Growth, Spectroscopy, and Laser Performance of a 2.79 μm Er: YSGG Single Crystal Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Single Crystal Fiber Growth

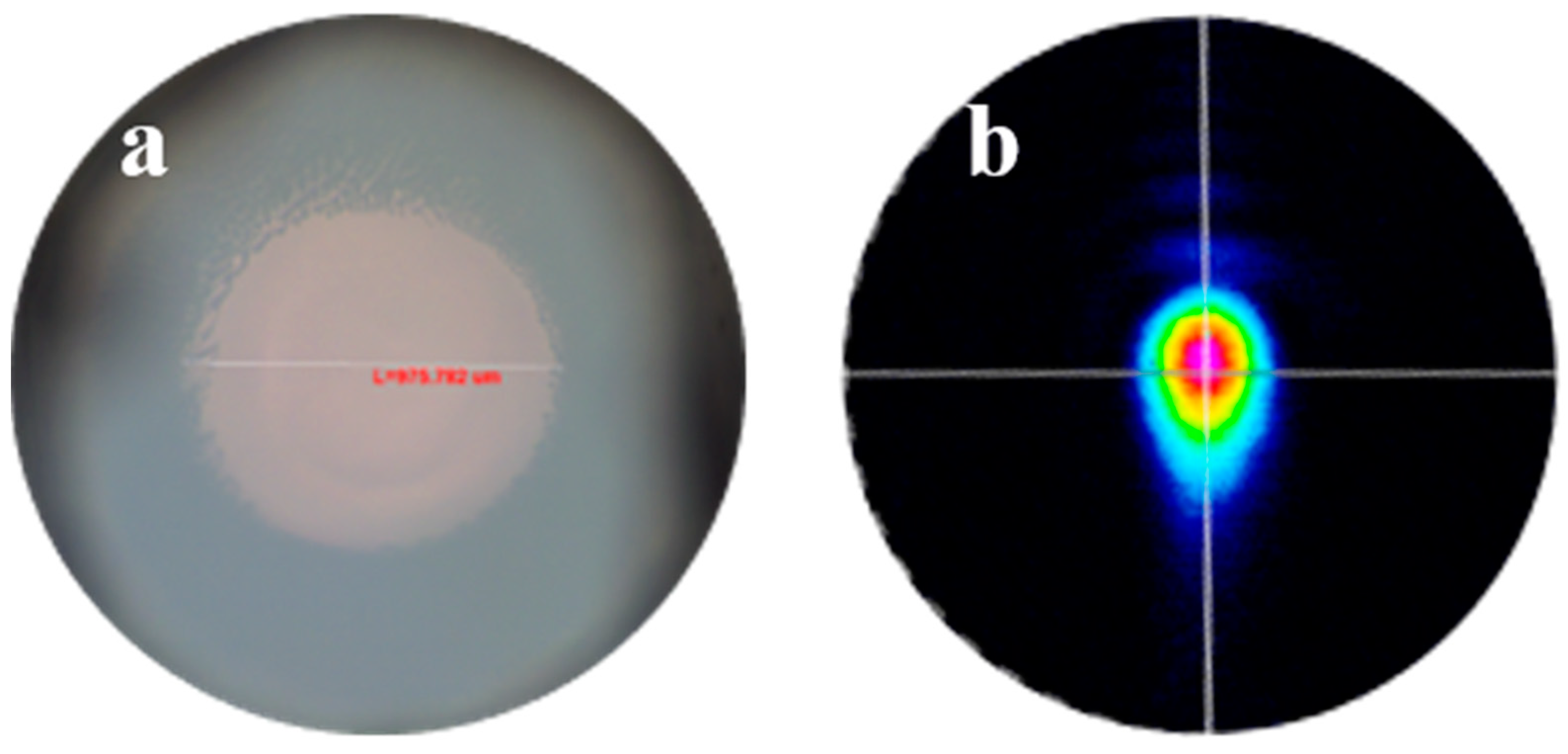

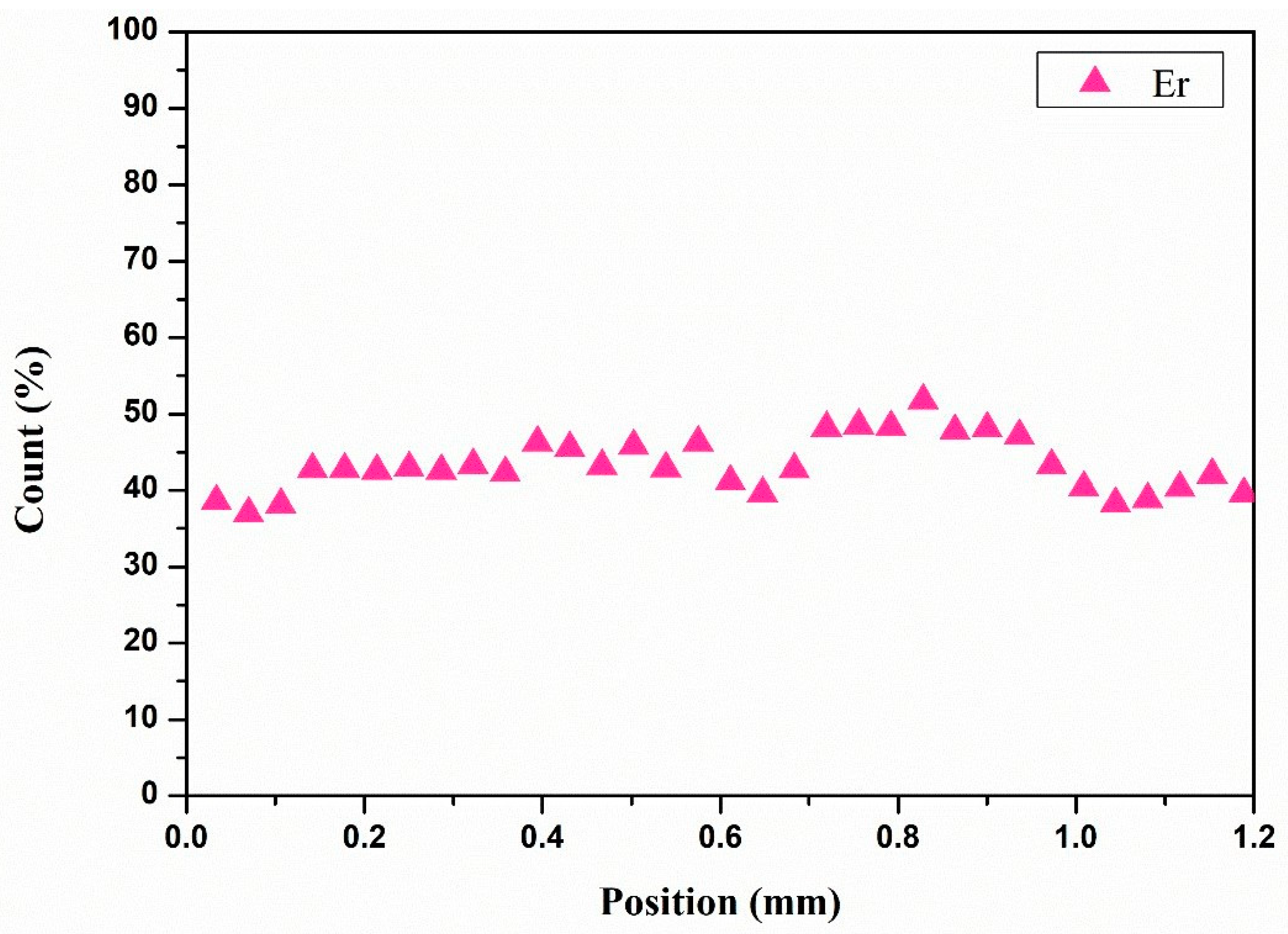

2.2. Crystal Quality of YSGG

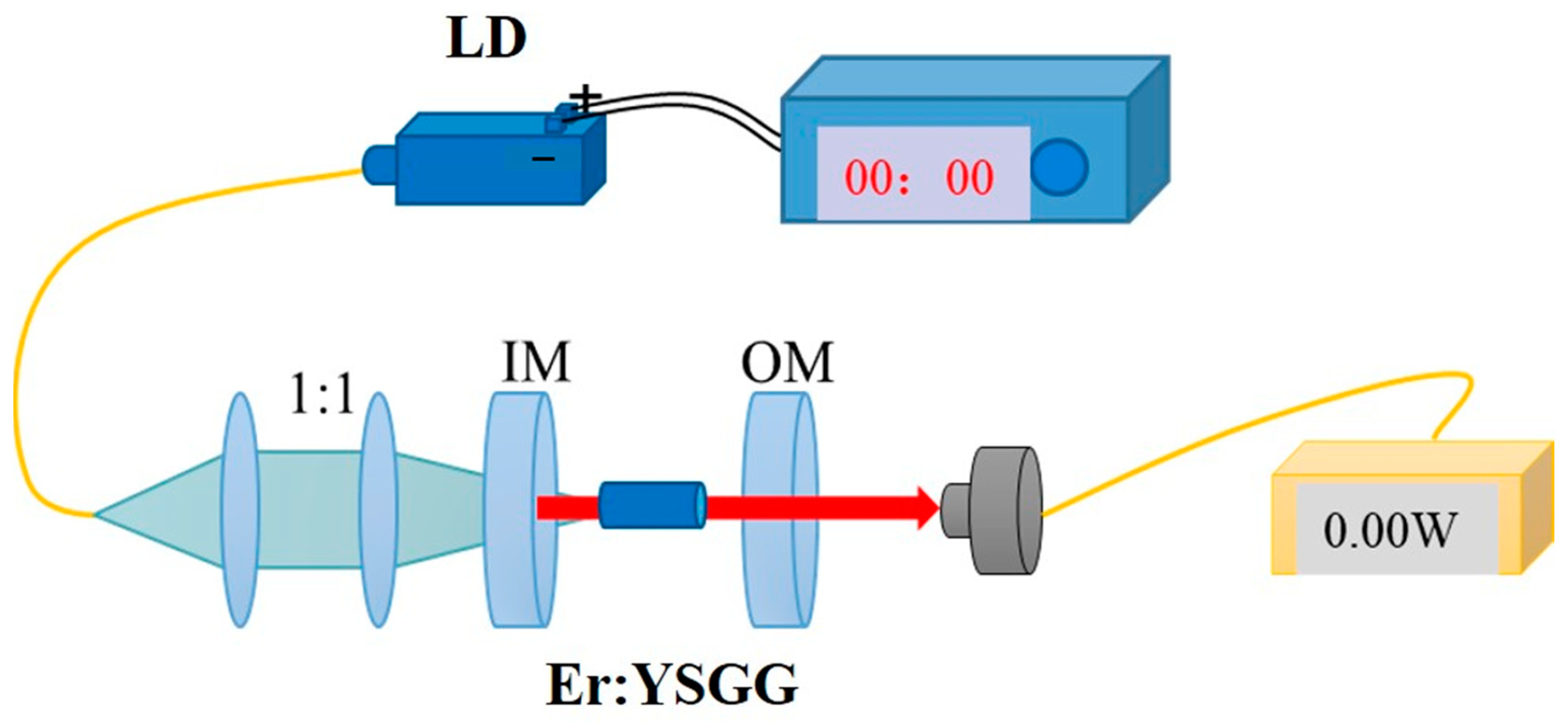

2.3. Laser Experiment

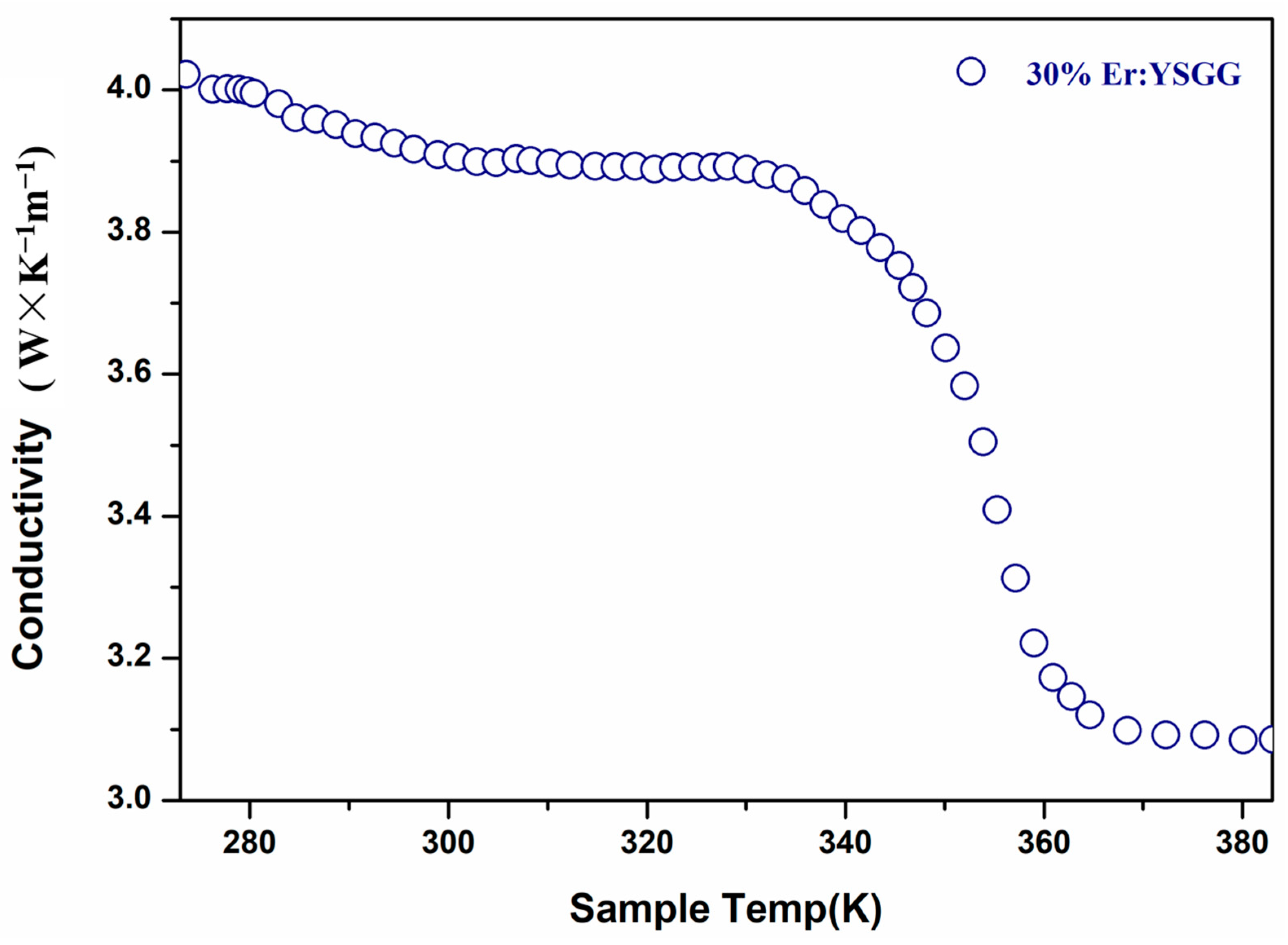

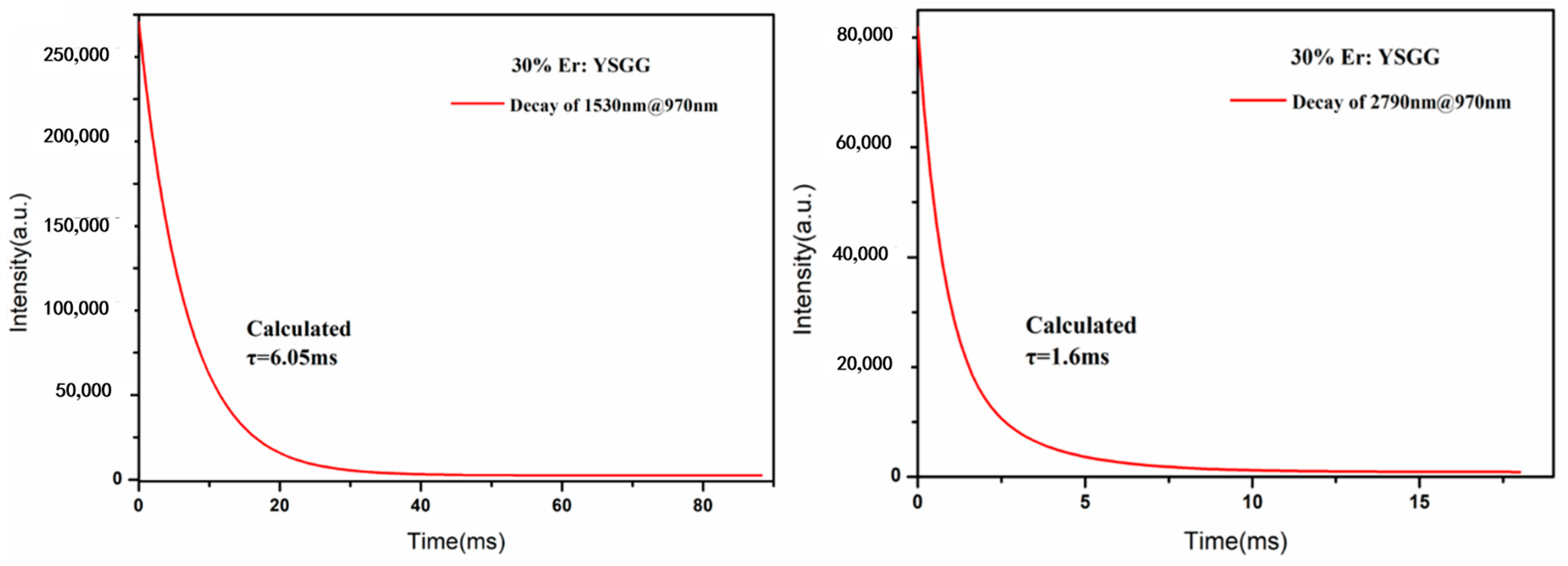

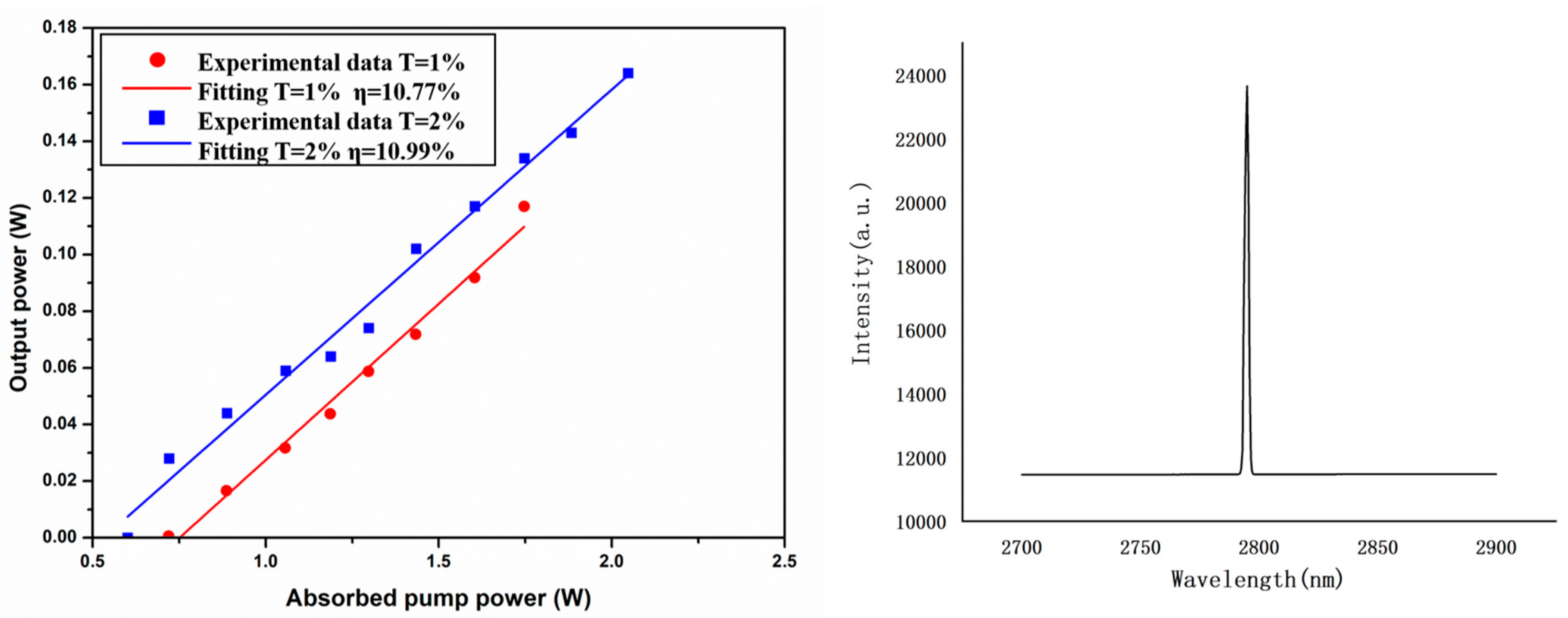

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bernier, M.; Faucher, D.; Caron, N.; Vallée, R. Highly stable and efficient erbium-doped 2.8 μm all fiber laser. Opt. Express 2009, 17, 16941. [Google Scholar] [CrossRef]

- Lopez, L.; Druon, F.; Georges, P.; Balembois, F. LED-pumped Er: Cr: YSGG light sources. Opt. Express 2023, 31, 27604–27611. [Google Scholar] [CrossRef]

- Ziolek, C.; Ernst, H.; Will, G.F.; Lubatschowski, H.; Welling, H.; Ertmer, W. High-repetition-rate, high-average-power, diode-pumped 2.94-μm Er:YAG laser. Opt. Lett. 2001, 26, 599. [Google Scholar] [CrossRef] [PubMed]

- Tokita, S.; Murakami, M.; Shimizu, S.; Hashida, M.; Sakabe, S. 12 W Q-switched Er:ZBLAN fiber laser at 2.8 μm. Opt. Lett. 2011, 36, 2812. [Google Scholar] [CrossRef]

- Tokita, S.; Hirokane, M.; Murakami, M.; Shimizu, S.; Hashida, M.; Sakabe, S. Stable 10 W Er: ZBLAN fiber laser operating at 2.71–2.88 μm. Opt. Lett. 2010, 35, 3943–3945. [Google Scholar] [CrossRef] [PubMed]

- Denker, B.; Galagan, B.; Osiko, V.; Sverchkov, S.; Balbashov, A.M.; Hellstrm, J.E.; Pasiskevicius, V.; Laurell, F. Yb3+, Er3+:YAG at high temperatures: Energy transfer and spectroscopic properties. Opt. Commun. 2007, 271, 142. [Google Scholar] [CrossRef]

- Vega-Duran, J.T.; Barbosa-Garcia, O.; Diaz-Torres, L.A.; Meneses, M.A. Effects of energy back transfer on the luminescence of Yb and Er ions in YAG. Appl. Phys. Lett. 2000, 76, 2032. [Google Scholar] [CrossRef]

- Klier, D.T.; Kumke, M.U. Analysing the effect of the crystal structure on upconversion luminescence in Yb3+, Er3+-co-doped NaYF4 nanomaterials. J. Mater. Chem. C 2015, 3, 11228–11238. [Google Scholar] [CrossRef]

- Saleta Reig, D.; Grauel, B.; Konyushkin, V.A.; Nakladov, A.N.; Fedorov, P.P.; Busko, D.; Howard, I.A.; Richards, B.S.; Resch-Genger, U.; Kuznetsov, S.V.; et al. Upconversion properties of SrF2: Yb3+, Er3+ single crystals. J. Mater. Chem. C 2020, 8, 4093–4101. [Google Scholar] [CrossRef]

- Li, X.; Zhang, P.; Yin, H.; Zhu, S.; Li, Z.; Hang, Y.; Chen, Z. Sensitization and deactivation effects of Nd3+ on the Er3+: 2.7 μm emission in PbF2 crystal. Opt. Mater. Express 2019, 9, 1698–1708. [Google Scholar] [CrossRef]

- Wiesholler, L.M.; Frenzel, F.; Grauel, B.; Würth, C.; Resch-Genger, U.; Hirsch, T. Yb, Nd, Er-doped upconversion nanoparticles: 980 nm versus 808 nm excitation. Nanoscale 2019, 11, 13440–13449. [Google Scholar] [CrossRef] [PubMed]

- Loiko, P.A.; Arbabzadah, E.A.; Damzen, M.J.; Mateos, X.; Dunina, E.B.; Kornienko, A.A.; Yasukevich, A.S.; Skoptsov, N.A.; Yumashev, K.V. Judd–Ofelt analysis and stimulated-emission cross-sections for highly doped (38 at%) Er: YSGG laser crystal. J. Lumin. 2016, 171, 226–233. [Google Scholar] [CrossRef]

- Hu, Q.; Nie, H.; Mu, W.; Yin, Y.; Zhang, J.; Zhang, B.; He, J.; Jia, Z.; Tao, X. Bulk growth and an efficient mid-IR laser of high-quality Er:YSGG crystals. CrystEngComm 2019, 21, 1928. [Google Scholar] [CrossRef]

- Pianassola, M.; Loveday, M.; Chakoumakos, B.C.; Koschan, M.; Melcher, C.L.; Zhuravleva, M. Crystal growth and elemental homogeneity of the multicomponent rare-earth garnet (Lu1/6Y1/6Ho1/6Dy1/6Tb1/6Gd1/6) 3Al5O12. Cryst. Growth Des. 2020, 20, 6769–6776. [Google Scholar] [CrossRef]

- Yokota, Y.; Nihei, T.; Tanaka, K.; Sakairi, K.; Chani, V.; Ohashi, Y.; Kurosawa, S.; Kamada, K.; Yoshikawa, A. Fabrication of metallic fibers with high melting point and poor workability by unidirectional solidification. Adv. Eng. Mater. 2018, 20, 1700506. [Google Scholar] [CrossRef]

- Fernández-Carrión, A.J.; Bourret, J.; Sharp, J.; Xing, M.; Duclère, J.R.; Colas, M.; Cornette, J.; Carles, P.; Genevois, C.; Brisset, F.; et al. Elaboration and Luminescence Properties of Laser-Heated Pedestal Growth Sr3Al2O6-Based Fibers. Cryst. Growth Des. 2022, 22, 6828–6836. [Google Scholar] [CrossRef]

- Bera, S.; Ohodnicki Jr, P.; Collins, K.; Fortner, M.; Picard, Y.N.; Liu, B.; Buric, M. Dopant segregation in YAG single crystal fibers grown by the laser heated pedestal growth technique. J. Cryst. Growth 2020, 547, 125801. [Google Scholar] [CrossRef]

- Chen, H.; Buric, M.; Ohodnicki, P.R.; Nakano, J.; Liu, B.; Chorpening, B.T. Review and perspective: Sapphire optical fiber cladding development for harsh environment sensing. Appl. Phys. Rev. 2018, 5, 011102. [Google Scholar] [CrossRef]

- Pirzio, F.; Jun, S.; Tacchini, S.; Di Lieto, A.; Piccinno, G.; Tonelli, M.; Agnesi, A. Multi-watt amplification in a birefringent Yb:LiLuF4 single crystal fiber grown by micro-pulling-down. Opt. Lett. 2019, 44, 4095–4098. [Google Scholar] [CrossRef]

- Pearton, S.J.; Yang, J.; Cary, P.H.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A review of Ga2O3 materials, processing, and devices. Appl. Phys. Rev. 2018, 5, 011301. [Google Scholar] [CrossRef]

- Dubinskii, M.; Zhang, J.; Fromzel, V.; Chen, Y.; Yin, S.; Luo, C. Low-loss ‘crystalline-core/crystalline-clad’ (C4) fibers for highly power scalable high efficiency fiber lasers. Opt. Express 2018, 26, 5092–5101. [Google Scholar] [CrossRef] [PubMed]

- Dinerman, B.J.; Moulton, P.F. CW Laser Operation from Er:YAG, Er:GGG, Er:YSGG and Er:BYF. In Proceedings of the Lasers & Electro-optics Society Meeting, Boston, MA, USA, 16–19 November 1992. [Google Scholar]

- Arbabzadah, E.; Chard, S.; Amrania, H.; Phillips, C.; Damzen, M. Comparison of a diode pumped Er:YSGG and Er:YAG laser in the bounce geometry at the 3 μm transition. Opt. Express 2011, 19, 25860–25865. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhang, L.; Zhang, P.; Hang, Y. Nd3+ as effective sensitization and deactivation ions in Nd, Er: LaF3 crystal for the 2.7 μm lasers. J. Alloys Compd. 2020, 827, 154268. [Google Scholar] [CrossRef]

- Nannuri, S.H.; Samal, A.R.; Subash, C.K.; Santhosh, C.; George, S.D. Tuning of structural, laser power-dependent and temperature dependent luminescence properties of NaYF4: Yb, Er (Y: 88%, Yb: 10 and Er: 2%) submicron crystals using Cr3+ ion do**. J. Alloys Compd. 2019, 777, 894–901. [Google Scholar] [CrossRef]

| Er: YSGG | |

|---|---|

| Ga | 34.6 (wt%) |

| Y | 31.2 (wt%) |

| Er | 22.7 (wt%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, B.; Wang, M.; Zhang, J.; Jia, Z.; Wang, Z. Growth, Spectroscopy, and Laser Performance of a 2.79 μm Er: YSGG Single Crystal Fibers. Materials 2024, 17, 429. https://doi.org/10.3390/ma17020429

Wu B, Wang M, Zhang J, Jia Z, Wang Z. Growth, Spectroscopy, and Laser Performance of a 2.79 μm Er: YSGG Single Crystal Fibers. Materials. 2024; 17(2):429. https://doi.org/10.3390/ma17020429

Chicago/Turabian StyleWu, Baiyi, Meng Wang, Jian Zhang, Zhitai Jia, and Zefeng Wang. 2024. "Growth, Spectroscopy, and Laser Performance of a 2.79 μm Er: YSGG Single Crystal Fibers" Materials 17, no. 2: 429. https://doi.org/10.3390/ma17020429

APA StyleWu, B., Wang, M., Zhang, J., Jia, Z., & Wang, Z. (2024). Growth, Spectroscopy, and Laser Performance of a 2.79 μm Er: YSGG Single Crystal Fibers. Materials, 17(2), 429. https://doi.org/10.3390/ma17020429