Effect of Laser Power on Microstructure and Properties of WC-12Co Composite Coatings Deposited by Laser-Based Directed Energy Deposition

Abstract

:1. Introduction

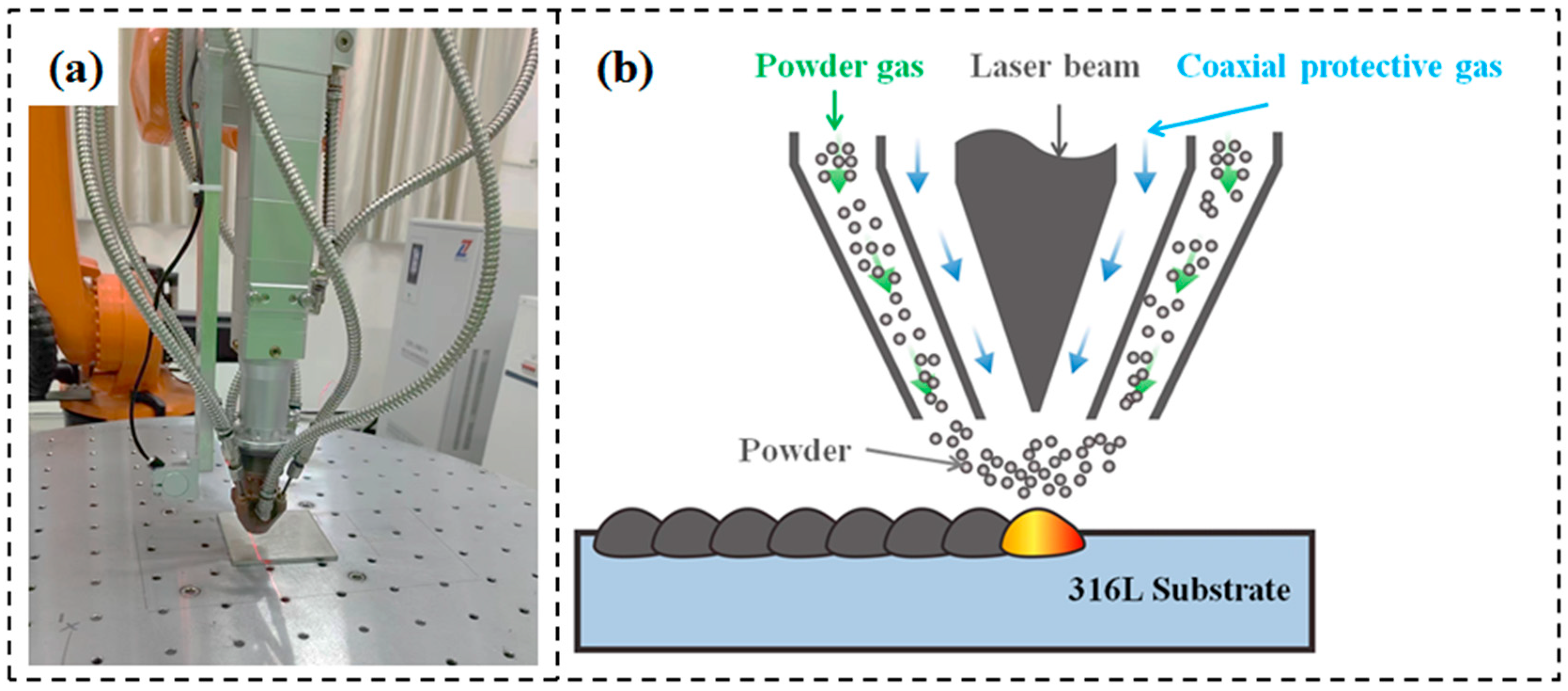

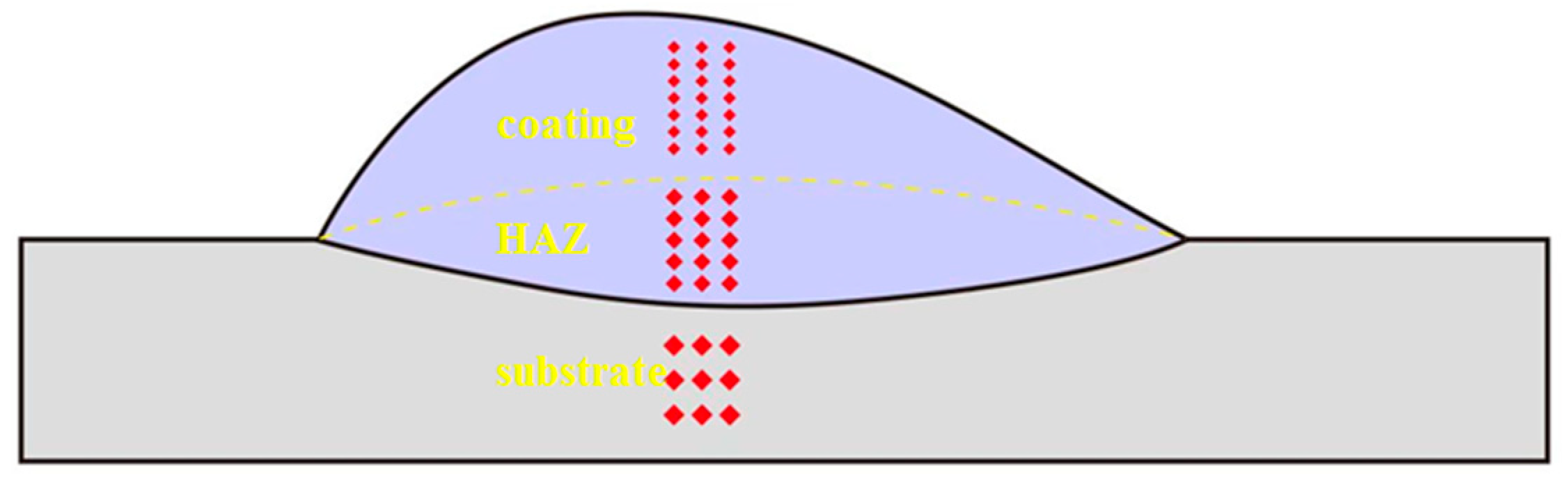

2. Experimental Section

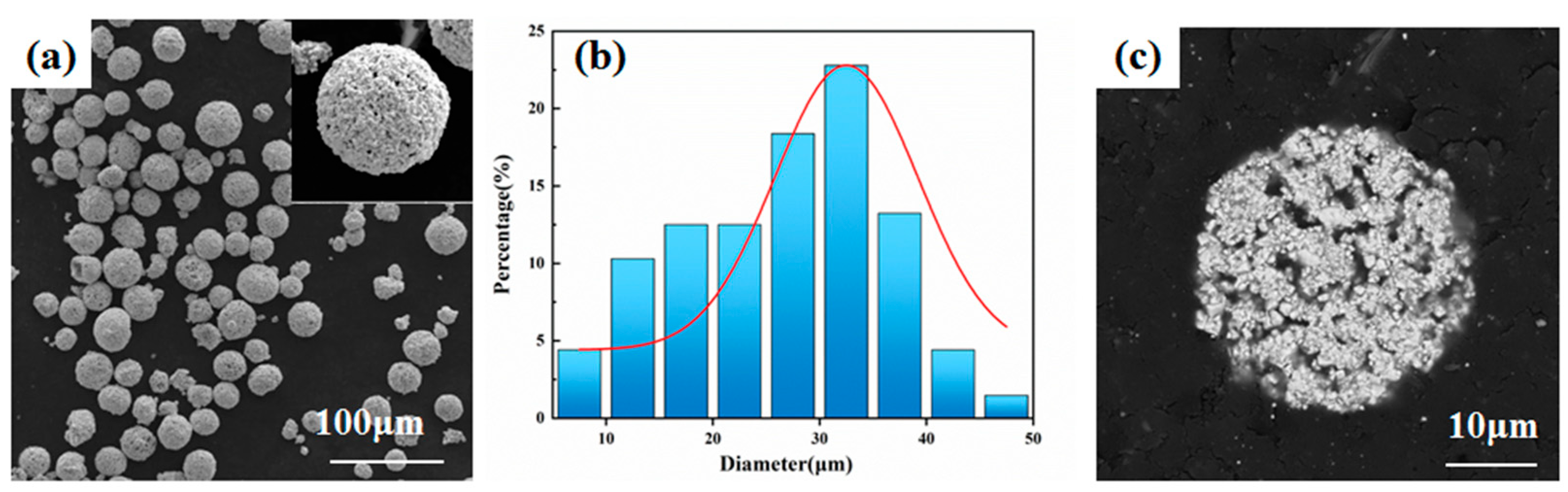

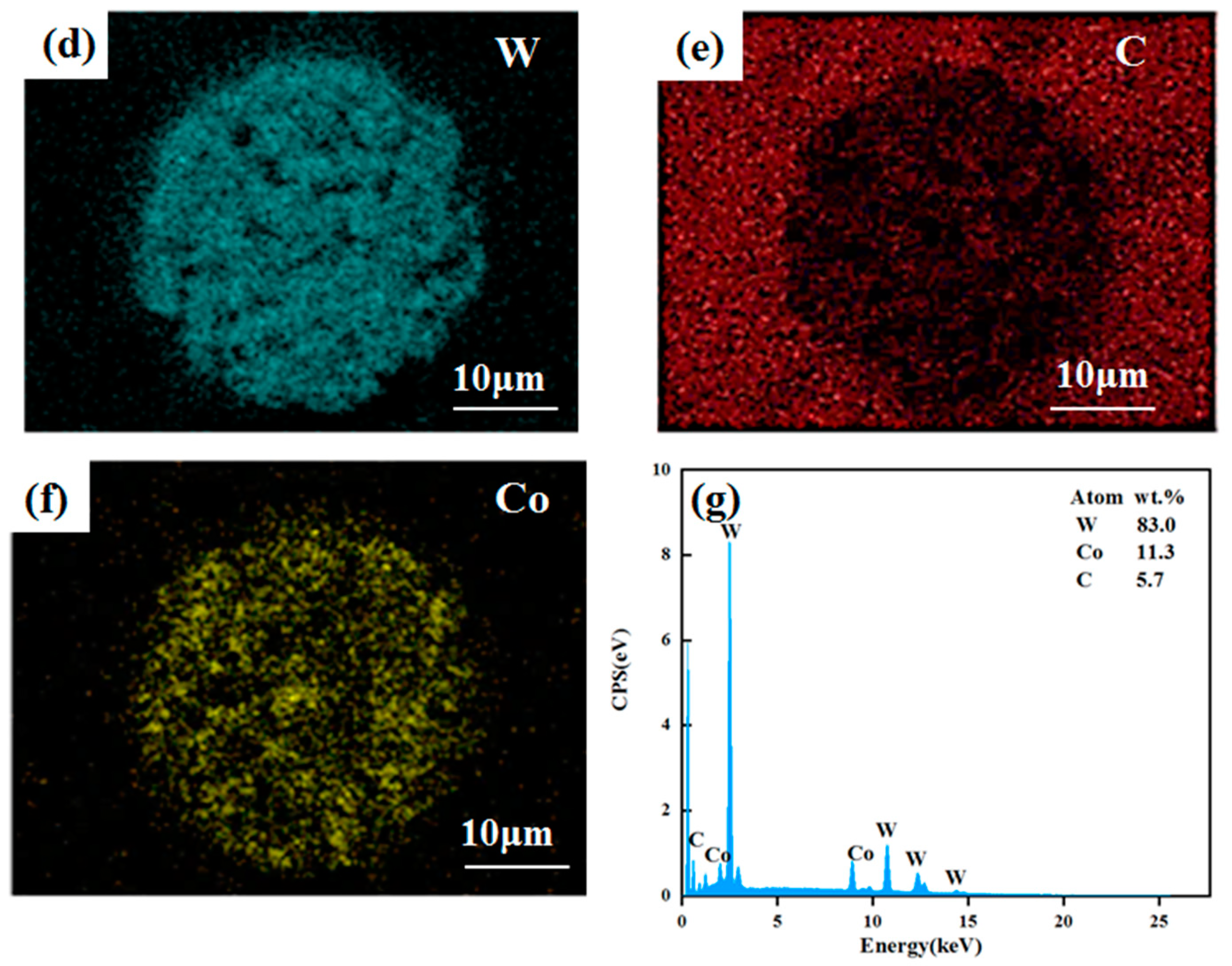

2.1. Materials

2.2. Experimental Processes

3. Results

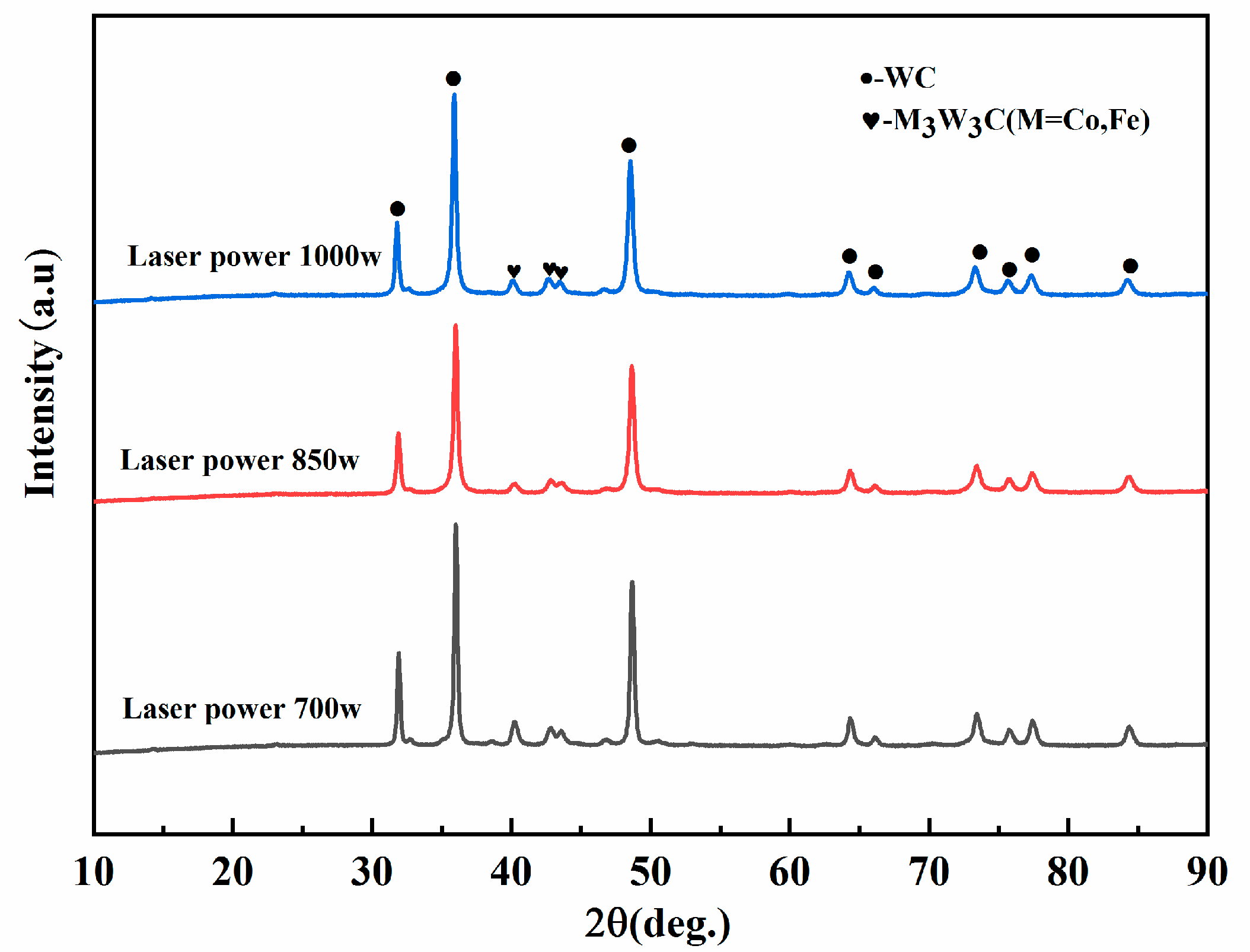

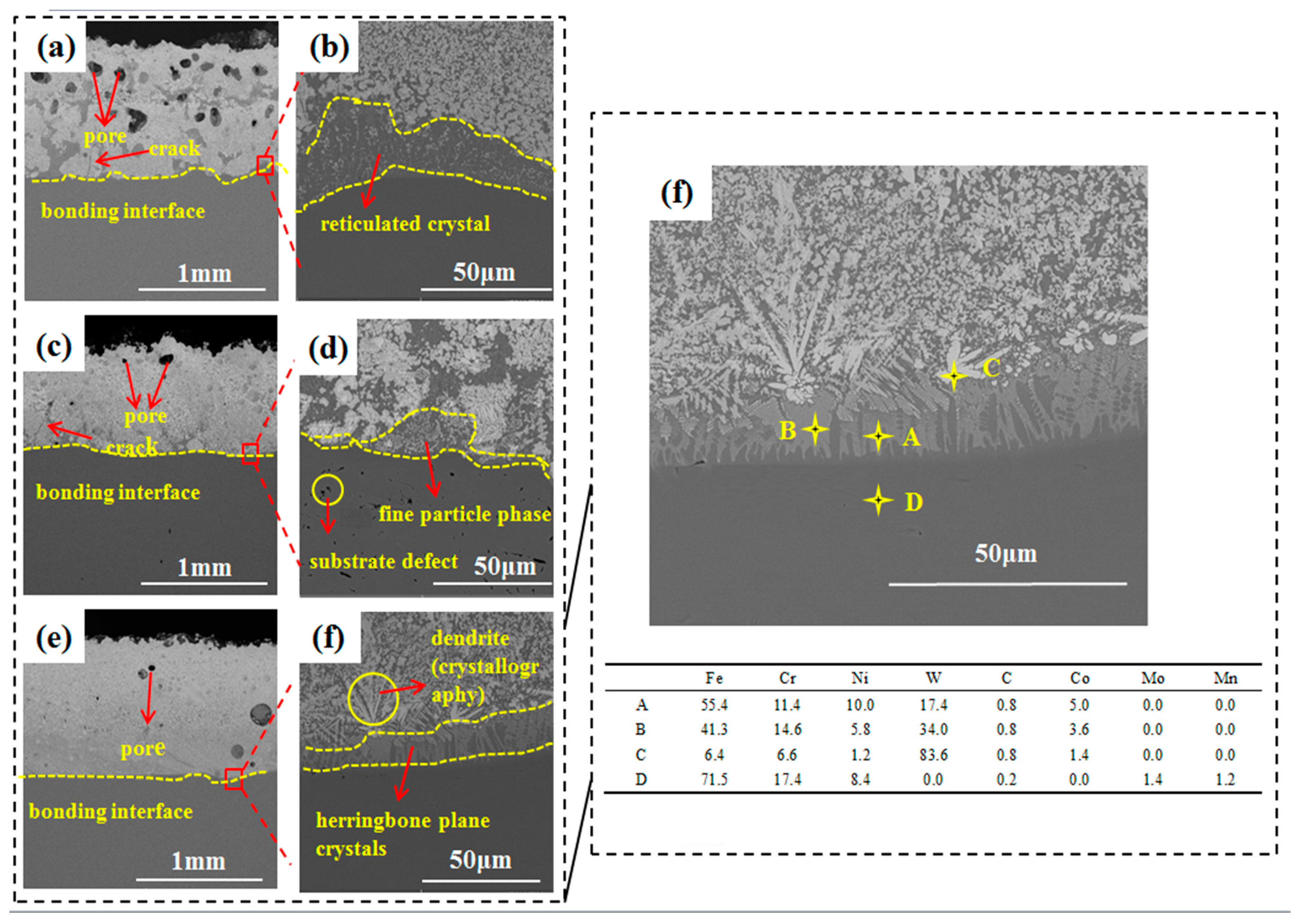

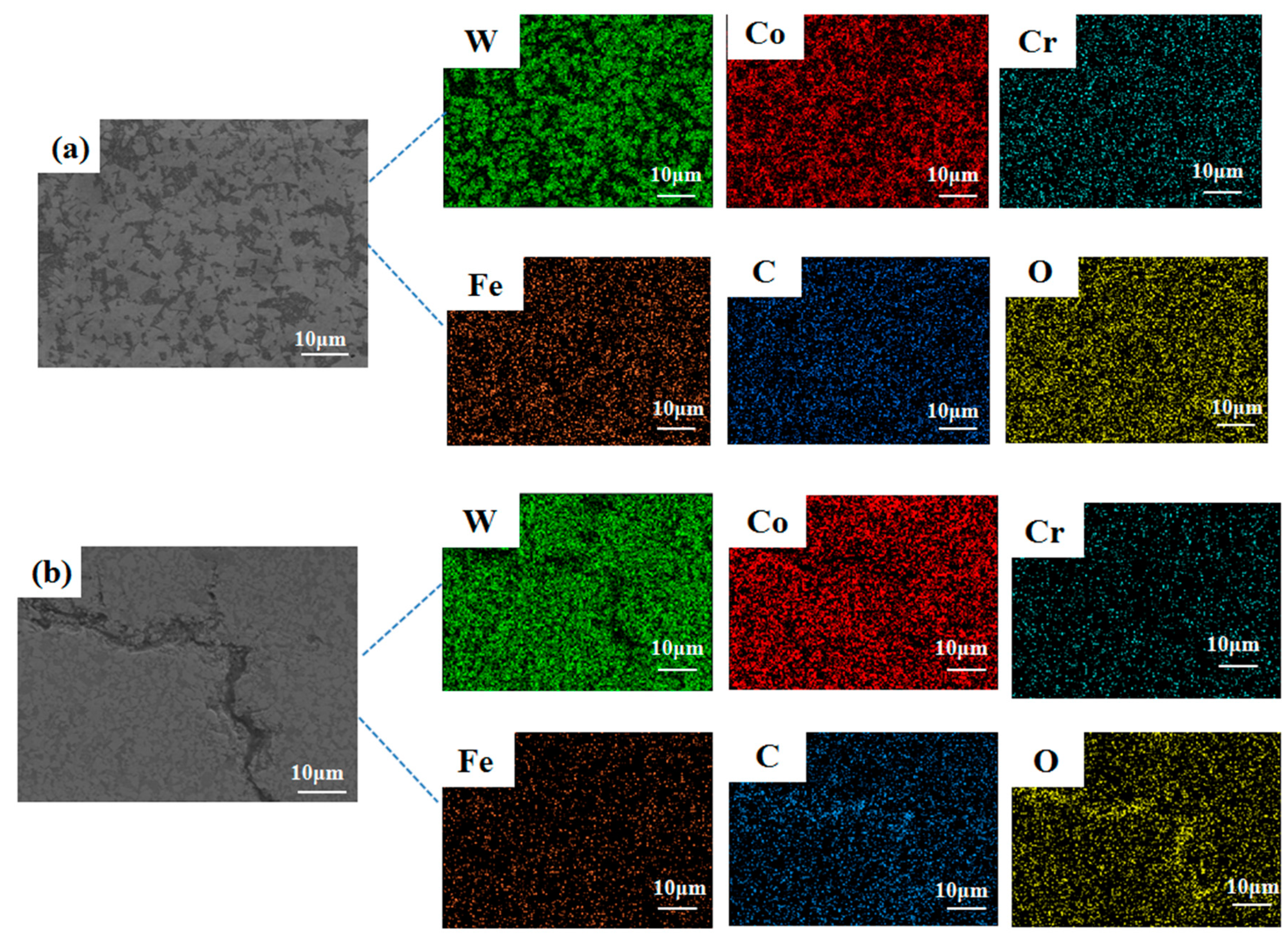

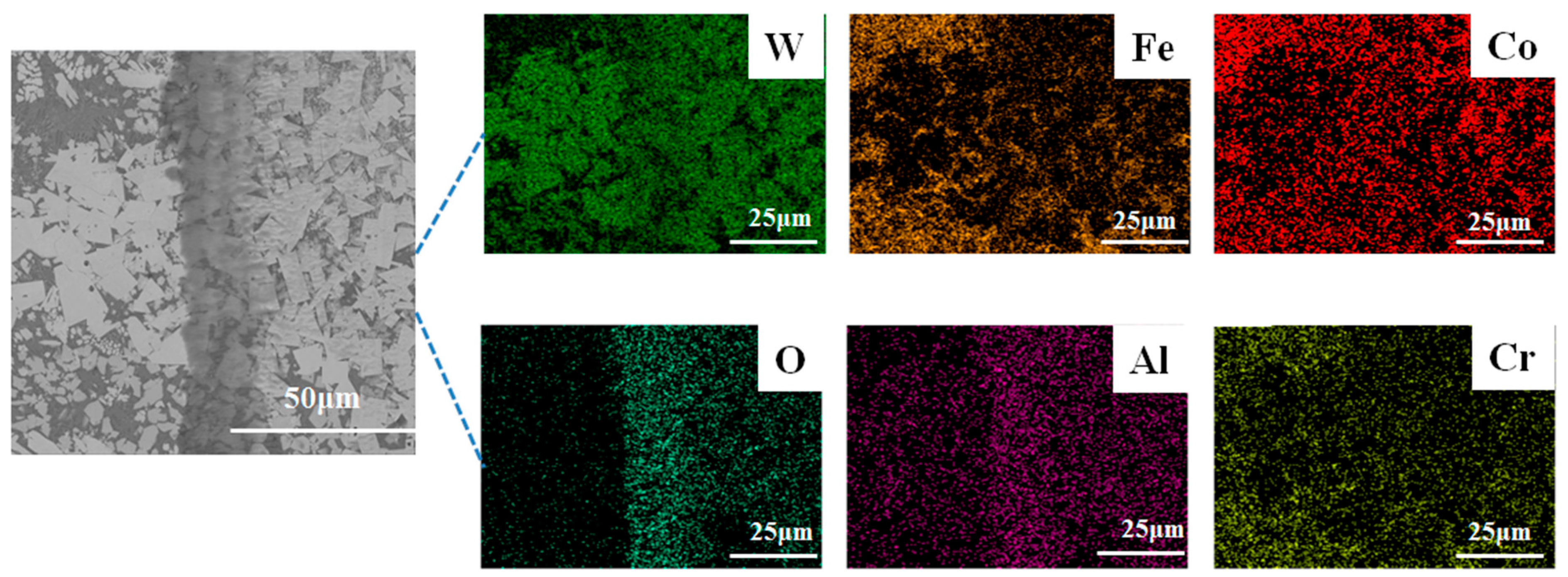

3.1. Microstructure Evolutions

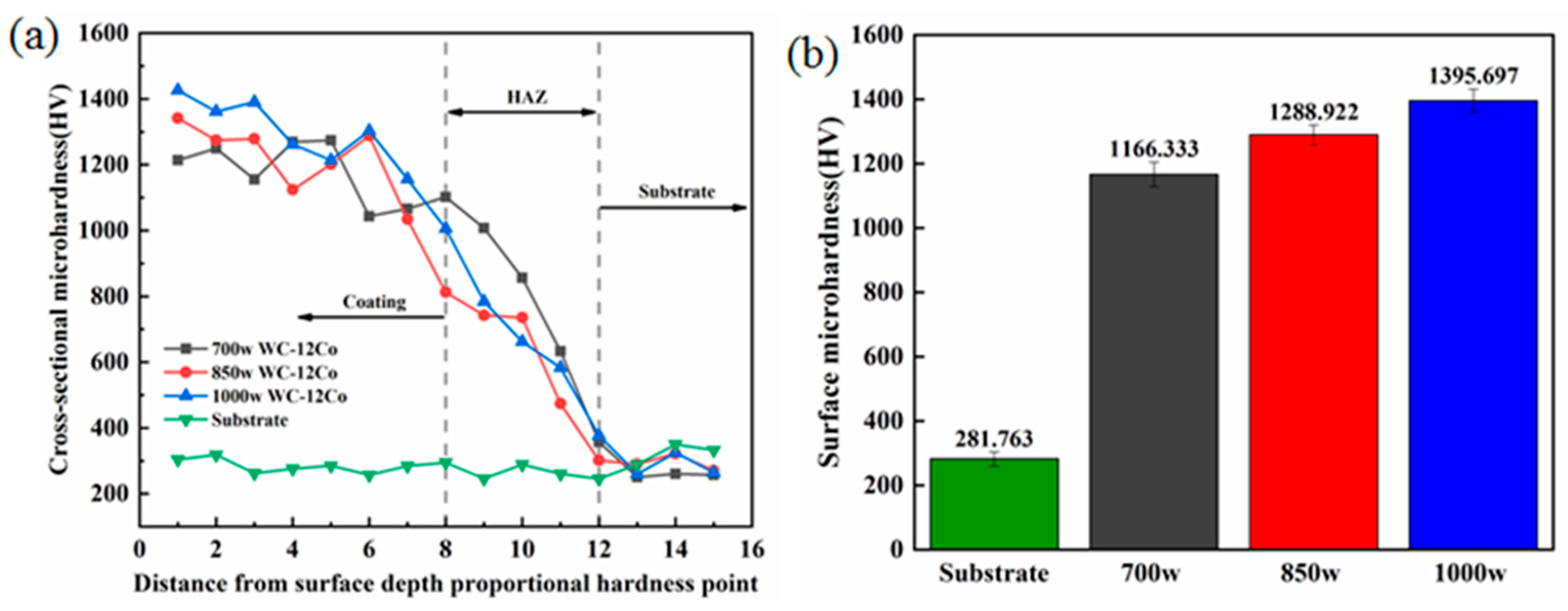

3.2. Hardness

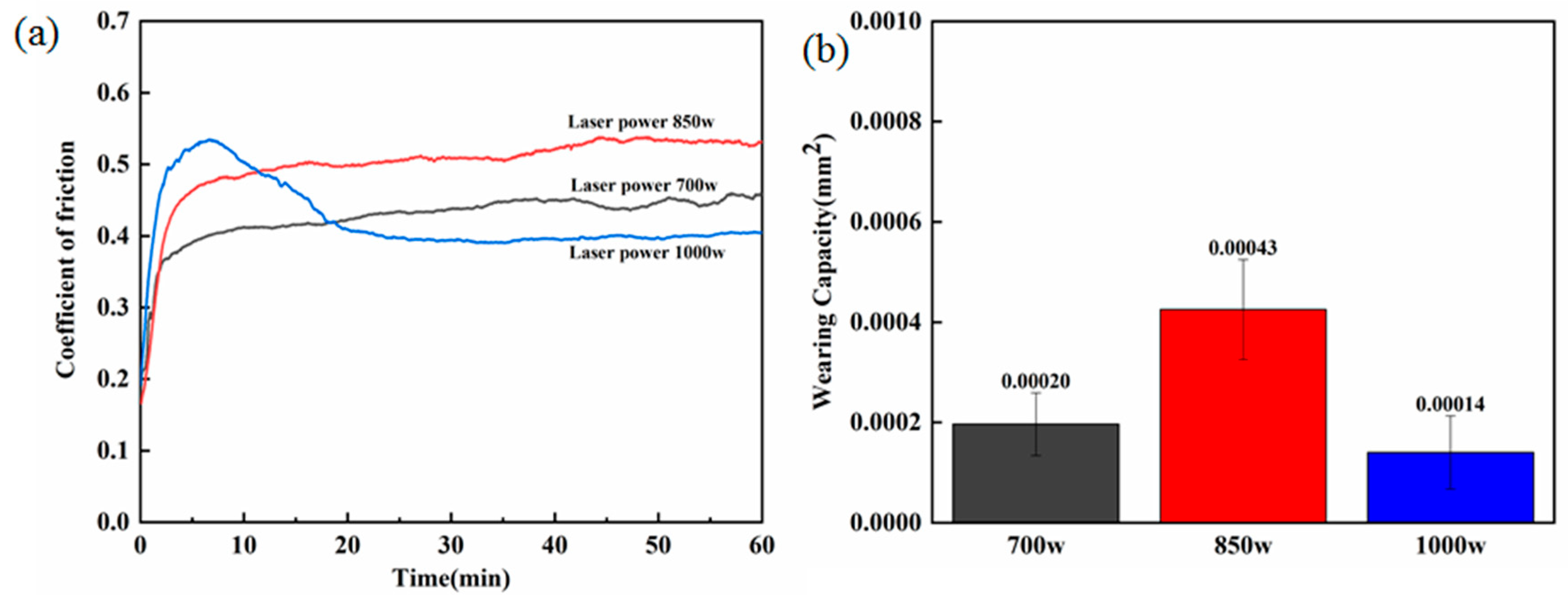

3.3. Wear Resistance

4. Discussions

4.1. Evolution of Pores and the Bounding Strength

4.2. The Inhibition of Crack

4.3. Wear Resistance Mechanism

5. Conclusions

- (1)

- WC-12Co composite coatings prepared by adopting a high-precision coaxial powder feeding system during the DED-LB processing revealed a large number of dendritic carbides and herringbone plane crystals at the matrix bonding interface.

- (2)

- With the increase in laser power from 700 W to 1000 W, the average hardness of the coating surface gradually increased from 1166.33 HV to 1395.70 HV, which was about 4–5 times of the average hardness of the substrate (about 281.76 HV). Moreover, the coatings deposited at 1000 W showed better wear resistance.

- (3)

- The laser power has a significant effect on the energy input, which determines the melting extent of the Co phases around WC particles and the bonding strength between the substrate and the coatings. Adjusting the laser power can significantly reduce the pores in the WC-12Co composite coating, promote the formation of a large number of dendritic carbides and herringbone plane crystals at the matrix bonding interface, improve the bonding strength between the coatings and the substrate, make the WC phase distribution more uniform, and refine the grains, so as to achieve the effect of improving the mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mazumder, J.; Choi, J.; Nagarathnam, K.; Koch, J.; Hetzner, D. The direct metal deposition of H13 tool steel for 3-D components. JOM 1997, 49, 55–60. [Google Scholar] [CrossRef]

- ASTM-F2792-12a; Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- Sahraoui, T.; Fenineche, N.E.; Montavon, G.; Coddet, C. Structure and wear behaviour of HVOF sprayed Cr3C2–NiCr and WC–Co coatings. Mater. Des. 2003, 24, 309–313. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-based directed energy deposition (DED-LB) of advanced materials. Mater. Sci. Eng. A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Kim, K.W.; Kale, A.B.; Cho, Y.H.; Park, S.H.; Lee, K.A. Microstructural and wear properties of WC-12Co cemented carbide fabricated by direct energy deposition. Wear 2023, 518–519, 204653. [Google Scholar] [CrossRef]

- ISO/ASTM No. 52900; Standard Guide for Additive Manufacturing—General Principles—Terminology. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 30 August 2023).

- Salmi, A.; Iuliano, L.; Pilagatti, A.N.; Atzeni, E.; Tzimanis, K.; Porevopoulos, N.; Bikas, H.; Stavropoulos, P. Process window development of DED-LB/M process with coaxial wire for stainless steel AISI 316L. Int. J. Exp. Des. Process Optim. 2024, 7, 1–26. [Google Scholar] [CrossRef]

- Karouanas, P.F.; Bikas, H.; Stavropoulos, P. A practical simulation approach for the support of wire arc DED additive manufacturing systems design. Procedia Comput. Sci. 2024, 232, 3161–3172. [Google Scholar] [CrossRef]

- Bai, X.; Colegrove, P.; Ding, J.; Zhou, X.; Diao, C.; Bridgeman, P.; Hönnige, J.R.; Zhang, H.; Williams, S. Numerical analysis of heat transfer and fluid flow in multilayer deposition of PAW-based wire and arc additive manufacturing. Int. J. Heat Mass Transf. 2018, 124, 504–516. [Google Scholar] [CrossRef]

- Ge, J.; Ma, T.; Chen, Y.; Jin, T.; Fu, H.; Xiao, R.; Lei, Y.; Lin, J. Wire-arc additive manufacturing H13 part: 3D pore distribution, microstructural evolution, and mechanical performances. J. Alloys Compd. 2019, 783, 145–155. [Google Scholar] [CrossRef]

- Haftlang, F.; Kim, H.S. A perspective on precipitation-hardening high-entropy alloys fabricated by additive manufacturing. Mater. Des. 2021, 211, 110161. [Google Scholar] [CrossRef]

- da Silva, E.N.; Santos, A.A.A.D.; Nascimento, R.M.D.; Alves, S.M.; da Silva Guimarães, R.; Filgueira, M. Investigation of characteristics and properties of spark plasma sintered ultrafine WC-6.4Fe3.6Ni alloy as potential alternative WC-Co hard metals. Int. J. Refract. Met. Hard Mater. 2021, 101, 105669. [Google Scholar] [CrossRef]

- Chen, C.; Huang, B.; Liu, Z.; Li, Y.; Zou, D.; Liu, T.; Chang, Y.; Chen, L. Additive manufacturing of WC-Co cemented carbides: Process, microstructure, and mechanical properties. Addit. Manuf. 2023, 63, 103410. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, D.; Nie, L.; Wellmann, D.; Tian, Y. Additive manufacturing of WC-Co hardmetals: A review. Int. J. Adv. Manuf. Technol. 2020, 108, 1653–1673. [Google Scholar] [CrossRef]

- Wu, X.; Shen, J.; Jiang, F.; Wu, H.; Li, L. Study on the oxidation of WC-Co cemented carbide under different conditions. Int. J. Refract. Met. Hard Mater. 2021, 94, 105381. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Shoja-Razavi, R. An empirical-statistical model for laser cladding of WC-12Co powder on AISI 321 stainless steel. Opt. Laser Technol. 2017, 97, 180–186. [Google Scholar] [CrossRef]

- Son, S.; Park, J.M.; Park, S.H.; Yu, J.-H.; Kwon, H.; Kim, H.S. Correlation between microstructural heterogeneity and mechanical properties of WC-Co composite additively manufactured by selective laser melting. Mater. Lett. 2021, 293, 129683. [Google Scholar] [CrossRef]

- Farahmand, P.; Liu, S.; Zhang, Z.; Kovacevic, R. Laser cladding assisted by induction heating of Ni–WC composite enhanced by nano-WC and La2O3. Ceram. Int. 2014, 40, 15421–15438. [Google Scholar] [CrossRef]

- Paul, C.P.; Alemohammad, H.; Toyserkani, E.; Khajepour, A.; Corbin, S. Cladding of WC–12 Co on low carbon steel using a pulsed Nd:YAG laser. Mater. Sci. Eng. A 2007, 464, 170–176. [Google Scholar] [CrossRef]

- Hu, M.; Tang, J.-C.; Chen, X.-G.; Ye, N.; Zhao, X.-Y.; Xu, M.-M. Microstructure and properties of WC-12Co composite coatings prepared by laser cladding. Trans. Nonferrous Met. Soc. China 2020, 30, 1017–1030. [Google Scholar] [CrossRef]

- Singh, J.; Thakur, L.; Angra, S. A study of tribological behaviour and optimization of WC-10Co-4Cr Cladding. Surf. Eng. 2020, 37, 70–79. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Barekat, M.; Hashemi, S.H. Friction and wear behavior of laser cladded WC-Co and Ni/WC-Co deposits at high temperature. Int. J. Refract. Met. Hard Mater. 2019, 81, 137–148. [Google Scholar] [CrossRef]

- Gu, D.; Ma, J.; Chen, H.; Lin, K.; Xi, L. Laser additive manufactured WC reinforced Fe-based composites with gradient reinforcement/matrix interface and enhanced performance. Compos. Struct. 2018, 192, 387–396. [Google Scholar] [CrossRef]

- Song, H.; Lei, J.; Xie, J.; Wu, S.; Wang, L.; Shou, W. Laser melting deposition of K403 superalloy: The influence of processing parameters on the microstructure and wear performance. J. Alloys Compd. 2019, 805, 551–564. [Google Scholar] [CrossRef]

- Feng, K.; Chen, Y.; Deng, P.; Li, Y.; Zhao, H.; Lu, F.; Li, R.; Huang, J.; Li, Z. Improved high-temperature hardness and wear resistance of Inconel 625 coatings fabricated by laser cladding. J. Mater. Process. Technol. 2017, 243, 82–91. [Google Scholar] [CrossRef]

- Shim, D.-S.; Baek, G.-Y.; Seo, J.-S.; Shin, G.-Y.; Kim, K.-P.; Lee, K.-Y. Effect of layer thickness setting on deposition characteristics in direct energy deposition (DED) process. Opt. Laser Technol. 2016, 86, 69–78. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- He, S.; Park, S.; Shim, D.-S.; Yao, C.; Zhang, W.-J. Study on microstructure and abrasive behaviors of inconel 718-WC composite coating fabricated by laser-directed energy deposition. J. Mater. Res. Technol. 2022, 21, 2926–2946. [Google Scholar] [CrossRef]

- Zhou, S.; Zeng, X.; Hu, Q.; Huang, Y. Analysis of crack behavior for Ni-based WC composite coatings by laser cladding and crack-free realization. Appl. Surf. Sci. 2008, 255, 1646–1653. [Google Scholar] [CrossRef]

- Afzal, M.; Khan, A.N.; Mahmud, T.B.; Khan, T.I.; Ajmal, M. Effect of laser melting on plasma sprayed WC-12wt.%Co coatings. Surf. Coat. Technol. 2015, 266, 22–30. [Google Scholar] [CrossRef]

- Zhao, J.; Li, R.; Feng, A.; Feng, H. Effect of rare earth La2O3 particles on structure and properties of laser cladding WC-Ni60 composite coatings. Surf. Coat. Technol. 2024, 479, 130569. [Google Scholar] [CrossRef]

- Liverani, E.; Ascari, A.; Fortunato, A. Multilayered WC–Co coatings by Direct Energy Deposition-based cladding: Effect of laser remelting on interface defects. Surf. Coat. Technol. 2023, 464, 129556. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, J.; Chen, Y.; Hou, Z.; Zhao, Q.; Li, Y.; Zhu, L.; Zhang, F.; Zhao, Y. On enhancing wear resistance of titanium alloys by laser cladded WC-Co composite coatings. Int. J. Refract. Met. Hard Mater. 2022, 107, 105902. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Shoja-Razavi, R. Kinetics and oxidation behavior of laser clad WC-Co and Ni/WC-Co coatings. Ceram. Int. 2018, 44, 12805–12814. [Google Scholar] [CrossRef]

- Chuang, H. Effect of laser power on the organization and tribological properties of laser melted Ni-60% WC coatings. Appl. Laser 2024, 44, 40–50. [Google Scholar]

| Elements | Fe | Cr | Ni | P | S | Mn | Si | Mo | N | C |

|---|---|---|---|---|---|---|---|---|---|---|

| Percent (wt.%) | Bal. | 16.080 | 10.090 | 0.027 | 0.005 | 1.150 | 0.450 | 2.030 | 0.048 | 0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Yang, H.; Liu, Y.; Li, F.; Yi, J.; Eckert, J. Effect of Laser Power on Microstructure and Properties of WC-12Co Composite Coatings Deposited by Laser-Based Directed Energy Deposition. Materials 2024, 17, 4215. https://doi.org/10.3390/ma17174215

Li W, Yang H, Liu Y, Li F, Yi J, Eckert J. Effect of Laser Power on Microstructure and Properties of WC-12Co Composite Coatings Deposited by Laser-Based Directed Energy Deposition. Materials. 2024; 17(17):4215. https://doi.org/10.3390/ma17174215

Chicago/Turabian StyleLi, Wen, Husen Yang, Yichun Liu, Fengxian Li, Jianhong Yi, and Jürgen Eckert. 2024. "Effect of Laser Power on Microstructure and Properties of WC-12Co Composite Coatings Deposited by Laser-Based Directed Energy Deposition" Materials 17, no. 17: 4215. https://doi.org/10.3390/ma17174215

APA StyleLi, W., Yang, H., Liu, Y., Li, F., Yi, J., & Eckert, J. (2024). Effect of Laser Power on Microstructure and Properties of WC-12Co Composite Coatings Deposited by Laser-Based Directed Energy Deposition. Materials, 17(17), 4215. https://doi.org/10.3390/ma17174215