Preparation of eGaIn NDs/TPU Composites for X-ray Radiation Shielding Based on Electrostatic Spinning Technology

Abstract

:1. Introduction

2. Material and Method

2.1. Material

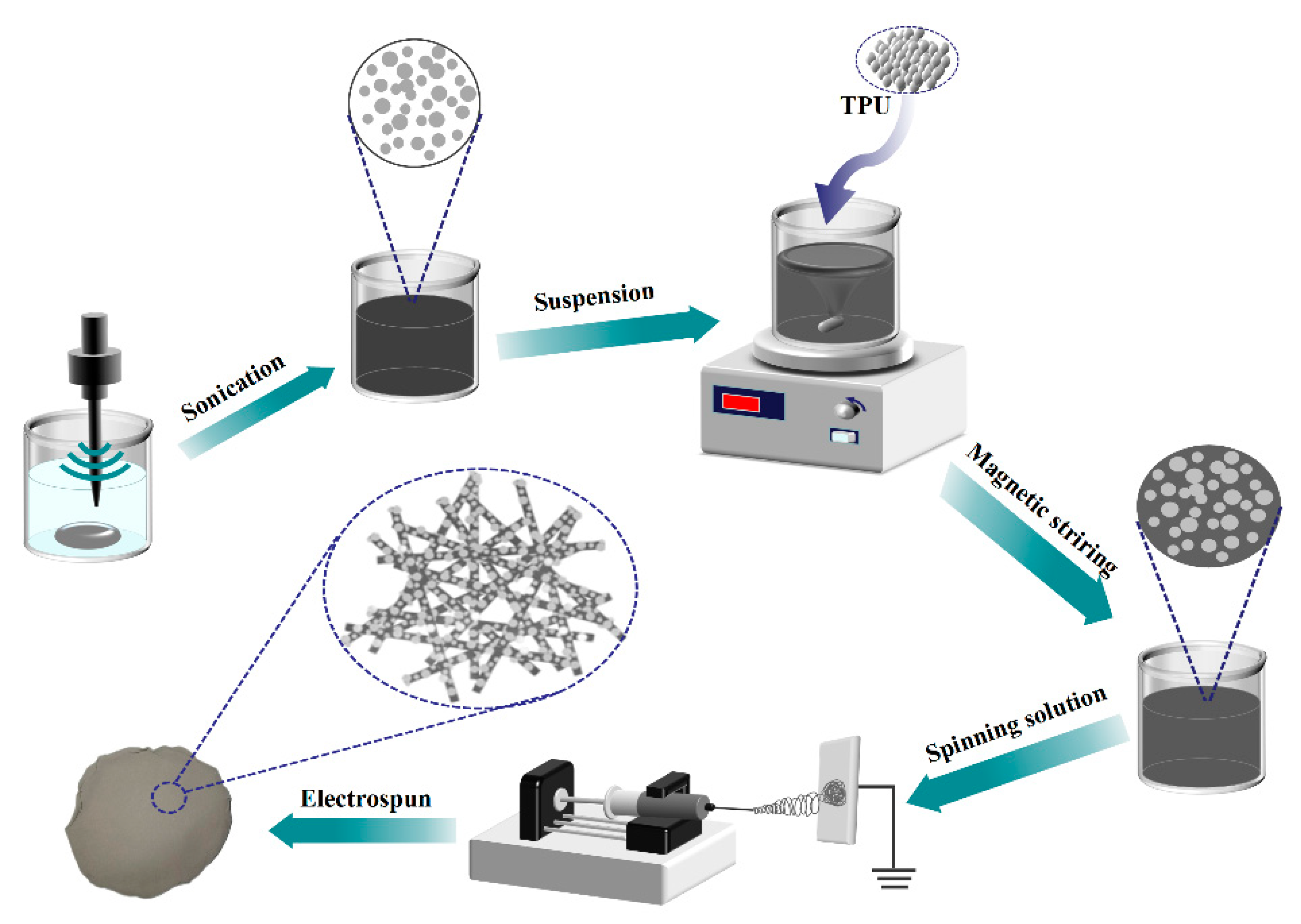

2.2. Preparation of eGaIn NDs/TPU Nanofiber Mats

2.3. Material Characterization

2.4. Evaluation of X-ray Radiation Shielding Performance

2.5. Basic Photon Attenuation Parameters

3. Results and Discussion

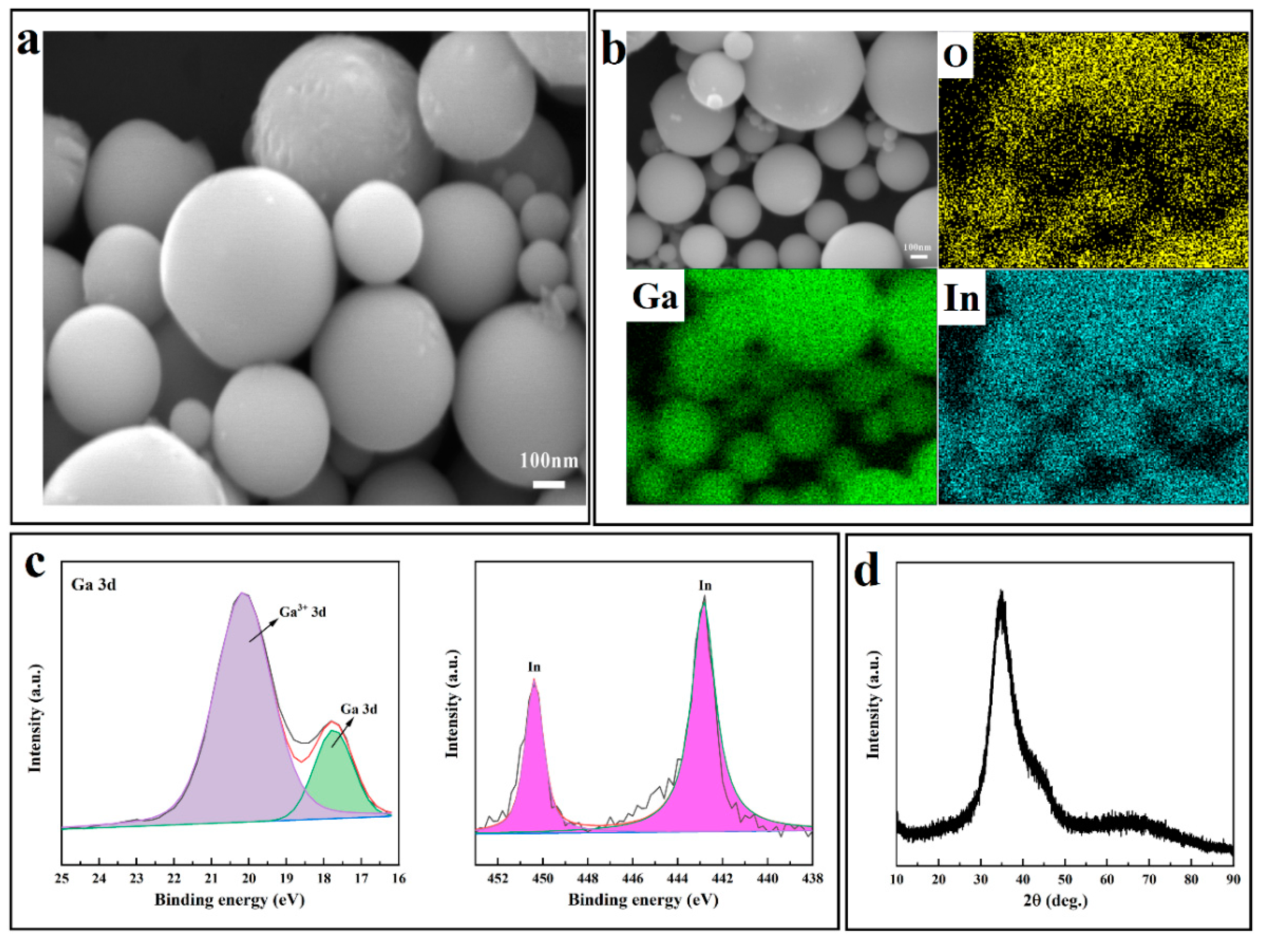

3.1. eGaIn NDs Structural and Morphological Analysis

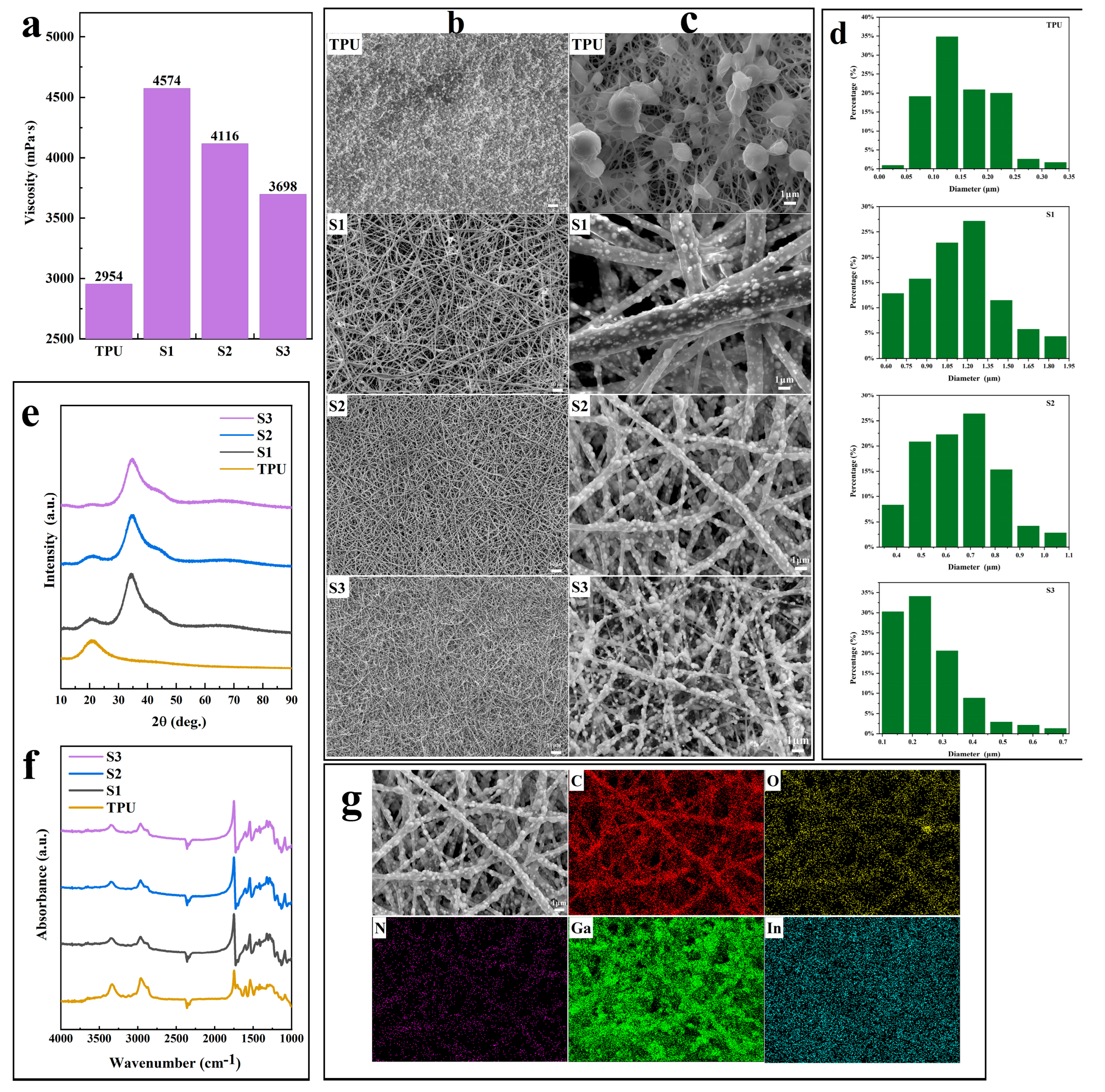

3.2. eGaIn NDs/TPU Nanofiber Mats: Structural and Morphological Analysis

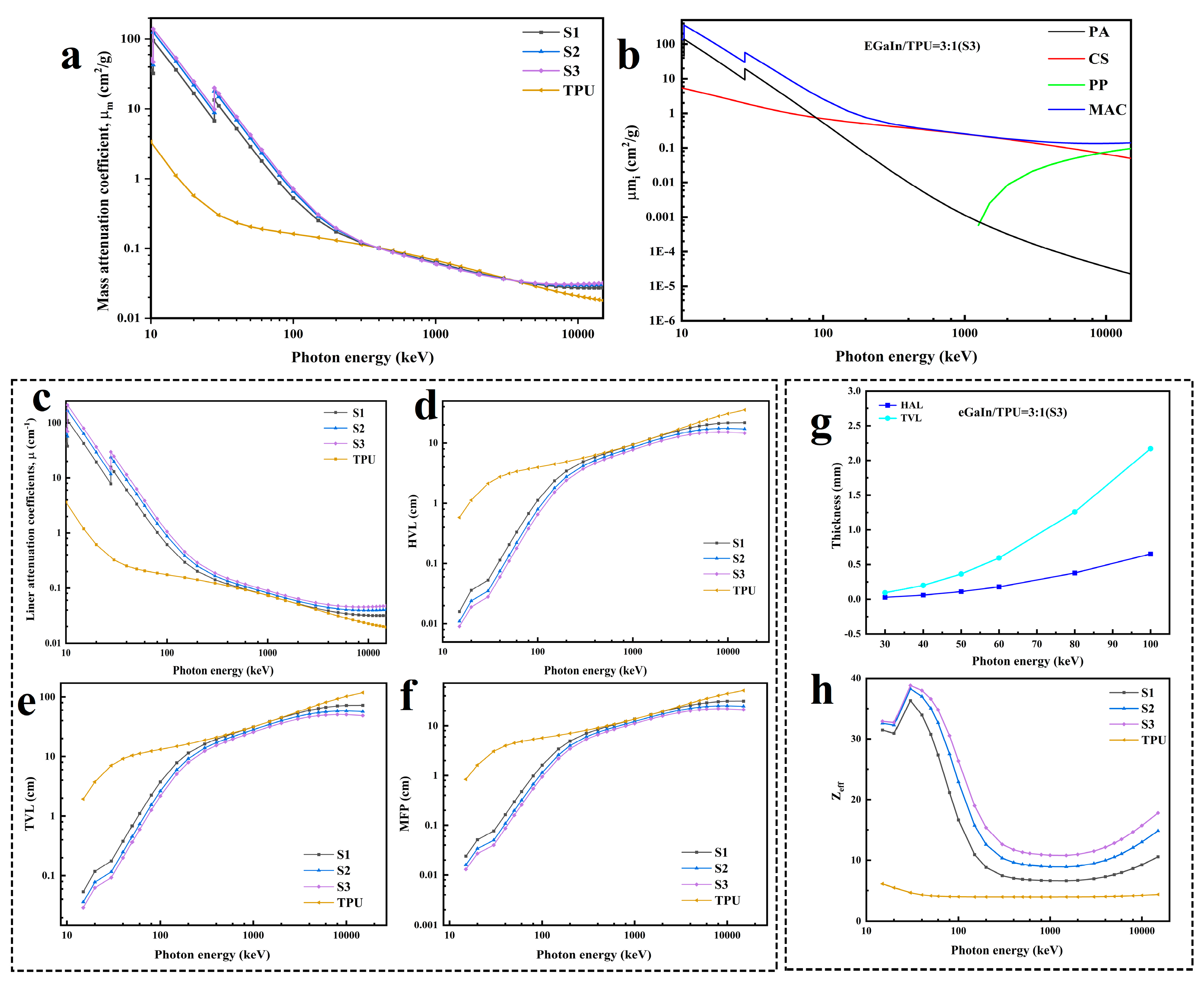

3.3. Evaluation of X-ray Shielding Performance of eGaIn NDs/TPU Nanofiber Mats

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yun, J.; Hou, J.; Jang, W.; Kim, S.Y.; Byun, H. Electrospun Tungsten-Polyurethane Composite Nanofiber Mats for Medical Radiation-Shielding Applications. ChemNanoMat 2021, 8, e202100387. [Google Scholar] [CrossRef]

- Yu, L.; Yap, P.L.; Santos, A.M.C.; Tran, D.N.H.; Losic, D. Lightweight polyester fabric with elastomeric bismuth titanate composite for high-performing lead-free X-ray shielding. Radiat. Phys. Chem. 2023, 205, 110726. [Google Scholar] [CrossRef]

- Hashemi, S.A.; Mousavi, S.M.; Faghihi, R.; Arjmand, M.; Sina, S.; Amani, A.M. Lead oxide-decorated graphene oxide/epoxy composite towards X-Ray radiation shielding. Radiat. Phys. Chem. 2018, 146, 77–85. [Google Scholar] [CrossRef]

- Akkurt, I.; Alomari, A.; Imamoglu, M.Y.; Ekmekçi, I. Medical radiation shielding in terms of effective atomic numbers and electron densities of some glasses. Radiat. Phys. Chem. 2023, 206, 110767. [Google Scholar] [CrossRef]

- Okafor, C.E.; Okonkwo, U.C.; Okokpujie, I.P. Trends in reinforced composite design for ionizing radiation shielding applications: A review. J. Mater. Sci. 2021, 56, 11631–11655. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Askari, M.; Ezzati, S.N. X-ray attenuating nanocomposite based on polyaniline using Pb nanoparticles. Synth. Met. 2014, 196, 68–75. [Google Scholar] [CrossRef]

- AbuAlRoos, N.J.; Baharul Amin, N.A.; Zainon, R. Conventional and new lead-free radiation shielding materials for radiation protection in nuclear medicine: A review. Radiat. Phys. Chem. 2019, 165, 108439. [Google Scholar] [CrossRef]

- Jamal AbuAlRoos, N.; Azman, M.N.; Baharul Amin, N.A.; Zainon, R. Tungsten-based material as promising new lead-free gamma radiation shielding material in nuclear medicine. Phys. Med. 2020, 78, 48–57. [Google Scholar] [CrossRef]

- Seenappa, L.; Manjunatha, H.C.; Chandrika, B.M.; Sridhar, K.N.; Hanumantharayappa, C. Gamma, X-ray and neutron interaction parameters of Mg–Gd–Y–Zn–Zr alloys. Radiat. Phys. Chem. 2018, 150, 199–206. [Google Scholar] [CrossRef]

- Rani, N.; Vermani, Y.K.; Singh, T. Gamma radiation shielding properties of some Bi-Sn-Zn alloys. J. Radiol. Prot. 2020, 40, 296–310. [Google Scholar] [CrossRef]

- Rammah, Y.S. Influence of Ag2O insertion on alpha, proton and γ-rays safety features of TeO2.ZnO.Na2O glasses: Potential use for nuclear medicine applications. Ceram. Int. 2020, 46, 18151–18159. [Google Scholar] [CrossRef]

- Prabhu, S.; Bubbly, S.G.; Gudennavar, S.B. X-Ray and γ-Ray Shielding Efficiency of Polymer Composites: Choice of Fillers, Effect of Loading and Filler Size, Photon Energy and Multifunctionality. Polym. Rev. 2022, 63, 246–288. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric composite materials for radiation shielding: A review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Ahn, Y.; Song, S.H.; Lee, D. Tungsten nanoparticle anchoring on boron nitride nanosheet-based polymer nanocomposites for complex radiation shielding. Compos. Sci. Technol. 2022, 221, 109353. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Su, Y.; Liu, T.; Yu, H.; Yang, Y.; Li, X.; Guo, B. Preparation and radiation shielding properties of Gd2O3/PEEK composites. Polym. Compos. 2015, 36, 651–659. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef] [PubMed]

- Eatemadi, A.; Daraee, H.; Zarghami, N.; Melat Yar, H.; Akbarzadeh, A. Nanofiber: Synthesis and biomedical applications. Artif. Cells Nanomed. Biotechnol. 2016, 44, 111–121. [Google Scholar] [CrossRef]

- Massoumi, B.; Massoumi, R.; Aali, N.; Jaymand, M. Novel nanostructured star-shaped polythiophene, and its electrospun nanofibers with gelatin. J. Polym. Res. 2016, 23, 1–11. [Google Scholar] [CrossRef]

- Noor Azman, N.Z.; Wan Mohamed, W.F.I.; Ramli, R.M. Synthesis and characterization of electrospun n-ZnO/n-Bi2O3/epoxy-PVA nanofiber mat for low X-ray energy shielding application. Radiat. Phys. Chem. 2022, 195, 110102. [Google Scholar] [CrossRef]

- Hazlan, M.H.; Jamil, M.; Ramli, R.M.; Noor Azman, N.Z. X-ray attenuation characterisation of electrospun Bi2O3/PVA and WO3/PVA nanofibre mats as potential X-ray shielding materials. Appl. Phys. A 2018, 124, 1–9. [Google Scholar] [CrossRef]

- Ye, D.; Peng, Z.; Liu, J.; Huang, Y. Self-Limited ultraviolet laser sintering of liquid metal particles for μm-Thick flexible electronics devices. Mater. Des. 2022, 223, 111189. [Google Scholar] [CrossRef]

- Liu, H.; Xin, Y.; Bisoyi, H.K.; Peng, Y.; Zhang, J.; Li, Q. Stimuli-Driven Insulator-Conductor Transition in a Flexible Polymer Composite Enabled by Biphasic Liquid Metal. Adv. Mater. 2021, 33, e2104634. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Liu, J. Liquid Metal Based Stretchable Radiation-Shielding Film. J. Med. Devices 2015, 9, 014502. [Google Scholar] [CrossRef]

- Lou, P.; Teng, X.; Jia, Q.; Wang, Y.; Zhang, L. Preparation and structure of rare earth/thermoplastic polyurethane fiber for X-ray shielding. J. Appl. Polym. Sci. 2019, 136, 47435. [Google Scholar] [CrossRef]

- Wu, J.; Hu, J.; Wang, K.; Zhai, Y.; Wang, Z.; Feng, Y.; Fan, H.; Wang, K.; Duan, Y. Flexible stretchable low-energy X-ray (30–80 keV) radiation shielding material: Low-melting-point Ga(1)In(1)Sn(7)Bi(1) alloy/thermoplastic polyurethane composite. Appl. Radiat. Isot. 2023, 192, 110603. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Hu, J.; Chen, T.; Tang, J.; Zhai, Y.; Feng, Y.; Zhao, Z.; Fan, H.; Wang, K. Radiation shielding properties of flexible liquid metal-GaIn alloy. Prog. Nucl. Energy 2021, 135, 103696. [Google Scholar] [CrossRef]

- Agar, O.; Tekin, H.O.; Sayyed, M.I.; Korkmaz, M.E.; Culfa, O.; Ertugay, C. Experimental investigation of photon attenuation behaviors for concretes including natural perlite mineral. Results Phys. 2019, 12, 237–243. [Google Scholar] [CrossRef]

- Singh, T.; Kaur, P.; Singh, P.S. A study of photon interaction parameters in some commonly used solvents. J. Radiol. Prot. 2007, 27, 79–85. [Google Scholar] [CrossRef]

- Han, I.; Demir, L. Determination of mass attenuation coefficients, effective atomic and electron numbers for Cr, Fe and Ni alloys at different energies. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2009, 267, 3–8. [Google Scholar] [CrossRef]

- Rashidi, M.; Rezaei, A.; Bijari, S.; Jaymand, M.; Samadian, H.; Arkan, E.; Zahabi, S.S.; Hosseini, M. Microfibers nanocomposite based on polyacrylonitrile fibers/bismuth oxide nanoparticles as X-ray shielding material. J. Appl. Polym. Sci. 2021, 138, 50755. [Google Scholar] [CrossRef]

- Li, X.; Li, M.; Zong, L.; Wu, X.; You, J.; Du, P.; Li, C. Liquid Metal Droplets Wrapped with Polysaccharide Microgel as Biocompatible Aqueous Ink for Flexible Conductive Devices. Adv. Funct. Mater. 2018, 28, 1804197. [Google Scholar] [CrossRef]

- He, J.H.; Liu, Y.; Xu, L. Apparatus for preparing electrospun nanofibres: A comparative review. Mater. Sci. Technol. 2013, 26, 1275–1287. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.-K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Lasprilla-Botero, J.; Álvarez-Láinez, M.; Lagaron, J.M. The influence of electrospinning parameters and solvent selection on the morphology and diameter of polyimide nanofibers. Mater. Today Commun. 2018, 14, 1–9. [Google Scholar] [CrossRef]

- Ji, Z.; Han, Y.; Yan, L.; Jian, Z.; Hongyu, S.; Ning, M. Estimation of viscosity and phase inversion point for oil-water mixture. Energy Procedia 2018, 153, 180–185. [Google Scholar]

- Lin, Y.; Genzer, J.; Dickey, M.D. Attributes, Fabrication, and Applications of Gallium-Based Liquid Metal Particles. Adv. Sci. 2020, 7, 2000192. [Google Scholar] [CrossRef]

- Tang, Q.; Gao, K. Structure analysis of polyether-based thermoplastic polyurethane elastomers by FTIR, 1H NMR and 13C NMR. Int. J. Polym. Anal. Charact. 2017, 22, 569–574. [Google Scholar] [CrossRef]

- Tekin, H.O.; Kilicoglu, O. The influence of gallium (Ga) additive on nuclear radiation shielding effectiveness of Pd/Mn binary alloys. J. Alloys Compd. 2020, 815, 152484. [Google Scholar] [CrossRef]

- Kaur, T.; Sharma, J.; Singh, T. Review on scope of metallic alloys in gamma rays shield designing. Prog. Nucl. Energy 2019, 113, 95–113. [Google Scholar] [CrossRef]

- Mahmoud, K.A.; Tashlykov, O.L.; Sayyed, M.I.; Kavaz, E. The role of cadmium oxides in the enhancement of radiation shielding capacities for alkali borate glasses. Ceram. Int. 2020, 46, 23337–23346. [Google Scholar] [CrossRef]

| Sample ID | eGaIn NDs/TPU | eGaIn NDs Loading (wt%) | Elemental Composition (wt%) | ρ (g/cm3) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Ga | In | C | H | O | N | ||||

| S1 | 1/1 | 50.0 | 32.8 | 17.2 | 29.6 | 3.3 | 14.6 | 2.5 | 1.168 |

| S2 | 2/1 | 66.7 | 43.4 | 23.4 | 19.6 | 2.2 | 9.7 | 1.7 | 1.334 |

| S3 | 3/1 | 75.0 | 48.9 | 26.0 | 14.8 | 1.7 | 7.3 | 1.3 | 1.487 |

| TPU | 0/1 | 0.0 | 0 | 0 | 59.1 | 6.6 | 29.1 | 5.2 | 1.082 |

| Photon Energy (keV) | S3 | S2 | ||||

|---|---|---|---|---|---|---|

| Phy-X (cm2/g) | WinXCom (cm2/g) | Δ (%) | Phy-X (cm2/g) | WinXCom (cm2/g) | Δ (%) | |

| 15 | 53.5957 | 53.6000 | −0.0043 | 47.7775 | 47.7800 | −0.0025 |

| 20 | 24.6719 | 24.6700 | 0.0019 | 22.0004 | 22.0000 | 0.0004 |

| 30 | 16.6127 | 16.6100 | 0.0027 | 14.8893 | 14.8900 | −0.0007 |

| 40 | 7.7309 | 7.7320 | −0.0011 | 6.9403 | 6.9400 | 0.0003 |

| 50 | 4.2364 | 4.2370 | −0.0006 | 3.8119 | 3.8120 | −0.0001 |

| 60 | 2.6020 | 2.6020 | 0.0000 | 2.3482 | 2.3480 | 0.0002 |

| 80 | 1.2310 | 1.2310 | 0.0000 | 1.1199 | 1.1200 | −0.0001 |

| 100 | 0.7135 | 0.7135 | 0.0000 | 0.6556 | 0.6556 | 0.0000 |

| 150 | 0.3057 | 0.3057 | 0.0000 | 0.2887 | 0.2887 | 0.0000 |

| 200 | 0.1945 | 0.1945 | 0.0000 | 0.1879 | 0.1879 | 0.0000 |

| 300 | 0.1254 | 0.1254 | 0.0000 | 0.1242 | 0.1242 | 0.0000 |

| 400 | 0.1010 | 0.1010 | 0.0000 | 0.1011 | 0.1011 | 0.0000 |

| 500 | 0.0879 | 0.0880 | 0.0000 | 0.0885 | 0.0885 | 0.0000 |

| 600 | 0.0793 | 0.0793 | 0.0000 | 0.0800 | 0.0800 | 0.0000 |

| 800 | 0.0680 | 0.0680 | 0.0000 | 0.0688 | 0.0688 | 0.0000 |

| 1000 | 0.0604 | 0.0604 | 0.0000 | 0.0612 | 0.0612 | 0.0000 |

| 1500 | 0.0490 | 0.0490 | 0.0000 | 0.0496 | 0.0496 | 0.0000 |

| 2000 | 0.0428 | 0.0428 | 0.0000 | 0.0433 | 0.0433 | 0.0000 |

| 3000 | 0.0365 | 0.0365 | 0.0000 | 0.0366 | 0.0367 | 0.0000 |

| 4000 | 0.0335 | 0.0335 | 0.0000 | 0.0334 | 0.0334 | 0.0000 |

| 5000 | 0.0319 | 0.0319 | 0.0000 | 0.0316 | 0.0316 | 0.0000 |

| 6000 | 0.0311 | 0.0311 | 0.0000 | 0.0306 | 0.0306 | 0.0000 |

| 8000 | 0.0306 | 0.0306 | 0.0000 | 0.0297 | 0.0297 | 0.0000 |

| 10,000 | 0.0307 | 0.0307 | 0.0000 | 0.0296 | 0.0296 | 0.0000 |

| 15,000 | 0.0319 | 0.0319 | 0.0000 | 0.0304 | 0.0304 | 0.0000 |

| Photon energy (keV) | S1 | TPU | ||||

| Phy-X (cm2/g) | WinXCom (cm2/g) | Δ (%) | Phy-X (cm2/g) | WinXCom (cm2/g) | Δ (%) | |

| 15 | 36.1943 | 36.2000 | −0.0057 | 1.1003 | 1.1000 | 0.0003 |

| 20 | 16.6824 | 16.6800 | 0.0024 | 0.5694 | 0.5694 | 0.0000 |

| 30 | 11.1289 | 11.1300 | −0.0011 | 0.3009 | 0.3009 | 0.0000 |

| 40 | 5.2087 | 5.2100 | −0.0013 | 0.2327 | 0.2327 | 0.0000 |

| 50 | 2.8799 | 2.8800 | −0.0001 | 0.2051 | 0.2051 | 0.0000 |

| 60 | 1.7902 | 1.7910 | −0.0008 | 0.1901 | 0.1901 | 0.0000 |

| 80 | 0.8748 | 0.8749 | −0.0001 | 0.1729 | 0.1729 | 0.0000 |

| 100 | 0.5277 | 0.5278 | −0.0001 | 0.1620 | 0.1620 | 0.0000 |

| 150 | 0.2511 | 0.2511 | 0.0000 | 0.1437 | 0.1438 | −0.0001 |

| 200 | 0.1731 | 0.1731 | 0.0000 | 0.1311 | 0.1311 | 0.0000 |

| 300 | 0.1214 | 0.1214 | 0.0000 | 0.1137 | 0.1137 | 0.0000 |

| 400 | 0.1012 | 0.1012 | 0.0000 | 0.1017 | 0.1017 | 0.0000 |

| 500 | 0.0896 | 0.0896 | 0.0000 | 0.0929 | 0.0929 | 0.0000 |

| 600 | 0.0815 | 0.0815 | 0.0000 | 0.0859 | 0.0859 | 0.0000 |

| 800 | 0.0705 | 0.0705 | 0.0000 | 0.0754 | 0.0754 | 0.0000 |

| 1000 | 0.0629 | 0.0629 | 0.0000 | 0.0678 | 0.0678 | 0.0000 |

| 1500 | 0.0510 | 0.0510 | 0.0000 | 0.0552 | 0.0552 | 0.0000 |

| 2000 | 0.0443 | 0.0443 | 0.0000 | 0.0473 | 0.0473 | 0.0000 |

| 3000 | 0.0370 | 0.0370 | 0.0000 | 0.0380 | 0.0380 | 0.0000 |

| 4000 | 0.0332 | 0.0332 | 0.0000 | 0.0325 | 0.0325 | 0.0000 |

| 5000 | 0.0309 | 0.0309 | 0.0000 | 0.0288 | 0.0289 | 0.0000 |

| 6000 | 0.0295 | 0.0295 | 0.0000 | 0.0263 | 0.0263 | 0.0000 |

| 8000 | 0.0280 | 0.0280 | 0.0000 | 0.0229 | 0.0229 | 0.0000 |

| 10,000 | 0.0274 | 0.0274 | 0.0000 | 0.0209 | 0.0209 | 0.0000 |

| 15,000 | 0.0273 | 0.0273 | 0.0000 | 0.0181 | 0.0181 | 0.0000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, K.; Wu, J.; Hu, J.; Mou, J.; Li, L.; Feng, Y.; Deng, Z. Preparation of eGaIn NDs/TPU Composites for X-ray Radiation Shielding Based on Electrostatic Spinning Technology. Materials 2024, 17, 272. https://doi.org/10.3390/ma17020272

Wang J, Wang K, Wu J, Hu J, Mou J, Li L, Feng Y, Deng Z. Preparation of eGaIn NDs/TPU Composites for X-ray Radiation Shielding Based on Electrostatic Spinning Technology. Materials. 2024; 17(2):272. https://doi.org/10.3390/ma17020272

Chicago/Turabian StyleWang, Jing, Kaijun Wang, Jiale Wu, Jin Hu, Jiangfeng Mou, Lian Li, Yongjin Feng, and Zhongshan Deng. 2024. "Preparation of eGaIn NDs/TPU Composites for X-ray Radiation Shielding Based on Electrostatic Spinning Technology" Materials 17, no. 2: 272. https://doi.org/10.3390/ma17020272