Deformation Mechanisms Dominated by Decomposition of an Interfacial Misfit Dislocation Network in Ni/Ni3Al Multilayer Structures

Abstract

:1. Introduction

2. Numerical Models and Methodology

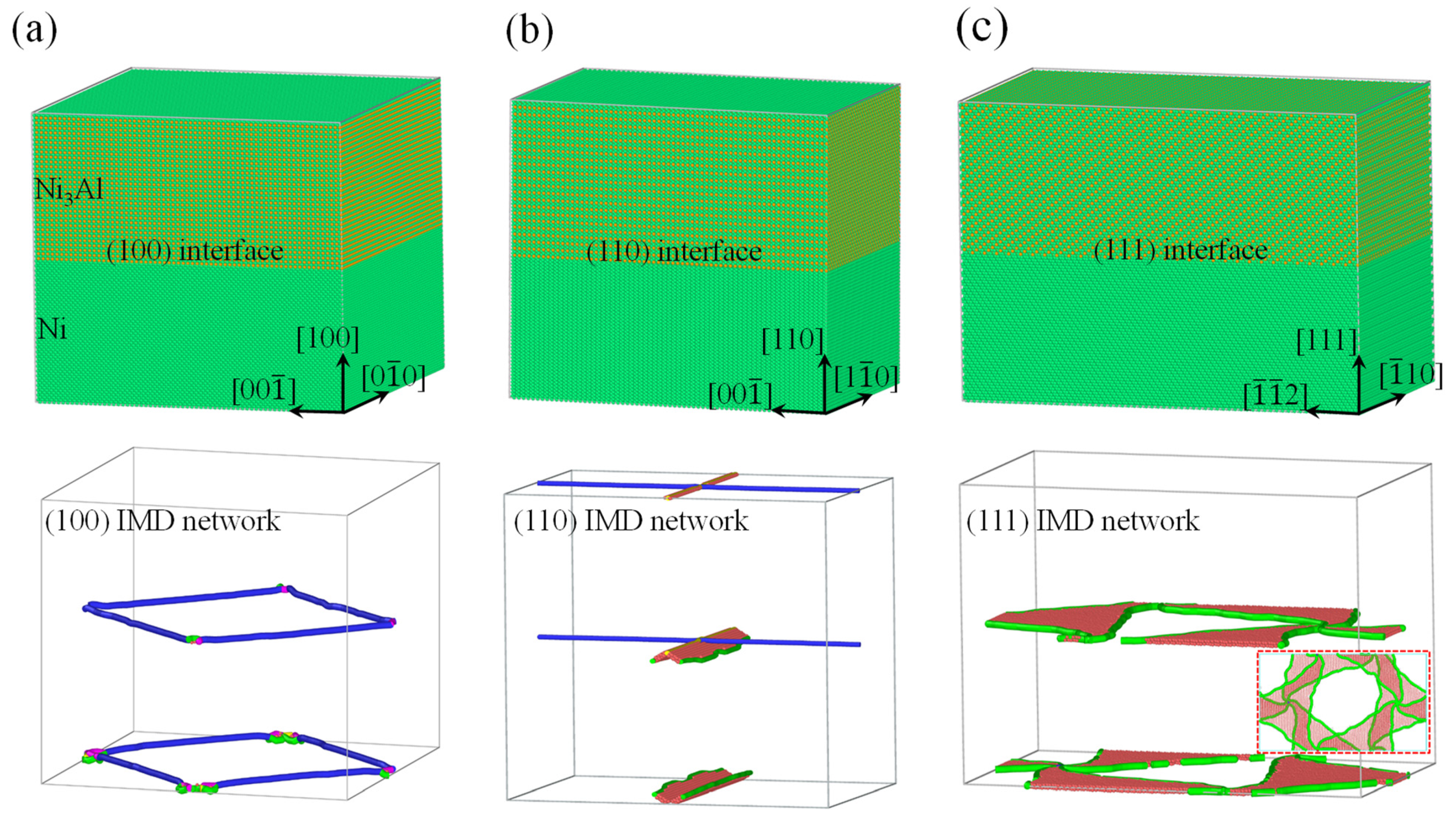

2.1. Ni/Ni3Al Heterogeneous Interface Models

2.2. Molecular Dynamics Simulation

3. Results

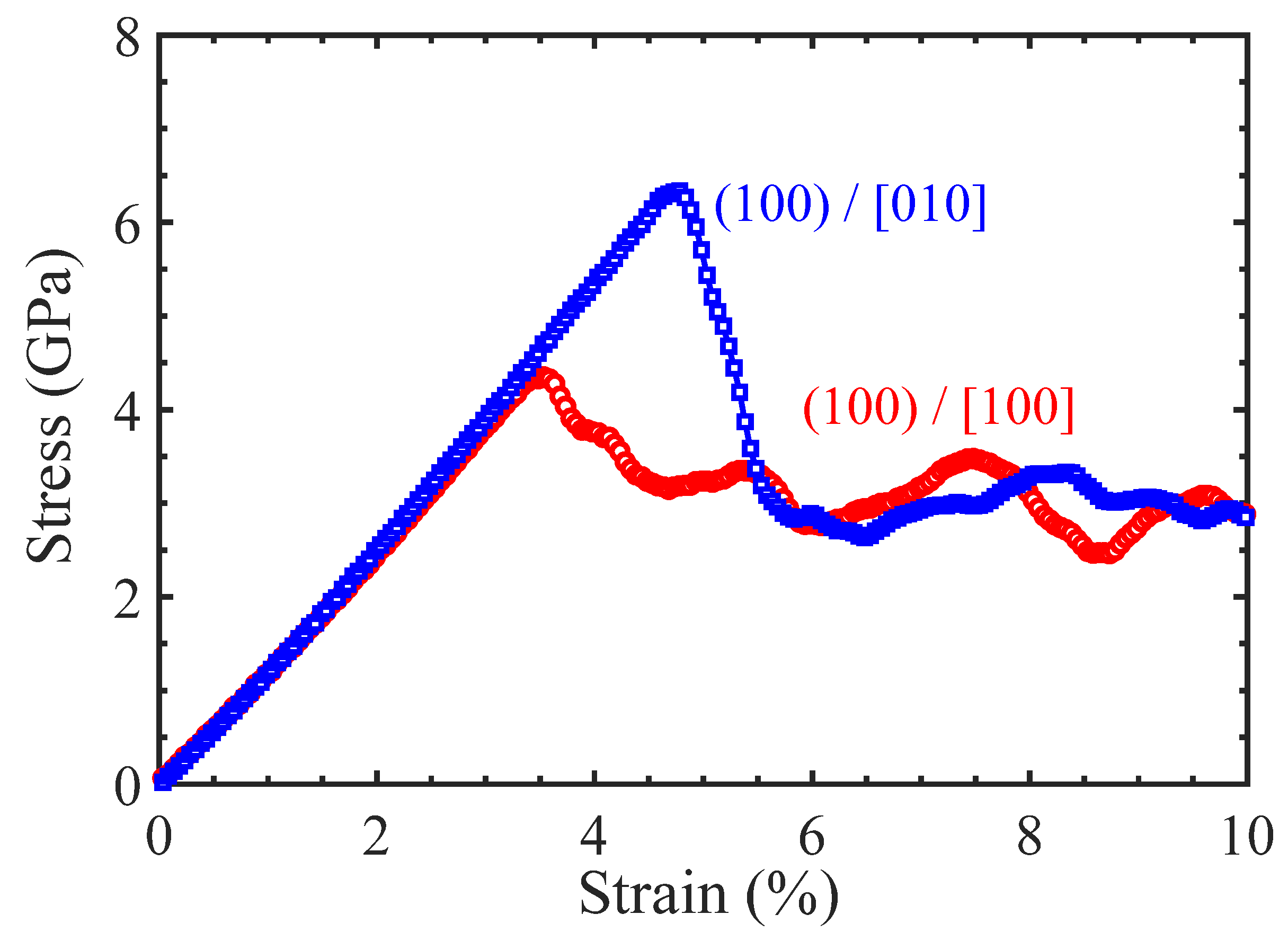

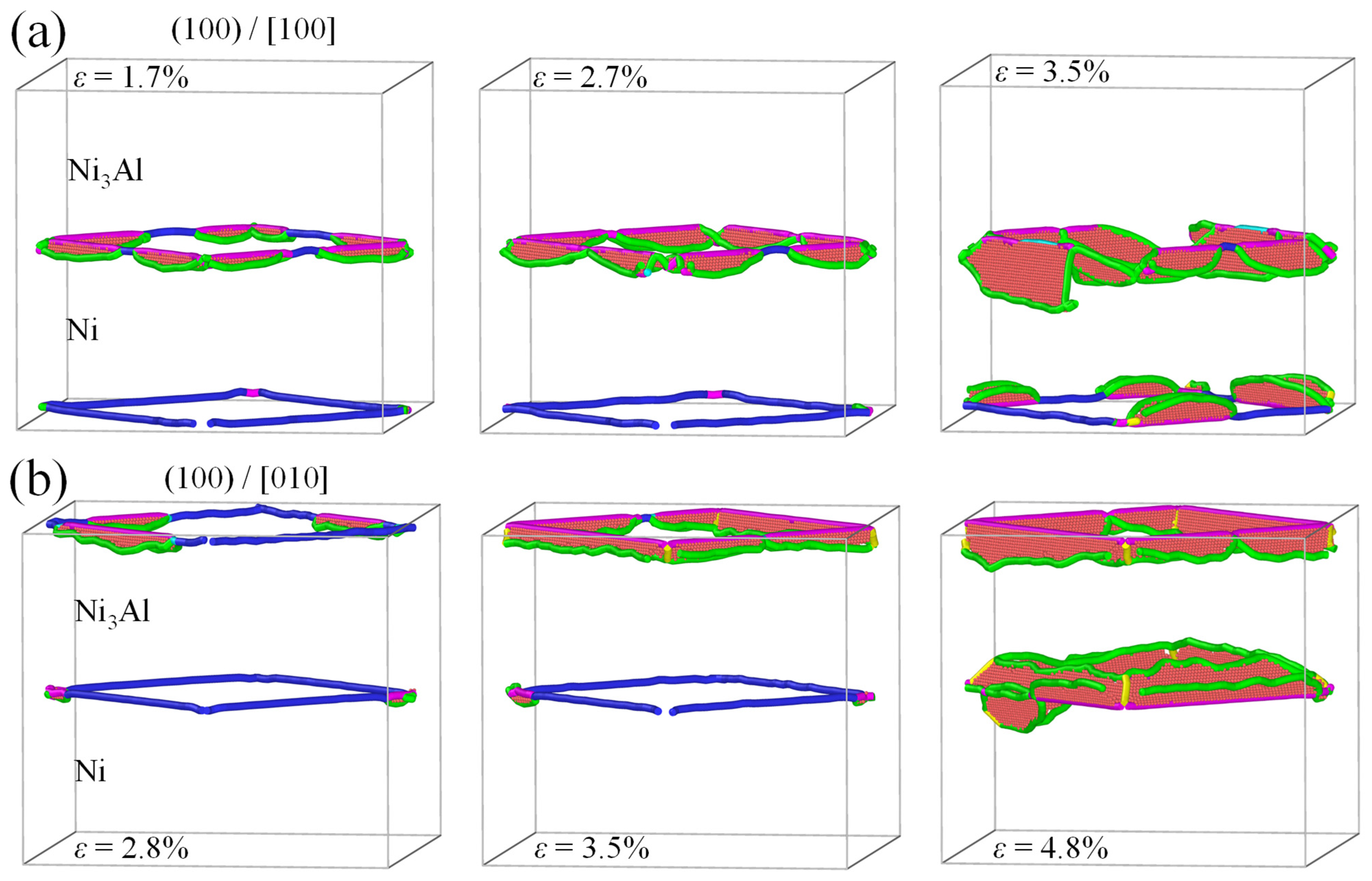

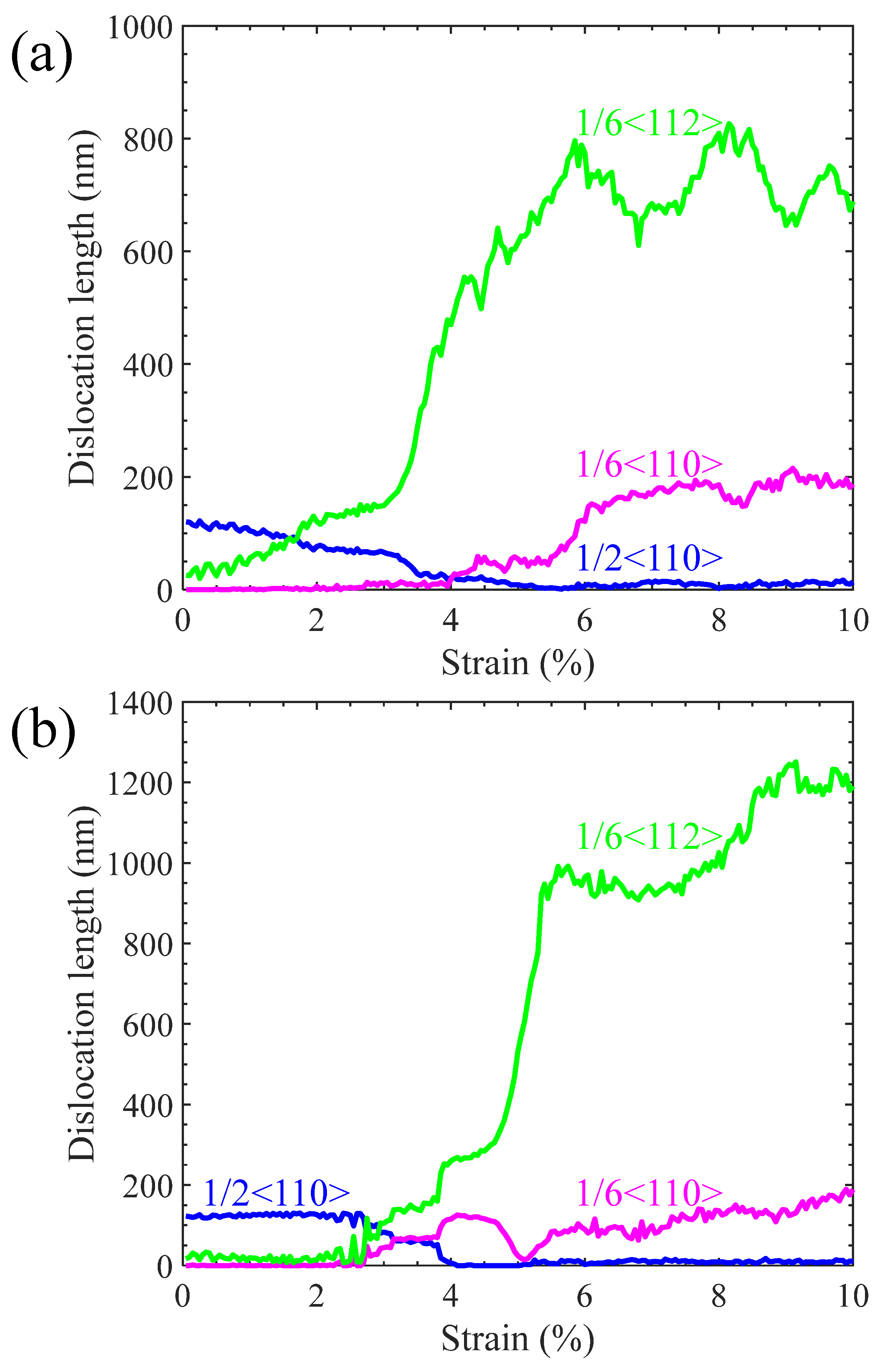

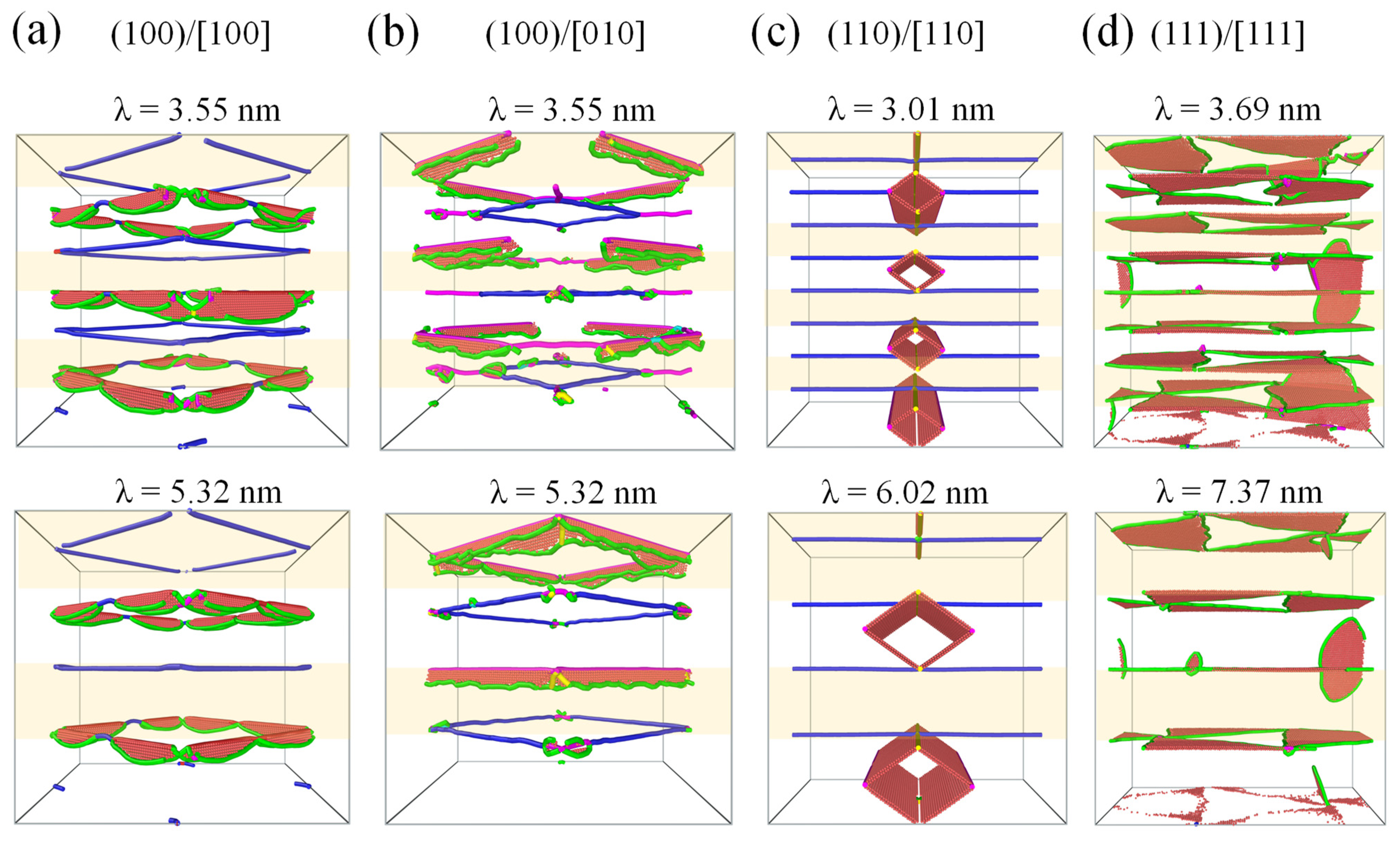

3.1. Ni/Ni3Al (100) Interface

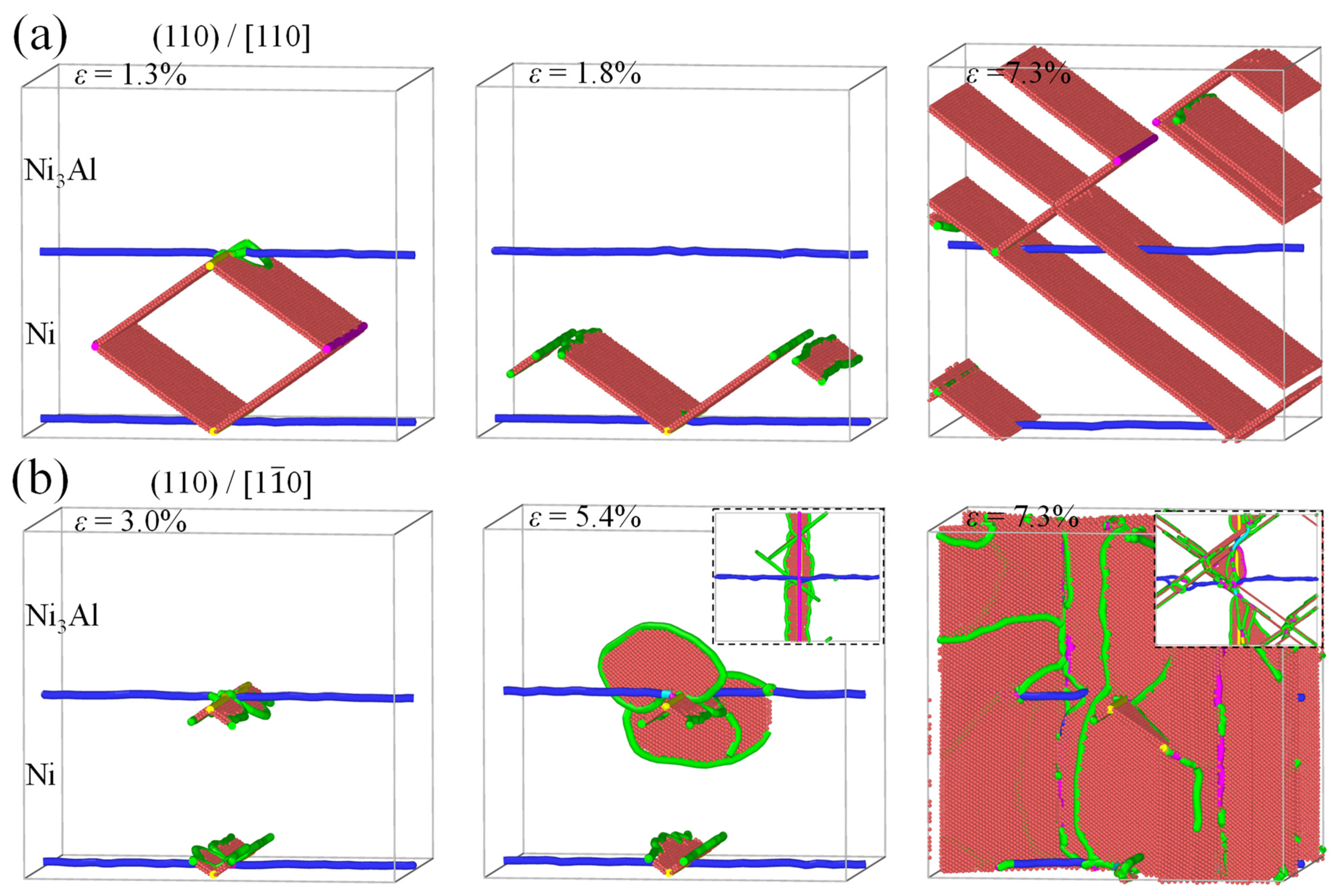

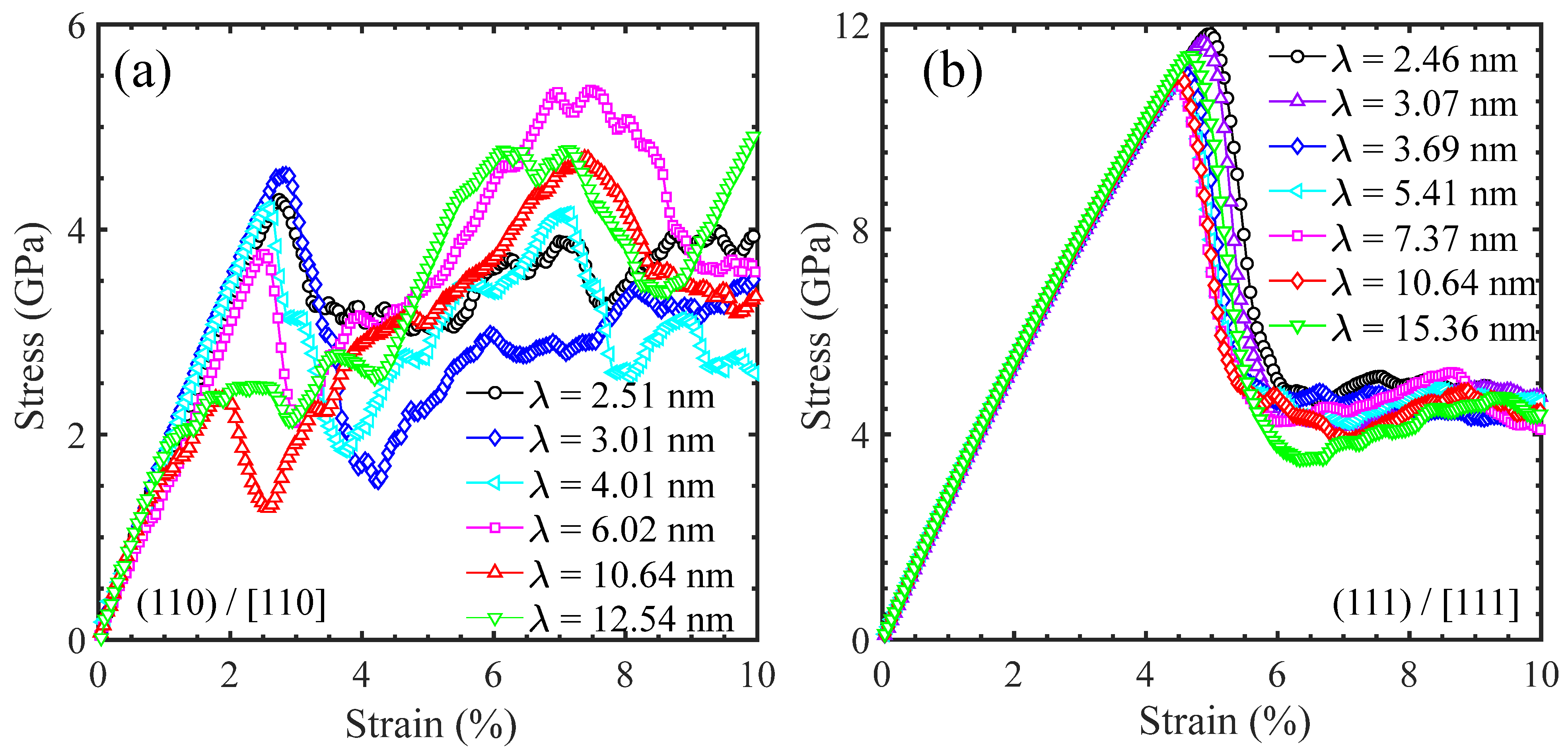

3.2. Ni/Ni3Al (110) Interface

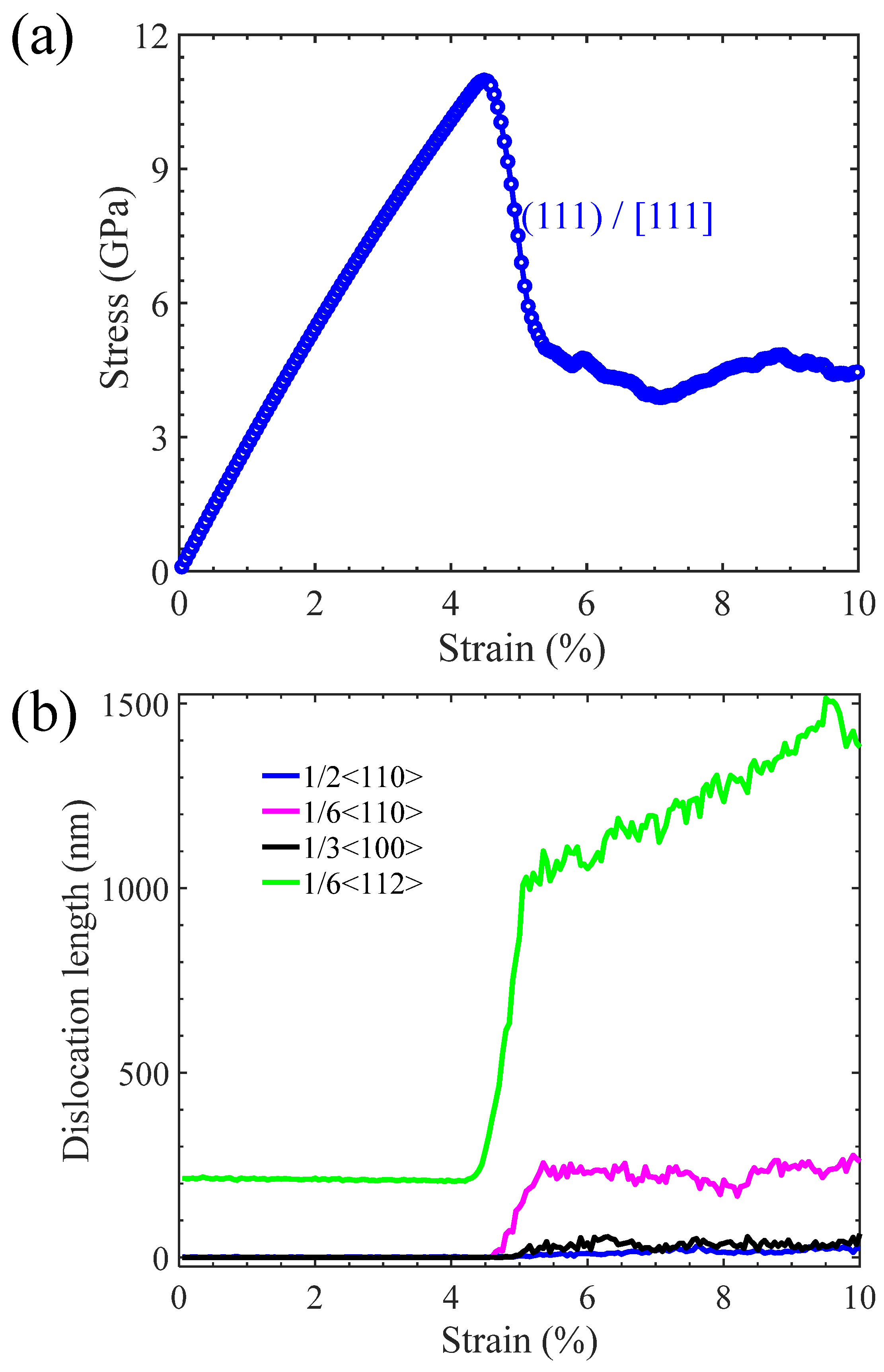

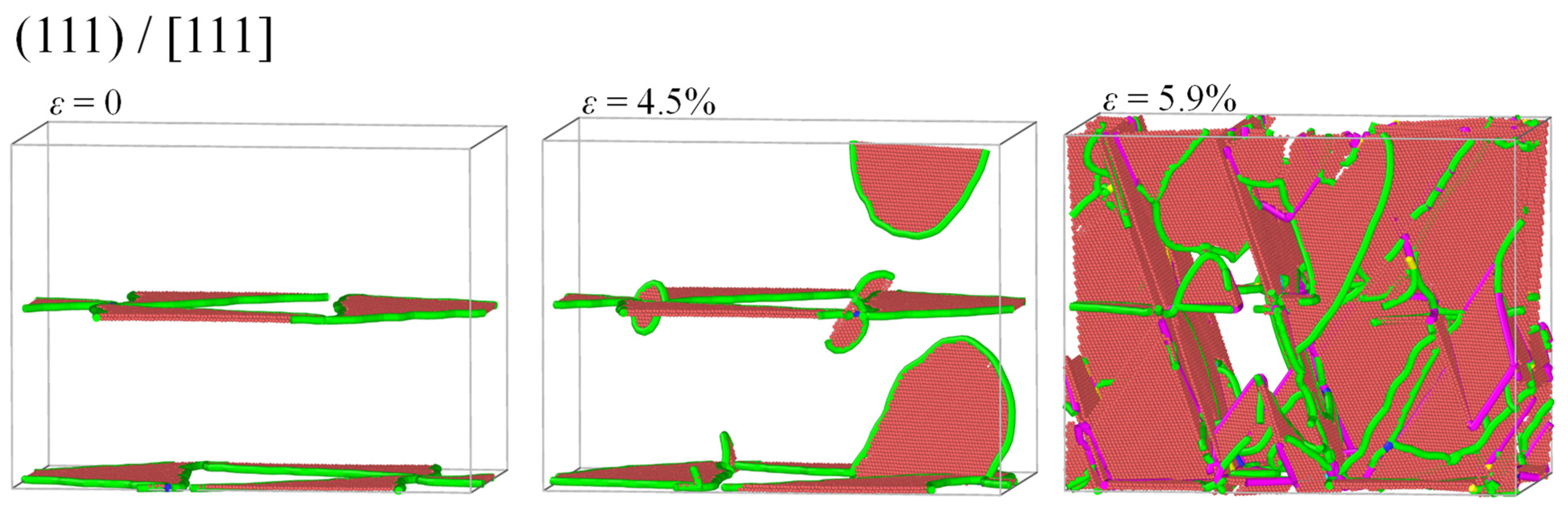

3.3. Ni/Ni3Al (111) Interface

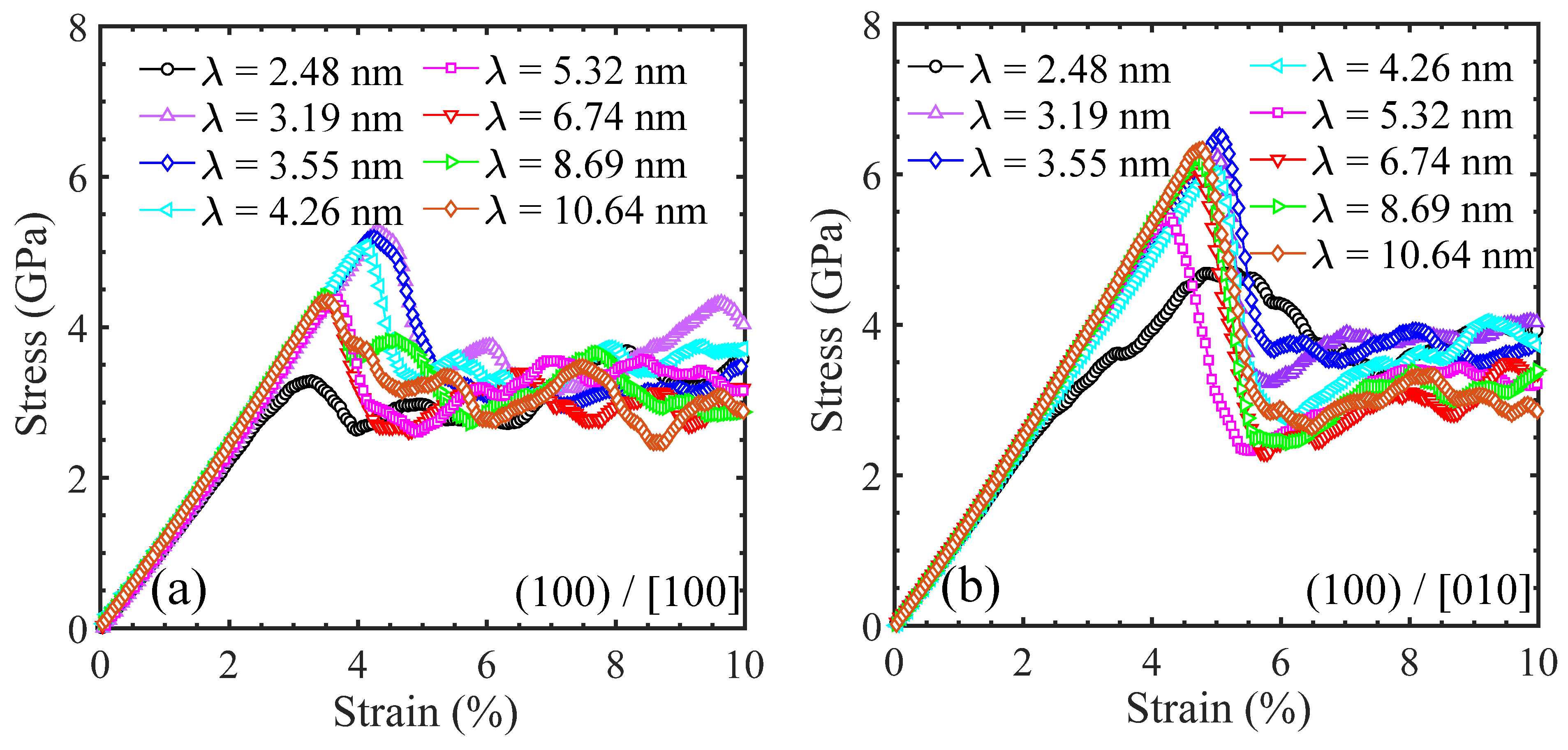

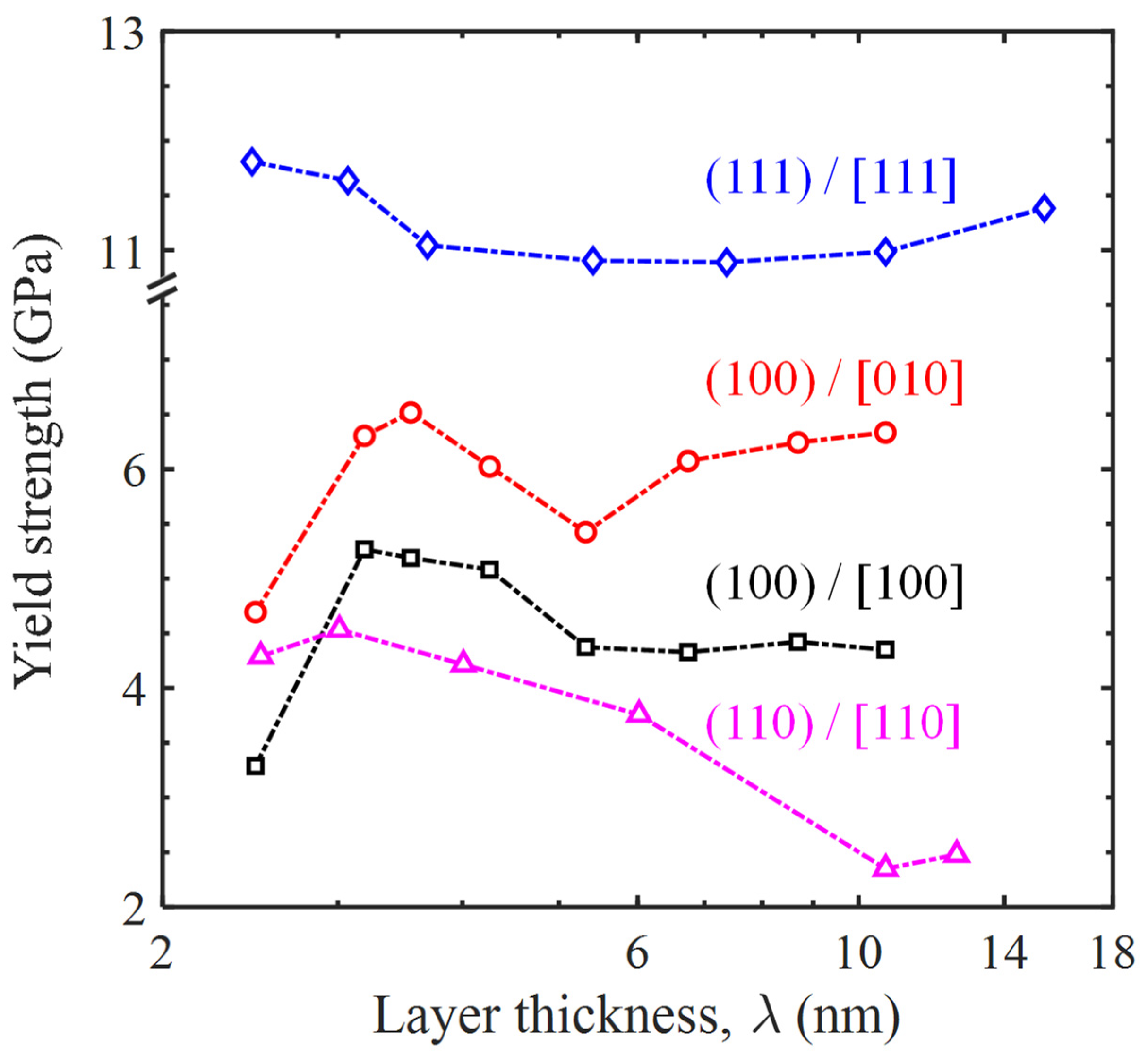

3.4. Effects of Layer Thickness for Ni/Ni3Al Multilayer Structure

4. Discussion

5. Conclusions

- Whether the Ni/Ni3Al (100) interfacial configuration is tensibly loaded along the [100] or [010] orientation, it encounters the same 1/2<110> → 1/6<112> + 1/6<112> + 1/6<110> dislocation decomposition reaction. However, dislocations evolve in the Ni and Ni3Al layers for the two orientations, respectively;

- As tensile loading is along the [110] orientation, decomposition of the Ni/Ni3Al (110) IMD network initiates from the propagation of 1/6<112> Shockley dislocations and stacking faults behind them. This causes the yielding of the Ni/Ni3Al (110) multilayer structure in advance in contrast to the case of loading, which is along the [10] orientation. The 1/2<110> perfect dislocations always remain stable, showing an insensitivity to loading orientations;

- The decomposition of the Ni/Ni3Al (111) IMD network is derived from the generation of new 1/6<112> Shockley dislocations at its triangular corners. The newly formed 1/6<112> Shockley dislocations extend into both Ni and Ni3Al layers;

- It is expected that these findings can provide new insights into a deep understanding of the evolution of IMD networks dominated deformation mechanism of Ni/Ni3Al heterogeneous multilayer structures and benefit their wide applications in the aerospace industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, W.S.; Zhao, X.B.; Yue, L.; Zhang, Z. Microstructural evolution and creep mechanisms in Ni-based single crystal superalloys: A review. J. Alloys Compd. 2020, 819, 152954. [Google Scholar] [CrossRef]

- Pineau, A.; Antolovich, S.D. High temperature fatigue of nickel-base superalloys—A review with special emphasis on deformation modes and oxidation. Eng. Failure Anal. 2009, 16, 2668–2697. [Google Scholar] [CrossRef]

- Long, H.B.; Mao, S.C.; Liu, Y.N.; Zhang, Z.; Han, X.D. Microstructural and compositional design of Ni-based single crystalline superalloys—A review. J. Alloys Compd. 2018, 743, 203–220. [Google Scholar] [CrossRef]

- Shuang, F.; Dai, Z.H.; Aifantis, K.E. Strengthening in metal/graphene composites: Capturing the transition from interface to precipitate hardening. ACS Appl. Mater. Interfaces 2021, 12, 26610–26620. [Google Scholar] [CrossRef] [PubMed]

- Wan, K.W.; He, J.X.; Shi, X.H. Construction of High Accuracy Machine Learning Interatomic Potential for Surface/Interface of Nanomaterials—A Review. Adv. Mater. 2023, 36, 2305758. [Google Scholar] [CrossRef]

- Li, X.W.; Liang, J.S.; Shi, T.; Yang, D.N.; Chen, X.C.; Zhang, C.W.; Liu, Z.H.; Liu, D.Z.; Zhang, Q.X. Tribological behaviors of vacuum hot-pressed ceramic composites with enhanced cyclic oxidation and corrosion resistance. Ceram. Int. 2020, 46, 12911–12920. [Google Scholar] [CrossRef]

- Tian, S.G.; Zhou, H.H.; Zhang, J.H.; Yang, H.C.; Xu, Y.B.; Hu, Z.Q. Formation and role of dislocation networks during high temperature creep of a single crystal nickel base superalloy. Mater. Sci. Eng. A 2000, 279, 160–165. [Google Scholar]

- Tang, Y.J.; Fu, Z.; Raos, G.D.; Ma, F.; Zhao, P.; Hou, Y.J. Molecular dynamics simulation of adhesion at the asphalt-aggregate interface: A review. Surf. Interfaces 2024, 44, 103706. [Google Scholar] [CrossRef]

- Du, Y.Z.; Chen, Y.H.; Yuan, X.Y.; Liu, P.; Long, M.J.; Chen, D.F. Potential mechanisms of interstitial atomic enhancement and interface failure behavior in Ni3Co/Cu systems. Appl. Surf. Sci. 2023, 629, 157388. [Google Scholar] [CrossRef]

- Zhang, C.; Feng, K.; Li, Z.G.; Lu, F.G.; Huang, J.; Wu, Y.X. Microstructure and mechanical properties of sputter deposited Ni/Ni3Al multilayer films at elevated temperature. Appl. Surf. Sci. 2016, 378, 408–417. [Google Scholar] [CrossRef]

- Sun, C.; Maloy, S.A.; Baldwin, K.; Wang, Y.Q.; Valdez, J.A. Phase Stability of Ni/Ni3Al Multilayers Under Thermal Annealing and Irradiation. JOM 2020, 72, 3995–4001. [Google Scholar] [CrossRef]

- Yu, J.G.; Zhang, Q.X.; Liu, R.; Yue, Z.F.; Tang, M.K.; Li, X.W. Molecular dynamics simulation of crack propagation behaviors at the Ni/Ni3Al grain boundary. RSC Adv. 2014, 4, 32749–32754. [Google Scholar] [CrossRef]

- Shang, J.; Yang, F.; Li, C.; Wei, N.; Tan, X. Size effect on the plastic deformation of pre-void Ni/Ni3Al interface under uniaxial tension: A molecular dynamics simulation. Comput. Mater. Sci. 2018, 148, 200–206. [Google Scholar] [CrossRef]

- Liu, C.Y.; Wang, F.; Yuan, P.F.; Guo, Z.X.; Yu, J.G.; Jia, Y. Atomistic view of thin Ni/Ni3Al (001) under uniaxial tension of twist grain boundaries. RSC Adv. 2014, 4, 4552–4557. [Google Scholar] [CrossRef]

- Hocker, S.; Schmauder, S.; Kumar, P. Molecular dynamics simulations of Ni/NiAl interfaces. Eur. Phys. J. B 2011, 82, 133–141. [Google Scholar] [CrossRef]

- Voter, A.F.; Chen, S.P. Accurate interatomic potentials for Ni, Al and Ni3Al. MRS Proc. 1986, 82, 175. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Fu, Q.; Wang, J.; Xiao, P.; Ke, F.J.; Lu, C. Interactions between butterfly-like prismatic dislocation loop pairs and planar defects in Ni3Al. Phys. Chem. Chem. Phys. 2021, 23, 10377–10383. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Mishin, Y. Atomistic modeling of the γ and γ′-phases of the Ni–Al system. Acta Mater. 2004, 52, 1451–1467. [Google Scholar] [CrossRef]

- Du, Y.Z.; Hu, H.; Yuan, X.Y.; Long, M.J.; Chen, D.F. Novel insights into interstitial atoms synergistically augmenting the mechanical characteristics of NiCo coating and interfacial strength with Cu substrate. J. Alloys Comp. 2024, 983, 173728. [Google Scholar] [CrossRef]

- Arora, K.; Kishida, K.; Tanaka, K.; Inui, H. Effects of lattice misfit on plastic deformation behavior of single-crystalline micropillars of Ni-based superalloys. Acta Mater. 2017, 138, 119–130. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Fu, Q.; Wang, J.; Xiao, P.; Ke, F.J.; Lu, C. Theoretical model for yield strength of monocrystalline Ni3Al by simultaneously considering size and strain rate. T. Norferr. Metal. Soc. 2024, 33, 816–823. [Google Scholar] [CrossRef]

- Wang, Y.D.; Dai, K.Q.; Lu, W.J.; Chen, S.H.; Li, J.J. Remarkable strengthening of nanolayered metallic composites by nanoscale crystalline interfacial layers. Mater. Today Commun. 2024, 39, 108809. [Google Scholar] [CrossRef]

- Dai, K.Q.; Zhang, C.; Li, J.J. Shear banding suppression in Cu/TiZrNb nanolayered composites through dual crystalline/amorphous interfaces. Mater. Today Commun. 2024, 38, 108481. [Google Scholar] [CrossRef]

- Shuang, F.; Aifantis, K.E. A first molecular dynamics study for modeling the microstructure and mechanical behavior of Si nanopillars during lithiation. ACS Appl. Mater. Interfaces 2021, 13, 21310–21319. [Google Scholar] [CrossRef] [PubMed]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Zhao, B.; Zhao, P.Y.; Liu, H.; Pan, J.S.; Wu, J.W. Investigation on surface generation mechanism of single-crystal silicon in grinding: Surface crystal orientation effect. Mater. Today Commun. 2023, 34, 105125. [Google Scholar] [CrossRef]

- Li, L.; Zeng, Y.; Li, J.; Zhao, Y.C.; Yuan, T.Y.; Yue, Z.F. Effect of crystal orientation on elastic stresses and vibration characteristics of nickel-based single crystal turbine blade. Mater. Today Commun. 2023, 35, 106135. [Google Scholar] [CrossRef]

- Shuang, F.; Aifantis, K.E. Relating the strength of graphene/metal composites to the graphene orientation and position. Scr. Mater. 2020, 181, 70–75. [Google Scholar] [CrossRef]

- Li, X.Y.; Wei, Y.J.; Lu, L.; Lu, K.; Gao, H.J. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 2010, 464, 877–880. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Fu, Q.; Wang, J.; Xiao, P.; Ke, F.J.; Lu, C. Interaction between the edge dislocation dipole pair and interfacial misfit dislocation network in Ni-Based single crystal superalloys. Int. J. Solids Struct. 2021, 228, 111128. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Fu, Q.; Wang, J.; Xiao, P.; Ke, F.J.; Lu, C. Atomistic modeling for the extremely low and high temperature-dependent yield strength in a Ni-based single crystal superalloy. Mater. Today Commun. 2021, 27, 102451. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zhang, X.; Yang, R.; Wang, J.; Lu, C. Deformation Mechanisms Dominated by Decomposition of an Interfacial Misfit Dislocation Network in Ni/Ni3Al Multilayer Structures. Materials 2024, 17, 4006. https://doi.org/10.3390/ma17164006

Zhang Z, Zhang X, Yang R, Wang J, Lu C. Deformation Mechanisms Dominated by Decomposition of an Interfacial Misfit Dislocation Network in Ni/Ni3Al Multilayer Structures. Materials. 2024; 17(16):4006. https://doi.org/10.3390/ma17164006

Chicago/Turabian StyleZhang, Zhiwei, Xingyi Zhang, Rong Yang, Jun Wang, and Chunsheng Lu. 2024. "Deformation Mechanisms Dominated by Decomposition of an Interfacial Misfit Dislocation Network in Ni/Ni3Al Multilayer Structures" Materials 17, no. 16: 4006. https://doi.org/10.3390/ma17164006