Analysis of Thermal Properties of Materials Used to Insulate External Walls

Abstract

1. Introduction

- Thermal conductivity: materials with low thermal conductivity are more effective at reducing heat transfer.

- Durability: materials should withstand environmental conditions without degrading over time.

- Cost-effectiveness: the initial cost should be balanced against long-term savings.

- Environmental impact: life cycle assessment can evaluate the environmental footprint of different materials, taking into account production, use, and disposal.

2. Materials and Methods

- the heat transfer coefficient through the external wall Uc,

- the influence of linear thermal bridge on the thermal transmittance of the external wall,

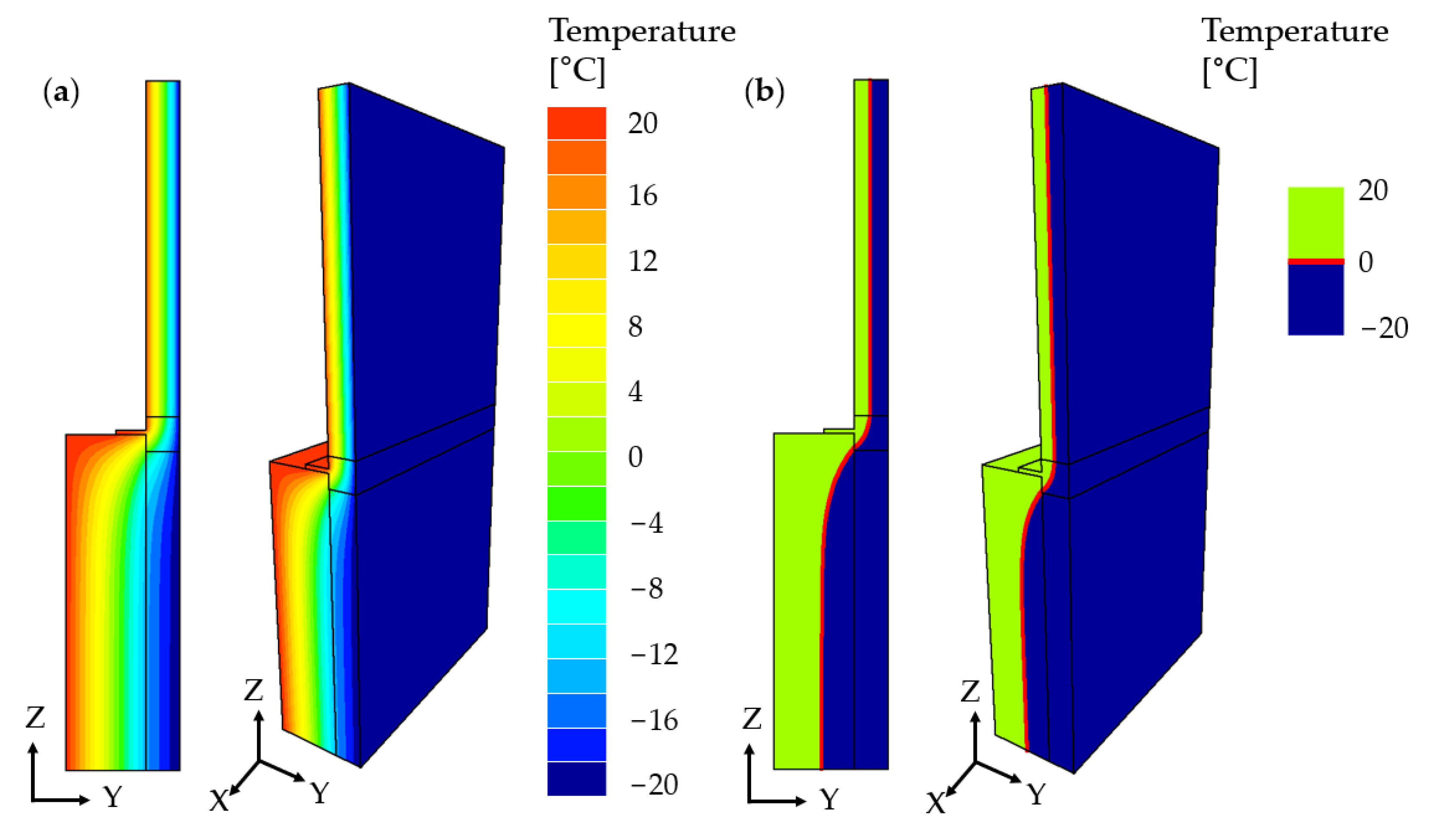

- the temperature distribution within the external wall,

- the risk of condensation on the internal wall surface (risk of mold growth).

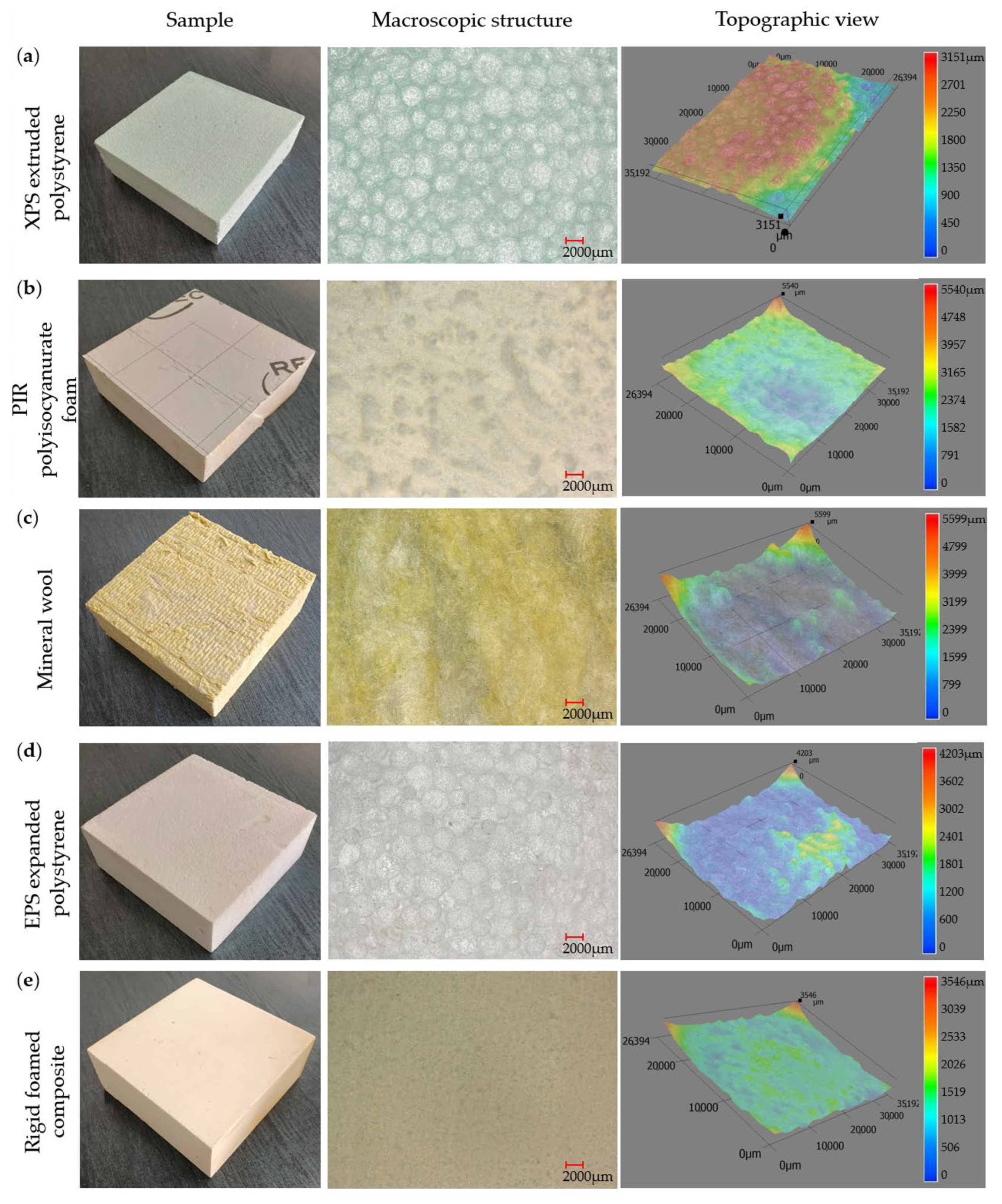

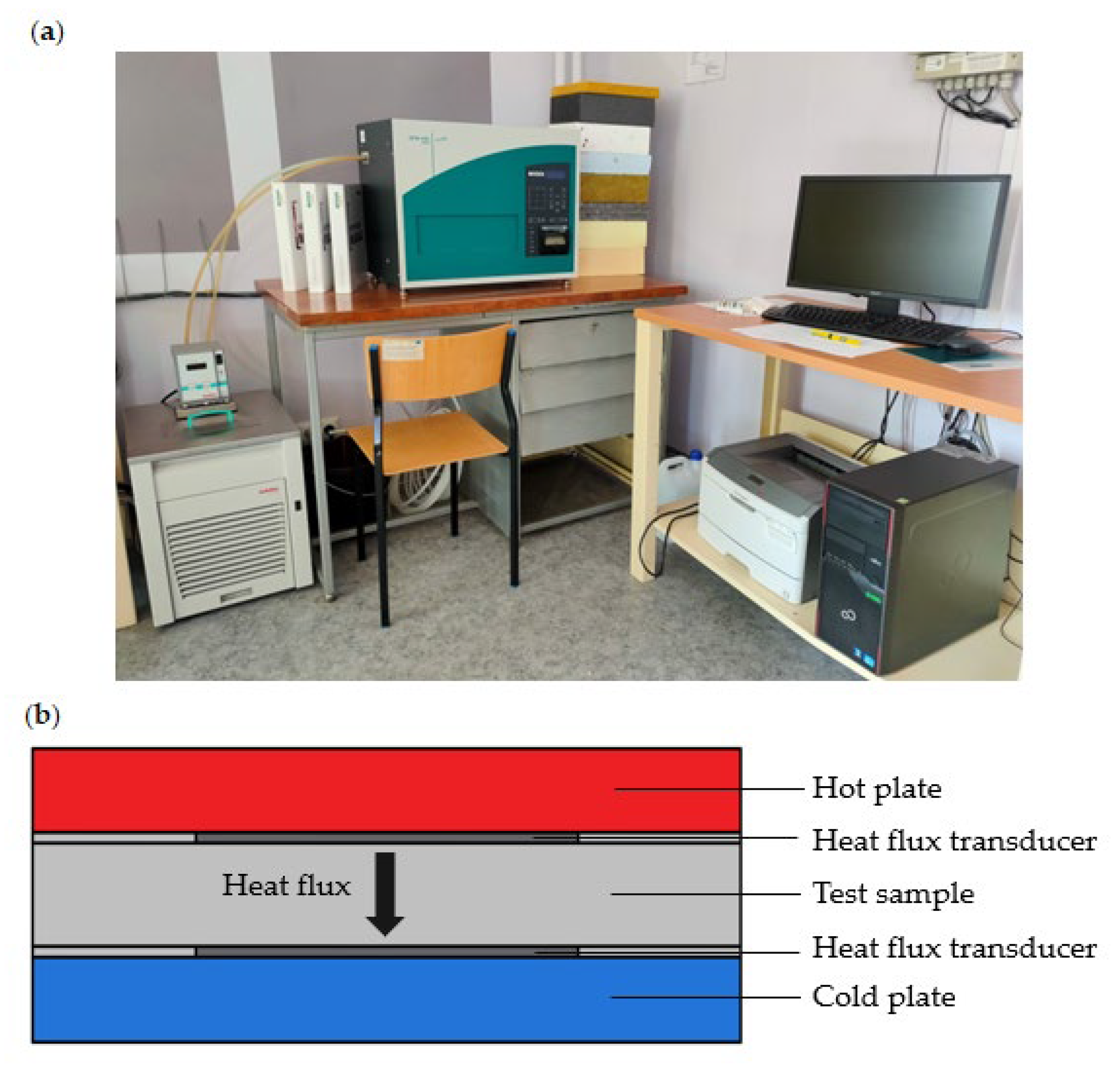

2.1. Experimental Research in a Plate Apparatus

- λ—thermal conductivity [W/(m·K)]

- Q—heat flux [W],

- A—sample area [m2],

- L—sample thickness [m],

- ΔT—temperature difference between the plates [K].

- –

- temperature of the cold plate: −10 °C,

- –

- temperature of the hot plate: 10 °C,

- –

- temperature of the sample: 23 °C,

- –

- pressure: 2 kPa,

- –

- air temperature around the test stand: 20 °C,

- –

- ambient relative humidity: 50%.

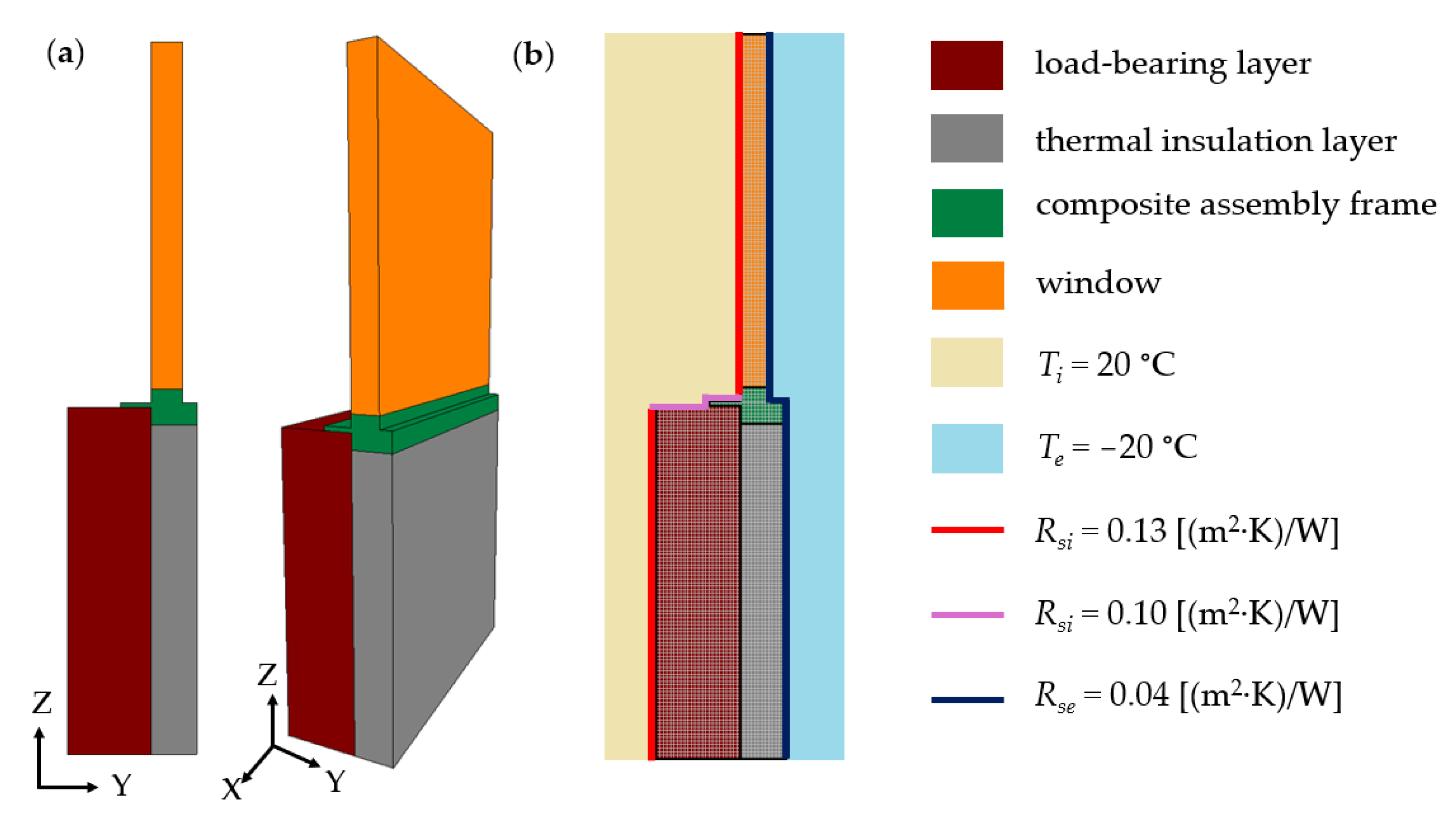

2.2. Numerical Analyzes and Analytical Calculations

- –

- a load-bearing layer, 0.24 m thick, made of cellular blocks with a thermal conductivity coefficient λ = 0.16 W/(m·K),

- –

- a thermal insulation layer, 0.10 m thick, made of the five analyzed insulating materials,

- –

- a composite mounting frame made of material with a thermal conductivity coefficient λ = 0.020 W/(m·K),

- –

- a window with a heat transfer coefficient Uw = 0.6 W/(m2·K).

- determination of heat loss through the flat envelope by calculating the corrected heat transfer coefficient Uc [W/(m2·K)] in accordance with EN ISO 6946 [29];

- assessment of the risk of surface condensation (mold growth) by determining the temperature factor at the internal surface ƒRsi [−] in accordance with EN ISO 13788 [30];

- calculation of the linear heat transmittance coefficient Ψ [W/(m2·K)] in accordance with EN ISO 10211 [31].

- –

- leaks in the thermal insulation layer,

- –

- mechanical fasteners penetrating the thermal insulation layer.

- Uc—corrected value of heat transfer coefficient [W/(m2·K)],

- ΔUg—correction for leaks in the thermal insulation layer [W/(m2·K)],

- ΔUf—correction for mechanical fasteners in the thermal insulation layer [W/(m2·K)].

- fRsi—temperature factor at the internal surface of the envelope [−],

- fRsi(crit)—critical value of the temperature factor at the internal surface of the envelope [−].

- fRsi—temperature factor at the internal surface of the envelope [−],

- Tsi,min—minimum internal surface temperature according to heat flow calculations [°C],

- Te—external temperature used in the calculations [°C],

- Ti—internal temperature used in the calculations [°C].

- simplified, assuming an internal temperature of Ti = 20 °C and average monthly relative air humidity in the room of φi = 50%, in which case fRsi(crit) = 0.72,

- precise, according to the procedure described in the EN ISO 13788 standard [30].

- Ψ—linear heat transmittance coefficient [W/(m·K)],

- L2D—linear thermal coupling coefficient, representing the total heat flux through the two-dimensional joint, with a temperature difference between environments [W/(m·K)],

- Ui—heat transfer coefficient of the i-th component or section of the envelope [W/(m2·K)],

- li—length of the component or section of the envelope corresponding to the given Ui value [m].

3. Results and Discussion

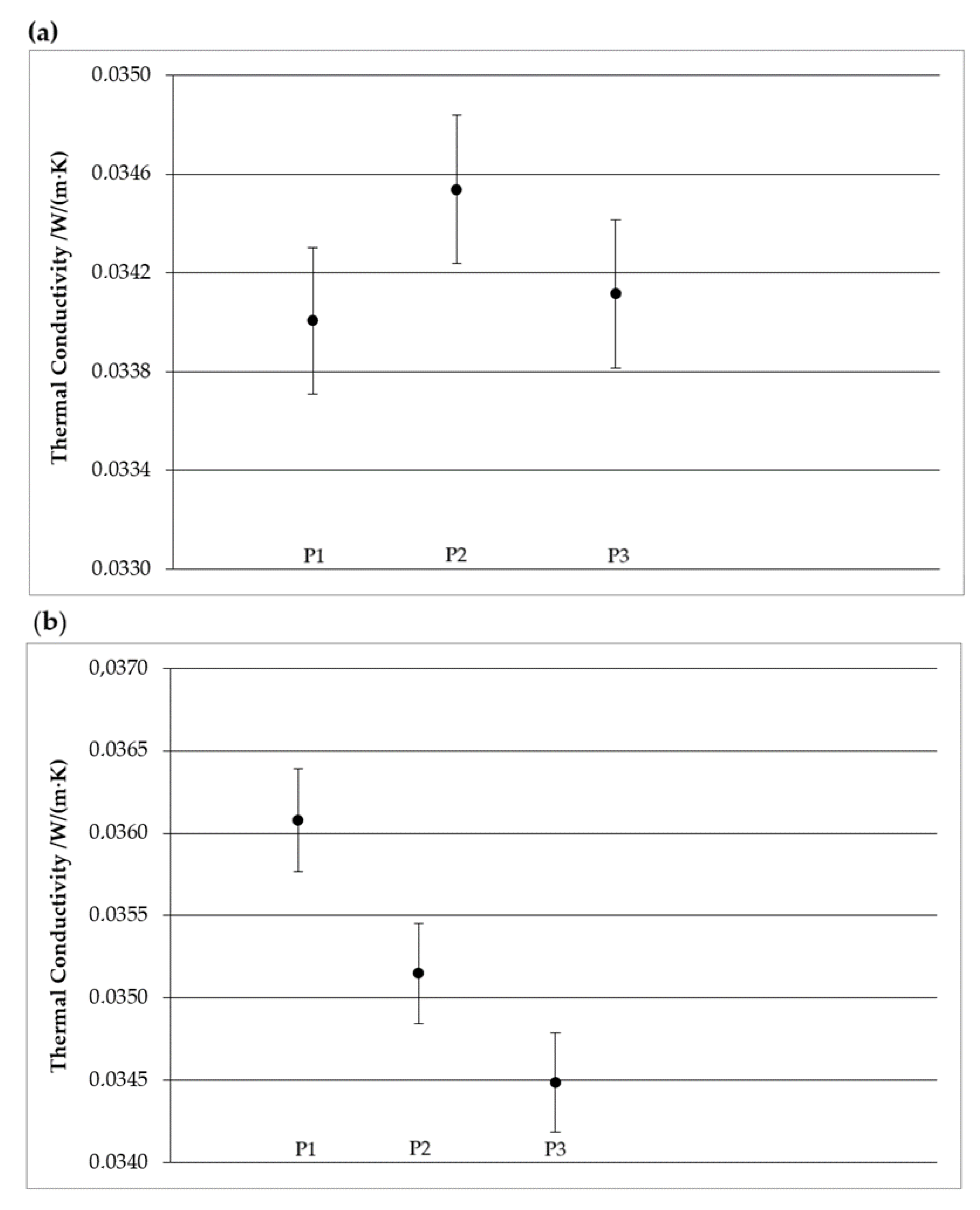

3.1. Experimental Research Results

- λavg—average thermal conductivity coefficient for n tests [W/(m·K)],

- λi—individual thermal conductivity coefficient [W/(m·K)],

- n—number of tests conducted for the given insulation material.

3.2. Numerical Analyzes and Analytical Calculations Results

- a minimum of 0.03 m to 0.04 m when using the declared thermal conductivity coefficients in the calculations,

- a minimum of 0.03 m to 0.05 m when using the measured thermal conductivity coefficients in the calculations.

- further analysis of the impact of environmental conditions and storage conditions on samples (e.g., extended storage periods, storage during the spring and summer seasons),

- determining the effect of insulation material thickness on thermal conductivity,

- investigating the hygroscopic properties of selected insulation materials,

- conducting analyses on insulation materials derived from recycling.

- assessing the risk of interstitial condensation in external walls,

- evaluating the potential use of artificial intelligence tools in assessing thermal and moisture properties of insulation materials.

4. Conclusions

- the analysis and testing of thermal insulation materials showed that improper storage of samples leads to a deterioration in thermal properties,

- inadequate storage resulted in a 4% increase in the thermal conductivity coefficient for standard thermal insulation materials and a 19% increase for the composite material,

- the measurements of thermal insulation materials with a heterogeneous structure reveal greater uncertainty,

- the lack of knowledge regarding the actual thermal properties of materials, and consequently, inappropriate selection of insulation layer thicknesses, affects the basic thermal performance of external walls; this, in particular, leads to increased heat loss through the largest structural elements of buildings, directly resulting in higher heating costs and indirectly in increased greenhouse gas emissions,

- each analysed configuration of external wall layers should be assessed during the design phase for the risk of surface condensation and the position of the wall frost line,

- the thermal parameters of the thermal insulation layer influence the value of the linear heat transmittance coefficient Ψ resulting from window installation.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations Environment Programme. Global Status Report for Buildings and Construction: Beyond Foundations—Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector; United Nations Environment Programme, 2024. 2023. Available online: https://www.unep.org/resources/report/global-status-report-buildings-and-construction (accessed on 20 August 2023).

- Asatov, N.; Djurayev, U.; Aliyev, M.; Sagatov, B.; Abdurakhmonov, A. Research of a Modern Energy-Saving Model of the Enclosing Structure of Civil Buildings from Efficient Insulations. E3S Web Conf. 2024, 497, 02009. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Cao, Y.; Gao, Y.; Hou, C.; Zhang, L.; Shen, Q. Optimization of the Wall Thermal Insulation Characteristics Based on the Intermittent Heating Operation. Case Stud. Constr. Mater. 2018, 9, e00188. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; Maria Mauro, G.; Napolitano, D.F. Building Envelope Design: Multi-Objective Optimization to Minimize Energy Consumption, Global Cost and Thermal Discomfort. Application to Different Italian Climatic Zones. Energy 2019, 174, 359–374. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation Materials for the Building Sector: A Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A Review and Evaluation of Thermal Insulation Materials and Methods for Thermal Energy Storage Systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Petrosyan, A.L. Determination of Optimal Thermal Insulation Layer Thickness of Outer Structures of Buildings According to the Load of Heating and Cooling System. IOP Conf. Ser. Mater. Sci. Eng. 2019, 698, 022058. [Google Scholar] [CrossRef]

- Gori, P.; Guattari, C.; Evangelisti, L.; Asdrubali, F. Design Criteria for Improving Insulation Effectiveness of Multilayer Walls. Int. J. Heat Mass Transf. 2016, 103, 349–359. [Google Scholar] [CrossRef]

- Wi, S.; Park, J.H.; Kim, Y.U.; Yang, S.; Kim, S. Thermal, Hygric, and Environmental Performance Evaluation of Thermal Insulation Materials for Their Sustainable Utilization in Buildings. Environ. Pollut. 2021, 272, 116033. [Google Scholar] [CrossRef] [PubMed]

- Choi, G.-S.; Kang, J.-S.; Jeong, Y.-S.; Lee, S.-E.; Sohn, J.-Y. An Experimental Study on Thermal Properties of Composite Insulation. Thermochim. Acta 2007, 455, 75–79. [Google Scholar] [CrossRef]

- Baldinelli, G.; Bianchi, F.; Gendelis, S.; Jakovics, A.; Morini, G.L.; Falcioni, S.; Fantucci, S.; Serra, V.; Navacerrada, M.A.; Díaz, C.; et al. Thermal Conductivity Measurement of Insulating Innovative Building Materials by Hot Plate and Heat Flow Meter Devices: A Round Robin Test. Int. J. Therm. Sci. 2019, 139, 25–35. [Google Scholar] [CrossRef]

- EL Assaad, M.; Colinart, T.; Lecompte, T. Thermal Conductivity Assessment of Moist Building Insulation Material Using a Heat Flow Meter Apparatus. Build. Environ. 2023, 234, 110184. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Xia, X.; Setunge, S.; Shi, L. A Review of Internal and External Influencing Factors on Energy Efficiency Design of Buildings. Energy Build. 2020, 216, 109944. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, P.; Chen, M.; Chen, Y. Analysis of Energy-Saving Effects of Different Building Exterior Wall Insulation Materials. In Proceedings of the Environmental Governance, Ecological Remediation and Sustainable Development; Han, D., Bashir, M.J.K., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 1433–1439. [Google Scholar]

- Shen, Z.; Shrestha, S.; Howard, D.; Feng, T.; Hun, D.; She, B. Machine Learning–Assisted Prediction of Heat Fluxes through Thermally Anisotropic Building Envelopes. Build. Environ. 2023, 234, 110157. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine Learning: Trends, Perspectives, and Prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

- Wang, Z.; Srinivasan, R.S. A Review of Artificial Intelligence Based Building Energy Use Prediction: Contrasting the Capabilities of Single and Ensemble Prediction Models. Renew. Sustain. Energy Rev. 2017, 75, 796–808. [Google Scholar] [CrossRef]

- Wang, Z.; Hong, T.; Piette, M.A. Building Thermal Load Prediction through Shallow Machine Learning and Deep Learning. Appl. Energy 2020, 263, 114683. [Google Scholar] [CrossRef]

- Zhang, L.; Wen, J.; Li, Y.; Chen, J.; Ye, Y.; Fu, Y.; Livingood, W. A Review of Machine Learning in Building Load Prediction. Appl. Energy 2021, 285, 116452. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, M.; Chen, Z.; Chen, Z.; Ji, Y. Physical Energy and Data-Driven Models in Building Energy Prediction: A Review. Energy Rep. 2022, 8, 2656–2671. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Leitão, D.; Boaventura-Cunha, J.; Martins, F.F. Trombe Wall Thermal Performance: Data Mining Techniques for Indoor Temperatures and Heat Flux Forecasting. Energy Build. 2021, 252, 111407. [Google Scholar] [CrossRef]

- Martínez-Comesaña, M.; Febrero-Garrido, L.; Granada-Álvarez, E.; Martínez-Torres, J.; Martínez-Mariño, S. Heat Loss Coefficient Estimation Applied to Existing Buildings through Machine Learning Models. Appl. Sci. 2020, 10, 8968. [Google Scholar] [CrossRef]

- HFM 446 Lambda Medium Eco-Line. Available online: https://analyzing-testing.netzsch.com/en/products/thermal-conductivity/hfm-446-lambda-eco-line-medium (accessed on 11 July 2024).

- Adamus, J.; Pomada, M. Analysis of the Influence of External Wall Material Type on the Thermal Bridge at the Window-to-Wall Interface. Materials 2023, 16, 6585. [Google Scholar] [CrossRef]

- TRISCO: Steady-State 3D—Orthogonal. Available online: https://www.physibel.be/en/products/trisco (accessed on 20 September 2023).

- ISO 6946:2017; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 13788:2013-05; Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 10211:2017; Thermal Bridges in Building Construction—Heat Flows and Surface Temperatures—Detailed Calculations. International Organization for Standardization: Geneva, Switzerland, 2017.

- Pomada, M.; Adamus, J.; Boruszewski, A. Numerical and Experimental Analysis of Heat Flow at Window-to-Wall Interface. Energies 2022, 15, 3837. [Google Scholar] [CrossRef]

- Adamus, J.; Pomada, M. Selected Issues of Choosing Composite Materials for Window Supporting Beams. J. Build. Eng. 2020, 32, 101542. [Google Scholar] [CrossRef]

- Regulation of the Minister of Infrastructure of 12 April 2002 on Technical Conditions to be Met by Buildings and Their Location. Available online: https://www.global-regulation.com/translation/poland/3353940/regulation-of-the-minister-of-infrastructure-of-12-april-2002-on-technical-conditions%252c-which-should-correspond-to-the-buildings-and-their-location.html (accessed on 20 August 2023).

- The Passive House Institute: Information, Criteria and Algorithms for Certified Passive House Components: Sun Protection and Window Installation Systems. Available online: https://passiv.de/en/03_certification/01_certification_components/02_certification_criteria/02_certification_criteria.htm (accessed on 20 August 2023).

- ISO 12831-1:2017; Energy Performance of Buildings—Method for Calculation of the Design Heat Load—Part 1: Space Heating Load, Module M3-3. International Organization for Standardization: Geneva, Switzerland, 2017.

| Insulation Material | Heat Transfer Coefficient λD [W/(m·K)] |

|---|---|

| XPS extruded polystyrene | 0.034 |

| PIR polyisocyanurate foam | 0.022 |

| Mineral wool | 0.035 |

| EPS expanded polystyrene | 0.032 |

| Rigid foamed composite | 0.020 |

| Insulation Material | Mass [kg] | Density [kg/m3] | Test Time [min] | Average Test Time [min] | Coefficient λ [W/(m·K)] | Average Coefficient λavg [W/(m·K)] |

|---|---|---|---|---|---|---|

| XPS extruded polystyrene | 0.152 | 17.1 | 90 | 76 | 0.03401 | 0.03422 |

| 59 | 0.03454 | |||||

| 78 | 003411 | |||||

| PIR polyisocyanurate foam | 0.278 | 30.5 | 213 | 482 | 0.02201 | 0.02230 |

| 696 | 0.02282 | |||||

| 536 | 0.02206 | |||||

| Mineral wool | 0.696 | 77.7 | 91 | 108 | 0.03467 | 0.03532 |

| 107 | 0.03524 | |||||

| 127 | 0.03606 | |||||

| EPS expanded polystyrene | 0.200 | 22.0 | 72 | 75 | 0.03271 | 0.03233 |

| 70 | 0.03221 | |||||

| 84 | 0.03208 | |||||

| Rigid foamed composite | 0.554 | 61.4 | 1145 | 700 | 0.02272 | 0.02229 |

| 242 | 0.02202 | |||||

| 714 | 0.02213 |

| Insulation Material | Mass [kg] | Density [kg/m3] | Test Time [min] | Average Test Time [min] | Coefficient λ [W/(m·K)] | Average Coefficient λavg [W/(m·K)] |

|---|---|---|---|---|---|---|

| XPS extruded polystyrene | 0.152 | 17.1 | 67 | 78 | 0.03405 | 0.03408 |

| 100 | 0.03404 | |||||

| 66 | 003414 | |||||

| PIR polyisocyanurate foam | 0.286 | 31.3 | 267 | 458 | 0.02282 | 0.02222 |

| 653 | 0.02139 | |||||

| 454 | 0.02244 | |||||

| Mineral wool | 0.745 | 83.3 | 68 | 94 | 0.03608 | 0.03524 |

| 116 | 003516 | |||||

| 97 | 0.03449 | |||||

| EPS expanded polystyrene | 0.202 | 22.5 | 92 | 89 | 0.03217 | 0.03247 |

| 95 | 0.03253 | |||||

| 80 | 0.03271 | |||||

| Rigid foamed composite | 0.554 | 61.4 | 1150 | 1173 | 0.02216 | 0.02214 |

| 1420 | 0.02247 | |||||

| 949 | 0.02178 |

| Insulation Material | Mass [kg] | Density [kg/m3] | Test Time [min] | Average Test Time [min] | Coefficient λ [W/(m·K)] | Average Coefficient λavg [W/(m·K)] |

|---|---|---|---|---|---|---|

| XPS extruded polystyrene | 0.150 | 17.0. | 98 | 95 | 0.03544 | 0.03541 |

| 123 | 0.03531 | |||||

| 65 | 0.03548 | |||||

| PIR polyisocyanurate foam | 0.281 | 30.7 | 142 | 701 | 0.02235 | 0.02297 |

| 824 | 0.02367 | |||||

| 1136 | 0.02289 | |||||

| Mineral wool | 0.719 | 80.2 | 107 | 133 | 0.03649 | 0.03688 |

| 110 | 0.03737 | |||||

| 183 | 0.03677 | |||||

| EPS expanded polystyrene | 0.198 | 22.1 | 85 | 106 | 0.03361 | 0.03317 |

| 107 | 0.03296 | |||||

| 127 | 0.03294 | |||||

| Rigid foamed composite | 0.574 | 63.6 | 204 | 224 | 0.02366 | 0.02380 |

| 213 | 0.02371 | |||||

| 255 | 0.02402 |

| Insulation Material | Average Coefficient λavg [W/(m·K)] | ||||

|---|---|---|---|---|---|

| Declared Values | Group 1 Samples (Control) | Group 2 Samples | Group 3 Samples | Relative Error | |

| XPS extruded polystyrene | 0.034 | 0.03422 | 0.03408 | 0.03541 | 4.1 |

| PIR polyisocyanurate foam | 0.022 | 0.02230 | 0.02222 | 0.02297 | 4.4 |

| Mineral wool | 0.035 | 0.03532 | 0.03524 | 0.03688 | 5.4 |

| EPS expanded polystyrene | 0.032 | 0.03233 | 0.03247 | 0.03317 | 3.7 |

| Rigid foamed composite | 0.020 | 0.02229 | 0.02214 | 0.02380 | 19.0 |

| Insulation Material | Standard Deviation sd [W/(m·K)] | |||||

|---|---|---|---|---|---|---|

| Group 1 Samples (Control) | Group 2 Samples | Group 3 Samples | ||||

| Average Coefficient λavg | Standard Deviation sd | Average Coefficient λavg | Standard Deviation sd | Average Coefficient λavg | Standard Deviation sd | |

| XPS extruded polystyrene | 0.03422 | 0.00028 | 0.03408 | 0.00006 | 0.03541 | 0.00009 |

| PIR polyisocyanurate foam | 0.02230 | 0.00045 | 0.02222 | 0.00074 | 0.02297 | 0.00066 |

| Mineral wool | 0.03532 | 0.00070 | 0.03524 | 0.00080 | 0.03688 | 0.00045 |

| EPS expanded polystyrene | 0.03233 | 0.00033 | 0.03247 | 0.00027 | 0.03317 | 0.00038 |

| Rigid foamed composite | 0.02229 | 0.00038 | 0.02214 | 0.00035 | 0.02380 | 0.00020 |

| Insulation Material | Thermal Conductivity Coefficients λ W/(m·K) | Heat Transfer Coefficient UC W/(m2·K) | |

|---|---|---|---|

| XPS extruded polystyrene | Declared value λD | 0.034 | 0.230 |

| Intended value λavg | 0.035 | 0.234 | |

| PIR polyisocyanurate foam | Declared value λD | 0.022 | 0.178 |

| Intended value λavg | 0.023 | 0.183 | |

| Mineral wool | Declared value λD | 0.035 | 0.234 |

| Intended value λavg | 0.037 | 0.241 | |

| EPS expanded polystyrene | Declared value λD | 0.032 | 0.222 |

| Intended value λavg | 0.033 | 0.226 | |

| Rigid foamed composite | Declared value λD | 0.020 | 0.168 |

| Intended value λavg | 0.024 | 0.188 | |

| Insulation Material | Thermal Conductivity Coefficients λ W/(m·K) | Insulation Layer Thickness [m] | Heat Transfer Coefficient Uc W/(m2·K) | |

|---|---|---|---|---|

| XPS extruded polystyrene | Declared value λD | 0.034 | 0.13 | 0.198 |

| Intended value λavg | 0.035 | 0.14 | 0.192 | |

| PIR polyisocyanurate foam | Declared value λD | 0.022 | - | 0.178 |

| Intended value λavg | 0.023 | - | 0.183 | |

| Mineral wool | Declared value λD | 0.035 | 0.14 | 0.192 |

| Intended value λavg | 0.037 | 0.15 | 0.191 | |

| EPS expanded polystyrene | Declared value λD | 0.032 | 0.13 | 0.191 |

| Intended value λavg | 0.033 | 0.13 | 0.194 | |

| Rigid foamed composite | Declared value λD | 0.020 | - | 0.168 |

| Intended value λavg | 0.024 | - | 0.188 | |

| Insulation Material | Thermal Conductivity Coefficients λ W/(m·K) | Wall Surface Temperature [°C] | Temperature Factor fRsi [−] | |

|---|---|---|---|---|

| XPS extruded polystyrene | Declared value λD | 0.034 | 18.87 | 0.972 |

| Intended value λavg | 0.035 | 18.83 | 0.971 | |

| PIR polyisocyanurate foam | Declared value λD | 0.022 | 19.16 | 0.979 |

| Intended value λavg | 0.023 | 19.11 | 0.978 | |

| Mineral wool | Declared value λD | 0.035 | 18.85 | 0.971 |

| Intended value λavg | 0.037 | 18.79 | 0.970 | |

| EPS expanded polystyrene | Declared value λD | 0.032 | 18.83 | 0.971 |

| Intended value λavg | 0.033 | 18.81 | 0.970 | |

| Rigid foamed composite | Declared value λD | 0.020 | 19.22 | 0.981 |

| Intended value λavg | 0.024 | 19.06 | 0.976 | |

| Insulation Material | Thermal Conductivity Coefficients λ W/(m·K) | Linear Heat Transmittance Coefficient Ψ [W/(m·K)] | |

|---|---|---|---|

| XPS extruded polystyrene | Declared value λD | 0.034 | 0.0082298 |

| Intended value λavg | 0.035 | 0.0086556 | |

| PIR polyisocyanurate foam | Declared value λD | 0.022 | 0.0054062 |

| Intended value λavg | 0.023 | 0.0056367 | |

| Mineral wool | Declared value λD | 0.035 | 0.0086556 |

| Intended value λavg | 0.037 | 0.0089941 | |

| EPS expanded polystyrene | Declared value λD | 0.032 | 0.0078780 |

| Intended value λavg | 0.033 | 0.0081364 | |

| Rigid foamed composite | Declared value λD | 0.020 | 0.0050722 |

| Intended value λavg | 0.024 | 0.0057369 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pomada, M.; Kieruzel, K.; Ujma, A.; Palutkiewicz, P.; Walasek, T.; Adamus, J. Analysis of Thermal Properties of Materials Used to Insulate External Walls. Materials 2024, 17, 4718. https://doi.org/10.3390/ma17194718

Pomada M, Kieruzel K, Ujma A, Palutkiewicz P, Walasek T, Adamus J. Analysis of Thermal Properties of Materials Used to Insulate External Walls. Materials. 2024; 17(19):4718. https://doi.org/10.3390/ma17194718

Chicago/Turabian StylePomada, Marta, Klaudia Kieruzel, Adam Ujma, Paweł Palutkiewicz, Tomasz Walasek, and Janina Adamus. 2024. "Analysis of Thermal Properties of Materials Used to Insulate External Walls" Materials 17, no. 19: 4718. https://doi.org/10.3390/ma17194718

APA StylePomada, M., Kieruzel, K., Ujma, A., Palutkiewicz, P., Walasek, T., & Adamus, J. (2024). Analysis of Thermal Properties of Materials Used to Insulate External Walls. Materials, 17(19), 4718. https://doi.org/10.3390/ma17194718