Estimation of Quality of Seam Welds in AlMgSi(Cu) Extrusion by Using an Original Device for Weldability Testing

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterisation of AlMgSi(Cu) Alloys

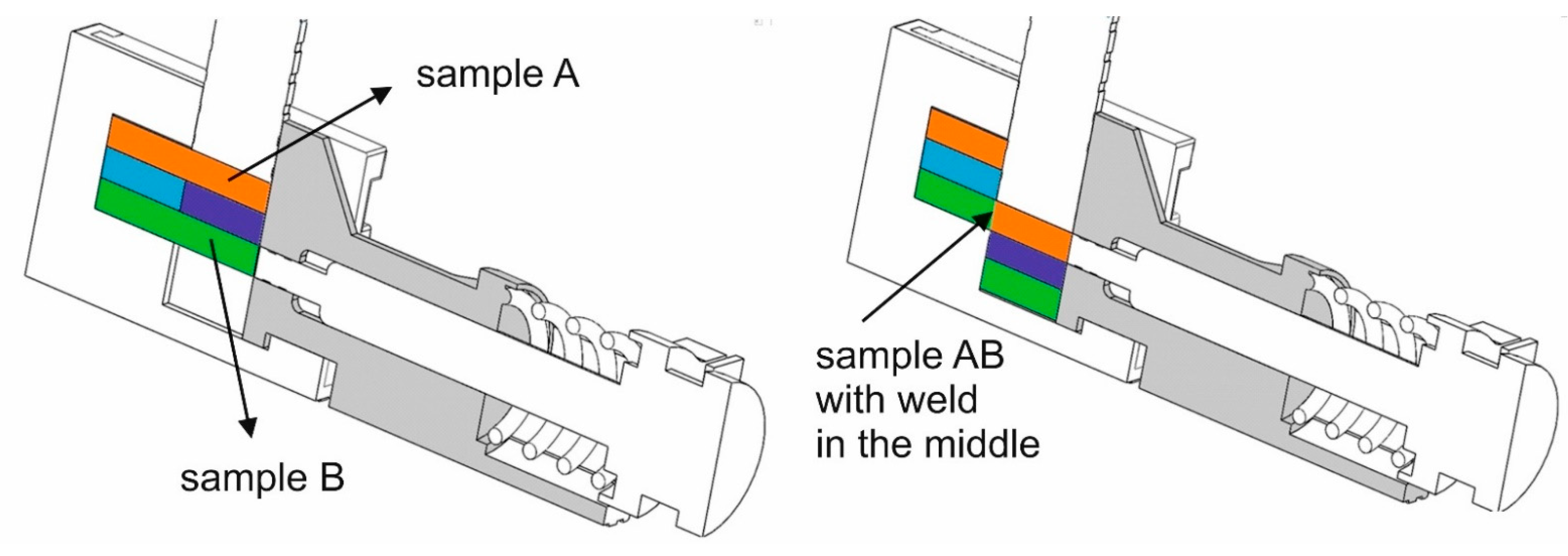

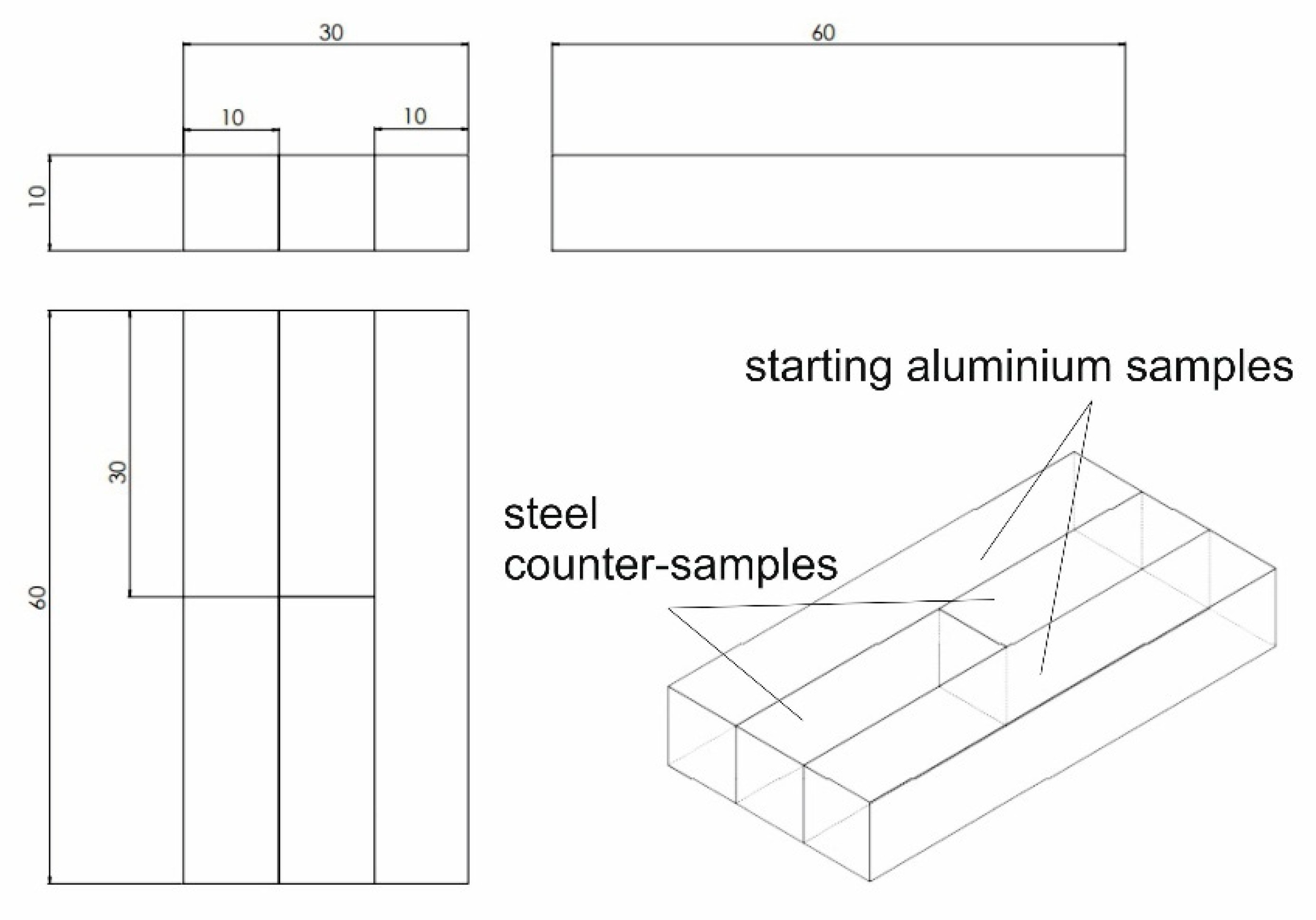

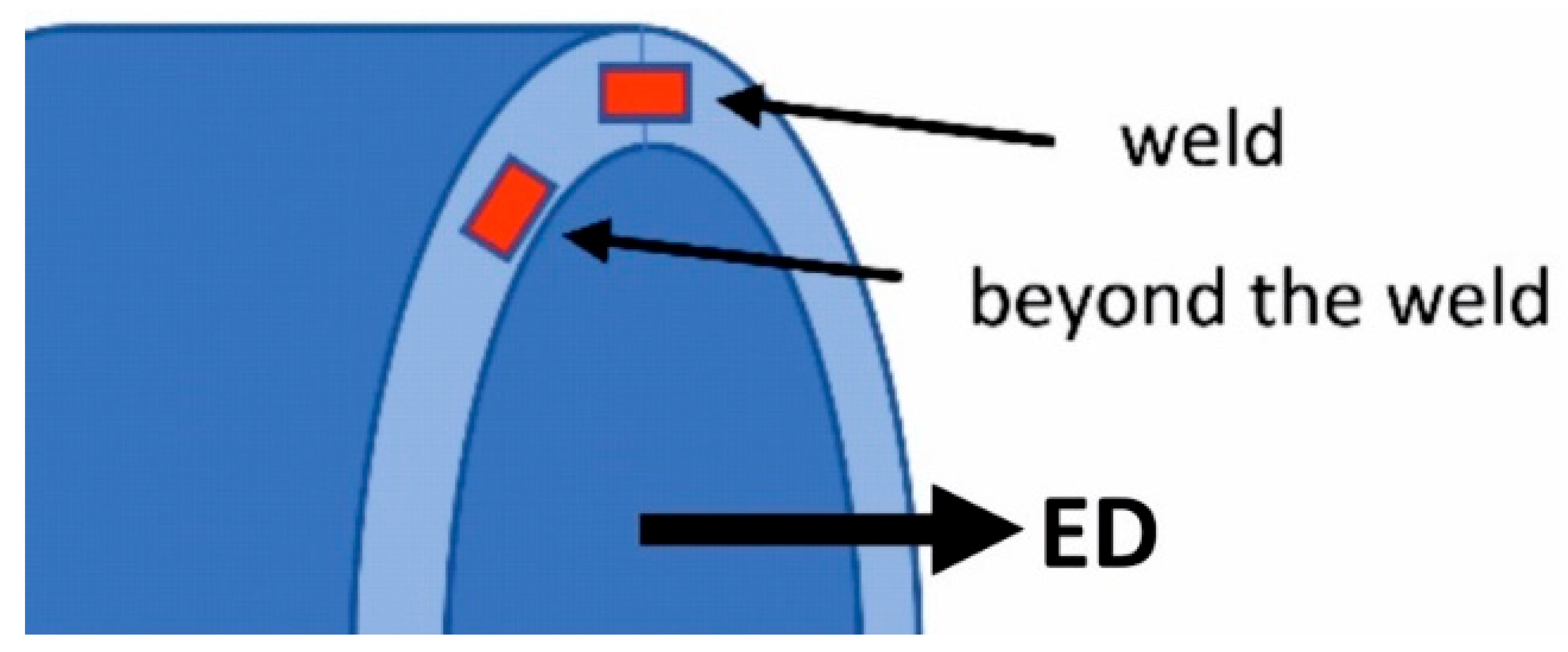

2.2. Device for Predicting the Seam Weld Quality of Extrudates

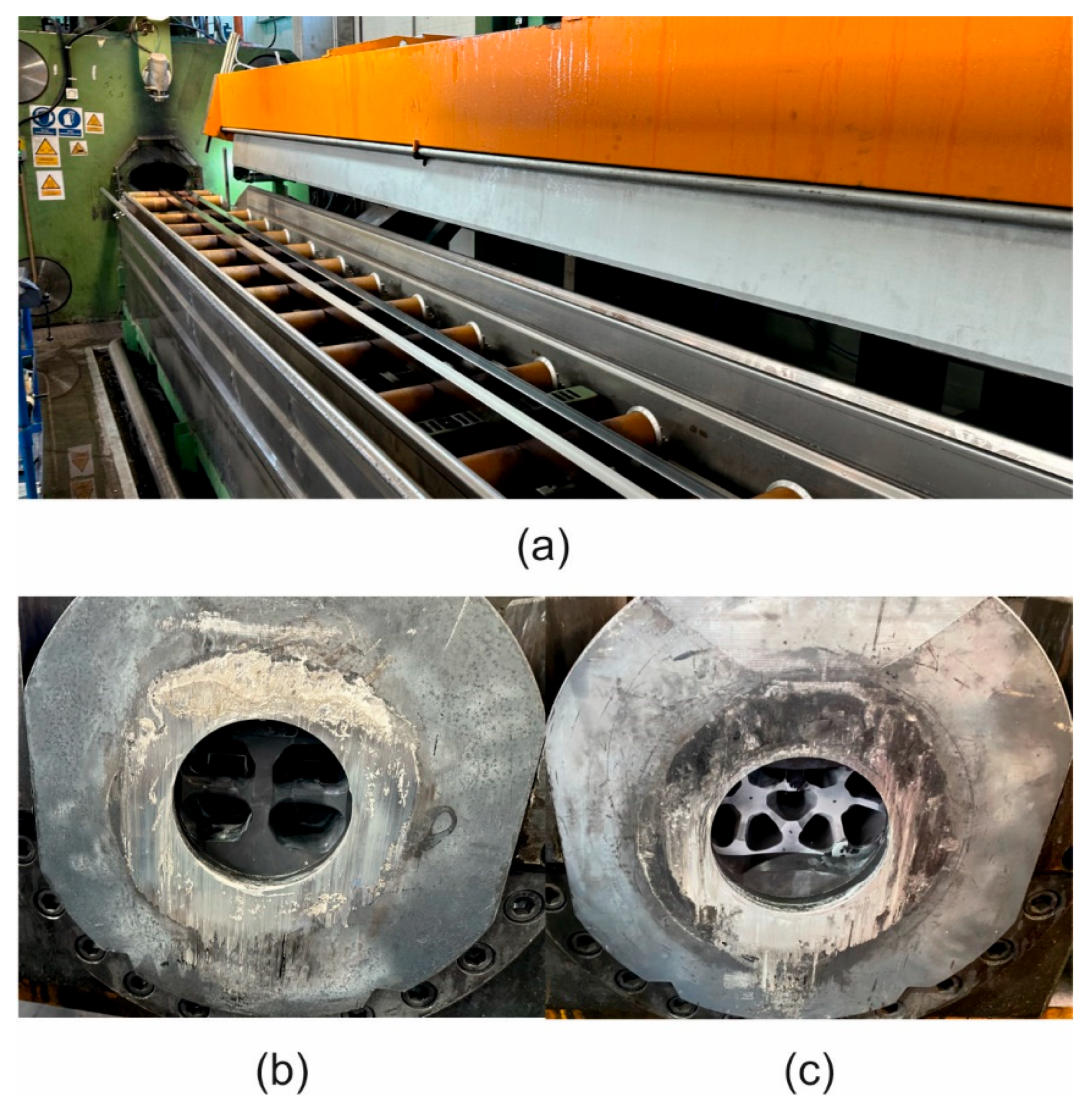

2.3. Extrusion Process

2.4. Methodology of the Microstructural and Mechanical Examination

3. Results

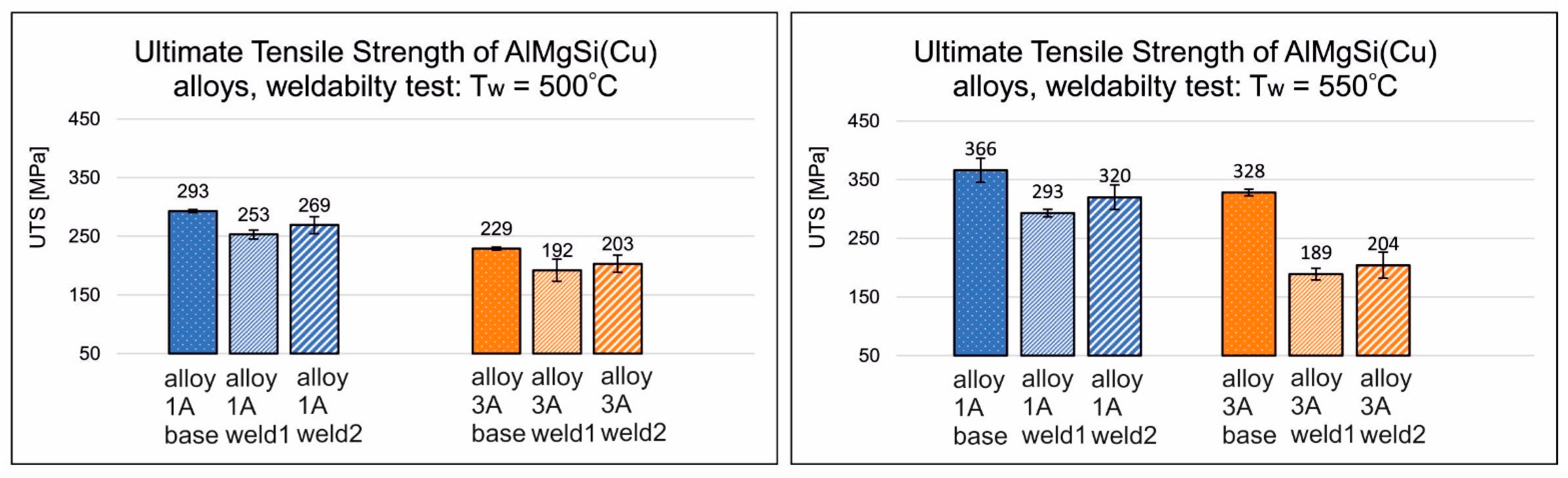

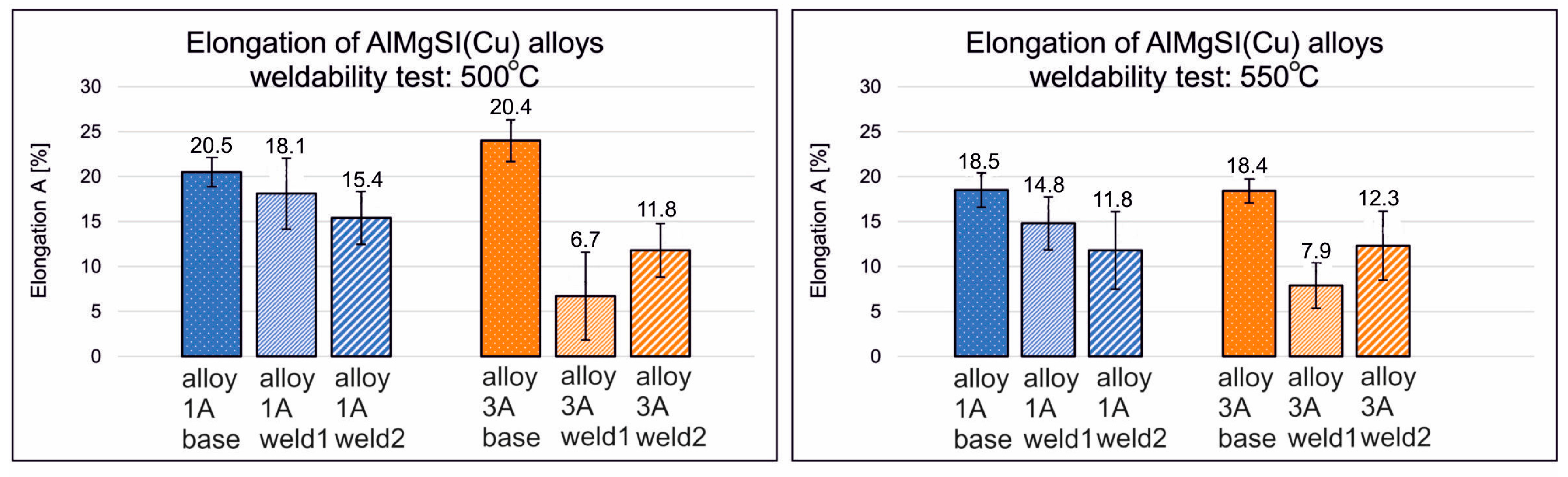

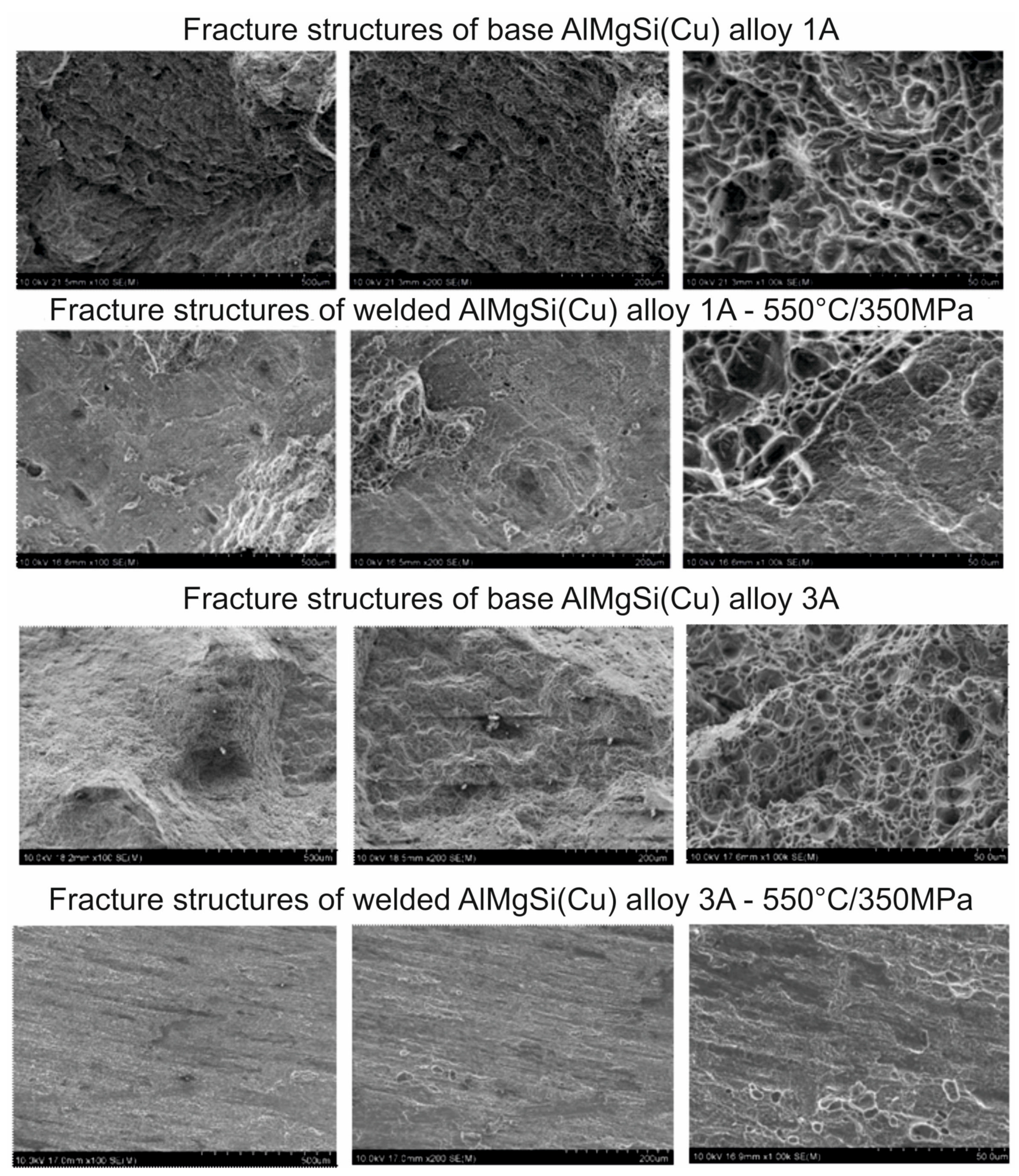

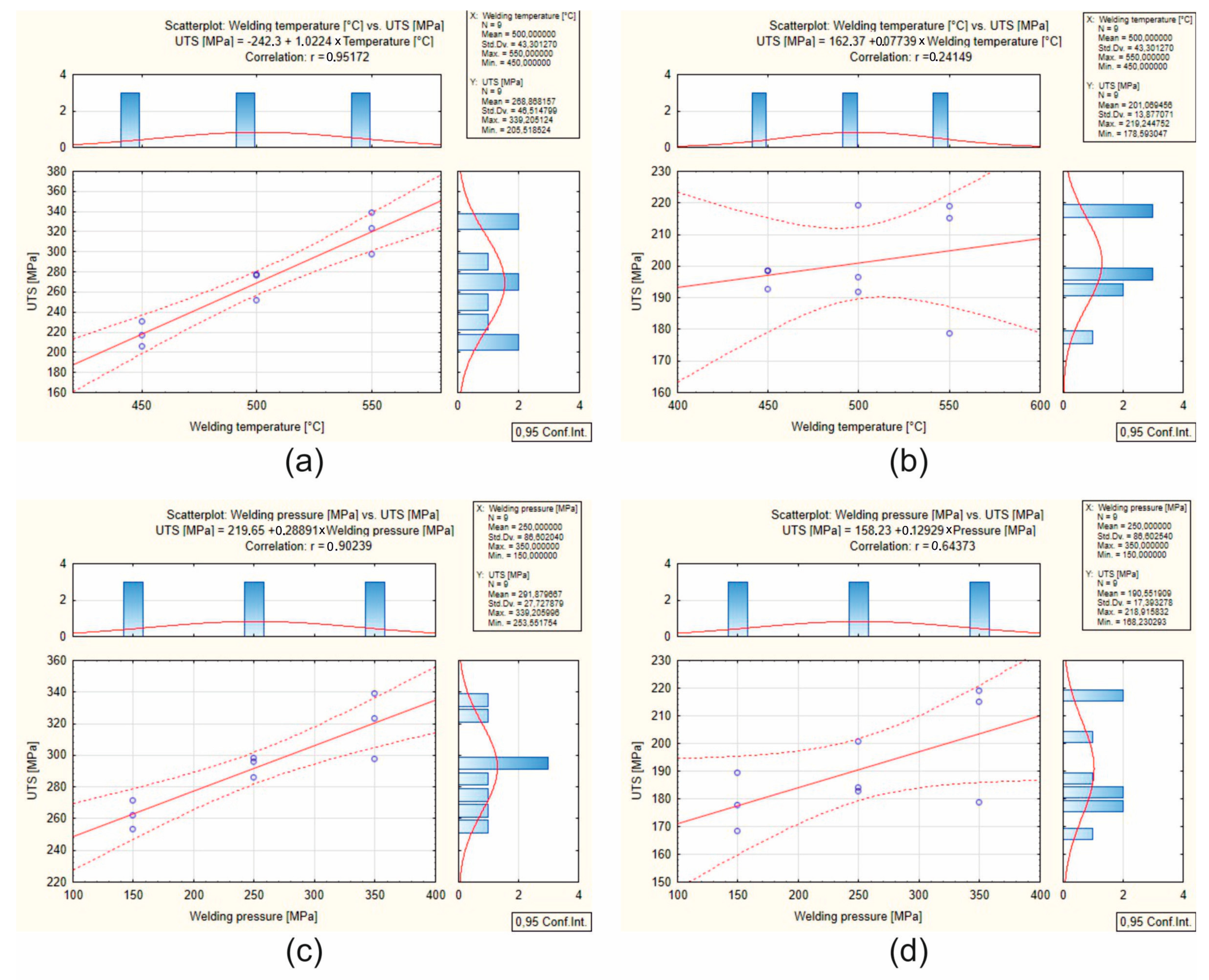

3.1. Weldability Testing

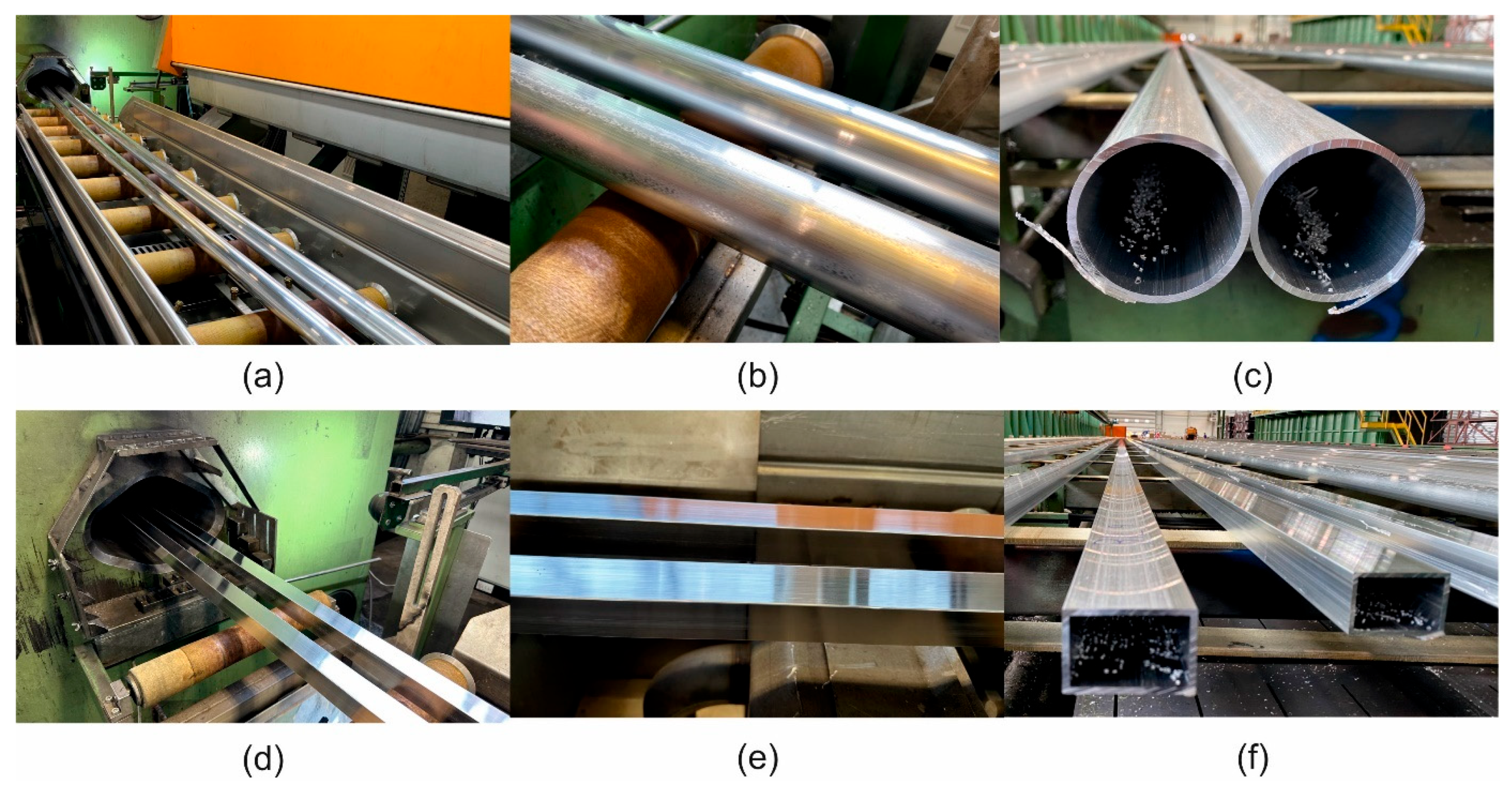

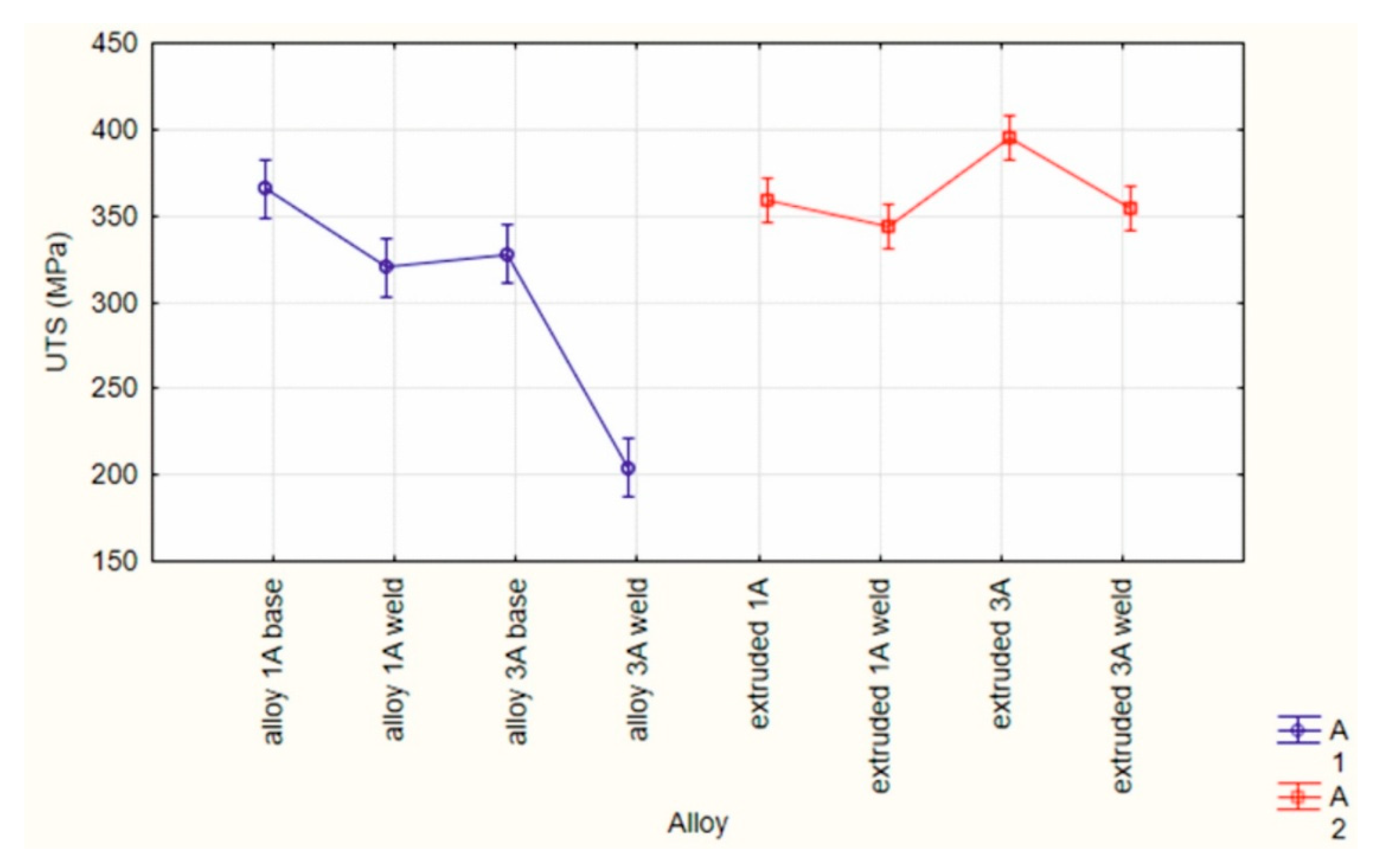

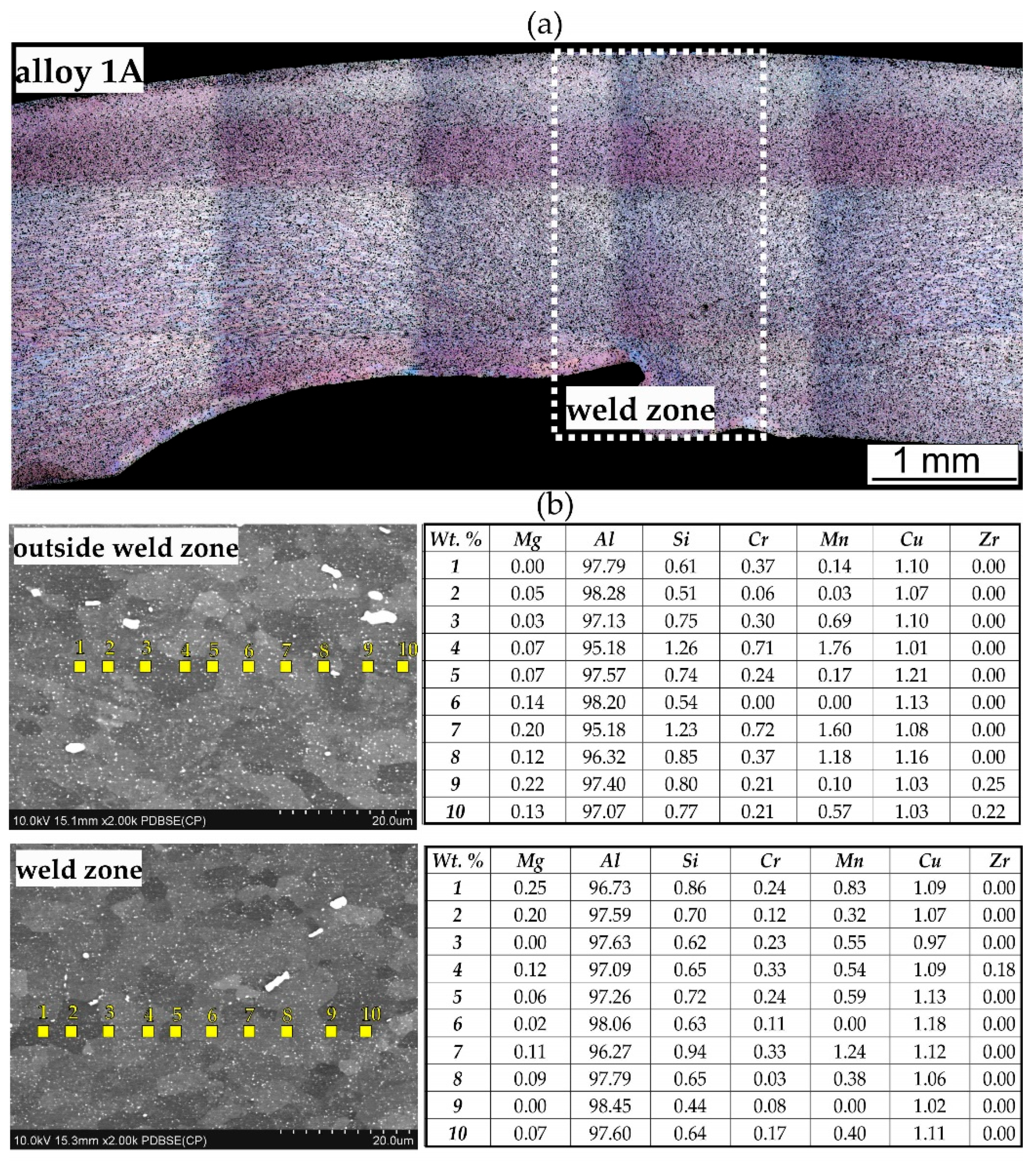

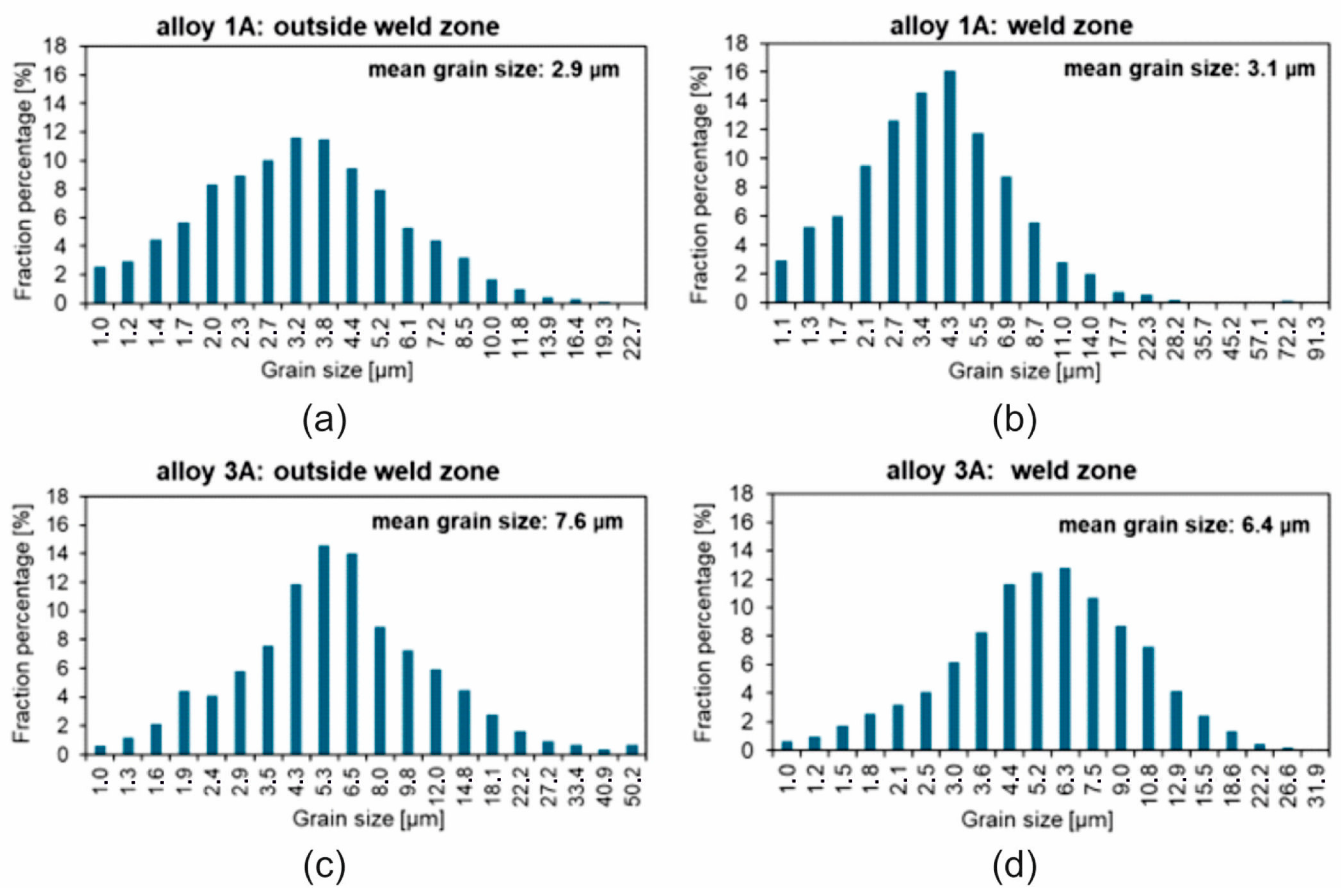

3.2. Extrusion Trials

4. Discussion

5. Conclusions

- A new original laboratory method of predicting the seam weld quality of AlMgSi(Cu) extrudates was proposed and positively verified in industrial extrusion trials. This allows the stress temperature conditions of metal welding to be modelled accurately during the extrusion of hollow sections using porthole dies. Crucially, it allows the actual conditions of metal welding to be reproduced without air, as with the welding chamber of porthole dies. This method makes it possible to determine the weldability of a metal during extrusion by determining the so-called relative weld strength, i.e., the strength of a welded sample relative to the strength of a non-welded sample of the base material. The values determined by this method for the minimum welding temperature and minimum welding stress necessary to produce a high-quality metal bond in the welding chambers of porthole dies can effectively support the design of extrusion dies using numerical FEA methods. In practice, this can mean minimisation of the number of costly attempts to implement the extrusion die in technological practice. Research revealed that this method is very rigorous for the weldability of the metal during extrusion, and the results obtained are generally somewhat underestimated, as they does not take into account the factor of pre-plasticisation of the metal in the inlet channels of the porthole die, which is beneficial for the weldability of the metal.

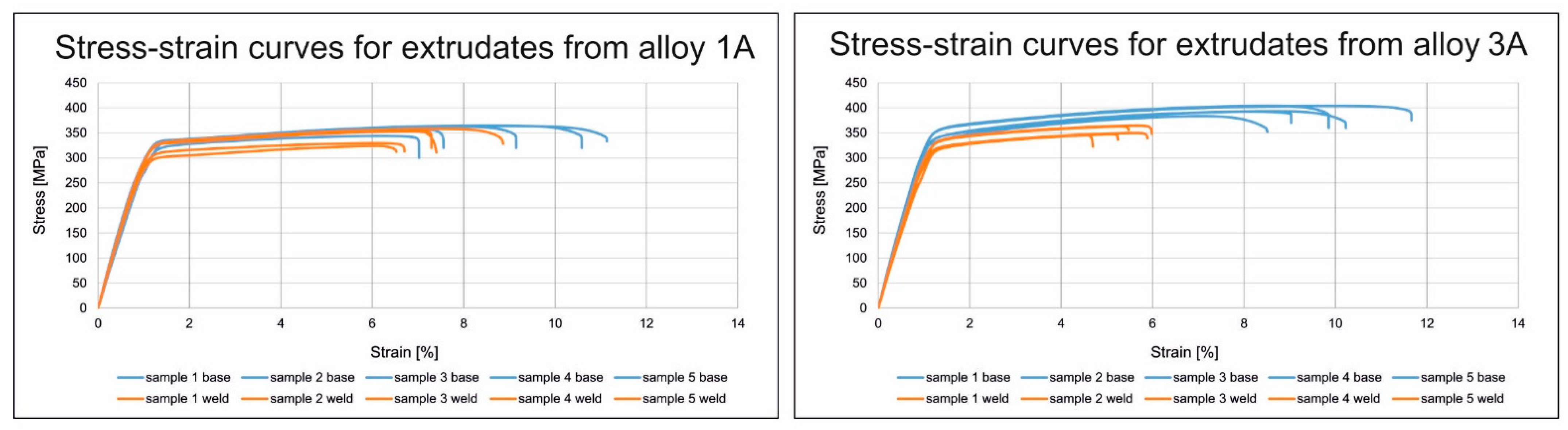

- Investigations into the material structure and mechanical properties showed that, even with a relatively high Cu content in AlMgSi alloys (above 1.2%), it is possible to obtain high-strength longitudinal welds in extruded profiles. Alloy 1A with a Cu content of 0.61% is characterised by the highest weldability during extrusion, with the relative strength of weld being at the level of 96% as a result of the fine-grained structure, which confirmed the result obtained in the weldability tests: 87% for a welding temperature of 550 °C and a unit welding pressure of 350 MPa. In the case of alloy 3A with a Cu content of 1.22%, high weldability in the extrusion process was also obtained at the level of 89% (in this case, a few larger grains were observed compared to those in alloy 1A), which may indicate the formation of a high-strength weld in the extruded product. For both alloys 1A and 3A, no significant variation in structure or chemical composition was found between the weld zone and the rest of the area, although slightly more high-angle grain boundaries were observed for alloy 3A, which may indicate the slightly lower resistance of this alloy to crack propagation, particularly under stress. In addition, high values of HAGBs for alloy 1A facilitate better strain accommodation within the material, reducing the risk of premature failure, which indicates better weld quality for this alloy.

- A Cu content in AlMgSi alloys in the range of up to 1.2% is not an obstacle to obtaining a high-strength extruded product. Another aspect of the product quality that should also be taken into account relates to the quality of its surface. This can be effectively enhanced by cooling the die with liquid nitrogen, which also has a positive effect on maximising the metal exit speed, improving the efficiency of the production process of extrusion of AlMgSi alloys with above-standard Cu addition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Valberg, H. Extrusion welding in aluminium extrusion. Int. J. Mater. Prod. Technol. 2002, 17, 497–556. [Google Scholar] [CrossRef]

- Donati, L.; Tomesani, L. The effect of die design on the production and seam weld quality of extruded aluminium profiles. J. Mater. Process. Technol. 2005, 164–165, 1025–1031. [Google Scholar] [CrossRef]

- Donati, L.; Tomesani, L. Extrusion welds in hollow AA6060 profiles: FEM simulation, product characterization, and welding conditions reproduced in laboratory experiments (part I). In Proceedings of the 8th International Conference on Advanced Technology of Plasticity, Verona, Italy, 9–13 October 2005. [Google Scholar]

- Donati, L.; Tomesani, L.; Minak, G. Characterization of seam weld quality in AA6082 extruded profiles. J. Mater. Process. Technol. 2007, 191, 127–131. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, J.; Li, J.; Liu, J.; Zhang, H.; Wang, X. Microstructural Characterization of Extrusion Welds in 6xxx Aluminum alloys. In Proceedings of the 3rd International Conference on Material, Mechanical and Manufacturing Engineering (IC3ME 2015), Guangzhou, China, 27–28 June 2015. [Google Scholar]

- Loukus, A.; Subhash, G.; Imaninejad, M. Mechanical properties and microstructural characterization of extrusion welds in AA6082-T4. J. Mater. Sci. 2004, 39, 6561–6569. [Google Scholar] [CrossRef]

- Bakker, A.J. Weld Seams in Aluminium Alloy Extrusions Microstructure and Properties. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2016. [Google Scholar]

- Kloppenborg, T.; Schwane, M.; Ben, K.N.; Tekkaya, A.E.; Brosius, A. Experimental and numerical analysis of material flow in porthole die extrusion. Key Eng. Mater. 2012, 491, 97–104. [Google Scholar] [CrossRef]

- Jo, H.H.; Lee, S.K.; Jung, C.S.; Kim, B.M. A non-steady state FE analysis of Al tubes hot extrusion by a porthole die. J. Mater. Process. Technol. 2006, 173, 223–231. [Google Scholar] [CrossRef]

- Filice, L.; Gagliardi, F.; Ceretti, E.; Fratini, L.; Giardini, C.; La Spisa, D. Analysis of joint quality along welding plane. Key Eng. Mater. 2010, 424, 79–86. [Google Scholar]

- Tang, D.; Zhang, Q.; Li, D.; Peng, Y. Numerical and experimental study on seam welding behavior in extrusion of micro-channel Tube. Key Eng. Mater. 2012, 491, 189–195. [Google Scholar] [CrossRef]

- Selvaggio, A.; Segatori, A.; Guzel, A.; Donati, L.; Tomesani, L.; Tekkaya, A.E. Extrusion Benchmark 2011: Evaluation of different design strategies on process conditions, die deflection and seam weld quality in hollow profiles. Key Eng. Mater. 2012, 491, 1–10. [Google Scholar] [CrossRef]

- Reggiani, B.; Segatori, A.; Donati, L.; Tomesani, L. Finite element modeling of the charge welds evolution in a porthole die. Key Eng. Mater. 2012, 491, 19–26. [Google Scholar] [CrossRef]

- Szczegoliewatych, A.; Kowalski, B.; Nowak, C. Isljedowanije wlijania dawljenja na procznost szwow połuczennych priessowoj swarkoj. Cwetnyje Mietałły 1970, 11, 66–71. [Google Scholar]

- Cook, J.; Smith, A.; Lee, R. Welding of Aluminium and Magnesium Alloys. U.S. Patent No. 4078712 1978. [Google Scholar]

- Akeret, R. Properties of pressure welds in extrusion aluminum alloy sections. J. Inst. Met. 1972, 100, 202–207. [Google Scholar]

- Ceretti, E.; Fratini, L.; Gagliardi, F.; Giardini, C. A new approach to study material bonding in extrusion porthole dies. Ann. CIRP-Manuf. Technol. 2009, 58, 259–262. [Google Scholar] [CrossRef]

- D’Urso, G.; Longo, M.; Ceretti, E.; Giardini, C. Coupled simulative-experimental procedure for studying the solid state bonding phenomena. Key Eng. Mater. 2012, 491, 173–180. [Google Scholar] [CrossRef]

- Akeret, R. Extrusion welds in aluminum sections, t. I: Technology. Aluminium 1992, 68, 965–973. [Google Scholar]

- Valberg, H. Extrusion welding in porthole die extrusion. In Proceedings of the 6th International Aluminium Extrusion Technology Seminar ET’96, Chicago, IL, USA, 14–17 May 1996; pp. 213–224. [Google Scholar]

- Zasadzinski, J.; Richert, J.; Misiołek, W.Z. Weld quality in extruded aluminum hollow sections. Light Met. Age 1993, 51, 8–13. [Google Scholar]

- Lu, X.; Zhang, C.; Zhao, G.; Guan, Y.; Chen, L.; Gao, A. State-of-the-art of extrusion welding and proposal of a method to evaluate quantitatively welding quality during three-dimensional extrusion process. Mater. Des. 2015, 89, 737–748. [Google Scholar] [CrossRef]

- Sariyarlioglu, E.C.; Welo, T.; Ma, J. Prediction of longitudinal seam weld quality in multi-chamber aluminium extrusion. In Proceedings of the Material Forming-ESAFORM 2024, Materials Research Proceedings 41, Toulouse, France, 24–26 April 2024. [Google Scholar]

- Kniazkin, I.; Vlasov, A. Quality prediction of longitudinal seam welds in aluminium profile extrusion based on simulation. Procedia Manuf. 2020, 50, 433–438. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, W.; Shi, Z.; Lin, J. Investigation of die designs on welding quality and billet material utilization for multi-container extrusion of wide stiffened aluminium panels. Int. J. Adv. Manuf. Technol. 2023, 127, 4149–4162. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, G.; Zhang, W.; Sun, L.; Wang, X.; Lv, Z. Interfacial bonding mechanism and length evaluation method of the longitudinal welds in the unsteady deformation process of porthole die extrusion of aluminum alloy profiles. J. Mater. Res. Technol. 2022, 20, 1624–1644. [Google Scholar] [CrossRef]

- Bingöl, S.; Bozaci, A. Experimental and Numerical Study on the Strength of Aluminum Extrusion Welding. Materials 2015, 8, 4389–4399. [Google Scholar] [CrossRef] [PubMed]

- Lv, J.; Shi, Z.; Yu, J.; Li, W.; Lin, J. Analysis of solid-state welding in extruding wide aluminium hollow profiles using a new three-container extrusion system. J. Manuf. Process. 2023, 94, 146–158. [Google Scholar] [CrossRef]

- Reggiani, B.; Donati, L. Comparison of experimental methods to evaluate seam welds quality in extruded profiles. Trans. Nonferrous Met. Soc. China 2020, 30, 3619–3634. [Google Scholar] [CrossRef]

- Leśniak, D.; Libura, W.; Zasadziński, J.; Latos, T. Method of Testing the Weldability of Metals or Alloys Under the Conditions of Extrusion Through Bridge. Dies. Patent No PL243256B1, 24 July 2023. [Google Scholar]

- Flewitt, P.E.J.; Wild, R.K. Grain Boundaries, Their Microstructure and Chemistry; John Wiley and Sons, Ltd.: Chichester, UK, 2001. [Google Scholar]

| Alloy Denotation | Si | Fe | Cu | Mg | Cr | Zn | Ti | Zr |

|---|---|---|---|---|---|---|---|---|

| AlMgSi(Cu) alloy 1A | 1.04 | 0.05 | 0.61 | 0.68 | 0.25 | 0.01 | 0.02 | 0.15 |

| AlMgSi(Cu) alloy 3A | 1.21 | 0.06 | 1.22 | 0.80 | 0.41 | 0.01 | 0.02 | 0.15 |

| Alloy | Solidus Temperature, °C | Incipient Melting Heat, J/g |

|---|---|---|

| AlMgSi(Cu) alloy 1A | 544.0 | 0.61 |

| AlMgSi(Cu) alloy 3A | 509.2 | 0.21 |

| AlMgSi(Cu) alloy 1A (homogenised) | 596.1 | 0.13 |

| AlMgSi(Cu) alloy 3A (homogenised) | 574.6 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogusz, M.; Leśniak, D.; Zasadziński, J.; Libura, W.; Leszczyńska-Madej, B.; Madura, J.; Latos, T.; Limanówka, K.; Płonka, B. Estimation of Quality of Seam Welds in AlMgSi(Cu) Extrusion by Using an Original Device for Weldability Testing. Materials 2024, 17, 5448. https://doi.org/10.3390/ma17225448

Bogusz M, Leśniak D, Zasadziński J, Libura W, Leszczyńska-Madej B, Madura J, Latos T, Limanówka K, Płonka B. Estimation of Quality of Seam Welds in AlMgSi(Cu) Extrusion by Using an Original Device for Weldability Testing. Materials. 2024; 17(22):5448. https://doi.org/10.3390/ma17225448

Chicago/Turabian StyleBogusz, Marek, Dariusz Leśniak, Józef Zasadziński, Wojciech Libura, Beata Leszczyńska-Madej, Jacek Madura, Tomasz Latos, Kamila Limanówka, and Bartłomiej Płonka. 2024. "Estimation of Quality of Seam Welds in AlMgSi(Cu) Extrusion by Using an Original Device for Weldability Testing" Materials 17, no. 22: 5448. https://doi.org/10.3390/ma17225448

APA StyleBogusz, M., Leśniak, D., Zasadziński, J., Libura, W., Leszczyńska-Madej, B., Madura, J., Latos, T., Limanówka, K., & Płonka, B. (2024). Estimation of Quality of Seam Welds in AlMgSi(Cu) Extrusion by Using an Original Device for Weldability Testing. Materials, 17(22), 5448. https://doi.org/10.3390/ma17225448