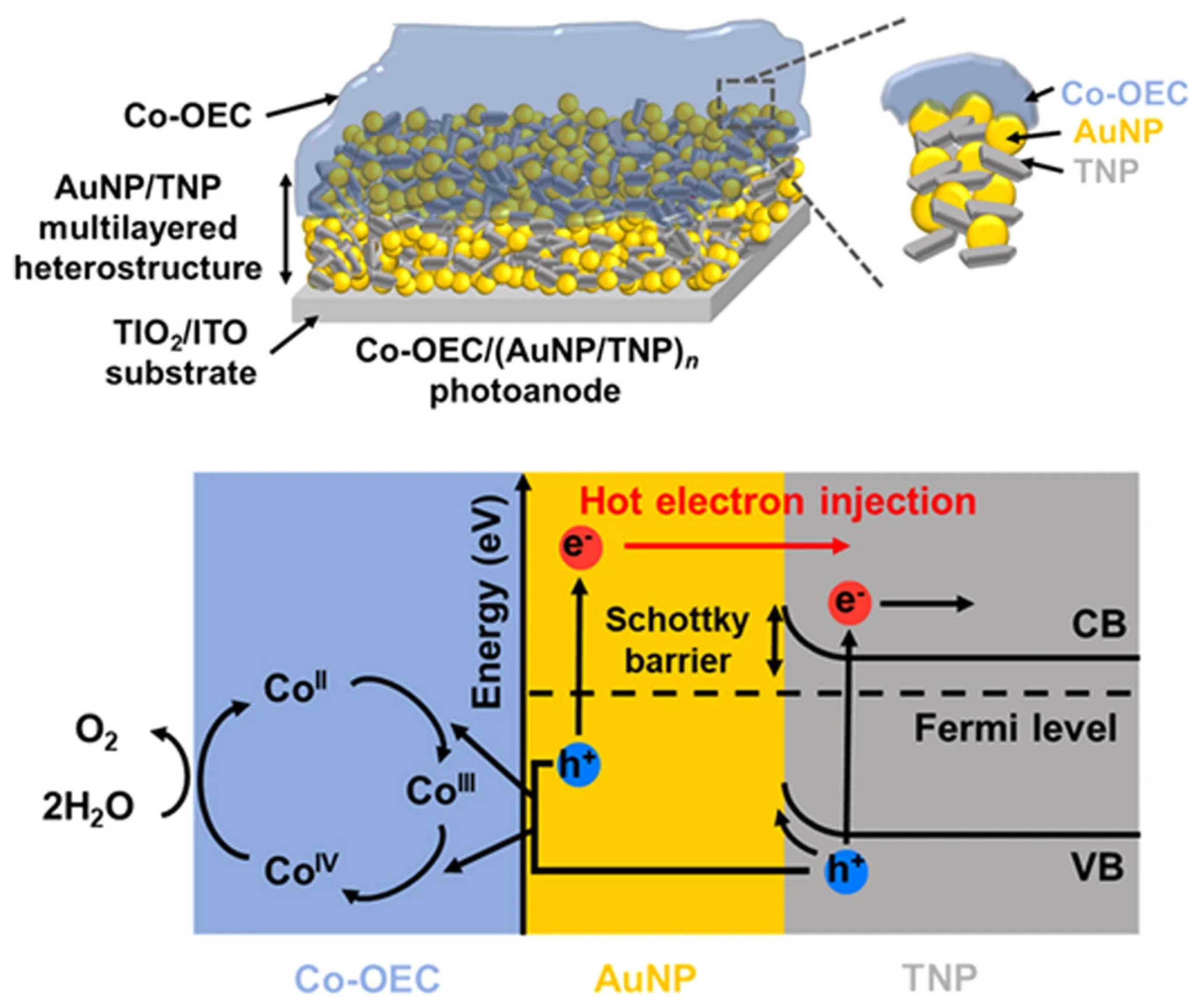

- Kim, J.; Son, H.Y.; Nam, Y.S. Multilayered Plasmonic Heterostructure of Gold and Titania Nanoparticles for Solar Fuel Production. Sci. Rep. 2018, 8, 10464. [Google Scholar] [CrossRef]

- Malhotra, A.; Kothari, K.; Maldovan, M. Enhancing Thermal Transport in Layered Nanomaterials. Sci. Rep. 2018, 8, 1880. [Google Scholar] [CrossRef]

- Feng, B.; Li, Z.; Zhang, X. Prediction of Size Effect on Thermal Conductivity of Nanoscale Metallic Films. Thin Solid Films 2009, 517, 2803–2807. [Google Scholar] [CrossRef]

- Dong, L.; Wei, G.; Cheng, T.; Tang, J.; Ye, X.; Hong, M.; Hu, L.; Yin, R.; Zhao, S.; Cai, G.; et al. Thermal Conductivity, Electrical Resistivity, and Microstructure of Cu/W Multilayered Nanofilms. ACS Appl. Mater. Interfaces 2020, 12, 8886–8896. [Google Scholar] [CrossRef] [PubMed]

- García-Pastor, F.A.; Montelongo-Vega, J.B.; Tovar-Padilla, M.V.; Cardona-Castro, M.A.; Alvarez-Quintana, J. Robust Metallic Nanolaminates Having Phonon-Glass Thermal Conductivity. Materials 2020, 13, 4954. [Google Scholar] [CrossRef] [PubMed]

- Lim, M.; Ordonez-Miranda, J.; Lee, S.S.; Lee, B.J.; Volz, S. Thermal-Conductivity Enhancement by Surface Electromagnetic Waves Propagating along Multilayered Structures with Asymmetric Surrounding Media. Phys. Rev. Appl. 2019, 12, 034044. [Google Scholar] [CrossRef]

- Miao, W.; Wang, M. Importance of Electron-Phonon Coupling in Thermal Transport in Metal/Semiconductor Multilayer Films. Int. J. Heat Mass Transf. 2023, 200, 123538. [Google Scholar] [CrossRef]

- Giri, A.; Walton, S.G.; Tomko, J.; Bhatt, N.; Johnson, M.J.; Boris, D.R.; Lu, G.; Caldwell, J.D.; Prezhdo, O.V.; Hopkins, P.E. Ultrafast and Nanoscale Energy Transduction Mechanisms and Coupled Thermal Transport across Interfaces. ACS Nano 2023, 17, 14253–14282. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Liu, F.; Hu, S.; Song, H.; Yang, S.; Jiang, H.; Wang, T.; Koh, Y.K.; Zhao, C.; Kang, F.; et al. Inelastic Phonon Transport across Atomically Sharp Metal/Semiconductor Interfaces. Nat. Commun. 2022, 13, 4901. [Google Scholar] [CrossRef]

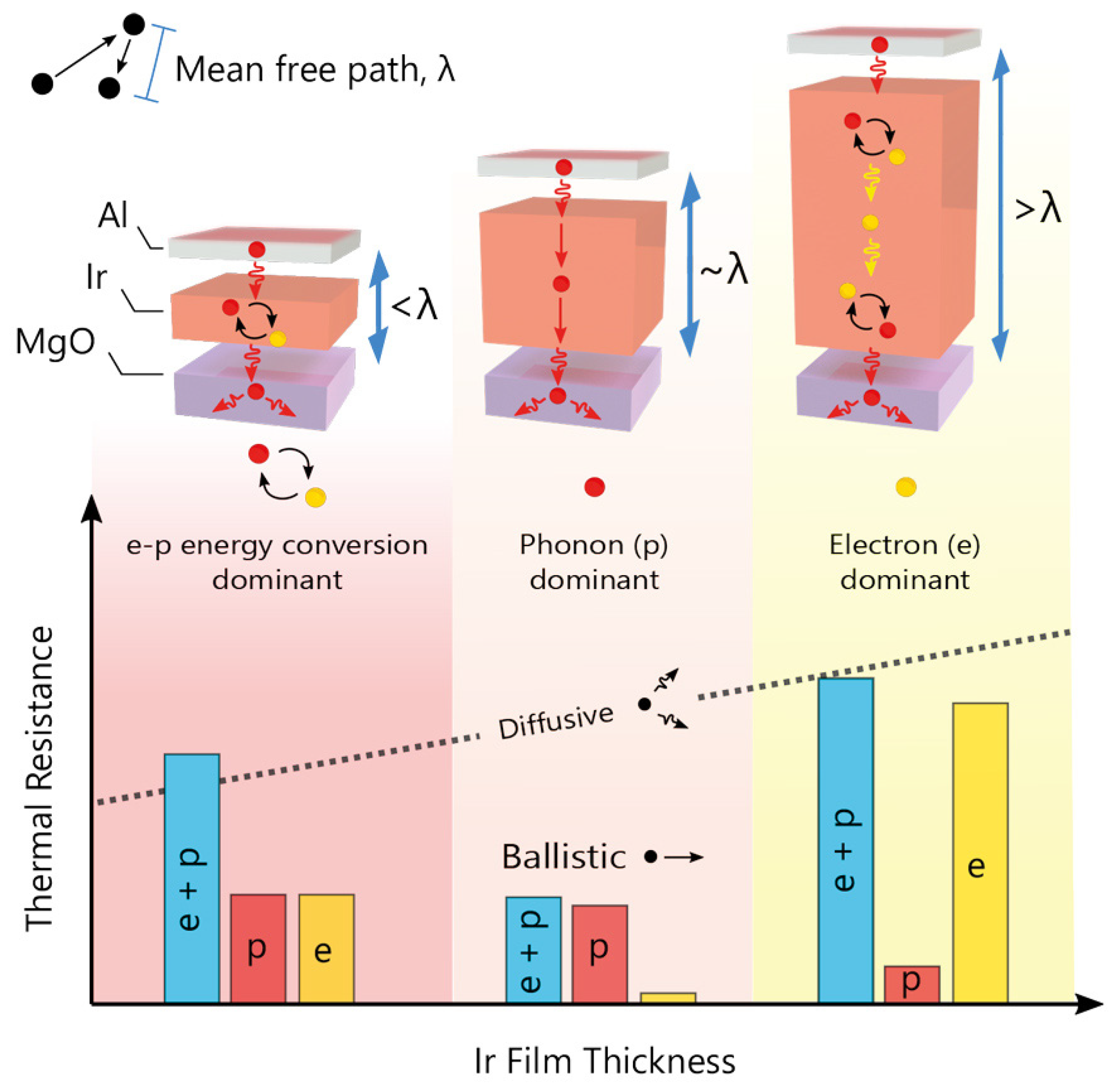

- Herzog, M.; von Reppert, A.; Pudell, J.; Henkel, C.; Kronseder, M.; Back, C.H.; Maznev, A.A.; Bargheer, M. Phonon-Dominated Energy Transport in Purely Metallic Heterostructures. Adv. Funct. Mater. 2022, 32, 2206179. [Google Scholar] [CrossRef]

- Perez, C. How Electrons and Phonons Promote Heat Transfer in Material Systems. Res. Outreach 2023, 200, 123538. [Google Scholar] [CrossRef]

- Xie, S.; Zhu, H.; Zhang, X.; Wang, H. A Brief Review on the Recent Development of Phonon Engineering and Manipulation at Nanoscales. Int. J. Extrem. Manuf. 2024, 6, 012007. [Google Scholar] [CrossRef]

- Ishibe, T.; Okuhata, R.; Kaneko, T.; Yoshiya, M.; Nakashima, S.; Ishida, A.; Nakamura, Y. Heat Transport through Propagon-Phonon Interaction in Epitaxial Amorphous-Crystalline Multilayers. Commun. Phys. 2021, 4, 153. [Google Scholar] [CrossRef]

- Misra, A.; Kung, H.; Embury, J.D. Preface to the Viewpoint Set on: Deformation and Stability of Nanoscale Metallic Multilayers. Scr. Mater. 2004, 50, 707–710. [Google Scholar] [CrossRef]

- Naghdi, S.; Rhee, K.; Hui, D.; Park, S. A Review of Conductive Metal Nanomaterials as Conductive, Transparent, and Flexible Coatings, Thin Films, and Conductive Fillers: Different Deposition Methods and Applications. Coatings 2018, 8, 278. [Google Scholar] [CrossRef]

- Runde, S.; Ahrens, H.; Wulff, H.; Helm, C.A. Stable Metal/Metal Hydroxide Multilayers with Controlled Nanoscale Thickness Prepared from Liquid Metal Droplets with Oxide Skin. J. Phys. Chem. C 2022, 126, 11254–11264. [Google Scholar] [CrossRef]

- Meyerovich, A.E.; Ponomarev, I.V. Quantum Size Effect in Conductivity of Multilayer Metal Films. Phys. Rev. B 2003, 67, 165411. [Google Scholar] [CrossRef]

- Zhang, X.-G.; Butler, W.H. Conductivity of Metallic Films and Multilayers. Phys. Rev. B 1995, 51, 10085–10103. [Google Scholar] [CrossRef]

- Macdonald, D.K.C.; Sarginson, K. Size Effect Variation of the Electrical Conductivity of Metals. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1950, 203, 223–240. [Google Scholar] [CrossRef]

- Li, N. Mechanical Properties and Radiation Tolerance of Metallic Multilayers. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2010. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebrahimi, M.; Luo, B.; Wang, Q.; Attarilar, S. Enhanced Multifaceted Properties of Nanoscale Metallic Multilayer Composites. Materials 2024, 17, 4004. https://doi.org/10.3390/ma17164004

Ebrahimi M, Luo B, Wang Q, Attarilar S. Enhanced Multifaceted Properties of Nanoscale Metallic Multilayer Composites. Materials. 2024; 17(16):4004. https://doi.org/10.3390/ma17164004

Chicago/Turabian StyleEbrahimi, Mahmoud, Bangcai Luo, Qudong Wang, and Shokouh Attarilar. 2024. "Enhanced Multifaceted Properties of Nanoscale Metallic Multilayer Composites" Materials 17, no. 16: 4004. https://doi.org/10.3390/ma17164004

APA StyleEbrahimi, M., Luo, B., Wang, Q., & Attarilar, S. (2024). Enhanced Multifaceted Properties of Nanoscale Metallic Multilayer Composites. Materials, 17(16), 4004. https://doi.org/10.3390/ma17164004