Effects of Process Parameters and Process Defects on the Flexural Fatigue Life of Ti-6Al-4V Fabricated by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Background

2.1. Lack of Fusion Defects

2.2. Keyhole Defects

2.3. Process Window Parameters

2.4. Surface Roughness

3. Materials and Methods

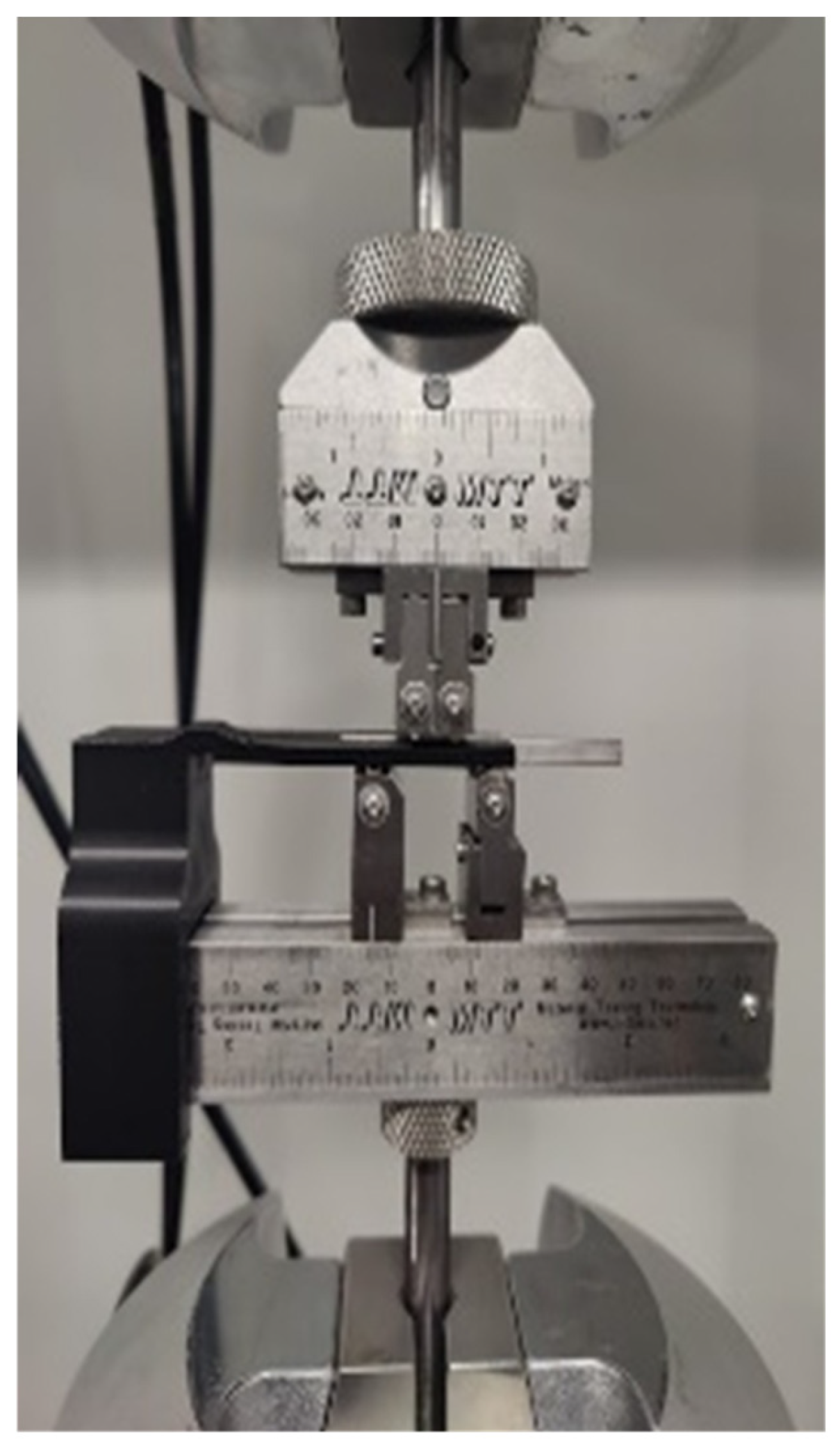

3.1. Four-Point Bending Fatigue

3.2. Powder Feedstock and Printing

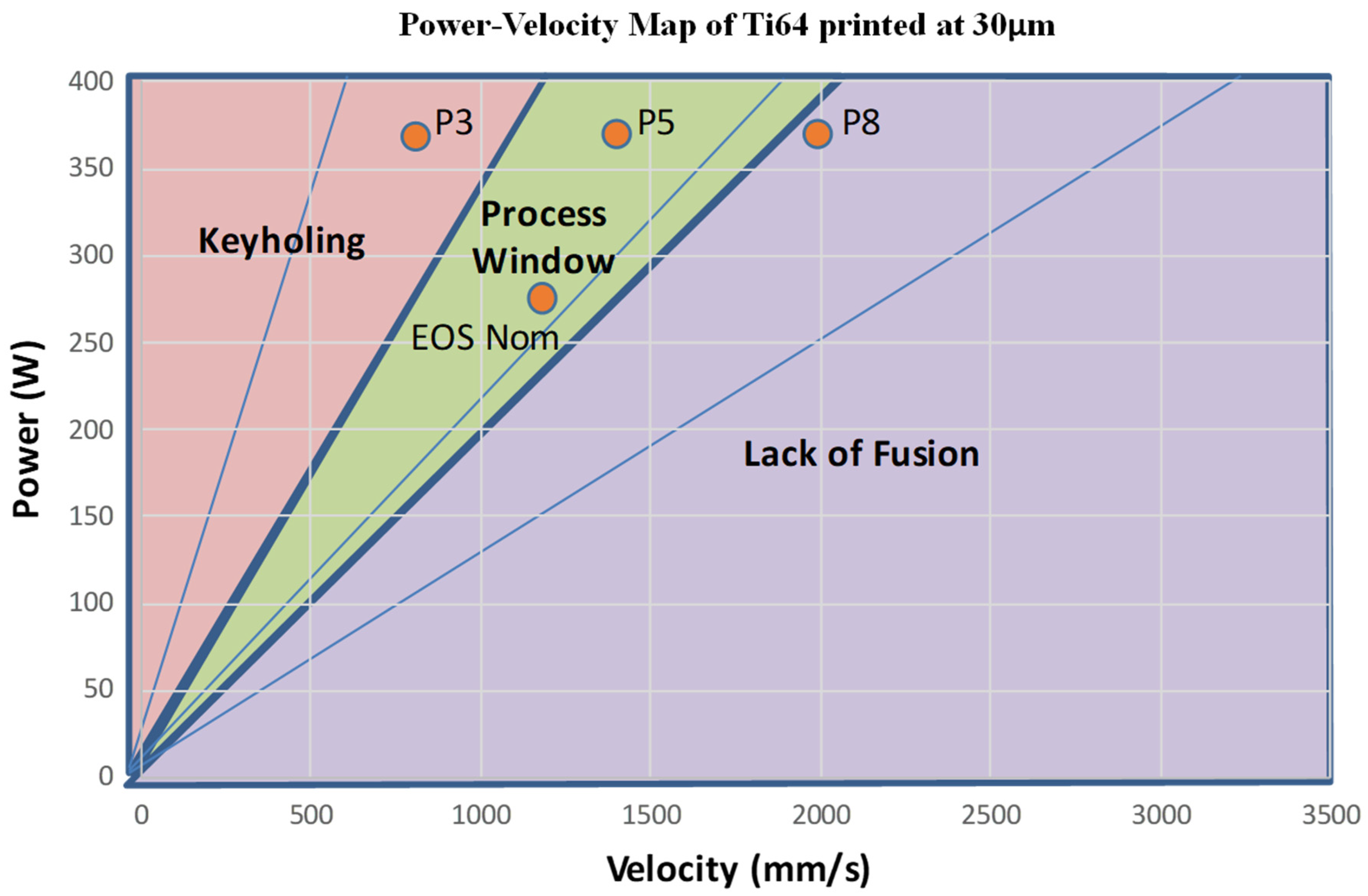

3.3. Printing Parameters

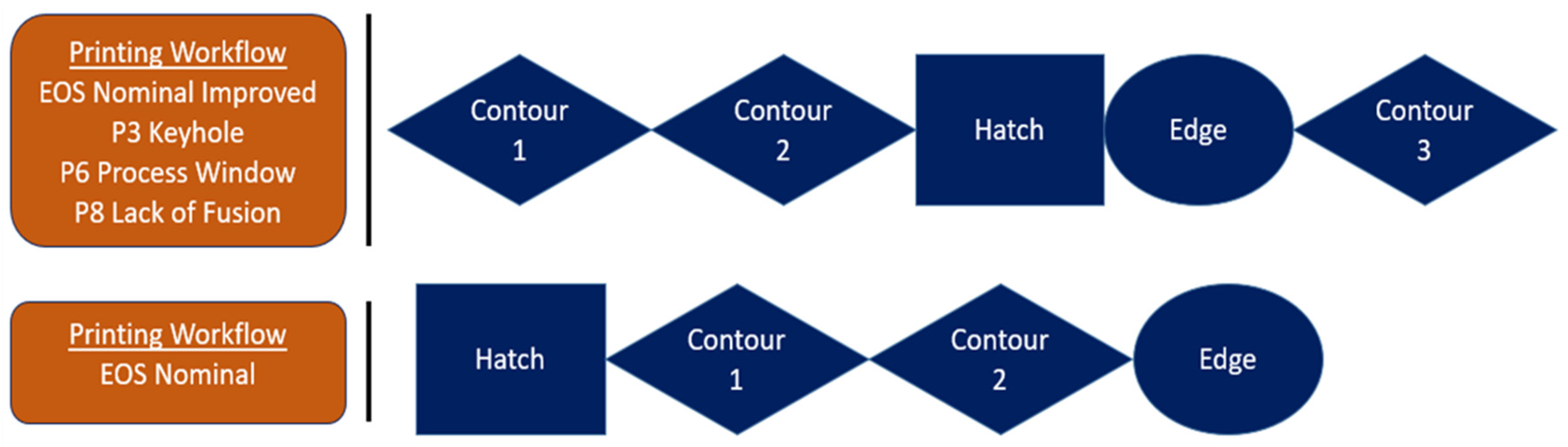

3.4. Scanning Strategies

3.5. Fatigue Testing

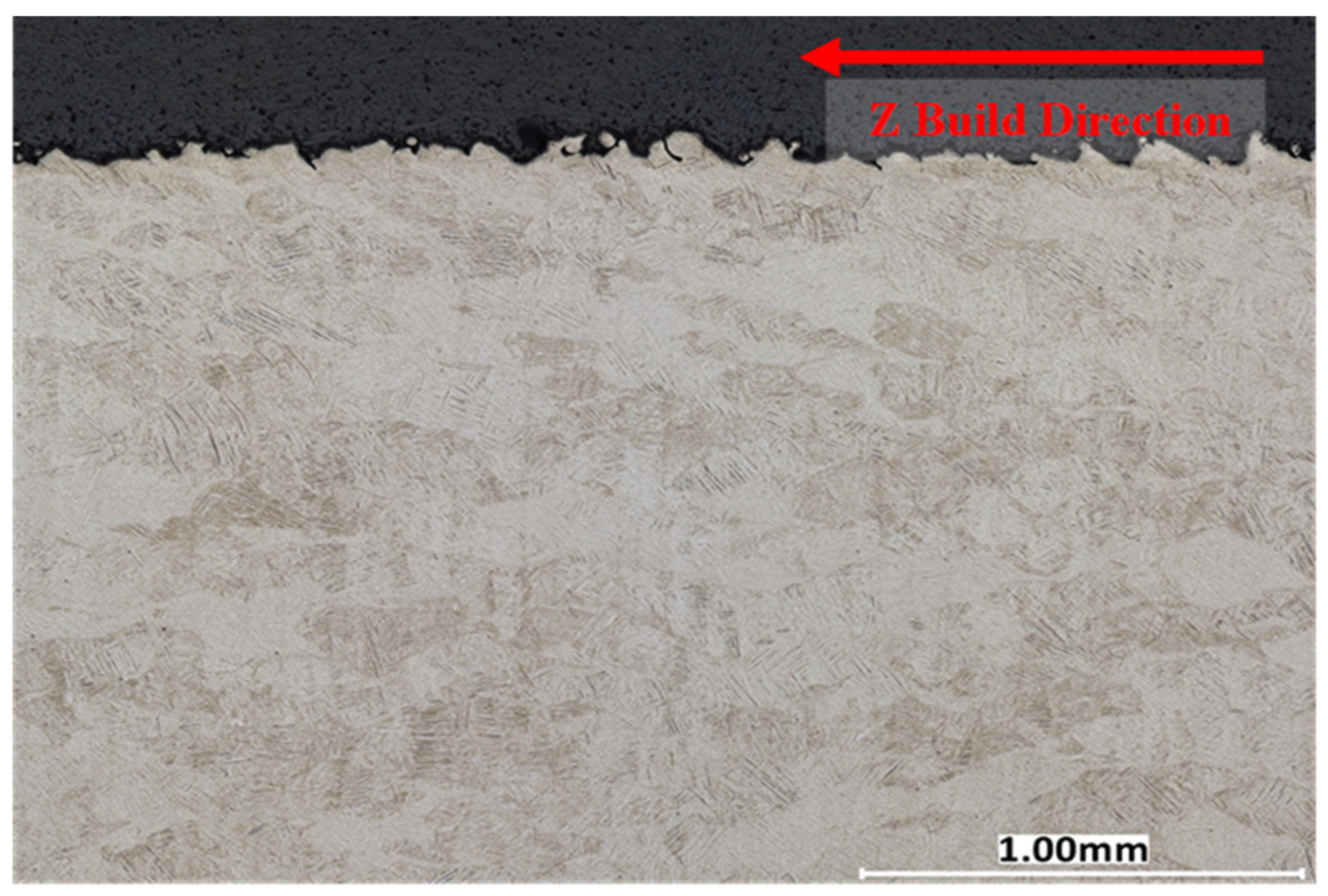

3.6. Porosity Analysis

4. Results and Discussion

4.1. Internal Defect (Porosity) Analysis

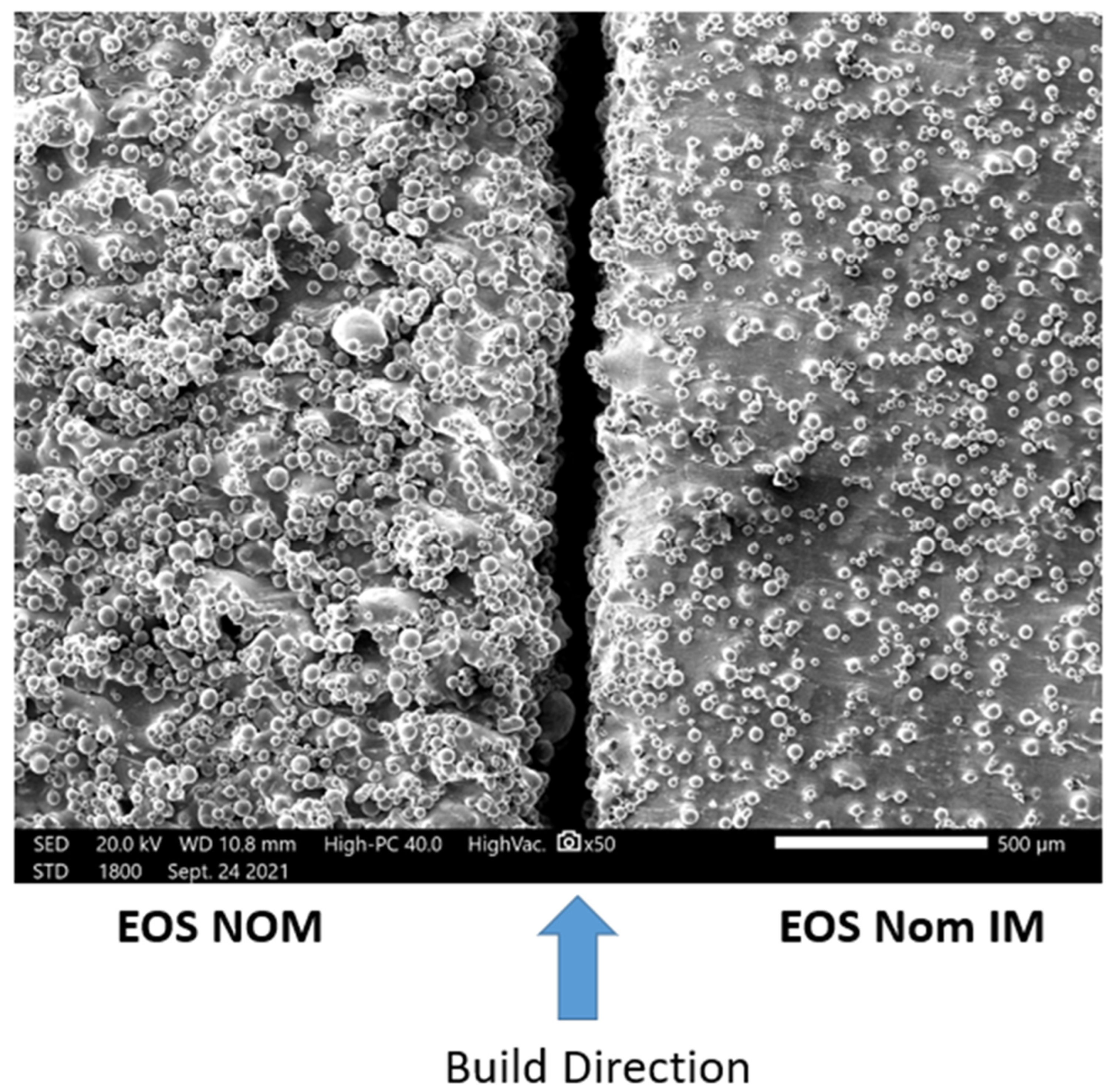

4.2. Surface Roughness Analysis and Comparison

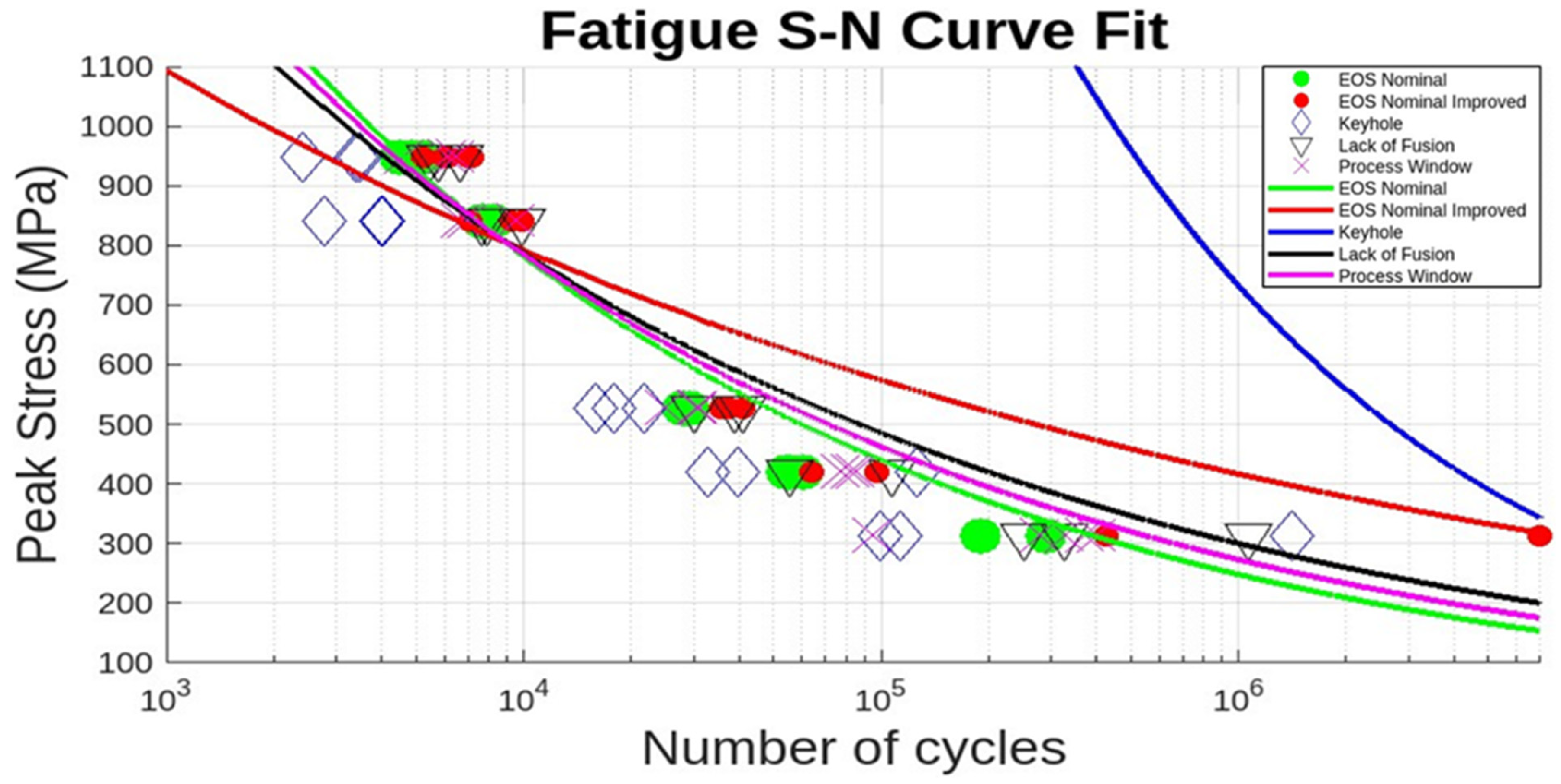

4.3. Fatigue Performance Analysis and Comparison

4.4. S–N Curve Fitting with the Basquin Stress–Life Relation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schultz, W. A history of fatigue. Eng. Fract. Mech. 1996, 54, 263–300. [Google Scholar] [CrossRef]

- Fuchs, H.O.; Stephens, R.I.; Saunders, H. Metal Fatigue in Engineering; Wiley: New York, NY, USA, 1980. [Google Scholar] [CrossRef]

- Basquin, O.H. The experimental law of endurance tests. Proc. ASTM 1910, 10, 625–630. [Google Scholar]

- Bannantine, J.A.; Comer, J.J.; Handrock, J.L. (Eds.) Fundamentals of Metal Fatigue; Prentice Hall: Englewood Cliffs, NJ, USA, 1989. [Google Scholar]

- DebRoy, T.; Wei, H.C.; Zuback, J.S.; Mukherjee, A.M.; Elmer, J.W.; Milewski, J.O.; Deese, A.M.; Wilson-Held, A.; De, A.; Zhang, W. Additive manufacturing of metallic components: Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Zhan, Z.; He, X.; Tang, D.; Dang, L.; Li, A.; Xia, Q.; Berto, F.; Li, H. Recent developments and Future trends in fatigue life assessment of additively manufactured metals with a particular Emphasis on machine learning modeling. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 4425–4464. [Google Scholar] [CrossRef]

- Berto, F.; Plessis, A.D. Fatigue in Additive Manufactured Metals, 1st ed.; Elsevier: New York, NY, USA, 2023; 520p. [Google Scholar]

- Zhang, Z.; Xu, Z. Fatigue database of additively manufactured alloys. Sci. Data 2023, 10, 249. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Liu, Z.; He, B.; Lyu, T.; Zou, Y. A Review on Additive Manufacturing of Titanium Alloys for Aerospace Applications: Directed Energy Deposition and Beyond Ti-6Al-4V. JOM 2021, 73, 1804–1818. [Google Scholar] [CrossRef]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of Process Parameters on the Surface Roughness of Overhanging Structures in Laser Powder Bed Fusion Additive Manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef]

- Oliveira, J.P.; LaLonde, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The influence of porosity on fatigue crack initiation in additively manufactured titanium components. Sci. Rep. 2017, 7, 7308. [Google Scholar] [CrossRef] [PubMed]

- Le, V.-D.; Pessard, E.; Morel, F.; Edy, F. Influence of porosity on the fatigue behavior of additively fabricated Ti alloys. MATEC Web Conf. 2018, 165, 02008. [Google Scholar] [CrossRef][Green Version]

- Cao, F.; Zhang, T.; Ryder, M.A.; Lados, D.A. A review of fatigue properties of additively manufactured Ti-6Al-4V. JOM 2018, 70, 349–357. [Google Scholar] [CrossRef]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. Fatigue performance of selective laser melted Ti6Al4V components: State of the art. Mater. Res. Express 2018, 6, 012002. [Google Scholar] [CrossRef]

- Sanaei, N.; Fateumi, A. Defects in additive manufactured metals and their fatigue performance.: A state-of-the-art review. Prog. Mater. Sci. 2021, 117, 100724. [Google Scholar] [CrossRef]

- Ye, C.; Zhang, C.; Zhao, J.; Dong, Y. Effects of post-processing on the surface finish, porosity, residual stresses and fatigue performance of additively manufactured metals: A review. J. Mater. Engr. Perform. 2021, 30, 6407–6425. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Liu, E.W.; Patres, A.; Qian, M.; Brandt, M. Insitu tailoring of microstructure in addidively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Ter Haar, G.M.; Becker, T.H. Selective laser melting produced Ti-6Al-4V post-process heat treatments achieve superior tensile properties. Materials 2018, 11, 146. [Google Scholar] [CrossRef]

- Qian, M.; Xu, W.; Brandt, M.; Tang, H.P. Additive manufacturing and post processing of Ti-6Al-4V for superior mechanical properties. MRS Bull. 2020, 61, 763–775. [Google Scholar]

- Narra, S.P.; Rollett, A.D.; Ngo, A.; Scannapieco, D.; Shahabi, M.; Reddy, T.; Pauza, J.; Taylor, H.; Gobert, C.; Diewald, E.; et al. Process qualification of laser powder bed fusion based on processing-defect structure-fatigue properties in Ti-6Al-4V. J. Mater. Process. Technol. 2023, 311, 117775. [Google Scholar] [CrossRef]

- Gockel, J.; Sheridan, L.; Koerper, B.; Whip, B. The influence of additive manufacturing processing parameters on surface roughness and fatigue life. Int. J. Fatigue 2019, 124, 380–388. [Google Scholar] [CrossRef]

- Lee, S.; Rasoolian, B.; Silva, D.F.; Pegues, J.W.; Shamsaei, N. Surface roughness parameter and modeling for fatigue behavior of additive manufactured parts: A non-destructive data-driven approach. Add. Manuf. 2021, 46, 102094. [Google Scholar] [CrossRef]

- Yeratapally, S.R.; Lang, C.G.; Glaessgen, E.H. A computational study to investigate the effects of defect geometries on the fatigue crack driven forces in powder-bed AM materials. Amer. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Wang, D.; Han, H.; Sa, B.; Li, K.; Yan, J.; Zhang, J.; Liu, J.; He, Z.; Wang, N.; Yan, M. A review and a statistical analysis of porosity in metals additively manufactured by laser powder bed fusion. Opto-Electron. Adv. 2022, 5, 210058. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review of the effects of process-induced porosity on the machanical properties of metals and alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Cao, S.; Zou, Y.; Lim, C.V.S.; Wu, X. Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: Process, post-process treatment, microstructure, and property. Light. Adv. Manuf. 2021, 2, 313–332. [Google Scholar] [CrossRef]

- Kahlin, M.; Ansell, H.; Basu, D.; Kerwin, A.; Newton, L.; Smith, B.; Moverare, J. Improved fatigue strength of additively manufactured Ti6Al4V by surface post processing. Int. J. Fatigue 2020, 134, 105497. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. Mitigation of lack of fusion defects in powder bed fusion additive manufacturing. J. Manuf. Process. 2018, 36, 442–449. [Google Scholar] [CrossRef]

- Hills, M.A.; Malcolm, J.S.; Dhansay, N.M.; Becker, T.H. High cycle fatigue strength of hot isostatically pressed and chemically etched laser powder bed fusion produced Ti-6Al-4V. Int. J. Fatigue 2023, 175, 107774. [Google Scholar] [CrossRef]

- Grzesik, W. Influence of different machining processes on fatigue life performance of engineered surfaces: A short review. J. Mach. Eng. 2022, 22, 18–30. [Google Scholar] [CrossRef]

- Foti, P.; Razavi, N.; Fatemi, A.; Berto, F. Multiaxial fatigue of additively manufactured metallic components: A review of the failure mechanisms and fatigue life prediction methodologies. Prog. Mater. Sci. 2023, 137, 101126. [Google Scholar] [CrossRef]

- Ariza, D.A.; Arrieta, E.; Banuelos, C.; Colon, B.J.; Murr, L.E.; Wicker, R.B.; Beamer, C.; Medina, F. Comparison of fatigue like behavior between 4-point and uniaxial loading for L-PBF Ti-6Al-4V after HIP treatments. Results Mater. 2024, 22, 100579. [Google Scholar] [CrossRef]

- Rogers, J.; Gian, M.; Elambasseril, J.; Burvill, C.; Brice, C.; Wallbrink, C.; Brandt, M.; Leary, M. Fatigue test date applicability for additive manufacture: A method for quantifying the uncertainty of AM fatigue data. Mater. Des. 2023, 231, 111978. [Google Scholar] [CrossRef]

- Greitemeier, D.; Donne, C.D.; Syassen, F.; Eufinger, J.; Melz, T. Effect of surface roughness on fatigue performance of additively manufactured T-6Al-4V. Mater. Sci. Technol. 2016, 32, 629–634. [Google Scholar] [CrossRef]

- He, B.; Ding, S.; Shi, Z. A comparison between profile and areal surface roughness parameters. Metrol. Meas. Syst. 2021, 28, 413–438. [Google Scholar] [CrossRef]

- Gordon, J.V.; Narra, S.P.; Cunningham, R.W.; Liu, H.; Chen, H.; Suter, R.M.; Beuth, J.L.; Rollett, A.D. Defect structure process maps for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 36, 101552. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy; process optimization and mechanical properties development. Mater. Design 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Islam, Z.; Agrawal, A.K.; Rankouhi, B.; Magnin, C.; Anderson, M.H.; Pfefferkorn, F.E.; Thoma, D.J. A high-throughput method to define additive manufacturing process parameters: Application to haynes 282. Met. Mater. Trans. A 2021, 53, 250–263. [Google Scholar] [CrossRef]

- Shrestha, S.; Chou, K. Formation of keyhole and lack of fusion pores during the laser powder bed fusion process. Manuf. Lett. 2022, 32, 19–23. [Google Scholar] [CrossRef]

- Macías, J.G.S.; Elangeswaran, C.; Zhao, L.; Buffière, J.-Y.; Van Hooreweder, B.; Simar, A. Fatigue crack nucleation and growth in laser powder bed fusion AlSi10Mg under as built and post-treated conditions. Mater. Des. 2021, 210, 110084. [Google Scholar] [CrossRef]

- Coeck, S.; Bisht, M.; Plas, J.; Verbist, F. Prediction of lack of fusion porosity in selective laser melting based on melt pool monitoring data. Addit. Manuf. 2019, 25, 347–356. [Google Scholar] [CrossRef]

- Yadollahi, A.; Mahtabi, M.; Khalili, A.; Doude, H.; Newman, J., Jr. Fatigue life prediction of additively manufactured material: Effects of surface roughness, defect size, and shape. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1602–1614. [Google Scholar] [CrossRef]

- Gatto, A.; Bassoli, E.; Denti, L.; Sola, A.; Tognoli, E.; Comin, A.; Porro, J.A.; Cordovilla, F.; Angulo, I.; Ocaña, J.L. Effect of Three Different Finishing Processes on the Surface Morphology and Fatigue Life of A357.0 Parts Produced by Laser-Based Powder Bed Fusion. Adv. Eng. Mater. 2019, 21, 1801357. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Schijve, J. (Ed.) “Fatigue Tests”. In Fatigue of Structures and Materials; Springer: Dordrecht, The Netherlands, 2009; pp. 395–418. [Google Scholar] [CrossRef]

- Cheng, H.; Sun, L.; Wang, Y.; Liu, L.; Chen, X. Fatigue test setups and analysis methods for asphalt mixture: A state-of-the-art review. J. Road Eng. 2022, 2, 279–308. [Google Scholar] [CrossRef]

- Sobotka, J.C.; Enright, M.P.; McClung, R.C. Application of critical distances to fatigue pores. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1646–1661. [Google Scholar] [CrossRef]

- Gillham, B.; Yankin, A.; McNamara, F.; Tomonto, C.; Huang, C.; Suete, J.; Donnell, G.O.; Trimble, D.; Yin, S.; Taylor, D.; et al. Tailoring the theory of critical distances to better assess the combined effect of complete geometries and process-inherent defects during fatigue assessment of SLM Ti-6Al-4V. Int. J. Fatigue 2023, 11, 107602. [Google Scholar] [CrossRef]

- Kwofie, S. An exponential stress function for predicting fatigue strength and life due to mean stresses. Int. J. Fatigue 2001, 23, 829–836. [Google Scholar] [CrossRef]

- Krajeinovic, D. Damage Mechanics; Elsevier: Amsterdam, The Netherlands, 1960. [Google Scholar]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Kun, F.; Carmona, H.A.; Andrade, J.J.S.; Herrmann, H.J. Universality behind Basquin’s law of fatigue. Phys. Rev. Lett. 2008, 100, 094301. [Google Scholar] [CrossRef]

- Yi, M.; Tang, W.; Zhu, Y.; Liang, C.; Tang, Z.; Yin, Y.; He, W.; Sun, S.; Su, S. A holistic review on fatigue properties of additively manufactured metals. J. Mater. Process. Technol. 2023, 118425. [Google Scholar] [CrossRef]

- Johnsen, A.R.; Petersen, J.E.; Pedersen, M.M.; Yıldırım, H.C. Factors affecting the fatigue strength of additively manufactured Ti-6Al-4V parts. Weld World 2024, 68, 361–409. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Zhou, L.; Lou, Y.; Liu, S.; Zheng, D.; Yi, M. Progress in additive manufacturing, additive repair and fatigue evaluation of aviation titanium alloy blades. Mater. Res. Lett. 2023, 11, 973–1012. [Google Scholar] [CrossRef]

- Rinaldi, A.; Peralta, P.; Krajcinovic, D.; Lai, Y.-C. Prediction of scatter in fatigue properties using discrete damage mechanics. Int. J. Fatigue 2006, 28, 1069–1080. [Google Scholar] [CrossRef]

| Alloy | Ti | Al | V | Fe | O | C | N | Y | H |

|---|---|---|---|---|---|---|---|---|---|

| Ti-6Al-4V | Balance | 6.09 | 3.89 | 0.22 | 0.149 | 0.011 | 0.013 | <9 × 10−4 | 8 × 10−4 |

| Process Parameters | Laser Power (J) | Scanning Velocity (mm/s) |

|---|---|---|

| P3 Keyhole | 370 | 800 |

| P5 Process Window | 370 | 1400 |

| P8 Lack of Fusion | 370 | 2000 |

| EOS Nominal | 280 | 1200 |

| EOS Nominal Improved | 280 | 1200 |

| EOS Nominal Contour Strategy | |||||

|---|---|---|---|---|---|

| Contour 1 Offset (µm) | Contour 1 Power (W) | Contour 1 Scanning Speed (mm/s) | Contour 2 Offset (µm) | Contour 2 Power (W) | Contour 2 Scanning Speed (mm/s) |

| 20 | 150 | 1250 | 0 | 150 | 1250 |

| EOS Nominal Improved, P3, P5, P8 Contour Strategy | ||||||||

|---|---|---|---|---|---|---|---|---|

| Contour 1 Offset (µm) | Contour 1 Power (W) | Contour 1 Scanning Speed (mm/s) | Contour 2 Offset (µm) | Contour 2 Power (W) | Contour 2 Scanning Speed (mm/s) | Contour 3 Offset (µm) | Contour 3 Power (W) | Contour 3 Scanning Speed (mm/s) |

| 0 | 100 | 450 | 80 | 100 | 450 | 0 | 100 | 550 |

| Printing Parameter | Power (W) | Scanning Speed (mm/s) | % Porosity | Circularity Avg. | Number of Defects | Avg. dia. (µm) |

|---|---|---|---|---|---|---|

| P3 Keyhole | 370 | 800 | 0.385 ± 0.004 | 0.76 ± 0.04 | 3861 | 29 |

| P5 Process Window | 370 | 1400 | 0.106 ± 0.012 | 0.63 ± 0.06 | 1363 | 32 |

| P8 Lack of Fusion | 370 | 2000 | 0.215 ± 0.046 | 0.58 ± 0.05 | 2708 | 26 |

| EOS Nominal | 280 | 1200 | 0.008 ± 0.004 | 0.66 ± 0.06 | 231 | 22 |

| EOS Nominal Improved | 280 | 1200 | 0.017 ± 0.012 | 0.57 ± 0.05 | 143 | 19 |

| Process Parameter | Sa (µm) | Sv (µm) | Svk (µm) |

|---|---|---|---|

| EOS Nominal | 15 | 122 | 17 |

| EOS Nominal Improved | 7 | 92 | 9 |

| Keyhole | 12 | 78 | 15 |

| Lack of Fusion | 8 | 48 | 8 |

| Process Window | 9 | 64 | 11 |

| Process Error by Process Parameter | |||||

|---|---|---|---|---|---|

| Stress Level Tested | NOM | NOM IM | Keyhole | Lof | PW |

| 312 MPa | 9% | 17% | 449% | 11% | 8% |

| 420 MPa | 17% | 43% | 387% | 23% | 13% |

| 528 Mpa | 12% | 26% | 539% | 15% | 15% |

| 840 MPa | −3% | −3% | 664% | −2% | −2% |

| 946 MPa | −3% | −10% | 618% | −6% | −7% |

| Average % Error | 6% | 15% | 532% | 8% | 5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramirez, B.; Banuelos, C.; De La Cruz, A.; Nabil, S.T.; Arrieta, E.; Murr, L.E.; Wicker, R.B.; Medina, F. Effects of Process Parameters and Process Defects on the Flexural Fatigue Life of Ti-6Al-4V Fabricated by Laser Powder Bed Fusion. Materials 2024, 17, 4548. https://doi.org/10.3390/ma17184548

Ramirez B, Banuelos C, De La Cruz A, Nabil ST, Arrieta E, Murr LE, Wicker RB, Medina F. Effects of Process Parameters and Process Defects on the Flexural Fatigue Life of Ti-6Al-4V Fabricated by Laser Powder Bed Fusion. Materials. 2024; 17(18):4548. https://doi.org/10.3390/ma17184548

Chicago/Turabian StyleRamirez, Brandon, Cristian Banuelos, Alex De La Cruz, Shadman Tahsin Nabil, Edel Arrieta, Lawrence E. Murr, Ryan B. Wicker, and Francisco Medina. 2024. "Effects of Process Parameters and Process Defects on the Flexural Fatigue Life of Ti-6Al-4V Fabricated by Laser Powder Bed Fusion" Materials 17, no. 18: 4548. https://doi.org/10.3390/ma17184548

APA StyleRamirez, B., Banuelos, C., De La Cruz, A., Nabil, S. T., Arrieta, E., Murr, L. E., Wicker, R. B., & Medina, F. (2024). Effects of Process Parameters and Process Defects on the Flexural Fatigue Life of Ti-6Al-4V Fabricated by Laser Powder Bed Fusion. Materials, 17(18), 4548. https://doi.org/10.3390/ma17184548