Thermomechanical Properties of Ramie Fiber/Degradable Epoxy Resin Composites and Their Performance on Cylinder Inner Lining

Abstract

1. Introduction

2. Materials and Methods

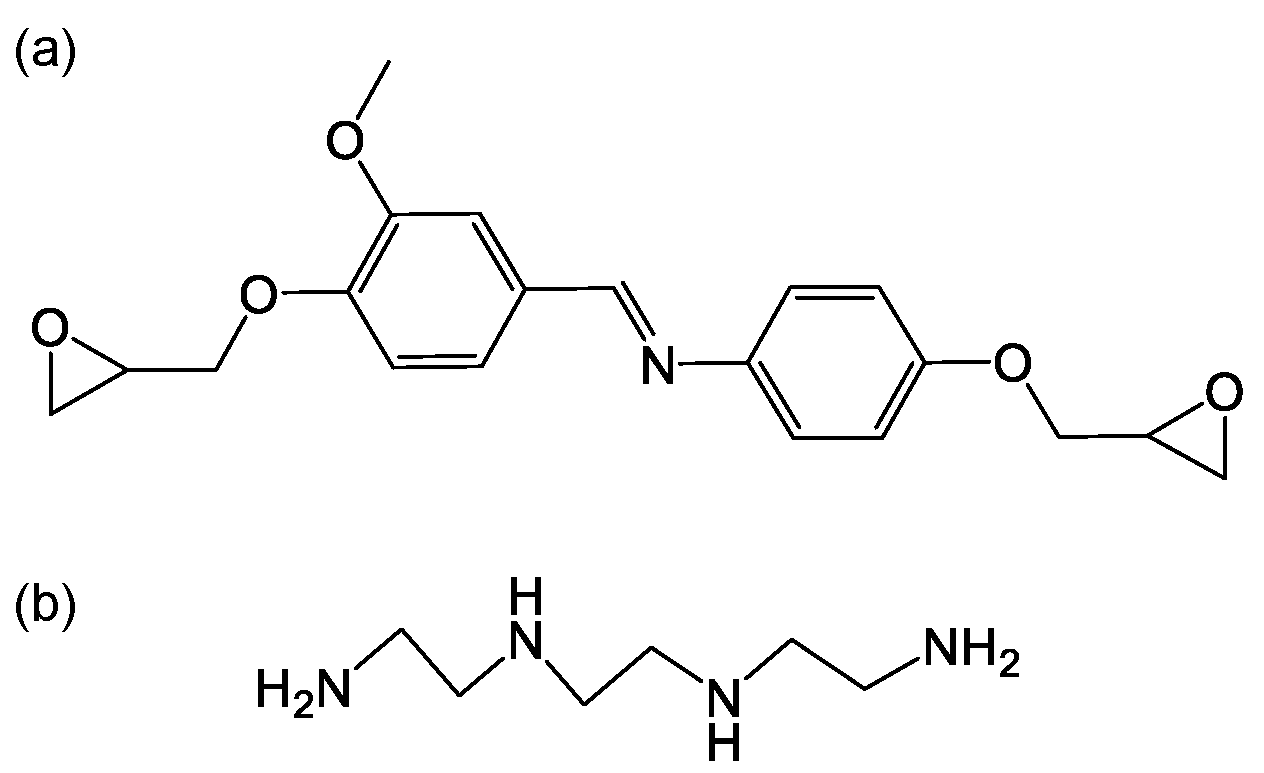

2.1. Materials

2.2. Testing Instruments and Conditions

2.2.1. Heat Treatment of Ramie Fiber

2.2.2. Differential Scanning Calorimeter (DSC) Measurements

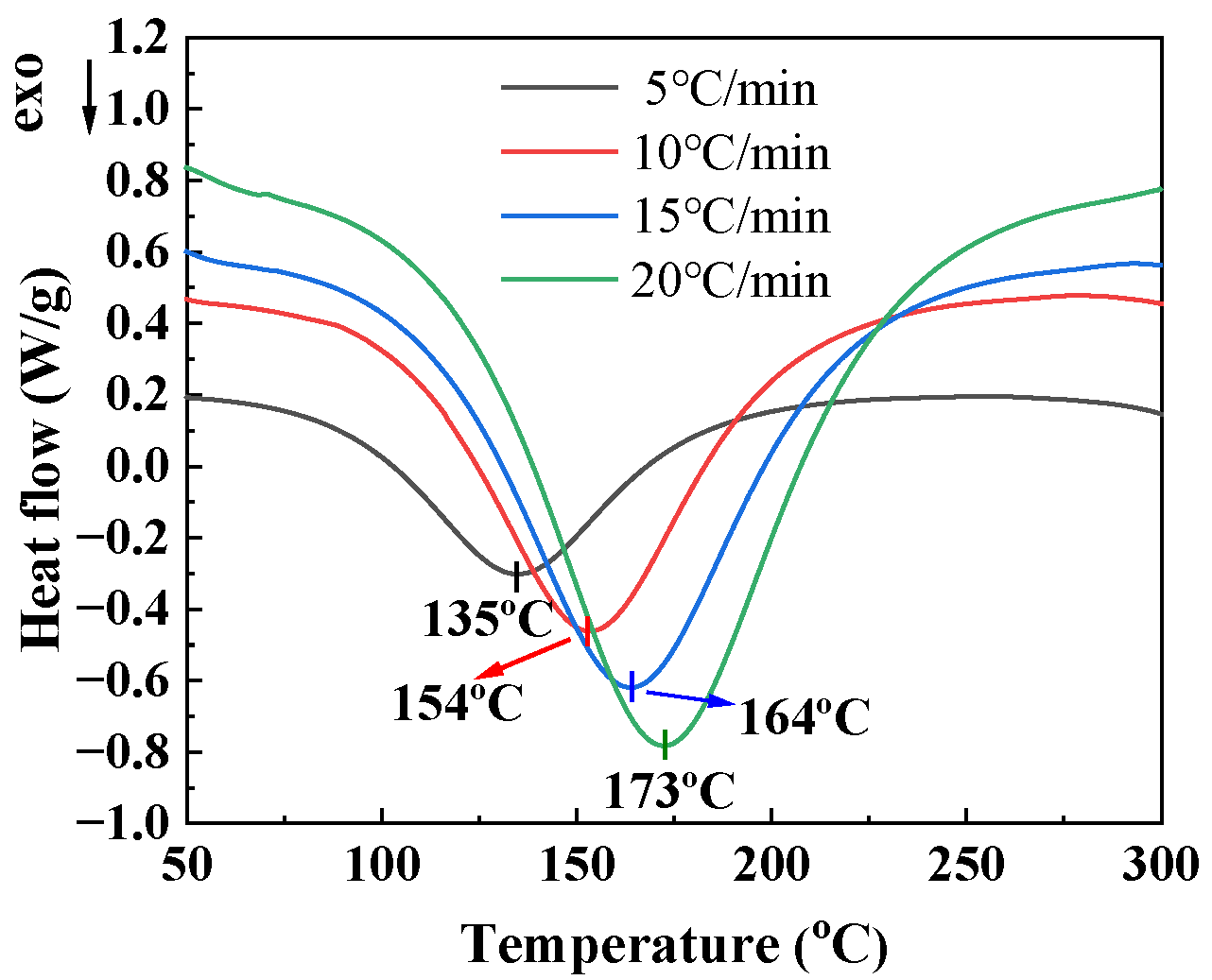

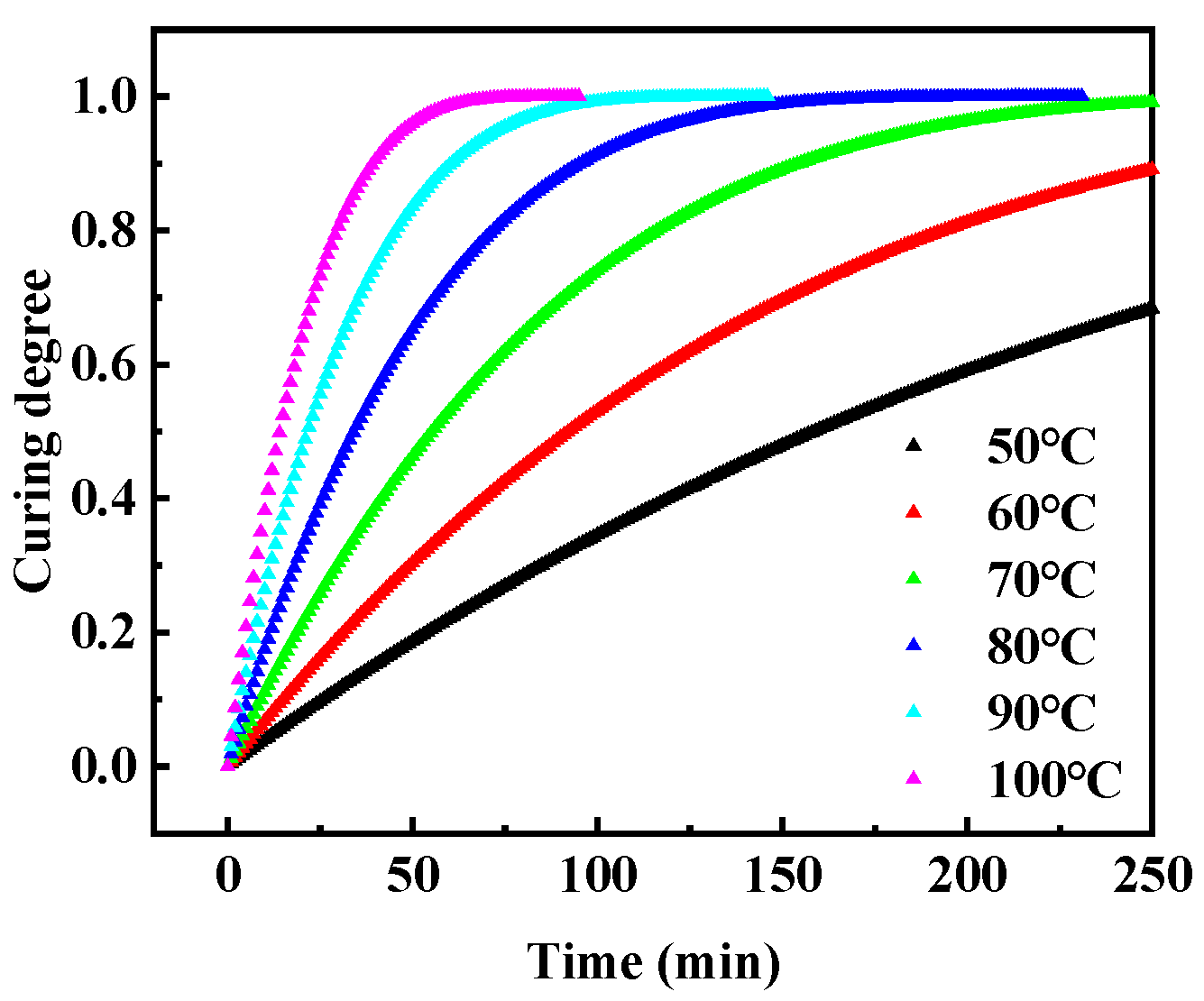

2.2.3. Curing Kinetics of RFRDE

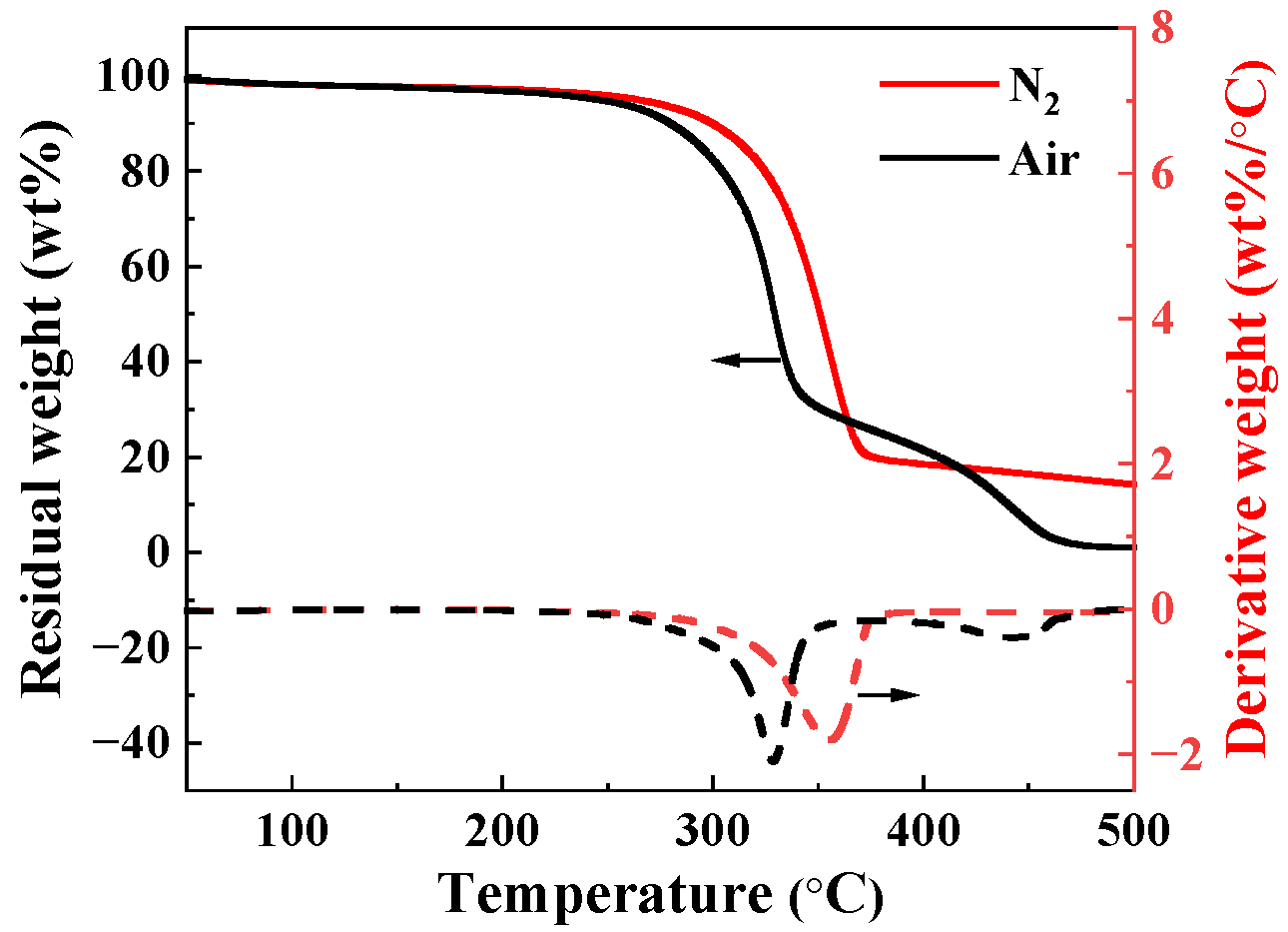

2.2.4. Thermal Properties

2.2.5. Mechanical Properties

2.2.6. PE/RFRDE Adhesive Strength Test

2.3. Scanning Electron Microscope

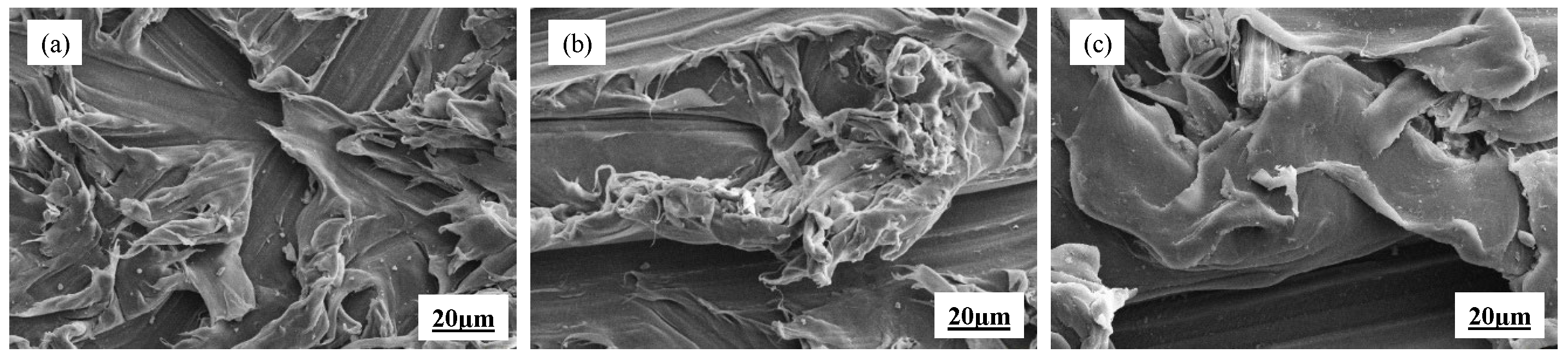

2.4. PE-RFRDE Gas Cylinder Winding

3. Results

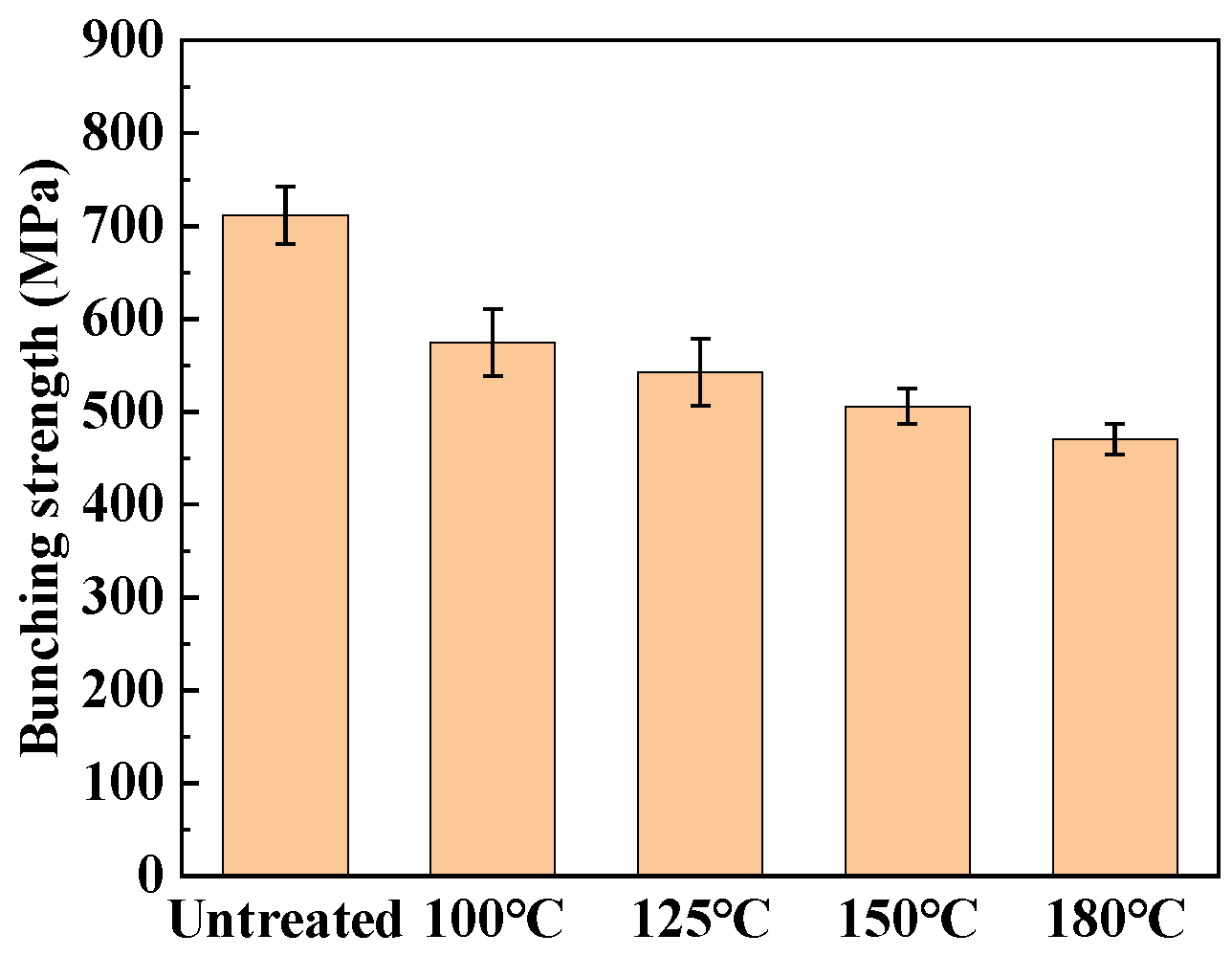

3.1. Mechanical Properties of Ramie Fibers with Heat Treatment

3.2. Curing Kinetics Model of Degradable Epoxy Resin

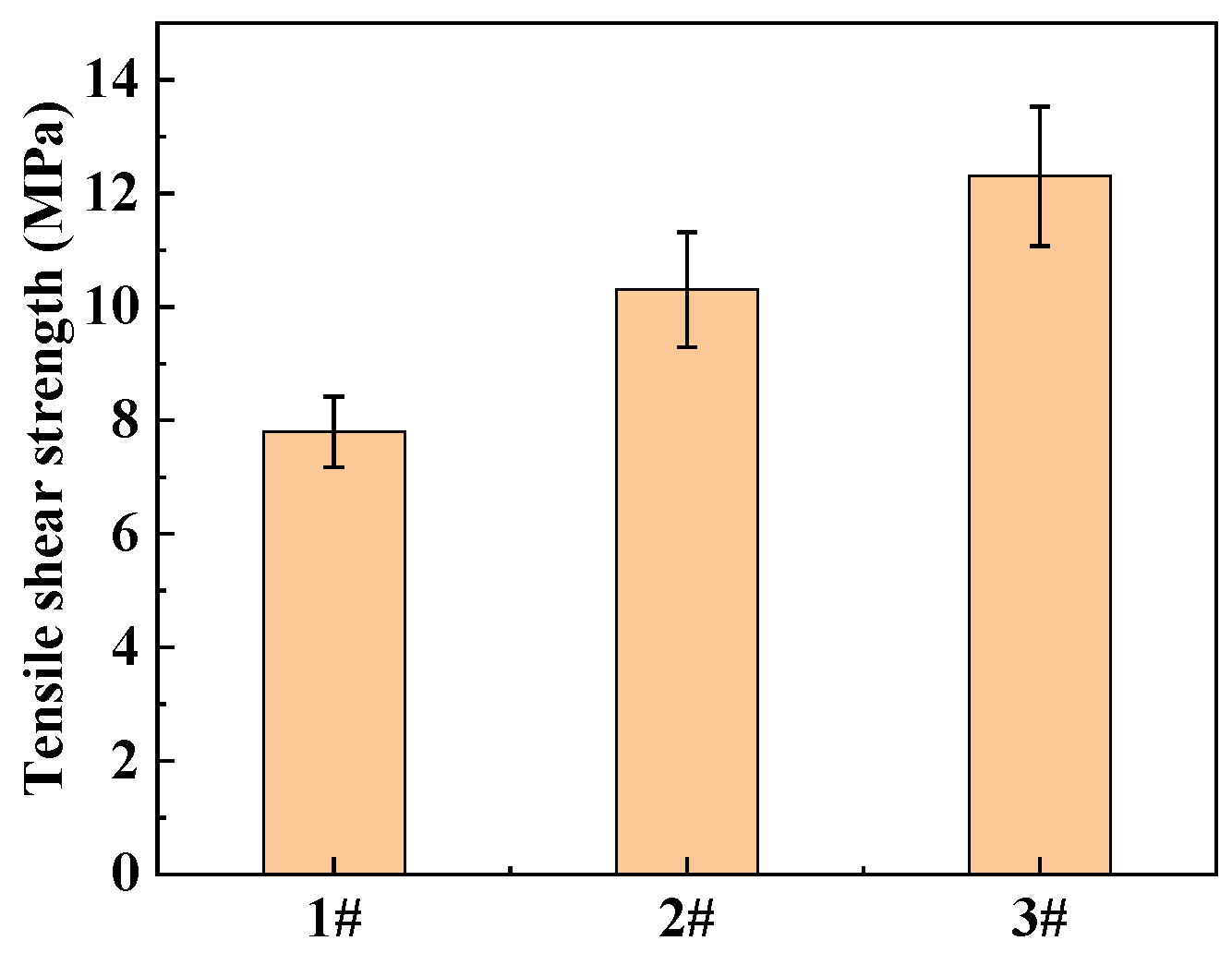

3.3. The Effect of Different Treatment Processes on the Interface Strength between Polyethylene Plastics and RFRDE

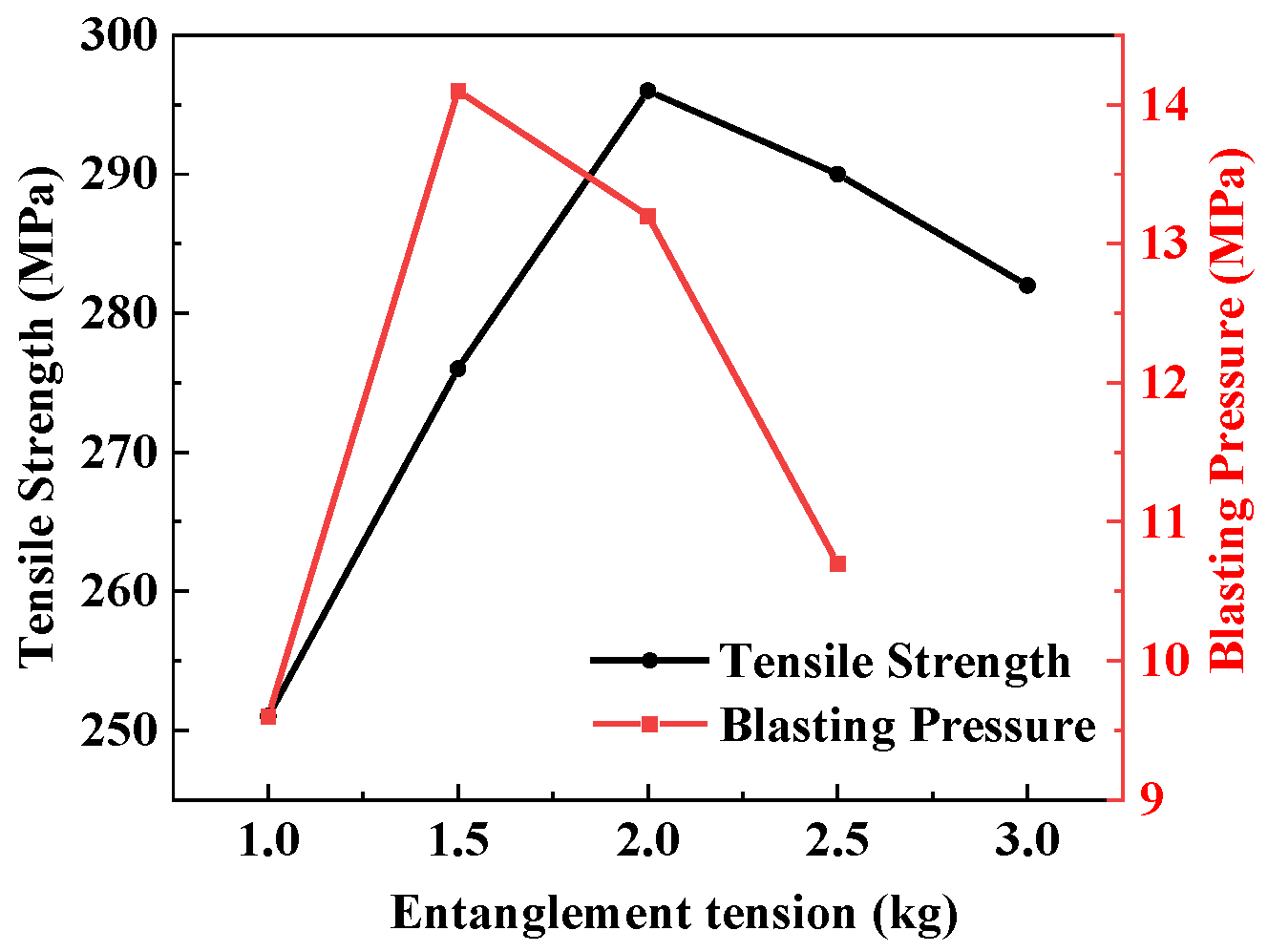

3.4. The Influence of Winding Tension on the Burst Strength of Gas Cylinders

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Huang, Q.; Liu, Y.; Zhao, B.; Li, J. Review of the hydrogen permeation test of the polymer liner material of type IV on-board hydrogen storage cylinders. Materials 2023, 16, 5366. [Google Scholar] [CrossRef] [PubMed]

- Barthélémy, H.; Weber, M.; Barbier, F. Hydrogen storage: Recent improvements and industrial perspectives. Int. J. Hydrogen Energy 2017, 42, 7254–7262. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Zhao, B.; Wang, D.; Guo, S.; Song, J.; Li, X. Research on Temperature Rise of Type IV Composite Hydrogen Storage Cylinders in Hydrogen Fast-Filling Process. Energies 2023, 16, 2918. [Google Scholar] [CrossRef]

- Su, Y.; Lv, H.; Zhou, W.; Zhang, C. Review of the hydrogen permeability of the liner material of type IV on-board hydrogen storage tank. World Electr. Veh. J. 2021, 12, 130. [Google Scholar] [CrossRef]

- Gonzalez, D.C.; Mena, A.; Ruiz, G.; Ortega, J.J.; Poveda, E.; Minguez, J.; Yu, R.; De La Rosa, Á.; Vicente, M.A. Size effect of steel fiber–reinforced concrete cylinders under compressive fatigue loading: Influence of the mesostructure. Int. J. Fatigue 2023, 167, 107353. [Google Scholar] [CrossRef]

- Zhang, M.; Lv, H.; Kang, H.; Zhou, W.; Zhang, C. A literature review of failure prediction and analysis methods for composite high-pressure hydrogen storage tanks. Int. J. Hydrogen Energy 2019, 44, 25777–25799. [Google Scholar] [CrossRef]

- Azeem, M.; Ya, H.H.; Alam, M.A.; Kumar, M.; Stabla, P.; Smolnicki, M.; Gemi, L.; Khan, R.; Ahmed, T.; Ma, Q. Application of filament winding technology in composite pressure vessels and challenges: A review. J. Energy Storage 2022, 49, 103468. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, M.; Zu, L.; Jia, X.; Shen, A.; Yang, Q.; Xu, K. Investigation on failure behaviors of 70 MPa Type IV carbon fiber overwound hydrogen storage vessels. Compos. Struct. 2021, 259, 113387. [Google Scholar] [CrossRef]

- Park, G.; Jang, H.; Kim, C. Design of composite layer and liner for structure safety of hydrogen pressure vessel (type 4). J. Mech. Sci. Technol. 2021, 35, 3507–3517. [Google Scholar] [CrossRef]

- Benrabah, Z.; Ilinca, F.; Giraldeau, F.; Bournival, S.; Bardetti, A. Contribution to modeling hydrogen permeation and thickness optimization in blow molded plastic liners for on-board compressed hydrogen tanks. Int. J. Hydrogen Energy 2024, 51, 688–694. [Google Scholar] [CrossRef]

- Abedini, S.; Dong, C.; Davies, I.J. Finite element analysis of edge crack delamination and optimisation of functionally graded interlayer for coated stainless steel in hydrogen storage applications. Surf. Coat. Technol. 2019, 372, 148–159. [Google Scholar] [CrossRef]

- Yang, J.; Bai, R.; Chen, B.; Suo, Z. Hydrogel adhesion: A supramolecular synergy of chemistry, topology, and mechanics. Adv. Funct. Mater. 2020, 30, 1901693. [Google Scholar] [CrossRef]

- Shao, C.; Wang, M.; Meng, L.; Chang, H.; Wang, B.; Xu, F.; Yang, J.; Wan, P. Mussel-inspired cellulose nanocomposite tough hydrogels with synergistic self-healing, adhesive, and strain-sensitive properties. Chem. Mater. 2018, 30, 3110–3121. [Google Scholar] [CrossRef]

- Dehaghani, R.C.; Shokrieh, M.; Taheri-Behrooz, F. An investigation on effects of acid etching duration on adhesive bonding of polyethylene to E-glass/epoxy composites. Int. J. Adhes. Adhes. 2018, 85, 177–183. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Amin, I.Y.; Damayanti, R.; Lubis, M.A.R.; Wulandari, A.P.; Nurindah; Iswanto, A.H. A comprehensive review on natural fibers: Technological and socio-economical aspects. Polymers 2021, 13, 4280. [Google Scholar] [CrossRef] [PubMed]

- Bogard, F.; Bach, T.; Abbes, B.; Bliard, C.; Maalouf, C.; Bogard, V.; Beaumont, F.; Polidori, G. A comparative review of Nettle and Ramie fiber and their use in biocomposites, particularly with a PLA matrix. J. Nat. Fibers 2022, 19, 8205–8229. [Google Scholar] [CrossRef]

- Masseteau, B.; Michaud, F.; Irle, M.; Roy, A.; Alise, G. An evaluation of the effects of moisture content on the modulus of elasticity of a unidirectional flax fiber composite. Compos. Part A Appl. Sci. Manuf. 2014, 60, 32–37. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Mechanical properties and water absorption behaviour of recycled cellulose fibre reinforced epoxy composites. Polym. Test. 2012, 31, 620–628. [Google Scholar] [CrossRef]

- Wang, W.-m.; Cai, Z.-s.; Yu, J.-y.; Xia, Z.-p. Changes in composition, structure, and properties of jute fibers after chemical treatments. Fibers Polym. 2009, 10, 776–780. [Google Scholar] [CrossRef]

- Pejić, B.M.; Kramar, A.D.; Obradović, B.M.; Kuraica, M.M.; Žekić, A.A.; Kostić, M.M. Effect of plasma treatment on chemical composition, structure and sorption properties of lignocellulosic hemp fibers (Cannabis sativa L.). Carbohydr. Polym. 2020, 236, 116000. [Google Scholar] [CrossRef]

- Anidha, S.; Latha, N.; Muthukkumar, M. Reinforcement of Aramid fiber with bagasse epoxy bio-degradable composite: Investigations on mechanical properties and surface morphology. J. Mater. Res. Technol. 2019, 8, 3198–3212. [Google Scholar] [CrossRef]

- Wang, D.; Bai, T.; Cheng, W.; Xu, C.; Wang, G.; Cheng, H.; Han, G. Surface modification of bamboo fibers to enhance the interfacial adhesion of epoxy resin-based composites prepared by resin transfer molding. Polymers 2019, 11, 2107. [Google Scholar] [CrossRef] [PubMed]

- Issazadeh, S.; Khan, M.J.; Gan, H.; Zhang, J.; Henderson, L.C.; Varley, R.J. Synthesis and cure kinetics of bisoxazoline monomers during cationic ring—opening polymerization. J. Appl. Polym. Sci. 2024, 141, e54900. [Google Scholar] [CrossRef]

- De Baere, I.; Van Paepegem, W.; Quaresimin, M.; Degrieck, J. On the tension–tension fatigue behaviour of a carbon reinforced thermoplastic part I: Limitations of the ASTM D3039/D3479 standard. Polym. Test. 2011, 30, 625–632. [Google Scholar] [CrossRef]

- Noble, T.; Davidson, J.R.; Floreani, C.; Bajpai, A.; Moses, W.; Dooher, T.; McIlhagger, A.; Archer, E.; Ó Brádaigh, C.M.; Robert, C. Powder epoxy for one-shot cure, out-of-autoclave applications: Lap shear strength and Z-pinning study. J. Compos. Sci. 2021, 5, 225. [Google Scholar] [CrossRef]

- Yu, T.; Ren, J.; Li, S.; Yuan, H.; Li, Y. Effect of fiber surface-treatments on the properties of poly(lactic acid)/ramie composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 499–505. [Google Scholar] [CrossRef]

- Xu, W.B.; Bao, S.P.; Shen, S.J.; Hang, G.P.; He, P.S. Curing kinetics of epoxy resin–imidazole–organic montmorillonite nanocomposites determined by differential scanning calorimetry. J. Appl. Polym. Sci. 2003, 88, 2932–2941. [Google Scholar] [CrossRef]

- Song, M.-Y.; Kwak, Y.-J. Determination of the activation energy for hydride decomposition using a Sieverts-type apparatus and the kissinger equation. Metals 2022, 12, 265. [Google Scholar] [CrossRef]

- Vyazovkin, S. Is the Kissinger equation applicable to the processes that occur on cooling? Macromol. Rapid Commun. 2002, 23, 771–775. [Google Scholar] [CrossRef]

- Li, L.; Zou, H.; Liang, M.; Chen, Y. Study on the effect of poly(oxypropylene) diamine modified organic montmorillonite on curing kinetics of epoxy nanocomposties. Thermochim. Acta 2014, 597, 93–100. [Google Scholar] [CrossRef]

- Zhao, N.; Fu, Z.; Sun, Y.; Pu, X.; Luo, L. Digital-twin driven energy-efficient multi-crane scheduling and crane number selection in workshops. J. Clean. Prod. 2022, 336, 130175. [Google Scholar] [CrossRef]

- Moller, J.C.; Berry, R.J.; Foster, H.A. On the nature of epoxy resin post-curing. Polymers 2020, 12, 466. [Google Scholar] [CrossRef] [PubMed]

- Bai, T.; Wang, D.; Yan, J.; Cheng, W.; Cheng, H.; Shi, S.Q.; Wang, G.; Han, G. Wetting mechanism and interfacial bonding performance of bamboo fiber reinforced epoxy resin composites. Compos. Sci. Technol. 2021, 213, 108951. [Google Scholar] [CrossRef]

- Ariawan, D.; Mohd Ishak, Z.A.; Salim, M.S.; Mat Taib, R.; Ahmad Thirmizir, M.Z. Wettability and interfacial characterization of alkaline treated kenaf fiber-unsaturated polyester composites fabricated by resin transfer molding. Polym. Compos. 2017, 38, 507–515. [Google Scholar] [CrossRef]

- Liu, F.; Shi, Z.; Dong, Y. Improved wettability and interfacial adhesion in carbon fibre/epoxy composites via an aqueous epoxy sizing agent. Compos. Part A Appl. Sci. Manuf. 2018, 112, 337–345. [Google Scholar] [CrossRef]

- Ma, J.; Jiang, L.; Dan, Y.; Huang, Y. Study on the inter-laminar shear properties of carbon fiber reinforced epoxy composite materials with different interface structures. Mater. Des. 2022, 214, 110417. [Google Scholar] [CrossRef]

| Untreated | 100 °C | 125 °C | 150 °C | 180 °C | |

|---|---|---|---|---|---|

| Bundled yarn strength (MPa) | 710 | 575 | 553 | 518 | 469 |

| Decline in percentage (%) | / * | 19 | 22 | 29 | 34 |

| Heating Rate (β, °C/min) | Ti (°C) | Tp (°C) | Tf (°C) | ΔH (J/g) |

|---|---|---|---|---|

| 5 | 37.4 ± 0.1 | 135.1 ± 0.7 | 252.1 ± 0.8 | −374.9 ± 0.5 |

| 10 | 42.5 ± 0.3 | 153.5 ± 0.4 | 268.9 ± 0.3 | −373.2 ± 0.2 |

| 15 | 45.5 ± 0.6 | 163.9 ± 0.2 | 289.3 ± 0.6 | −347.2 ± 0.3 |

| 20 | 48.3 ± 0.2 | 172.6 ± 0.1 | 294.2 ± 0.2 | −377.8 ± 0.1 |

| Curing Temperature | Tensile Strength (MPa) | Tensile Modulus (GPa) | Curing Degree (%) |

|---|---|---|---|

| 100 °C | 296 ± 12 | 21 ± 0.8 | 85 ± 4 |

| 125 °C | 288 ± 9 | 25 ± 0.5 | 91 ± 3 |

| 150 °C | 281 ± 13 | 25.6 ± 0.3 | 95 ± 1 |

| 180 °C | 237 ± 7 | 26.3 ± 0.7 | 98 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, J.; Lyu, J.; Cai, Y. Thermomechanical Properties of Ramie Fiber/Degradable Epoxy Resin Composites and Their Performance on Cylinder Inner Lining. Materials 2024, 17, 4802. https://doi.org/10.3390/ma17194802

Geng J, Lyu J, Cai Y. Thermomechanical Properties of Ramie Fiber/Degradable Epoxy Resin Composites and Their Performance on Cylinder Inner Lining. Materials. 2024; 17(19):4802. https://doi.org/10.3390/ma17194802

Chicago/Turabian StyleGeng, Jingqi, Jiale Lyu, and Yingchun Cai. 2024. "Thermomechanical Properties of Ramie Fiber/Degradable Epoxy Resin Composites and Their Performance on Cylinder Inner Lining" Materials 17, no. 19: 4802. https://doi.org/10.3390/ma17194802

APA StyleGeng, J., Lyu, J., & Cai, Y. (2024). Thermomechanical Properties of Ramie Fiber/Degradable Epoxy Resin Composites and Their Performance on Cylinder Inner Lining. Materials, 17(19), 4802. https://doi.org/10.3390/ma17194802