Microstructure, Mechanical Properties and Wear Behaviors of Ultrafine-Grain WC-Based Cermets with Different Binder Phases Fabricated by Spark Plasma Sintering

Abstract

1. Introduction

2. Materials and Experimental Methods

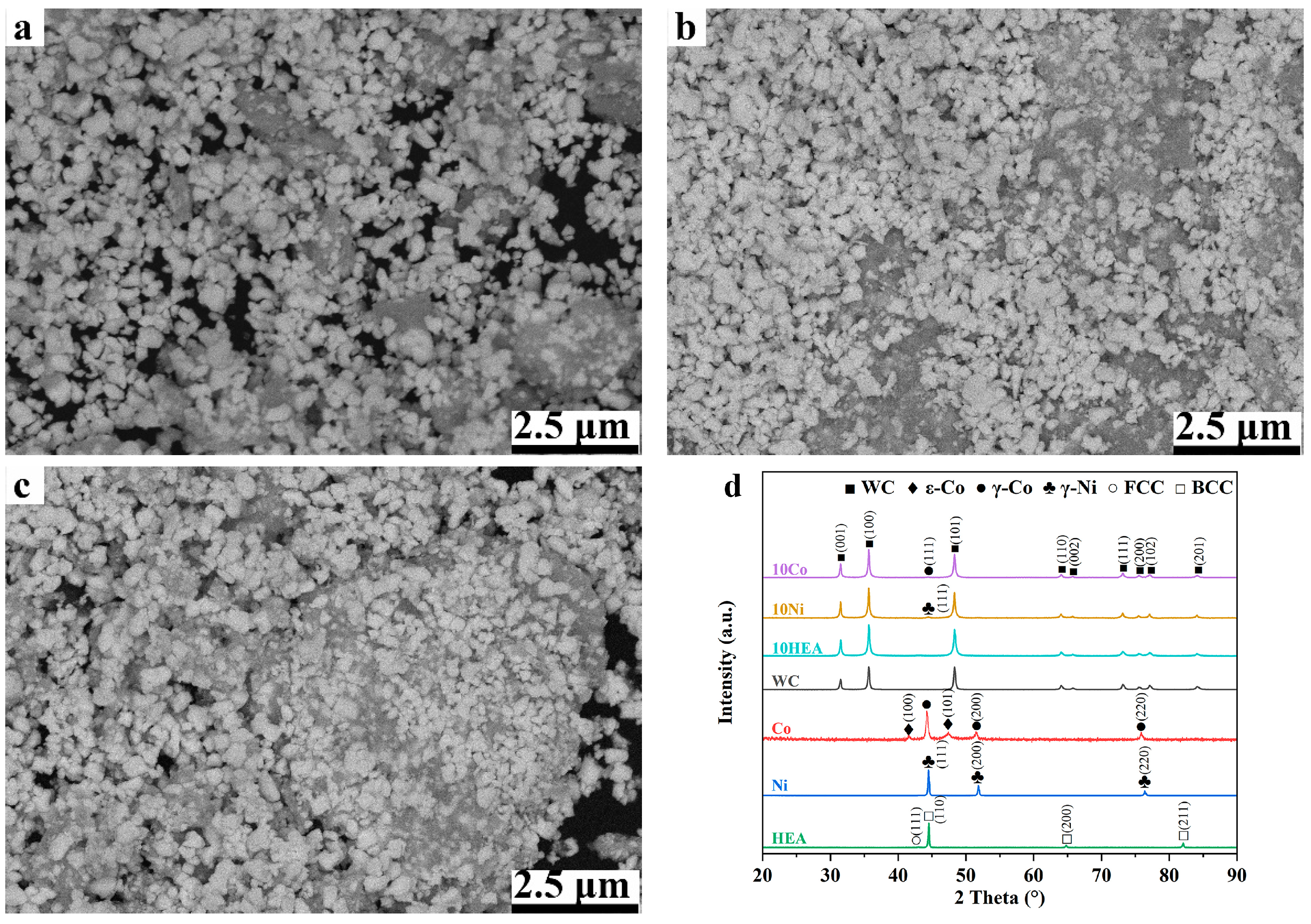

2.1. Raw Powders

2.2. Sintering Technique

2.3. Microstructure Observation

2.4. Mechanical Properties

2.5. Wear Test

3. Results and Discussion

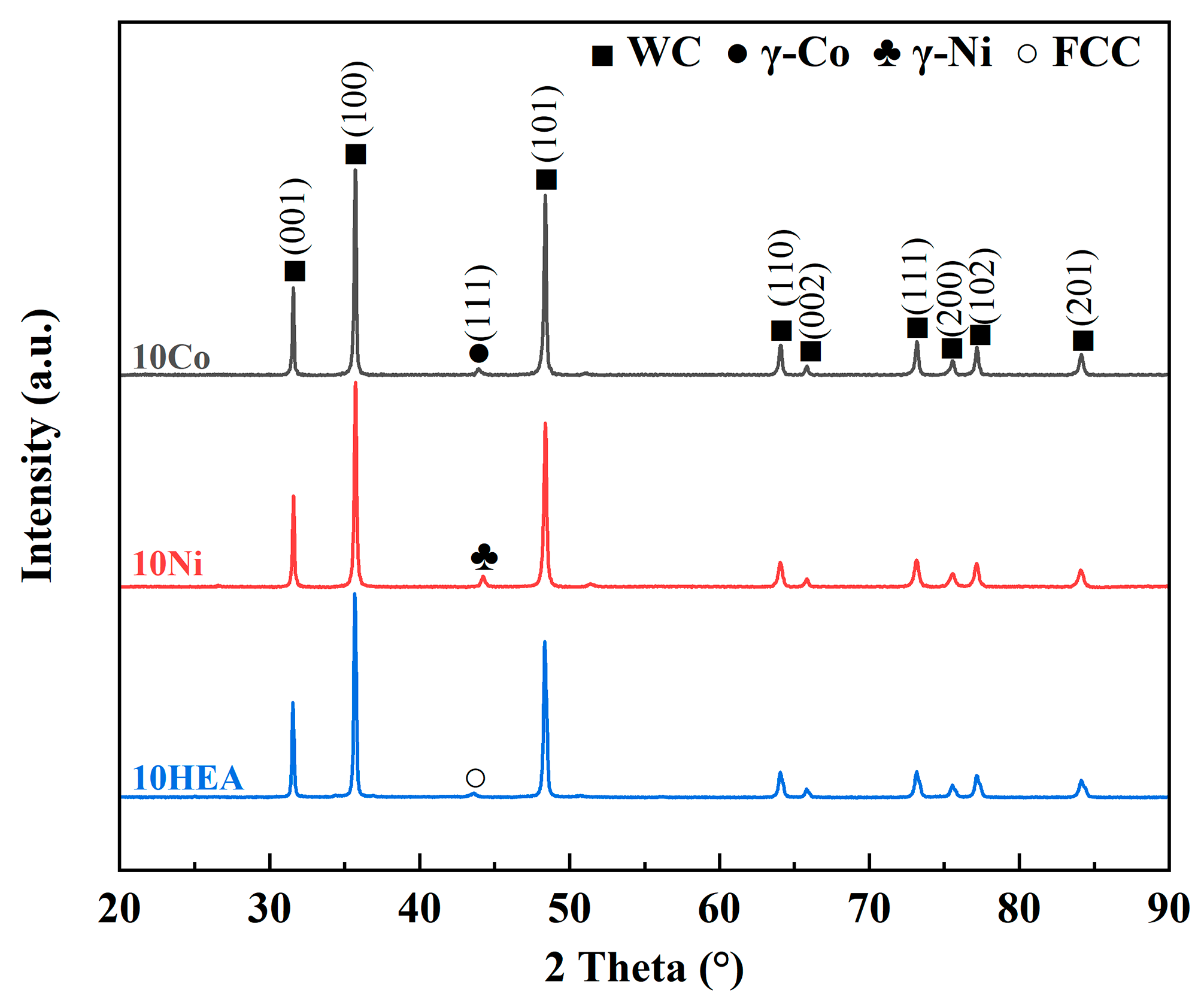

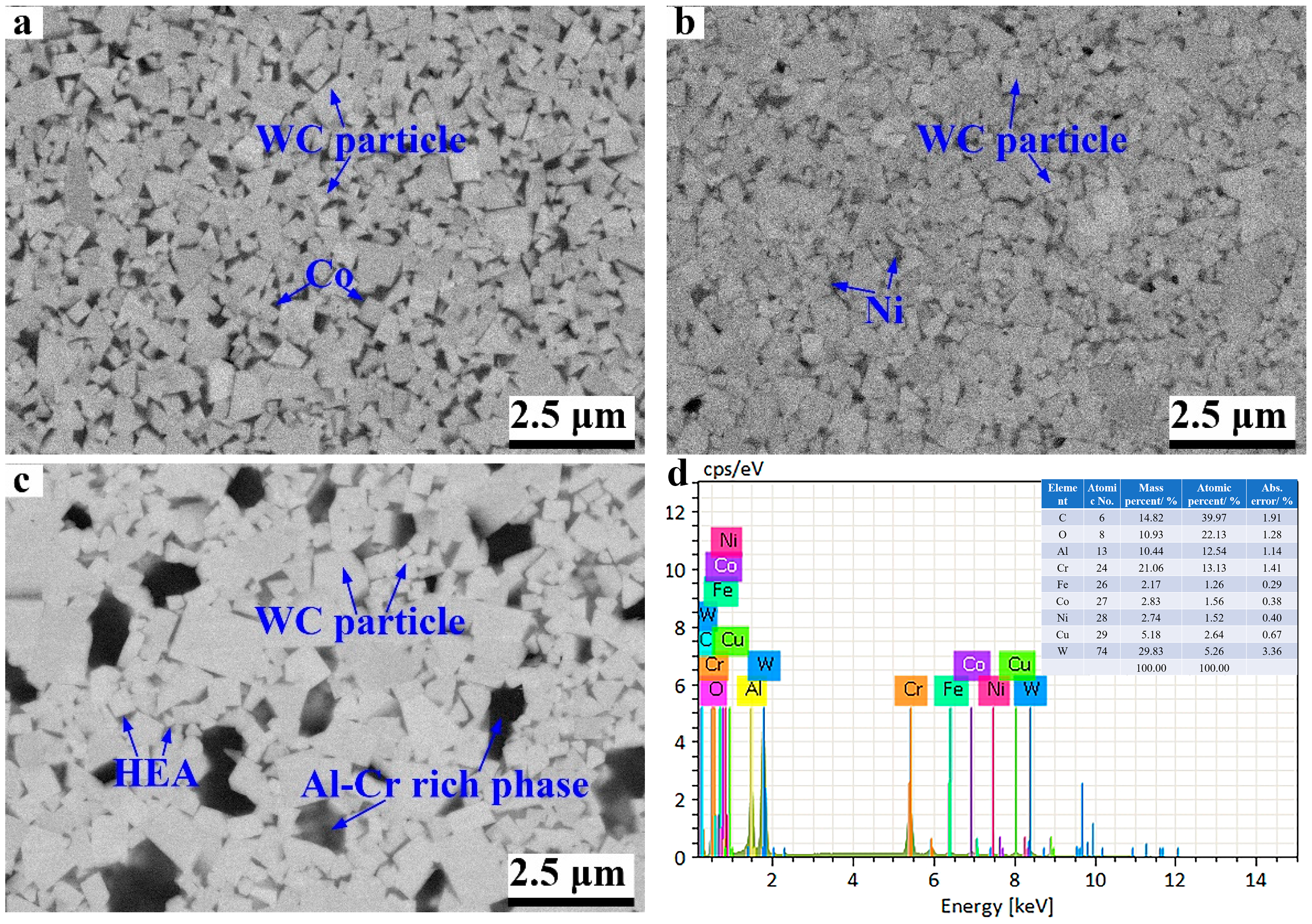

3.1. Microstructure of the Sintered WC-Based Cermets

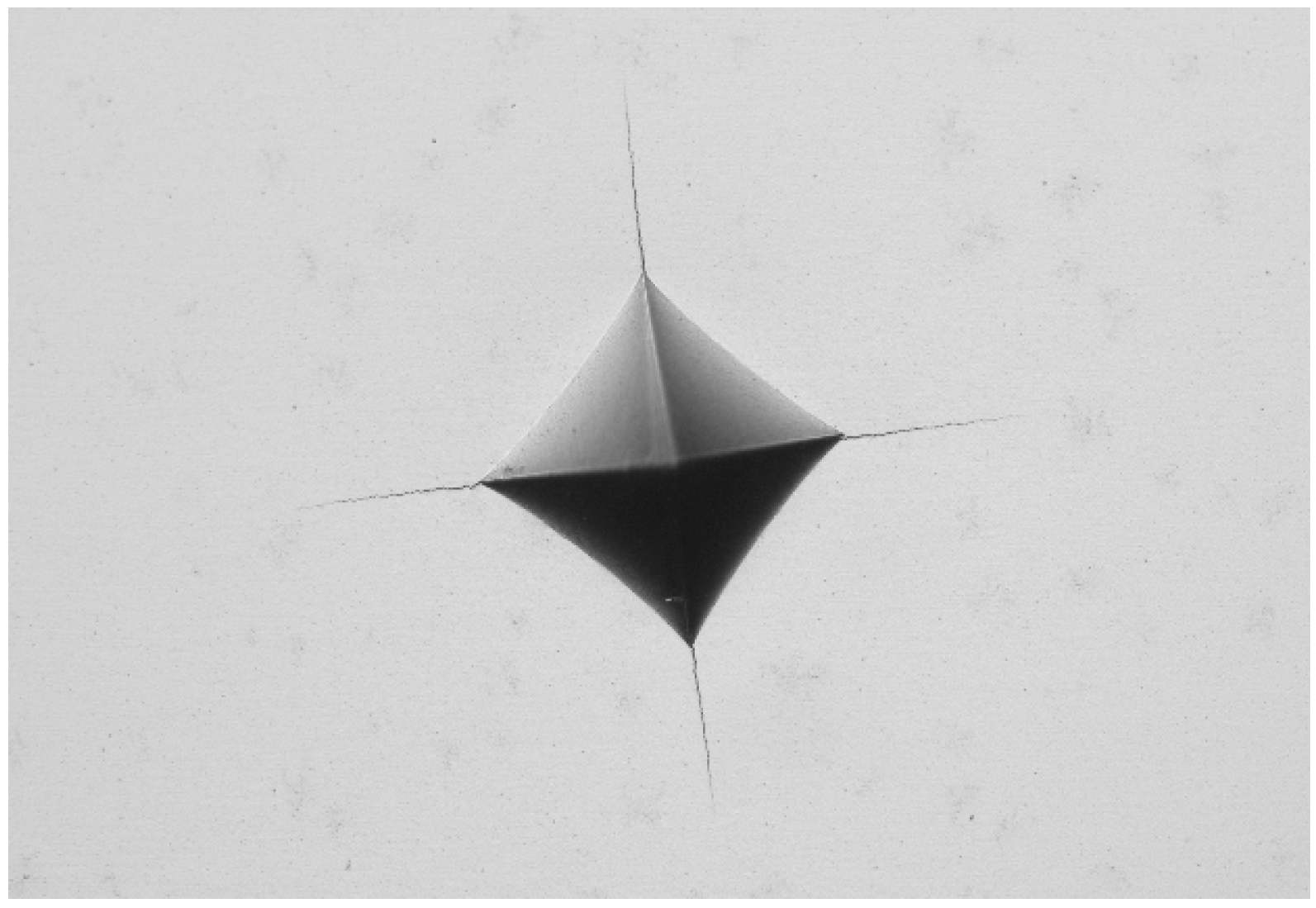

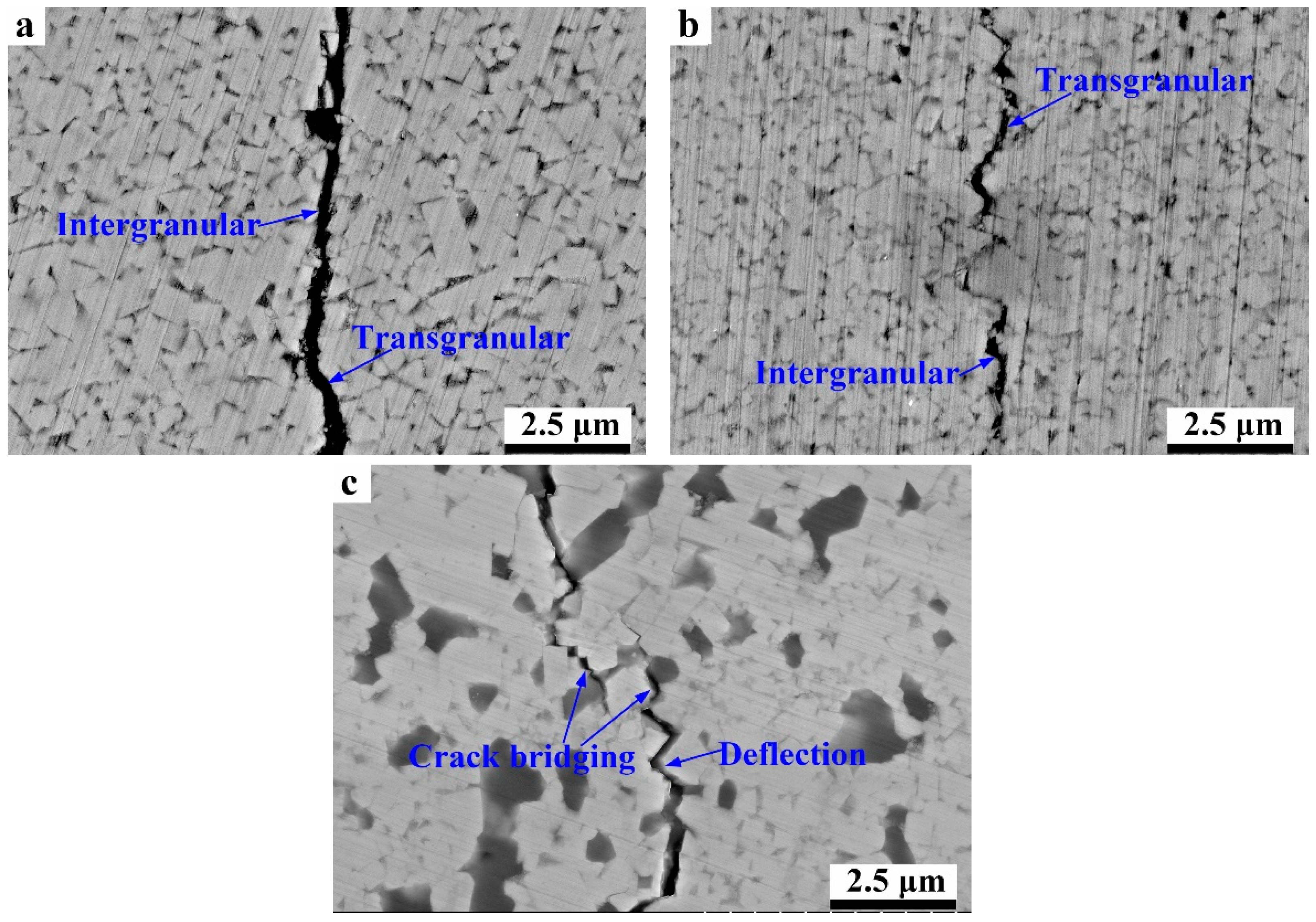

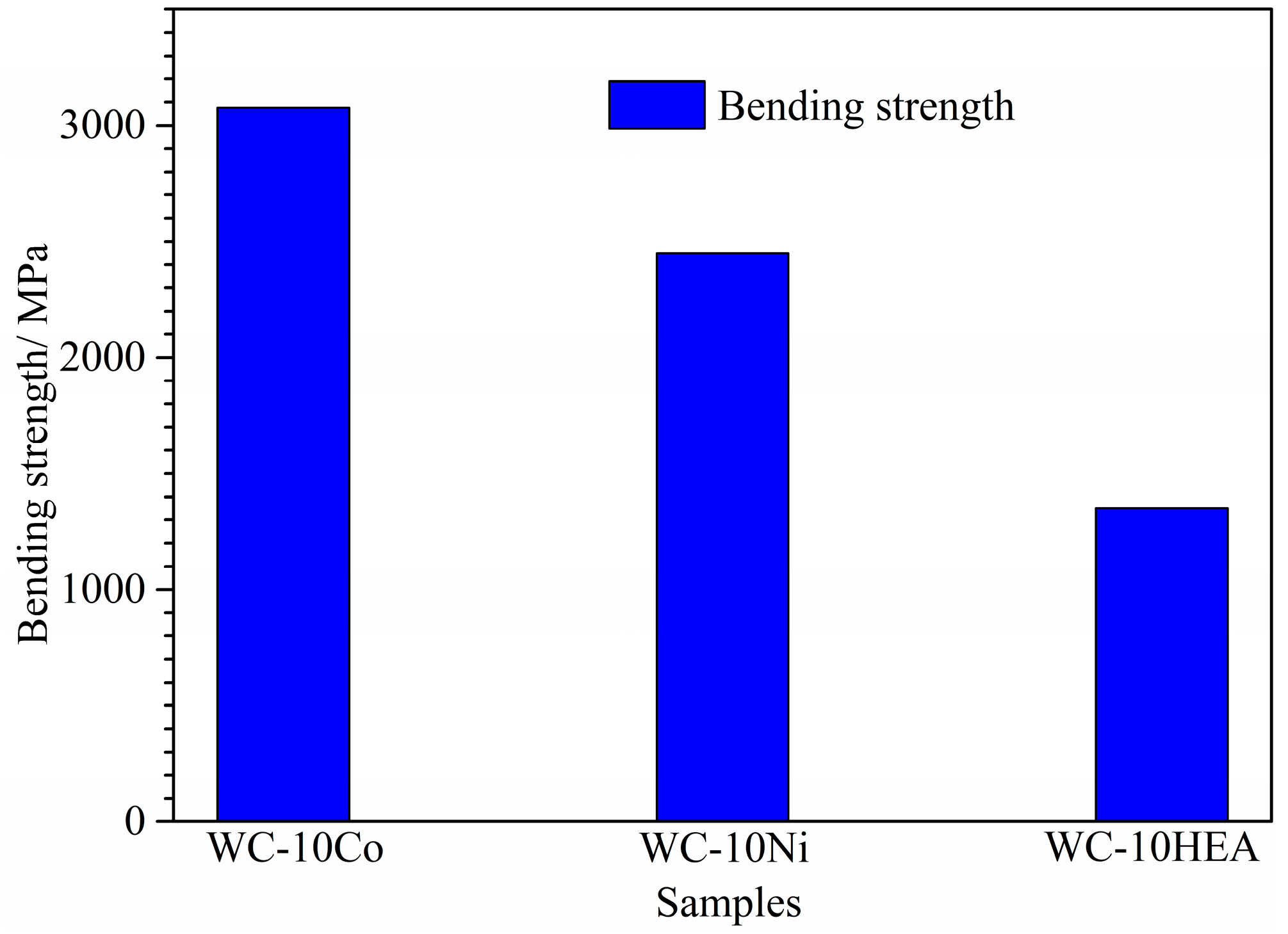

3.2. Mechanical Properties

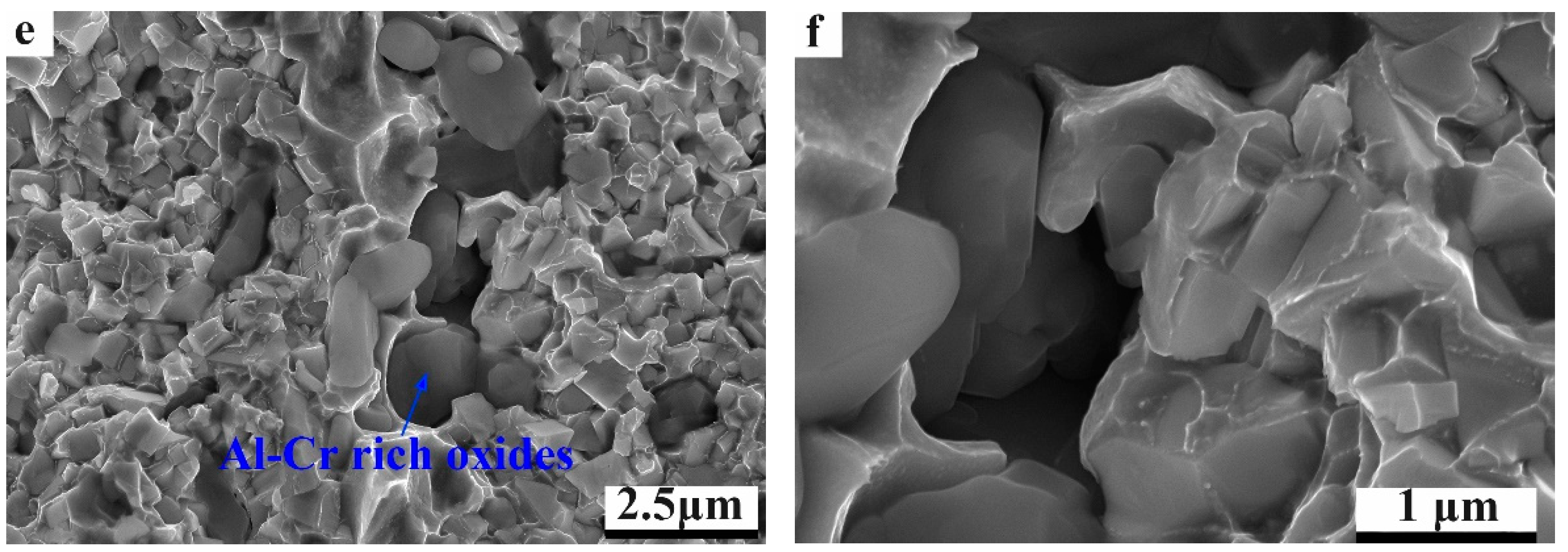

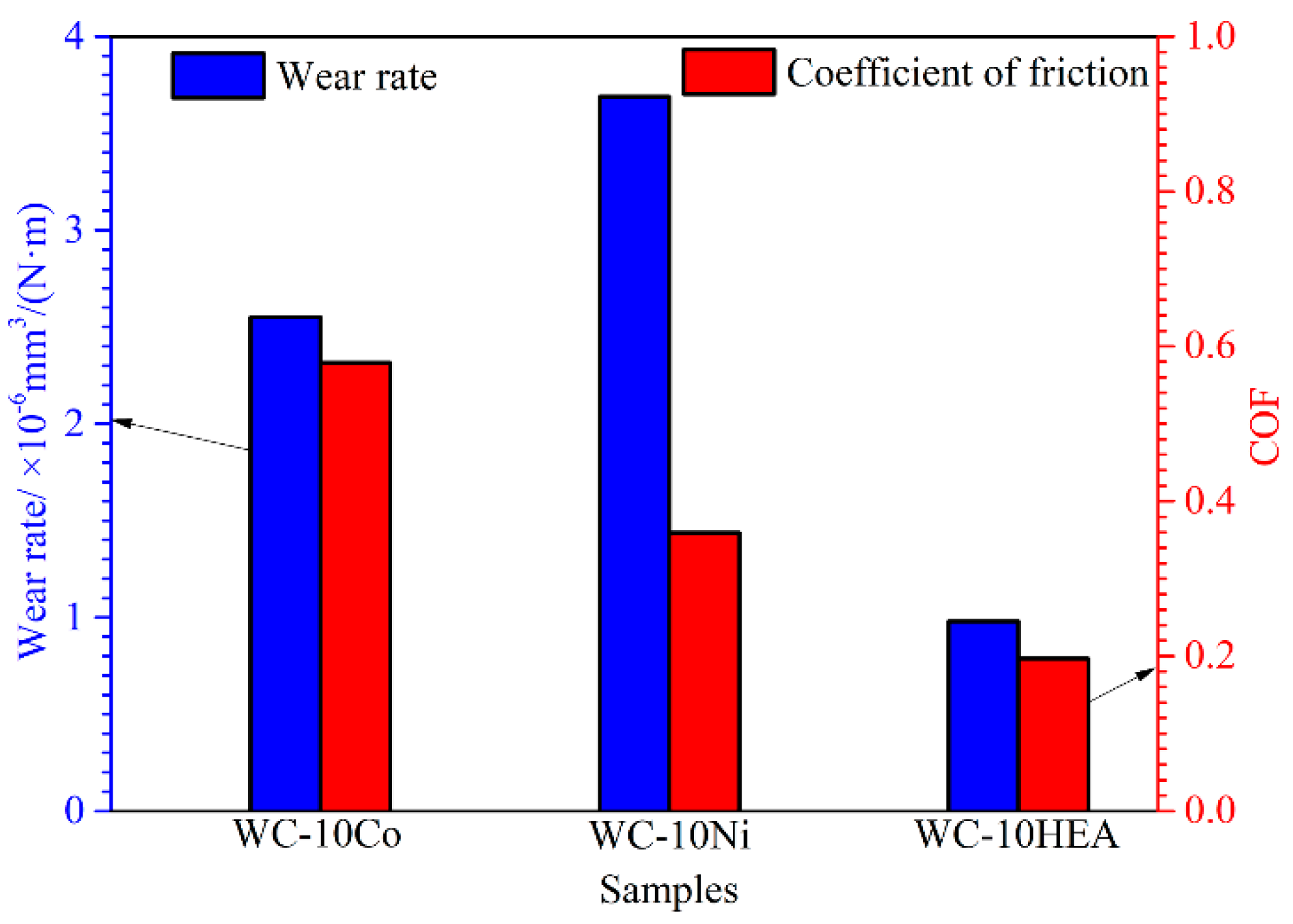

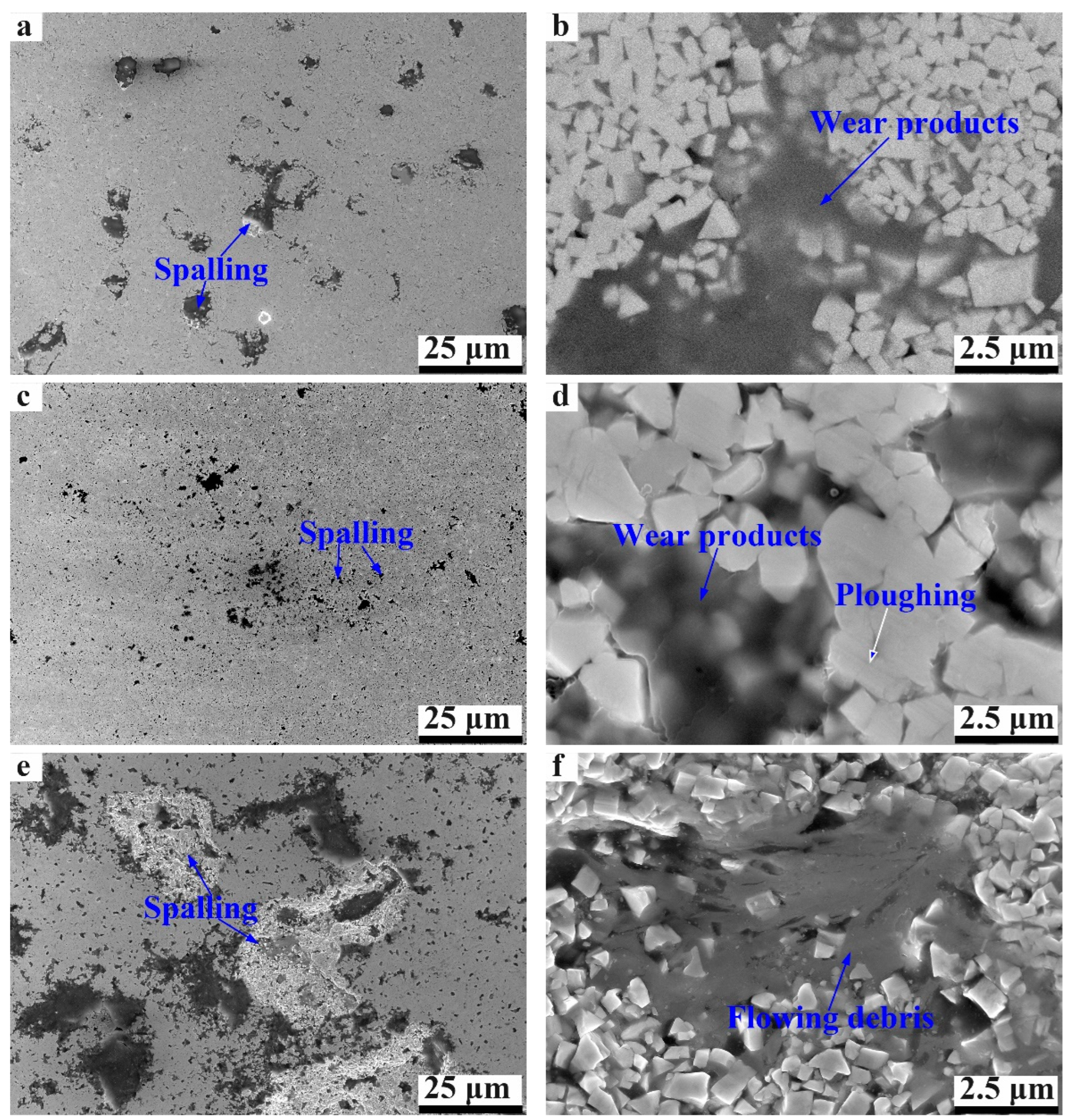

3.3. Wear Resistance

4. Conclusions

- (1)

- WC-based cermets fabricated using SPS show ultrafine WC grains with an average size less than 410 nm. WC-10HEA shows larger WC grain size and lower relative density than WC-10Co and WC-10Ni.

- (2)

- WC-10HEA cermet has the highest hardness and fracture toughness of 93.2 HRA and 11.3 MP·m1/2, respectively, owing to the higher hardness of the HEA phase and longer propagation paths during fracturing.

- (3)

- The bending strength is only 1349.62 MPa, which is much lower than that of WC-10Co; the poor bending strength is mainly attributed to the low relative density, coarser WC particles and existence of a Cr-Al rich phase.

- (4)

- Compared to WC-10Co and WC-10Ni, WC-10HEA shows the lowest wear rate of 0.98 × 10−6 mm3/(N·m) and a COF of 0.196. The higher hardness and fracture toughness contribute to the higher wear resistance, while the wear product film consisting of Fe, Co, Ni and Cu improves the lubricating performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghasali, E.; Ebadzadeh, T.; Alizadeh, M.; Razavi, M. Mechanical and microstructural properties of WC-based cermets: A comparative study on the effect of Ni and Mo binder phases. Ceram. Int. 2018, 44, 2283–2291. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, K.; Hu, Y.; Dong, Y. Microstructure and properties of coarse WC-10CoCrFeMnNi cemented carbide by mechanical alloying and hot pressing sintering. Mater. Today Commun. 2023, 37, 107137. [Google Scholar] [CrossRef]

- Gille, G.; Szesny, B.; Dreyer, K.; van den Berg, H.; Schmidt, J.; Gestrich, T.; Leitner, G. Submicron and ultrafine grained hardmetals for microdrills and metal cutting inserts. Int. J. Refract. Met. Hard Mater. 2002, 20, 3–22. [Google Scholar] [CrossRef]

- Tang, X.; Wang, Z.; Huang, L.; Wang, X.; Chang, T.; Huang, P.; Zhu, Z. Preparation, properties and microstructure of high hardness WC-Co cemented carbide tool materials for ultra-precision machining. Int. J. Refract. Met. Hard Mater. 2023, 116, 106356. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, Z.; Qin, Y.; Bao, Z.; Luo, L. Ultrafine/nano WC-Co cemented carbide: Overview of preparation and key technologies. J. Mater. Res. Technol. 2023, 27, 5822–5839. [Google Scholar] [CrossRef]

- Chang, S.-H.; Chen, S.-L. Characterization and properties of sintered WC–Co and WC–Ni–Fe hard metal alloys. J. Alloys Compd. 2014, 585, 407–413. [Google Scholar] [CrossRef]

- Santos, R.F.; Rocha, A.M.F.; Bastos, A.C.; Cardoso, J.P.; Rodrigues, F.; Fernandes, C.M.; Sacramento, J.; Ferreira, M.G.S.; Senos, A.M.R.; Fonseca, C.; et al. Microstructural characterization and corrosion resistance of WC-Ni-Cr-Mo composite—The effect of Mo. Int. J. Refract. Met. Hard Mater. 2020, 86, 105090. [Google Scholar] [CrossRef]

- Zhou, P.L.; Xiao, D.H.; Zhou, P.F.; Yuan, T.C. Microstructure and properties of ultrafine grained AlCrFeCoNi/WC cemented carbides. Ceram. Int. 2018, 44, 17160–17166. [Google Scholar] [CrossRef]

- Rong, H.; Peng, Z.; Ren, X.; Peng, Y.; Wang, C.; Fu, Z.; Qi, L.; Miao, H. Ultrafine WC–Ni cemented carbides fabricated by spark plasma sintering. Mater. Sci. Eng. A 2012, 532, 543–547. [Google Scholar] [CrossRef]

- Silvestroni, L.; Gilli, N.; Migliori, A.; Sciti, D.; Watts, J.; Hilmas, G.E.; Fahrenholtz, W.G. Binderless WC with high strength and toughness up to 1500 °C. J. Eur. Ceram. Soc. 2020, 40, 2287–2294. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Luo, Y.; Wu, M. Fabrication and characterization of WC-AlCoCrCuFeNi high-entropy alloy composites by spark plasma sintering. J. Alloys Compd. 2018, 754, 163–170. [Google Scholar] [CrossRef]

- Liang, F.; Du, J.; Su, G.; Zhang, P.; Zhang, C. Investigating the effect of Al, Mo or Mn addition to CoCrFeNi entropy alloys on the interface binding properties of WC/HEA cemented carbides. Mater. Today Commun. 2023, 35, 105891. [Google Scholar] [CrossRef]

- Zeng, S.; Jin, Y.; Zhou, R.; Wu, X.; Su, W.; Tang, X. Strengthening and toughening of WC-Ni alloys by adding novel (Ti, Hf, Ta, Nb, Zr)(C, N) high entropy powder. Int. J. Refract. Met. Hard Mater. 2024, 118, 106436. [Google Scholar] [CrossRef]

- Lee, J.-H.; Oh, I.-H.; Jang, J.-H.; Hong, S.-K.; Park, H.-K. Mechanical properties and microstructural evolution of WC-binderless and WC-Co hard materials by the heat treatment process. J. Alloys Compd. 2019, 786, 1–10. [Google Scholar] [CrossRef]

- Tehrani, H.M.; Shoja-Razavi, R.; Erfanmanesh, M.; Hashemi, S.H.; Barekat, M. Evaluation of the mechanical properties of WC-Ni composite coating on an AISI 321 steel substrate. Opt. Laser Technol. 2020, 127, 106138. [Google Scholar] [CrossRef]

- Su, W.; Sun, Y.; Liu, J.; Feng, J.; Ruan, J. Effects of Ni on the microstructures and properties of WC–6Co cemented carbides fabricated by WC–6(Co, Ni) composite powders. Ceram. Int. 2015, 41, 3169–3177. [Google Scholar] [CrossRef]

- Huang, Z.; Ren, X.; Liu, M.; Xu, C.; Zhang, X.; Guo, S.; Chen, H. Effect of Cu on the microstructures and properties of WC-6Co cemented carbides fabricated by SPS. Int. J. Refract. Met. Hard Mater. 2017, 62, 155–160. [Google Scholar] [CrossRef]

- Eso, O.; Wang, X.; Wolf, S.; Puzz, T. Property correlations of WC-Co with modified binders. Int. J. Refract. Met. Hard Mater. 2024, 118, 106482. [Google Scholar] [CrossRef]

- Pu, G.; Lin, L.; Ang, R.; Zhang, K.; Liu, B.; Liu, B.; Peng, T.; Liu, S.; Li, Q. Outstanding radiation tolerance and mechanical behavior in ultra-fine nanocrystalline Al1.5CoCrFeNi high entropy alloy films under He ion irradiation. Appl. Surf. Sci. 2020, 516, 146129. [Google Scholar] [CrossRef]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar] [CrossRef]

- Holmström, E.; Lizárraga, R.; Linder, D.; Salmasi, A.; Wang, W.; Kaplan, B.; Mao, H.; Larsson, H.; Vitos, L. High entropy alloys: Substituting for cobalt in cutting edge technology. Appl. Mater. Today 2018, 12, 322–329. [Google Scholar] [CrossRef]

- Soria-Biurrun, T.; Navarrete-Cuadrado, J.; Lozada-Cabezas, L.; Ibarreta-Lopez, F.; Martinez-Pampliega, R.; Sánchez-Moreno, J.M. Microstructure, mechanical properties and fracture behavior of NiCoCrTiAl and FeNiCoCr new alternative binders for WC based hardmetals. Int. J. Refract. Met. Hard Mater. 2022, 103, 105748. [Google Scholar] [CrossRef]

- Mueller-Grunz, A.; Alveen, P.; Rassbach, S.; Useldinger, R.; Moseley, S. The manufacture and characterization of WC-(Al)CoCrCuFeNi cemented carbides with nominally high entropy alloy binders. Int. J. Refract. Met. Hard Mater. 2019, 84, 105032. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, J.; Cheng, Q. Microstructure and sliding wear behavior of (AlCoCrFeNi)1−x(WC)x. Ceram. Int. 2022, 48, 19399–19411. [Google Scholar] [CrossRef]

- Yang, C.-M.; Liu, X.-B.; Liu, Y.-F.; Zhu, Z.-X.; Meng, Y.; Zhou, H.-B.; Zhang, S.-H. Effect of Cu-doping on tribological properties of laser-cladded FeCoCrNiCux high-entropy alloy coatings. Tribol. Int. 2023, 188, 108868. [Google Scholar] [CrossRef]

- Nayebi, B.; Asl, M.S.; Akhlaghi, M.; Ahmadi, Z.; Tayebifard, S.A.; Salahi, E.; Shokouhimehr, M.; Mohammadi, M. Spark plasma sintering of TiB2-based ceramics with Ti3AlC2. Ceram. Int. 2021, 47, 11929–11934. [Google Scholar] [CrossRef]

- Bathula, S.; Saravanan, M.; Dhar, A. Nanoindentation and Wear Characteristics of Al 5083/SiCp Nanocomposites Synthesized by High Energy Ball Milling and Spark Plasma Sintering. J. Mater. Sci. Technol. 2012, 28, 969–975. [Google Scholar] [CrossRef]

- Buravleva, A.A.; Fedorets, A.N.; Vornovskikh, A.A.; Ognev, A.V.; Nepomnyushchaya, V.A.; Sakhnevich, V.N.; Lembikov, A.O.; Kornakova, Z.E.; Kapustina, O.V.; Tarabanova, A.E.; et al. Spark Plasma Sintering of WC-Based 10wt%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes. Materials 2022, 15, 1091. [Google Scholar] [CrossRef]

- Shon, I.-J.; Kim, B.-R.; Doh, J.-M.; Yoon, J.-K.; Woo, K.-D. Properties and rapid consolidation of ultra-hard tungsten carbide. J. Alloys Compd. 2010, 489, L4–L8. [Google Scholar] [CrossRef]

- Buravlev, I.Y.; Shichalin, O.O.; Papynov, E.K.; Golub, A.V.; Gridasova, E.A.; Buravleva, A.A.; Yagofarov, V.Y.; Dvornik, M.I.; Fedorets, A.N.; Reva, V.P.; et al. WC-5TiC-10Co hard metal alloy fabrication via mechanochemical and SPS techniques. Int. J. Refract. Met. Hard Mater. 2021, 94, 105385. [Google Scholar] [CrossRef]

- GB/T 6569-2006; Fine Ceramics (Advanced Ceramics, advanced Technical Ceramics)—Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature. Standards Press of China: Beijing, China, 2006.

- Jian, Y.; Qi, H.; Zhang, J.; Kong, H.; Huang, Z.; Xing, J. Effects of trace Si addition on the microstructure evolution and mechanical properties of MoAlB ceramic. J. Alloys Compd. 2023, 941, 168873. [Google Scholar] [CrossRef]

- Schubert, W.D.; Neumeister, H.; Kinger, G.; Lux, B. Hardness to toughness relationship of fine-grained WC-Co hardmetals. Int. J. Refract. Met. Hard Mater. 1998, 16, 133–142. [Google Scholar] [CrossRef]

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Nino, A.; Izu, Y.; Sekine, T.; Sugiyama, S.; Taimatsu, H. Effects of ZrC and SiC addition on the microstructures and mechanical properties of binderless WC. Int. J. Refract. Met. Hard Mater. 2017, 69, 259–265. [Google Scholar] [CrossRef]

- Furushima, R.; Katou, K.; Nakao, S.; Sun, Z.M.; Shimojima, K.; Hosokawa, H.; Matsumoto, A. Relationship between hardness and fracture toughness in WC–FeAl composites fabricated by pulse current sintering technique. Int. J. Refract. Met. Hard Mater. 2014, 42, 42–46. [Google Scholar] [CrossRef]

- Lay, S.; Antoni-Zdziobek, A.; Pötschke, J.; Herrmann, M. Microstructural investigations in binderless tungsten carbide with grain growth inhibitors. Int. J. Refract. Met. Hard Mater. 2020, 93, 105340. [Google Scholar] [CrossRef]

- Kim, H.-C.; Yoon, J.-K.; Doh, J.-M.; Ko, I.-Y.; Shon, I.-J. Rapid sintering process and mechanical properties of binderless ultra fine tungsten carbide. Mater. Sci. Eng. A 2006, 435–436, 717–724. [Google Scholar] [CrossRef]

- Bartkowska, A.; Swadźba, R.; Popławski, M.; Bartkowski, D. Microstructure, microhardness, phase analysis and chemical composition of laser remelted FeB-Fe2B surface layers produced on Vanadis-6 steel. Opt. Laser Technol. 2016, 86, 115–125. [Google Scholar] [CrossRef]

- Bartkowski, D.; Bartkowska, A. Wear resistance in the soil of Stellite-6/WC coatings produced using laser cladding method. Int. J. Refract. Met. Hard Mater. 2017, 64, 20–26. [Google Scholar] [CrossRef]

- Cha, S.I.; Hong, S.H. Microstructures of binderless tungsten carbides sintered by spark plasma sintering process. Mater. Sci. Eng. A 2003, 356, 381–389. [Google Scholar] [CrossRef]

- Demir, B.; Ayas, E. Synthesis of Cr2AlB2 MAB phase via Spark Plasma Sintering: Effect of temperature, dwell time, and Al content. Materialia 2022, 22, 101416. [Google Scholar] [CrossRef]

- Bei, G.P.; Gauthier-Brunet, V.; Tromas, C.; Dubois, S.; Scattergood, R. Synthesis, Characterization, and Intrinsic Hardness of Layered Nanolaminate Ti3AlC2 and Ti3Al0.8Sn0.2C2 Solid Solution. J. Am. Ceram. Soc. 2012, 95, 102–107. [Google Scholar] [CrossRef]

- Aguilar-Hurtado, J.Y.; Vargas-Uscategui, A.; Paredes-Gil, K.; Palma-Hillerns, R.; Tobar, M.J.; Amado, J.M. Boron addition in a non-equiatomic Fe50Mn30Co10Cr10 alloy manufactured by laser cladding: Microstructure and wear abrasive resistance. Appl. Surf. Sci. 2020, 515, 146084. [Google Scholar] [CrossRef]

- Cao, Z.; Jian, Y.; Zhao, Z.; Xiao, P.; Xu, L.; Huang, Z. On the reaction mechanism of Mo2FeB2-based cermets and wear transition induced by self-lubricating tribo-oxide layer. Int. J. Refract. Met. Hard Mater. 2023, 110, 106012. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Barekat, M.; Hashemi, S.H. Friction and wear behavior of laser cladded WC-Co and Ni/WC-Co deposits at high temperature. Int. J. Refract. Met. Hard Mater. 2019, 81, 137–148. [Google Scholar] [CrossRef]

- Benamor, A.; Hadji, Y.; Kota, S.; Chiker, N.; Liu, L.; Haddad, A.; Sahraoui, T.; Ying, G.; Hadji, M. Friction and wear characteristics of the nanolaminated ternary transition metal boride: Mn2AlB2. Wear 2022, 492–493, 204232. [Google Scholar] [CrossRef]

| Species | Purity | D50/μm | Producers |

|---|---|---|---|

| WC | >99.9% | 0.6 | Ying Rui Technology Co., Ltd., Shenzhen, China |

| Co | >99.9% | 1.0 | |

| Ni | >99.9% | 1.0 | |

| HEA | >99.9% | 10.0 |

| Samples | Binder Phase | Grain Size/nm | Density, % | Hardness/HRC | Vickers Hardness/HV | Fracture Toughness/MPa·m1/2 | Bending Strength/MPa | COF | Wear Rate/10−6 mm3/(N·m) |

|---|---|---|---|---|---|---|---|---|---|

| WC-10Co | Co | 363 | 99.6 | 92.75 | 1911.5 | 11.27571 | 3075.78 | 0.5789 | 2.55 |

| WC-10Ni | Ni | 375 | 99.82 | 92.2 | 1864.8 | 10.7915 | 2450.23 | 0.3593 | 3.69 |

| WC-10HEA | AlCoCrNiFeCu | 404 | 98.14 | 93.24 | 2055.3 | 11.30462 | 1349.62 | 0.1965 | 0.98 |

| Samples | W | C | Si | O | Co | Ni | Al | Cr | Fe | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| WC-10Co | 19.04 | 5.64 | 16.32 | 54.66 | 2.13 | |||||

| WC-10Ni | 22.05 | 12.81 | 15.41 | 46.01 | 3.65 | |||||

| WC-10HEA | 2.96 | 9.06 | 2.27 | 3.02 | 20.63 | 21.32 | 2.59 | 1.28 | 17.63 | 18.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, K.; Wang, Z.; Cao, P.; Peng, X.; Chen, C.; Liu, Q.; Xie, S.; Wu, X.; Jian, Y. Microstructure, Mechanical Properties and Wear Behaviors of Ultrafine-Grain WC-Based Cermets with Different Binder Phases Fabricated by Spark Plasma Sintering. Materials 2024, 17, 659. https://doi.org/10.3390/ma17030659

Xu K, Wang Z, Cao P, Peng X, Chen C, Liu Q, Xie S, Wu X, Jian Y. Microstructure, Mechanical Properties and Wear Behaviors of Ultrafine-Grain WC-Based Cermets with Different Binder Phases Fabricated by Spark Plasma Sintering. Materials. 2024; 17(3):659. https://doi.org/10.3390/ma17030659

Chicago/Turabian StyleXu, Kangwei, Zhe Wang, Peipei Cao, Xiangyang Peng, Chao Chen, Qingsong Liu, Shufeng Xie, Xiaoyu Wu, and Yongxin Jian. 2024. "Microstructure, Mechanical Properties and Wear Behaviors of Ultrafine-Grain WC-Based Cermets with Different Binder Phases Fabricated by Spark Plasma Sintering" Materials 17, no. 3: 659. https://doi.org/10.3390/ma17030659

APA StyleXu, K., Wang, Z., Cao, P., Peng, X., Chen, C., Liu, Q., Xie, S., Wu, X., & Jian, Y. (2024). Microstructure, Mechanical Properties and Wear Behaviors of Ultrafine-Grain WC-Based Cermets with Different Binder Phases Fabricated by Spark Plasma Sintering. Materials, 17(3), 659. https://doi.org/10.3390/ma17030659