Petrophysical Analyses of Rock Construction Materials from a Roman Rural Settlement in Podšilo Bay on Rab Island (North-East Adriatic, Croatia)

Abstract

:1. Introduction

- (1)

- It can be used for a variety of structures of any size and arrangement in plans, the contours of which can be recognized by geo-radar prospecting (GPR);

- (2)

- It can be applied for the recognition of any rock material, both in terms of identification and mineral composition studies (optical microscope, SEM EDS);

- (3)

- It allows for the planning of specialized geomechanical tests with low availability of test material (multistage stress tests preceded by detailed recognition with X-ray tomography).

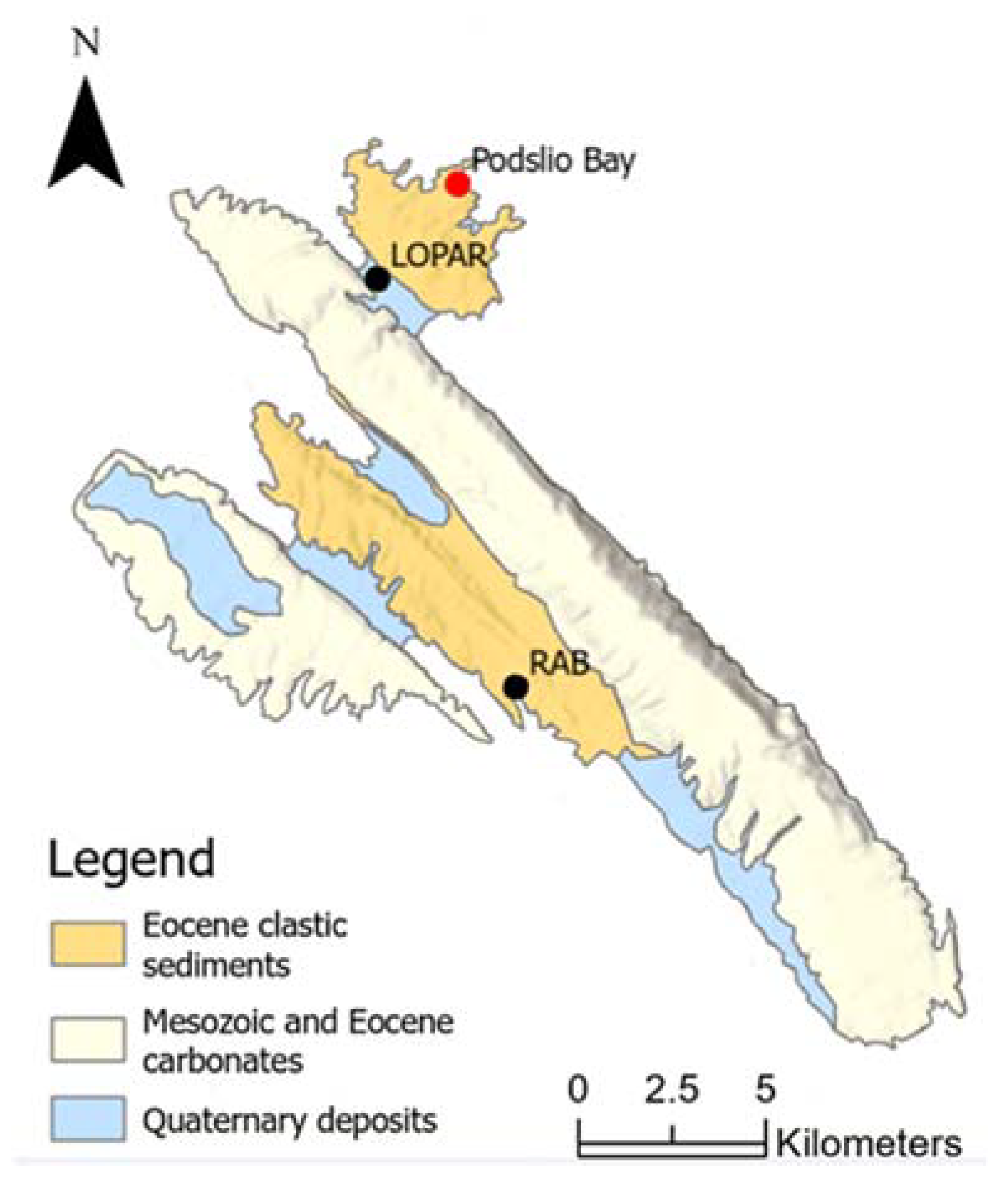

2. Geological Setting

3. Material and Methods

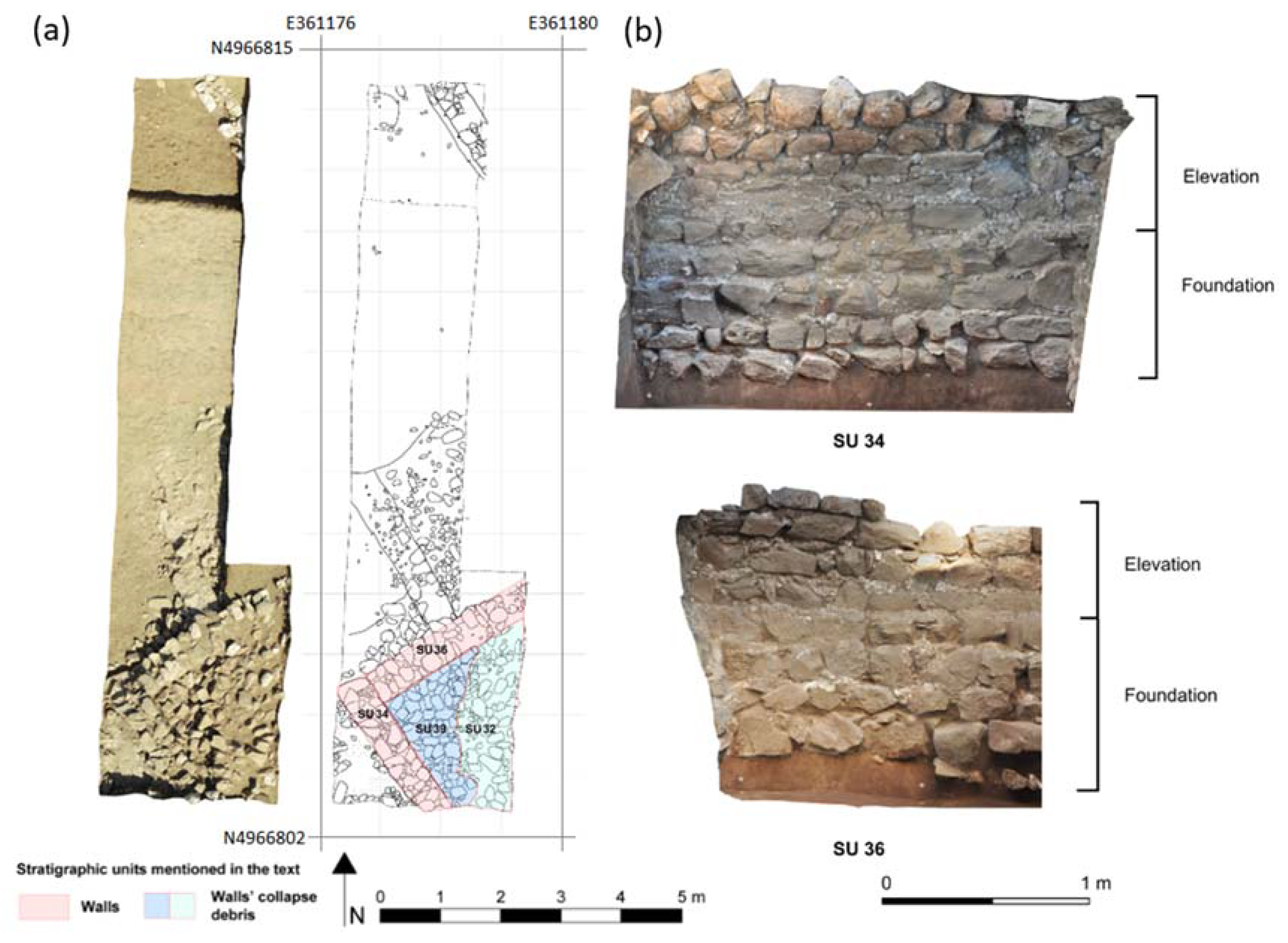

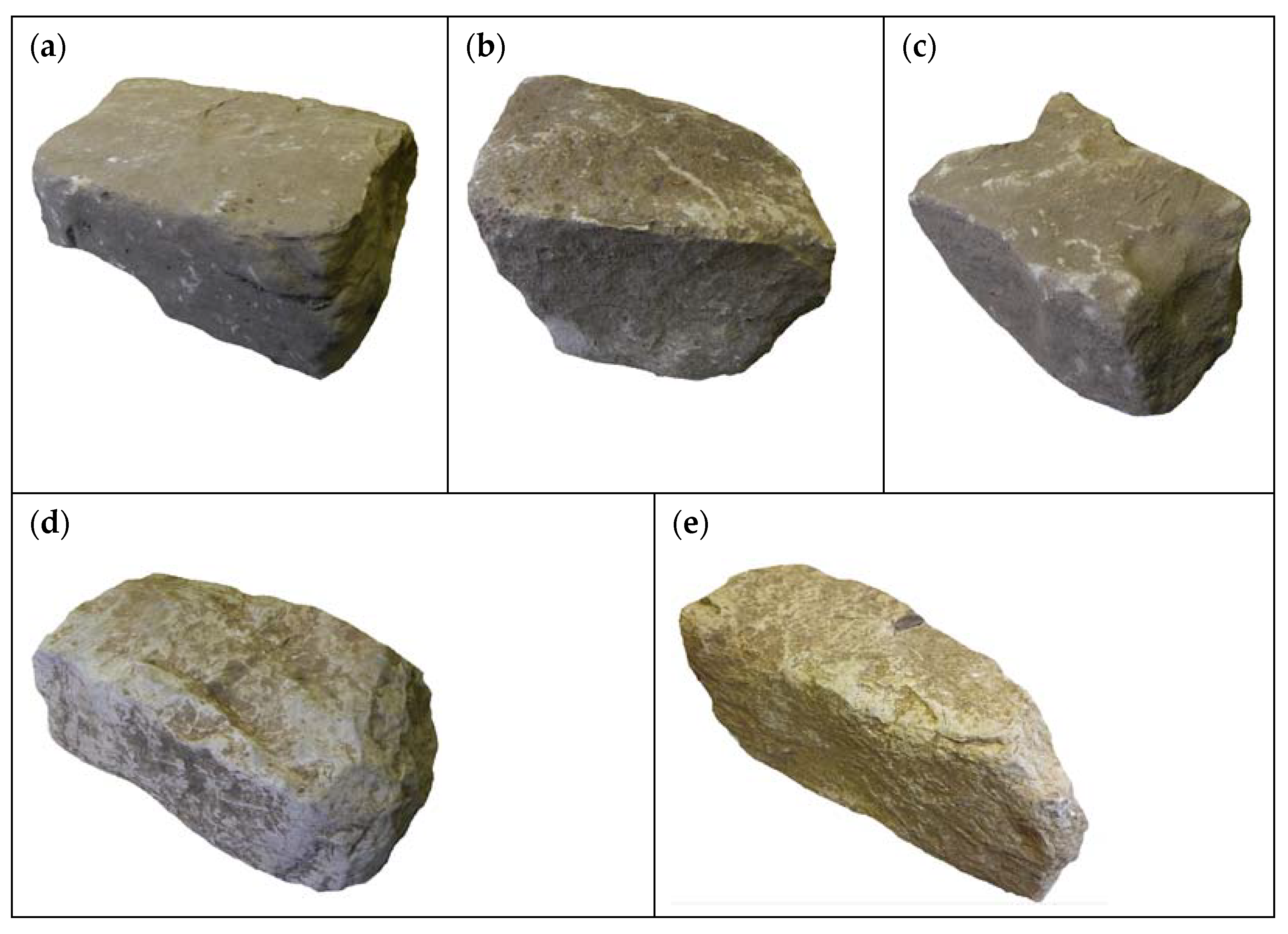

3.1. Material

3.2. Methods

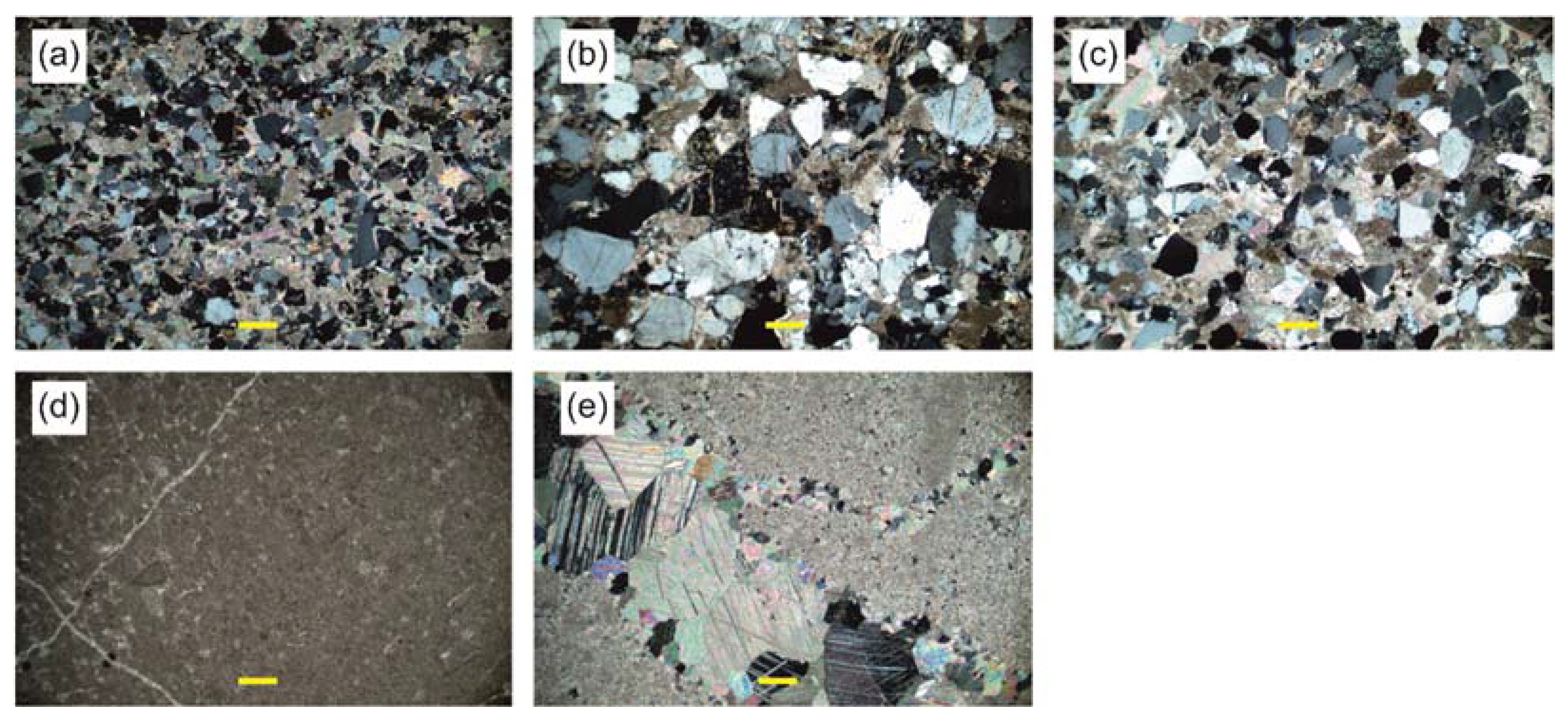

3.2.1. Polarised Light Microscopy

3.2.2. Scanning Electron Microscopy (SEM)

3.2.3. X-ray Microtomography

3.2.4. Geomechanical Tests

Unconfined Uniaxial Compressive Strength Tests

- Uniaxial compressive strength σu,

- Elastic constants: Young’s modulus E and Poisson’s ratio ν.

Triaxial Compressive Strength Tests

- Differential failure stress σ = σ1 − σ3,

- Elastic constants: Young’s modulus E and Poisson’s ratio ν.

Indirect Tensile Strength Tests

4. Results

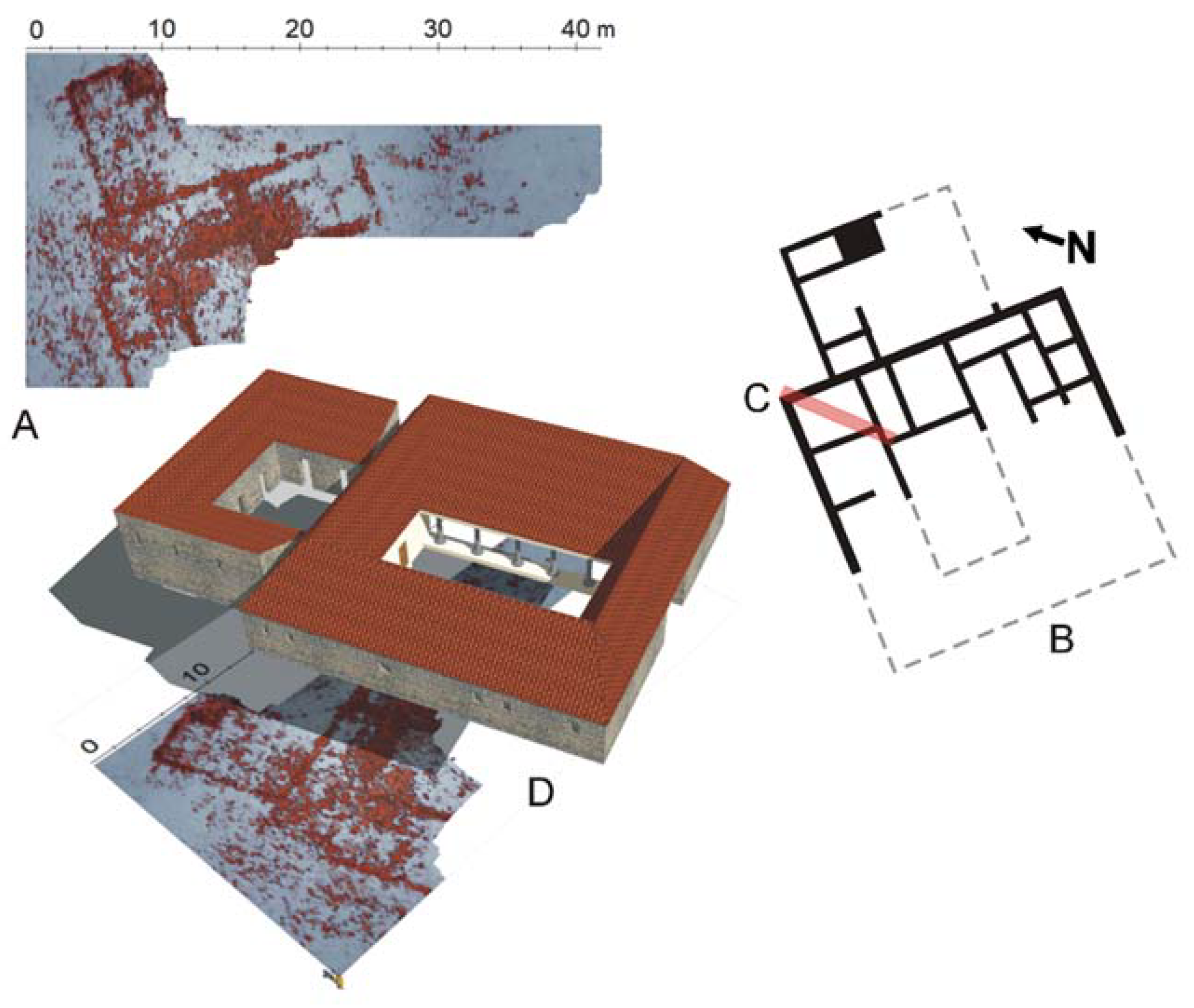

4.1. GPR Results

4.2. Macroscopic and Microscopic Analyses

4.3. X-ray Microtomography Analysis

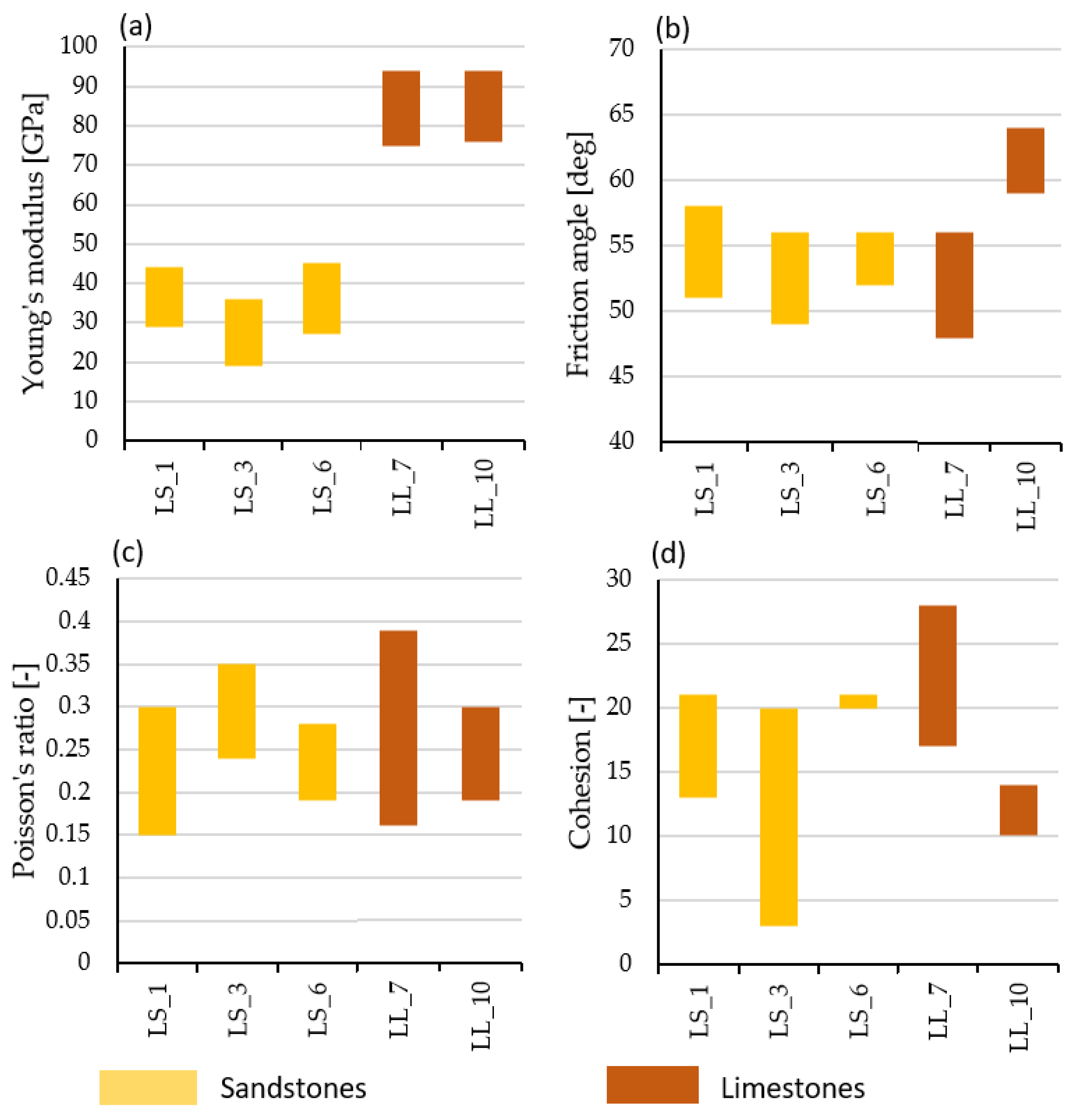

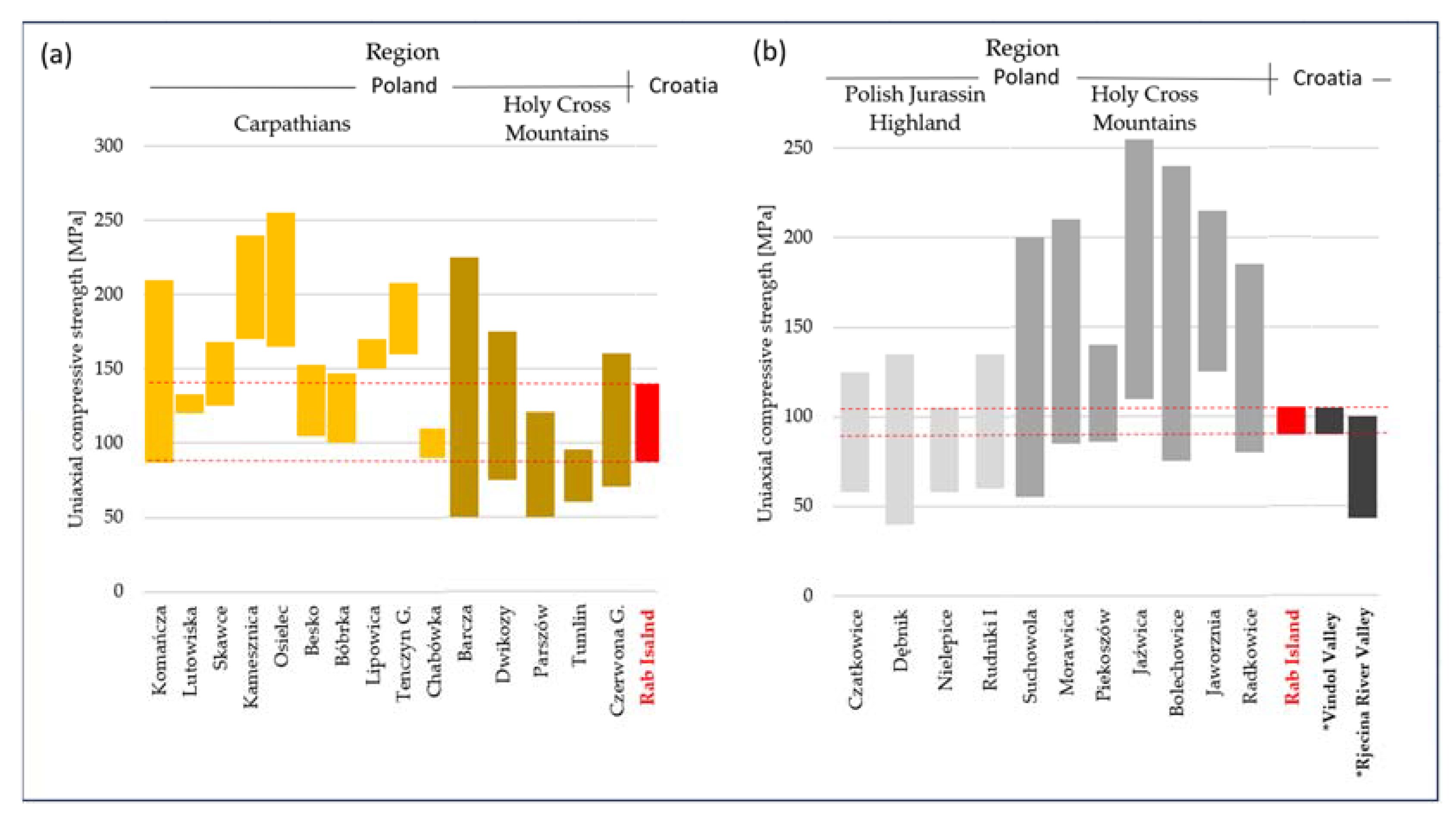

4.4. Geomechanical Properties

5. Discussion

- -

- Joint tensile cracking and joint slipping—dependent on mortar strength and joint geometry,

- -

- Unit direct tensile cracking and unit diagonal tensile cracking—mechanisms that depend on the strength of bricks or stone blocks (units),

- -

- Masonry crushing—mechanism conditioned by the strength of the masonry as a unit.

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Starac, A. Rimsko Vladanje u Histriji i Liburniji: Društveno i Pravno Uređenje Prema Literarnoj, Natpisnoj i Arheološkoj građi II. Liburnija (Roman Rule in Istria and Liburnia: Social and Legal Regulation according to Literary, Epigraphic and Archaeological Material II. Liburnia); Arheološki Muzej Istre: Pula, Croatia, 2000. [Google Scholar]

- Suić, M. Antički Grad na Istočnom Jadranu, 2nd ed.; Golden Marketing-Tehnička Knjiga: Zagreb, Croatia, 2003. [Google Scholar]

- Kurilić, A. Landscape transformations in Roman Dalmatia. MEFRA 2022, 134, 89–101. [Google Scholar] [CrossRef]

- Bowden, W. Villas of the Eastern Adriatic and Ionian Coastlands. In The Roman Villa in the Mediterranean Basin: Late Republic to Late Antiquity; Marzano, A., Métraux, G.P.R., Eds.; Cambridge University Press: Cambridge, UK, 2018; pp. 377–398. [Google Scholar] [CrossRef]

- Kilić-Matić, A. A Contribution To The Study Of Building Techniques And Structures At Roman Villae Rusticae On The Coast Of The Roman Province Of Dalmatia. Opvscvla Archaeol. 2004, 28, 91–109. [Google Scholar]

- Buzov, M. The Ancient Quarries in Croatia. The Technology of Extracting Stone. In Interdisciplinary Studies on Ancient Stone, Proceedings of the IX ASMOSIA Conference (Tarragona 2009), Tarragona, 8–13 June 2009; Gutiérrez Garcia-M., A., Lapuente Mercadal, P., Rodà de Llanza, I., Eds.; Institut Català d’Arqueologia Clàssica: Tarragona, Spain, 2012; pp. 628–635. [Google Scholar]

- Parica, M. The Remains of Infrastructural Facilities of the Ancient Quarries on Zadar Islands (Croatia). In Interdisciplinary Studies on Ancient Stone, Proceedings of the XI ASMOSIA Conference (Split 2015), Split, Croatia, 18–22 May 2015; Matetić Poljak, D., Marsaović, K., Eds.; University of Split: Split, Croatia, 2018; pp. 941–949. [Google Scholar]

- Lipovac Vrkljan, G.; Šiljeg, B. Lopar-Podšilo, Archaeological Rescue Excavation of a Roman Kiln in 2009. Ann. Instituti Archaeol. 2010, VI, 64–69. [Google Scholar]

- Welc, F.; Mieszkowski, R.; Lipovac Vrkljan, G.; Konestra, A. An Attempt to Integration of Different Geophysical Methods (Magnetic, GPR and ERT). A Case Study From the Late Roman Settlement On the Island of Rab in Croatia. Stud. Quat. 2017, 34, 47–59. [Google Scholar] [CrossRef]

- Welc, F. Geoarchaeology of Pottery Workshop Sites in Roman Dalmatia. In Pottery Production, Landscape and Economy of Roman Dalmatia: Interdisciplinary Approaches; Lipovac Vrkljan, G., Konestra, A., Eds.; Archaeopress: Oxford, UK, 2018; pp. 62–70. [Google Scholar]

- Welc, F.; Konestra, A.; Dugonjić, A.; Gračanin, P.A.; Rabiega, K.; Nowacki, B. Multidisciplinary insight into late Roman rural settlement on the northeastern Adriatic coast of Croatia: Island of Rab case study. Pol. Archaeol. Mediterr. 2019, 28, 433–454. [Google Scholar] [CrossRef]

- Konestra, A.; Welc, F.; Androić Gračanin, P.; Rabiega, K.; Nowacki, B.; Kukela, A. Rab island settlement typology and organisation through a diachronic approach—First data from a multidisciplinary research. Ann. Instituti Archaeol. 2020, XVI, 229–244. [Google Scholar]

- Konestra, A.; Welc, F.; Androić Gračanin, P.; Weker, W. An Insight into Craft Activities in Rural Areas of Dalmatia Province—First Data on Iron Working at the Roman Settlement in Lopar (Island of Rab). In Secrets of Iron—From Raw Material to an Iron Object, Proceedings of the 7th International Conference of Mediaeval Archaeology of the Institute of Archaeology, Zagreb, Croatia, 10–11 September 2020; Sekelj Ivančan, T., Karavidović, T., Tkalčec, T., Krznar, S., Belaj, J., Eds.; Institut za Arheologiju: Zagreb, Croatia, 2022; pp. 159–169. [Google Scholar]

- Mannoni, T.; Boato, A. Archeologia e storia del cantiere di costruzione. Arqueol. Arquit. 2002, 30, 39–53. [Google Scholar] [CrossRef]

- Pizzo, A. La Arqueología de la Construcción. Un laboratorio para el análisis de la arquitectura de época romana. Arqueol. Arquit. 2009, 6, 31–45. [Google Scholar] [CrossRef]

- Kurzawska, A.; Sobkowiak-Tabaka, I. Mikroprzeszłość. Badania Specjalistyczne w Archeologii; Kurzawska, A., Sobkowiak-Tabaka, I., Eds.; Wydział Archeologii UAM: Poznań, Poland, 2021; p. 454. Available online: https://hdl.handle.net/10593/26710 (accessed on 20 September 2023).

- Rapp, G. Archaeomineralogy; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Dessales, H. The Archaeology of Construction: A New Approach to Roman Architecture. Ann. Hist. Sci. Soc.—Engl. Ed. 2017, 72, 69–86. [Google Scholar] [CrossRef]

- Dessales, H. Les Savoir-Faire des Maçons Romains, Entre Connaissance Technique et Disponibilité des Matériaux. Le cas Pompéien. In Les Savoirs Professionnels des Gens de Métier: Études sur le Monde du Travail Dans les Sociétés Urbaines de l’empire Romain; Monteix, N., Tran, N., Eds.; Publications du Centre Jean Bérard: Naples, Italy, 2011; pp. 41–63. [Google Scholar] [CrossRef]

- Caporeale, S. Archeologia dei cantieri di età romana. Archeol. Dell’architettura 2010, 15, 171–180. [Google Scholar]

- Djuric, B.; Davidovic, J.; Maver, A.; Riznar, I. Stone use in Roman towns: Resources, transport, products and clients: Case study Sirmium: Second report. Starinar 2007, 57, 83–100. [Google Scholar] [CrossRef]

- Ignatakis, C. Mechanical characteristics of ancient roman masonry. Proc. IABSE Symp. 1993, 433–440. [Google Scholar]

- Zoghlami, K.; Martín-Martín, J.D.; Gómez-Gras, D.; Navarro, A.; Parcerisa, D.; Rosell, J.R. The building stone of the Roman city of Dougga (Tunisia): Provenance, petrophysical characterisation and durability. Comptes Rendus Geosci. 2017, 349, 402–411. [Google Scholar] [CrossRef]

- De Vos, M. Caratteristiche della Costruzione degli Impianti Produttivi Rurali nell’Africa Proconsularis. In Arqueología de la Construcción, 1. Los Procesos Constructivos en el Mundo Romano: Italia y Provincias Occidentales (Mérida, Instituto de Arqueología, 25–26 de Octubre de 2007); Archivo Español de Arqueología Suppl., 50; Caporeale, S., Dessales, H., Pizzo, A., Eds.; Consejo Superior de Investigaciones Científicas: Mérida, Spain, 2008; pp. 269–284. [Google Scholar]

- Bacchetta, A. Edilizia Rurale Romana. Materiali e Tecniche Costruttive Nella Pianura Padana (II sec. a.C.-IV sec. d.C.) (Flos Italiae. Documenti di Archeologia della Cisalpina Romana 4); All’Insegna del Giglio: Firenze, Italy, 2003. [Google Scholar]

- Mamužić, P.; Milan, A.; Korolija, B.; Borović, I.; Majcen, Ž. Basic Geological Map of the Republic of Croatia, Scale 1:100 000: Sheet RAB L33-114; Croatian Geological Survey (Department of Geology): Zagreb, Croatia, 1969; ISBN 978-953-6907-26-7. [Google Scholar]

- Lužar-Oberiter, B.; Mikulčić Pavlaković, S.; Crnjaković, M.; Babić, L. Variable sources of beach sands of north Adriatic islands: Examples from Rab and Susak. Geol. Croat. 2008, 61, 379–384. [Google Scholar] [CrossRef]

- Kovačić, M. Geothermal properties of the northern part of the island of Rab. Geol. Croat. 2013, 66, 29–37. [Google Scholar] [CrossRef]

- Popov, O.; Talovina, I.; Lieberwirth, H.; Duriagina, A. Quantitative Microstructural Analysis and X-ray Computed Tomography of Ores and Rocks—Comparison of Results. Minerals 2020, 10, 129. [Google Scholar] [CrossRef]

- Kaczmarek, Ł.D.; Zhao, Y.; Konietzky, H.; Wejrzanowski, T.; Maksimczuk, M. Numerical Approach in Recognition of Selected Features of Rock Structure from Hybrid Hydrocarbon Reservoir Samples Based on Microtomography. Stud. Geotech. Mech. 2017, 39, 13–26. [Google Scholar] [CrossRef]

- ASTM D7012-14e1; Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures. ASTM: West Conshohocken, PA, USA, 2014.

- Bieniawski, Z.T.; Bernede, M.J. Suggested Methods for Determining the Uniaxial Compressive Strength and Deformability of Rock Materials. In The Complete ISRM Suggested Methods for Rock Characterization Testing and Monitoring: 1974–2006; Ulusay, R., Hudson, J.A., Eds.; ISRM: Salzburg, Austria, 2007; pp. 137–140. [Google Scholar]

- ISRM 2007b. Suggested Methods for Determining the Strength of Rock Materials in Triaxial Compression. In The Complete ISRM Suggested Methods for Rock Characterization Testing and Monitoring: 1974–2006; Ulusay, R.; Hudson, J.A. (Eds.) ISRM: Salzburg, Austria, 2007; pp. 159–164. [Google Scholar]

- ASTM D3967-08; Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM International: West Conshohocken, PA, USA, 1981.

- Folk, R.L. Practical Petrographic Classification of Limestones. AAPG Bull. 1959, 43, 1–38. [Google Scholar] [CrossRef]

- Folk, R.L. Spectral Subdivision of Limestone Types. In Classification of Carbonate Rocks—A Symposium; Ham, W.E., Ed.; American Association of Petroleum Geologists: Tulsa, OK, USA, 1962; pp. 62–84. [Google Scholar]

- Otani, J.; Watanabe, Y.; Chevalier, B. Introduction of X-ray CT application in geotechnical engineering—Theory and practice. IOP Conf. Ser. Mater. Sci. Eng. 2010, 10, 012089. [Google Scholar] [CrossRef]

- PN-EN ISO 14689:2018; Geotechnical Investigation and Testing—Identification, Description and Classification of Rock. Part 1: Identification and Description. PKN: Warsaw, Poland, 2006.

- Russell, B. The Economics of the Roman Stone Trade; Oxford University Press (OUP): Oxford, UK, 2013; ISBN 9780199656394. [Google Scholar]

- Lourenço, P.B. Computational Strategies for Masonry Structures. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1996. [Google Scholar]

- Columbu, S.; Lisci, C.; Sitzia, F.; Lorenzetti, G.; Lezzerini, M.; Pagnotta, S.; Raneri, S.; Legnaioli, S.; Palleschi, V.; Gallello, G.; et al. Mineralogical, petrographic and physical-mechanical study of Roman construction materials from the Maritime Theatre of Hadrian’s Villa (Rome, Italy). Measurement 2018, 127, 264–276. [Google Scholar] [CrossRef]

- Vasconcelos, G.; Lourenço, P.B. In-Plane Experimental Behavior of Stone Masonry Walls under Cyclic Loading. J. Struct. Eng. 2009, 135, 1269–1277. [Google Scholar] [CrossRef]

- Terzic, V.; Villanueva, P.K.; Saldana, D.; Yoo, D.Y. Framework for modelling post-earthquake functional recovery of buildings. Eng. Struct. 2021, 246, 113074. [Google Scholar] [CrossRef]

- Forcellini, D. An expeditious framework for assessing the seismic resilience (SR) of structural configurations. Structures 2023, 56, 105015. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Q.; Geng, J. Microstructural characterization of limestone exposed to heat with XRD, SEM and TG-DSC. Mater. Charact. 2017, 134, 285–295. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Q.; He, H.; Cao, L.; Zhang, W.; Wang, B. Pore characteristics and mechanical properties of sandstone under the influence of temperature. Appl. Therm. Eng. 2017, 113, 537–543. [Google Scholar] [CrossRef]

- Vračević, D.; Dugonjić Jovančević, S.; Peranić, J.; Hodanić, M. Determination of Uniaxial Compressive Strength of Limestone. Zb. Radowa (Građevinski Fak. Sveučilišta U Rijeci) 2019, 22, 123–140. [Google Scholar] [CrossRef]

- Pollak, D.; Gulam, V.; Bostjančić, I. A visual determination method for uniaxial compressive strength estimation based on Croatian carbonate rock materials. Eng. Geol. 2017, 231, 68–80. [Google Scholar] [CrossRef]

| Lithological Type | Structural Characteristics Based on Computed Microtomography Test Results |

|---|---|

| LS_1 fine-grained sandstone | Compact structure, no cracks with a dilation exceeding ~0.04 mm. CT porosity (0.02%) very low at a given voxel of 41.5 um. Equivalent pore diameter dominating in the smallest range of 41.5–124.5 μm (98% contribution to porosity). |

| LS_3 medium-grained sandstone | Compact structure, no cracks with a dilation exceeding ~0.05 mm. Image of pore space, characterised by fine gradation of pores in the test sample. Recorded CT porosity of sample: ~0.08%, where pores of about 0.1 mm (about 74%) dominate; voxel size 46.5 μm. |

| LS_6 fine-grained sandstone | Grain size about 0.2 mm, CT porosity low (0.17%), pores characterised mainly by an equivalent diameter of 41.5—207.5 μm (80%). Structure compact, with single larger voids or cracks. |

| LL_7 mudstone | Compact structure, individual pores larger than voxel size (46.5 μm), some cracks filled with secondary mineralization (presence of characteristic “seam” forms). |

| LL_10 sparitic limestone | Compact structure, with small pores and individual cracks filled with secondary mineralization. |

| Lithological Type | Colour | Bulk Density ρ [kg/m3] | Longitudinal Wave Velocity Vp [m/s] | |

|---|---|---|---|---|

σ (N) | ||||

| Sandstone | LS_1 | dark grey | 2609 17 (11) | 4632 248 (17) |

| LS_3 | light brown | 2541 24 (12) | 3258 232 (17) | |

| LS_6 | light grey | 2561 37 (12) | 3434 255 (12) | |

| Limestone | LL_7 | dark grey | 2637 40 (12) | 6335 135 (18) |

| LL_10 | grey | 2664 44 (10) | 6375 124 (18) | |

| Lab. Symbols | Indirect Tensile Strength σt [MPa] | Uniaxial Compression Tests | ||

|---|---|---|---|---|

| Uniaxial Compressive Strength σu [MPa] | Young’s Modulus E [GPa] | Poisson’s Ratio ν [-] | ||

| Min-Max | ||||

| LS_1 | 11.5–14.5 (13.5) | 129 | 30 | |

| LS_3 | 5.8–8.0 (7.0) | 87–91 | 17–20 | 0.23 |

| LS_6 | 5.5–80 (6.5) | 140 | 27 | |

| LL_7 | 4.5–9.9 (7.6) | 105 | 90 | |

| LL_10 | 9.8–117 (10.6) | 90 | 82 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trzciński, J.; Wójcik, E.; Kiełbasiński, K.; Łukaszewski, P.; Zaremba, M.; Kaczmarek, Ł.; Dziedziczak, R.; Kotowski, J.; Konestra, A.; Welc, F.; et al. Petrophysical Analyses of Rock Construction Materials from a Roman Rural Settlement in Podšilo Bay on Rab Island (North-East Adriatic, Croatia). Materials 2024, 17, 359. https://doi.org/10.3390/ma17020359

Trzciński J, Wójcik E, Kiełbasiński K, Łukaszewski P, Zaremba M, Kaczmarek Ł, Dziedziczak R, Kotowski J, Konestra A, Welc F, et al. Petrophysical Analyses of Rock Construction Materials from a Roman Rural Settlement in Podšilo Bay on Rab Island (North-East Adriatic, Croatia). Materials. 2024; 17(2):359. https://doi.org/10.3390/ma17020359

Chicago/Turabian StyleTrzciński, Jerzy, Emilia Wójcik, Kamil Kiełbasiński, Paweł Łukaszewski, Małgorzata Zaremba, Łukasz Kaczmarek, Robert Dziedziczak, Jakub Kotowski, Ana Konestra, Fabian Welc, and et al. 2024. "Petrophysical Analyses of Rock Construction Materials from a Roman Rural Settlement in Podšilo Bay on Rab Island (North-East Adriatic, Croatia)" Materials 17, no. 2: 359. https://doi.org/10.3390/ma17020359

APA StyleTrzciński, J., Wójcik, E., Kiełbasiński, K., Łukaszewski, P., Zaremba, M., Kaczmarek, Ł., Dziedziczak, R., Kotowski, J., Konestra, A., Welc, F., Wejrzanowski, T., & Jaroszewicz, J. (2024). Petrophysical Analyses of Rock Construction Materials from a Roman Rural Settlement in Podšilo Bay on Rab Island (North-East Adriatic, Croatia). Materials, 17(2), 359. https://doi.org/10.3390/ma17020359