Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review

Abstract

1. Introduction

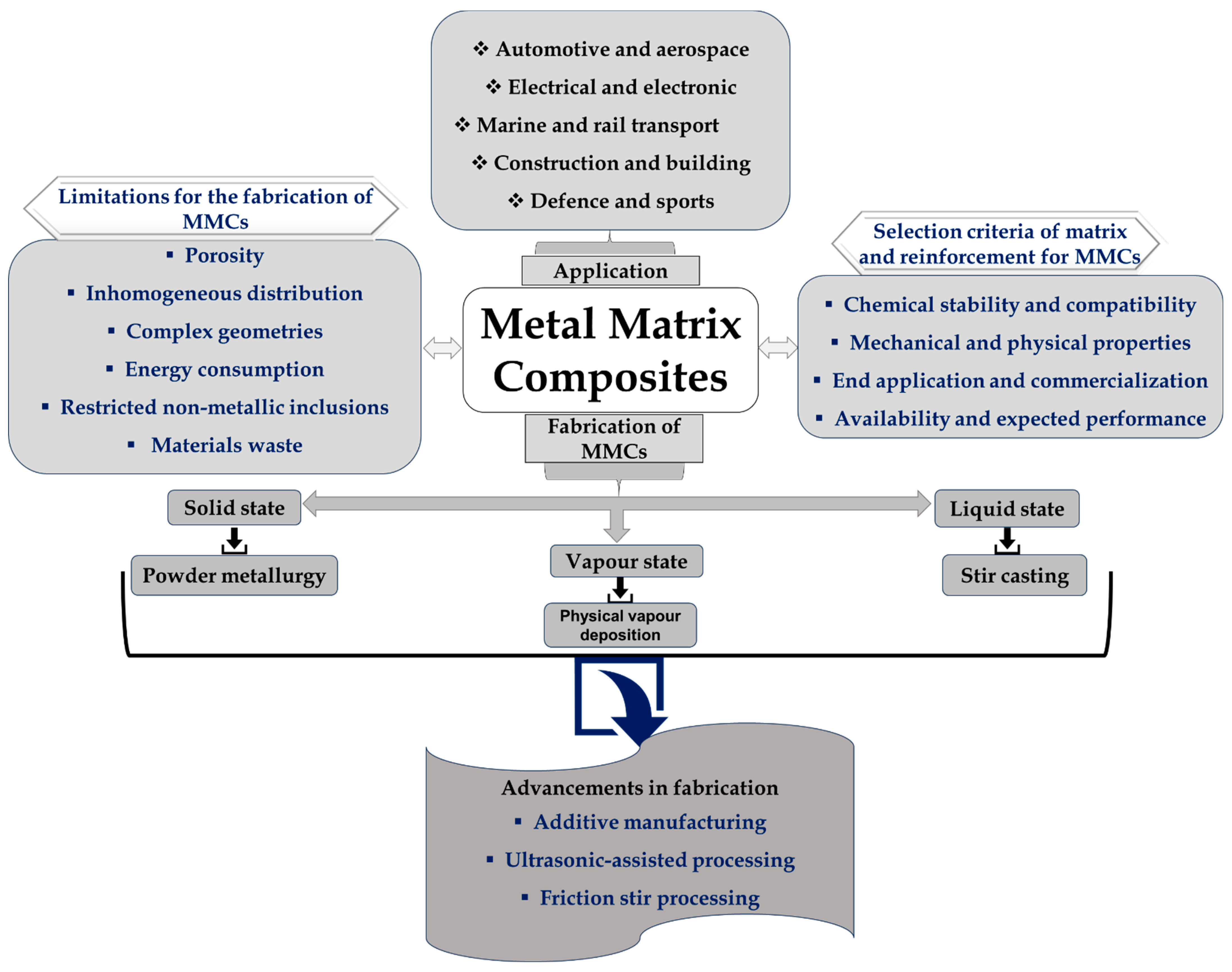

1.1. Overview of Metal Matrix Composites

- Mechanical properties:Strength and stiffness: MMCs’ strength and stiffness are enhanced by the addition of reinforcements, such as fibers or ceramic particles. Since the reinforcements are usually stiffer and stronger than the matrix material, the load is transmitted from the matrix to them.Toughness: MMCs’ toughness is influenced by the type and distribution of reinforcement. By stopping the spread of cracks, reinforcements arranged uniformly can increase durability.

- Wear resistance:Surface hardness: The wear resistance of MMCs is enhanced by the hardness of the reinforcing elements, such as ceramic particles. Wear during operation can be decreased by a tougher surface created by a well-dispersed reinforcing structure.Load distribution: By minimizing localized stress concentrations and increasing wear resistance, a uniform distribution of reinforcements aids in a more even distribution of the load.

- Thermal properties:Thermal conductivity: MMCs’ thermal conductivity is influenced by their structural face, namely the kind and arrangement of reinforcements. For example, adding carbon fibers can improve MMCs’ heat conductivity.Thermal expansion: The reinforcing structure has an impact on the coefficient of thermal expansion (CTE) of MMCs. A well-designed structure can minimize thermal expansion mismatch between the matrix and reinforcements, improving dimensional stability.

- Fatigue performance:Crack initiation and propagation: MMCs’ fatigue performance is influenced by their structure, particularly the interface between the matrix and reinforcements. A strong interface can inhibit crack start and propagation, improving fatigue life.Load transmission: An essential component of fatigue performance is the reinforcements’ capacity to efficiently transmit load to the matrix. Effective load transmission is ensured by a well-bonded contact, which lowers the possibility of fatigue failure.

- Corrosion resistance:Protective layers: To increase corrosion resistance, protective layers or coatings on the reinforcements can be included in the construction of MMCs. Coatings, for instance, can stop galvanic corrosion between reinforcements and the matrix.Barrier effect: Corrosive agents may find it more difficult to permeate the matrix material when reinforcements are evenly distributed.

- Processing and manufacturability:Flow properties: During processing, the size and form of the reinforcements, in particular, have an impact on the flow properties of MMCs. A uniform distribution can be more easily achieved with smaller particles due to their improved flowability.Defect formation: Agglomeration and porosity are two examples of flaws that the structure may affect. By reducing these flaws, advanced manufacturing methods, including friction stir casting and ultrasonic-assisted stir casting, enhance the overall quality and functionality of MMCs.

- Interface properties:Bonding strength: The effectiveness of MMCs depends critically on the interaction between the matrix and reinforcements. Improved mechanical qualities and effective load transmission are guaranteed by a robust interface.Chemical compatibility: The qualities of the interface are influenced by the matrix and reinforcements’ chemical compatibility. Improved interfacial bonding can be facilitated by sophisticated processing methods, improving MMCs’ overall performance.

1.2. Review Methodology

- ❖

- To gather and examine literature on recent implementations for the fabrication of MMCs over the previous five years, with a focus on improving the quality of composite products.

- ❖

- To examine the outcomes and determine how the latest developments help to achieve good-quality MMCs with enhanced physical properties.

- ❖

- To recognize and explore the effects of fabrication parameters on MMCs in the existing literature concerning their applications in various industries.

- ❖

- To present a thorough synthesis of the results and provide an in-depth understanding of the major issues, developments, and trends in advancements for fabrication of MMCs.

2. Advances in Fabrication Methods of MMCs

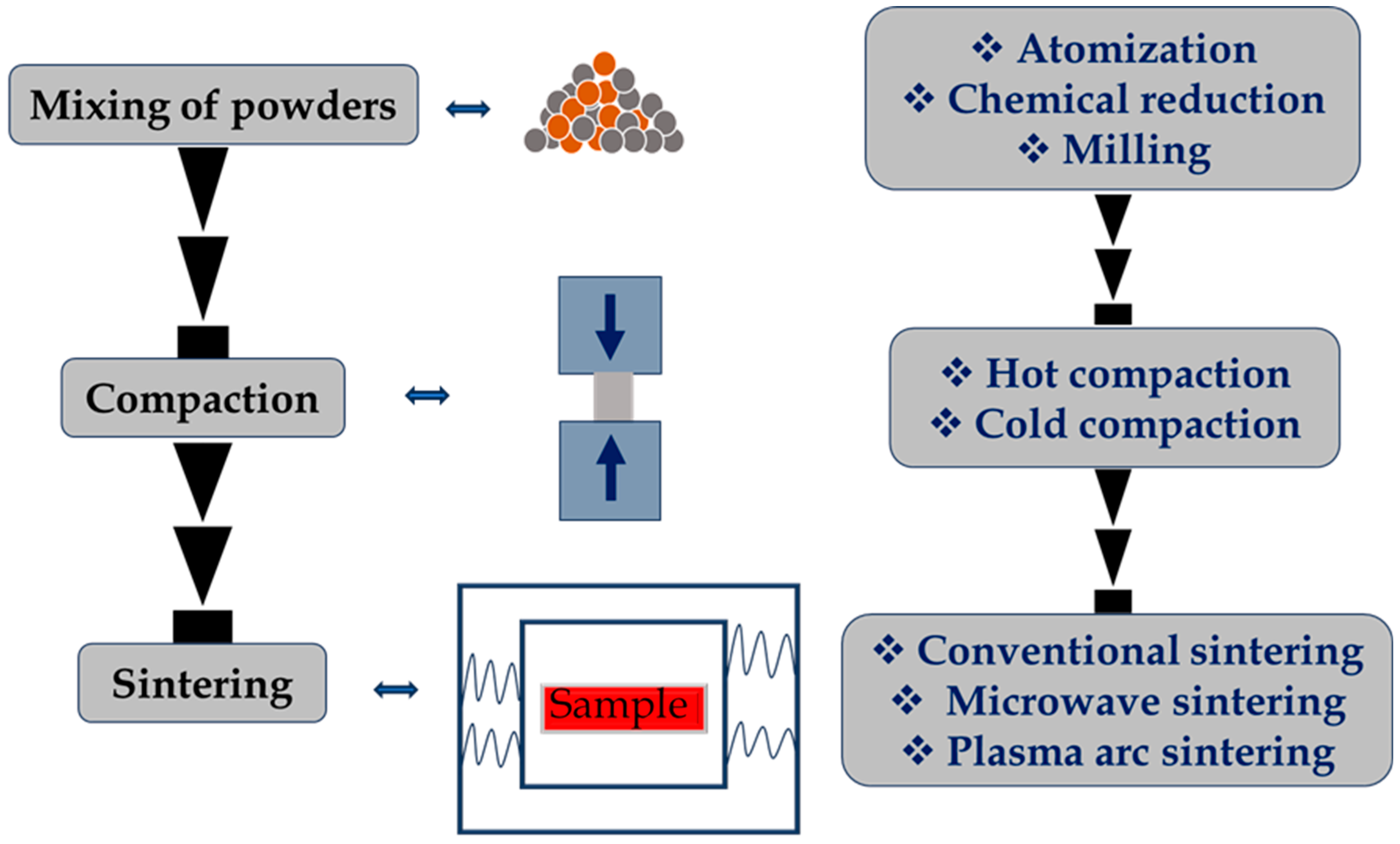

2.1. Advances in Solid-State Processes

2.2. Advances in Liquid-State Processes

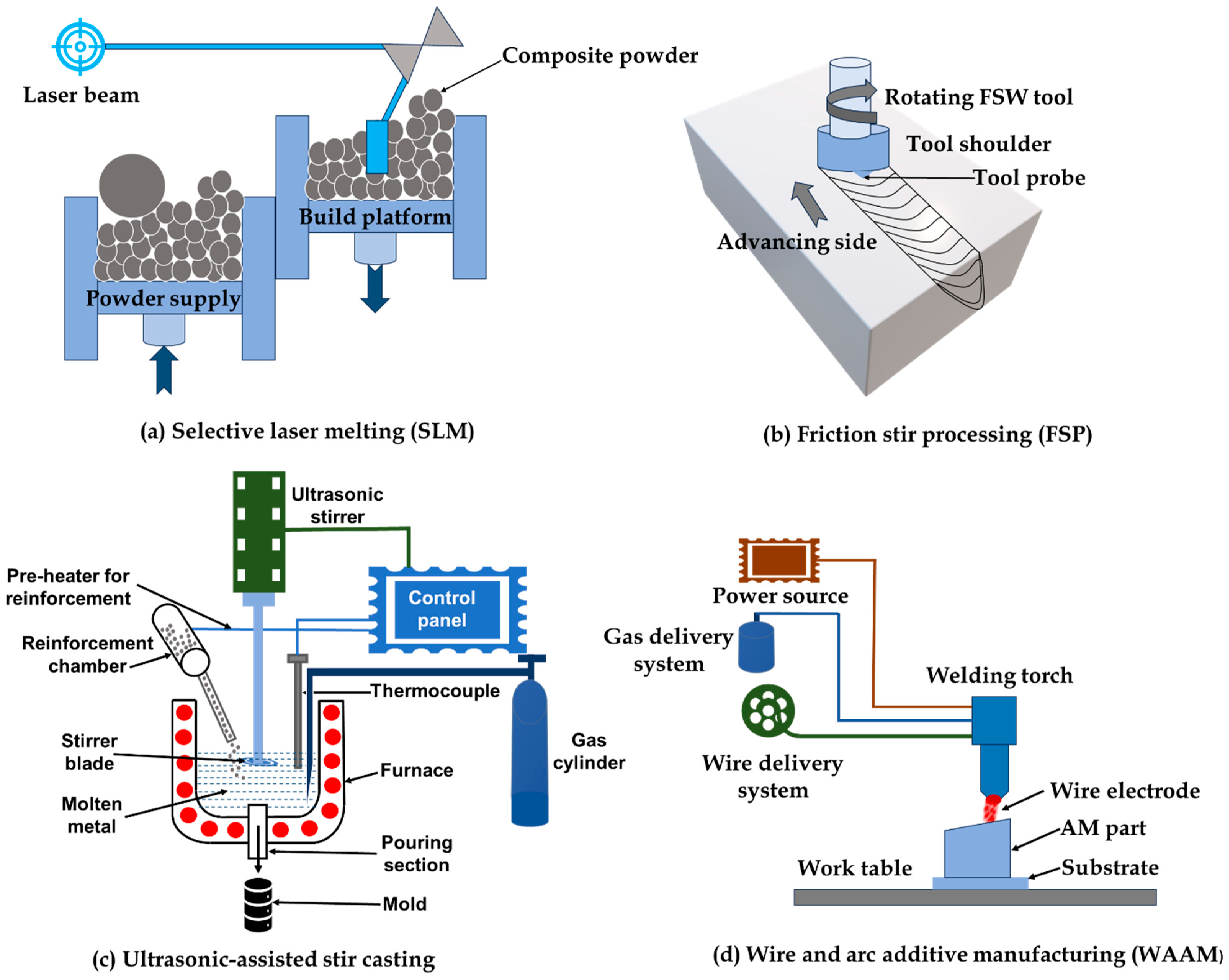

3. Novel and Modern Methods for MMC Fabrication

| Reference | Material and Technique | Findings |

|---|---|---|

| [52] | In718/ZrB2; 3D printed laser powder bed fusion | Tensile tests at 650 °C exhibited a 10%–15% increase in strength and reduced elongation. |

| [54] | Al/CNT; Selective laser melting | High microhardness of 154.12 HV and a tensile strength of 420.8 MPa. |

| [55] | Ti/WC; Wire and arc additive manufacturing (WAAM) | Strong metallurgical bonds between the particles and the matrix were produced with the cost-effective WAAM and paraxial WC powder injection. |

| [59] | AZ91D/Al2O3; Ultrasonic-assisted stir casting | 29.23% greater wear resistance and 43% higher hardness compared to the AZ91 Mg matrix alloy. |

| [60] | Al-A356/ micro-Al2O3, nano-Al2O3; Ultrasonic-assisted stir casting | A356 matrix composites containing nano-Al2O3 showed superior mechanical characteristics compared to micro-Al2O3 particles. |

| [61] | AA7075/ZrB2/Fly Ash; Ultrasonic-assisted stir casting | The specific wear rate was reduced by 46.94% for the fabricated hybrid Al-based MMCs as compared to the base alloy. |

| [62] | Al6061/2SiC-xGr; Ultrasonic-assisted stir casting | The wear rate and COF of hybrid nanocomposites decreased by up to 73% and 17.7%, respectively. |

| [63] | AZ91/TiB2; Ultrasonic-assisted stir casting | The ultrasonic agitation of the liquid melt caused uniform dispersion of TiB2 reinforcement particles in the composites, which consequently improved the composites’ microhardness and wear. |

| [64] | AA6061/B4C; Ultrasonic-assisted stir casting | The ultrasonication enabled the improvements in specific UTS (36.32%), specific compressive (43.92%), specific VH (53.41%), and specific BHN (50.89%) at such a low 4 wt.% of B4C. |

| [65] | Al-Cu-Mg-alloy/SiC/palm sprout shell ash (PSSA); Ultrasonic-assisted stir casting | With improvements in the strength of 29.15% and 27.64%, respectively, among all composites, 2:2 wt.% SiC and PSSA hybrid reinforced composites demonstrated a significant improvement in both tensile and flexural strength. |

| [70] | AA7075/B4C/SiC/Rice Husk Ash (RHA); Friction stir-processing (FSP) | AA7075/B4C composite was found to be 1.5–1.6 times stronger than the base metal; B4C was determined to be the most effective reinforcement when compared to SiC and RHA. AA7075/RHA composites exhibited 11% greater microhardness values than the base metal. |

| [71] | Al 7075/eggshell waste material/ SiC/Al2O3/Ti; FSP | At the ideal process parameters, RF = Ti + Egg Shell, TS = 2250 rpm, and TA = 20, a range of hardness values was observed for the FSP of the A7075 alloy, using eggshell waste as well as SiC/Al2O3/Ti reinforcement. |

| [72] | AA6063/B4C; Self-assembled monolayer (SAM) method and FSP | FSPed AA6063/B4C nanocomposite showed superior wear resistance due to the presence of hard B4C particles. The SAM technique achieved enhanced mechanical properties and homogenous distribution of B4C nanoparticles across the treated area. |

| [73] | AA6061/AZ31, copper/ fly ash; FSP | Regardless of the type of matrix material utilized, FSP is an appropriate technique to generate fly ash-reinforced MMCs. |

| [74] | Al2024/SiC; FSP | SiC particles embedded in FSPed samples increased microhardness by 50% over the as-received state. |

| [75] | AA2024/Al2O3; FSP | UTS and elongation of the cold sprayed (CSed) AA2024/Al2O3 MMCs were enhanced by FSP, with UTS and elongation increased by up to 27.4% and 25.9%, respectively. |

| [76] | AA7075/B4C and FSP | Ideal parameters of the FSP process, 1600 rotating speed and 30 mm/min feed rate, yielded better wear resistance for the AA7075/B4C composites compared to the base material. |

| [77] | AlSi12/Ni60Nb20Ta20; Gas pressure infiltration process | MMC reinforced with metallic glass exhibits substantially better strength than the pure AlSi12-matrix. The strength of AlSi12/Ni60Nb20Ta20 MMC is 280.11 MPa in the x and y directions and 430.51 MPa in the z direction. |

| [84] | AZ91/SiC; Stir casting with RSM and ANN approaches | Desirability function analysis showed that 312.8 RPM stirring speed, 11.9 min stirring duration, and 9.9 wt% particle were the ideal parameter conditions for maximal mechanical characteristics. According to ANN and RSM analysis, the wt.% of particles has the greatest influence on the mechanical characteristics of the composites. |

| [85] | Al 6061/SiC, Gr, Talc, Al2O3, Fly ash, B4C; Stir casted through ANN modelling | With an overall regression (R) value of 0.96118, the model predicted UTS and hardness with a mean squared error of 0.0058606, respectively. |

| [86] | AA2219/TiC, Al2O3, Si3N4; Stir-squeeze casting with K-nearest neighbor (KNN) and grey wolf optimization (GWO) approaches | Improved tensile strength ranging between 134.75 and 159.50 MPa, and improved hardness ranging between 80.75 and 82.92 HB. |

| [88] | Al-TiB2; Ultrasonic stir casting with ANN, GA approaches | The lowest porosity value of 3.88, which corresponds to the optimal casting parameter, was obtained after applying ANN-GA. |

4. Conclusions

- Powder metallurgy is gaining popularity as a viable substitute for traditional sand casting and offers several advantages over it, particularly in terms of refining composite potentials. Stir casting is a popular fabrication process for MMCs because of its ease of use, adaptability, and affordability for mass industrial production.

- The aerospace, defense, transportation, and power generating industries have all benefited greatly from advancements in solid-state techniques for manufacturing MMCs. But compared to approaches like powder metallurgy, advances in solid-state techniques like friction stir processing ensure better dispersion of reinforcements, higher densification, and improved interfacial bonding, which eventually produce MMCs with superior physical properties.

- Liquid state processing techniques for MMC production have yielded considerable improvements in terms of ease of use, reduced costs, and enhanced material characteristics. Improvements in MMC fabrication have made it possible to fabricate MMCs with improved tensile, wear, and metallurgical properties in spite of the drawbacks of traditional liquid state methods, such as insufficient particle wetting and the creation of undesired intermetallic particles. The prospective applications of MMCs in sectors such as aerospace, defense, transportation, and power generation have been extended due to these improvements.

- The production of specific parts in industries like aerospace and healthcare has been made possible by advances in additive manufacturing (AM), particularly in metal 3D printing techniques like selective laser melting (SLM). The use of AM techniques for manufacturing MMCs has benefits in terms of cost, time efficiency, precision, and quality.

- In terms of microstructure and mechanical qualities, the ultrasonic-assisted stir casting process has proven to be significantly superior to conventional stir casting processes. It has been concluded that using ultrasonic vibration during the casting process can improve the mechanical properties of MMCs by refining grain size and promoting a more uniform dispersion of reinforcing particles.

- In comparison to conventional processes, the friction stir processing technique fabricates composites that are more promising for a variety of applications due to better strength, hardness, and ductility.

- The fabrication of MMCs is greatly improved by the ANN, GA, and machine learning type intelligent techniques. This leads to improvements in property prediction and process optimization. This technical development is essential to producing high-performing materials with specific applications.

- The development of MMCs using recycled resources, such as borosilicate glass and scrap aluminum, exemplifies a waste-reduction strategy that maximizes mechanical qualities without sacrificing sustainability. This approach encourages ecologically friendly behaviors, which not only enhances material performance but also supports the sustainable development goals.

- Utilizing low-energy sintering techniques in regulated environments can result in low-cost, high-performing composites with decreased porosity. The future of the industry depends on reducing waste and optimizing resource utilization, which in turn supports a circular economy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Aluminum oxide | Al2O3 |

| Boron carbide | B4C |

| Carbon nanotubes | CNT |

| Copper | Cu |

| Graphite | Gr |

| Silicon carbide | SiC |

| Al-based MMC | AMC |

| Additive manufacturing | AM |

| Coefficient of friction | COF |

| Double pressing-double sintering | DPDS |

| Friction stir processing | FSP |

| Hot pressing | HP |

| Silicon nitride | Si3N4 |

| Titanium diboride | TiB2 |

| Titanium oxide | TiO2 |

| Tungsten carbide | WC |

| Zirconium oxide | ZrO2 |

| Computer aided drafting | CAD |

| Mg-based MMC | MMMC |

| Selective laser melting | SLM |

| Weight percentage | wt.% |

| Metal matrix nanocomposites | MMNCs |

| Ultimate tensile strength | UTS |

| Friction stir processing | FSP |

References

- Kavimani, V.; Soorya Prakash, K.; Thankachan, T. Experimental investigations on wear and friction behaviour of SiC/@r-GO reinforced Mg matrix composites produced through solvent-based powder metallurgy. Compos. Part B Eng. 2019, 162, 508–521. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Kumar, A.; Omrani, E.; Kim, C.; Rohatgi, P. Synthesis, characterization, and properties of graphene reinforced metal-matrix nanocomposites. Compos. Part B Eng. 2020, 183, 107664. [Google Scholar] [CrossRef]

- Kim, H.; Qaiser, N.; Hwang, B. Electro-Mechanical Response of Stretchable PDMS Composites with a Hybrid Filler System. Facta Univ. Ser. Mech. Eng. 2023, 21, 51–61. [Google Scholar] [CrossRef]

- Abd El Aal, M.I.A.; El Aal, H.H.; El-Fahhar, A.Y.; Gadallah, E.A. The Mechanical Properties of Aluminum Metal Matrix Composites Processed by High-Pressure Torsion and Powder Metallurgy. Materials 2022, 15, 8827. [Google Scholar] [CrossRef]

- Sarmah, P.; Gupta, K. A Review on the Machinability Enhancement of Metal Matrix Composites by Modern Machining Processes. Micromachines 2024, 15, 947. [Google Scholar] [CrossRef]

- Vencl, A.; Bobic, I.; Arostegui, S.; Bobic, B.; Marinković, A.; Babić, M. Structural, mechanical and tribological properties of A356 aluminium alloy reinforced with Al2O3, SiC and SiC+ graphite particles. J. Alloys Compd. 2010, 502, 631–639. [Google Scholar] [CrossRef]

- Reddy, P.V.; Kumar, G.S.; Krishnudu, D.M.; Rao, H.R. Mechanical and Wear Performances of Aluminium-Based Metal Matrix Composites: A Review. J. Bio-Tribo-Corros. 2020, 6, 83. [Google Scholar] [CrossRef]

- Singh, R.; Singh, G. Investigations of Al-SiC AMC prepared by vacuum moulding assisted stir casting. J. Manuf. Process. 2015, 19, 142–147. [Google Scholar] [CrossRef]

- Sweet, G.A.; Hexemer, R.L.; Donaldson, I.W.; Taylor, A.; Bishop, D.P. Powder metallurgical processing of a 2xxx series aluminum powder metallurgy metal alloy reinforced with AlN particulate additions. Mater. Sci. Eng. A 2019, 755, 10–17. [Google Scholar] [CrossRef]

- Singh, L.; Singh, B.; Saxena, K.K. Manufacturing techniques for metal matrix composites (MMC): An overview. Adv. Mater. Process. Technol. 2020, 6, 441–457. [Google Scholar] [CrossRef]

- Seikh, Z.; Sekh, M.; Mandal, G.; Sengupta, B.; Sinha, A. Metal Matrix Composites Processed Through Powder Metallurgy: A Brief Overview. J. Inst. Eng. India Ser. D 2024, 1–4. [Google Scholar] [CrossRef]

- Meignanamoorthy, M.; Ravichandran, M.; Ramakrishnan, K. Synthesis of Metal Matrix Composites via Powder Metallurgy Route: A Review. Mech. Mech. Eng. 2018, 22, 59–69. [Google Scholar] [CrossRef]

- Hussein, M.K.; Jameel, W.W.; Fadhil, N.; Sabah, A. Fabrication of Copper-Graphite MMCs Using Powder Metallurgy Technique. J. Eng. 2018, 24, 49–59. [Google Scholar] [CrossRef]

- Stergioudi, F.; Prospathopoulos, A.; Farazas, A.; Tsirogiannis, E.C.; Michailidis, N. Mechanical Properties of AA2024 Aluminum/MWCNTs Nanocomposites Produced Using Different Powder Metallurgy Methods. Metals 2022, 12, 1315. [Google Scholar] [CrossRef]

- Haque, S.; Rahman, M.A.; Shaikh, R.R.; Sirajudeen, N.; Kamaludeen, M.B.; Sahu, O. Effect of powder metallurgy process parameters on tribology and micro hardness of Al6063-nano Al2O3 MMCs. Mater. Today Proc. 2022, 68, 1030–1037. [Google Scholar] [CrossRef]

- Sergi, A.; Khan, R.H.U.; Irukuvarghula, S.; Meisnar, M.; Makaya, A.; Atta, M.M. Development of Ni-base metal matrix composites by powder metallurgy hot isostatic pressing for space applications. Adv. Powder Technol. 2022, 33, 103411. [Google Scholar] [CrossRef]

- Nor Zamani, N.A.; Iqbal, A.; Nuruzzaman, D.M. Tribo-mechanical characterisation of self-lubricating aluminium based hybrid metal matrix composite fabricated via powder metallurgy. Materialia 2020, 14, 100936. [Google Scholar] [CrossRef]

- Nayak, K.C.; Pandey, A.K.; Date, P.P. Mechanical and physical characterization of powder metallurgy based aluminium metal matrix hybrid composite. Mater. Today Proc. 2020, 33, 5408–5413. [Google Scholar] [CrossRef]

- Paul, S.; Islam, M.M. Fabrication of aluminum metal matrix composites reinforced with TiO2 by powder metallurgy techniques. In Proceedings of the International Conference on Mechanical Engineering and Renewable Energy 2021 (ICMERE 2021), Chattogram, Bangladesh, 12–14 December 2021. [Google Scholar]

- Surya, M.S.; Prasanthi, G. Tribological Behaviour of Aluminum Silicon Carbide Functionally Graded Material. Tribol. Ind. 2018, 40, 247–253. [Google Scholar] [CrossRef]

- Tosun, G.; Kurt, M. The porosity, microstructure, and hardness of Al-Mg composites reinforced with micro particle SiC/Al2O3 produced using powder metallurgy. Compos. Part B Eng. 2019, 174, 106965. [Google Scholar] [CrossRef]

- Parveen, A.; Chauhan, N.R.; Suhaib, M. Influence of Process Parameters and Reinforcements on Aluminum Hybrid Composites Developed by Powder Metallurgy Process. Phys. Met. Metallogr. 2021, 122, 1007–1013. [Google Scholar] [CrossRef]

- Satishkumar, P.; Mahesh, G.; Meenakshi, R.; Vijayan, S.N. Tribological characteristics of powder metallurgy processed Cu-WC/SiC metal matrix composites. Mater. Today Proc. 2021, 37, 459–465. [Google Scholar] [CrossRef]

- Aydin, F.; Sun, Y.; Turan, M.E. The effect of TiB2 content on wear and mechanical behavior of AZ91 magnesium matrix composites produced by powder metallurgy. Powder Metall. Met. Ceram. 2019, 57, 612–616. [Google Scholar] [CrossRef]

- Balcı, Ö.; Prashanth, K.G.; Scudino, S.; Somer, M.; Eckert, J. Powder metallurgy of Al-based composites reinforced with Fe-based glassy particles: Effect of microstructural modification. Particul. Sci. Technol. 2019, 37, 286–291. [Google Scholar] [CrossRef]

- Bharathi, P.; Kumar, T.S. Mechanical Characteristics and Wear Behaviour of Al/SiC and Al/SiC/B4C Hybrid Metal Matrix Composites Fabricated Through Powder Metallurgy Route. Silicon 2023, 15, 4259–4275. [Google Scholar] [CrossRef]

- Aydin, F.; Sun, Y.; Ahlatci, H.; Turen, Y. Investigation of Microstructure, Mechanical and Wear Behaviour of B4C Particulate Reinforced Magnesium Matrix Composites by Powder Metallurgy. Trans. Indian Inst. Met. 2018, 71, 873–882. [Google Scholar] [CrossRef]

- Mahdi, S.M.; Ghalib, L. Corrosion Behavior of Al/SiC Composite Prepared by Powder Metallurgy in Chloride Environments. J. Bio- Tribo-Corros. 2022, 8, 8. [Google Scholar] [CrossRef]

- Nayak, K.C.; Rane, K.K.; Date, P.P.; Srivatsan, T.S. Synthesis of an Aluminum Alloy Metal Matrix Composite Using Powder Metallurgy: Role of Sintering Parameters. Appl. Sci. 2022, 12, 8843. [Google Scholar] [CrossRef]

- Yadav, M.; Kumaraswamidhas, L.A.; Singh, S.K. Investigation of solid particle erosion behavior of Al-Al2O3 and Al-ZrO2 metal matrix composites fabricated through powder metallurgy technique. Tribol. Int. 2022, 172, 107636. [Google Scholar] [CrossRef]

- Mu, D.K.Q.; Zhang, Z.; Xie, Y.H.; Liang, J.M.; Wang, J.; Zhang, D.L. The microstructures and mechanical properties of a 5vol%SiC/AA2024 nanocomposite fabricated by powder metallurgy. Mater. Charact. 2021, 175, 111090. [Google Scholar] [CrossRef]

- Nishanth, M.; Patel, G.M.; Satish, K.G. A Study on Various Properties of SiC Reinforced with AA7075 MMC by Powder Metallurgy Technique. IJIRT 2019, 6. [Google Scholar]

- Prajapati, P.K.; Chaira, D. Fabrication and Characterization of Cu-B4C Metal Matrix Composite by Powder Metallurgy: Effect of B4C on Microstructure, Mechanical Properties and Electrical Conductivity. Trans. Indian Inst. Met. 2019, 72, 673–684. [Google Scholar] [CrossRef]

- Kumar Sharma, A.; Bhandari, R.; Aherwar, A.; Pinca-Bretotean, C. A study of fabrication methods of aluminum-based composites focused on stir casting process. Mater. Today Proc. 2020, 27, 1608–1612. [Google Scholar] [CrossRef]

- Vijaya, D.J.; Kumar, J.P.; Smart, D.S.R. Analysis of hybrid aluminium composite material reinforced with Ti and NbC nanoparticles processed through stir casting. Mater. Today Proc. 2022, 51, 561–570. [Google Scholar] [CrossRef]

- Singh, A.K.; Soni, S.; Rana, R.S. A Critical Review on Synthesis of Aluminum Metallic Composites through Stir Casting: Challenges and Opportunities. Adv. Eng. Mater. 2020, 22, 2000322. [Google Scholar] [CrossRef]

- Thakur, A.; Joshi, S.; Singh, A. A brief review on mechanical properties of Al-MMCs fabricated by stir casting route & applications. E3S Web. Conf. 2021, 309, 01227. [Google Scholar] [CrossRef]

- Moona, G.; Walia, R.S.; Rastogi, V.; Sharma, R. Aluminium metal matrix composites: A retrospective investigation. Indian J. Pure Appl. Phys. 2018, 56, 164–175. [Google Scholar]

- Justin, J.; Hillary, M.; Sundaramoorthy, R.; Dixon, J.; Joseph, J.; Kalidas, K.; Manickaraj, K. Influence of stir casting route process parameters in fabrication of aluminium matrix composites—A review. Mater. Today Proc. 2021, 45, 6660–6664. [Google Scholar]

- Fenghong, C.; Chang, C.; Zhenyu, W.; Muthuramalingam, T.; Anbuchezhiyan, G. Effects of Silicon Carbide and Tungsten Carbide in Aluminium Metal Matrix Composites. Silicon 2019, 11, 2625–2632. [Google Scholar] [CrossRef]

- Santhosh, M.S.; Natrayan, L.; Kaliappan, S.; Patil, P.P.; Rao, Y.S.; Kumar, T.N.S.; Dhanraj, J.A. Mechanical and Wear Behaviour of Nano-Fly Ash Particle-Reinforced Mg Metal Matrix Composites Fabricated by Stir Casting Technique. J. Nanomater. 2022, 2022, 5465771. [Google Scholar] [CrossRef]

- Kumar, B.A.; Krishnan, M.M.; Sahayaraj, A.F.; Reda, M.; Refaai, A.; Yuvaraj, G.; Madhesh, D. Characterization of the Aluminium Matrix Composite Reinforced with Silicon Nitride (AA6061/Si3N4) Synthesized by the Stir Casting Route. Adv. Mater. Sci. Eng. 2022, 2022, 8761865. [Google Scholar] [CrossRef]

- Mummoorthi, D.; Rajkumar, M.; Ganesh Kumar, S.; Kim, H.-S. Advancement and characterization of Al-Mg-Si alloy using reinforcing materials of Fe2O3 and B4C composite produced by stir casting method. J. Mech. Sci. Technol. 2019, 33, 3213–3222. [Google Scholar] [CrossRef]

- Vanam, J.P.; Chiranjeevi, R.; Kumar, S.; Ramana, V.; Kumar, S. Effect of SiC on Mechanical, Microstructure and Tribological properties of Aluminum MMC processed by Stir Casting. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012057. [Google Scholar] [CrossRef]

- Ajagol, P.; Anjan, B.N.; Marigoudar, R.N.; Preetham Kumar, G.V. Effect of SiC Reinforcement on Microstructure and Mechanical Properties of Aluminum Metal Matrix Composite. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 012057. [Google Scholar] [CrossRef]

- Xiao, P.; Gao, Y.; Yang, X.; Xu, F.; Yang, C.; Li, B.; Li, Y.; Liu, Z.; Zheng, Q. Processing, microstructure and ageing behavior of in-situ submicron TiB2 particles reinforced AZ91 Mg matrix composites. J. Alloys Compd. 2018, 764, 96–106. [Google Scholar] [CrossRef]

- Patel, S.K.; Kuriachena, B.; Kumar, N.; Nateriya, R. The slurry abrasive wear behaviour and microstructural analysis of A 2024-SiC-ZrSiO4 metal matrix composite. Ceram. Int. 2018, 44, 6426–6432. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in Additive Manufacturing of High-Strength Aluminium Alloys and Current Developments in Hybrid Additive Manufacturing. Int. J. Lightweight Mater. Manuf. 2021, 4, 246–261. [Google Scholar] [CrossRef]

- Gong, G.; Ye, J.; Chi, Y.; Zhao, Z.; Wang, Z.; Xia, G.; Du, X.; Tian, H.; Yu, H.; Chen, C. Research Status of Laser Additive Manufacturing for Metal: A Review. J. Mater. Res. Technol. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W. A Review on Laser Deposition-Additive Manufacturing of Ceramics and Ceramic Reinforced Metal Matrix Composites. Ceram. Int. 2018, 44, 20599–20612. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Soro, N.; Kent, D.; Dargusch, M.S. Additive Manufacturing of Low-Cost Porous Titanium-Based Composites for Biomedical Applications: Advantages, Challenges and Opinion for Future Development. J. Alloys Comp. 2020, 827, 154263. [Google Scholar] [CrossRef]

- Tekoglu, E.; O’Brien, A.D.; Bae, J.-S.; Lim, K.-H.; Liu, J.; Kavak, S.; Zhang, Y.; Kime, S.Y.; Agaogulları, D.; Chen, W.; et al. Metal Matrix Composite with Superior Ductility at 800 °C: 3D Printed In718+ZrB₂ by Laser Powder Bed Fusion. Compos. Part B 2024, 268, 111052. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive Manufacturing of Metals: Microstructure Evolution and Multistage Control. J. Mater. Sci. Technol. 2021, 100, 224–236. [Google Scholar] [CrossRef]

- Gu, D.; Rao, X.; Dai, D.; Ma, C.; Xi, L.; Lin, K. Laser Additive Manufacturing of Carbon Nanotubes (CNTs) Reinforced Aluminum Matrix Nanocomposites: Processing Optimization, Microstructure Evolution and Mechanical Properties. Addi. Manuf. 2019, 29, 100801. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, S.; He, P.; Wei, Z. Particle Distribution and Interfacial Reaction of WC Reinforced Titanium Matrix Composites Fabricated by Wire and Arc Additive Manufacturing. Vacuum 2024, 219, 112680. [Google Scholar] [CrossRef]

- Idrisi, A.H.; Mourad, A.-H.I. Conventional Stir Casting versus Ultrasonic Assisted Stir Casting Process: Mechanical and Physical Characteristics of AMCs. J. Alloys Comp. 2019, 805, 502–508. [Google Scholar] [CrossRef]

- Kumar, D.; Thakur, L. Recent Studies on the Fabrication of Magnesium Based Metal Matrix Nano-Composites by Using Ultrasonic Stir Casting Technique-A Review. Mater. Sci. Forum 2019, 969, 889–894. [Google Scholar] [CrossRef]

- Mohanty, P.; Mahapatra, R.; Padhi, P.; Ramana, C.V.; Mishra, D.K. Ultrasonic Cavitation: An Approach to Synthesize Uniformly Dispersed Metal Matrix Nanocomposites-A Review. Nano-Struct. Nano-Objects 2020, 23, 100475. [Google Scholar] [CrossRef]

- Kumar, D.; Thakur, L. A Study of Development and Sliding Wear Behavior of AZ91D/Al2O3 Composites Fabricated by Ultrasonic-Assisted Stir Casting. Arab. J. Sci. Eng. 2023, 48, 2951–2967. [Google Scholar] [CrossRef]

- Aybarc, U.; Ertugrul, O.; Seydibeyoğlu, M.O. Effect of Al2O3 Particle Size on Mechanical Properties of Ultrasonic-Assisted Stir-Casted Al A356 Matrix Composites. Int. J. Met. 2021, 15, 638–649. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, B. Effect of T6 Heat Treatment on Mechanical and Tribological Properties of Fabricated AA7075/ZrB2/Fly Ash Hybrid Aluminum Metal Matrix Composite by Ultrasonic-Assisted Stir Casting Enroute. Int. J. Met. 2024, 18, 2396–2414. [Google Scholar] [CrossRef]

- Reddy, A.P.; Krishna, P.V.; Rao, R.N. Tribological Behaviour of Al6061-2SiC-xGr Hybrid Metal Matrix Nanocomposites Fabricated through Ultrasonically Assisted Stir Casting Technique. Silicon 2019, 11, 2853–2871. [Google Scholar] [CrossRef]

- Kumar, D.; Thakur, L. A Study of Processing and Parametric Optimization of Wear-Resistant AZ91-TiB2 Composite Fabricated by Ultrasonic-Assisted Stir Casting Process. Surf. Topogr. Metrol. Prop. 2022, 10, 025024. [Google Scholar] [CrossRef]

- Gudipudi, S.; Nagamuthu, S.; Subbian, K.S.; Prakasa, S.; Chilakalapalli, R. Enhanced Mechanical Properties of AA6061-B4C Composites Developed by a Novel Ultrasonic Assisted Stir Casting. Eng. Sci. Technol. Int. J. 2020, 23, 1233–1243. [Google Scholar] [CrossRef]

- Tenali, N.; Ganesan, G.; Babu, P.R. A Study on the Effects of Hybrid (SiC-PSSA) Nanosized Reinforcement on Mechanical and Tribological Behaviour of Al Alloy Based Metal Matrix Composite Produced by Ultrasonic Assisted Stir Casting. Mater. Res. Express 2024, 11, 075010. [Google Scholar] [CrossRef]

- Gangil, N.; Siddiquee, A.N.; Maheshwari, S.; Al-Ahmari, A.M.; Abidi, M.H. Art of Ex-Situ Aluminium Matrix Composite Fabrication through Friction Stir Processing. Arch. Metall. Mater. 2018, 63, 719–738. [Google Scholar] [CrossRef]

- Rathee, S.; Maheshwari, S.; Siddiquee, A.N.; Srivastava, M. A Review of Recent Progress in Solid State Fabrication of Composites and Functionally Graded Systems Via Friction Stir Processing. Crit. Rev. Solid State Mater Sci. 2018, 43, 334–366. [Google Scholar] [CrossRef]

- Kundurti, S.C.; Sharma, A. Fabrication of Surface Metal Matrix Composites for Structural Applications Using Friction Stir Processing—A Review. Mater. Today Proc. 2022, 56 Pt 3, 1468–1477. [Google Scholar] [CrossRef]

- Alladi, A.; Aluri, M.; Maddela, N.; Abbadi, C.R. Recent Progress of CNTs Reinforcement with Metal Matrix Composites Using Friction Stir Processing. Mater. Today Proc. 2021, 44, 1731–1738. [Google Scholar] [CrossRef]

- Butola, R.; Murtaza, Q. Fabrication and Optimization of AA7075 Matrix Surface Composites Using Taguchi Technique via Friction Stir Processing (FSP). Eng. Res. Exp. 2019, 1, 025015. [Google Scholar] [CrossRef]

- Kumar, S.; Srivastava, A.K.; Singh, R.K. Fabrication of AA7075 Hybrid Green Metal Matrix Composites by Friction Stir Processing Technique. Ann. Chim. -Sci. Matériaux 2020, 44, 295–300. [Google Scholar] [CrossRef]

- Pratap, C.; Chandra, P.; Butola, R.; Shukla, A. Fabrication and Characterization of AA6063/B4C Metal Matrix Surface Nanocomposite Using Friction Stir Processing. ECS J. Solid State Sci. Technol. 2022, 11, 033010. [Google Scholar] [CrossRef]

- Dinaharan, I.; Titilayo, E. Low Cost Metal Matrix Composites Based on Aluminum, Magnesium and Copper Reinforced with Fly Ash Prepared Using Friction Stir Processing. Compos. Commun. 2018, 9, 22–26. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Yapici, G.G. High Temperature Characteristics of Al2024/SiC Metal Matrix Composite Fabricated by Friction Stir Processing. Mater. Sci. Eng. A 2018, 731, 487–494. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.; Huang, C.; Yang, X.; Xu, Y. Optimization of Cold-Sprayed AA2024/Al2O3 Metal Matrix Composites via Friction Stir Processing: Effect of Rotation Speeds. J. Mater. Sci. Technol. 2018, 34, 2167–2177. [Google Scholar] [CrossRef]

- Sharma, H.; Tiwari, S.K.; Chauhan, V.S.; Kumar, R.; Gulati, P. Wear Analysis of Friction Stir Processed Aluminum Composite Reinforced by Boron Carbide. Mater. Today Proc. 2021, 46 Pt 6, 2141–2145. [Google Scholar] [CrossRef]

- Dittmann, K.; Trauth, A.; Weidenmann, K.A. Manufacturing and Characterization of an Interpenetrating Metal Matrix Composite Reinforced with a 3D-Printed Metallic Glass Lattice Structure (Ni60Nb20Ta20). Compos. Struct. 2024, 327, 117697. [Google Scholar] [CrossRef]

- Sharath, B.N.; Venkatesh, C.V.; Afzal, A.; Aslfattahi, N.; Aabid, A.; Baig, M.; Saleh, B. Multi Ceramic Particles Inclusion in the Aluminium Matrix and Wear Characterization through Experimental and Response Surface-Artificial Neural Networks. Materials 2021, 14, 2895. [Google Scholar] [CrossRef] [PubMed]

- Smirnov, A.; Kanakin, V.; Konovalov, A. Neural Network Modeling of Microstructure Formation in an AlMg6/10% SiC Metal Matrix Composite and Identification of Its Softening Mechanisms under High-Temperature Deformation. Appl. Sci. 2023, 13, 939. [Google Scholar] [CrossRef]

- Xue, J.; Huang, J.; Li, M.; Chen, J.; Wei, Z.; Cheng, Y.; Lai, Z.; Qu, N.; Liu, Y.; Zhu, J. Explanatory Machine Learning Accelerates the Design of Graphene-Reinforced Aluminium Matrix Composites with Superior Performance. Metals 2023, 13, 1690. [Google Scholar] [CrossRef]

- Priyadharshini, M.; Balaji, D.; Bhuvaneswari, V.; Rajeshkumar, L.; Sanjay, M.R.; Siengchin, S. Fiber Reinforced Composite Manufacturing with the Aid of Artificial Intelligence—A State-of-the-Art Review. Arch. Comput. Methods Eng. 2022, 29, 5511–5524. [Google Scholar] [CrossRef]

- Kordijazi, A.; Zhao, T.; Zhang, J.; Alrfou, K.; Rohatgi, P. A Review of Application of Machine Learning in Design, Synthesis, and Characterization of Metal Matrix Composites: Current Status and Emerging Applications. JOM 2021, 73, 1926–1942. [Google Scholar] [CrossRef]

- Bharath, L.; Kumaraswamy, J.; Manjunath, T.V.; Kulkarni, S.K.N. Evaluation of Microstructure and Prediction of Hardness of Al–Cu Based Composites by Using Artificial Neural Network and Linear Regression through Machine Learning Technique. Multiscale Multidiscip. Model. Exp. Des. 2024, 1–3. [Google Scholar] [CrossRef]

- Saleh, B.; Ma, A.; Fathi, R.; Radhika, N.; Yang, G.; Jiang, J. Optimized Mechanical Properties of Magnesium Matrix Composites Using RSM and ANN. Mater. Sci. Eng. B 2023, 290, 116303. [Google Scholar] [CrossRef]

- Singhal, S.; Khan, S.A.; Muaz, M.; Ahmed, E. Simulation of Mechanical Properties of Stir Cast Aluminum Matrix Composites through Artificial Neural Networks (ANN). Mater. Today Proc. 2023, 72, 1102–1109. [Google Scholar] [CrossRef]

- Adithiyaa, T.; Chandramohan, D.; Sathish, T. Optimal Prediction of Process Parameters by GWO-KNN in Stirring Squeeze Casting of AA2219 Reinforced Metal Matrix Composites. Mater. Today Proc. 2020, 21, 1000–1007. [Google Scholar] [CrossRef]

- Natrayan, L.; Kumar, M.S. An Integrated Artificial Neural Network and Taguchi Approach to Optimize the Squeeze Cast Process Parameters of AA6061/Al2O3/SiC/Gr Hybrid Composites Prepared by Novel Encapsulation Feeding Technique. Mater. Today Commun. 2020, 25, 101586. [Google Scholar] [CrossRef]

- Sheelwant, A.; Jadhav, P.M.; Reddy, S.K.N. ANN-GA Based Parametric Optimization of Al-TiB2 Metal Matrix Composite Material Processing Technique. Mater. Today Commun. 2021, 27, 102444. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarmah, P.; Gupta, K. Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials 2024, 17, 4635. https://doi.org/10.3390/ma17184635

Sarmah P, Gupta K. Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials. 2024; 17(18):4635. https://doi.org/10.3390/ma17184635

Chicago/Turabian StyleSarmah, Pallab, and Kapil Gupta. 2024. "Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review" Materials 17, no. 18: 4635. https://doi.org/10.3390/ma17184635

APA StyleSarmah, P., & Gupta, K. (2024). Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials, 17(18), 4635. https://doi.org/10.3390/ma17184635