Analysis of the Effect of Layer Height on the Interlayer Bond in Self-Compacting Concrete Mix in Slab Elements

Abstract

1. Introduction

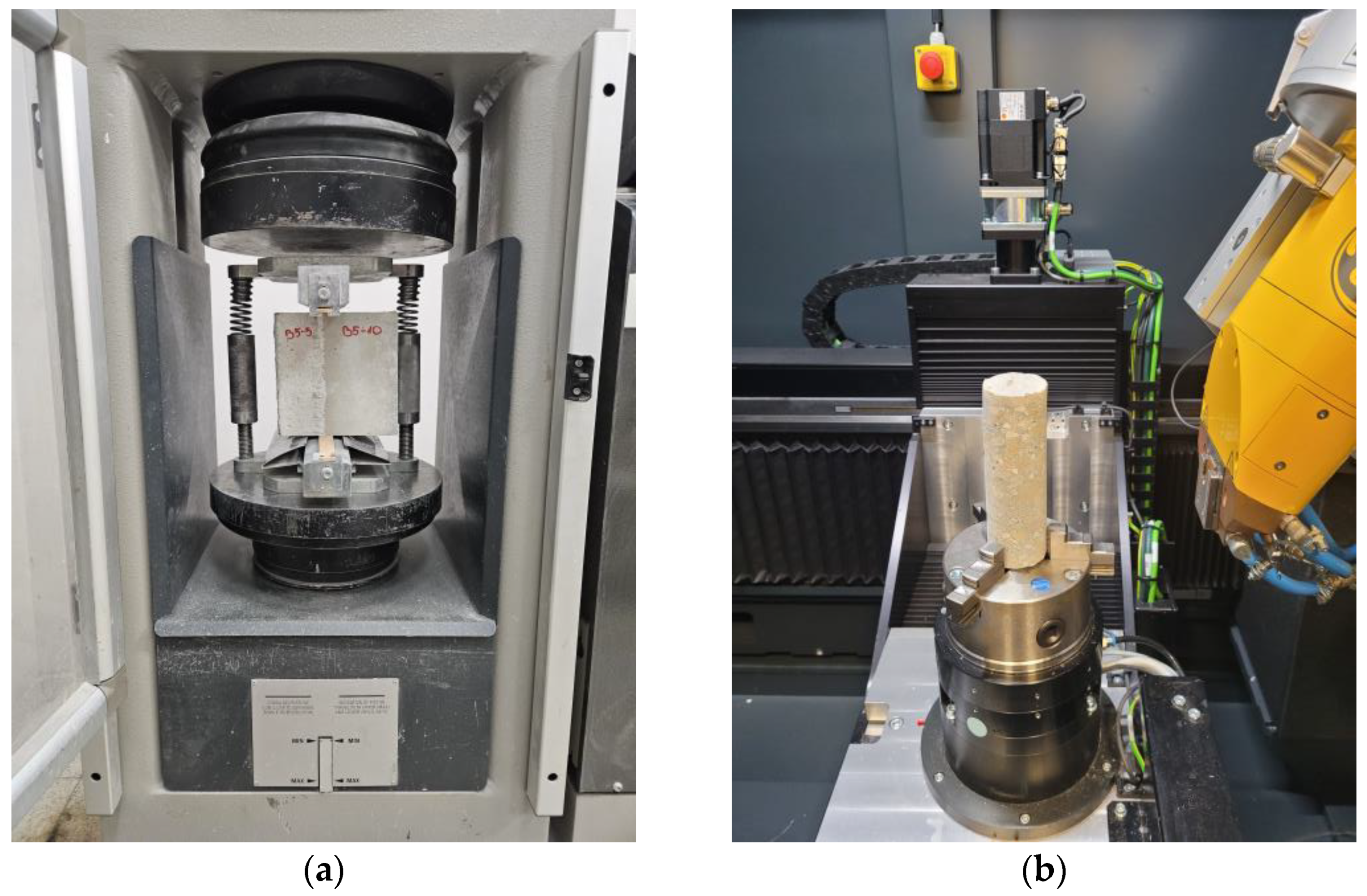

2. Materials and Methods

2.1. Concrete Mixture

2.2. Specimens and Basic Modules

2.3. Test Procedures

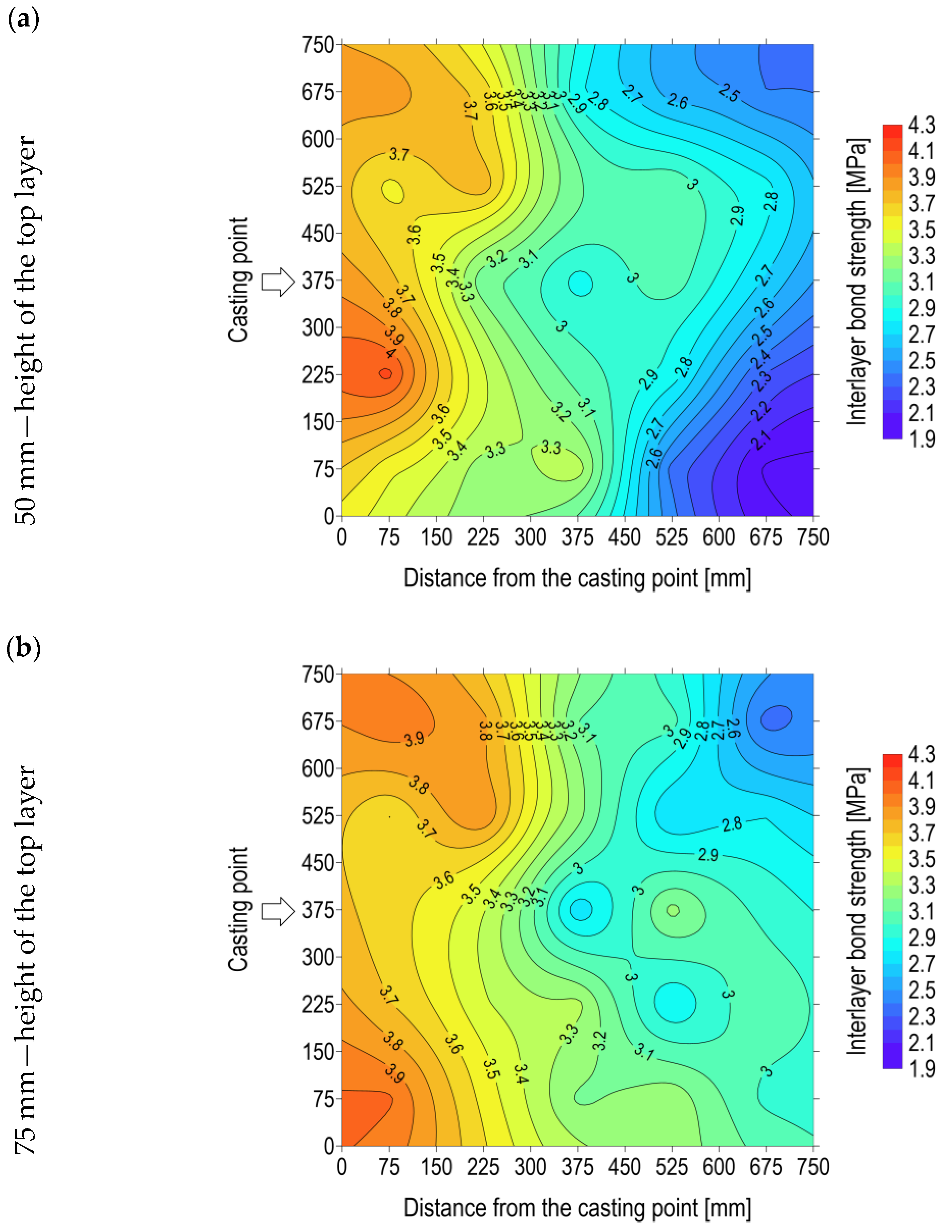

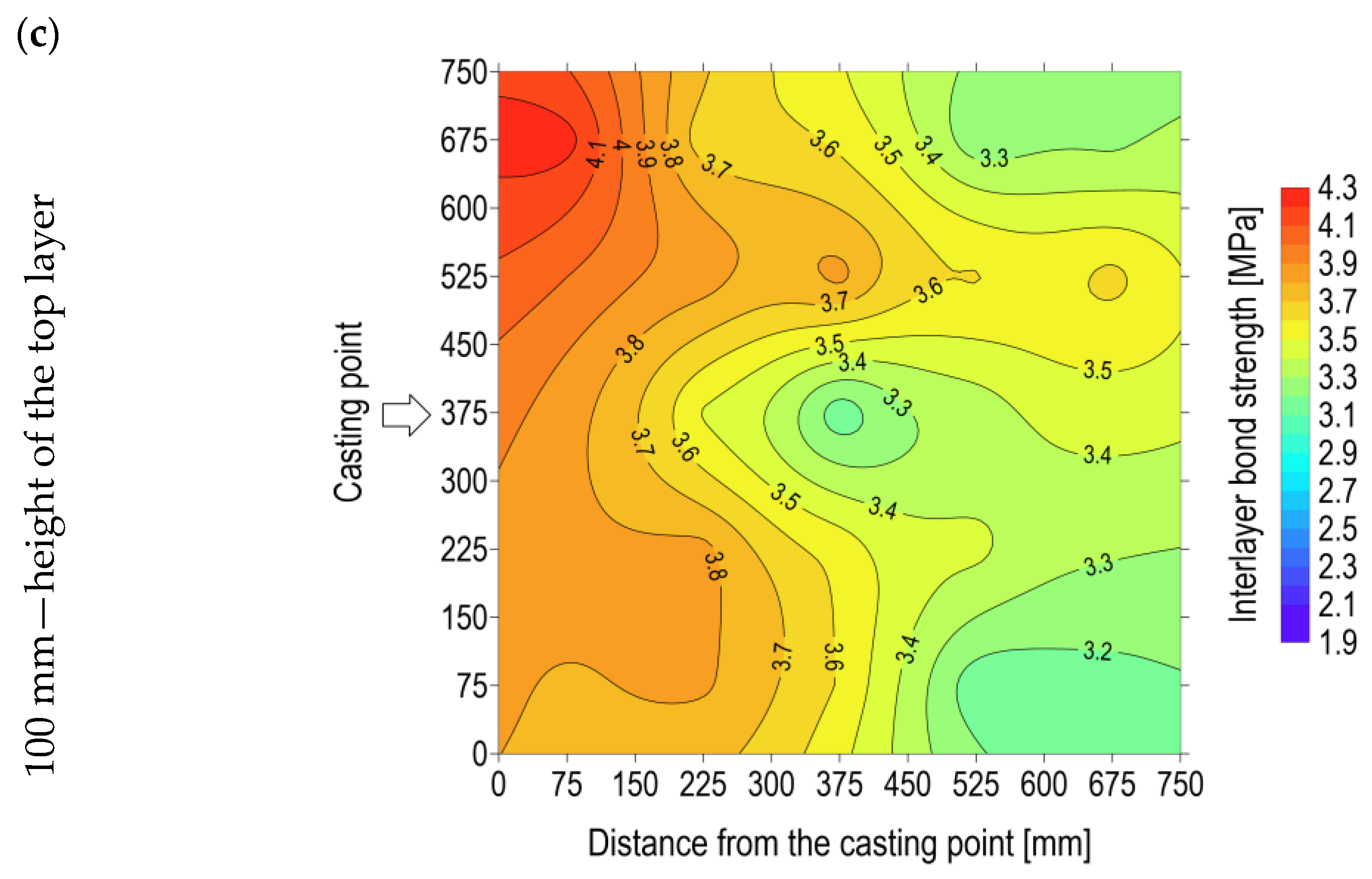

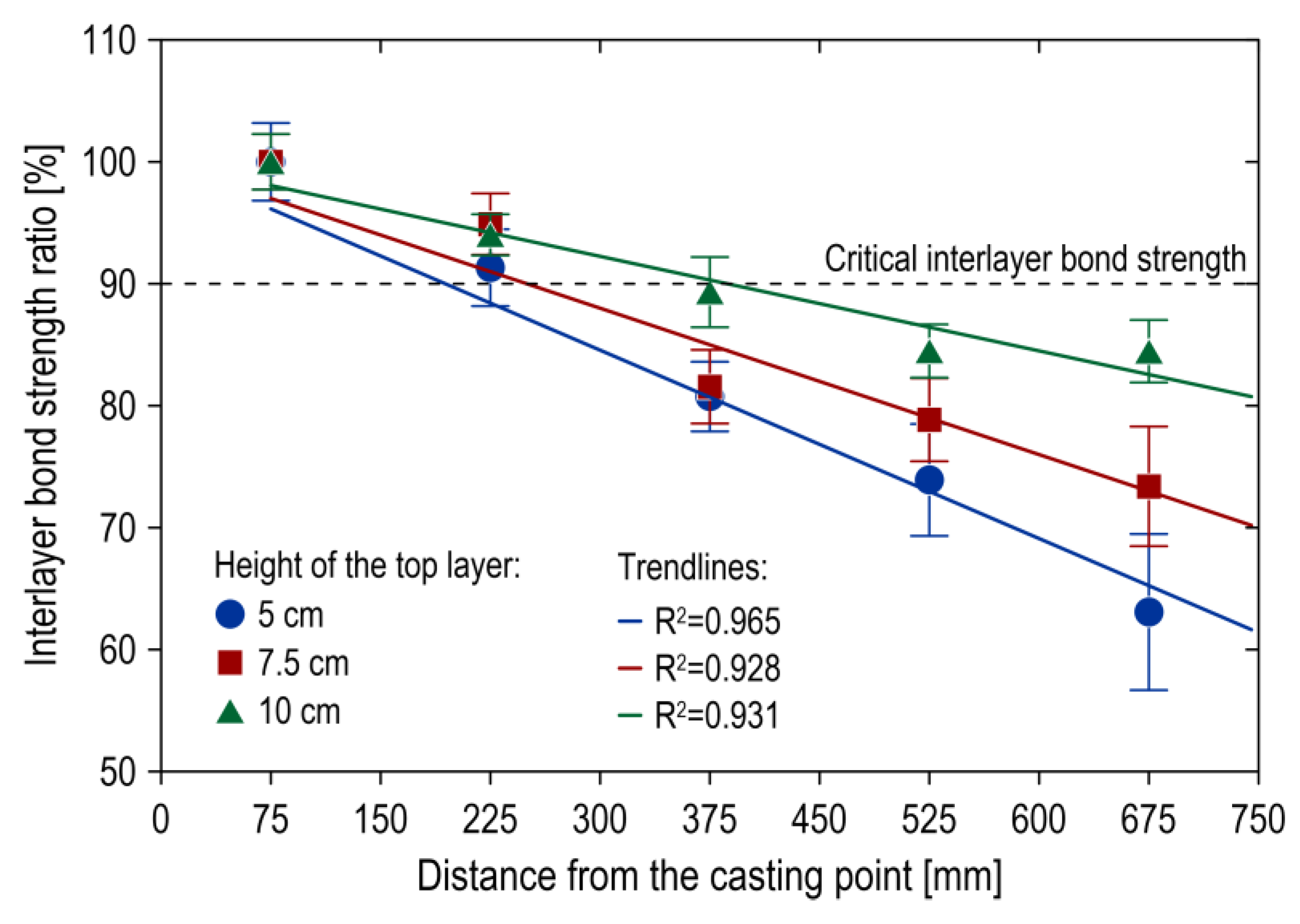

3. Results and Discussion

3.1. Fresh Mix Properties and Concrete Strength

3.2. Interlayer Bond Strength

4. Conclusions

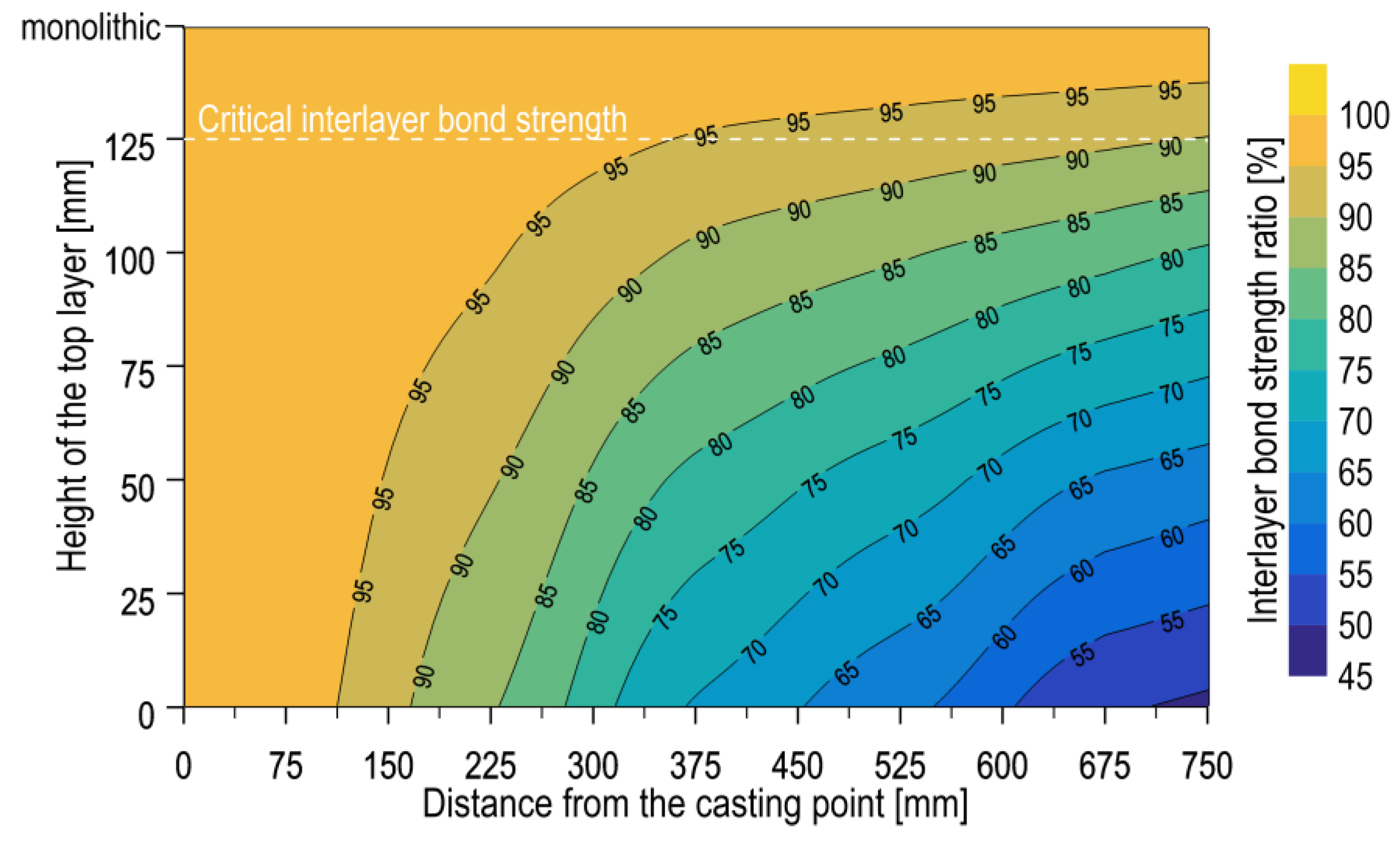

- In the context of the multilayer casting of slab elements, the delay in placing the top layer has a significant impact on the interlayer bond strength. It has been demonstrated that the interlayer bond strength is influenced by both the height of the top layer and its free-flow distance from the mix casting point.

- The study revealed that the lower the top layer, the more pronounced the impact of distance from the casting location on the decrease in interlayer bond strength. The maximum decrease in interlayer bond strength along the element compared to the monolithic specimen was observed for layers of 50, 75, and 100 mm, at 38.2%, 27.3%, and 13.0%, respectively.

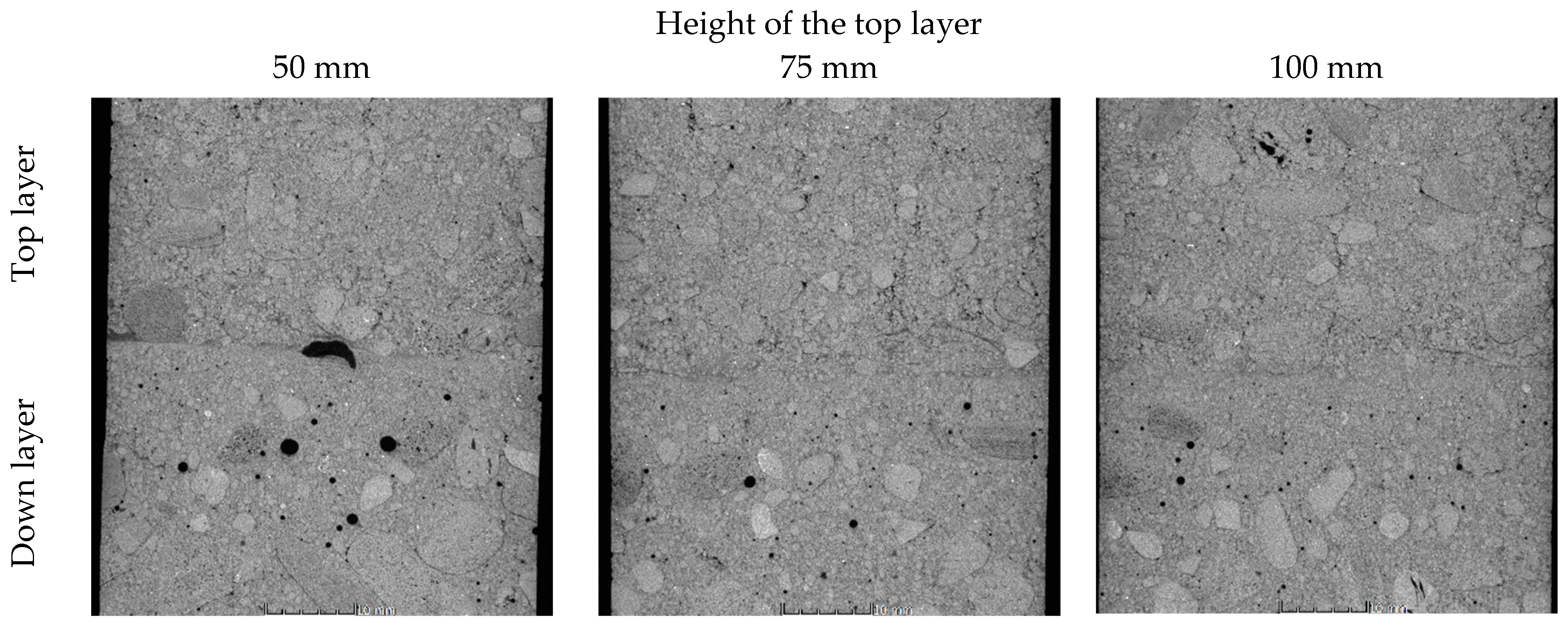

- The study revealed significant differences in the mixing pattern of the concrete layers depending on the height of the top layer. The greater the height of the top layer, the more irregular the course of the layer contact and the more intense the mixing of the layers within the element cross-section. The mixing of the layers thus produced precludes the possibility of a continuous structural weakening of the structure.

- In the case of multilayer SCC placement, it is recommended that the free flow of the mix over the previously placed layer be restricted when concreting is interrupted for longer periods. This is particularly pertinent to areas where the flow speed is reduced, such as corners, narrowing in the formwork, and so forth. An alternative approach is to adjust the height of subsequent layers to align with the free-flow distance. In accordance with the test conditions presented in this study, the top layer should be at least 125 mm in height.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Self-Compacting Concrete: Materials, Properties, and Applications; Siddique, R., Ed.; Woodhead Publishing: Sawston, UK, 2020; ISBN 978-0-12-817369-5. [Google Scholar]

- Okamura, H.; Ouchi, M. Self-Compacting Concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Domone, P. A Review of the Hardened Mechanical Properties of Self-Compacting Concrete. Cem. Concr. Compos. 2007, 29, 1–12. [Google Scholar] [CrossRef]

- Khayat, K.H.; Feys, D. Design, Production and Placement of Self-Consolidating Concrete; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 9789048196630. [Google Scholar]

- RILEM TC 228-MPS. In Mechanical Properties of Self-Compacting Concrete: State-of-the-Art Report of the RILEM TC 228-MPS; Khayat, K., De Schutter, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- De Schutter, G.; Bartos, P.J.M.; Domone, P. Self-Compacting Concrete; Whittles Publishing: Dunbeath, UK, 2008; ISBN 9781904445302. [Google Scholar]

- Aslani, F.; Nejadi, S. Bond Behavior of Reinforcement in Conventional and Self-Compacting Concrete. Adv. Struct. Eng. 2012, 15, 2033–2051. [Google Scholar] [CrossRef]

- Roussel, N.; Cussigh, F. Distinct-Layer Casting of SCC: The Mechanical Consequences of Thixotropy. Cem. Concr. Res. 2008, 38, 624–632. [Google Scholar] [CrossRef]

- Omran, A.F.; Khayat, K.H.; Naji, S. Portable Vane Test to Assess Structural Buildup at Rest of Self-Consolidating Concrete. ACI Mater. J. 2011, 108, 628–637. [Google Scholar] [CrossRef]

- Dybeł, P. Effect of Self-Compacting Concrete Placement Technology on the Load-Bearing Capacity of the Concrete-Concrete and Steel-Concrete Bond in Layered Elements. Cem. Wapno Beton 2023, 28, 210–224. [Google Scholar] [CrossRef]

- Jiao, D.; De Schryver, R.; Shi, C.; De Schutter, G. Thixotropic Structural Build-up of Cement-Based Materials: A State-of-the-Art Review. Cem. Concr. Compos. 2021, 122, 104152. [Google Scholar] [CrossRef]

- Coussot, P.; Roussel, N. Quantification de La Thixotropie Des Matériaux Cimentaires et de Ses Effet. Rev. Eur. De Génie Civ. 2006, 10, 45–63. [Google Scholar] [CrossRef]

- ACI Committee 237. ACI 237 R-07: Self-Consolidating Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2007; ISBN 9780870312441. [Google Scholar]

- EFNARC Specification and Guidelines for Self-Compacting Concrete. In European Federation of Specialist Construction Chemicals and Concrete System; EFNARC, Association House: Farnham, UK, 2002.

- RILEM TC 188-CSC. In Final Report of RILEM TC 188-CSC: Casting of Self Compacting Concrete; Skarendahl, A., Billberg, P., Eds.; RILEM Publications S.A.R.L.: Bagneux, France, 2006. [Google Scholar]

- EN 13670; The Execution of Concrete Structures. European Committee for Standardization: Brussels, Belgium, 2010.

- Dybeł, P.; Kucharska, M. Effect of Multilayer Casting Technology of Self-Compacting Concrete Slabs on the Load-Bearing Capacity of a Layer-to-Layer Joint. J. Build. Eng. 2023, 64, 105655. [Google Scholar] [CrossRef]

- Dybeł, P.; Kucharska, M. Effect of Placement Technology on the Bond Strength between Two Layers of Self-Compacting Concrete. Materials 2020, 13, 3330. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.-D.; Khayat, K.H.; Bonneau, O. Performance-Based Specifications of Self-Consolidating Concrete Used in Structural Applications, ACI Mat. J. 2006, 103, 121–129. [Google Scholar] [CrossRef]

- Shirzadi Javid, A.A.; Ghoddousi, P.; Ghodrati Amiri, G.; Donyadideh, K. A New Photogrammetry Method to Study the Relationship between Thixotropy and Bond Strength of Multi-Layers Casting of Self-Consolidating Concrete. Constr. Build. Mater. 2019, 204, 530–540. [Google Scholar] [CrossRef]

- Assaad, J.J.; Daou, Y. Bonding Agents to Mitigate Interfacial Strength Loss during Multi-Layer Concrete Casting. Proc. Inst. Civ. Eng. Constr. Mater. 2021, 174, 195–205. [Google Scholar] [CrossRef]

- Megid, W.A.; Khayat, K.H. Bond Strength in Multilayer Casting of Self-Consolidating Concrete. ACI Struct. J. 2017, 114, 467–476. [Google Scholar] [CrossRef]

- Navarrete, I.; Lopez, M.; Kurama, Y. Multi-Layer Casting of Self-Consolidating Concrete: Influence of Mortar Rheology and Casting Parameters on the Inter-Layer Bond Strength. Constr. Build. Mater. 2021, 303, 124492. [Google Scholar] [CrossRef]

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 12620:2010; Aggregates for Concrete. European Committee for Standarization: Brussels, Belgium, 2010.

- EN 12350-8; Testing Fresh Concrete, Part 8: Self-Compacting Concrete—Slump-Flow Test. European Committee for Standarization: Brussels, Belgium, 2010.

- EN 12350-10; Testing Fresh Concrete, Part 10: Self-Compacting Concrete—L-Box Test. European Committee for Standarization: Brussels, Belgium, 2010.

- ASTM C1611; Standard Test Method for Slump Flow of Self-Consolidating Concrete. ASTM International: West Conshohocken, PA, USA, 2018.

- EN 12390-3; Testing Hardened Concrete. Compressive Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2009.

- EN 12390-6; Testing Hardened Concrete. Tensile Splitting Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2009.

- Vicente, M.A.; González, D.C.; Mínguez, J. Recent Advances in the Use of Computed Tomography in Concrete Technology and Other Engineering Fields. Micron 2019, 118, 22–34. [Google Scholar] [CrossRef] [PubMed]

- Taheri-Shakib, J.; Al-Mayah, A. Effect of Corrosion Pit Distribution of Rebar on Pore, and Crack Characteristics in Concrete. Cem. Concr. Compos. 2024, 148, 105476. [Google Scholar] [CrossRef]

- Ahmed, H.; Kuva, J.; Punkki, J. Analysing Entrapped Pores in Concrete via X-ray Computed Tomography: Influence of Workability and Compaction Time. Constr. Build. Mater. 2024, 417, 135322. [Google Scholar] [CrossRef]

- The Self-Compacting Concrete European Project Group. The European Guidelines for Self Compacting Concrete: Specification, Production and Use. 2005. Available online: https://www.efca.info/efca-publications/concrete-construction/ (accessed on 6 August 2024).

| Row Designation (See Figure 1) | Monolithic Sample | Height of the Top Layer | ||||||

|---|---|---|---|---|---|---|---|---|

| 50 mm | 75 mm | 100 mm | ||||||

| fct,sp [MPa] | SD [MPa] | fct,sp [MPa] | SD [MPa] | fct,sp [MPa] | SD [MPa] | fct,sp [MPa] | SD [MPa] | |

| 1 | 3.85 | 0.40 | 3.77 | 0.24 | 3.82 | 0.17 | 3.96 | 0.18 |

| 2 | 3.44 | 0.24 | 3.62 | 0.20 | 3.73 | 0.14 | ||

| 3 | 3.04 | 0.19 | 3.11 | 0.21 | 3.54 | 0.23 | ||

| 4 | 2.78 | 0.29 | 3.01 | 0.23 | 3.35 | 0.16 | ||

| 5 | 2.38 | 0.30 | 2.80 | 0.28 | 3.35 | 0.17 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dybeł, P.; Kucharska, M. Analysis of the Effect of Layer Height on the Interlayer Bond in Self-Compacting Concrete Mix in Slab Elements. Materials 2024, 17, 4005. https://doi.org/10.3390/ma17164005

Dybeł P, Kucharska M. Analysis of the Effect of Layer Height on the Interlayer Bond in Self-Compacting Concrete Mix in Slab Elements. Materials. 2024; 17(16):4005. https://doi.org/10.3390/ma17164005

Chicago/Turabian StyleDybeł, Piotr, and Milena Kucharska. 2024. "Analysis of the Effect of Layer Height on the Interlayer Bond in Self-Compacting Concrete Mix in Slab Elements" Materials 17, no. 16: 4005. https://doi.org/10.3390/ma17164005

APA StyleDybeł, P., & Kucharska, M. (2024). Analysis of the Effect of Layer Height on the Interlayer Bond in Self-Compacting Concrete Mix in Slab Elements. Materials, 17(16), 4005. https://doi.org/10.3390/ma17164005