Experimental Tests and Numerical Analysis of Aerodynamic Properties of the Composite-Made Jet-Propelled Aerial Target

Abstract

1. Introduction

2. Materials and Methods

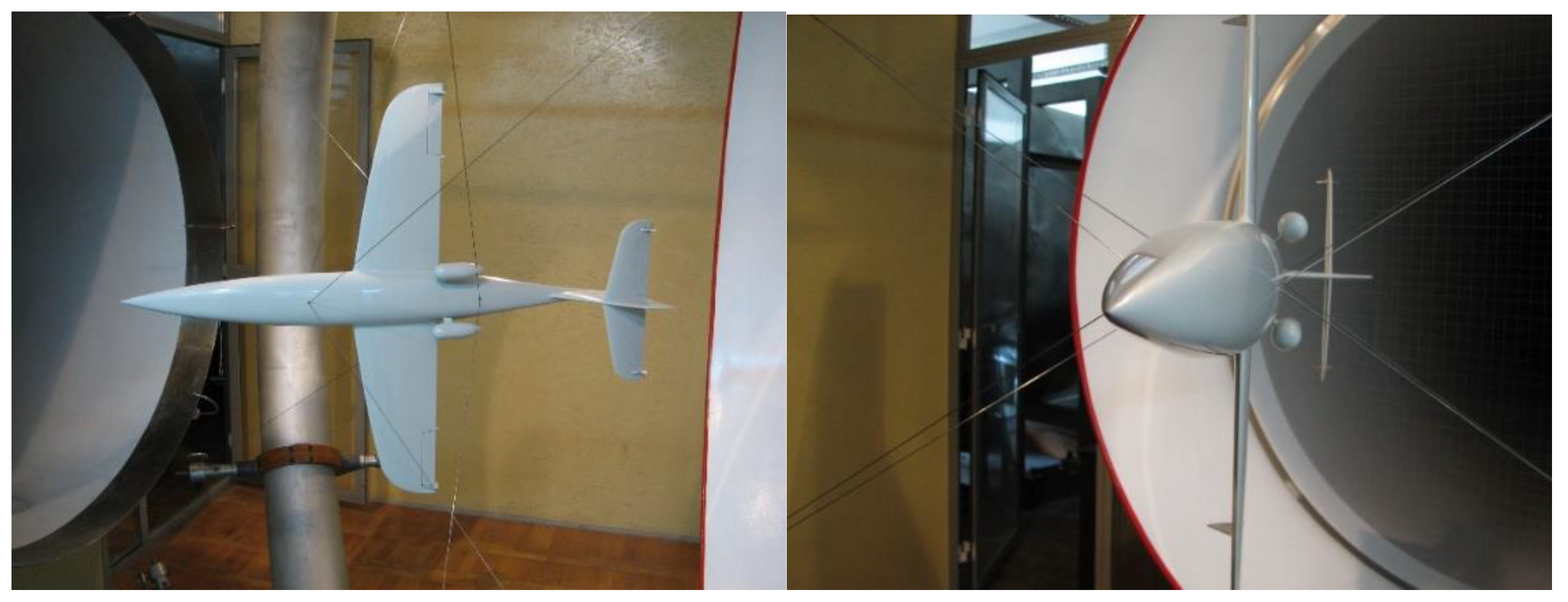

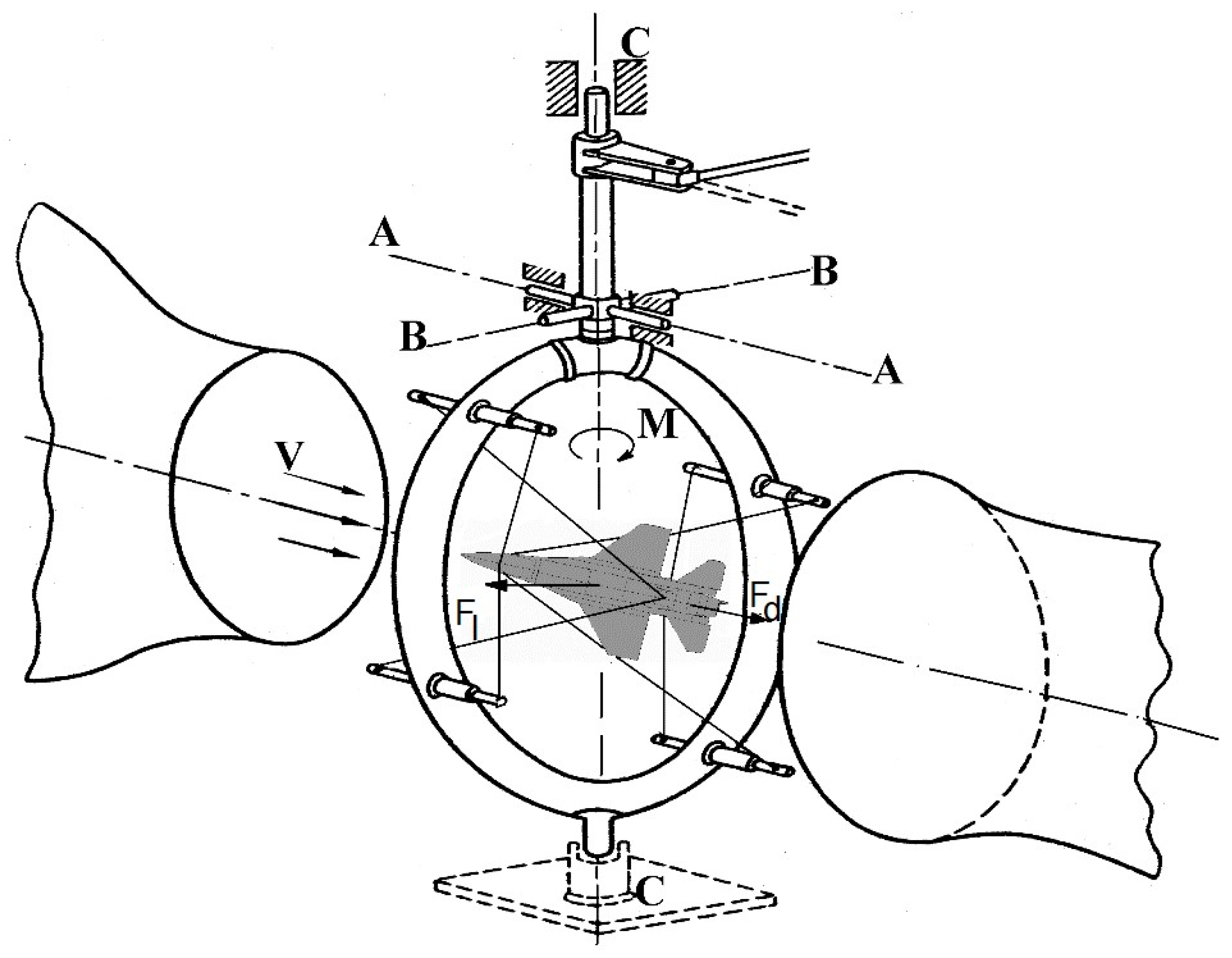

2.1. Wind Tunnel Tests

- -

- Drag force, i.e., the component of the resultant aerodynamic force in the direction of the longitudinal axis of the tunnel (this required the installation of an aerodynamic balance column enabling rotation about the A–A axis);

- -

- Lift force, i.e., the component of the resultant aerodynamic force in the direction of the horizontal axis, perpendicular to the longitudinal axis of the tunnel (supporting the aerodynamic balance column allowing its rotation relative to the B–B axis);

- -

- Pitching moment, i.e., the moment of force relative to the vertical axis of the tunnel (with the installation of an aerodynamic balance column allowing rotation relative to the C–C axis).

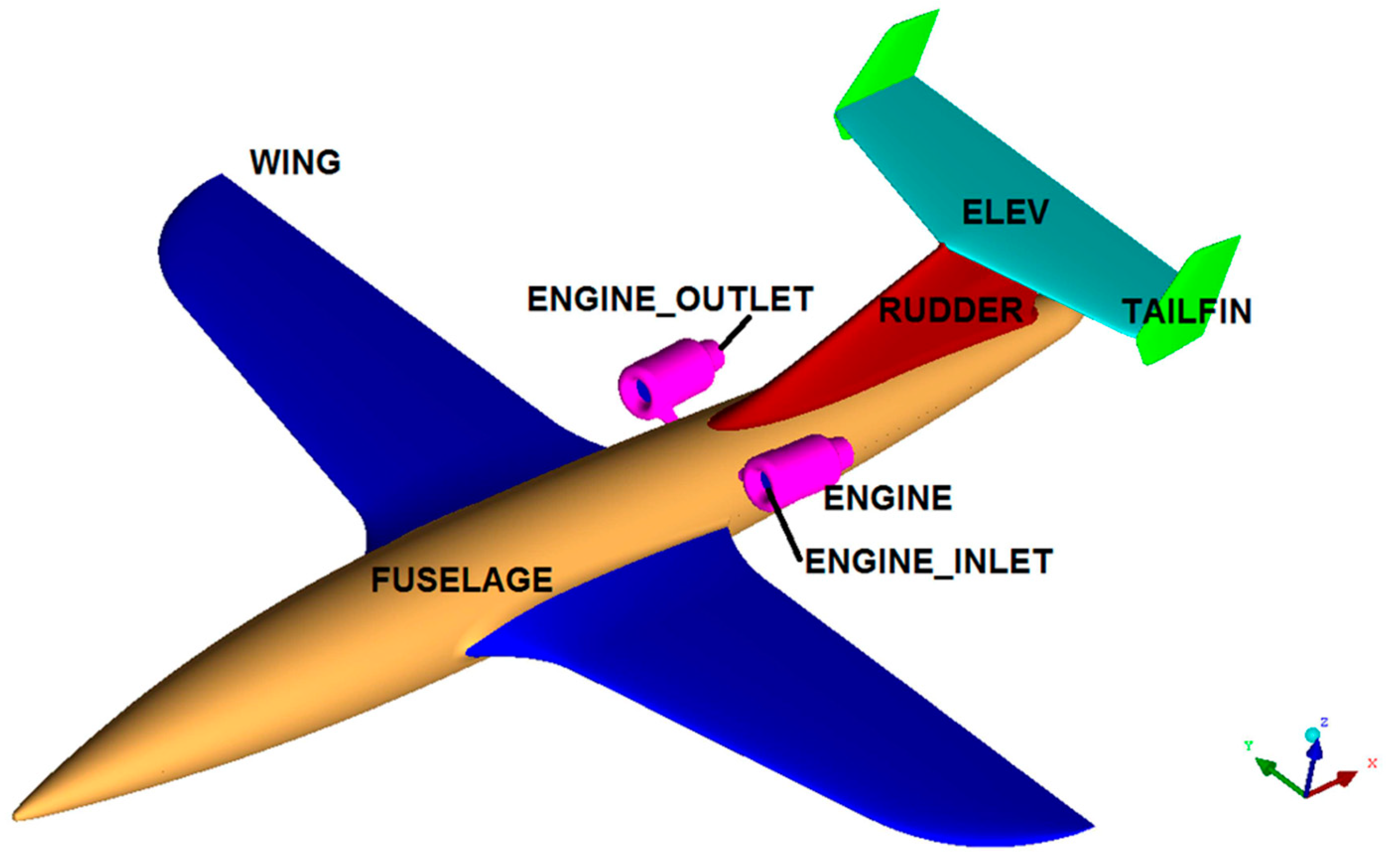

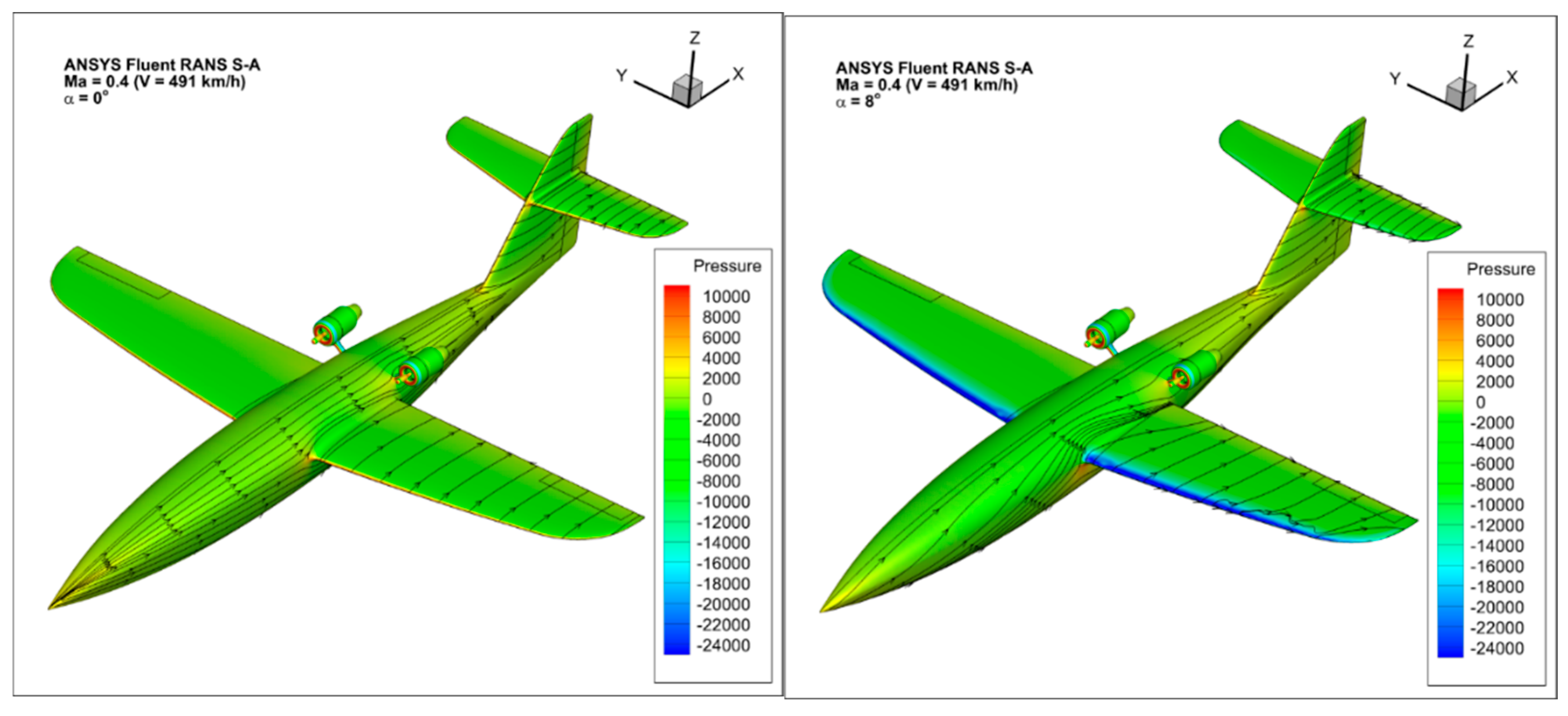

2.2. Computational Fluid Dynamics Analysis

- The Navier Stokes equation (equation of momentum conservation) in the following form:

- p—static pressure;

- and are, respectively, gravitational forces and external forces, e.g., increasing as a result of flow through a dispersed phase;

- —stress tensor.

- —kinematic viscosity;

- I—unit matrix.

- Equation of flow continuity (mass conservation equation in relation to fluid treated as a continuous medium) in the following form:

- Sm—mass source (e.g., as a result of evaporation of the dispersed phase).

- Energy conservation equation in the following form:

- k—thermal conductivity;

- E—total energy;

- —shear stress tensor.

3. Results and Discussion

3.1. Aerodynamic Characteristics of an Aerial Target Model in Symmetric Flow

- -

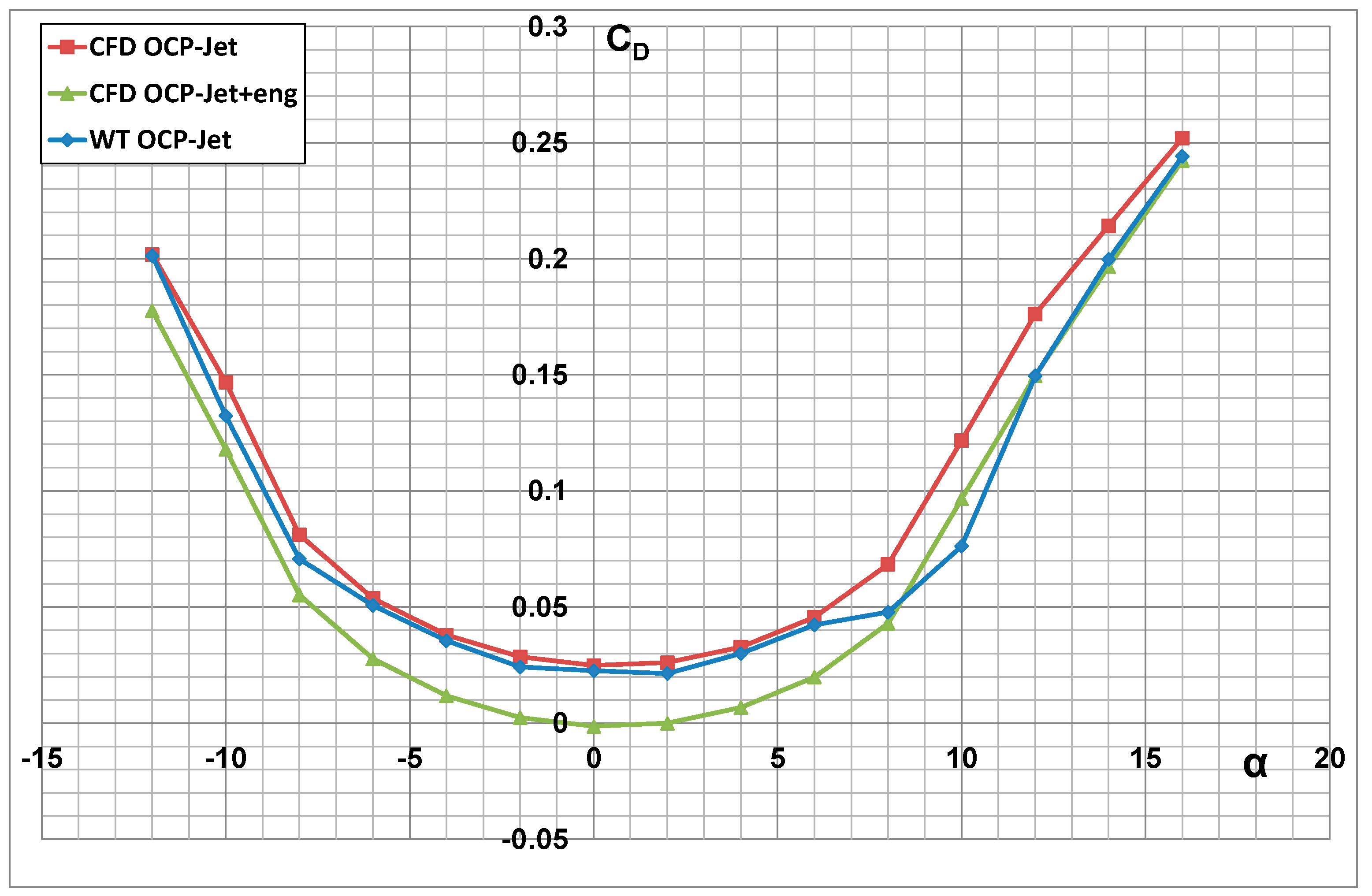

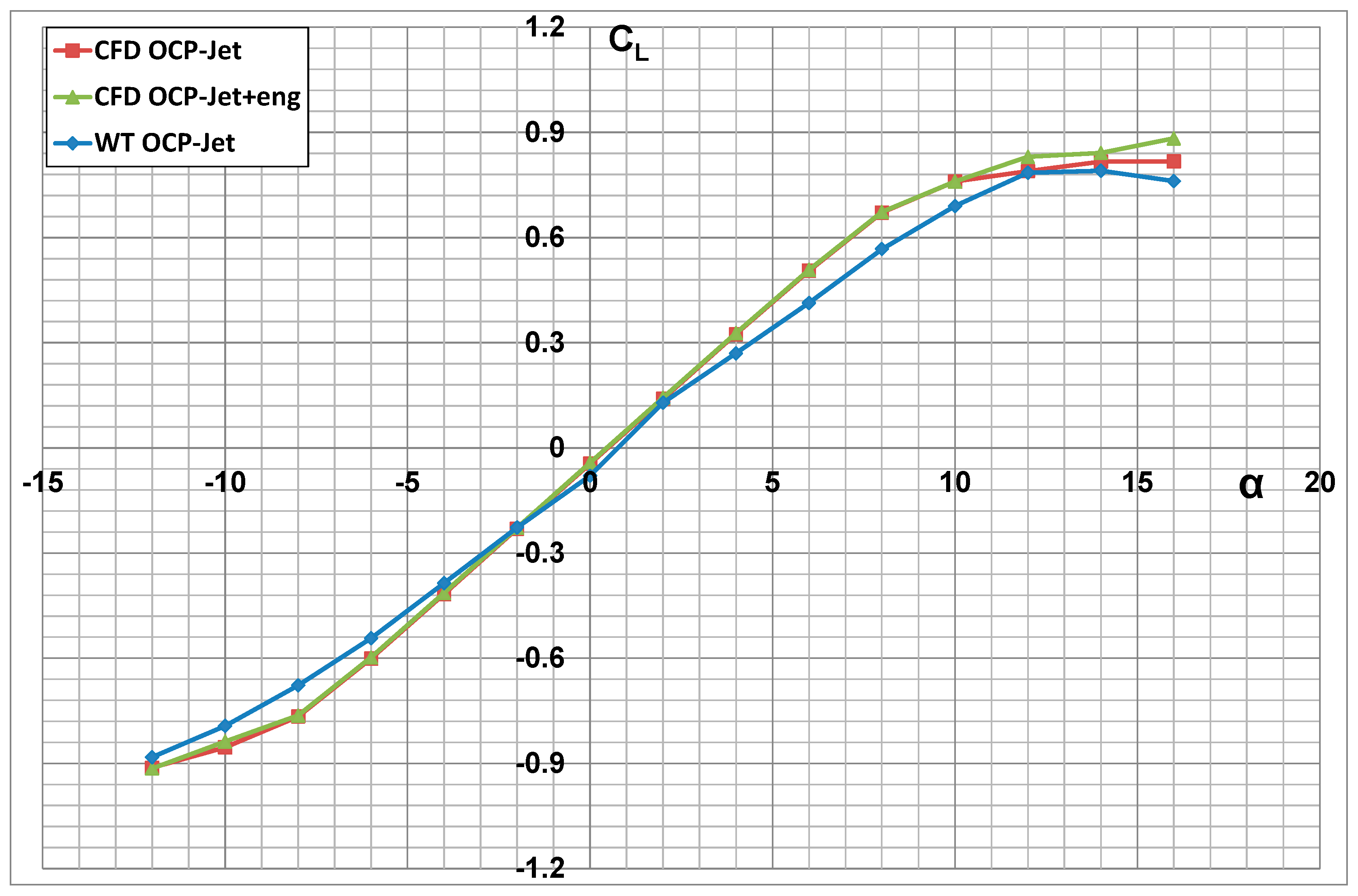

- In symmetric flow

- (a)

- CD = f(α)—drag coefficient as a function of angle of attack (AOA);

- (b)

- CL = f(α)—lift force coefficient as a function of AOA;

- (c)

- Cm = f(α)—pitching moment coefficient as a function of AOA;

- (d)

- E = L/D = f(α)—aerodynamic efficiency in function of AOA;

- (e)

- CL = f(CD)—lift force coefficient as a function of the drag force coefficient.

- -

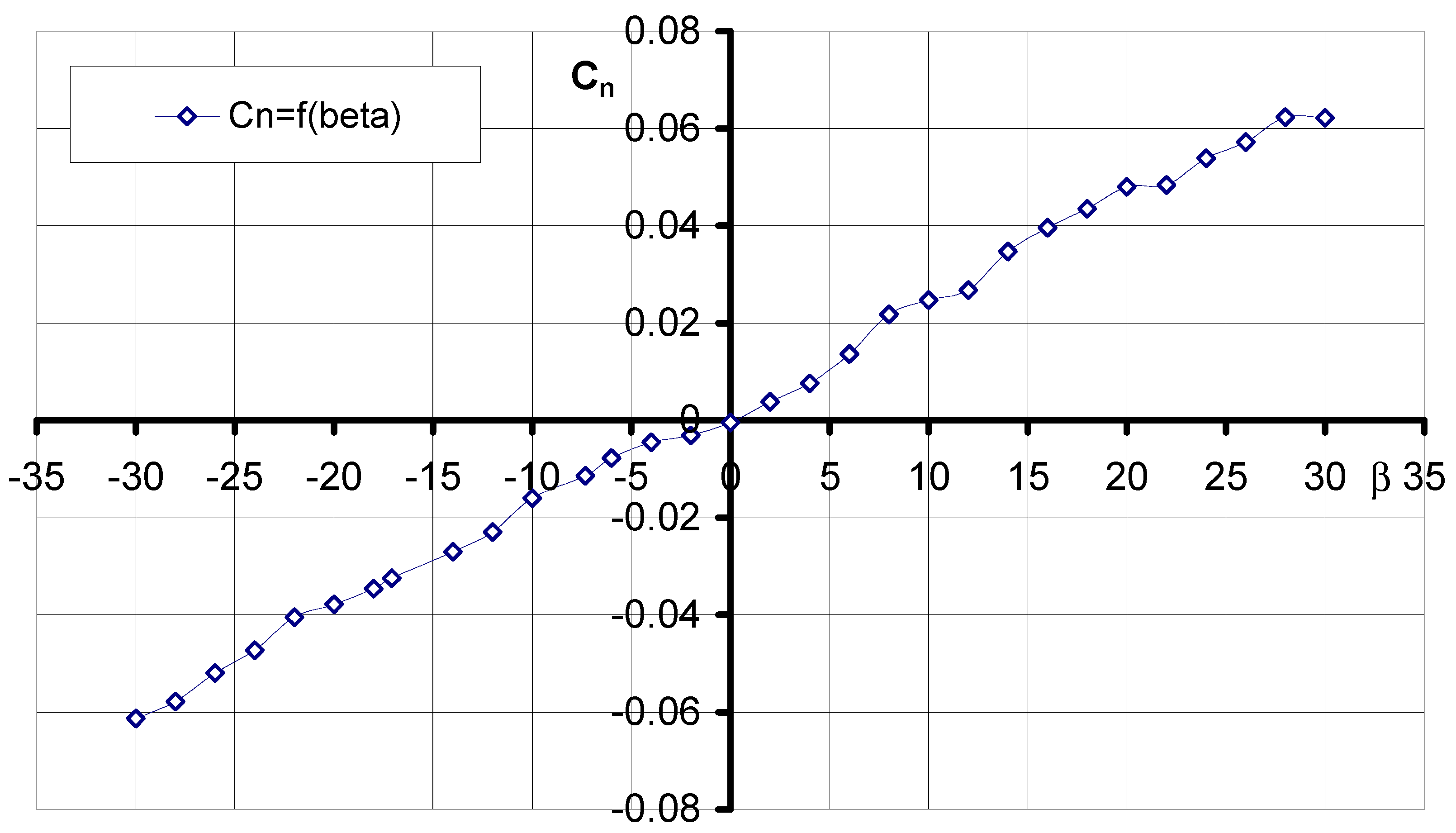

- In asymmetric flow

- (a)

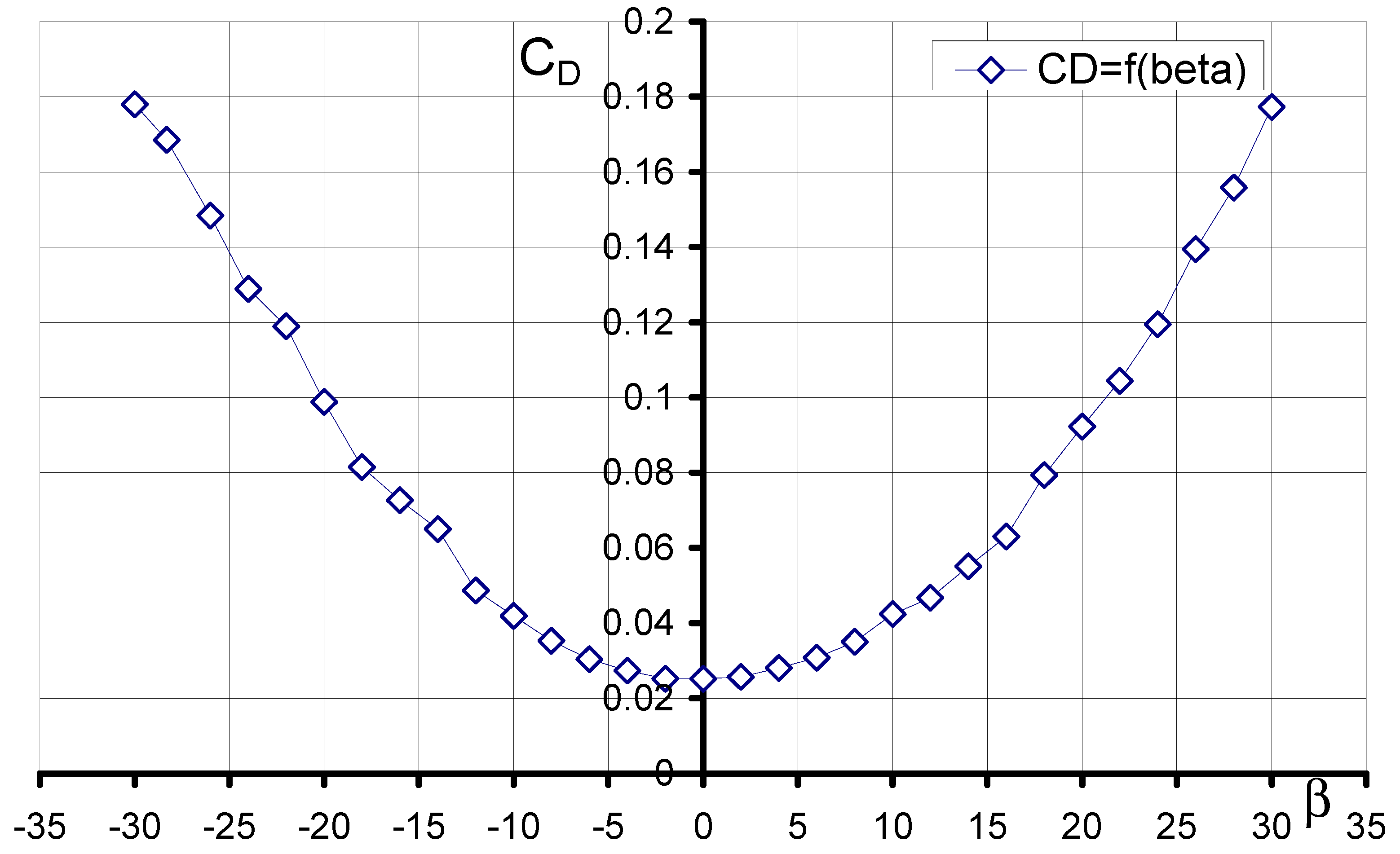

- CD = f(β)—drag coefficient as a function of the sideslip angle;

- (b)

- Cy = f(β)—lateral force coefficient as a function of the sideslip angle;

- (c)

- Cn = f(β)—coefficient of yawing moment as a function of the angle of side inclination.

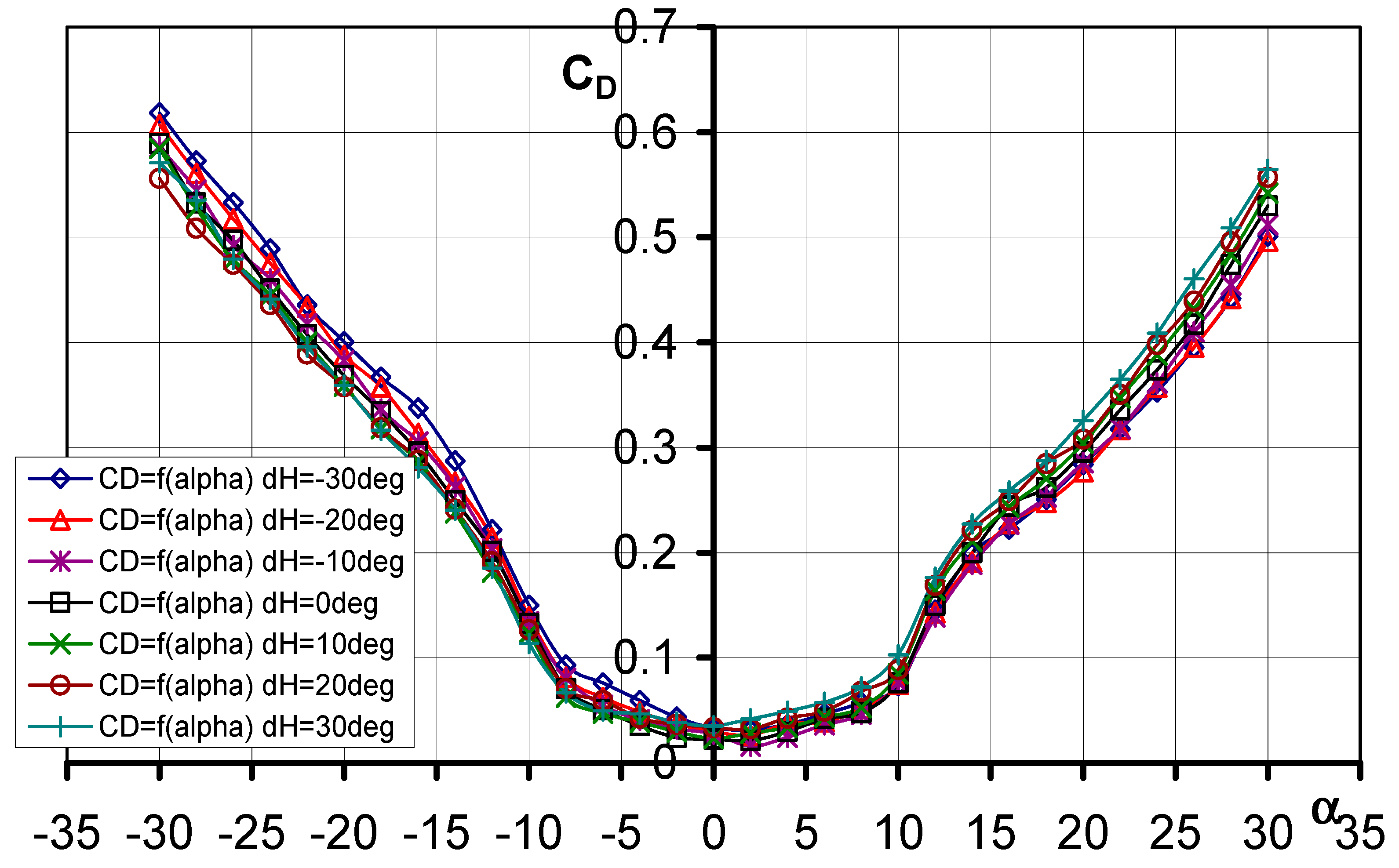

3.1.1. Aerodynamic Drag Coefficient CD = f(α, dH)

3.1.2. Lift Force Coefficient CL = f(α, dH)

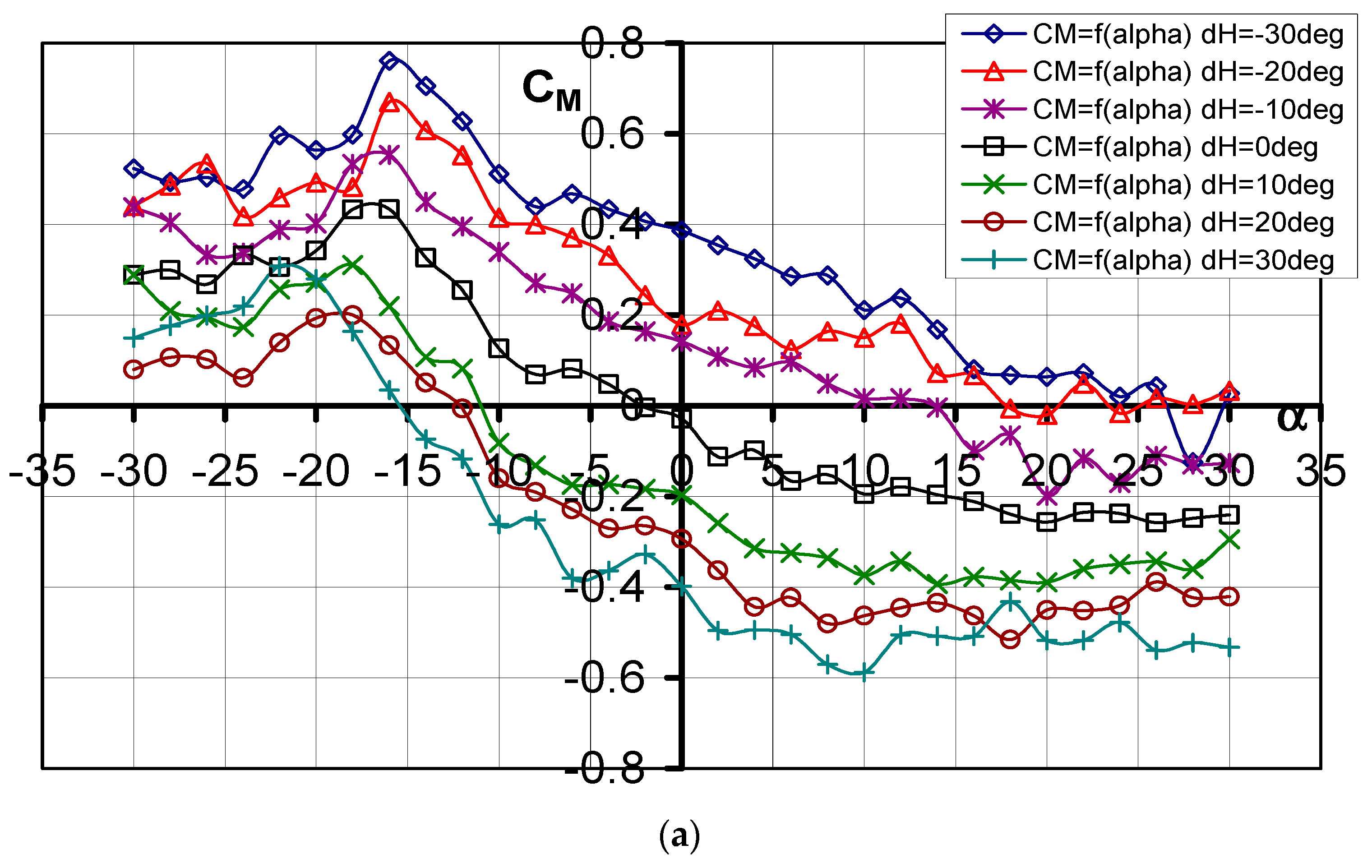

3.1.3. Pitching Moment Coefficient Cm = f(α, dH)

- xQ is the center of mass;

- xF is the aerodynamic center;

- bA is the mean aerodynamic chord.

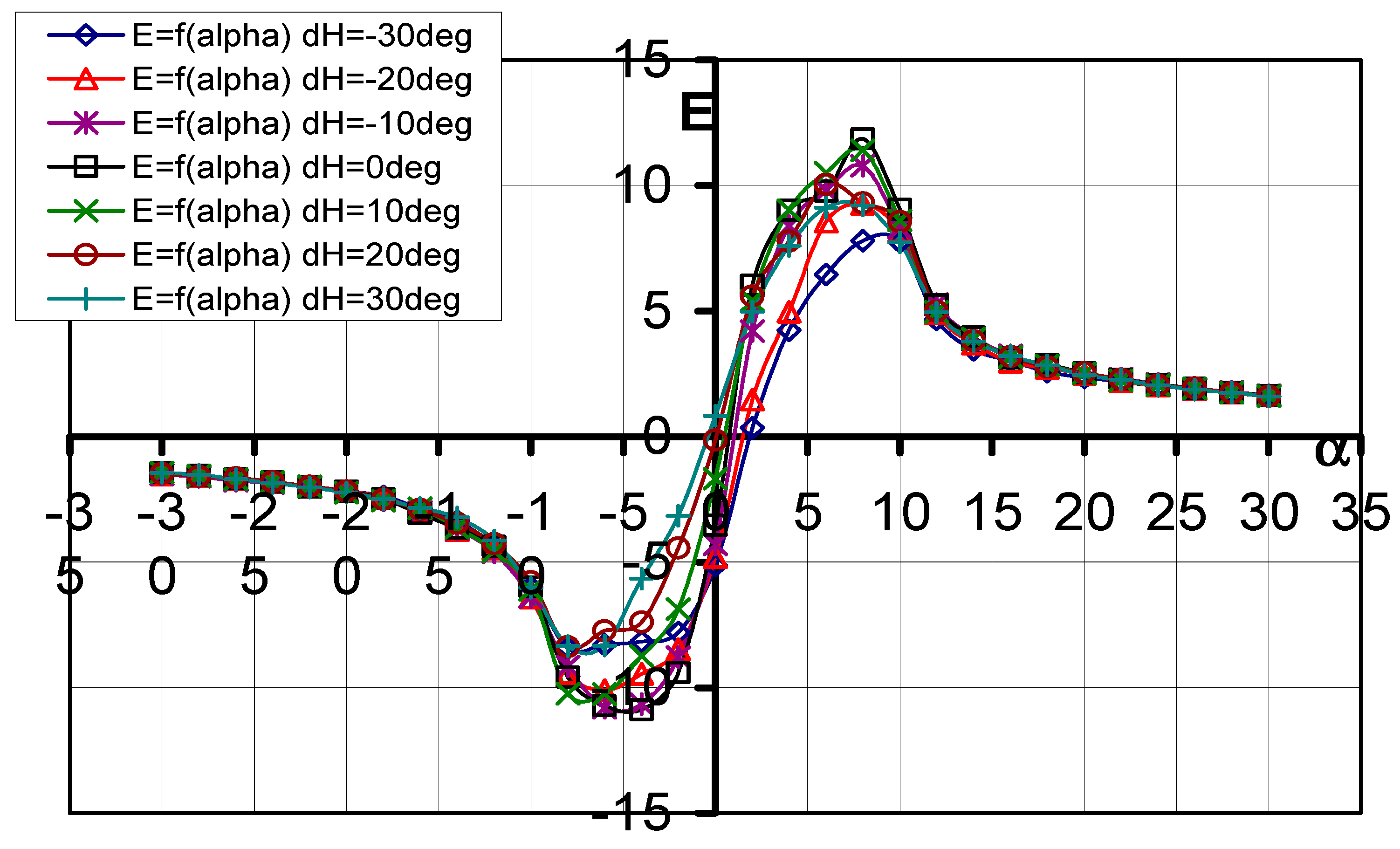

3.1.4. Aerodynamic Efficiency (Lift-to-Drag Ratio) E = f(α, dH)

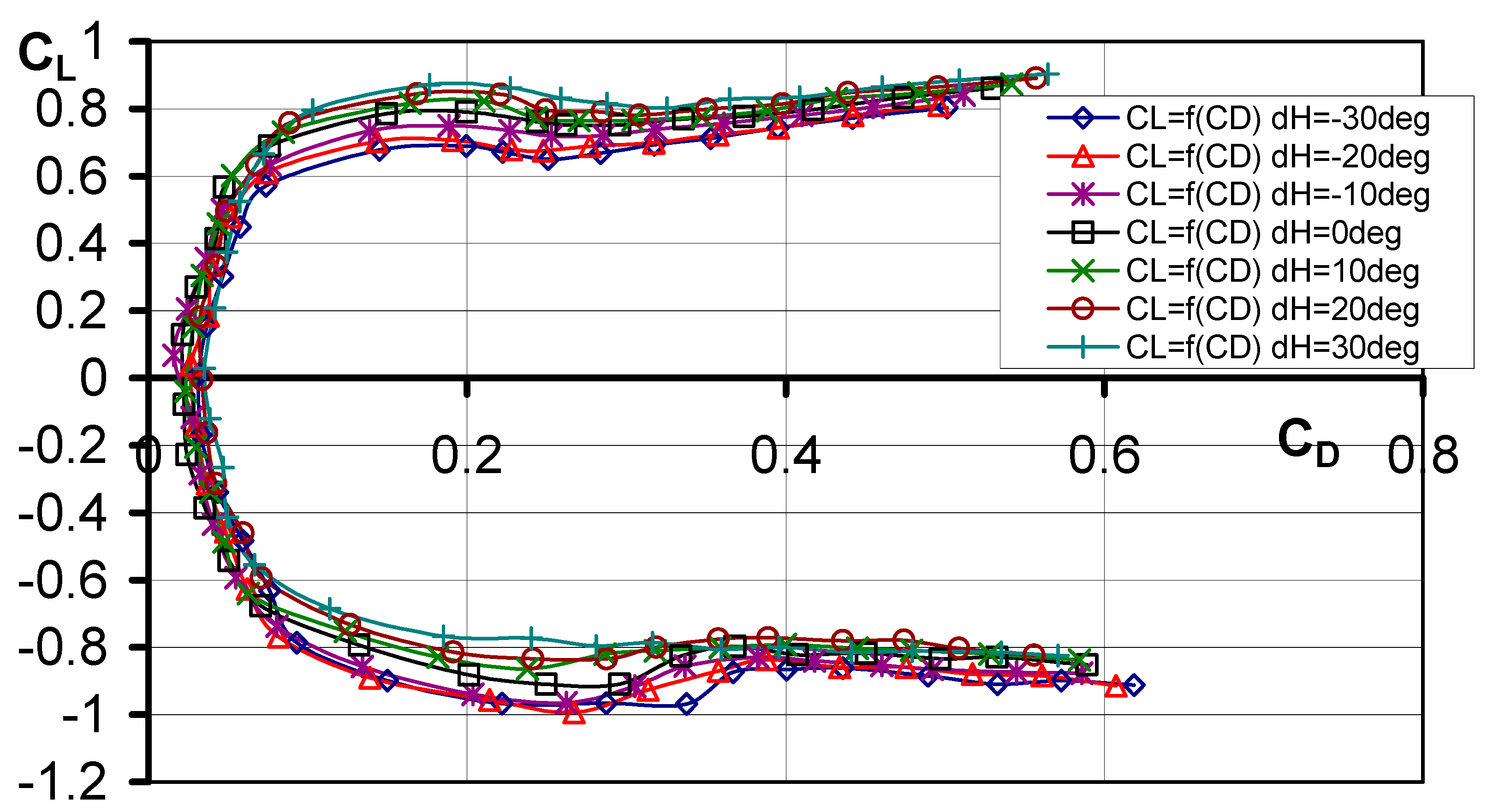

3.1.5. Lift Force Coefficient as a Function of Drag Force Coefficient CL = f(CD)

3.2. Aerodynamic Characteristics of an Aerial Target Model in Asymmetric Flow

3.3. Numerical Analysis of the Aerodynamic Characteristics of an Aerial Target with and without Engine Thrust Effect

4. Results and Discussion

- The lowest value of the drag coefficient was obtained for the model with elevator deflection dH = −10° and it was CD = 0.01599;

- The characteristics of the lift force coefficient are linear in the range of angles of attack from α = −10° to α = 10°;

- The aerial target model is statically stable longitudinally in the range of the AOA from α = −16° to α = 12°;

- Elevator deflection causes the characteristic Cm = f(α) to shift downwards;

- For all the configurations of the tested model, the optimum angle of attack is αopt = 8°;

- The maximum value of aerodynamic efficiency was obtained for dH = 0°;

- In an asymmetric flow, the maximum value of the drag force coefficient CD = 0.178 was obtained for both the sideslip angles β = −30° and β = 30°;

- The aerial target model is statically stable directionally in the investigated range of sideslip angles;

- The effect of engine thrust on the drag force coefficient value becomes less as the AOA increases;

- The thrust of the engine did not change the slope of the characteristic of the lift force coefficient characteristic ∂CL/∂α;

- A high and satisfied comparability was found between the results of the numerical analysis and the experimental tests.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Available online: https://en.wikipedia.org/wiki/Ryan_Firebee (accessed on 14 April 2024).

- Available online: https://en.wikipedia.org/wiki/Northrop_BQM-74_Chukar (accessed on 14 April 2024).

- Available online: https://en.wikipedia.org/wiki/Beechcraft_MQM-107_Streaker (accessed on 14 April 2024).

- Available online: https://en.wikipedia.org/wiki/Composite_Engineering_BQM-167_Skeeter (accessed on 14 April 2024).

- Available online: https://www.kratosdefense.com/systems-and-platforms/unmanned-systems/aerial/aerial-targets#BQM167?r=kusd (accessed on 17 April 2024).

- Available online: https://en.wikipedia.org/wiki/HESA_Karrar (accessed on 14 April 2024).

- Ciliberti, D.; Buonagura, G.; Nicolosi, F. Longitudinal Wind Tunnel Tests of the PROSIB 19-Pax Airplane. Appl. Sci. 2023, 13, 11928. [Google Scholar] [CrossRef]

- Cusati, V.; Corcione, S.; Ciliberti, D.; Nicolosi, F. Design Evolution and Wind Tunnel Tests of a Three-Lifting Surface Regional Transport Aircraft. Aerospace 2022, 9, 133. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, D.; Xu, X.; Li, G. Investigation of Reynolds Number Effects on Aerodynamic Characteristics of a Transport Aircraft. Aerospace 2021, 8, 177. [Google Scholar] [CrossRef]

- Giannelis, N.F.; Bykerk, T.; Vio, G.A. A Generic Model for Benchmark Aerodynamic Analysis of Fifth-Generation High-Performance Aircraft. Aerospace 2023, 10, 746. [Google Scholar] [CrossRef]

- Liu, J.; Qian, W.; Bai, Y. Numerical and Experimental Research on Flight Control of a V-Tail Configuration for the Wind Tunnel Model of Aircraft. Aerospace 2022, 9, 792. [Google Scholar] [CrossRef]

- Tabatabaei, N.; Hajipour, M.; Mallor, F.; Örlü, R.; Vinuesa, R.; Schlatter, P. RANS Modelling of a NACA4412 Wake Using Wind Tunnel Measurements. Fluids 2022, 7, 153. [Google Scholar] [CrossRef]

- Karkoulias, D.G.; Tzoganis, E.D.; Panagiotopoulos, A.G.; Acheimastos, S.-G.D.; Margaris, D.P. Computational Fluid Dynamics Study of Wing in Air Flow and Air–Solid Flow Using Three Different Meshing Techniques and Comparison with Experimental Results in Wind Tunnel. Computation 2022, 10, 34. [Google Scholar] [CrossRef]

- Hann, R.; Hearst, R.J.; Sætran, L.R.; Bracchi, T. Experimental and Numerical Icing Penalties of an S826 Airfoil at Low Reynolds Numbers. Aerospace 2020, 7, 46. [Google Scholar] [CrossRef]

- Colli, A.; Zanotti, A.; Gibertini, G. Wind Tunnel Experiments on Parallel Blade–Vortex Interaction with Static and Oscillating Airfoil. Fluids 2024, 9, 111. [Google Scholar] [CrossRef]

- Szwedziak, K.; Łusiak, T.; Bąbel, R.; Winiarski, P.; Podsędek, S.; Doležal, P.; Niedbała, G. Wind Tunnel Experiments on an Aircraft Model Fabricated Using a 3D Printing Technique. J. Manuf. Mater. Process. 2022, 6, 12. [Google Scholar] [CrossRef]

- Du, H.; Jiang, H.; Yang, Z.; Xia, H.; Chen, S.; Wu, J. Experimental Investigation of the Effect of Bio-Inspired Wavy Leading-Edges on Aerodynamic Performance and Flow Topologies of the Airfoil. Aerospace 2024, 11, 194. [Google Scholar] [CrossRef]

- Sönmez, M.; Pelin, C.; Georgescu, M.; Pelin, G.; Stelescu, M.; Nituica, M.; Stoian, G.; Alexandrescu, L.; Gurau, D. Unmanned aerial vehicles–classification, types of composite materials used in their structure and applications. In Proceedings of the ICAMS 2022–9th International Conference on Advanced Materials and Systems, Bucharest, Romania, 26–28 October 2022. [Google Scholar] [CrossRef]

- Available online: https://uav.com.pl/en (accessed on 15 April 2024).

- Pope, A. Wind-Tunnel Testing; Wiley, John & Sons: New York, NY, USA, 1954. [Google Scholar]

- Penkchjerst, R.; Cholder, D. Wind Tunnel Experiment Technology; Soviet Union: Moscow, Russia, 1955. [Google Scholar]

- Barlow, J.B.; Rae, W.H.; Pope, A. Low-Speed Wind Tunnel Testing, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Kowaleczko, G. Inverse Problem in Aircraft Flight Dynamics; Military University of Technology: Warsaw, Poland, 2003. [Google Scholar]

- Krzyżanowski, A. Mechanics of Flight; Military University of Technology: Warsaw, Poland, 2009. [Google Scholar]

- Jia, S.; Zhang, Z.; Zhang, H.; Song, C.; Yang, C. Wind Tunnel Tests of 3D-Printed Variable Camber Morphing Wing. Aerospace 2022, 9, 699. [Google Scholar] [CrossRef]

- Wang, K.; Zhou, Z. Aerodynamic Design, Analysis and Validation of a Small Blended-Wing-Body Unmanned Aerial Vehicle. Aerospace 2022, 9, 36. [Google Scholar] [CrossRef]

- Damljanović, D.; Vuković, D.; Ocokoljić, G.; Ilić, B.; Rašuo, B. Wind Tunnel Testing of ONERA-M, AGARD-B and HB-2 Standard Models at Off-Design Conditions. Aerospace 2021, 8, 275. [Google Scholar] [CrossRef]

- Frant, M.; Majcher, M.; Omen, Ł.; Zalewski, P. Experimental Study of Air-Assisted Rocket System Models for Launching Payloads into a Low Earth Orbit. Probl. Mechatron. Armament Aviat. Saf. Eng. 2022, 13, 67–82. [Google Scholar] [CrossRef]

- Hirsch, C. Numerical Computational of Internal and External Flows; John Wiley & Sons: Bognor Regis, UK, 1988. [Google Scholar]

- Ferziger, J.H.; Peric, M. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Available online: https://www.ansys.com/ (accessed on 25 February 2024).

- Available online: https://www.3ds.com/products/catia/icem-surf (accessed on 25 February 2024).

- Olejnik, A.; Zalewski, P.; Kiszkowiak, Ł.; Rogólski, R. Finite Element Analysis of the Suspended Satellite Rocket Weight Effect on the Strength and Deformability of the MiG-29 Aircraft Structure. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2023, 237, 3285–3303. [Google Scholar] [CrossRef]

- Frant, M.; Kachel, S.; Maślanka, W. Gust Modeling with State-of-the-Art Computational Fluid Dynamics (CFD) Software and Its Influence on the Aerodynamic Characteristics of an Unmanned Aerial Vehicle. Energies 2023, 16, 6847. [Google Scholar] [CrossRef]

- Kozakiewicz, A.; Kachel, S.; Frant, M.; Majcher, M. Intake System Performance Stability as a Function of Flow Throttling. Energies 2022, 15, 6291. [Google Scholar] [CrossRef]

- Olejnik, A.; Zalewski, P.; Kiszkowiak, Ł.; Dziubiński, A. Low Cost Satellite Launch System-Aerodynamic Feasibility Study. Aerospace 2022, 9, 284. [Google Scholar] [CrossRef]

- Olejnik, A.; Zalewski, P.; Kiszkowiak, Ł.; Rogólski, R.; Dziubiński, A.; Frant, M.; Majcher, M.; Omen, Ł. Combat aircraft as airborne launch platforms for space rockets. Aircr. Eng. Aerosp. Technol. 2022, 95, 629–636. [Google Scholar] [CrossRef]

- Mikołajczyk, A.; Dziubiński, A.; Kurnyta-Mazurek, P.; Kachel, S. Flow around an Aircraft Model—Comparison between Hydrodynamic Tunnel Tests and Computational Fluid Dynamics Simulations. Appl. Sci. 2023, 13, 13035. [Google Scholar] [CrossRef]

- Zalewski, P. Experimental Aerodynamic Characteristics of the “OCP” Model of a Jet Aerial Target; Report of the project entitled “Jet aerial targets with programmed flight path”, Contract No. DOBR/0065/R/ID1/2012/03; Military University of Technology: Warsaw, Poland, 2018. [Google Scholar]

- Rykaczewski, D.; Jastrzębski, G.; Szczepaniak, P.; Sibilski, K. Methodology for conducting preliminary and state tests of an aerial jet target set. J. KONBiN 2020, 50, 305–318. [Google Scholar] [CrossRef]

| dH° | −30° | −20° | −10° | 0° | 10° | 20° | 30° |

|---|---|---|---|---|---|---|---|

| α° (CD min) | 2 | 2 | 2 | 2 | 0 | 0 | 0 |

| CD min | 0.03162 | 0.02663 | 0.01599 | 0.02136 | 0.02352 | 0.03363 | 0.03528 |

| CD (α = −30°) | 0.61855 | 0.60718 | 0.58583 | 0.58911 | 0.58438 | 0.55594 | 0.57084 |

| CD (α = −10°) | 0.1501 | 0.13894 | 0.13428 | 0.13237 | 0.12347 | 0.12647 | 0.11383 |

| CD (α = −4°) | 0.05926 | 0.04835 | 0.04077 | 0.03544 | 0.03888 | 0.04248 | 0.04689 |

| CD (α = 0°) | 0.03309 | 0.02963 | 0.02746 | 0.02253 | 0.02352 | 0.03363 | 0.03528 |

| CD (α = 4°) | 0.03661 | 0.03732 | 0.02446 | 0.02998 | 0.03376 | 0.04272 | 0.04925 |

| CD (α = 10°) | 0.07361 | 0.07455 | 0.07626 | 0.07619 | 0.08473 | 0.08854 | 0.103 |

| CD (α = 30°) | 0.50115 | 0.49621 | 0.51205 | 0.52973 | 0.54183 | 0.55702 | 0.56464 |

| dH° | −30° | −20° | −10° | 0° | 10° | 20° | 30° |

|---|---|---|---|---|---|---|---|

| α° (CL = 0) | 2 | 1.5 | 1 | 1 | 0.5 | 0 | 0.5 |

| CL (α = −10°) | −0.89919 | −0.8909 | −0.85761 | −0.7930 | −0.75293 | −0.73197 | −0.68523 |

| CL (α = 0°) | −0.1699 | −0.1425 | −0.1178 | −0.079 | −0.0394 | −0.0047 | 0.02893 |

| CL (α = 10°) | 0.57024 | 0.6099 | 0.63362 | 0.68967 | 0.72973 | 0.75795 | 0.79622 |

| CL min | −0.9675 | −0.9937 | −0.9402 | −0.9100 | −0.8646 | −0.8349 | −0.8252 |

| αcr° | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| CL max | 0.8030 | 0.8101 | 0.8405 | 0.8611 | 0.8734 | 0.8912 | 0.90296 |

| dH° | −30° | −20° | −10° | 0° | 10° | 20° | 30° |

|---|---|---|---|---|---|---|---|

| α° (Cm = 0) | 26 | 17 | 14 | 2 | −11 | −12 | −15 |

| Cm (α = −10°) | 0.51132 | 0.41521 | 0.33886 | 0.12631 | −0.08181 | −0.15985 | −0.2618 |

| Cm (α = 0°) | 0.3866 | 0.1785 | 0.1417 | −0.0287 | −0.1967 | −0.2942 | −0.3984 |

| Cm (α = 10°) | 0.21151 | 0.1502 | 0.01633 | −0.19469 | −0.37356 | −0.46317 | −0.5879 |

| Cm (α kr) | 0.2377 | 0.1811 | 0.0165 | −0.1790 | −0.3436 | −0.4462 | −0.5051 |

| Cm min | −0.1245 | −0.0205 | −0.1988 | −0.2577 | −0.3894 | −0.5154 | −0.5328 |

| Cm max | 0.7609 | 0.6702 | 0.5533 | 0.4342 | 0.31089 | 0.2000 | 0.3080 |

| dH° | −30° | −20° | −10° | 0° | 10° | 20° | 30° |

|---|---|---|---|---|---|---|---|

| −αopt° | −8 | −6 | −6 | −4 | −6 | −8 | −8 |

| Emin | −8.437 | −10.094 | −10.799 | −10.880 | −10.263 | −8.377 | −8.337 |

| E (α = 0°) | −5.1342 | −4.808 | −4.291 | −3.529 | −1.676 | −0.141 | 0.820 |

| αopt° | 8 | 8 | 8 | 8 | 8 | 6 | 8 |

| Emax | 7.794 | 9.256 | 10.790 | 11.865 | 11.397 | 10.043 | 9.207 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frant, M.; Kiszkowiak, Ł.; Majcher, M.; Zalewski, P. Experimental Tests and Numerical Analysis of Aerodynamic Properties of the Composite-Made Jet-Propelled Aerial Target. Materials 2024, 17, 3575. https://doi.org/10.3390/ma17143575

Frant M, Kiszkowiak Ł, Majcher M, Zalewski P. Experimental Tests and Numerical Analysis of Aerodynamic Properties of the Composite-Made Jet-Propelled Aerial Target. Materials. 2024; 17(14):3575. https://doi.org/10.3390/ma17143575

Chicago/Turabian StyleFrant, Michał, Łukasz Kiszkowiak, Maciej Majcher, and Piotr Zalewski. 2024. "Experimental Tests and Numerical Analysis of Aerodynamic Properties of the Composite-Made Jet-Propelled Aerial Target" Materials 17, no. 14: 3575. https://doi.org/10.3390/ma17143575

APA StyleFrant, M., Kiszkowiak, Ł., Majcher, M., & Zalewski, P. (2024). Experimental Tests and Numerical Analysis of Aerodynamic Properties of the Composite-Made Jet-Propelled Aerial Target. Materials, 17(14), 3575. https://doi.org/10.3390/ma17143575