The Influence of Temperature in the Wire Drawing Process on the Wear of Drawing Dies

Abstract

:1. Introduction

2. Materials and Methods

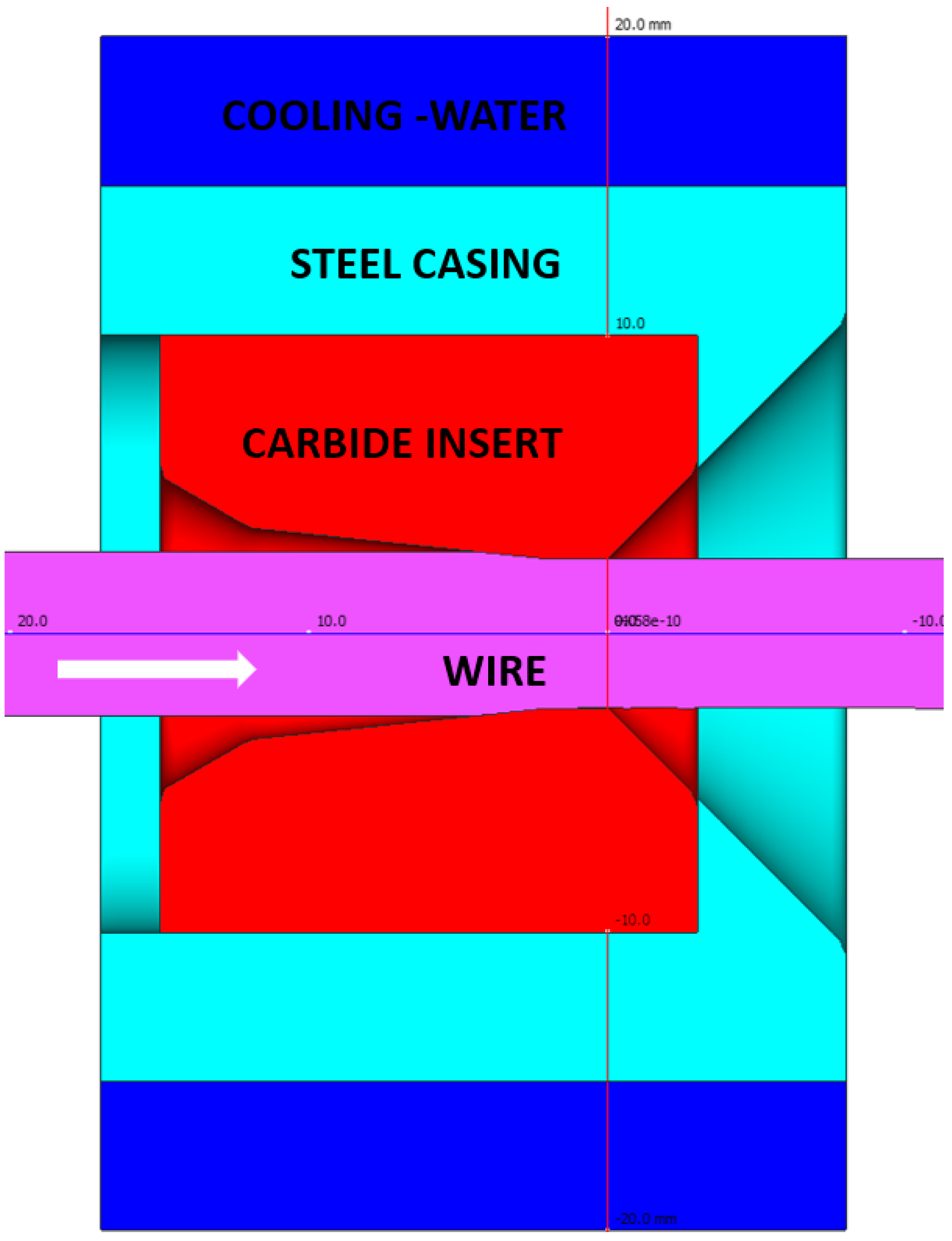

2.1. Computer Simulations of the Wire Drawing Process

- -

- Initial temperature: water 20 °C, drawing die housing 20 °C, insert 20 °C, wire 100 °C;

- -

- Thermal conductivity coefficient: wire insert: 1000 W/(m2-K); housing insert: 20,000 W/(m2-K); housing water: 10,000 W/(m2-K);

- -

- Friction coefficient: 0.07;

- -

- C45 steel properties, Table 1.

- -

- Young’s modulus of C45 steel—temperature-dependent;

- -

- Poisson’s number of C45 steel: 0.283;

- -

- Thermal conductivity of C45 steel: temperature-dependent;

- -

- The dependence of K10 carbide hardness on temperature was taken from the paper [26];

- -

- Carbide thermal conductivity: 80 W/(m·K);

- -

- Carbide heat capacity: 0.2 J/(g·K);

- -

- Carbide density: 14,700 kg/m3.

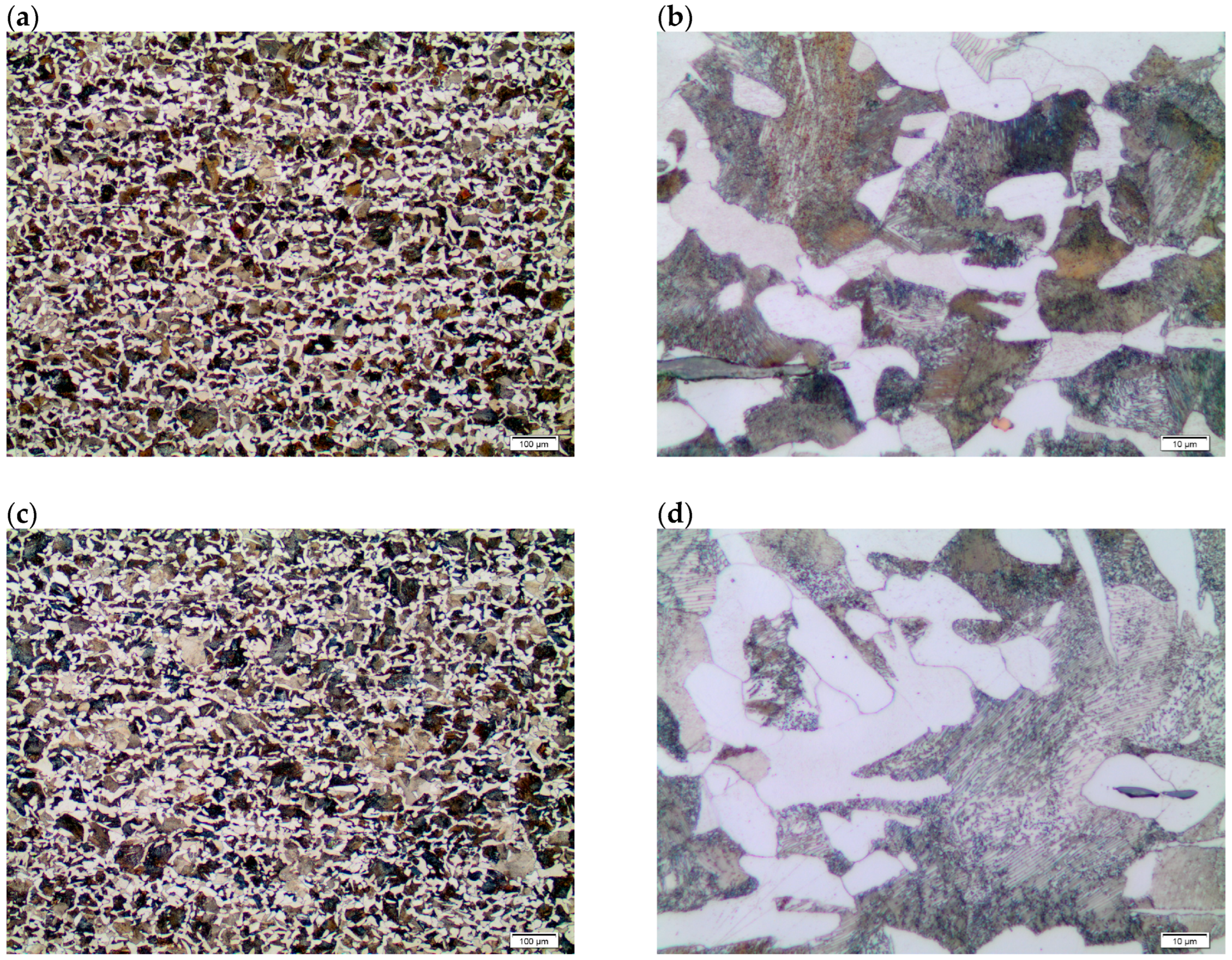

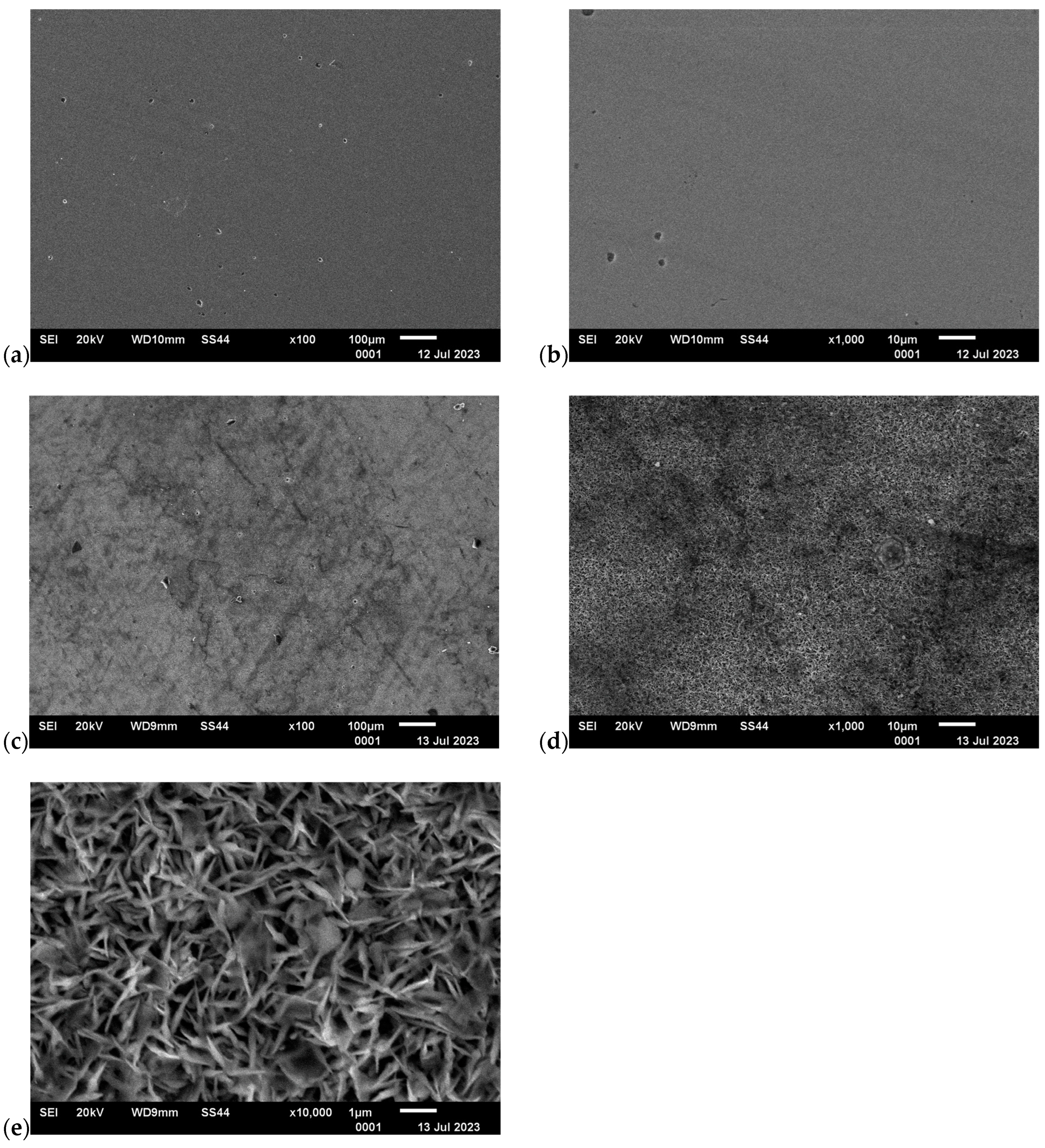

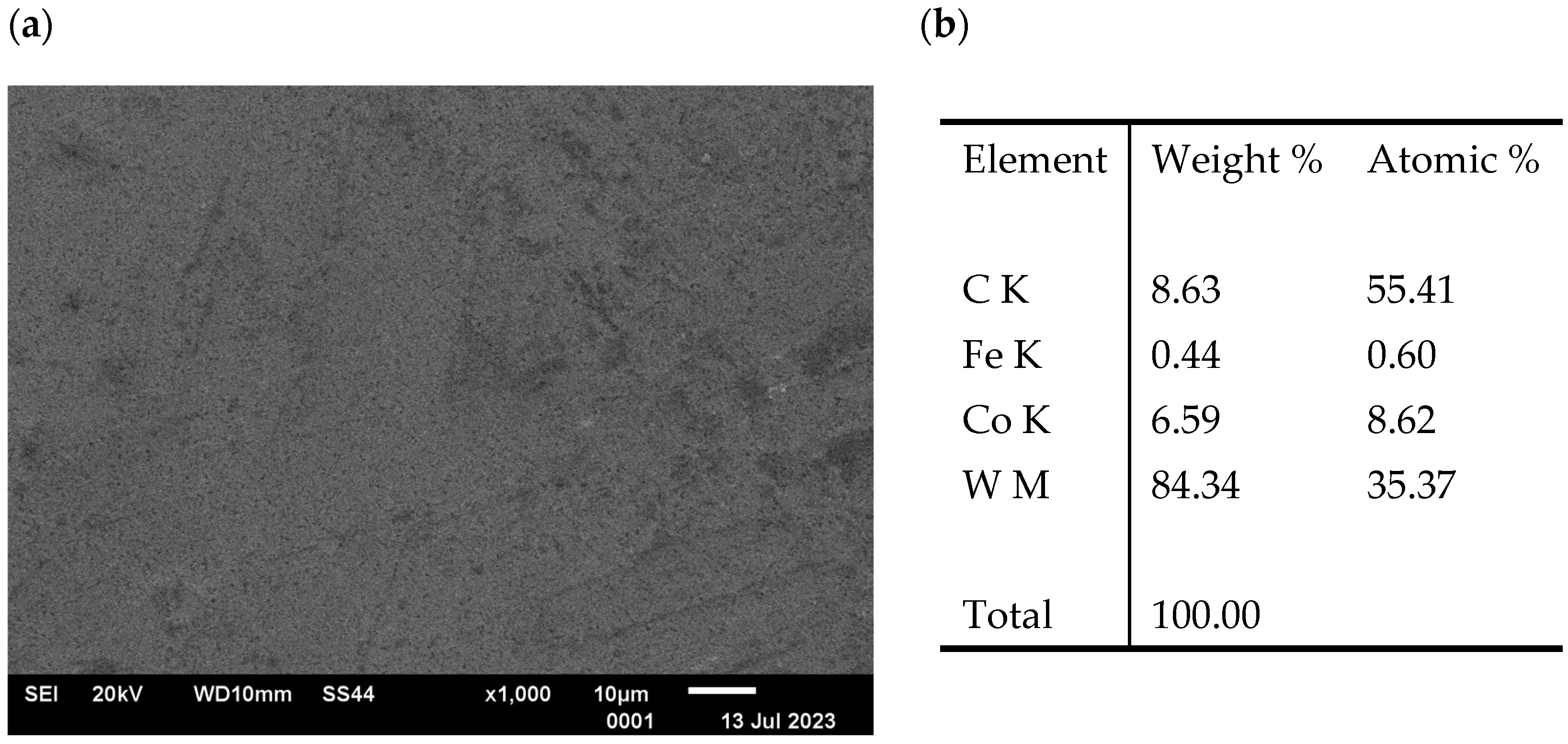

2.2. Tribological Tests

3. Results

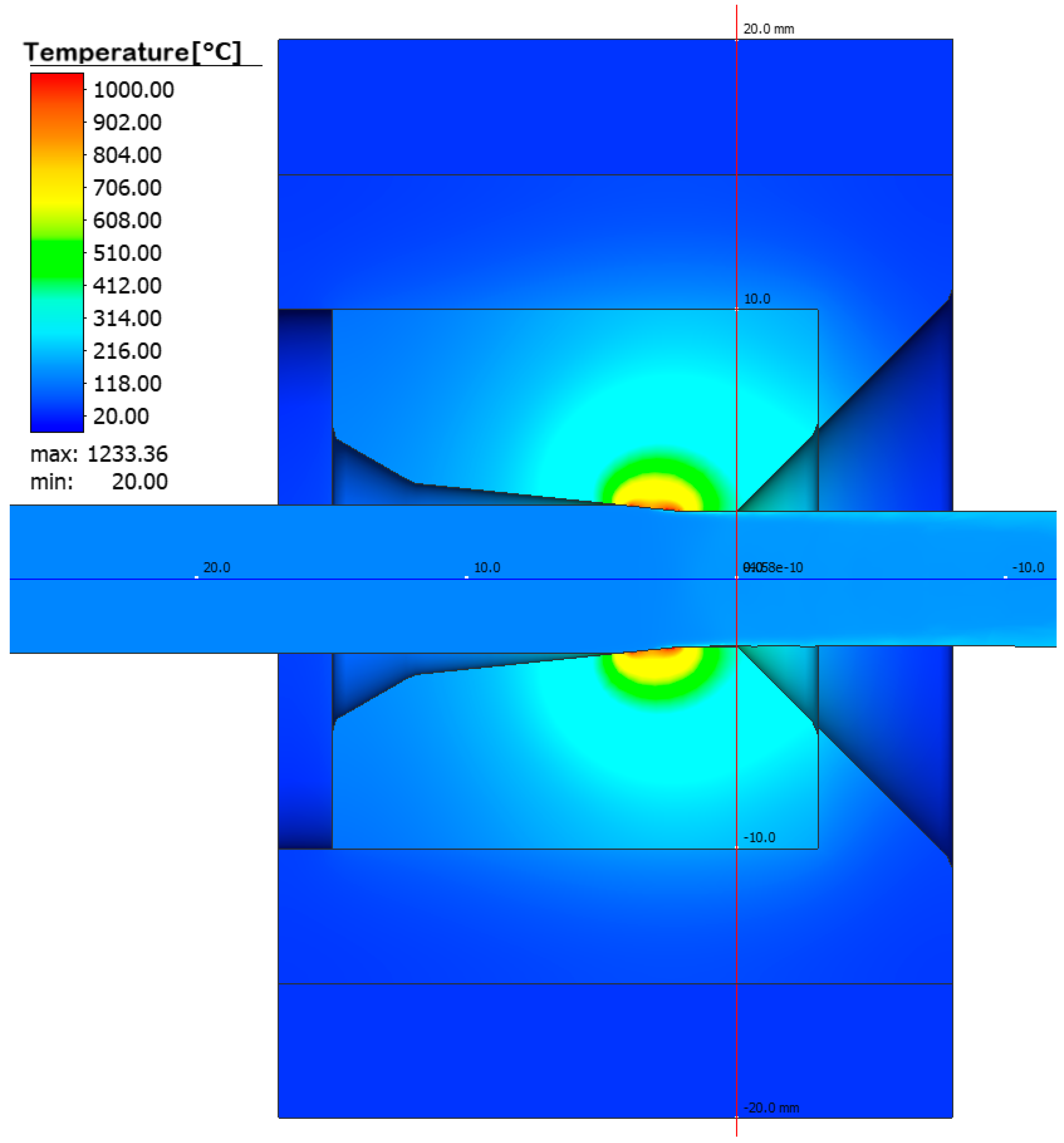

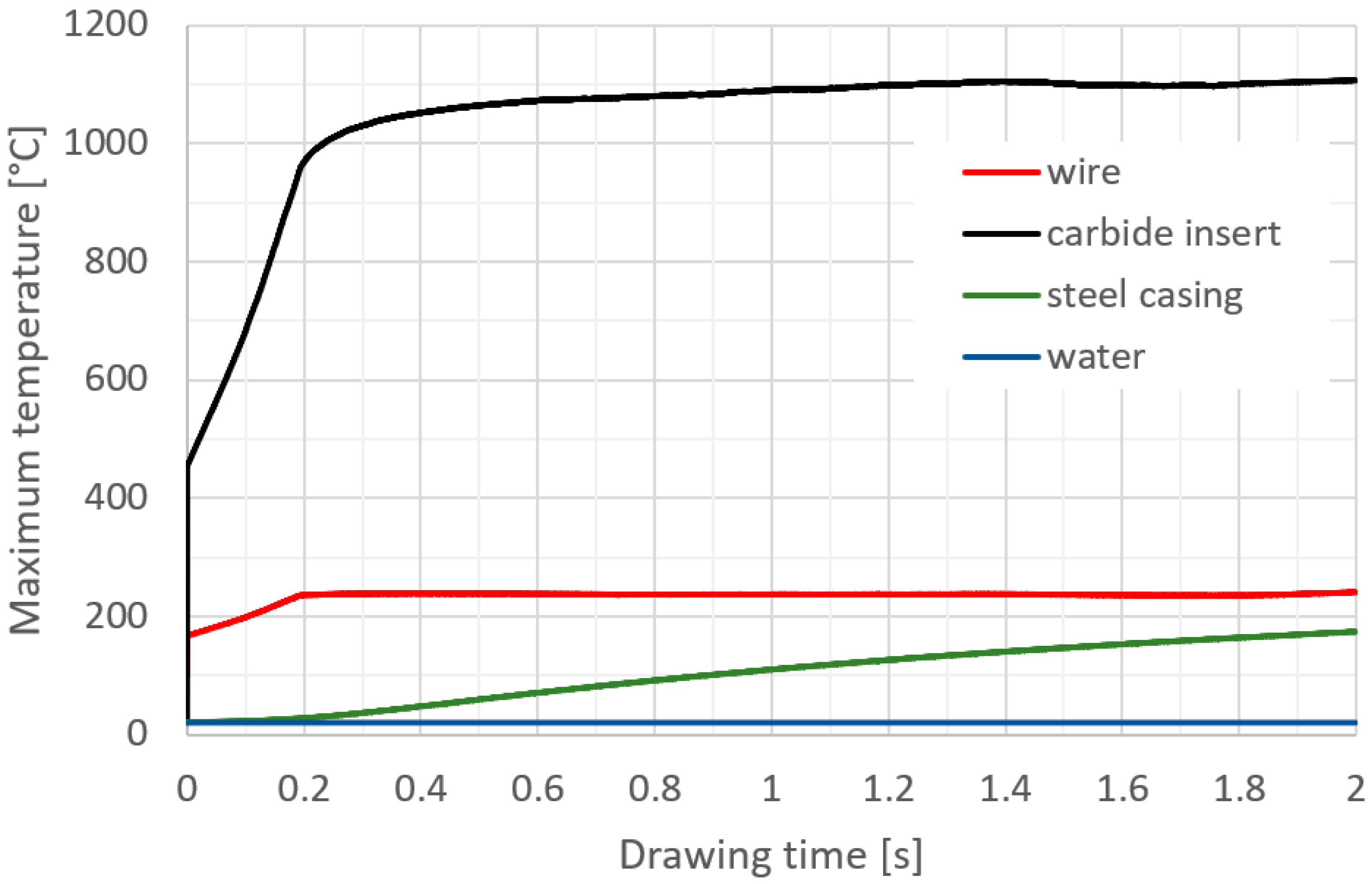

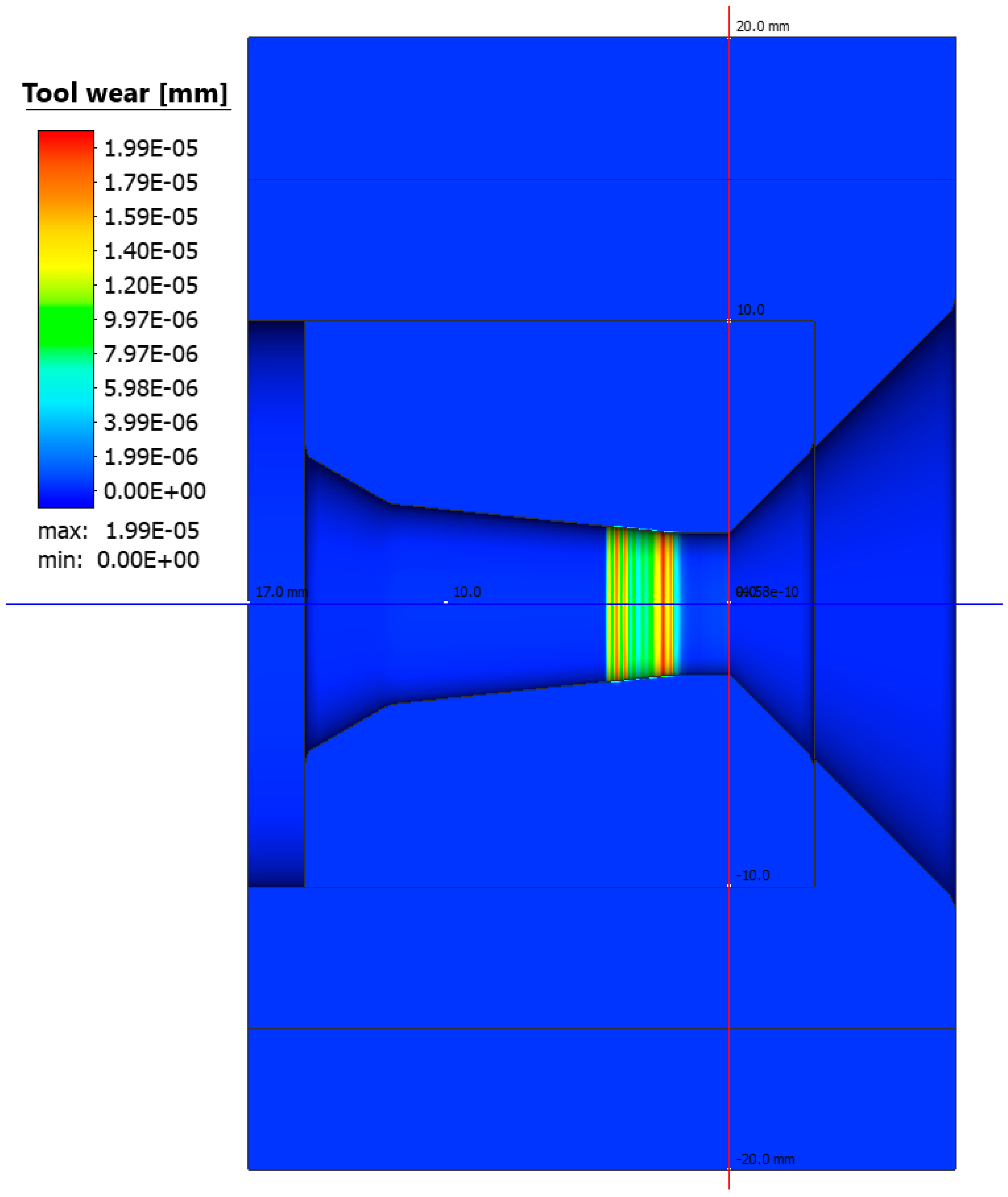

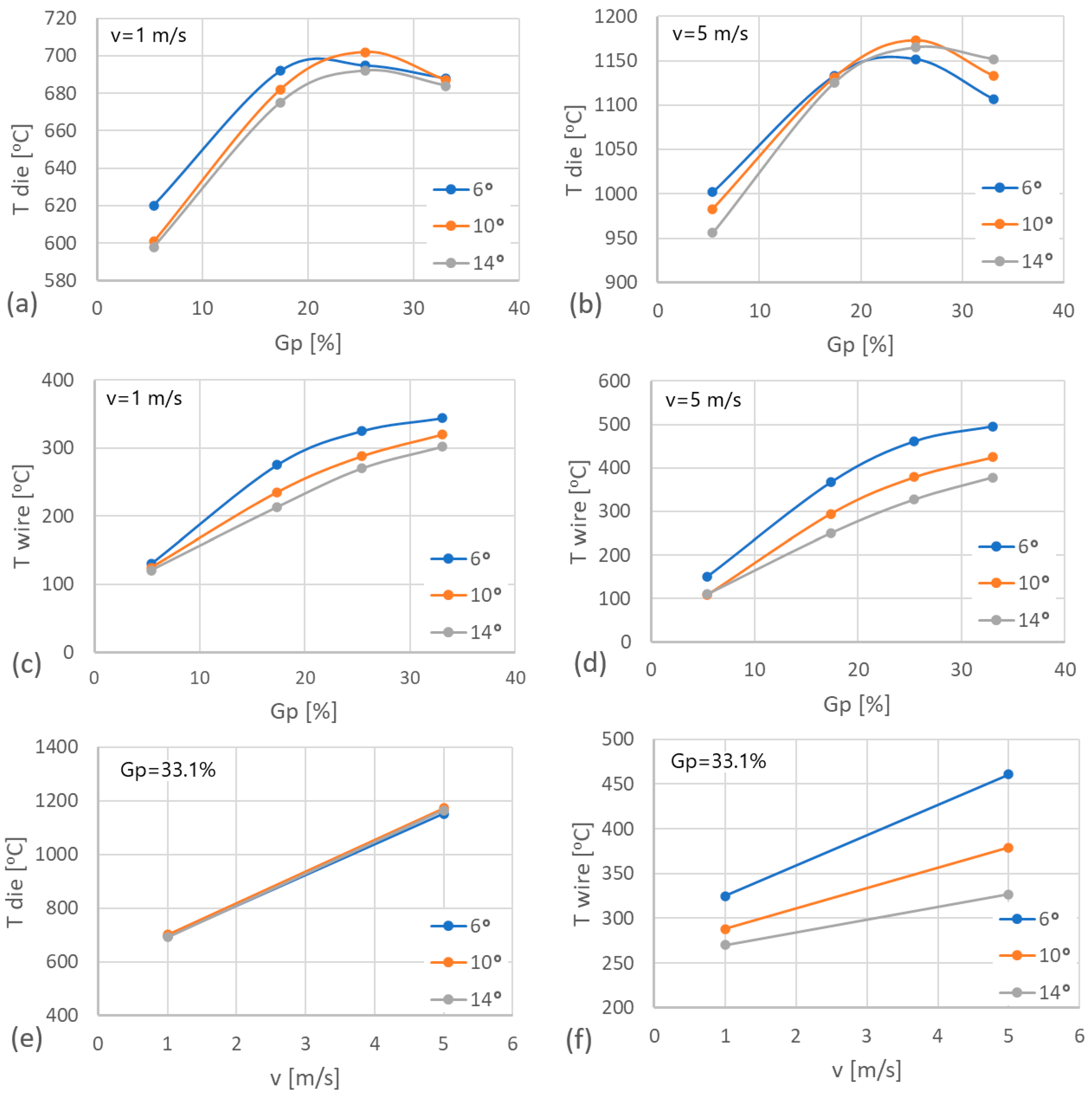

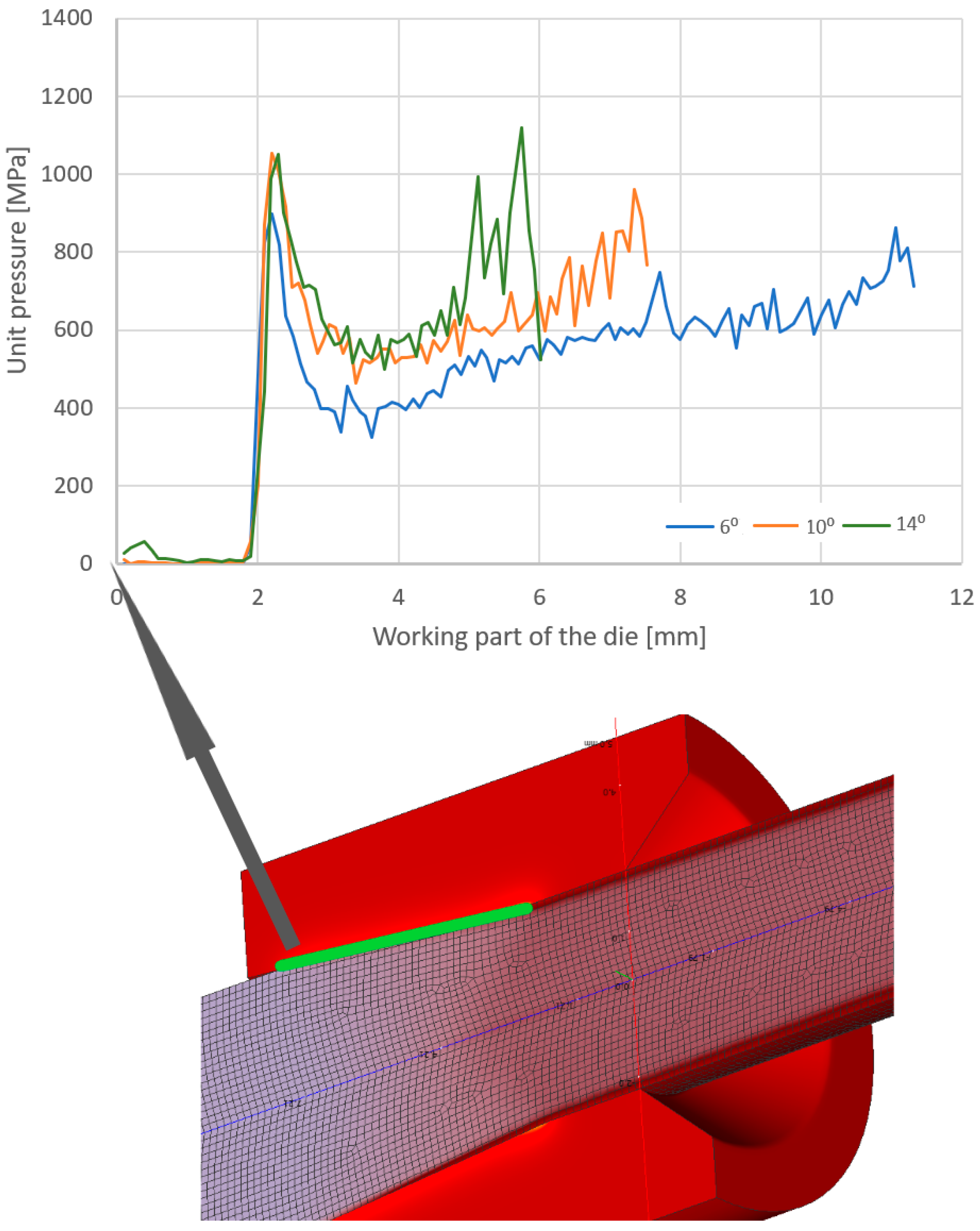

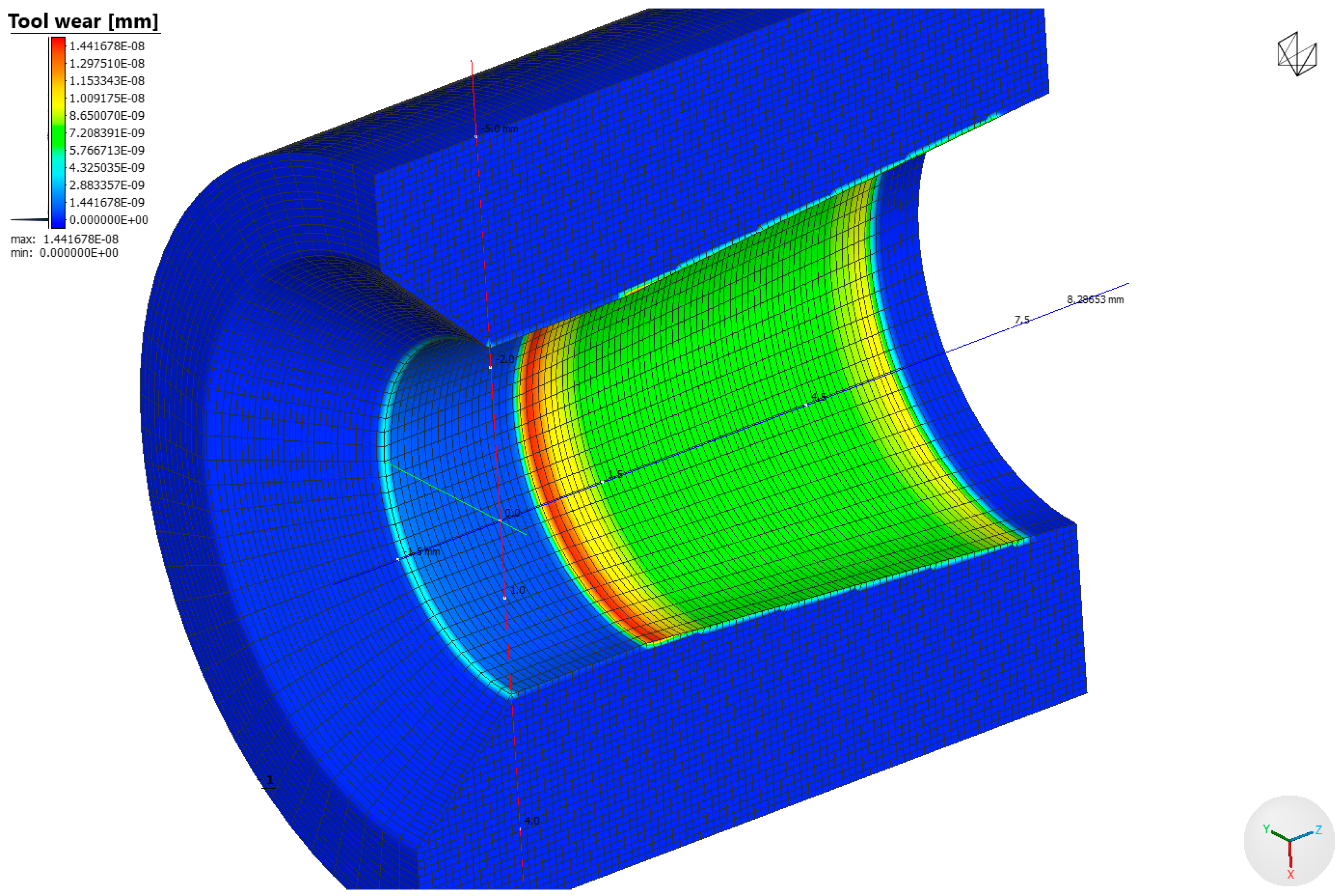

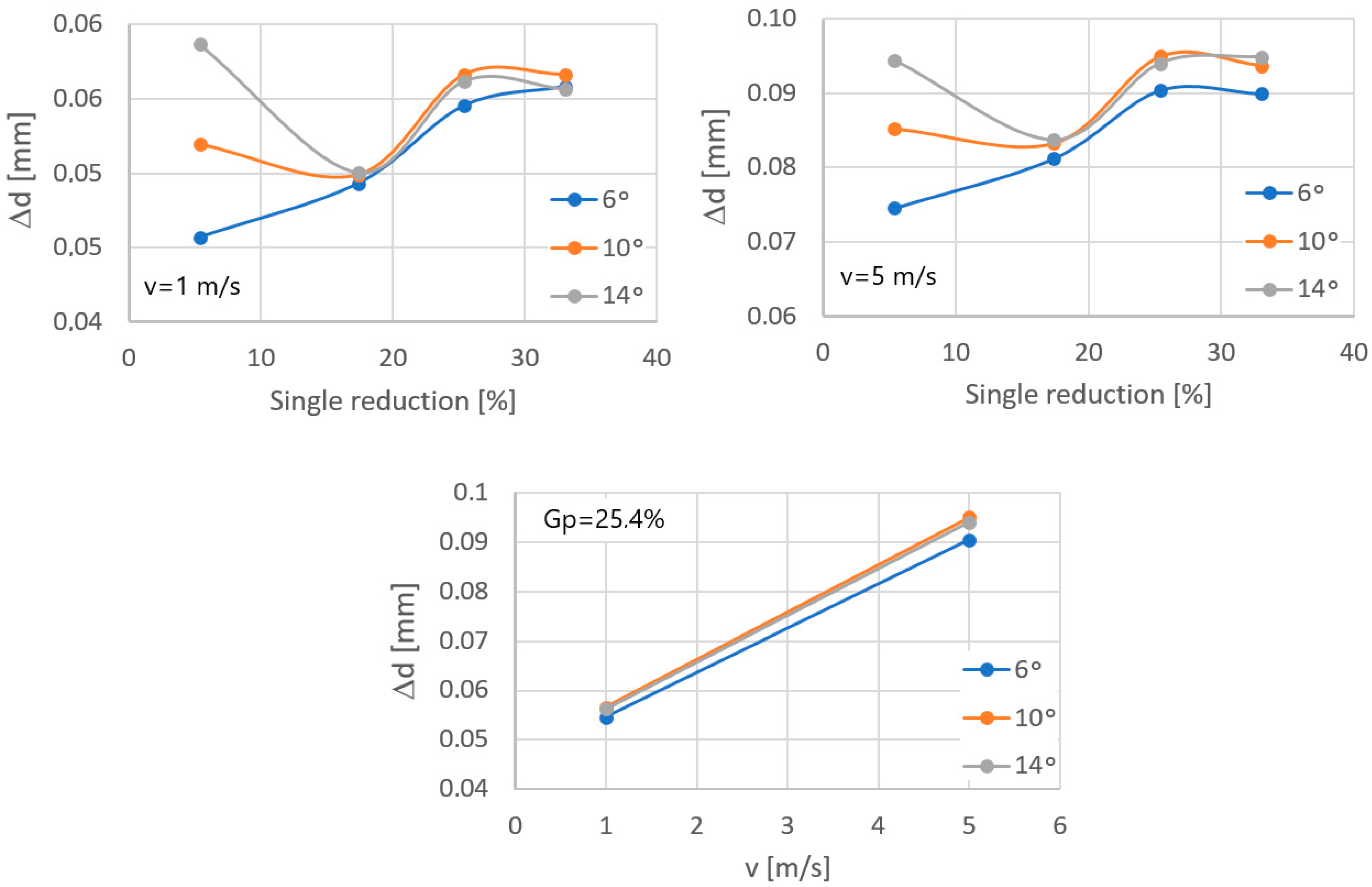

3.1. Numerical Analysis of the Drawing Process

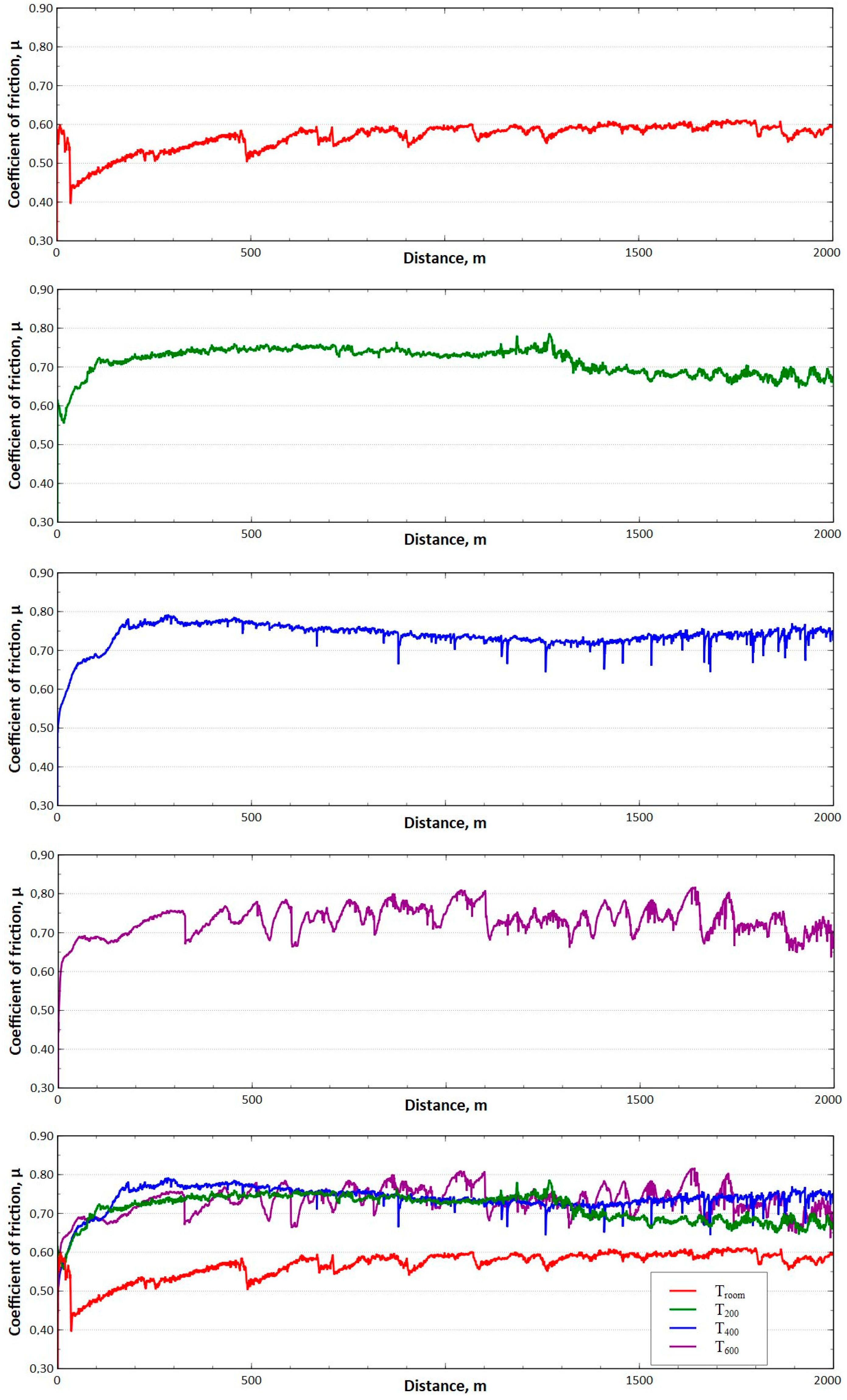

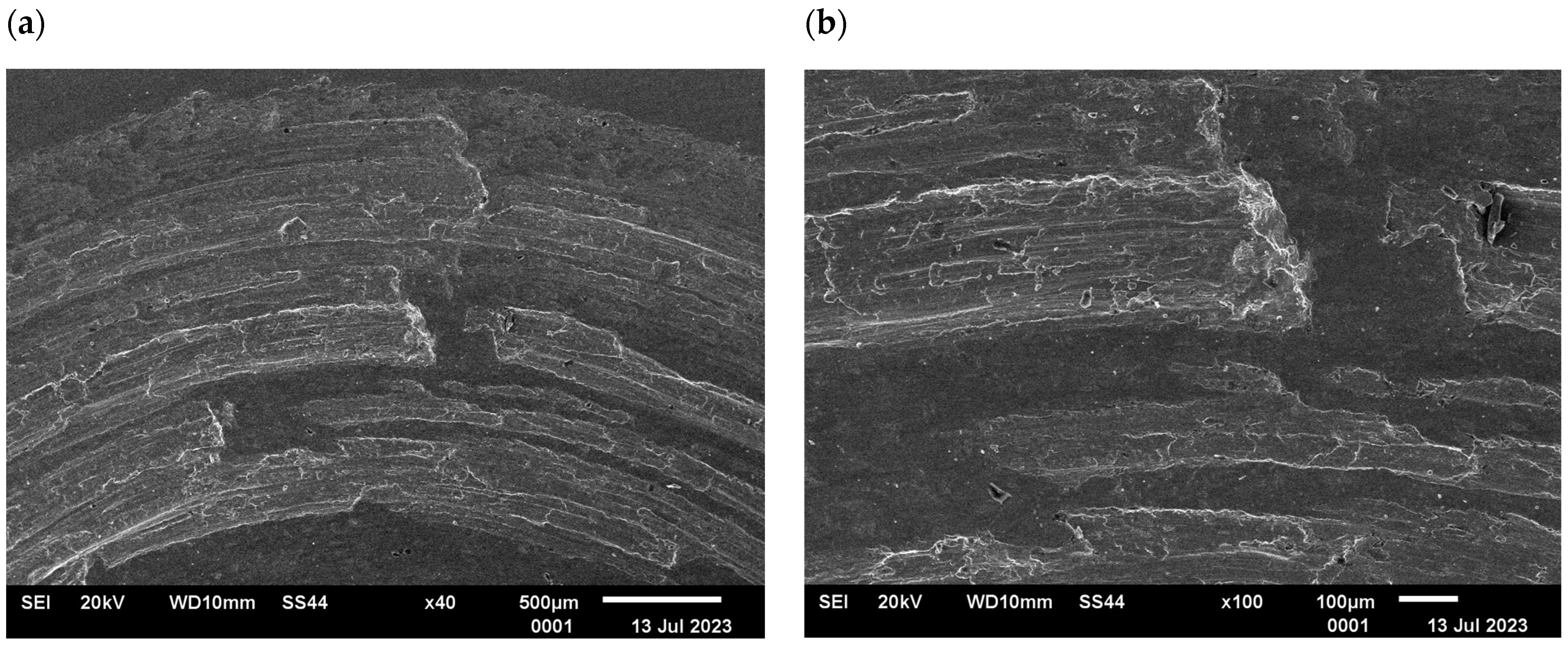

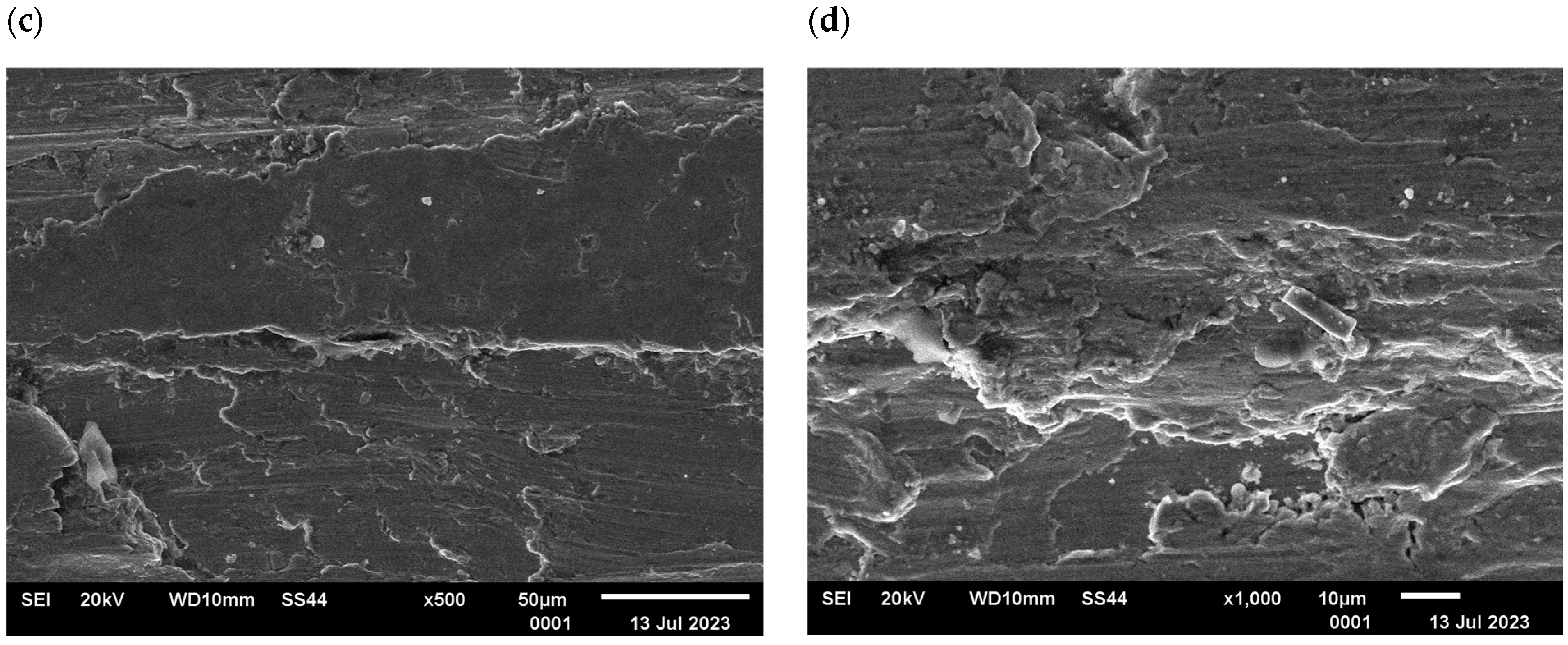

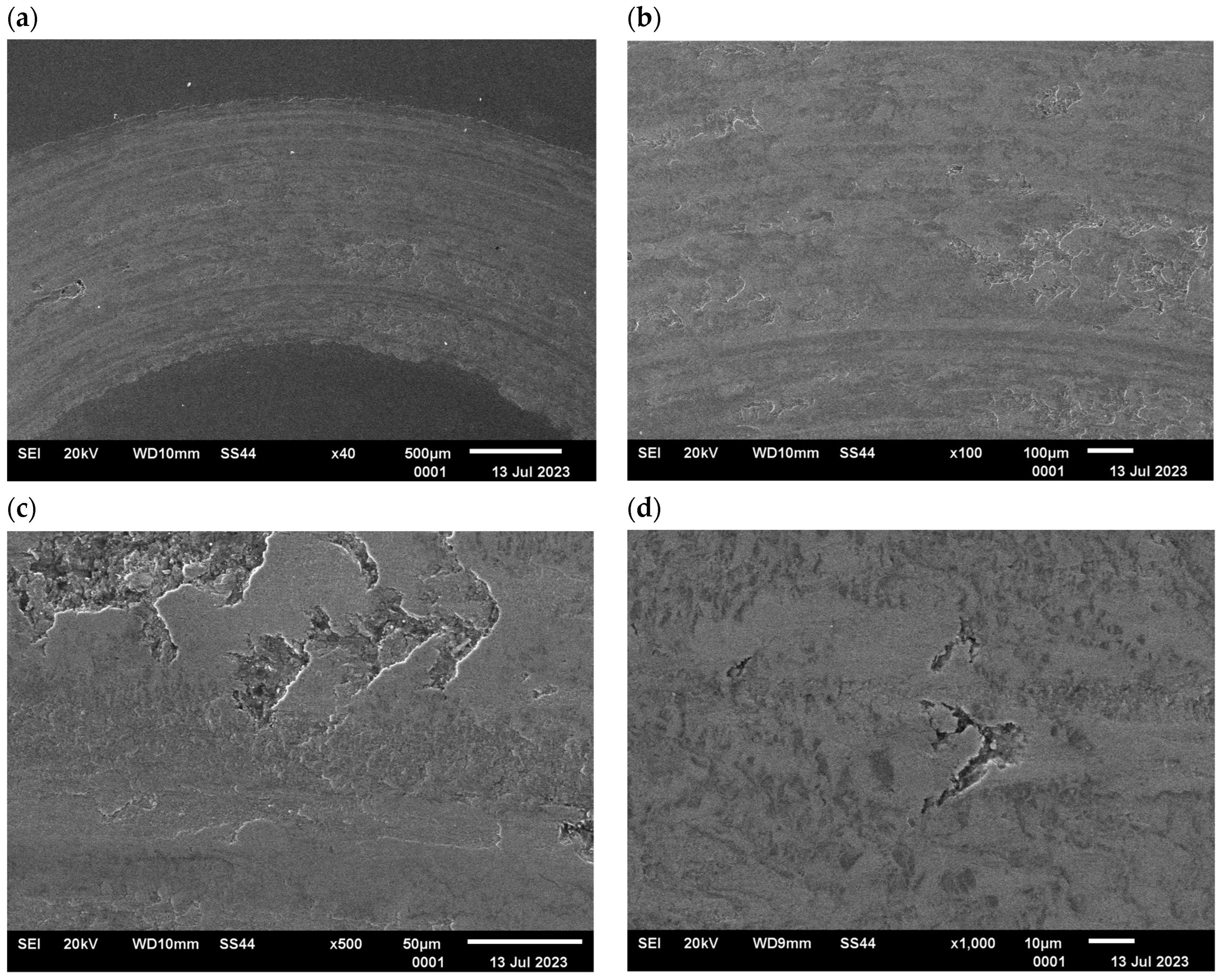

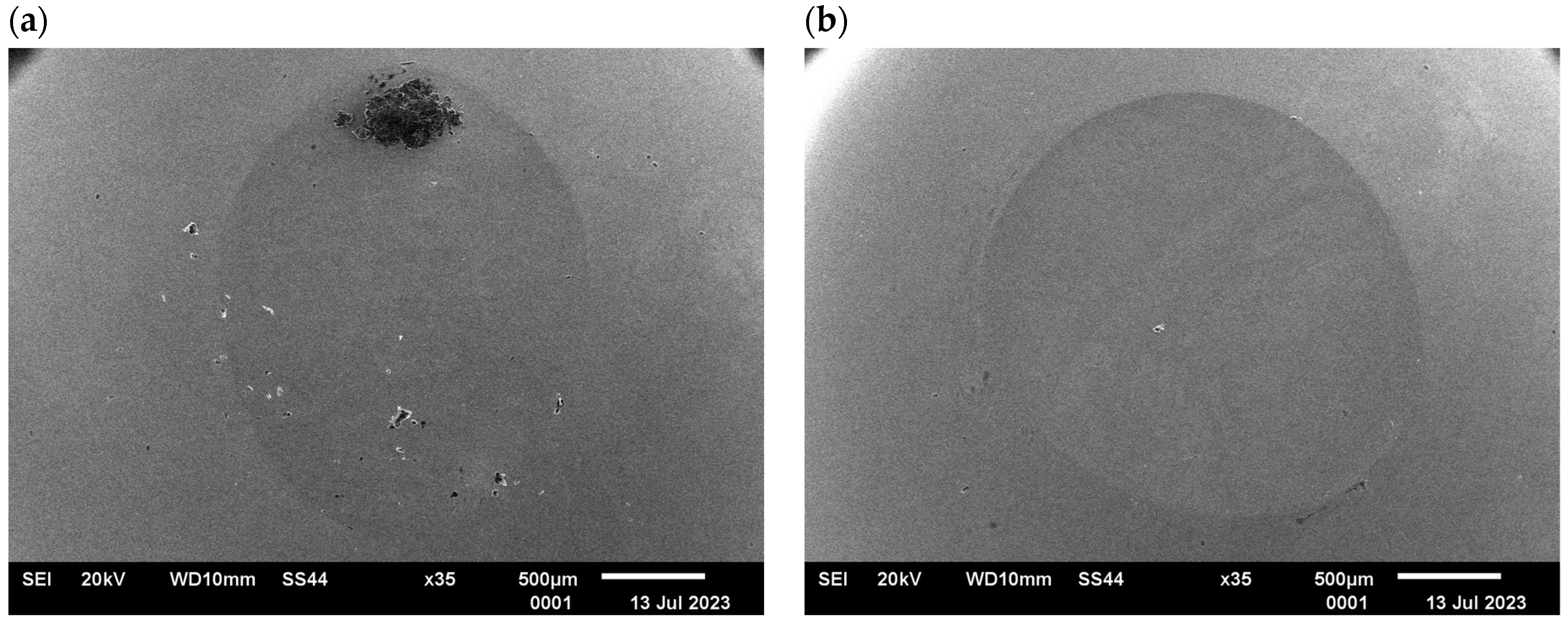

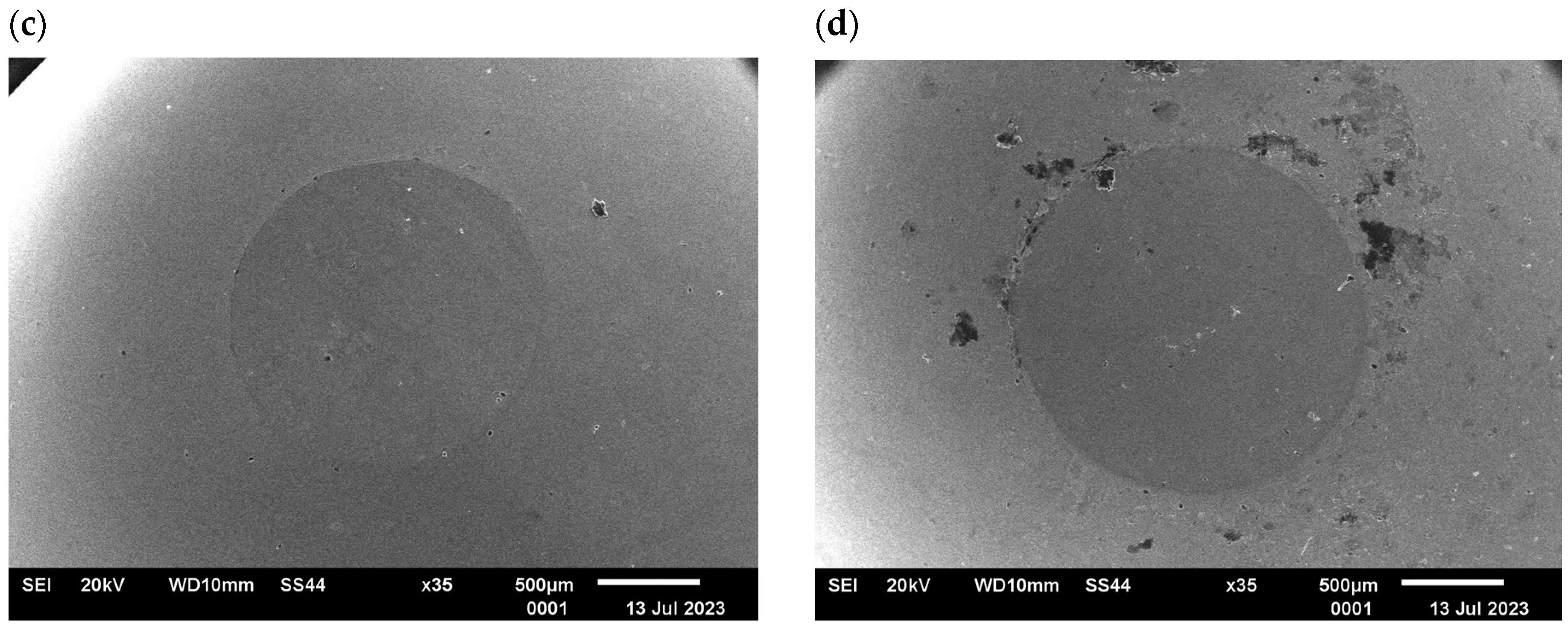

3.2. Results of Tribological Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Enghag, P. Steel Wire Technology; Materialteknik HB: Orebro, Sweden, 2002. [Google Scholar]

- Wright, R.N. Wire Technology. Process Engineering and Metallurgy; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Pirso, J.; Viljus, M.; Juhani, K.; Kuningas, M. Three-body abrasive wear of TiC-NiMo cermets. Tribol. Int. 2010, 43, 340–346. [Google Scholar] [CrossRef]

- Klaasen, H.; Kübarsepp, J. Abrasive wear performance of carbide composites. Wear 2006, 261, 520–526. [Google Scholar] [CrossRef]

- Bonny, K.; De Baets, P.; Vleugels, J.; Huang, S.; Van der Biest, O.; Lauwers, B. Impact of Cr3C2/VC addition on the dry sliding friction and wear response of WC-Co cemented carbides. Wear 2009, 267, 1642–1652. [Google Scholar] [CrossRef]

- Hollinger, S.; Georges, J.M.; Mazuyer, D.; Lorentz, G.; Aguerre, O.; Du, N. High-pressure lubrication with lamellar structures in aqueous lubricant. Tribol. Lett. 2001, 9, 143–151. [Google Scholar] [CrossRef]

- Suliga, M.; Wartacz, R.; Hawryluk, M. The Multi-Stage Drawing Process of Zinc-Coated Medium-Carbon Steel Wires in Conventional and Hydrodynamic Dies. Materials 2020, 13, 4871. [Google Scholar] [CrossRef] [PubMed]

- Sas-Boca, I.M.; Tintelecan, M.; Pop, M.; Iluţiu-Varvara, D.A. Severe reduction in section of copper wire using the technology of wire cold cassette roller dies. Procedia Manuf. 2018, 22, 73–78. [Google Scholar] [CrossRef]

- El Amine, K.; Larsson, J.; Pejryd, L. Experimental comparison of roller die and conventional wire drawing. J. Mater. Process. Technol. 2018, 257, 7–14. [Google Scholar] [CrossRef]

- Gillström, P.; Jarl, M. Mechanical descaling of wire rod using reverse bending and brushing. J. Mater. Process. Technol. 2006, 172, 332–340. [Google Scholar] [CrossRef]

- Smolarczyk, Z. Effect of descaling methods of wire rod on surface texture of drawn wires. Wire J. Int. 2001, 34, 76–81. [Google Scholar]

- Oehr, K.H.; Roth, R.C.A. Cleaning steel wire without acid. Wire J. Int. 1996, 29, 100–103. [Google Scholar]

- Lee, S.K.; Ko, D.C.; Kim, B.M. Pass schedule of wire drawing process to prevent delamination for high strength steel cord wire. Mater. Des. 2009, 30, 2919–2927. [Google Scholar] [CrossRef]

- Lee, S.K.; Lee, S.B.; Kim, B.M. Process design of multi-stage wet wire drawing for improving the drawing speed for 0.72 wt% C steel wire. J. Mater. Process. Technol. 2010, 210, 776–783. [Google Scholar] [CrossRef]

- Verma, S.; Sudhakar Rao, P. Design and analysis of process parameters on multistage wire drawing process—A review. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 9, 403–412. [Google Scholar] [CrossRef]

- Wright, R.N. Physical conditions in the lubricant layer. Proc. Annu. Conv. Wire Assoc. Int. 1996, 30, 145–149. [Google Scholar]

- Saied, E.K.; Elzeiny, N.I.; Elmetwally, H.T.; Abd-Eltwab, A.A. An experimental study of lubricant effect on wire drawing process. Int. J. Adv. Sci. Technol. 2020, 29, 560–568. [Google Scholar]

- Suliga, M. Analysis of the heating of steel wires during high speed multipass drawing process. Arch. Metall. Mater. 2014, 59, 1475–1480. [Google Scholar] [CrossRef]

- Hollinger, S.; Depraetere, E.; Giroux, O. Wear mechanism of tungsten carbide dies during wet drawing of steel tyre cords. Wear 2003, 255, 1291–1299. [Google Scholar] [CrossRef]

- Gillström, P.; Jarl, M. Wear of die after drawing of pickled or reverse bent wire rod. Wear 2007, 262, 858–867. [Google Scholar] [CrossRef]

- Nowotyńska, I.; Kut, S. The influence of die shape and back tension force on its wear in the process of wire drawing. Arch. Metall. Mater. 2019, 64, 1131–1137. [Google Scholar] [CrossRef]

- Stoyanov, P.; Romero, P.A.; Järvi, T.T.; Pastewka, L.; Scherge, M.; Stemmer, P.; Fischer, A.; Dienwiebel, M.; Moseler, M. Experimental and numerical atomistic investigation of the third body formation process in dry tungsten/tungsten-carbide tribo couples. Tribol. Lett. 2013, 50, 67–80. [Google Scholar] [CrossRef]

- Stoyanov, P.; Stemmer, P.; Järvi, T.T.; Merz, R.; Romero, P.A.; Scherge, M.; Kopnarski, M.; Moseler, M.; Fischer, A.; Dienwiebel, M. Friction and wear mechanisms of tungsten-carbon systems: A comparison of dry and lubricated conditions. ACS Appl. Mater. Interfaces 2013, 5, 6123–6135. [Google Scholar] [CrossRef] [PubMed]

- Magazzù, A.; Marcuello, C. Investigation of Soft Matter Nanomechanics by Atomic Force Microscopy and Optical Tweezers: A Comprehensive Review. Nanomaterials 2023, 13, 963. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Singh, S.; Aggarwal, V.; Singh, S.; Pimenov, D.Y.; Giasin, K.; Nadolny, K. Hand and Abrasive Flow Polished Tungsten Carbide Die: Optimization of Surface Roughness, Polishing Time and Comparative Analysis in Wire Drawing. Materials 2022, 15, 1287. [Google Scholar] [CrossRef] [PubMed]

- Dobrzański, L.A. Podstawy Nauki o Materiałach; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2012. [Google Scholar]

| Coefficient Values | |||||||

|---|---|---|---|---|---|---|---|

| C1 | C2 | m1 | m2 | l1 | l2 | n1 | n2 |

| 692.2 | −0.00064 | 0.000028 | 0.000709 | −0.0000473 | −0.01224 | −0.00031 | 0.162026 |

| Parameter | Variant I | Variant II | Variant III | Variant IV |

|---|---|---|---|---|

| Counter-sample | WC | |||

| Sampling frequency | 60 Hz | |||

| Abrasion radius | 3 mm | |||

| Load | 20 N | |||

| Linear velocity | 50 cm/s | |||

| Friction path | 13,000 m | |||

| Time | 26,000 s | |||

| Process temperature | ambient | 200 °C | 400 °C | 600 °C |

| Material | Mean Friction Coefficient | Mass Loss/Gain, g | ||

|---|---|---|---|---|

| Mean Friction Coefficient | Standard Deviation | Samples | Counter-Samples | |

| Variant I | 0.5642 | 0.0282 | 0.0141 | 0.0027 |

| Variant II | 0.5466 | 0.1101 | 0.0115 | 0.0041 |

| Variant III | 0.6729 | 0.0541 | +0.0051 | 0.0013 |

| Variant IV | 0.7572 | 0.0542 | +0.0372 | 0.0020 |

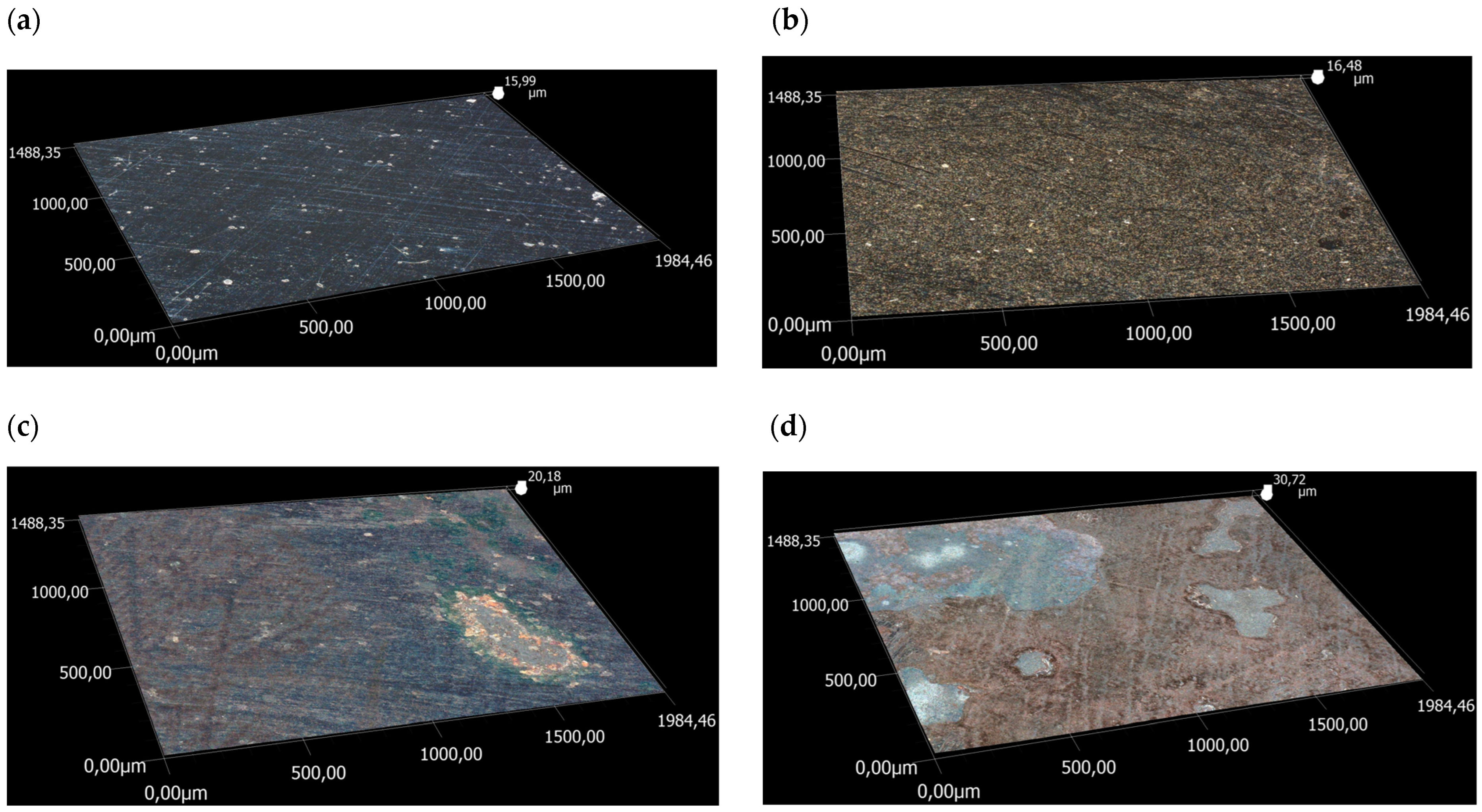

| Variant I | Variant II | Variant III | Variant IV | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel | Ball | Steel | Ball | Steel | Ball | Steel | Ball | ||||

| W, μm | D, μm | D, μm | W, μm | D, μm | D, μm | W, μm | D, μm | D, μm | W, μm | D, μm | D, μm |

| 2215 | 103 | 2249 | 2193 | 168 | 2197 | 1499 | 27 | 1498 | 1708 | 100 | 1716 |

| Parameter | Variant I | Variant II | Variant III | Variant IV |

|---|---|---|---|---|

| Sa, μm | 2.49 | 3.40 | 3.21 | 3.91 |

| Sq, μm | 13.03 | 3.99 | 3.89 | 4.81 |

| Sz, μm | 15.96 | 16.41 | 19.89 | 30.72 |

| Sp, μm | 5.82 | 6.20 | 8.66 | 18.85 |

| Sv, μm | 10.14 | 10.21 | 11.24 | 11.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suliga, M.; Szota, P.; Gwoździk, M.; Kulasa, J.; Brudny, A. The Influence of Temperature in the Wire Drawing Process on the Wear of Drawing Dies. Materials 2024, 17, 4949. https://doi.org/10.3390/ma17204949

Suliga M, Szota P, Gwoździk M, Kulasa J, Brudny A. The Influence of Temperature in the Wire Drawing Process on the Wear of Drawing Dies. Materials. 2024; 17(20):4949. https://doi.org/10.3390/ma17204949

Chicago/Turabian StyleSuliga, Maciej, Piotr Szota, Monika Gwoździk, Joanna Kulasa, and Anna Brudny. 2024. "The Influence of Temperature in the Wire Drawing Process on the Wear of Drawing Dies" Materials 17, no. 20: 4949. https://doi.org/10.3390/ma17204949

APA StyleSuliga, M., Szota, P., Gwoździk, M., Kulasa, J., & Brudny, A. (2024). The Influence of Temperature in the Wire Drawing Process on the Wear of Drawing Dies. Materials, 17(20), 4949. https://doi.org/10.3390/ma17204949