In Vitro Evaluation of Speed Sintering and Glazing Effects on the Flexural Strength and Microstructure of Highly Translucent Multilayered 5 mol% Yttria-Stabilized Zirconia

Abstract

:1. Introduction

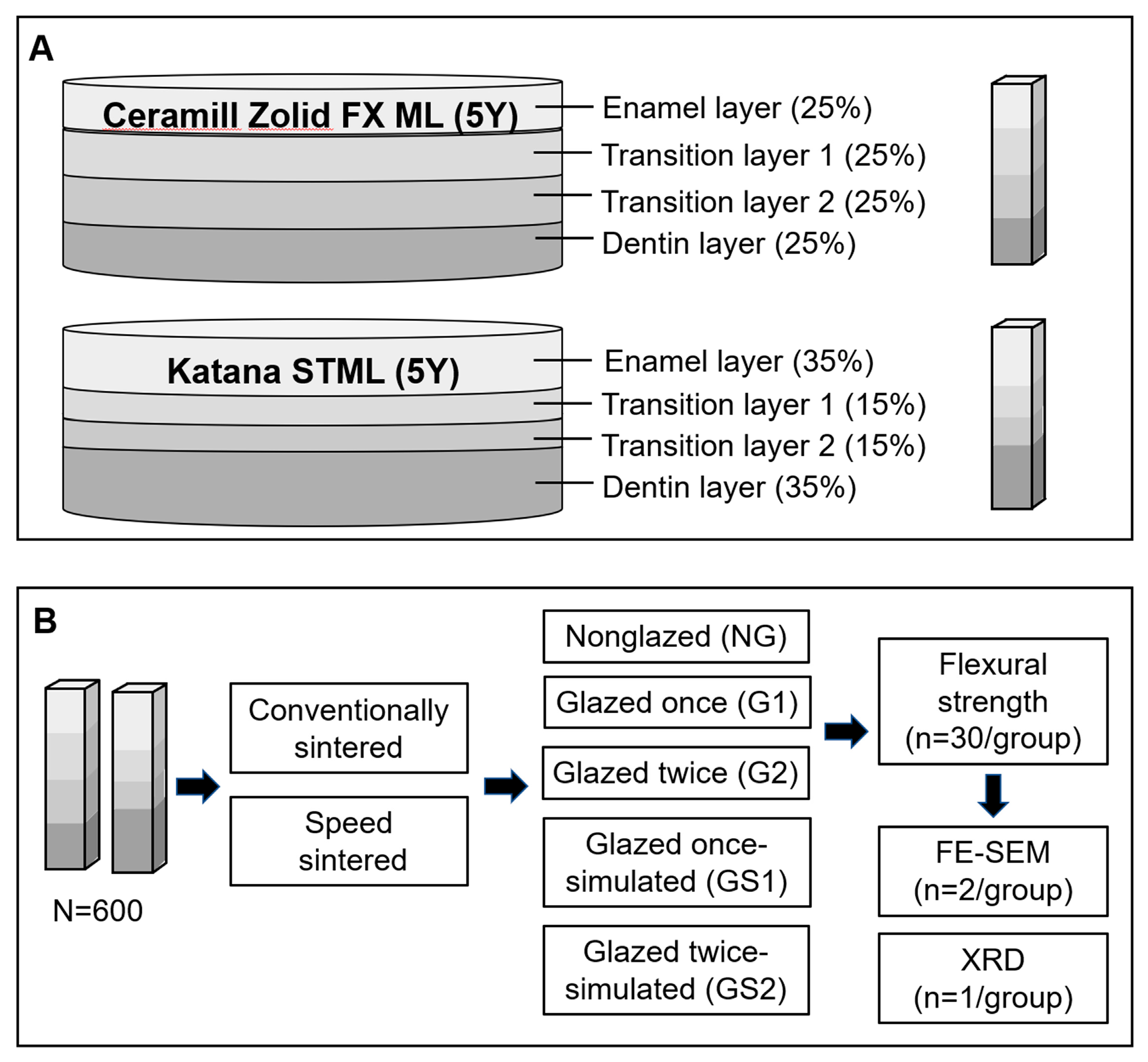

2. Materials and Methods

2.1. Sample Preparation

2.2. Flexural Strength Tests and Weibull Analysis

2.3. Field Emission Scanning Electron Microscopy (FE-SEM) Analysis

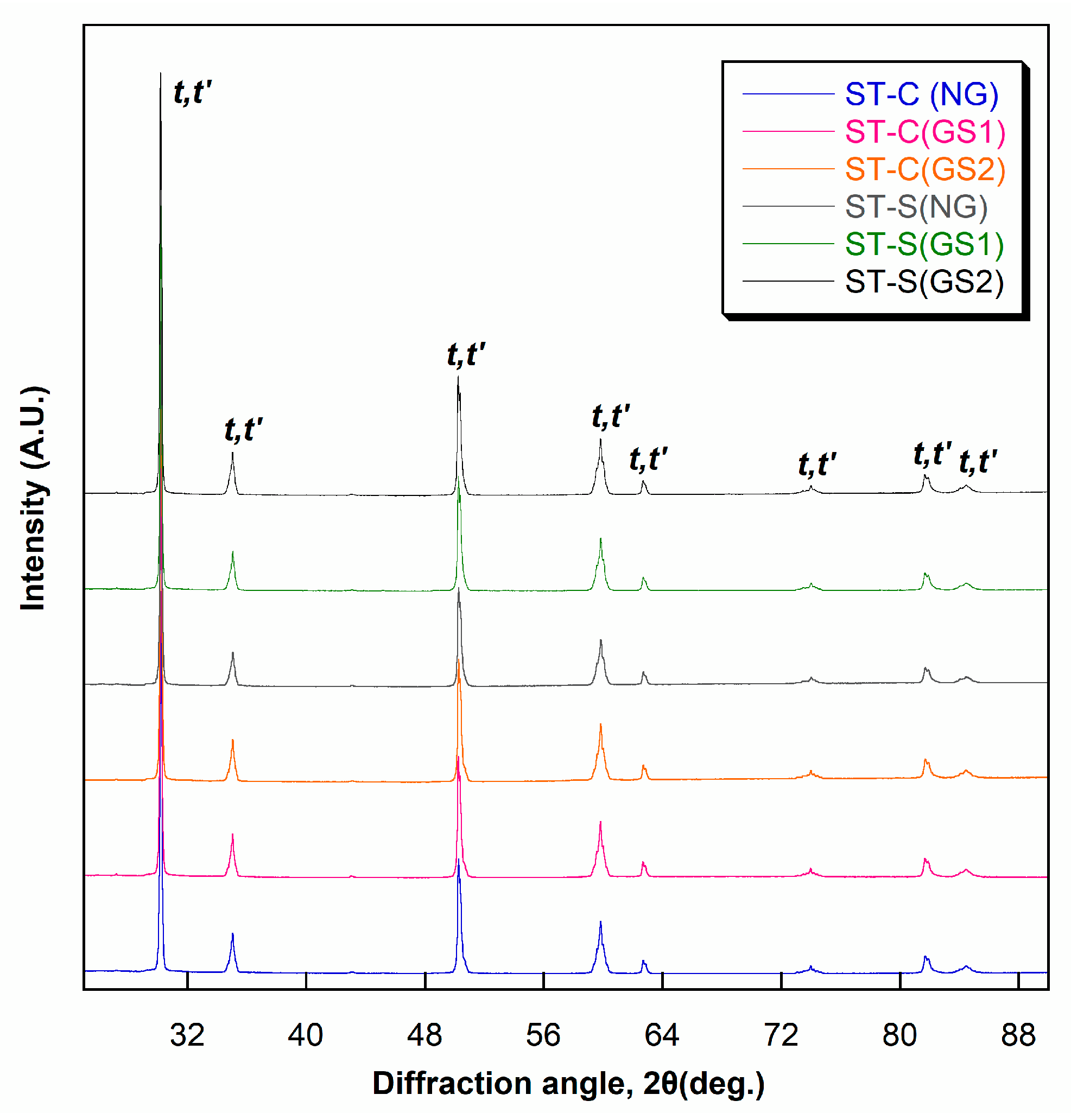

2.4. X-ray Diffraction (XRD) Study

2.5. Statistical Analysis

3. Results

3.1. Flexural Strength and Weibull Modulus

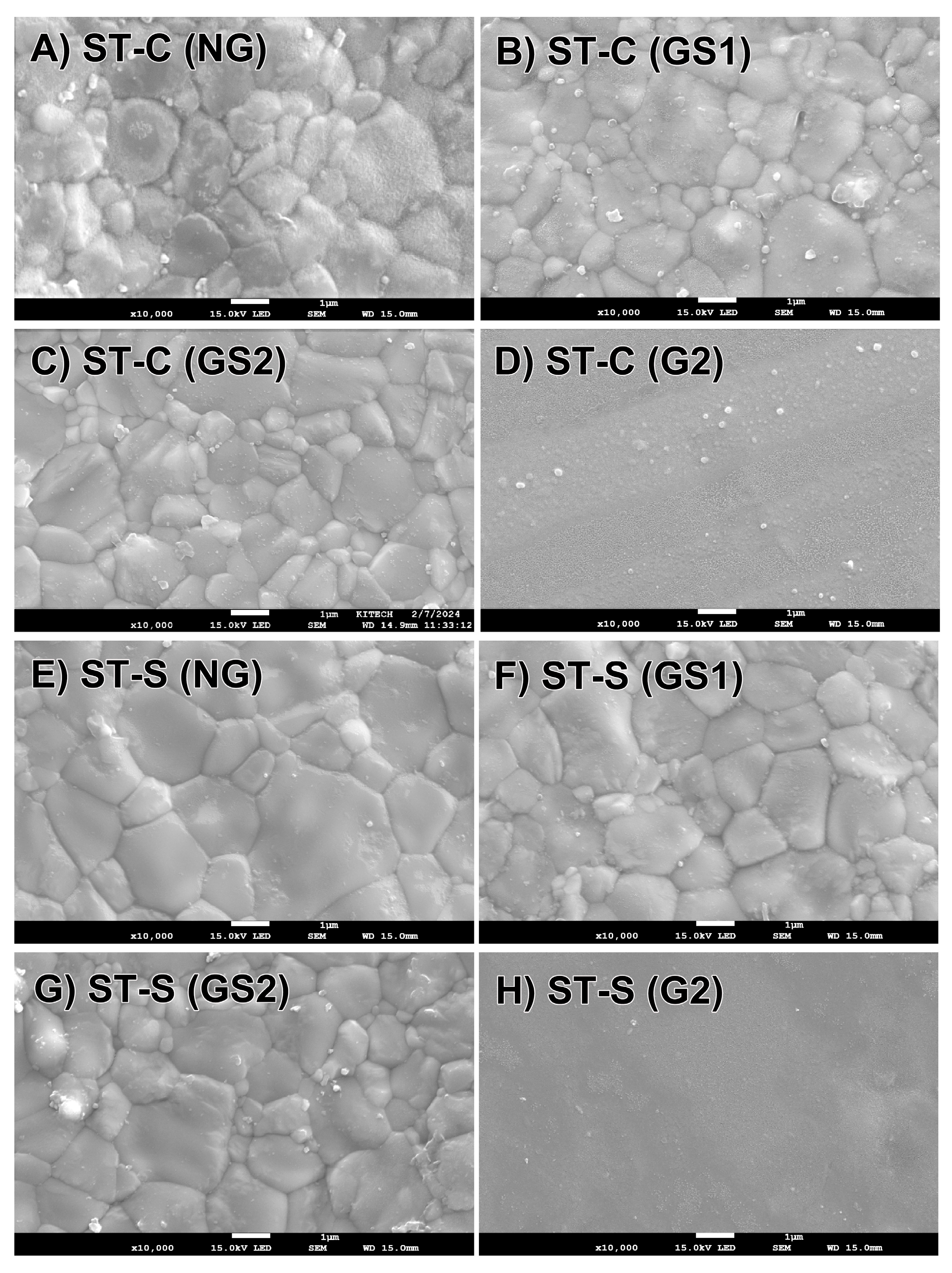

3.2. Microstructure

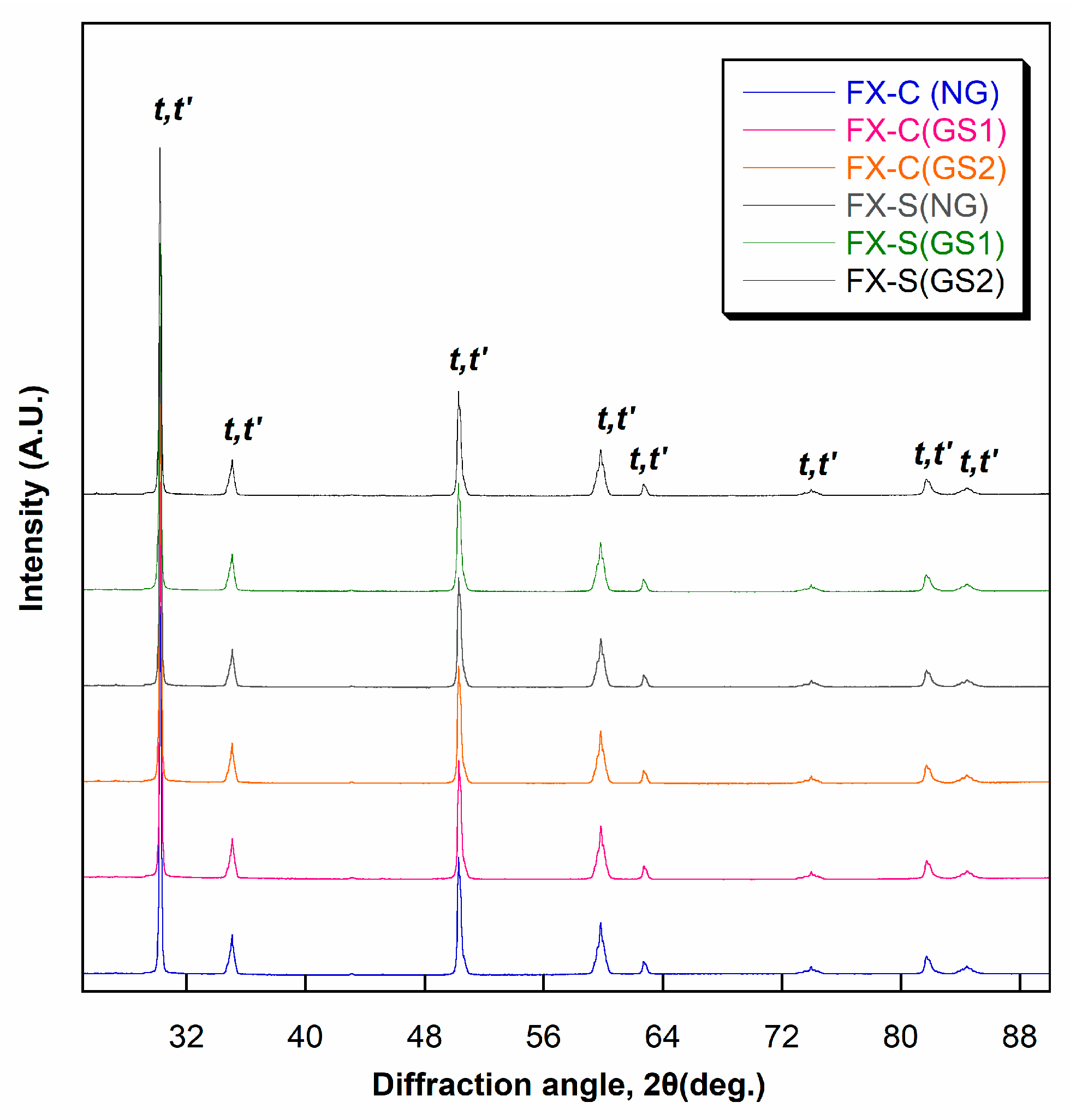

3.3. XRD Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ozer, F.; Naden, A.; Turp, V.; Mante, F.; Sen, D.; Blatz, M.B. Effect of thickness and surface modifications on flexural strength of monolithic zirconia. J. Prosthet. Dent. 2018, 119, 987–993. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Zhou, S.; Lai, R.; Liu, R.; Ma, S.; Zhou, Z.; Longquan, S. Load-bearing capacity and the recommended thickness of dental monolithic zirconia single crowns. J. Mech. Behav. Biomed. Mater. 2014, 35, 93–101. [Google Scholar] [CrossRef] [PubMed]

- Zadeh, P.N.; Lümkemann, N.; Sener, B.; Eichberger, M.; Stawarczyk, B. Flexural strength, fracture toughness, and translucency of cubic/tetragonal zirconia materials. J. Prosthet. Dent. 2018, 120, 948–954. [Google Scholar] [CrossRef]

- Uasuwan, P.; Juntavee, N.; Juntavee, A. Flexural strength of high yttrium oxide-doped monochrome and multilayered fully stabilized zirconia upon various sintered cooling rates. J. Prosthodont. 2023, 32, e118–e128. [Google Scholar] [CrossRef]

- Elsaka, S.E. Optical and mechanical properties of newly developed monolithic multilayer zirconia. J. Prosthodont. 2019, 28, e279–e284. [Google Scholar] [CrossRef]

- Labetić, A.; Klaser, T.; Skoko, Ž.; Jakovac, M.; Žic, M. Flexural strength and morphological study of different multilayer zirconia dental materials. Materials 2024, 17, 1143. [Google Scholar] [CrossRef]

- Alfrisany, N.M.; De Souza, G.M. Surface and bulk properties of zirconia as a function of composition and aging. J. Mech. Behav. Biomed. Mater. 2022, 126, 104994. [Google Scholar] [CrossRef]

- Kunrath, M.F.; Gupta, S.; Lorusso, F.; Scarano, A.; Noumbissi, S. Oral tissue interactions and cellular response to zirconia implant-prosthetic components: A critical review. Materials 2021, 14, 2825. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Inokoshi, M.; Nozaki, K.; Shimizubata, M.; Nakai, H.; Cho Too, T.D.; Minakuchi, S. Influence of high-speed sintering protocols on translucency, mechanical properties, microstructure, crystallography, and low-temperature degradation of highly translucent zirconia. Dent. Mater. 2022, 38, 451–468. [Google Scholar] [CrossRef]

- Inokoshi, M.; Shimizu, H.; Nozaki, K.; Takagaki, T.; Yoshihara, K.; Nagaoka, N.; Zhang, F.; Vleugels, J.; Van Meerbeek, B.; Minakuchi, S. Crystallographic and morphological analysis of sandblasted highly translucent dental zirconia. Dent. Mater. 2018, 34, 508–518. [Google Scholar] [CrossRef]

- Kolakarnprasert, N.; Kaizer, M.R.; Kim, D.K.; Zhang, Y. New multi-layered zirconias: Composition, microstructure and translucency. Dent. Mater. 2019, 35, 797–806. [Google Scholar] [CrossRef] [PubMed]

- Kongkiatkamon, S.; Rokaya, D.; Kengtanyakich, S.; Peampring, C. Current classification of zirconia in dentistry: An updated review. PeerJ 2023, 11, 15669. [Google Scholar] [CrossRef] [PubMed]

- Gseibat, M.; Sevilla, P.; Lopez-Suarez, C.; Rodriguez, V.; Pelaez, J.; Suarez, M.J. Performance of posterior third-generation monolithic zirconia crowns in a complete digital workflow: A three-year prospective clinical study. J. Dent. Sci. 2024, 19, 871–877. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.K.; Kim, S.H. Optical properties of pre-colored dental monolithic zirconia ceramics. J. Dent. 2016, 55, 75–81. [Google Scholar] [CrossRef]

- Carrabba, M.; Keeling, A.J.; Aziz, A.; Vichi, A.; Fabian Fonzar, R.; Wood, D.; Ferrari, M. Translucent zirconia in the ceramic scenario for monolithic restorations: A flexural strength and translucency comparison test. J. Dent. 2017, 60, 70–76. [Google Scholar] [CrossRef]

- Michailova, M.; Elsayed, A.; Fabel, G.; Edelhoff, D.; Zylla, I.M.; Stawarczyk, B. Comparison between novel strength-gradient and color-gradient multilayered zirconia using conventional and high-speed sintering. J. Mech. Behav. Biomed. Mater. 2020, 111, 103977. [Google Scholar] [CrossRef]

- Cokic, S.M.; Vleugels, J.; Van Meerbeek, B.; Camargo, B.; Willems, E.; Li, M.; Zhang, F. Mechanical properties, aging stability and translucency of speed-sintered zirconia for chairside restorations. Dent. Mater. 2020, 36, 959–972. [Google Scholar] [CrossRef]

- Khijmatgar, S.; Tumedei, M.; Tartaglia, G.; Crescentini, M.; Isola, G.; Sidoti, E.; Sforza, C.; Del Fabbro, M.; Tartaglia, G.M. Fifteen-year recall period on zirconia-based single crowns and fixed dental prostheses. A prospective observational study. BDJ Open 2024, 10, 54. [Google Scholar] [CrossRef]

- Vichi, A.; Zhao, Z.; Paolone, G.; Scotti, N.; Mutahar, M.; Goracci, C.; Louca, C. Factory crystallized silicates for monolithic metal-free restorations: A flexural strength and translucency comparison test. Materials 2022, 15, 7834. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H.F. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef]

- Alves, M.F.R.P.; De Campos, L.Q.B.; Simba, B.G.; Da Silva, C.R.M.; Strecker, K.; Dos Santos, C. Microstructural characteristics of 3Y-TZP ceramics and their effects on the flexural strength. Ceramics 2022, 5, 798–813. [Google Scholar] [CrossRef]

- Lawson, N.C.; Maharishi, A. Strength and translucency of zirconia after high-speed sintering. J. Esthet. Restor. Dent. 2020, 32, 219–225. [Google Scholar] [CrossRef]

- Technical Guide for Katana Zirconia. Available online: https://www.kuraraynoritake.eu/pub/media/pdfs/21945_1_Katana_Disc_Technical_Guide_Update_LR_nw_11.pdf (accessed on 21 August 2024).

- Shin, H.J.; Kwon, Y.H.; Seol, H.J. Effect of superspeed sintering on translucency, opalescence, microstructure, and phase fraction of multilayered 4 mol% yttria-stabilized tetragonal zirconia polycrystal and 6 mol% yttria-stabilized partially stabilized zirconia ceramics. J. Prosthet. Dent. 2023, 130, 254.e1–254.e10. [Google Scholar] [CrossRef] [PubMed]

- Lubauer, J.; Schuenemann, F.H.; Belli, R.; Lohbauer, U. Speed-sintering and the mechanical properties of 3–5 mol% Y2O3-stabilized zirconias. Odontology 2023, 111, 883–890. [Google Scholar] [CrossRef] [PubMed]

- Kauling, A.E.; Güth, J.; Erdelt, K.; Edelhoff, D.; Keul, C. Influence of speed sintering on the fit and fracture strength of 3-unit monolithic zirconia fixed partial dentures. J. Prosthet. Dent. 2019, 124, 380–386. [Google Scholar] [CrossRef]

- Alshahrani, A.M.; Lim, C.H.; Wolff, M.S.; Janal, M.N.; Zhang, Y. Current speed sintering and high-speed sintering protocols compromise the translucency but not strength of yttria-stabilized zirconia. Dent. Mater. 2024, 40, 664–673. [Google Scholar] [CrossRef]

- Al-Haj Husain, N.; Özcan, M.; Dydyk, N.; Joda, T. Conventional, speed sintering and high-speed sintering of zirconia: A systematic review of the current status of applications in dentistry with a focus on precision, mechanical and optical parameters. J. Clin. Med. 2022, 11, 11164892. [Google Scholar] [CrossRef]

- Manziuc, M.M.; Gasparik, C.; Burde, A.V.; Colosi, H.A.; Negucioiu, M.; Dudea, D. Effect of glazing on translucency, color, and surface roughness of monolithic zirconia materials. J. Esthet. Restor. Dent. 2019, 31, 478–485. [Google Scholar] [CrossRef]

- Toma, F.R.; Porojan, S.D.; Vasiliu, R.D.; Porojan, L. The effect of polishing, glazing, and aging on optical characteristics of multi-layered dental zirconia with different degrees of translucency. J. Funct. Biomater. 2023, 14, 68. [Google Scholar] [CrossRef]

- Aksoy, G.; Polat, H.; Polat, M.; Coskun, G. Effect of various treatment and glazing (coating) techniques on the roughness and wettability of ceramic dental restorative surfaces. Colloids Surf. B Biointerfaces. 2006, 53, 254–259. [Google Scholar] [CrossRef]

- Lobo, C.M.M.; Sacorague, S.C.M.C.; Silva, N.R.D.; Costa, A.K.F.; Alves, L.M.M.; Bottino, M.A.; Özcan, M.; Souza, R.O.D.A.E.; Melo, R.M.D. Effect of glazing application side and mechanical cycling on the biaxial flexural strength and weibull characteristics of a Y-TZP ceramic. J. Appl. Oral. Sci. 2020, 28, e20200438. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.G.; Li, K.C.; Lyons, K.M.; Waddell, J.N. Effect of two brands of glaze material on the flexural strength and probability of failure of high translucent monolithic zirconia. Materials 2021, 14, 7022. [Google Scholar] [CrossRef]

- Mohammadi-Bassir, M.; Babasafari, M.; Rezvani, M.B.; Jamshidian, M. Effect of coarse grinding, overglazing, and 2 polishing systems on the flexural strength, surface roughness, and phase transformation of yttrium-stabilized tetragonal zirconia. J. Prosthet. Dent. 2017, 118, 658–665. [Google Scholar] [CrossRef]

- Yener, E.S.; Özcan, M.; Kazazoglu, E. The effect of glazing on the biaxial flexural strength of different zirconia core materials. Acta Odontol. Latinoam. 2011, 24, 133–140. [Google Scholar]

- Kumchai, H.; Juntavee, P.; Sun, A.F.; Nathanson, D. Effect of glazing on flexural strength of full-contour zirconia. Int. J. Dent. 2018, 2018, 8793481. [Google Scholar] [CrossRef]

- Nam, M.G.; Park, M.G. Changes in the flexural strength of translucent zirconia due to glazing and low-temperature degradation. J. Prosthet. Dent. 2018, 120, 969. [Google Scholar] [CrossRef]

- Hafezeqoran, A.; Sabanik, P.; Koodaryan, R. Effect of sintering speed and polishing or glazing on the failure load of monolithic zirconia fixed partial dentures. Int. J. Prosthodont. 2022, 35, 405–409. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, A.O.; Fiorin, L.; Faria, A.C.L.; Ribeiro, R.F.; Rodrigues, R.C.S. Translucency and mechanical behavior of partially stabilized monolithic zirconia after staining, finishing procedures and artificial aging. Sci. Rep. 2022, 12, 16094. [Google Scholar] [CrossRef] [PubMed]

- Faul, F.; Erdfelder, E.; Buchner, A.; Lang, A.G. Statistical power analyses using G*Power 3.1: Tests for correlation and regression analyses. Behav. Res. Methods 2009, 41, 1149–1160. [Google Scholar] [CrossRef]

- ISO 6872. Dentistry, Ceramic Materials. International Standards Organization (ISO): Geneva, Switzerland, 2024.

- Mehrvar, C.; Curran, D.J.; Alhalawani, A.M.F.; Boyd, D.; Towler, M. Comparative study of weibull characteristic strength and mean strength of GPCs to confirm the minimum number of samples needed for confident strength reporting. J. Mech. Behav. Biomed. Mater. 2015, 43, 53–58. [Google Scholar] [CrossRef]

- Cho, M.H.; Seol, H.J. Effect of high-speed sintering on the optical properties, microstructure, and phase distribution of multilayered zirconia stabilized with 5 mol% yttria. Materials 2023, 16, 5570. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.K.; Yun, J.H.; Jung, W.K.; Lim, C.H.; Zhang, Y.; Kim, D.K. Mitigating grain growth in fully stabilized zirconia via a two-step sintering strategy for esthetic dental restorations. Int. J. Appl. Ceram. Technol. 2023, 20, 856–868. [Google Scholar] [CrossRef]

- Lamas, D.G.; Walsöe De Reca, N.E. X-ray diffraction study of compositionally homogeneous, nanocrystalline yttria-doped zirconia powders. J. Mater. Sci. 2000, 35, 5563–5567. [Google Scholar] [CrossRef]

- Howard, C.J.; Hill, R.J.; Reichert, B.E. Structures of the ZrO2 polymorphs at room temperature by high-resolution neutron powder diffraction. Acta Cryst. 1988, B44, 116–120. [Google Scholar] [CrossRef]

- Belli, R.; Hurle, K.; Schürrlein, J.; Petschelt, A.; Werbach, K.; Peterlik, H.; Rabe, T.; Mieller, B.; Lohbauer, U. A revised relationship between fracture toughness and Y2O3 content in modern dental zirconias. ChemRxiv 2021. [Google Scholar] [CrossRef]

- Nakamura, K.; Shishido, S.; Inagaki, R.; Kanno, T.; Barkarmo, S.; Svanborg, P.; Örtengren, U. Critical evaluations on the crystallographic properties of translucent dental zirconia ceramics stabilized with 3–6 mol% yttria. Dent. Mater. 2024, 40, 1425–1451. [Google Scholar] [CrossRef]

- Cho, M.H.; Seol, H.J. Optical Properties, Microstructure, and Phase Fraction of Multi-Layered Monolithic Zirconia with and without Yttria-Gradient. Materials 2023, 16, 41. [Google Scholar] [CrossRef]

- Kim, H.K. Effect of a rapid-cooling protocol on the optical and mechanical properties of dental monolithic zirconia containing 3–5mol% Y2O3. Materials 2020, 13, 1923. [Google Scholar] [CrossRef]

| Zirconia Material | Sintering Rate | Code | Stage | Heating and Cooling Rate (°C/min) | Temp. (°C) | Holding Time (min) |

|---|---|---|---|---|---|---|

| Ceramill Zolid FX ML | Conventional | FX-C | 1 | 8 | 1450 | 120 |

| 2 | −20 | 200 | 0 | |||

| Speed | FX-S | 1 | 60 | 980 | 0 | |

| 2 | 12 | 1350 | 0 | |||

| 3 | 15 | 1450 | 65 | |||

| 4 | −120 * | 700 | 0 | |||

| Katana STML | Conventional | ST-C | 1 | 10 | 1550 | 120 |

| 2 | −10 | 100 | 0 | |||

| Speed | ST-S | 1 | 120 | 1450 | 0 | |

| 2 | 10 | 1600 | 20 | |||

| 3 | −120 | 800 | 0 |

| Start Temp. (°C) | Dry (min) | Heating Rate (°C/min) | Final Temp. (°C) | Holding Time (min) | Vacuum |

|---|---|---|---|---|---|

| 480 | 2 | 45 | 820 | 1 | - |

| Variation Source | Type III Sum of Squares | Degree of Freedom | Mean Square | F-Statistic | p-Value |

|---|---|---|---|---|---|

| Corrected model | 1,229,372.482 a | 19 | 64,703.815 | 7.138 | <0.001 |

| Intercept | 198,477,217.375 | 1 | 198,477,217.375 | 21,896.561 | <0.001 |

| S | 222,562.786 | 1 | 222,562.786 | 24.554 | <0.001 |

| Z | 772,500.827 | 1 | 772,500.827 | 85.224 | <0.001 |

| G | 138,196.874 | 4 | 34,549.218 | 3.812 | 0.005 |

| S × Z | 19,227.619 | 1 | 19,227.619 | 2.121 | 0.146 |

| S × G | 49,086.356 | 4 | 12,271.589 | 1.354 | 0.249 |

| Z × G | 19,155.271 | 4 | 4788.818 | 0.528 | 0.715 |

| S × Z × G | 20,474.150 | 4 | 5118.537 | 0.565 | 0.688 |

| Error | 5,329,814.366 | 588 | 9064.310 | ||

| Total | 205,665,734.551 | 608 | |||

| Corrected total | 6,559,186.848 | 607 |

| Code | NG | G1 | G2 | GS1 | GS2 |

|---|---|---|---|---|---|

| FX-C | 657.35 Ac | 647.77 Ab | 593.30 Ab | 642.44 Ab | 622.11 Ab |

| (112.02) | (94.03) | (106.61) | (112.88) | (109.59) | |

| FX-S | 581.59 Ab | 588.01 Aab | 558.52 Aab | 583.04 Aab | 603.93 Ab |

| (111.02) | (99.37) | (105.21) | (105.81) | (94.69) | |

| ST-C | 564.12 ABab | 542.25 ABa | 505.70 Aa | 579.41 Bab | 558.26 ABab |

| (82.87) | (79.94) | (88.27) | (94.49) | (93.16) | |

| ST-S | 507.93 Aa | 530.66 Aa | 513.54 Aa | 540.43 Aa | 521.92 Aa |

| (75.30) | (91.97) | (77.46) | (74.56) | (73.61) |

| Code | m | NG | G1 | G2 | GS1 | GS2 |

|---|---|---|---|---|---|---|

| σ0 (MPa) | ||||||

| FX-C | m | 6.42 (4.89–8.42) | 8.87 (6.61–11.89) | 6.78 (5.11–9.01) | 6.63 (4.99–8.81) | 6.63 (5.02–8.75) |

| σ0 | 704.78 (664.33–747.70) | 686.36 (657.88–716.08) | 635.92 (601.58–672.22) | 689.49 (651.25–729.98) | 666.87 (629.92–705.98) | |

| FX-S | m | 6.10 (4.61–8.07) | 7.66 (5.87–9.98) | 6.26 (4.84–8.10) | 6.65 (5.15–8.58) | 8.32 (6.39–10.83) |

| σ0 | 626.43 (588.84–666.43) | 656.94 (628.92–686.21) | 638.02 (604.78–673.09) | 626.02 (595.25–658.38) | 667.46 (641.19–694.80) | |

| ST-C | m | 7.99 (6.03–10.56) | 7.41 (5.67–9.68) | 6.51 (4.94–8.57) | 7.04 (5.35–9.27) | 6.91 (5.26–9.08) |

| σ0 | 599.09 (571.40–628.11) | 576.50 (547.75–606.76) | 542.34 (511.72–574.79) | 618.76 (586.41–652.89) | 596.61 (564.89–630.11) | |

| ST-S | m | 8.11 (6.09–10.81) | 7.49 (5.56–10.08) | 7.99 (6.03–10.61) | 8.14 (6.22–10.64) | 7.82 (5.97–10.26) |

| σ0 | 539.66 (515.12–565.36) | 567.22 (539.50–596.35) | 545.73 (520.60–572.07) | 572.12 (546.13–599.35) | 553.81 (527.62–581.30) |

| Code | Grain Size (μm) | NG | GS1 | GS2 |

|---|---|---|---|---|

| FX-C | M | 0.871 Aa | 0.818 Aa | 0.869 Aa |

| ±SD | (0.230) | (0.197) | (0.199) | |

| FX-S | M | 0.850 Aa | 0.831 Aa | 0.810 Aa |

| ±SD | (0.112) | (0.174) | (0.142) | |

| ST-C | M | 1.660 Ab | 1.786 Ab | 1.705 Ab |

| ±SD | (0.109) | (0.128) | (0.199) | |

| ST-S | M | 1.679 Ab | 1.778 Ab | 1.705 Ab |

| ±SD | (0.123) | (0.186) | (0.139) |

| Phase Fraction (wt%) | Tetragonality (Axial Ratio) | Y2O3 Content (mol%) | ||||||

|---|---|---|---|---|---|---|---|---|

| t | t′ | t | t′ | t | t′ | Total | ||

| FX-C | NG | 37.6 | 62.4 | 1.0147 | 1.0043 | 2.96 | 7.33 | 5.68 |

| GS1 | 37.8 | 62.2 | 1.0147 | 1.0042 | 2.97 | 7.36 | 5.70 | |

| GS2 | 37.1 | 62.9 | 1.0149 | 1.0046 | 2.90 | 7.25 | 5.64 | |

| FX-S | NG | 37.2 | 62.8 | 1.0143 | 1.0046 | 3.13 | 7.19 | 5.68 |

| GS1 | 36.9 | 63.1 | 1.0141 | 1.0043 | 3.19 | 7.30 | 5.78 | |

| GS2 | 37.5 | 62.5 | 1.0142 | 1.0046 | 3.15 | 7.21 | 5.69 | |

| ST-C | NG | 28.2 | 71.8 | 1.0156 | 1.0045 | 2.61 | 7.23 | 5.92 |

| GS1 | 27.9 | 72.1 | 1.0158 | 1.0047 | 2.53 | 7.16 | 5.86 | |

| GS2 | 28.7 | 71.3 | 1.0156 | 1.0046 | 2.62 | 7.19 | 5.87 | |

| ST-S | NG | 27.2 | 72.8 | 1.0149 | 1.0049 | 2.90 | 7.04 | 5.91 |

| GS1 | 28.5 | 71.5 | 1.0147 | 1.0046 | 2.96 | 7.20 | 5.99 | |

| GS2 | 27.7 | 72.3 | 1.0145 | 1.0049 | 3.03 | 7.06 | 5.94 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, J.-I.; Kwon, Y.-H.; Seol, H.-J. In Vitro Evaluation of Speed Sintering and Glazing Effects on the Flexural Strength and Microstructure of Highly Translucent Multilayered 5 mol% Yttria-Stabilized Zirconia. Materials 2024, 17, 4634. https://doi.org/10.3390/ma17184634

Jeong J-I, Kwon Y-H, Seol H-J. In Vitro Evaluation of Speed Sintering and Glazing Effects on the Flexural Strength and Microstructure of Highly Translucent Multilayered 5 mol% Yttria-Stabilized Zirconia. Materials. 2024; 17(18):4634. https://doi.org/10.3390/ma17184634

Chicago/Turabian StyleJeong, Ji-In, Yong-Hoon Kwon, and Hyo-Joung Seol. 2024. "In Vitro Evaluation of Speed Sintering and Glazing Effects on the Flexural Strength and Microstructure of Highly Translucent Multilayered 5 mol% Yttria-Stabilized Zirconia" Materials 17, no. 18: 4634. https://doi.org/10.3390/ma17184634