Experimental Study on Mechanical Properties of Recycled Aggregate Mixed Soil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- (a).

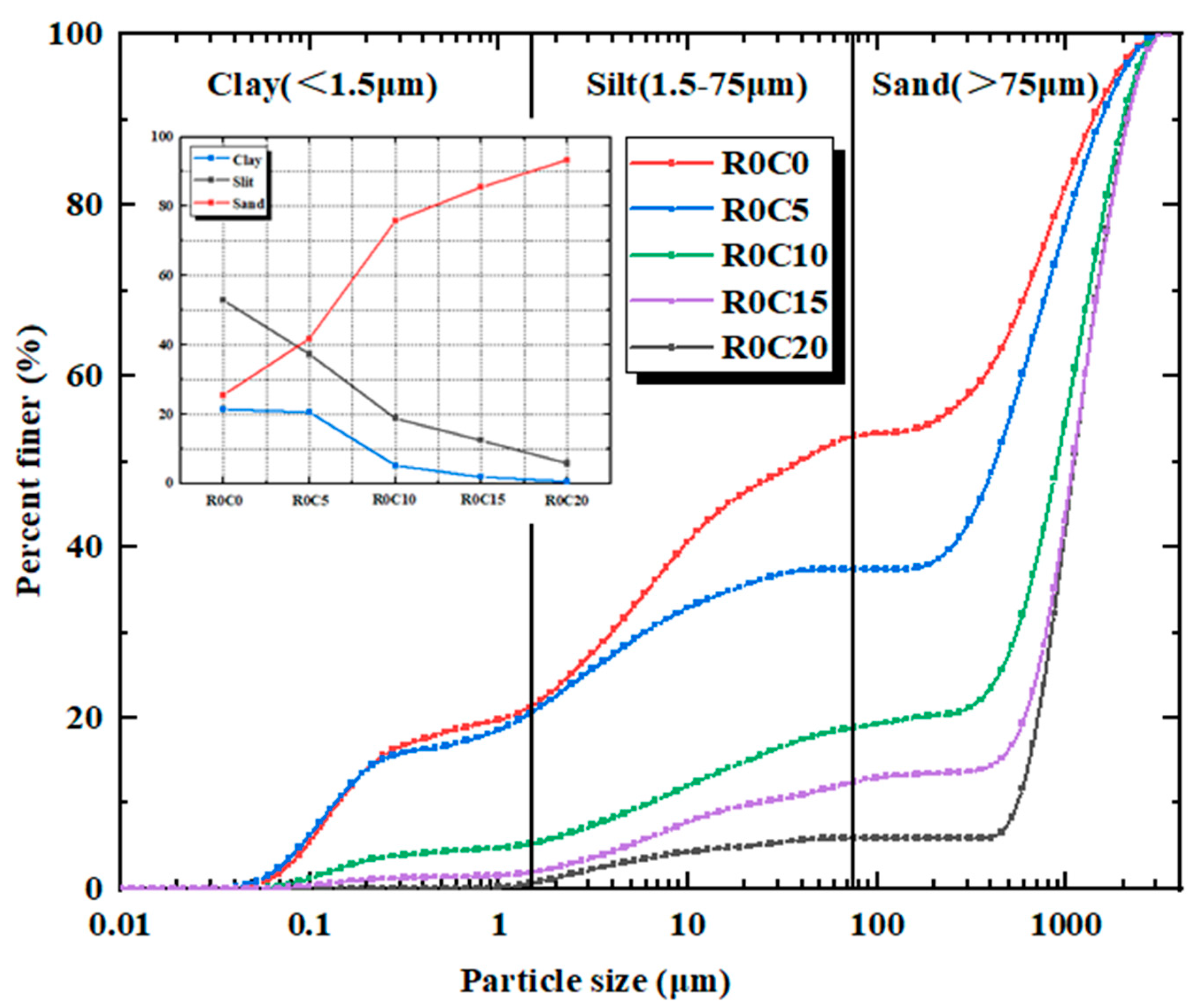

- The test soil utilized in this study originates from a region in Hainan Province and consists of red clay. The soil samples are all remolded. The original soil was dried and crushed, then sieved through a 2 mm mesh. Particles smaller than 2 mm were selected for the study, and their particle size distribution is presented in Figure 1. The properties of the red clay were measured according to the Standard for Geotechnical Test Methods (GB/T 50123-2019), with the results summarized in Table 1. Additionally, the mineral composition of the red clay was analyzed using X-ray diffraction (XRD), revealing that the red clay is predominantly composed of quartz and kaolinite, which account for 61.9% and 38.1% of the chemical composition, respectively.

- (b).

- The recycled aggregates used in the test were sourced from demolished old houses and laboratory waste concrete test blocks. After the manual removal of debris, the materials were processed, crushed, and sieved through a 2 mm screen. Aggregates with a particle size range of 1 mm to 2 mm were selected as one of the raw materials for this test. The recycled fine aggregate and curing agent utilized in the study are depicted in Figure 2.

- (c).

2.2. Sample Preparation

2.3. Test Equipment

2.4. Experimental Programs

3. Results

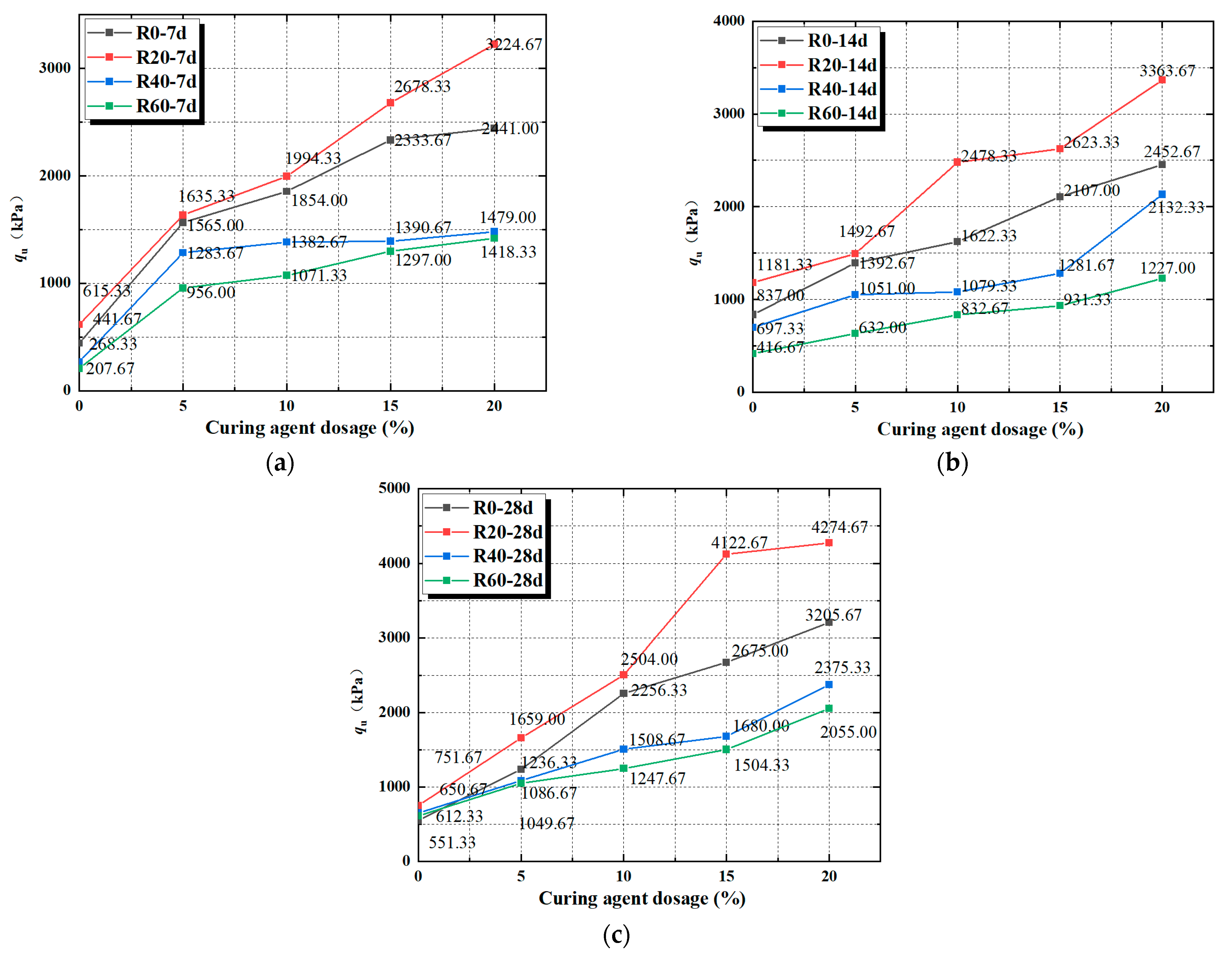

3.1. Effect of Curing Agent on Unconfined Compressive Strength

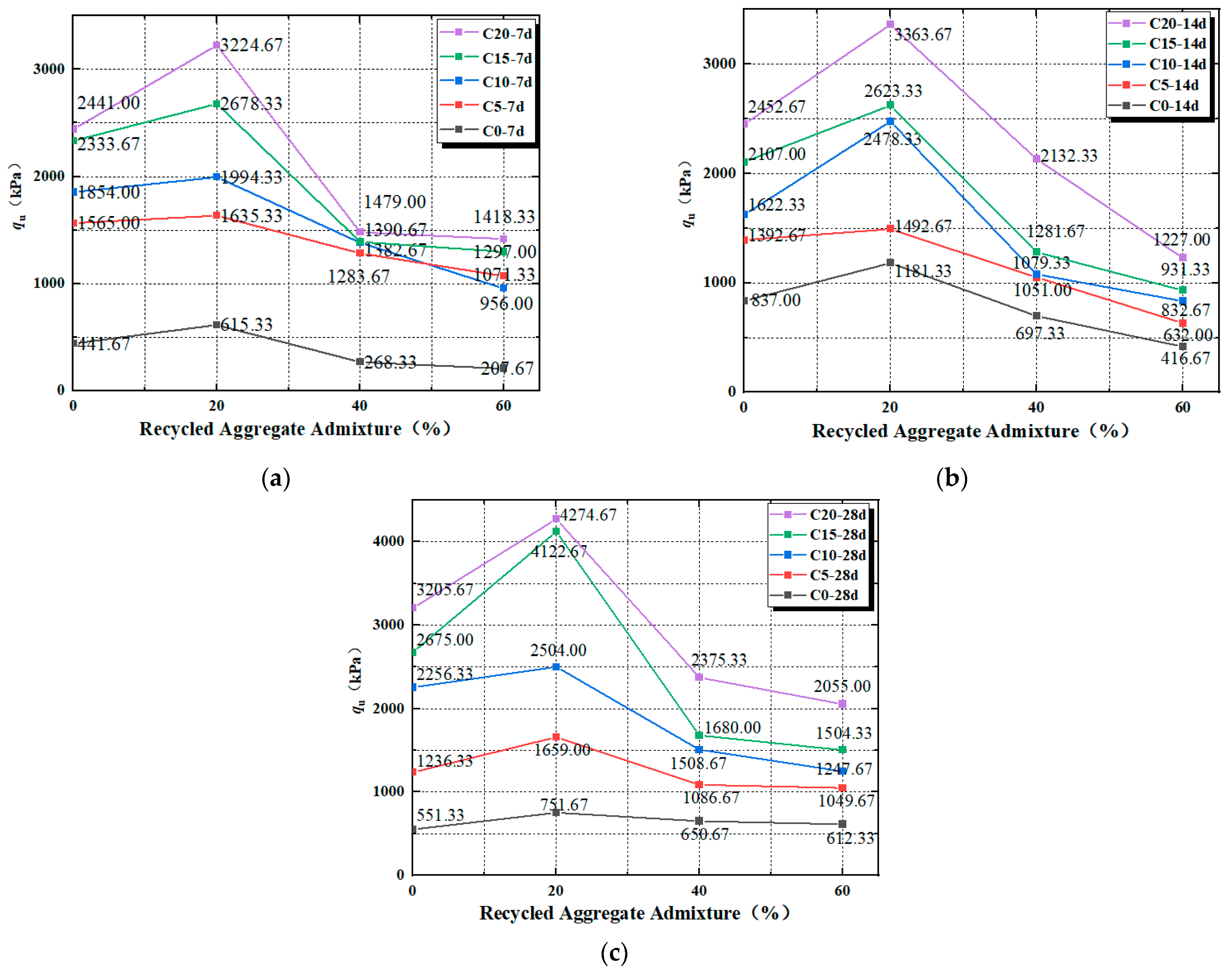

3.2. Effect of Recycled Aggregate on Unconfined Compressive Strength

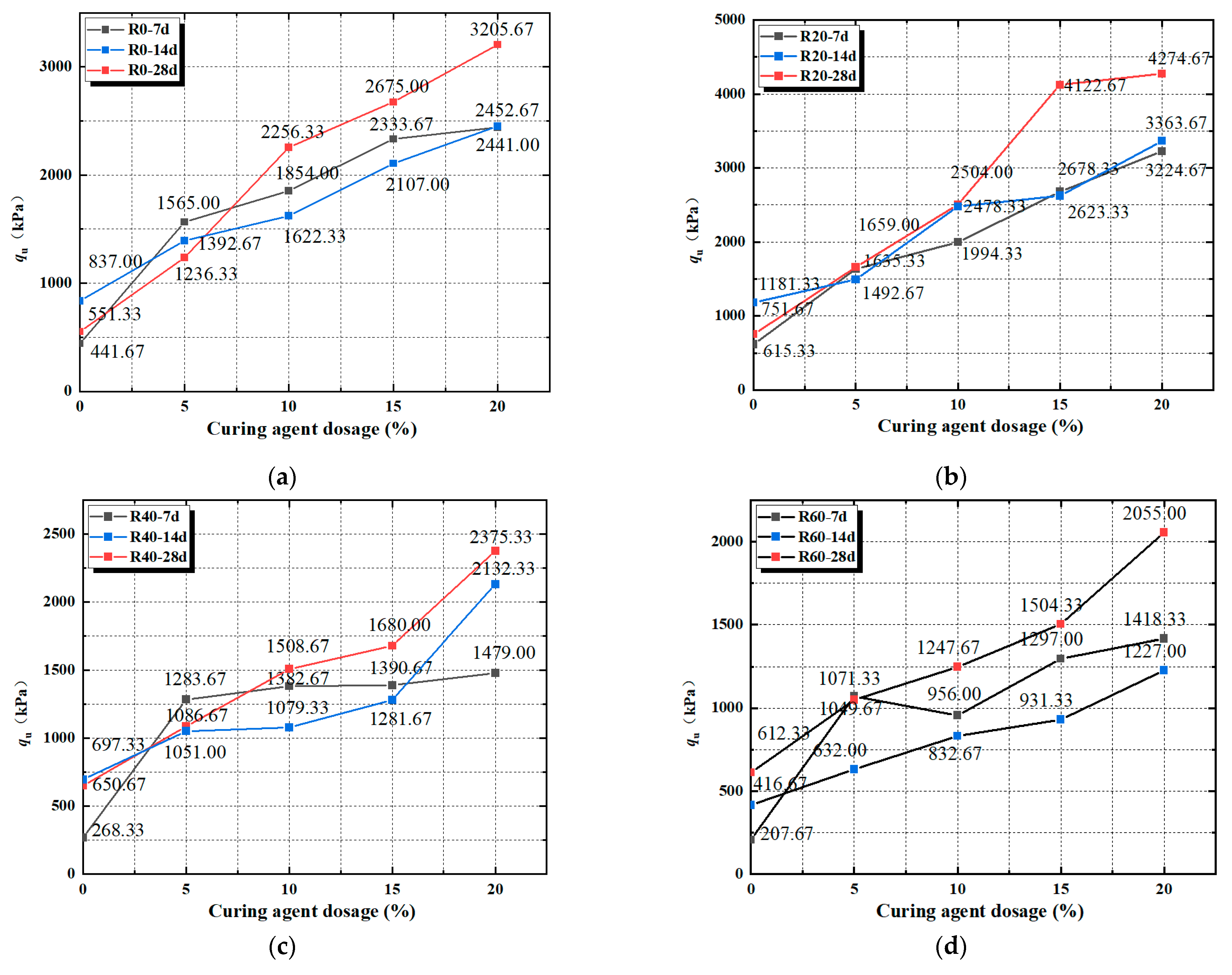

3.3. Effect of Age of Maintenance on Unconfined Compressive Strength

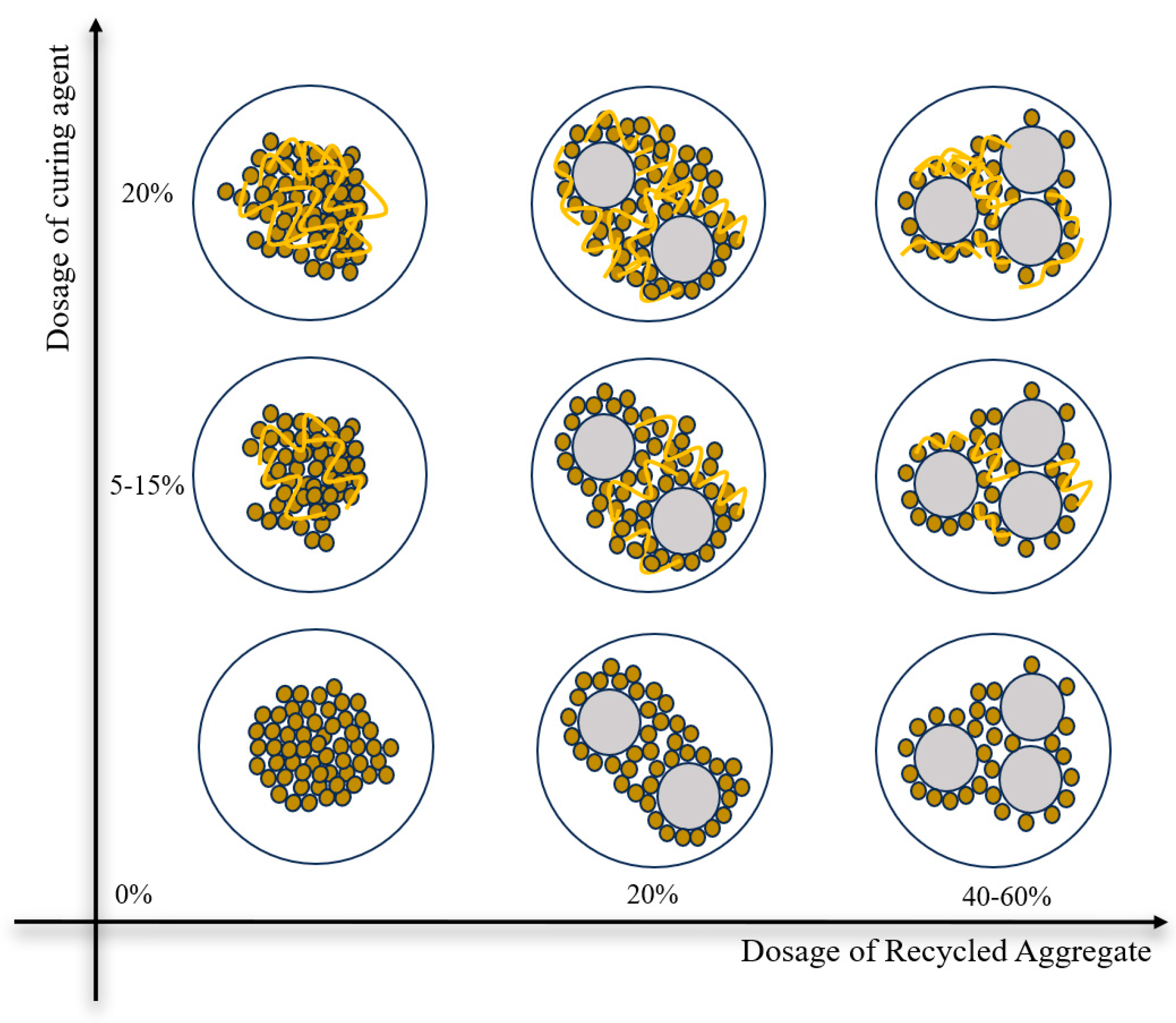

3.4. Mechanical Property Mechanism Analysis

3.5. Particle Size Distribution

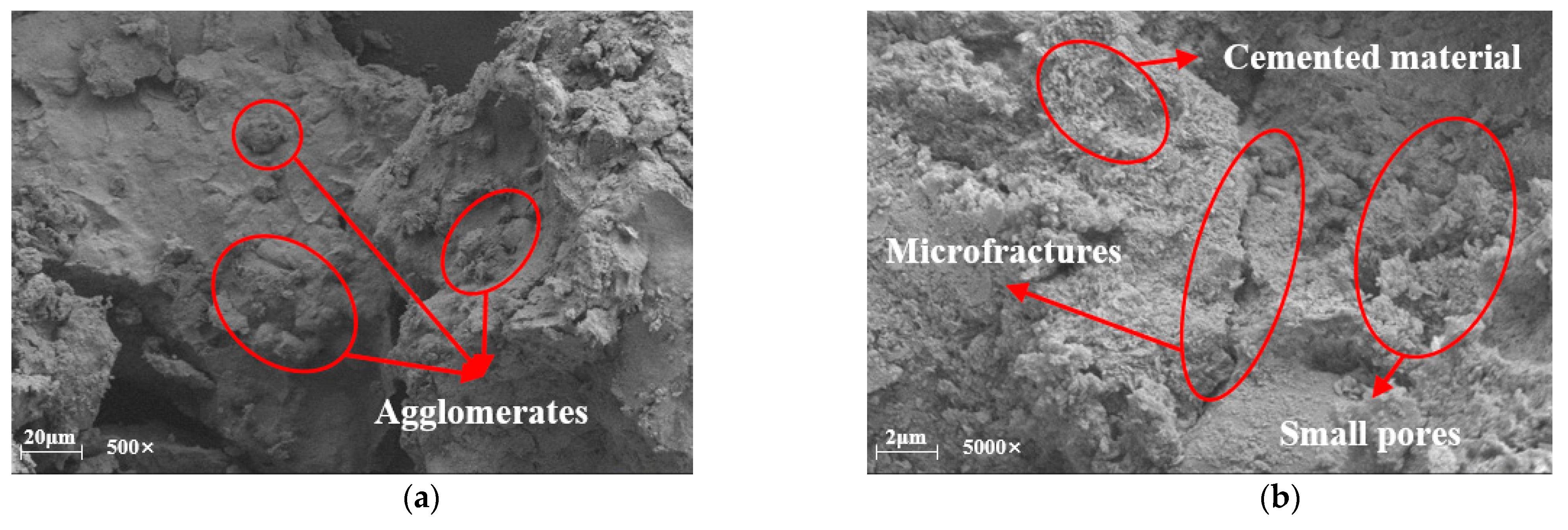

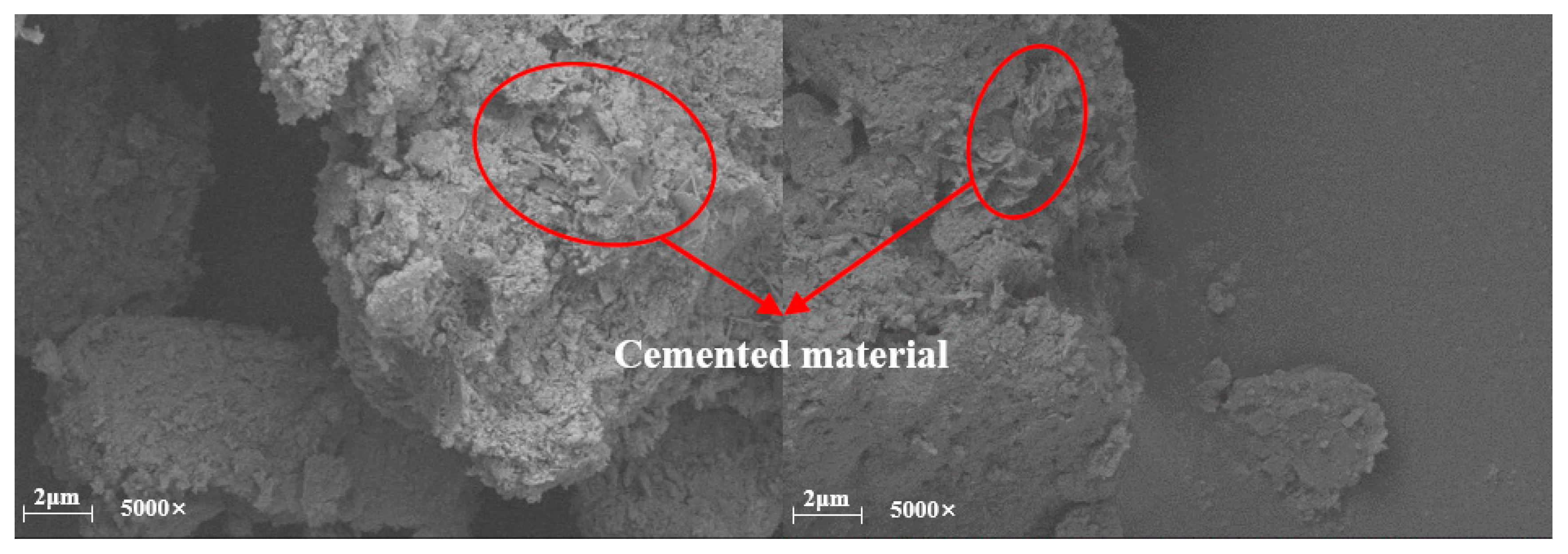

3.6. Field Emission Scanning Electron Microscope (FESEM)

4. Conclusions

- (a).

- The PSD curve of the mixed soil was gradually shifted to the right by the addition of curing agent to the red clay, and the shifting trend was more obvious with the increase in curing agent dosage. When the amount of curing agent reaches 20%, the proportion of coarse grains reaches the maximum, which indicates that the addition of curing agent not only changes the particle size in the mixed soil, but also induces the aggregation effect of red clay particles. This phenomenon proves that the curing agent can enhance the mechanical properties of the mixed soil from a microscopic aspect.

- (b).

- Using SEM scanning electron microscope (Thermo Fisher Scientific, Waltham, MA, USA) to scan and analyze the micrographs of specimens without added recycled aggregates (R0C0-28d, R0C10-28d, R0C20-28d), it was concluded that the cementing material produced by the hydration reaction of the curing agent inside the specimens and the red clay worked together to fill the pore structure and cracks of the specimens to make the specimens more compact, which further proved the mechanical properties of the curing agent-enhanced soil mixes from the microscopic point of view. The mechanical properties of the curing agent-enhanced mixed soil were proved.

- (c).

- Due to the addition of the recycled aggregate and curing agent, the mechanical properties of the soil mixture in the two dosages of 20% reached the maximum, which was considered because of the random distribution of the recycled aggregate inside the specimen by the red clay and the curing agent fully wrapped agglomerates, while the curing agent reaction of the cementing material was produced by the filling of its pores, so that the specimen was more crowded inside the specimen, so that the specimen can withstand higher pressures, and ultimately lead to the peak strength reaching the maximum.

- (d).

- Through the unconfined compressive strength test, and through the one-factor peak analysis method, the following conclusions were found: the maximum peak strength when the dosage of recycled aggregate was 20%, the maximum peak strength when the dosage of hardener was 20%, and the maximum peak strength when the maintenance time was 28 d. Therefore, for this study, the proportion program R20C20-28d was the optimal program, which provides a reference value for the actual project.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Wu, H.; Duan, H.; Zillante, G.; Zuo, J.; Yuan, H. Combining life cycle assessment and Building Information Modelling to account for carbon emission of building demolition waste: A case study. J. Clean. Prod. 2018, 172, 3154–3166. [Google Scholar] [CrossRef]

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, L. Sustainable waste management and waste to energy: Valuation of energy potential of MSW in the Greater Bay Area of China. Energy Policy 2022, 163, 112857. [Google Scholar] [CrossRef]

- Kim, J. Construction and demolition waste management in Korea: Recycled aggregate and its application. Clean Technol. Environ. Policy 2021, 23, 2223–2234. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef]

- Alsheyab, M.A.T. Recycling of construction and demolition waste and its impact on climate change and sustainable development. Int. J. Environ. Sci. Technol. 2022, 19, 2129–2138. [Google Scholar] [CrossRef]

- Álvarez, M.; Santos, P.; Lopes, P.; Abrantes, D.; Ferrández, D. Performance Characterisation of a New Plaster Composite Lightened with End-of-Life Tyres’ Recycled Materials for False Ceiling Plates. Materials 2022, 15, 5660. [Google Scholar] [CrossRef]

- Oliveira, M.L.S.; Izquierdo, M.; Querol, X.; Lieberman, R.N.; Saikia, B.K.; Silva, L.F. Nanoparticles from construction wastes: A problem to health and the environment. J. Clean. Prod. 2019, 219, 236–243. [Google Scholar] [CrossRef]

- Francart, N.; Widström, T.; Malmqvist, T. Influence of methodological choices on maintenance and replacement in building LCA. Int. J. Life Cycle Assess. 2021, 26, 2109–2126. [Google Scholar] [CrossRef]

- Xiao, J.; Xiao, Y.; Liu, Y.; Ding, T. Carbon emission analyses of concretes made with recycled materials considering CO2 uptake through carbonation absorption. Struct. Concr. 2021, 22, E58–E73. [Google Scholar] [CrossRef]

- De Luca, A.; Chen, L.; Gharehbaghi, K. Sustainable utilization of recycled aggregates: Robust construction and demolition waste reduction strategies. Int. J. Build. Pathol. Adapt. 2021, 39, 666–682. [Google Scholar] [CrossRef]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- Luo, L.; Yao, W.; Liao, G. Effect of Recycled Fine Aggregates on the Mechanical and Drying Shrinkage Properties of Alkali-Activated Recycled Concrete. Materials 2024, 17, 2102. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; She, A.; Yao, W. Investigation of Water Absorption Behavior of Recycled Aggregates and its Effect on Concrete Strength. Materials 2023, 16, 4505. [Google Scholar] [CrossRef]

- Bergmans, J.; Kazemi Kamyab, H.; Ghosh, D.; Van Mierloo, P.; Carens, H.; Nielsen, P. Carbonation of Recycled Concrete Aggregates for New Concrete and Concrete Fines to Make Cement-Free Hollow Blocks. Sustainability 2024, 16, 3494. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Silva, H.M.R.D.; Oliveira, J.R.M.; Moura, C.F.; Loureiro, C.D.A.; Silvestre, J.D.; Rodrigues, M.M.M. Mechanical and Environmental Performance of Asphalt Concrete with High Amounts of Recycled Concrete Aggregates (RCA) for Use in Surface Courses of Pavements. Sustainability 2023, 16, 248. [Google Scholar] [CrossRef]

- Liu, W.; Cao, W.; Zhang, J.; Wang, R.; Ren, L. Mechanical Behavior of Recycled Aggregate Concrete-Filled Steel Tubular Columns before and after Fire. Materials 2017, 10, 274. [Google Scholar] [CrossRef]

- Maduabuchukwu Nwakaire, C.; Poh Yap, S.; Chuen Onn, C.; Yuen, C.W.; Ibrahim, H.A. Utilisation of recycled concrete aggregates for sustainable highway pavement applications; a review. Constr. Build. Mater. 2020, 235, 117444. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- De Andrade Salgado, F.; De Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Reis, G.S.D.; Quattrone, M.; Ambrós, W.M.; Cazacliu, B.G.; Sampaio, C.H. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef] [PubMed]

- Cai, X.; Wu, K.; Huang, W.; Yu, J.; Yu, H. Application of recycled concrete aggregates and crushed bricks on permeable concrete road base. Road Mater. Pavement Des. 2021, 22, 2181–2196. [Google Scholar] [CrossRef]

- Shang, Y.; Cui, Z.; Zhang, Y. Experimental Study on the Synergistic Solidification of Soft Soil with Ceramic Powder–Slag–Phosphorus Slag. Sustainability 2023, 15, 15474. [Google Scholar] [CrossRef]

- Wu, J.; Liu, L.; Deng, Y.; Zhang, G.; Zhou, A.; Xiao, H. Use of recycled gypsum in the cement-based stabilization of very soft clays and its micro-mechanism. J. Rock Mech. Geotech. Eng. 2022, 14, 909–921. [Google Scholar] [CrossRef]

- Ekmen, A.B.; Algin, H.M.; Özen, M. Strength and stiffness optimisation of fly ash-admixed DCM columns constructed in clayey silty sand. Transp. Geotech. 2020, 24, 100364. [Google Scholar] [CrossRef]

- Tatsouka, F.; Guler, E.; Shehata, H.; Giroud, J.P. Innovative Infrastructure Solutions Using Geosynthetics. In Proceedings of the 3rd GeoMEast International Congress and Exhibition, Egypt 2019 on Sustainable Civil Infrastructures–The Official International Congress of the Soil-Structure Interaction Group in Egypt (SSIGE), Cairo, Egypt, 10–14 November 2019; Springer International Publishing: Cham, Germany, 2020. [Google Scholar]

- Bhavita Chowdary, V.; Ramanamurty, V.; Pillai, R.J. Experimental evaluation of strength and durability characteristics of geopolymer stabilised soft soil for deep mixing applications. Innov. Infrastruct. Solut. 2021, 6, 40. [Google Scholar] [CrossRef]

- Xing, H.; Xiong, F.; Zhou, F. Improvement for the strength of salt-rich soft soil reinforced by cement. Mar. Georesources Geotechnol. 2018, 36, 38–42. [Google Scholar]

- Jiang, N.; Wang, C.; Wang, Z.; Li, B.; Liu, Y. Strength Characteristics and Microstructure of Cement Stabilized Soft Soil Admixed with Silica Fume. Materials 2021, 14, 1929. [Google Scholar] [CrossRef]

- Bui Truong, S.; Nguyen Thi, N.; Nguyen Thanh, D. An Experimental Study on Unconfined Compressive Strength of Soft Soil-Cement Mixtures with or without GGBFS in the Coastal Area of Vietnam. Adv. Civ. Eng. 2020, 2020, 7243704. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, J.; Wang, Y.; Yi, N.; Cui, C. Strength Performance and Microstructure of Calcium Sulfoaluminate Cement-Stabilized Soft Soil. Sustainability 2021, 13, 2295. [Google Scholar] [CrossRef]

- Ngoc, B.V. Characteristics of Clay Soft Soil in the Mekong Delta of Vietnam and Improvement Result with Cement. Iraqi Geol. J. 2022, 55, 64–73. [Google Scholar] [CrossRef]

- Niu, W.; Guo, B.; Li, K.; Ren, Z.; Zheng, Y.; Liu, J.; Lin, H.; Men, X. Cementitous material based stabilization of soft soils by stabilizer: Feasibility and durabiliy assessment. Constr. Build. Mater. 2024, 425, 136046. [Google Scholar] [CrossRef]

- Qin, J.; Yi, Y. Use of gasification fly ash, sodium carbonate, and ground granulated blast-furnace slag for soft clay stabilization. Constr. Build. Mater. 2024, 426, 136072. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, Z.; Chen, K.; Xia, L. Experimental Investigation and Mechanism of Fly Ash/Slag-Based Geopolymer-Stabilized Soft Soil. Appl. Sci. 2022, 12, 7438. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Jahani, A.; Javadi, A.A.; Babalar, M. Assessment of different agents for stabilisation of a clay soil. Int. J. Pavement Eng. 2022, 23, 160–170. [Google Scholar] [CrossRef]

- Li, M.; Wang, Q.; Yang, J.; Guo, X.; Zhou, W. Strength and Mechanism of Carbonated Solidified Clay with Steel Slag Curing Agent. KSCE J. Civ. Eng. 2021, 25, 805–821. [Google Scholar] [CrossRef]

- Chen, R.; Congress, S.S.C.; Cai, G.; Duan, W.; Liu, S. Sustainable utilization of biomass waste-rice husk ash as a new solidified material of soil in geotechnical engineering: A review. Constr. Build. Mater. 2021, 292, 123219. [Google Scholar] [CrossRef]

- Latifi, N.; Marto, A.; Eisazadeh, A. Physicochemical behavior of tropical laterite soil stabilized with non-traditional additive. Acta Geotech. 2016, 11, 433–443. [Google Scholar] [CrossRef]

- Shen, J.; Xu, Y.; Chen, J.; Wang, Y. Study on the stabilization of a new type of waste solidifying agent for soft soil. Materials 2019, 12, 826. [Google Scholar] [CrossRef]

- Qiu, K.; Zeng, G.; Shu, B.; Luo, D. Study on the performance and solidification mechanism of multi-source solid-waste-based soft soil solidification materials. Materials 2023, 16, 4517. [Google Scholar] [CrossRef]

- Wang, A.; Dong, W.; Zhan, Q.; Zhou, J. Study on long term property of soft soil solidified with industrial waste residue and regenerated fine aggregate. Materials 2023, 16, 2447. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Lv, B.; Wu, Y.; Dai, M.; Pan, Y.; Li, N.; Wang, W.; Jiang, P. Experimental Research on the Mechanical Properties of Recycled Aggregate Particle Gradation and Addition on Modified Cement Soil. Crystals 2022, 12, 428. [Google Scholar] [CrossRef]

- Chaiyaput, S.; Arwaedo, N.; Kingnoi, N.; Nghia-Nguyen, T.; Ayawanna, J. Effect of curing conditions on the strength of soil cement. Case Stud. Constr. Mater. 2022, 16, e01082. [Google Scholar] [CrossRef]

| Relative Density of Soil/(g·cm−3) | Liquid Limit/% | Plastic Limit/% | Plasticity Index | Optimum Moisture Content/% |

|---|---|---|---|---|

| 2.71 | 50.1 | 22.7 | 27.4 | 20.1 |

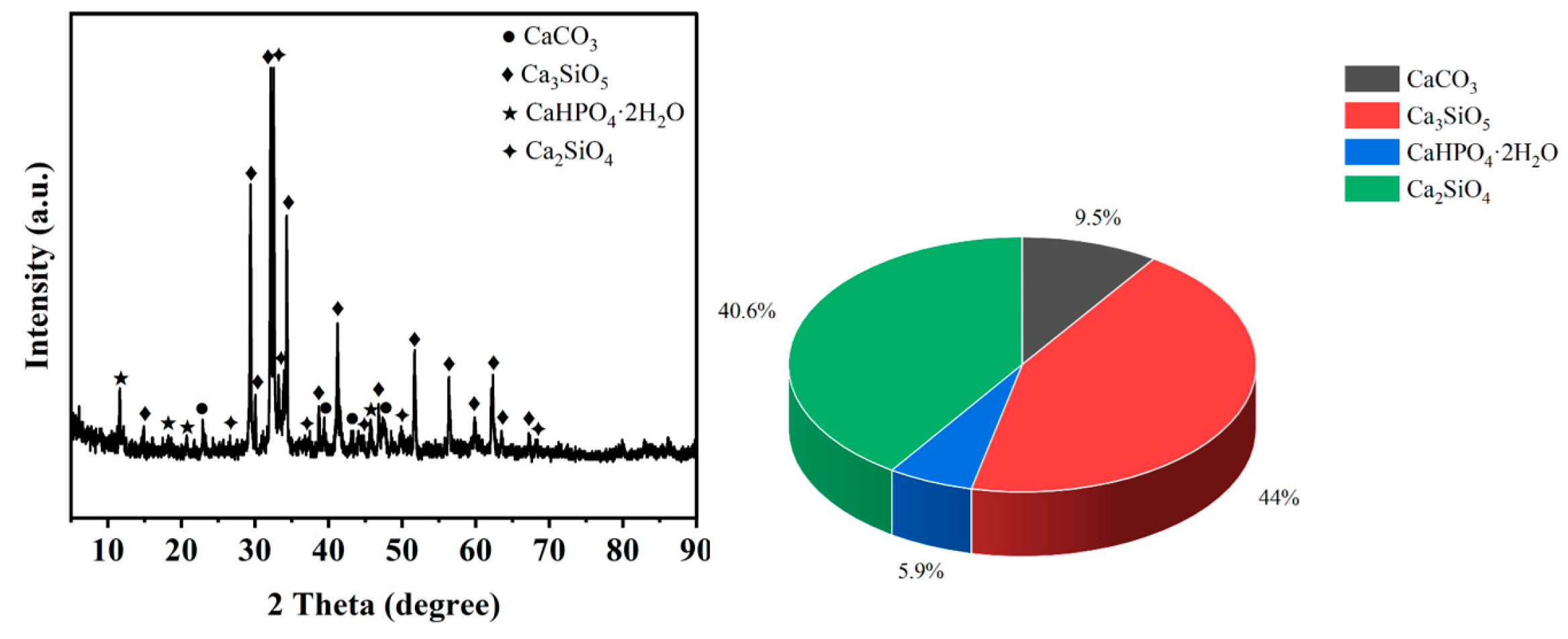

| Material Type | Calcite | Tricalcium Silicate | Calcium Phosphorite | Dicalcium Silicate |

|---|---|---|---|---|

| % | 9.5 | 44 | 5.9 | 40.6 |

| Moisture Content | Recycled Aggregate Admixture (R) | Dosage of Soft Soil Curing Agent (C) | Age of Conservation (M) |

|---|---|---|---|

| 20% | 0% | 0%, 5%, 10%, 15%, 20% | 7 d, 14 d, 28 d |

| 20% | 20% | 7 d, 14 d, 28 d | |

| 20% | 40% | 7 d, 14 d, 28 d | |

| 20% | 60% | 7 d, 14 d, 28 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Dong, Q.; Hu, J.; Liu, P.; Li, Z.; Chen, Y.; Xu, G. Experimental Study on Mechanical Properties of Recycled Aggregate Mixed Soil. Materials 2024, 17, 4448. https://doi.org/10.3390/ma17184448

Wang X, Dong Q, Hu J, Liu P, Li Z, Chen Y, Xu G. Experimental Study on Mechanical Properties of Recycled Aggregate Mixed Soil. Materials. 2024; 17(18):4448. https://doi.org/10.3390/ma17184448

Chicago/Turabian StyleWang, Xuliang, Qinxi Dong, Jun Hu, Peng Liu, Zetian Li, Yongzhan Chen, and Guoyang Xu. 2024. "Experimental Study on Mechanical Properties of Recycled Aggregate Mixed Soil" Materials 17, no. 18: 4448. https://doi.org/10.3390/ma17184448