The Contribution of Nano-Alumina to Ultra-High-Performance Cement-Based Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of Raw Materials

2.2. Preparation and Testing of Cement Paste Specimens

2.3. Preparation and Testing of High-Performance Concrete Specimens

3. Results

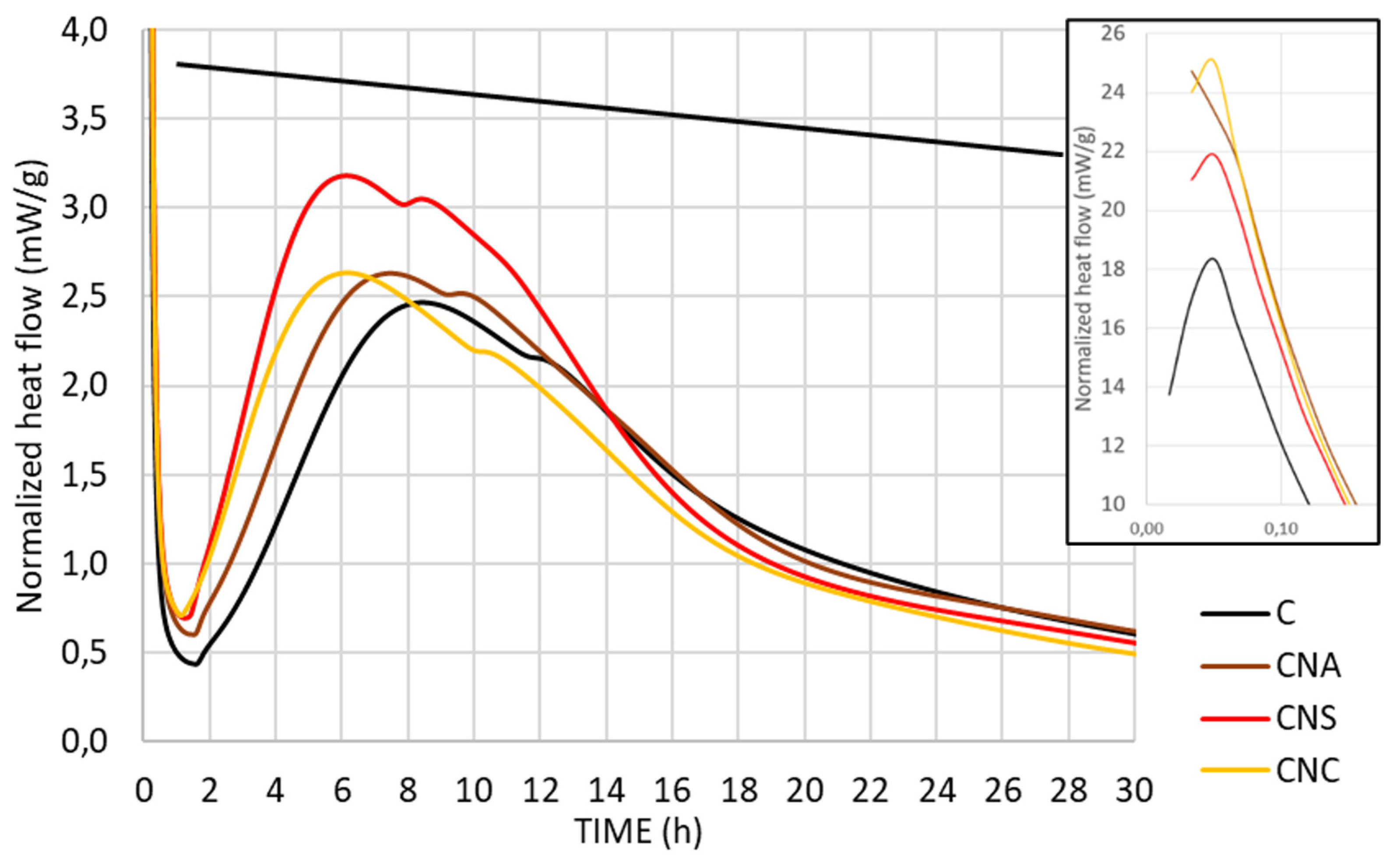

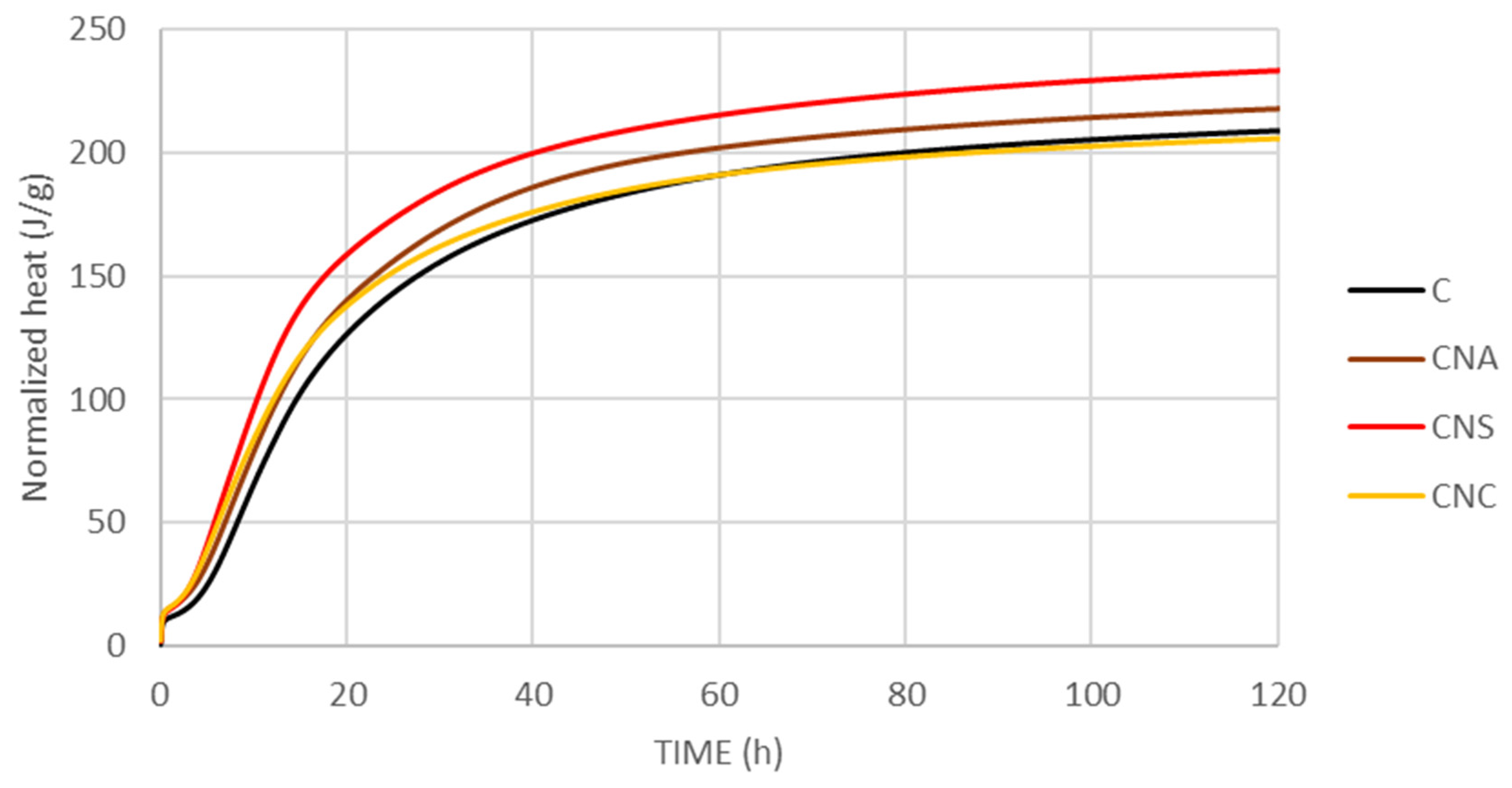

3.1. Heat of Hydration of Cement Pastes

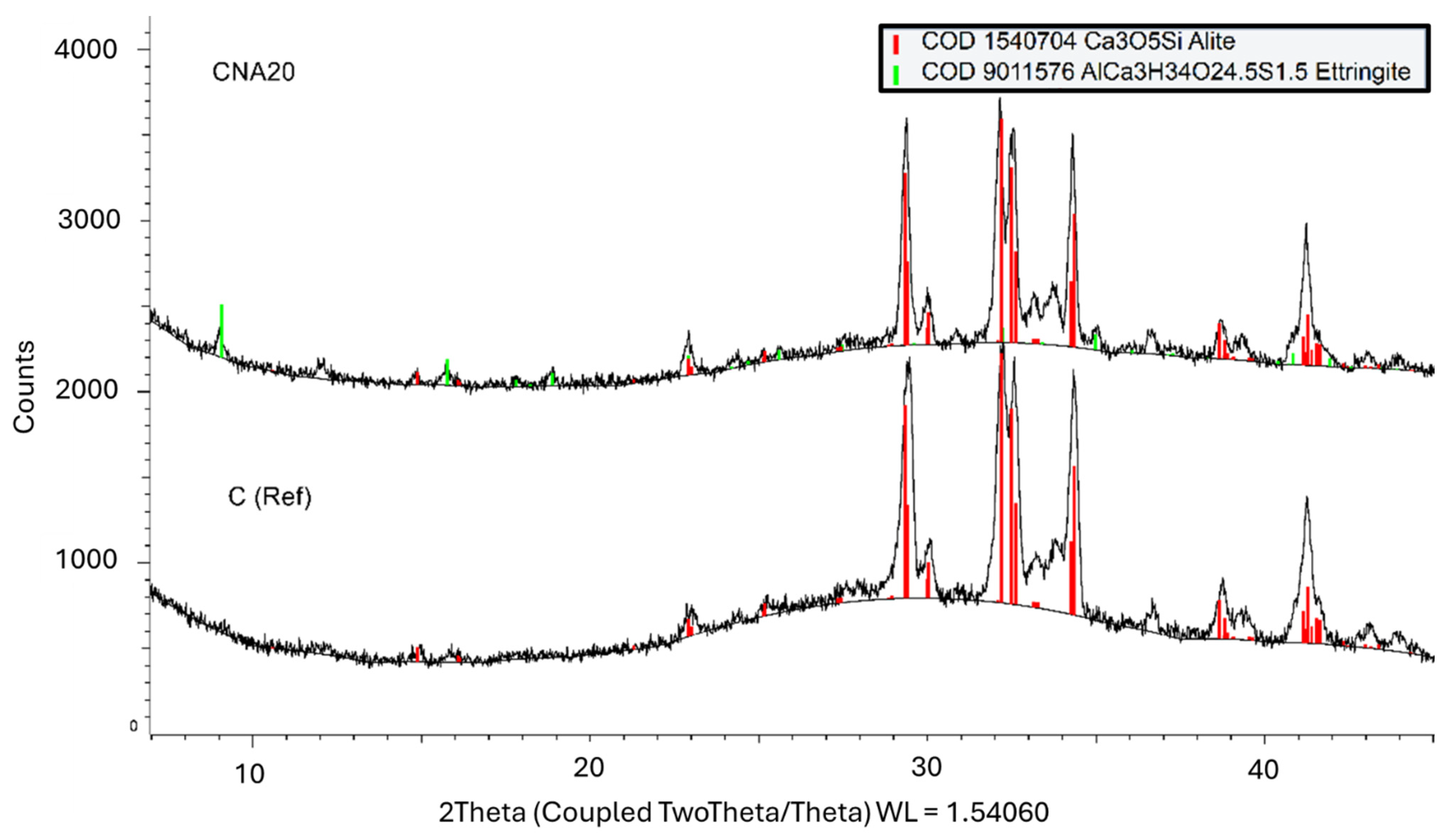

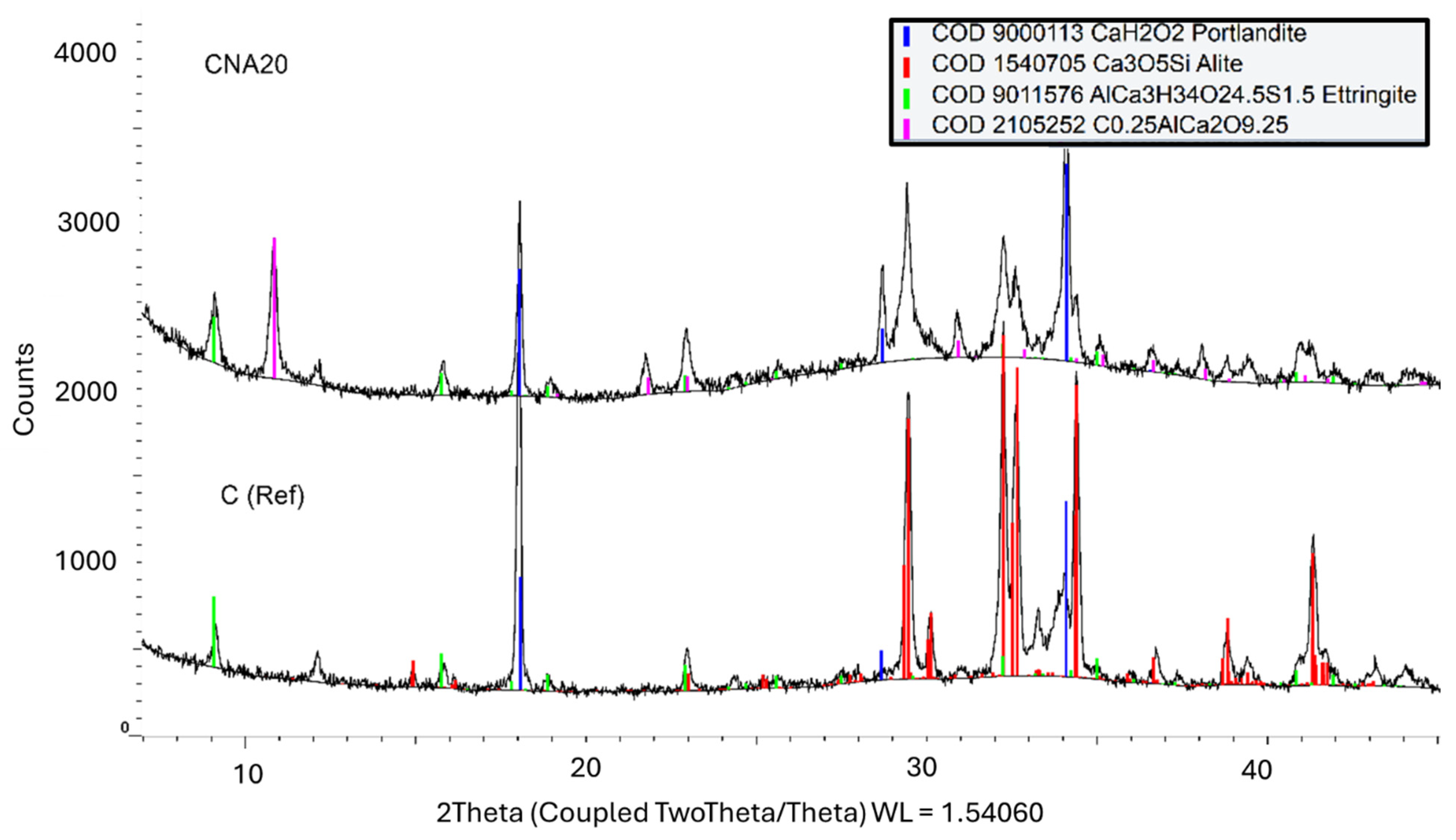

3.2. Early Age Diffraction Patterns

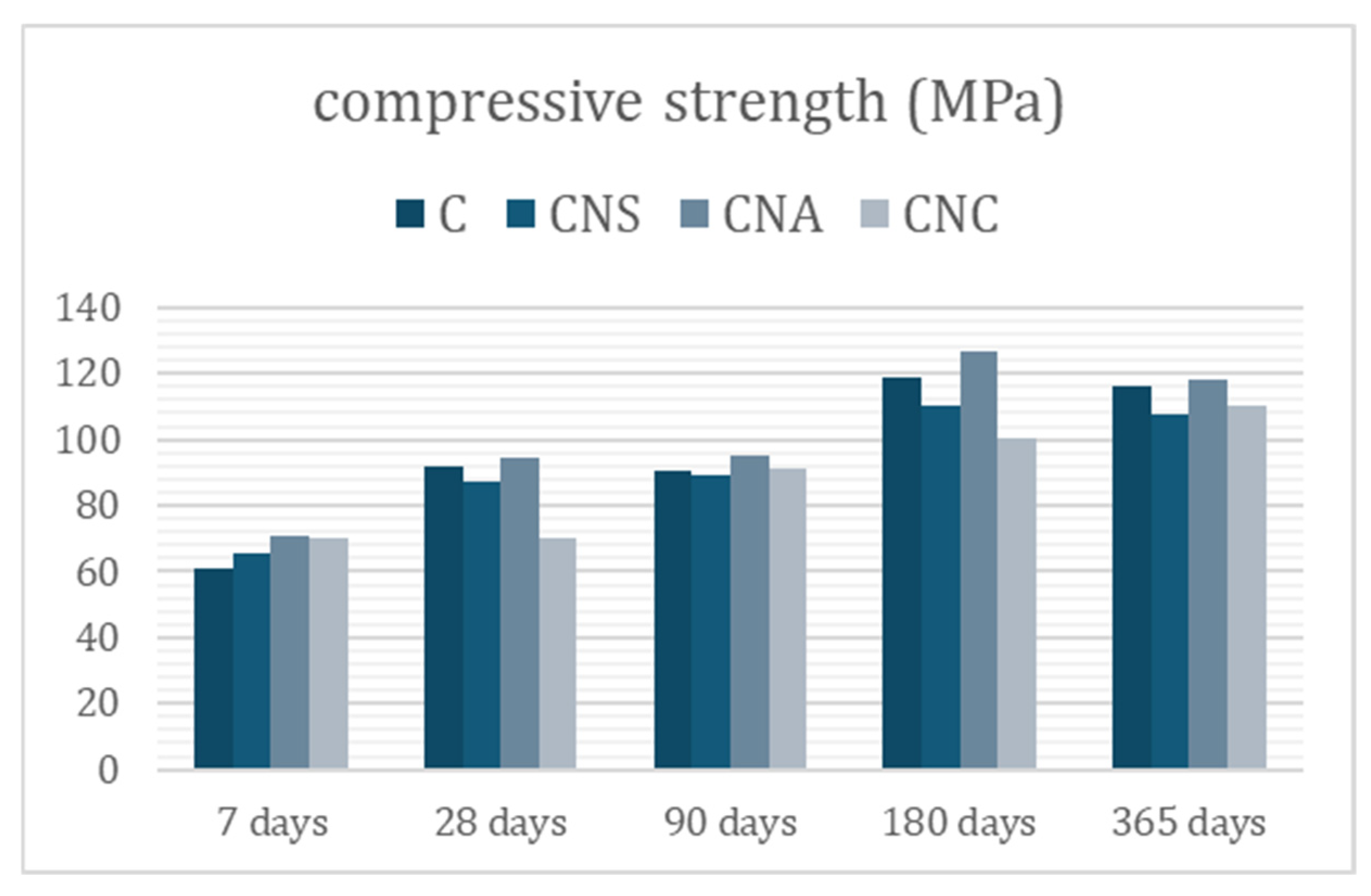

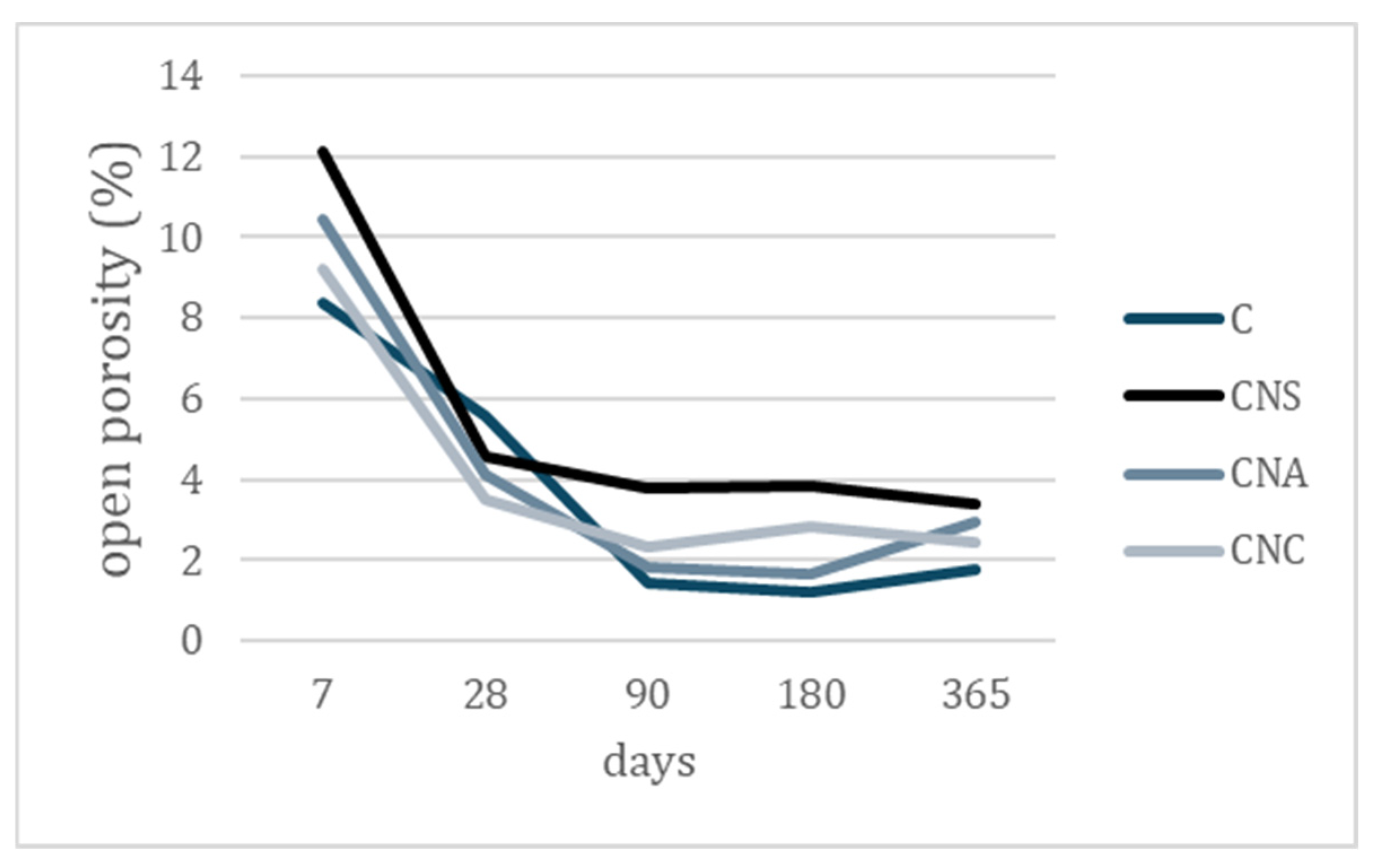

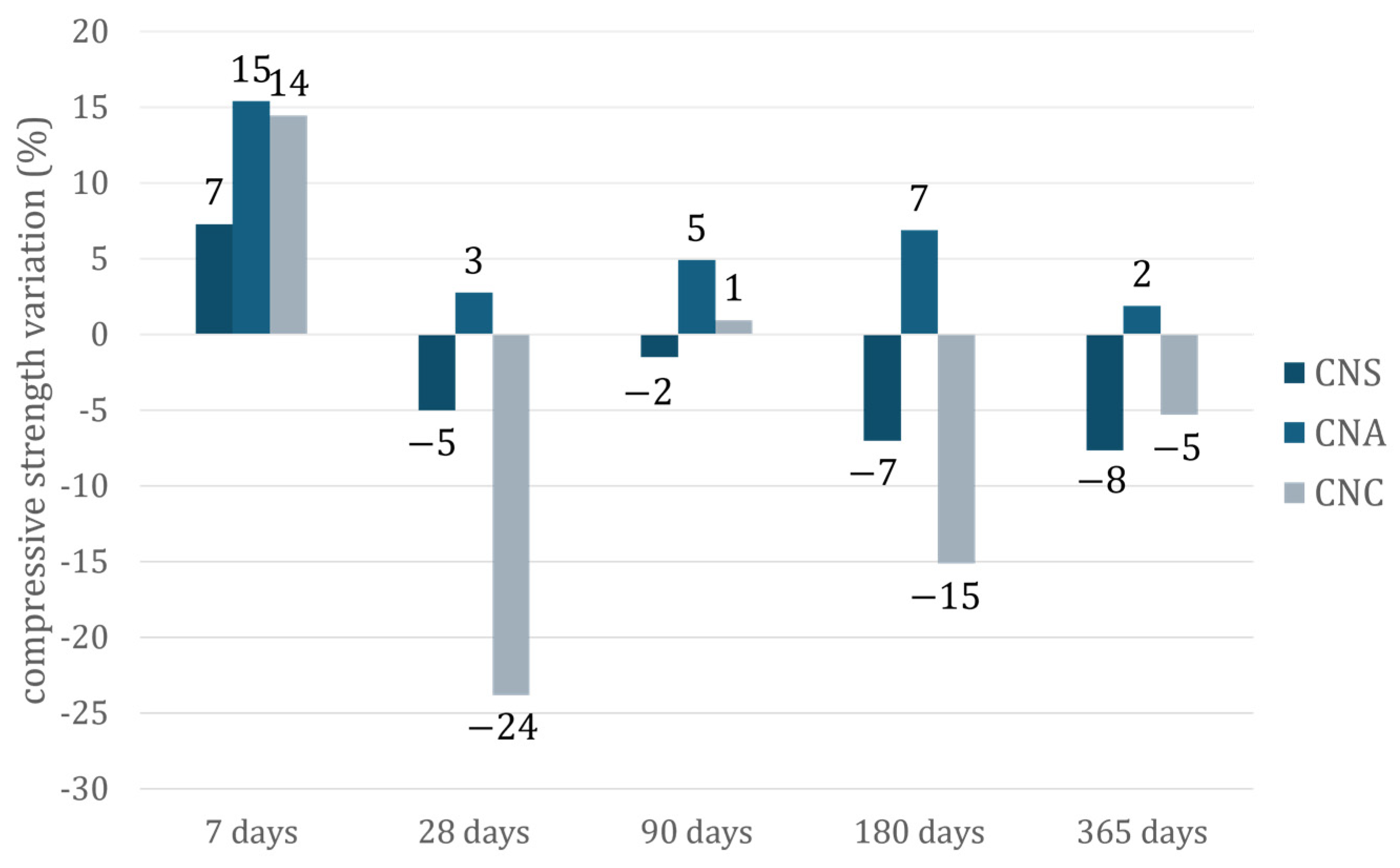

3.3. Compressive Strength and Open Porosity of Cement Pastes

4. Discussion

| NS | NA | NC |

|---|---|---|

| Reduces induction period and boosts early reaction rates | Accelerates early alite hydration and enhances sulfate ion absorption | Speeds up early hydration and microstructure formation |

| X | Early age ettringite support [27] | X |

| X | Early-age Ca-Al compounds support | X |

| Early-age C-S-H [41,42] | X | X |

| X | Carbonates [28] | Carbonates [43] |

| X | w/b | w/b |

| Increase compression only at an early age | Increase compression | Decrease compression |

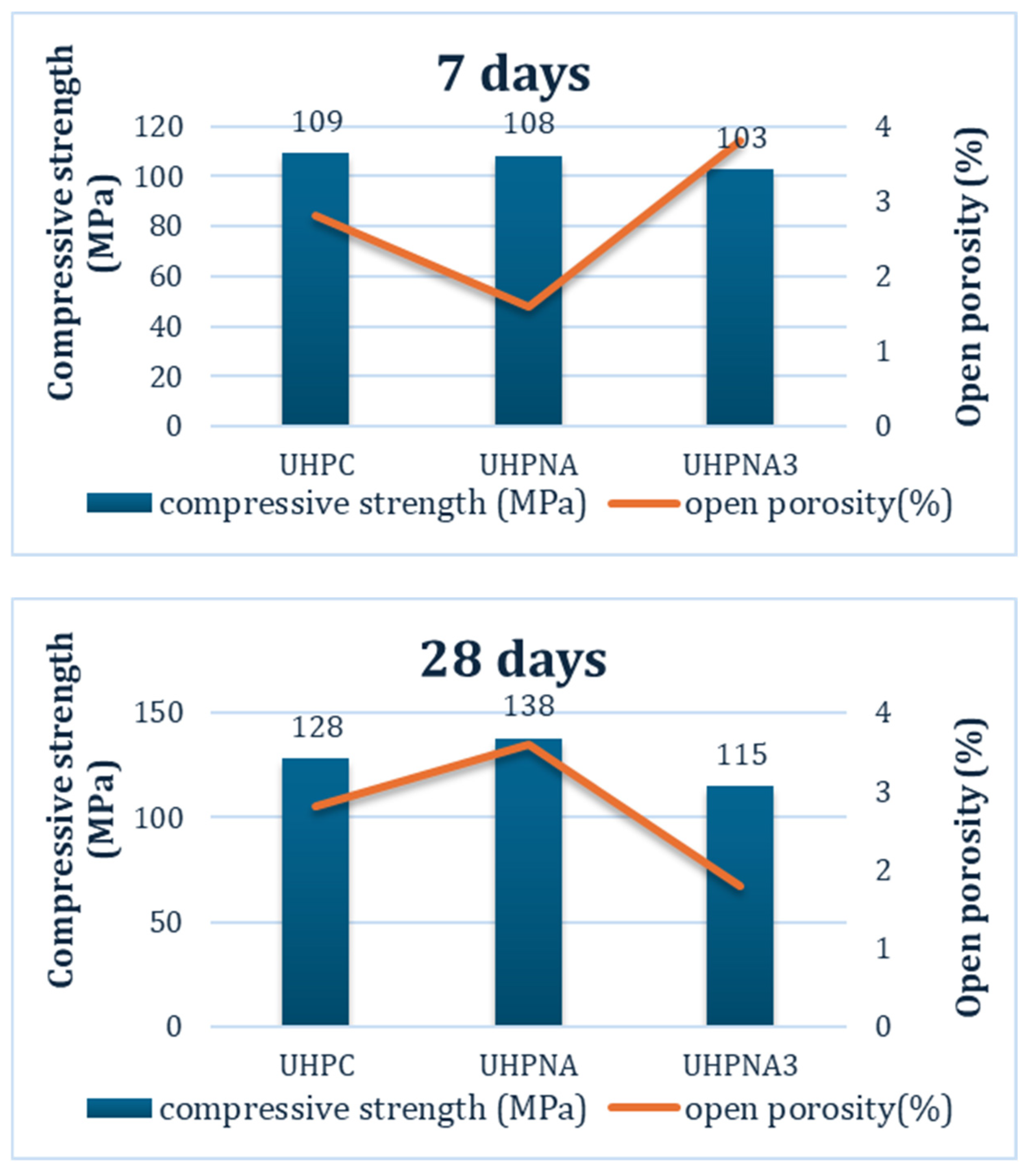

5. Ultra-High-Performance Concrete with NA

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ASTM C1856/C1856M-17; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–4.

- Amran, M.; Huang, S.S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of ultra-high performance concrete—A review. Constr. Build. Mater. 2020, 255, 119296. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, L.; Wei, H.; Wang, J. A Critical Review on Effect of Nanomaterials on Workability and Mechanical Properties of High-Performance Concrete. Adv. Civ. Eng. 2021, 2021, 8827124. [Google Scholar] [CrossRef]

- Mazanec, O.; Lowke, D.; Schiel, P. Mixing of high performance concrete: Effect of concrete composition and mixing intensity on mixing time. Mater. Struct./Mater. Constr. 2010, 43, 357–365. [Google Scholar] [CrossRef]

- Bharatkumar, B.H.; Narayanan, R.; Raghuprasad, B.K.; Ramachandramurthy, D.S. Mix proportioning of high performance concrete. Cem. Concr. Compos. 2001, 23, 71–80. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Duval, R.; Kadri, E.H. Influence of Silica Fume on the Workability and the compressive strength of high-performance concretes. Cem. Concr. Res. 1998, 28, 533–547. [Google Scholar] [CrossRef]

- Soundararajan, M.; Jayaprakash, S.; Maniarasan, S.K.; Gobinath, R. Predicting Strength Properties of High-Performance Concrete Modified with Natural Aggregates and Ferroslag under Varied Curing Conditions. Adv. Civ. Eng. 2023, 2023, 9960412. [Google Scholar] [CrossRef]

- Graybeal, B.A. Design and Construction of Field-Cast UHPC Connections; FHWA-HRT-14-084; Federal Highway Administration: Washington, DC, USA, 2014.

- Akhnoukh, A.K.; Buckhalter, C. Ultra-high-performance concrete: Constituents; mechanical properties, applications and current challenges. Case Stud. Constr. Mater. 2021, 15, e00559. [Google Scholar] [CrossRef]

- Sharma, R.; Jang, J.G.; Bansal, P.P. A comprehensive review on effects of mineral admixtures and fibers on engineering properties of ultra-high-performance concrete. J. Build. Eng. 2022, 45, 103314. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Oh, T.; Banthia, N. Nanomaterials in ultra-high-performance concrete (UHPC)—A review. Cem. Concr. Compos. 2022, 134, 104730. [Google Scholar] [CrossRef]

- Liu, C.; He, X.; Deng, X.; Wu, Y.; Zheng, Z.; Liu, J.; Hui, D. Application of nanomaterials in ultra-high performance concrete: A review. Nanotechnol. Rev. 2020, 9, 1427–1444. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C.; Tutikian, B.F.; Chen, Q. Mechanisms underlying the strength enhancement of UHPC modified with nano-SiO2 and nano-CaCO3. Cem. Concr. Compos. 2021, 119, 103992. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H.; Wan, S. Effects of different nanomaterials on hardening and performance of ultra-high strength concrete (UHSC). Cem. Concr. Compos. 2016, 70, 24–34. [Google Scholar] [CrossRef]

- Muzenski, S.; Flores-Vivian, I.; Farahi, B.; Sobolev, K. Towards ultrahigh performance concrete produced with aluminum oxide nanofibers and reduced quantities of silica fume. Nanomaterials 2020, 10, 2291. [Google Scholar] [CrossRef]

- Cuenca, E.; D’Ambrosio, L.; Lizunov, D.; Tretjakov, A.; Volobujeva, O.; Ferrara, L. Mechanical properties and self-healing capacity of Ultra High Performance Fibre Reinforced Concrete with alumina nano-fibres: Tailoring Ultra High Durability Concrete for aggressive exposure scenarios. Cem. Concr. Compos. 2021, 118, 103956. [Google Scholar] [CrossRef]

- Ghafoori, N.; Batilov, I.; Najimi, M.; Sharbaf, M.R. Sodium sulfate resistance of mortars containing combined nanosilica and microsilica. J. Mater. Civ. Eng. 2018, 30, 04018135. [Google Scholar] [CrossRef]

- Farzadnia, N.; Abang Ali, A.A.; Demirboga, R. Characterization of high strength mortars with nano alumina at elevated temperatures. Cem. Concr. Res. 2013, 54, 43–54. [Google Scholar] [CrossRef]

- Chu, H.; Wang, Q.; Gao, L.; Jiang, J.; Wang, F. An Approach of Producing Ultra-High-Performance Concrete with High Elastic Modulus by Nano-Al2O3: A Preliminary Study. Materials 2022, 15, 8118. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.J.; Wang, J. Development of ultra-high-performance concrete with various silica admixtures. ACI Mater. J. 2019, 116, 33–44. [Google Scholar] [CrossRef]

- B.E. 196-3:2003; British Standard Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness. British Standard: London, UK, 2003.

- Tsampali, E.; Tsardaka, E.C.; Pavlidou, E.; Paraskevopoulos, K.M.; Stefanidou, M. Comparative study of the properties of cement pastes modified with nano-silica and Nano-Alumina. Solid State Phenom. 2019, 286, 133–144. [Google Scholar] [CrossRef]

- BRITISH STANDARD BS EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. British Standard: London, UK, 1995.

- Tambara Júnior, L.U.D.; de Matos, P.R.; Lima, G.S.; Silvestro, L.; Rocha, J.C.; Campos, C.E.M.; Gleize, P.J.P. Effect of the nanosilica source on the rheology and early-age hydration of calcium sulfoaluminate cement pastes. Constr. Build. Mater. 2022, 327, 126942. [Google Scholar] [CrossRef]

- Zhou, J.; Zheng, K.; Liu, Z.; He, F. Chemical effect of nano-alumina on early-age hydration of Portland cement. Cem. Concr. Res. 2019, 116, 159–167. [Google Scholar] [CrossRef]

- Tsardaka, E.C.; Stefanidou, M. Study of the action of nano-alumina particles in hydrated lime pastes. J. Build. Eng. 2022, 46, 103808. [Google Scholar] [CrossRef]

- Lu, J.X.; Poon, C.S. Improvement of early-age properties for glass-cement mortar by adding nanosilica. Cem. Concr. Compos. 2018, 89, 18–30. [Google Scholar] [CrossRef]

- Isfahani, F.T.; Redaelli, E.; Li, W.; Sun, Y. Effects of nanosilica on early age stages of cement hydration, J Nanomater 2017, 2017. [CrossRef]

- Iskra-Kozak, W.; Konkol, J. The impact of Nano-Al2O3 on the physical and strength properties as well as on the morphology of cement composite crack surfaces in the early and later maturation age. Materials 2021, 14, 4441. [Google Scholar] [CrossRef] [PubMed]

- Zhan, B.J.; Xuan, D.X.; Poon, C.S. The effect of nanoalumina on early hydration and mechanical properties of cement pastes. Constr. Build. Mater. 2019, 202, 169–176. [Google Scholar] [CrossRef]

- Campillo, I.; Guerrero, A.; Dolado, J.S.; Porro, A.; Ibáñez, J.A.; Goñi, S. Improvement of initial mechanical strength by nanoalumina in belite cements. Mater. Lett. 2007, 61, 1889–1892. [Google Scholar] [CrossRef]

- Shao, Q.; Zheng, K.; Zhou, X.; Zhou, J.; Zeng, X. Enhancement of nano-alumina on long-term strength of Portland cement and the relation to its influences on compositional and microstructural aspects. Cem. Concr. Compos. 2019, 98, 39–48. [Google Scholar] [CrossRef]

- Mohseni, E.; Miyandehi, B.M.; Yang, J.; Yazdi, M.A. Single and combined effects of nano-SiO2, nano-Al2O3 and nano-TiO2 on the mechanical, rheological and durability properties of self-compacting mortar containing fly ash. Constr. Build. Mater. 2015, 84, 331–340. [Google Scholar] [CrossRef]

- Gowda, R.; Narendra, H.; Rangappa, D.; Prabhakar, R. Effect of nano-alumina on workability, compressive strength and residual strength at elevated temperature of Cement Mortar. Mater. Today Proc. 2017, 4, 12152–12156. [Google Scholar] [CrossRef]

- Fu, Q.; Zhao, X.; Zhang, Z.; Xu, W.; Niu, D. Effects of nanosilica on microstructure and durability of cement-based materials. Powder Technol. 2022, 404, 117447. [Google Scholar] [CrossRef]

- Elkady, H.; Serag, M.; Elfeky, M. Effect of Nano Silica De-agglomeration, and Methods of Adding Super-plasticizer on the Compressive Strength, and Workability of Nano Silica Concrete. Civ. Environ. Res. 2013, 3, 21–35. [Google Scholar]

- Yang, H.; Monasterio, M.; Zheng, D.; Cui, H.; Tang, W.; Bao, X.; Chen, X. Effects of nano silica on the properties of cement-based materials: A comprehensive review. Constr. Build. Mater. 2021, 282, 122715. [Google Scholar] [CrossRef]

- Abhilash, P.P.; Nayak, D.K.; Sangoju, B.; Kumar, R.; Kumar, V. Effect of nano-silica in concrete; a review. Constr. Build. Mater. 2021, 278, 122347. [Google Scholar] [CrossRef]

- Aggarwal, P.; Singh, R.P.; Aggarwal, Y. Use of nano-silica in cement based materials—A review. Cogent Eng. 2015, 2, 1078018. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Stefanidou, M.; Tsardaka, E.C.; Karozou, A. The influence of curing regimes in self-healing of nano-modified cement pastes. Materials 2020, 13, 5301. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S.; Riahi, S.; Shamekhi, S.F.; Khademno, A. Influence of Al2O3 nanoparticles on the compressive strength and workability of blended concrete. J. Am. Sci. 2010, 6, 6–9. [Google Scholar]

- Gowda, R.; Narendra, H.; Nagabushan, B.M.; Rangappa, D.; Prabhakara, R. Investigation of nano-alumina on the effect of durability and micro-structural properties of the cement mortar. Mater. Today Proc. 2017, 4, 12191–12197. [Google Scholar] [CrossRef]

- Yang, Z.; Sui, S.; Wang, L.; Feng, T.; Gao, Y.; Mu, S.; Tang, L.; Jiang, J. Improving the chloride binding capacity of cement paste by adding nano-Al2O3: The cases of blended cement pastes. Constr. Build. Mater. 2020, 232, 117219. [Google Scholar] [CrossRef]

- Muzenski, S.; Flores-Vivian, I.; Sobolev, K. Ultra-high strength cement-based composites designed with aluminum oxide nano-fibers. Constr. Build. Mater. 2019, 220, 177–186. [Google Scholar] [CrossRef]

- Piérard, J.; Dooms, B.; Cauberg, N. Evaluation of durability parameters of UHPC using accelerated lab tests. In Proceedings of the 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012. [Google Scholar]

- Ekolu, S.O. A review on effects of curing, sheltering, and CO2 concentration upon natural carbonation of concrete. Constr. Build. Mater. 2016, 127, 306–320. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Khazali, M.H.; Vosoughi, P. Effect of steam curing cycles on strength and durability of SCC: A case study in precast concrete. Constr. Build. Mater. 2013, 49, 807–813. [Google Scholar] [CrossRef]

- Sohail, M.G.; Kahraman, R.; Al Nuaimi, N.; Gencturk, B.; Alnahhal, W. Durability characteristics of high and ultra-high performance concretes. J. Build. Eng. 2021, 33, 101669. [Google Scholar] [CrossRef]

- Alarcon-Ruiz, L.; Platret, G.; Massieu, E.; Ehrlacher, A. The use of thermal analysis in assessing the effect of temperature on a cement paste. Cem. Concr. Res. 2005, 35, 609–613. [Google Scholar] [CrossRef]

- Hall, C.; Barnes, P.; Billimore, A.D.; Jupe, A.C.; Turrillas, X. Thermal decomposition of ettringite Ca6[Al(OH)6]2(SO4)3·26H2O. J. Chem. Soc.-Faraday Trans. 1996, 92, 2125–2129. [Google Scholar] [CrossRef]

- Das, S.K.; Mitra, A.; Poddar, P.K.D. Thermal analysis of hydrated calcium aluminates. J. Therm. Anal. 1996, 47, 765–774. [Google Scholar] [CrossRef]

| Method | Cement Ι42.5 Ν | |

|---|---|---|

| Density (g/cm3) | ASTM-C188-95 | 3.135 |

| Cl−% wt | IC | <0.01 |

| SO4−2% wt | IC | 2.03 |

| CaO% | XRF | 61.7 |

| MgO% | XRF | 1.20 |

| SO3% | XRF | 3.34 |

| Fe2O3% | XRF | 3.07 |

| Al2O3% | XRF | 3.14 |

| SiO2% | XRF | 15.0 |

| K2O% | XRF | 1.10 |

| Na2O% | XRF | - |

| TiO2% | XRF | 0.02 |

| Particle size | PSD | d (0.1): 2.438 μm d (0.5): 10.248 μm d (0.9): 28.661 μm |

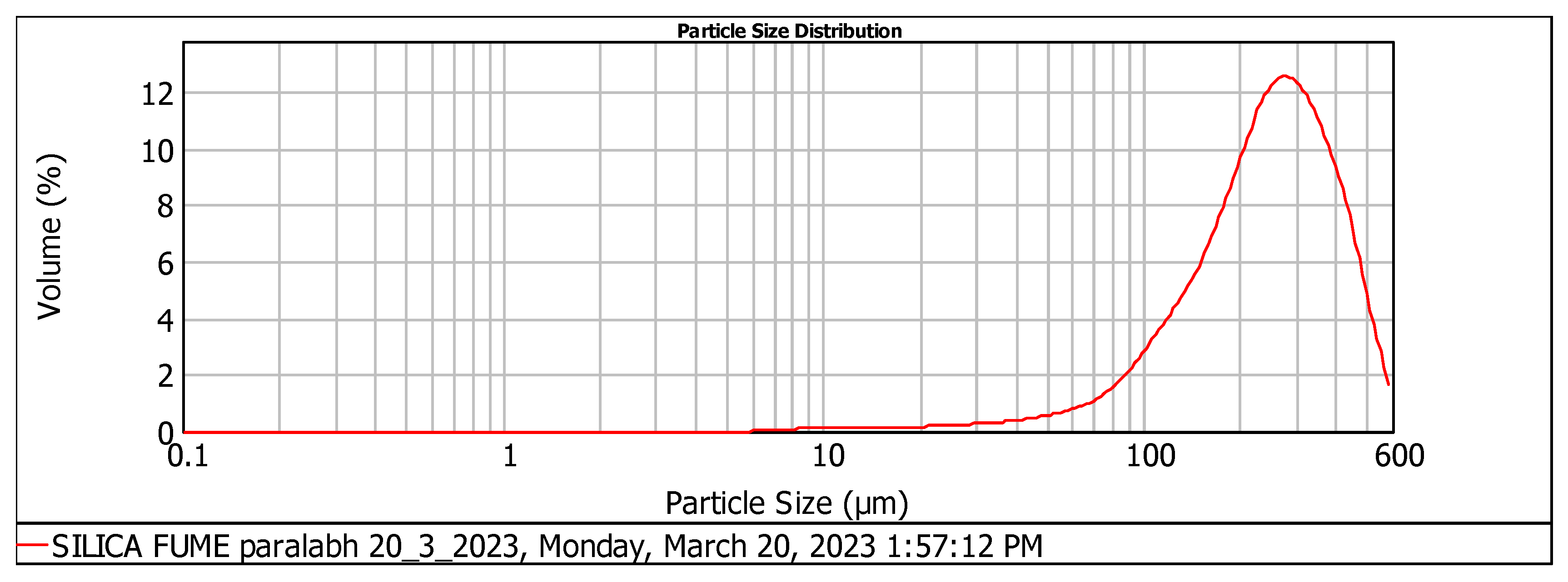

| D (0.1) (μm) | D (0.5) (μm) | D (0.9) (μm) | |

|---|---|---|---|

| Silica sand | 119.68 | 226.94 | 320.67 |

| Silica fume | 107.96 | 249.90 | 430.50 |

| Cement (g) | NS (% wt) | NA (% wt) | NC (% wt) | Water (g) | Consistency (mm) (6 ± 2 mm, EN 196-3) | |

|---|---|---|---|---|---|---|

| C | 1000 | - | - | - | 310 | 6.0 |

| CNS | 1000 | 1.5 | - | - | 310 | 8.0 |

| CNA | 1000 | - | 1.5 | - | 310 | 6.0 |

| CNC | 1000 | - | - | 1.5 | 310 | 6.0 |

| Cement (g) | Silica Fume (g) | Silica Sand (0–3 mm) (g) | NA (% wt) | SP (% wt) | w/b | Workability (cm) | |

|---|---|---|---|---|---|---|---|

| UHPC | 850 | 150 | 1000 | - | 3.0 | 0.23 | 16.9 |

| UHPNA | 850 | 150 | 1000 | 1.5 | 3.0 | 0.23 | 16.3 |

| UHPNA3 | 850 | 150 | 1000 | 3.0 | 3.0 | 0.23 | 16.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsardaka, E.-C.; Tsampali, E.; Stefanidou, M. The Contribution of Nano-Alumina to Ultra-High-Performance Cement-Based Systems. Materials 2024, 17, 4120. https://doi.org/10.3390/ma17164120

Tsardaka E-C, Tsampali E, Stefanidou M. The Contribution of Nano-Alumina to Ultra-High-Performance Cement-Based Systems. Materials. 2024; 17(16):4120. https://doi.org/10.3390/ma17164120

Chicago/Turabian StyleTsardaka, Eirini-Chrysanthi, Evangelia Tsampali, and Maria Stefanidou. 2024. "The Contribution of Nano-Alumina to Ultra-High-Performance Cement-Based Systems" Materials 17, no. 16: 4120. https://doi.org/10.3390/ma17164120

APA StyleTsardaka, E.-C., Tsampali, E., & Stefanidou, M. (2024). The Contribution of Nano-Alumina to Ultra-High-Performance Cement-Based Systems. Materials, 17(16), 4120. https://doi.org/10.3390/ma17164120