Effect of Amorphous Metallic Fibers on Thermal and Mechanical Properties of Lightweight Aggregate Cement Mortars Containing Carbon Nanotubes

Abstract

1. Introduction

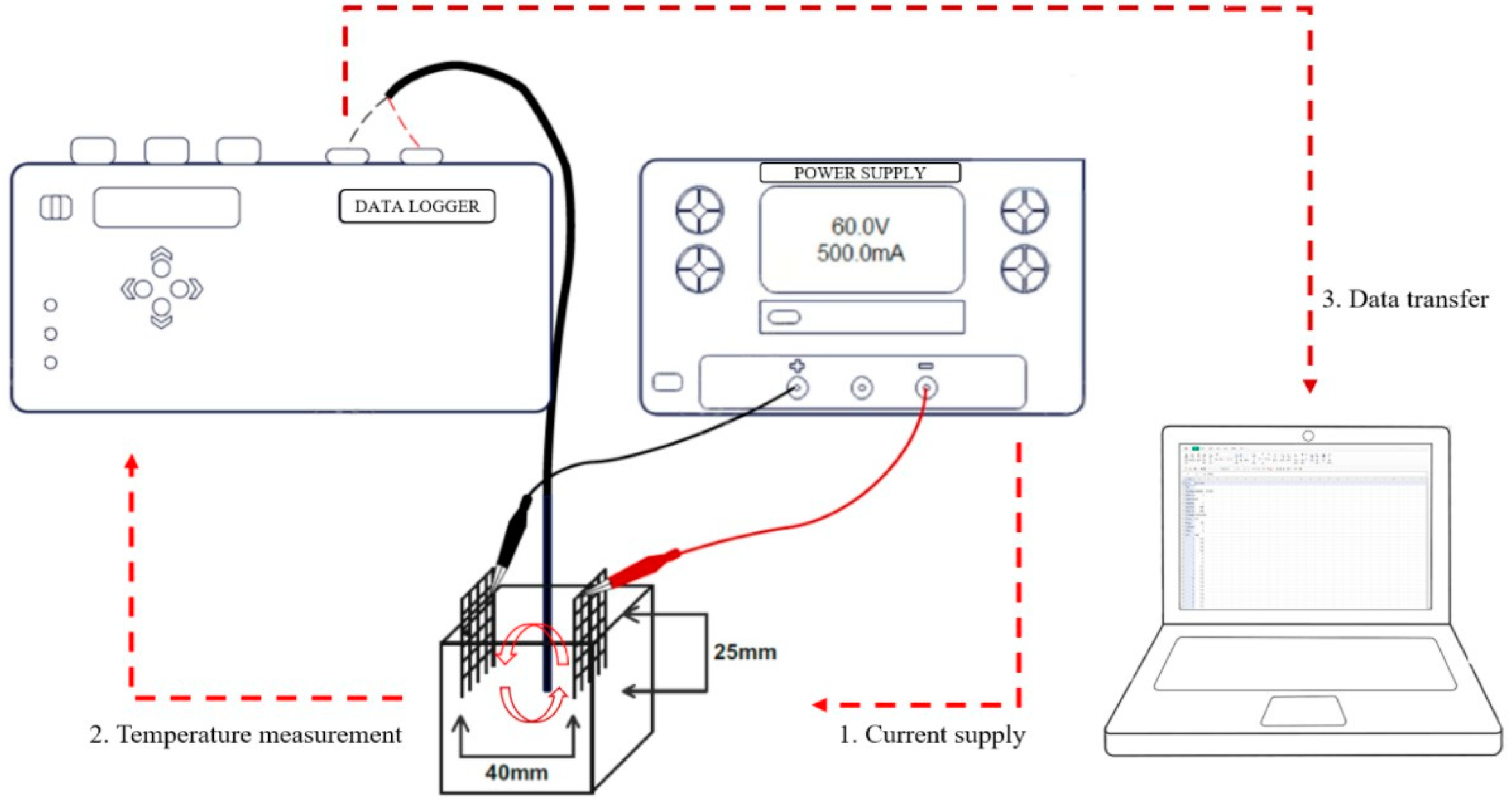

2. Materials and Experimental Methods

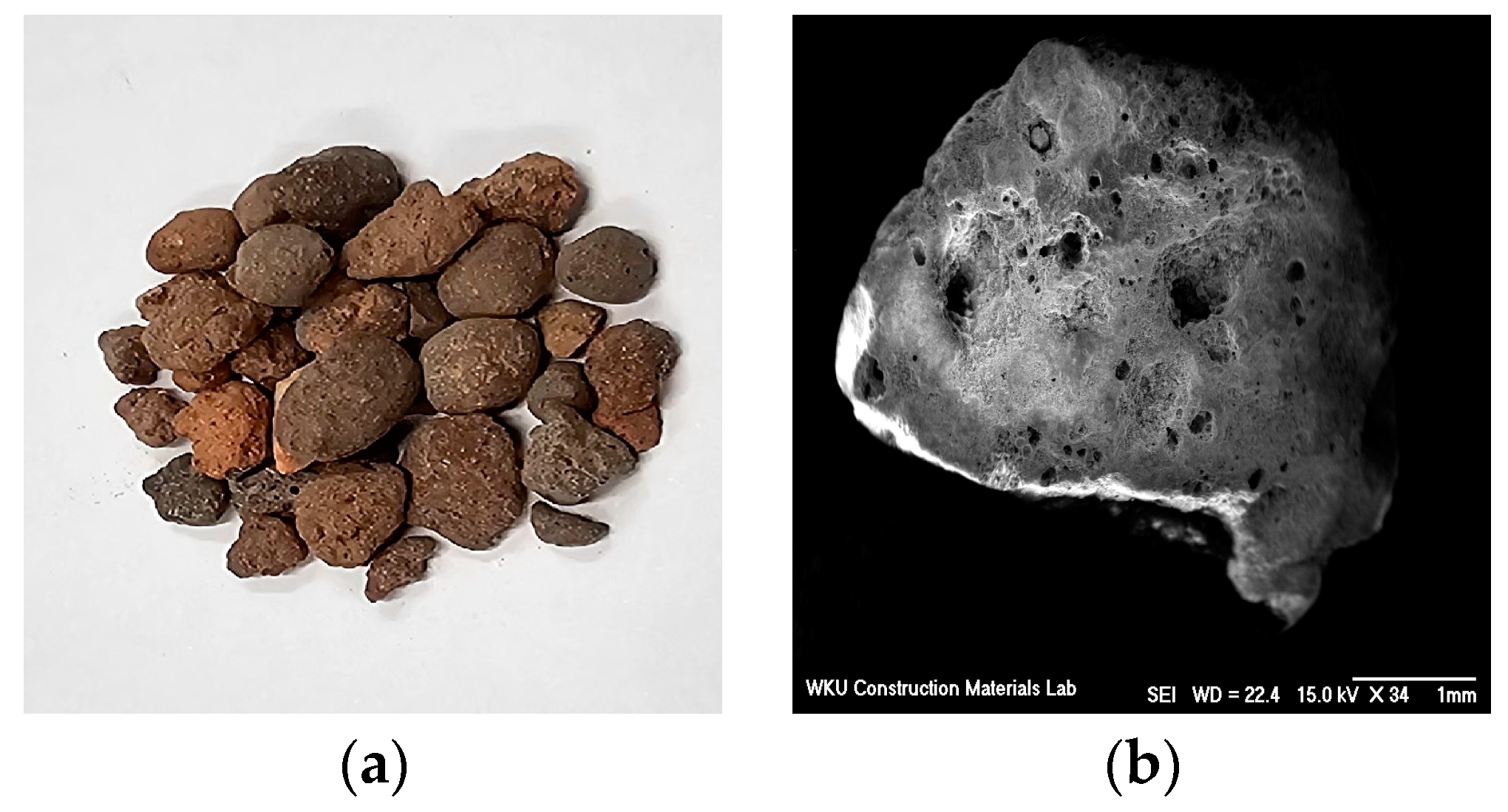

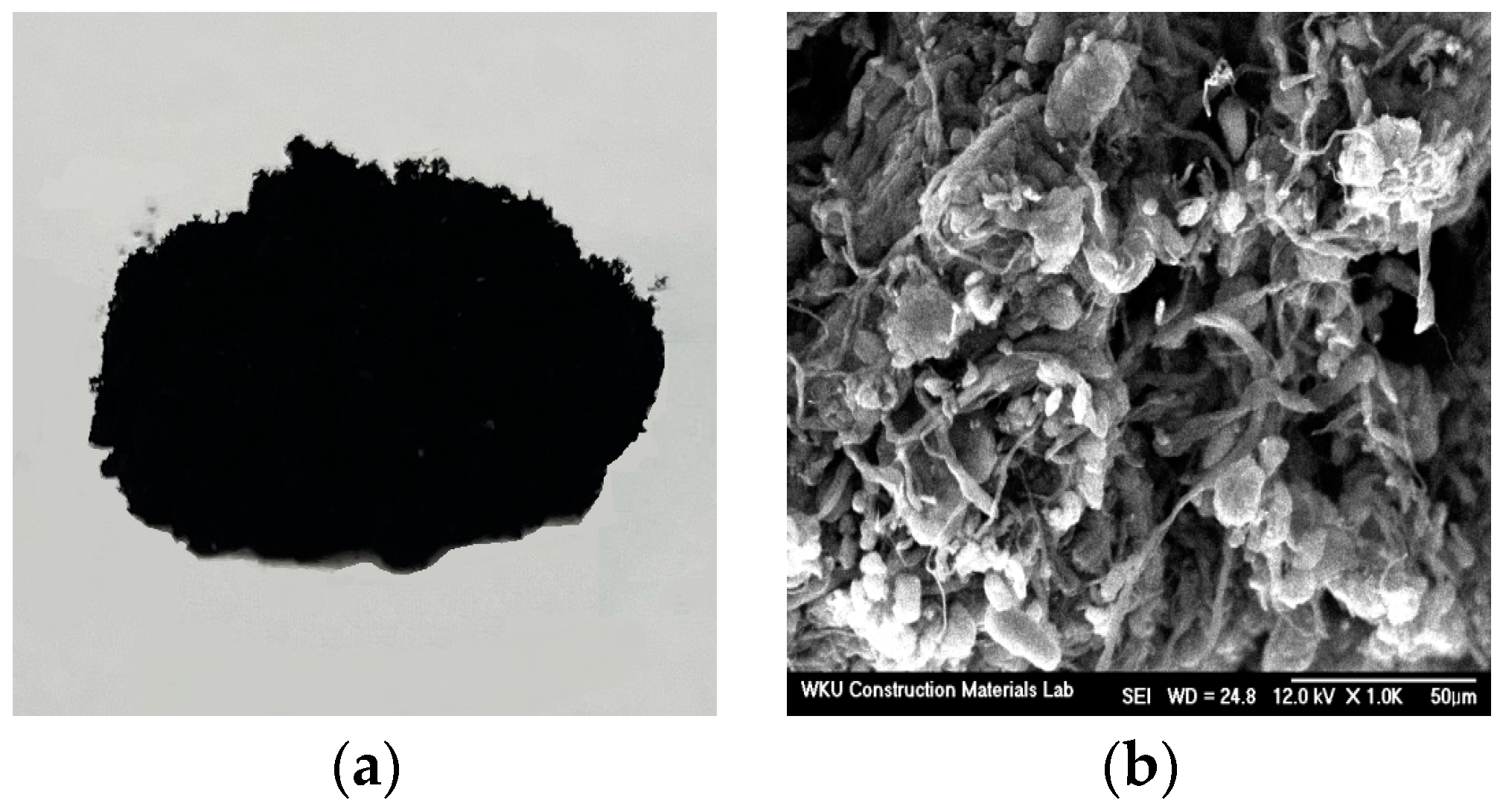

2.1. Materials

2.2. Mixing Proportions and Specimen Preparation

3. Experimental Results and Discussion

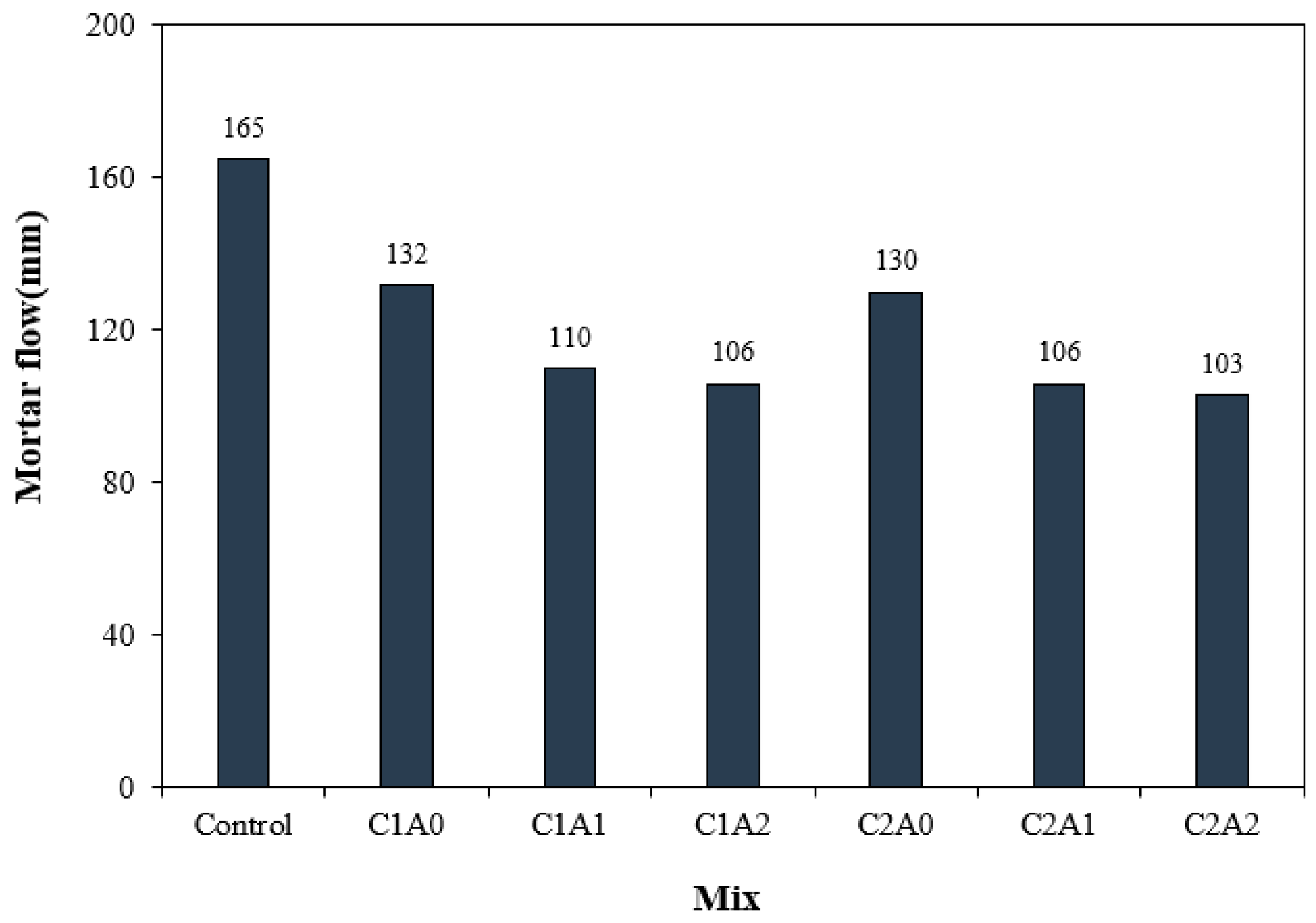

3.1. Mortar Flow

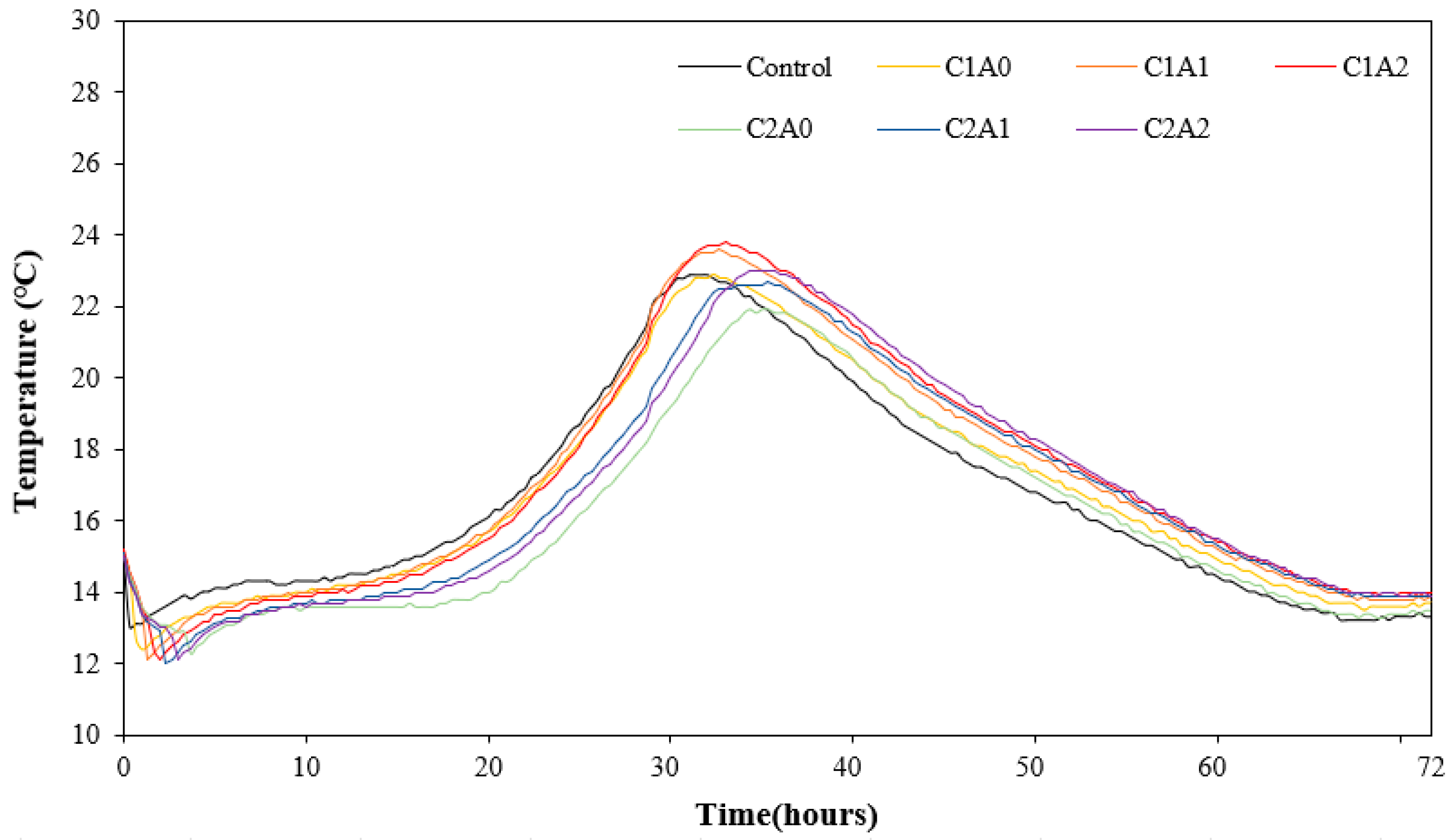

3.2. Heat of Microhydration

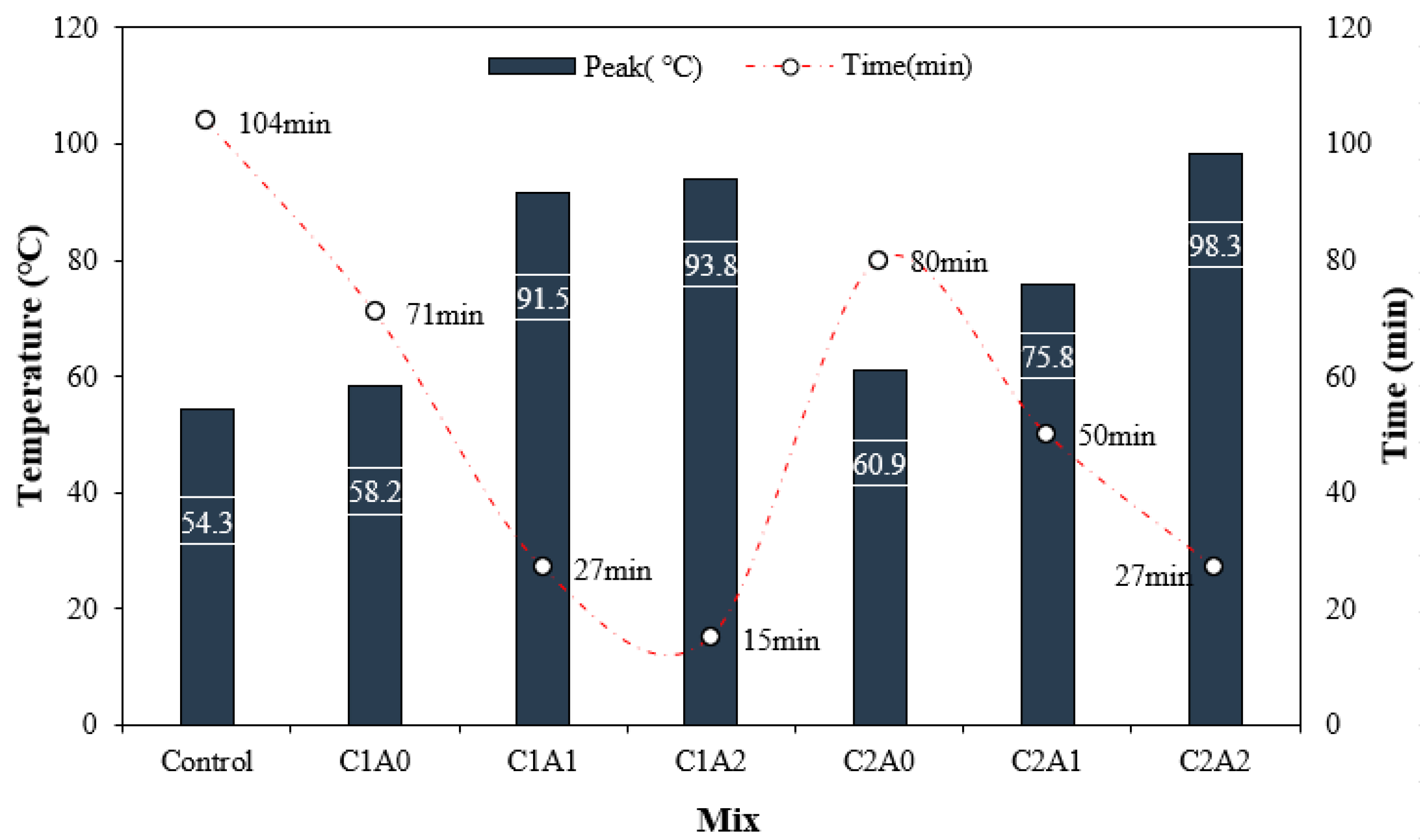

3.3. Thermal Properties

3.4. Compressive Strength

3.5. Split Tensile Strength

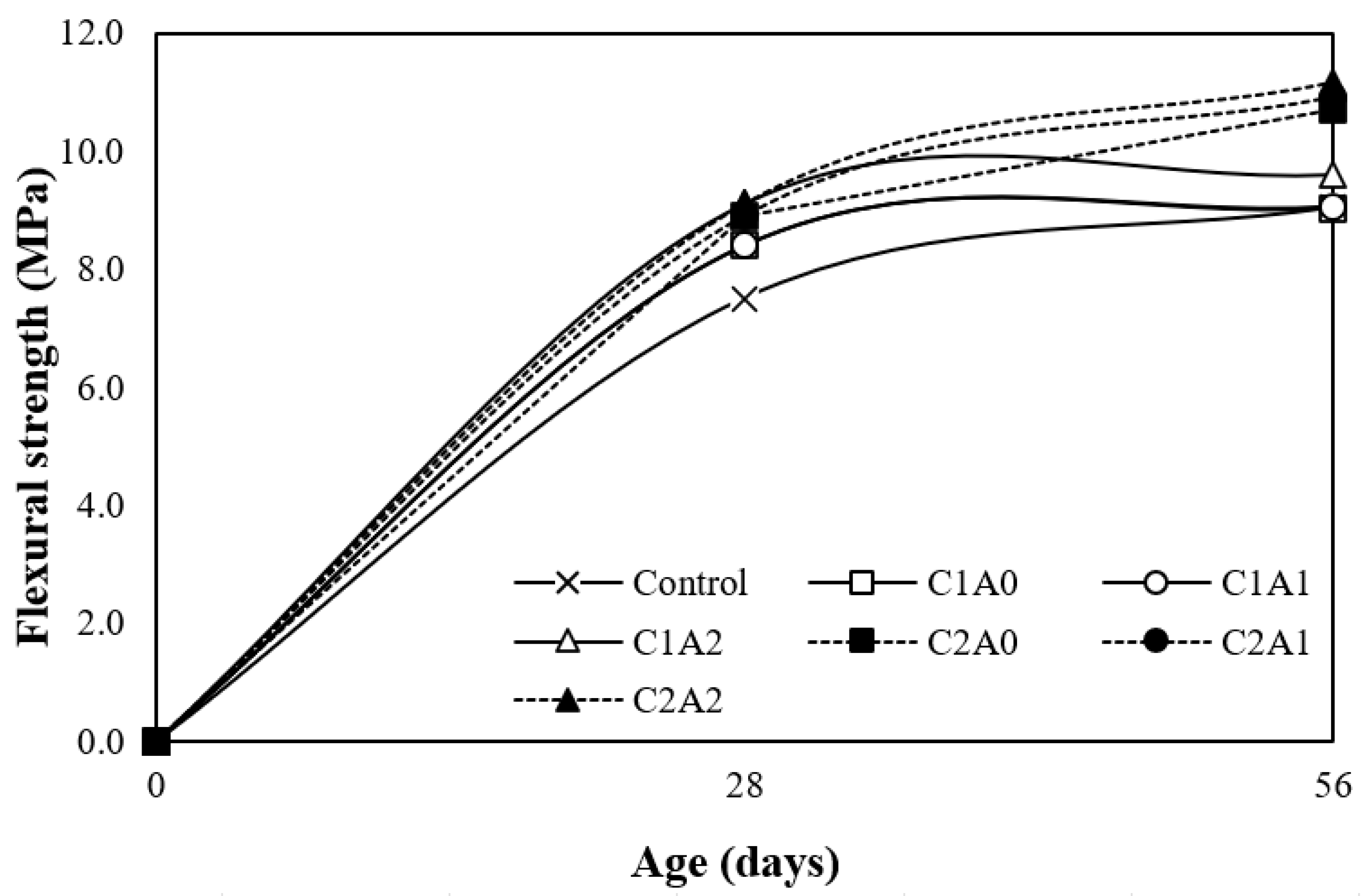

3.6. Flexural Strength

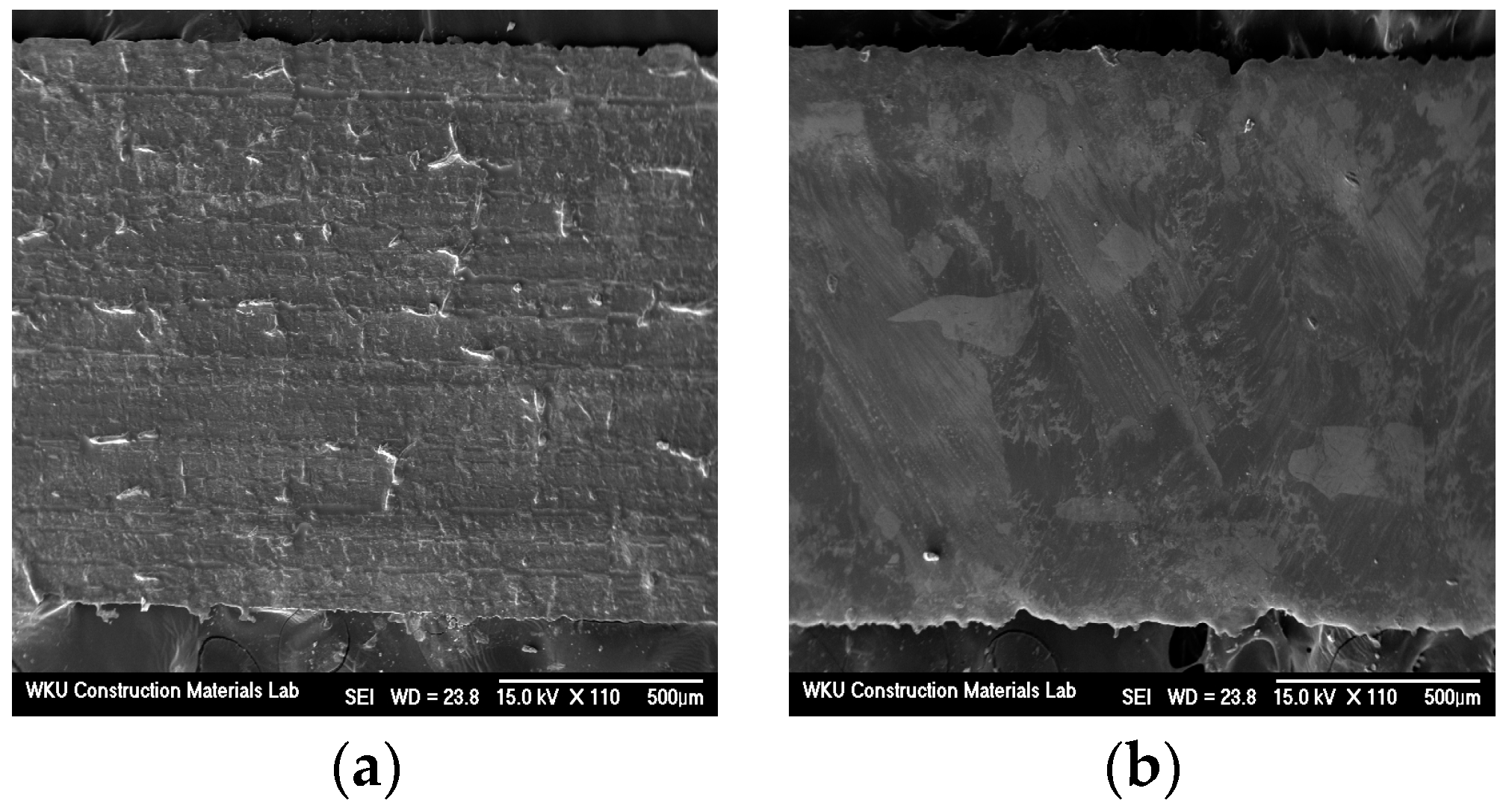

3.7. Microstructural Analysis

4. Conclusions

- As the amount of AMFs increased, the flow of the mortar sample decreased, and the flows of the C1A1 and C1A2 samples were approximately 16.6–19.6% lower than that of the C1A0 sample without AMFs.

- In the microhydration heat test, when only the CNT was used in the LWA mortar, the time to reach the peak temperature was delayed. However, when CNTs and AMFs were used together, the peak temperature increased.

- Through a thermal property test, the peak temperature of the sample using both CNTs and AMFs was found to be significantly higher than that of the sample using only CNTs. Thus, the peak temperature of the C1A1 and C2A2 samples using AMFs was approximately 91.5–93.8 °C, which was approximately 57.2–61.1% higher than the C1A0 sample without AMFs. In particular, the time to reach the peak temperature was approximately 15–27 min, which was 21.1–38.0% of that of the C1A0 sample.

- The 28-day compressive strength of the control sample was approximately 35.8 MPa, and the compressive strengths of the samples using CNTs and AMFs increased as the amount of AMFs increased.

- The 28-day split tensile strength of the sample using 20 kg/m3 of the AMF was approximately 3.6–3.8 MPa, which was approximately 46.1–50.0% higher than that of the sample using only CNTs. In particular, when the amount of AMFs was the same, the split tensile strength of the sample with 0.2% CNTs was greater than that of the sample with 0.1% CNTs.

- The 56-day flexural strength of the C2A2 sample using 0.2% CNTs and 20 kg/m3 AMFs was the highest at approximately 11.2 MPa. This value was approximately 24.4% higher than that of the control sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choi, S.J.; Mun, J.S.; Yang, K.H.; Kim, S.J. Compressive fatigue performance of fiber-reinforced lightweight concrete with high-volume supplementary cementitious materials. Cem. Concr. Compos. 2016, 73, 89–97. [Google Scholar] [CrossRef]

- Xiang, Z.H.; Wang, J.; Niu, J.G.; Xu, Y. Experimental Study on the Seismic Performance of Hollow Columns with Fiber Lightweight Aggregate Concrete. Buildings 2022, 12, 2164. [Google Scholar] [CrossRef]

- Real, S.; Bogas, J.A.; Pontes, J. Structural lightweight aggregate concrete exposed to marine environment for 5years. Constr. Build. Mater. 2021, 275, 122161. [Google Scholar] [CrossRef]

- Chen, P.; Wang, Z.; Cao, S.; Rong, X.; Shi, Z.; Wang, H. Study on axial compressive stress-strain relationship of alkali-activated slag lightweight aggregate concrete. Constr. Build. Mater. 2023, 364, 129991. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Durability of lightweight concretes with lightweight fly ash aggregates. Constr. Build. Mater. 2011, 25, 1430–1438. [Google Scholar] [CrossRef]

- Maghfouri, M.; Alimohammadi, V.; Gupta, R.; Saberian, M.; Azarsa, P.; Hashemi, M.; Asadi, I.; Roychand, R. Drying Shrinkage properties of expanded polystyrene (EPS) lightweight aggregate concrete: A review. Case Stud. Constr. Mater. 2022, 16, e00919. [Google Scholar] [CrossRef]

- Cui, H.Z.; Lo, T.Y.; Memon, S.A.; Xu, W. Effect of lightweight aggregates on the mechanical properties and brittleness of lightweight aggregate concrete. Constr. Build. Mater. 2012, 35, 149–158. [Google Scholar] [CrossRef]

- Dang, C.T.; Pham, M.; Dinh, N.H. Experimental Study on Compressive and Flexural Performance of Lightweight Cement-Based Composites Reinforced with Hybrid Short Fibers. Materials 2023, 16, 4457. [Google Scholar] [CrossRef]

- Choi, S.J.; Kim, J.H.; Bae, S.H.; Oh, T.G. Strength, Drying Shrinkage, and Carbonation Characteristic of Amorphous Metallic Fiber-Reinforced Mortar with Artificial Lightweight Aggregate. Materials 2020, 13, 4451. [Google Scholar] [CrossRef]

- Choi, S.J.; Hong, B.T.; Lee, S.J.; Won, J.P. Shrinkage and corrosion resistance of amorphous metallic-fiber-reinforced cement composites. Compos. Struct. 2014, 107, 537–543. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, R.; Liu, J. Experimental study on the durability of high-performance cementitious composites with amorphous metallic fibers. Constr. Build. Mater. 2023, 367, 130295. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Rudzionis, Z.; Ghosh, R. Influence of CNT, graphene nanoplate and CNT-graphene nanoplate hybrid on the properties of lightweight concrete, Assessment of High Thermal Effects on Carbon Nanotube (Cnt)- Reinforced Concrete. Mater. Proc. 2021, 44, 1979–1982. [Google Scholar]

- Du, Y.; Pundiene, I.; Pranckeviciene, J.; Zujevs, A.; Korjakins, A. Study on the Pore Structure of Lightweight Mortar with Nano-Additives. Nanomaterials 2023, 13, 2942. [Google Scholar] [CrossRef] [PubMed]

- Yoo, D.Y.; You, I.; Lee, S.J. Electrical properties of cement-based composites with carbon nanotubes, graphene and graphite nano fibers. Sensors 2017, 17, 1064. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.; Jang, D.; Yang, B.; Yoon, H.N.; Jang, J.G.; Park, S.; Lee, H.K. Material characterization and piezoresistive sensing capability assessment of thin-walled CNT-embedded ultra-high performance concrete. Cem. Concr. Compos. 2022, 134, 104808. [Google Scholar] [CrossRef]

- Abdulhameed, A.; Wahab, N.Z.A.; Mohtar, M.N.; Hamidon, M.N.; Shafie, S.; Halin, I.A. Method and Applications of Electrical Conductivity Enhancement of Materials Using Carbon Nanotubes. J. Electron. Mater. 2021, 50, 3207–3221. [Google Scholar] [CrossRef]

- Lee, J.I.; Bae, S.H.; Kim, J.H.; Choi, S.J. Effect of Cementitious Materials on the Engineering Properties of Lightweight Aggregate Mortars Containing Recycled Water. Materials 2022, 15, 1967. [Google Scholar] [CrossRef]

- KS L 5105; Testing Method for Compressive Strength of Hydraulic Cement Mortars. Korea Industrial Standards, Seoul (Korea); Korean Standards & Certification Information Center: Seoul, Republic of Korea, 2007.

- ASTM C 1753; Standard Practice for Evaluation Early Hydration of Hydraulic Cementitious Mixtures Using Thermal Measurements. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- Lee, J.I.; Kim, C.Y.; Yoon, J.H.; Choi, S.J. Study on the Engineering Properties of Cement Composites Using Carbon Nanotubes and Amorphous Metallic Fiber. J. Korea Concr. Institue 2024, 34, 73–84. [Google Scholar] [CrossRef]

- Maho, B.; Sukontosukkul, P.; Iam, G.S.; Sappakittipakorn, M.; Intarabut, D.; Suksiripattanapong, C.; Chindaprasirt, P.; Limkatanyu, S. Mechanical properties and electrical resistivity of multiwall carbon nanotubes incorporated into high calcium fly ash geopolymer. Case Stud. Constr. Mater. 2021, 15, e00785. [Google Scholar] [CrossRef]

- KS F 2423; Standard Test Method for Tensile Splitting Strength of Concrete. Korea Industrial Standards; Korean Standards & Certification Information Center: Seoul, Republic of Korea, 2011.

- KS F 2408; Standard Test Method for Flexural Strength of Concrete. Korea Industrial Standards, Seoul (Korea); Korean Standards & Certification Information Center: Seoul, Republic of Korea, 2016.

- Ahmad, J.; Zhou, Z. Properties of concrete with addition carbon nanotubes: A review. Constr. Build. Mater. 2023, 393, 132066. [Google Scholar] [CrossRef]

- Kim, J.S.; Cho, C.G.; Moon, H.J.; Kim, H.Y.; Lee, S.J.; Kim, W.J. Experimental on Tensile and Shear Characteristics of Amorphous Micro Steel (AMS) Fibre-reinforced Cementitious Composites. Int. J. Concr. Struct. Mater. 2017, 11, 647–655. [Google Scholar] [CrossRef]

- Xing, G.; Xu, Y.; Huang, J.; Lu, Y.; Miao, P.; Chindasiriphan, P.; Jongvivatsakul, P.; Ma, K. Research on the mechanical properties of steel fibers reinforced carbon nanotubes concrete. Constr. Build. Mater. 2023, 392, 131880. [Google Scholar] [CrossRef]

- Isfahani, F.T.; Li, W.; Redaelli, E. Dispersion of multi-walled carbon nanotubes and its effects on the properties of cement composites. Cem. Concr. Compos. 2016, 74, 154–163. [Google Scholar] [CrossRef]

- Adhikari, S.K.; Rudžionis, Ž.; Rajapriya, R. The Effect of Carbon Nanotubes on the Flowability, Mechanical, Microstructural and Durability Properties of Cementitious Composite: An Overview. Sustainability 2020, 12, 8362. [Google Scholar] [CrossRef]

- Zhang, J.; Ke, Y.; Zhang, J.; Han, Q.; Dong, B. Cement paste with well-dispersed multi-walled carbon nanotubes: Mechanism and performance. Constr. Build. Master 2020, 262, 120746. [Google Scholar] [CrossRef]

- Jang, D.I.; Yoon, H.N.; Lee, H.K.; Nam, I.W. Influence of water ingress on the electrical properties and electronmechanical sensing capabilities of CNT/cement composites. J. Build. Eng. 2021, 42, 103065. [Google Scholar] [CrossRef]

- Khan, M.S.; Hashmi, A.F.; Sharia, M.; Ibrahim, S.M. Effects of incorporating fibres on mechanical properties of fibre-reinforced concrete: A review. Mater. Proceeding, 2023; in press. [Google Scholar] [CrossRef]

- Miah, M.J.; Pei, J.; Kim, H.; Jang j., G. Flexural behavior porosity, and water absorpation of CO2-cured amorphous metallic-fiber-reinforced belite-rich cement composites. Constr. Build. Mater. 2023, 387, 131668. [Google Scholar] [CrossRef]

- Lim, K.M.; Lee, J.H. Electircal conductivity and compressive strength of cement paste with multiwalled carbon nanotubes and graphene nanoplatelets. Apple. Sci. 2022, 12, 1160. [Google Scholar] [CrossRef]

- Belli, A.; Mobil, A.; Belleze, T.; Tittareli, F. Commerical and recycled carbon/steel fibers for fiber-reinforced cement mortars with high electirical conductivity. Cem. Concr. Compos. 2020, 109, 103569. [Google Scholar] [CrossRef]

- Kin, H.; Kim, G.; Lee, S.; Choe, G.; Nam, J.; Nam, T.; Mechtcherine, V. Effects of strain rate on the tensile behavior of cementitious composites made with amorphous metallic fiber. Cem. Concr. Compos. 2020, 108, 103519. [Google Scholar]

- Dihn, N.H.; Choi, K.G.; Kim, H.S. Mechanical properties and Modeling of Amorphous Metallic Fiber-Reinforced Concrete in Compression. Int. J. Concr. Struct. Mater. 2016, 10, 221–236. [Google Scholar]

- Cui, K.; Liang, K.; Jiang, T.; Zhang, J.; Lau, D.; Chang, J. Understanding the role of carbon nanotubes in low-carbon concrete: From experiment to molecular dynamics. Cem. Concr. Compos. 2023, 142, 105189. [Google Scholar] [CrossRef]

- Silvestro, L.; Gleize, P.J.P. Effect of carbon nanotubes on compressive, flexural and tensile strengths of Portland cement-based materials: A systemic literature review. Constr. Build. Mater. 2020, 264, 120237. [Google Scholar] [CrossRef]

- Fang, M.; Chen, Y.M.; Deng, Y.; Wang, Z.; Zhu, M. Toughness improvement mechanism and evaluation of cement concrete for read pavement: A review. J. Road Eng. 2023, 3, 125–140. [Google Scholar] [CrossRef]

- Hassanpour, M.; Shanfigh, P.; Mahmud, H.B. Lightweight aggregate concrete fiber reinforcement—A review. Constr. Build. Mater. 2012, 37, 452–461. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Gdoutos, M.S.K.; Gdoutos, E.E.; Shan, S.P. Strength, energy absorption capability and self-sensing properties of multifunctional carbon nanotube reinforced mortars. Constr. Build. Mater. 2016, 120, 265–274. [Google Scholar] [CrossRef]

- Yang, J.M.; Shin, H.O.; Yu, D.Y. Benefits of using amorphous metallic fibers in concrete pavement for long-term performance. Arch. Civ. Mech. Eng. 2017, 17, 750–760. [Google Scholar] [CrossRef]

- Liu, X.; Wang, G.; Yu, J.; Liu, R.; Lyu, K.; Zuo, J.; Shan, S.P. Stress-sensitive of carbon ananotube-grafted-carbon fiber incorporated cement-based composites. J. Build. Eng. 2023, 64, 105589. [Google Scholar] [CrossRef]

- Fan, M.; Chen, F.; Zhang, X.; Wang, R.; Yu, R. Effect of Ca/Si ratio on the characteristics of alkali-activated ultra-high performance concrete (A-UHPC): From hydration kinetics to microscopic structure development. Constr. Build. Mater. 2023, 394, 132158. [Google Scholar] [CrossRef]

- Zhu, X.; Qian, C.; He, B.; Chen, Q.; Jiang, Z. Experimental study on the stability of C-S-H nanostructures with varying bulk CaO/SiO2 ratios under cryogenic attack. Cem. Concr. Res. 2020, 135, 106114. [Google Scholar] [CrossRef]

| SiO2 (wt%) | Al2O3 (wt%) | Fe2O3 (wt%) | CaO (wt%) | MgO (wt%) | K2O (wt%) | Blaine (cm2/g) | Density (g/cm3) | |

|---|---|---|---|---|---|---|---|---|

| Ordinary Portland cement | 17.43 | 6.50 | 3.57 | 64.4 | 2.55 | 1.17 | 3820 | 3.13 |

| FM | Density (g/cm3) | Water Absorption (%) | Unit Weight (kg/L) | |

|---|---|---|---|---|

| Lightweight aggregate (LWA) | 4.61 | 1.77 | 8.71 | 1010 |

| Specific Surface Area (m2/g) | Purity (wt%) | Bulk Density (g/mL) | Moisture Contents (wt%) | |

|---|---|---|---|---|

| CNT | 221 | 97.88 | 0.094 | 0.3 |

| Density (g/cm3) | Tensile Strength (N/mm2) | Length (mm) | |

|---|---|---|---|

| AMF | 7.2 | 1400 | 15 |

| Mix | W/C (%) | Water (kg/m3) | Cement (kg/m3) | CNT (C*wt%) | AMF (kg/m3) | LWA (S*%) |

|---|---|---|---|---|---|---|

| Control | 50 | 170 | 340 | 0 | 0 | 100 |

| C1A0 | 0.1 | 0 | ||||

| C1A1 | 10 | |||||

| C1A2 | 20 | |||||

| C2A0 | 0.2 | 0 | ||||

| C2A1 | 10 | |||||

| C2A2 | 20 |

| Mix | Ca (wt%) | Si (wt%) | Al (wt%) | Fe (wt%) | K (wt%) | O (wt%) | Ca/Si (%) |

|---|---|---|---|---|---|---|---|

| Control | 21.86 | 8.11 | 2.6 | 9.19 | 1.38 | 56.86 | 2.69 |

| C2A2 | 38.57 | 25.77 | 2.74 | - | 1.46 | 49.33 | 1.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.-J.; Lee, J.-I.; Kim, C.-Y.; Yoon, J.-H.; Kim, K.-H. Effect of Amorphous Metallic Fibers on Thermal and Mechanical Properties of Lightweight Aggregate Cement Mortars Containing Carbon Nanotubes. Materials 2024, 17, 5449. https://doi.org/10.3390/ma17225449

Choi S-J, Lee J-I, Kim C-Y, Yoon J-H, Kim K-H. Effect of Amorphous Metallic Fibers on Thermal and Mechanical Properties of Lightweight Aggregate Cement Mortars Containing Carbon Nanotubes. Materials. 2024; 17(22):5449. https://doi.org/10.3390/ma17225449

Chicago/Turabian StyleChoi, Se-Jin, Jae-In Lee, Chae-Young Kim, Joo-Ho Yoon, and Kwan-Ho Kim. 2024. "Effect of Amorphous Metallic Fibers on Thermal and Mechanical Properties of Lightweight Aggregate Cement Mortars Containing Carbon Nanotubes" Materials 17, no. 22: 5449. https://doi.org/10.3390/ma17225449

APA StyleChoi, S.-J., Lee, J.-I., Kim, C.-Y., Yoon, J.-H., & Kim, K.-H. (2024). Effect of Amorphous Metallic Fibers on Thermal and Mechanical Properties of Lightweight Aggregate Cement Mortars Containing Carbon Nanotubes. Materials, 17(22), 5449. https://doi.org/10.3390/ma17225449