Simulation and Experimental Study on the Effect of Superheat on Solidification Microstructure Evolution of Billet in Continuous Casting

Abstract

1. Introduction

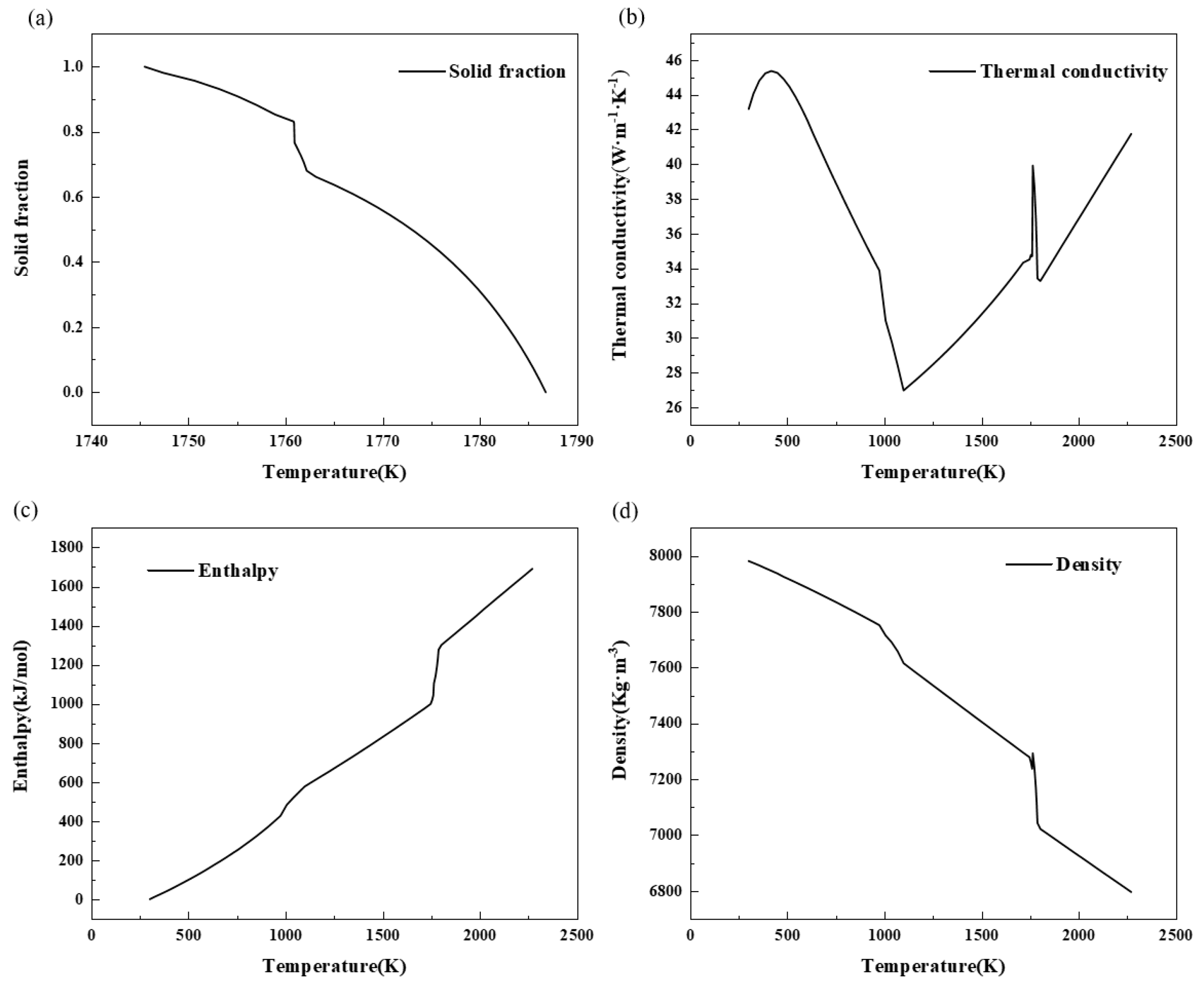

2. Materials and Methods

2.1. Nucleation Model

2.2. Dendrite Growth Model

2.3. Model Parameters and Boundary Conditions

- (1)

- The solidification shrinkage was not taken into account;

- (2)

- The self-nucleation was not taken into consideration;

- (3)

- The model assumes that the solidification process was carried out under equilibrium conditions, and each solid phase and liquid phase in the alloy were formed under their equilibrium conditions;

- (4)

- The model ignores the reverse reaction between the solid phase and liquid phase, and the formed solid phase no longer reacts with the liquid phase;

- (5)

- The simulation assumes that the elements in the alloy are ideally mixed, and the effect of element diffusion on the solidification structure was ignored.

3. Experimental Implementation

4. Results and Discussion

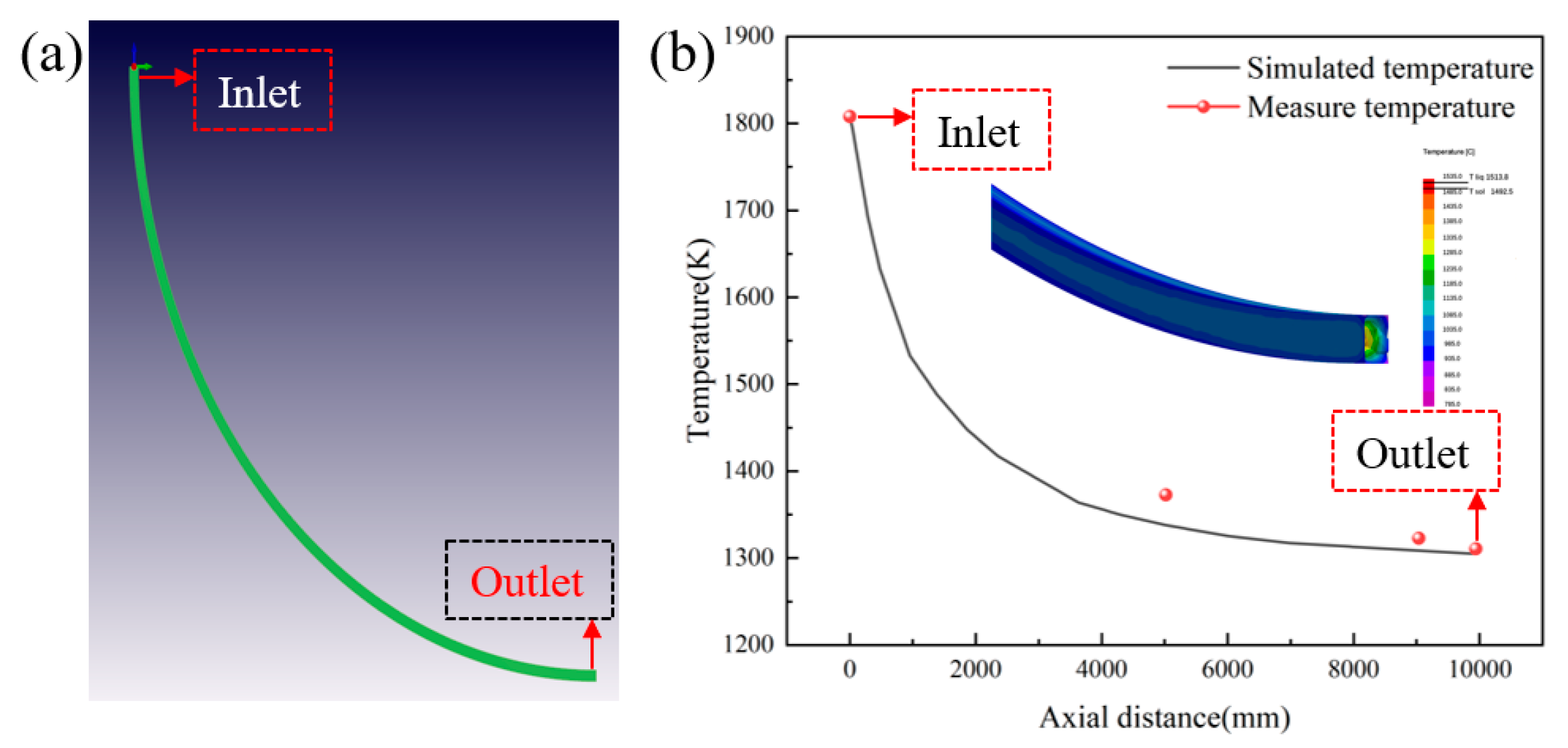

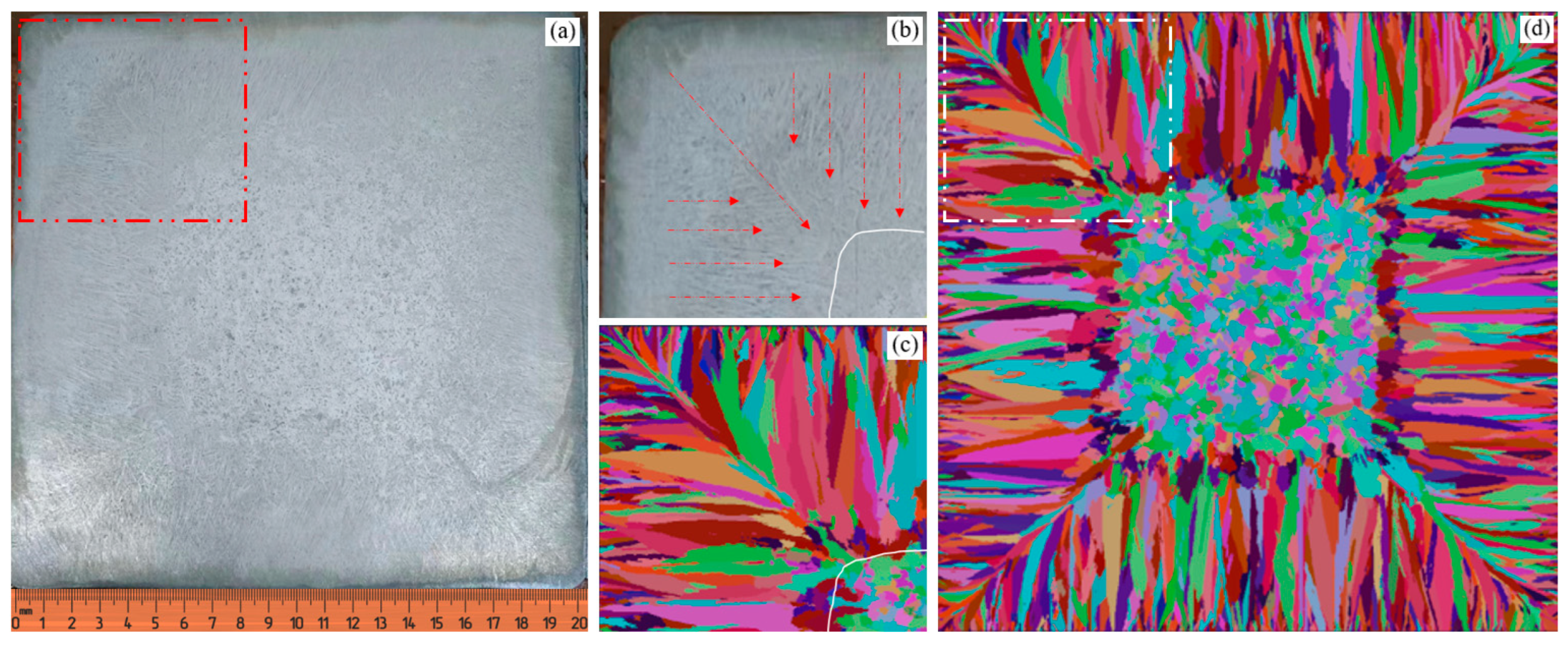

4.1. Simulation Verification

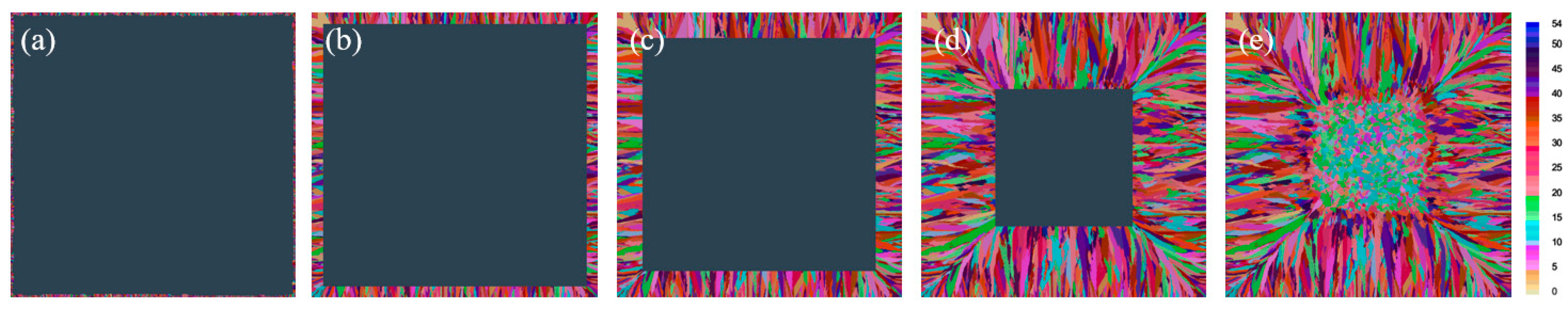

4.2. Simulation of Solidification Structure Evolution with Different Superheat

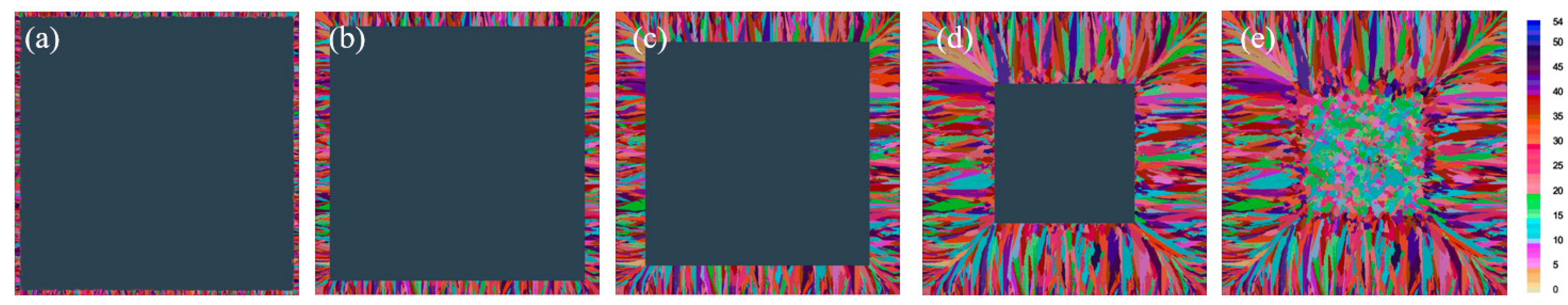

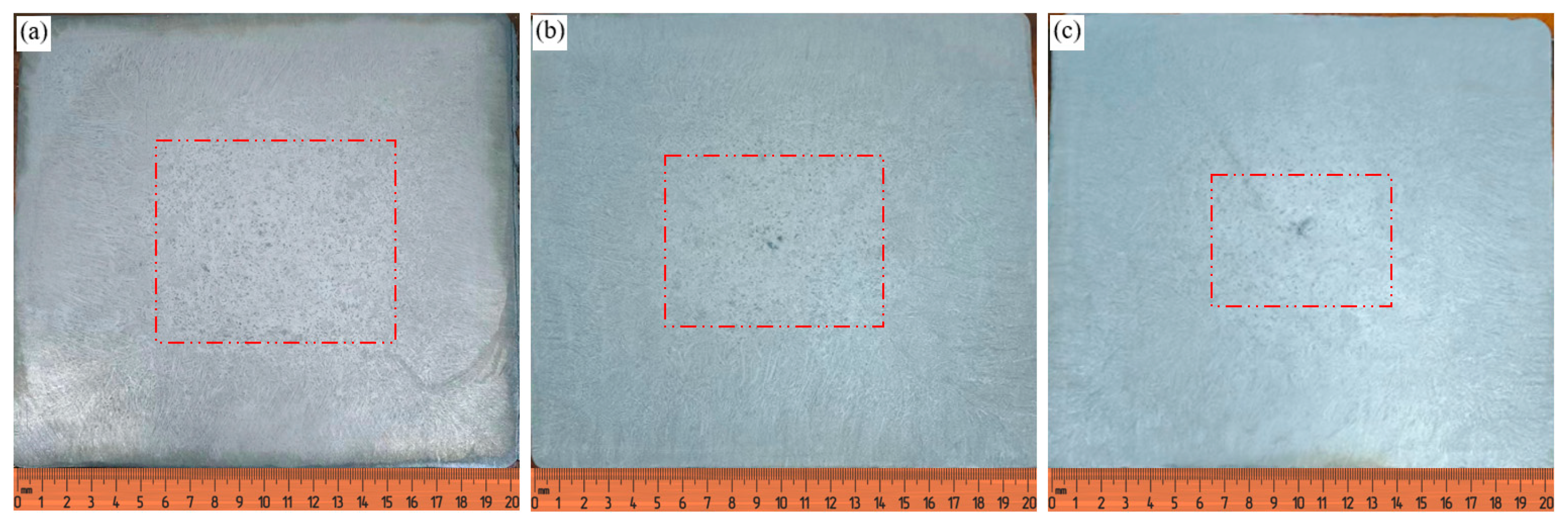

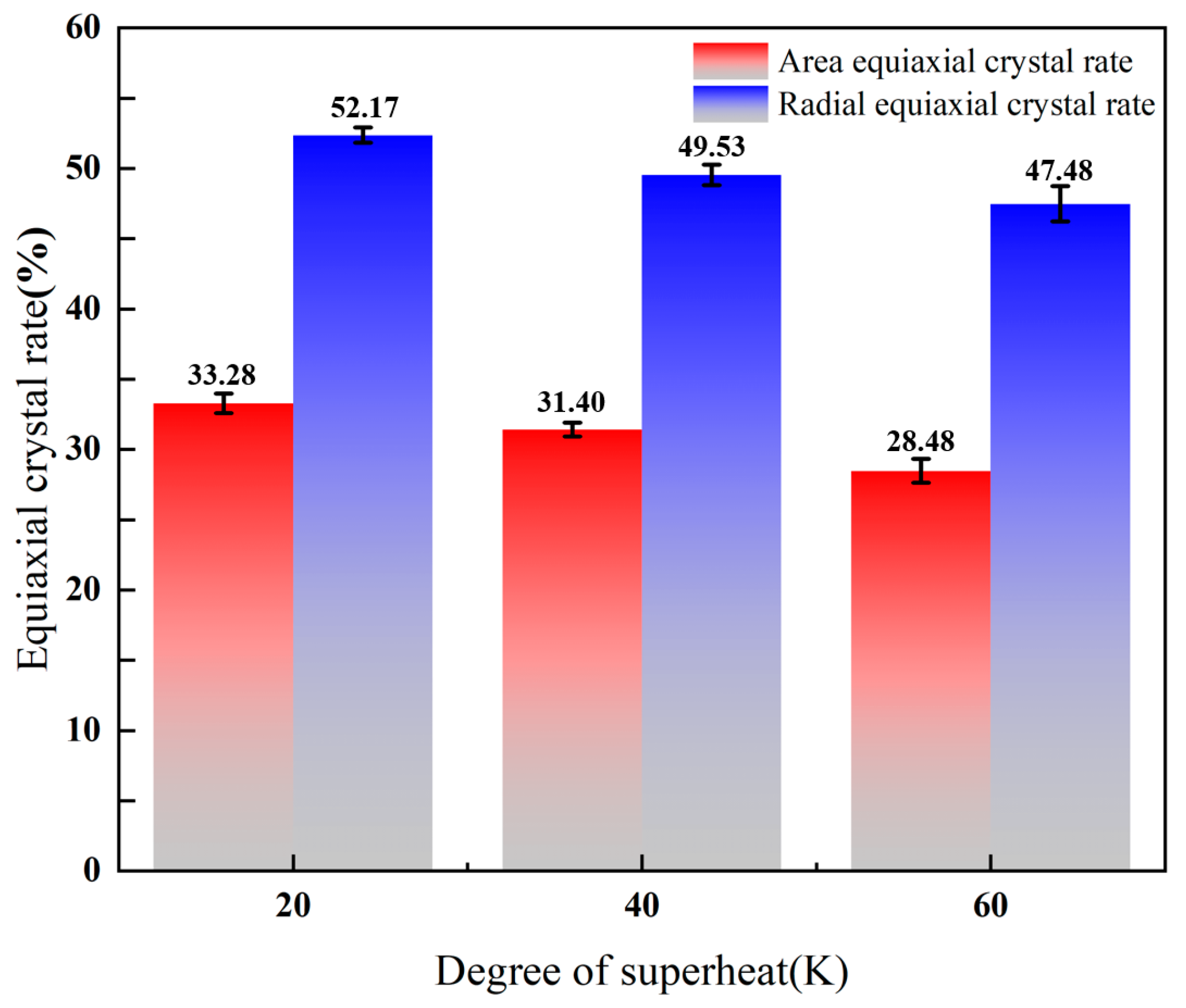

4.3. Experiment of Influence of Different Superheat on Solidification Structure

5. Conclusions

- (1)

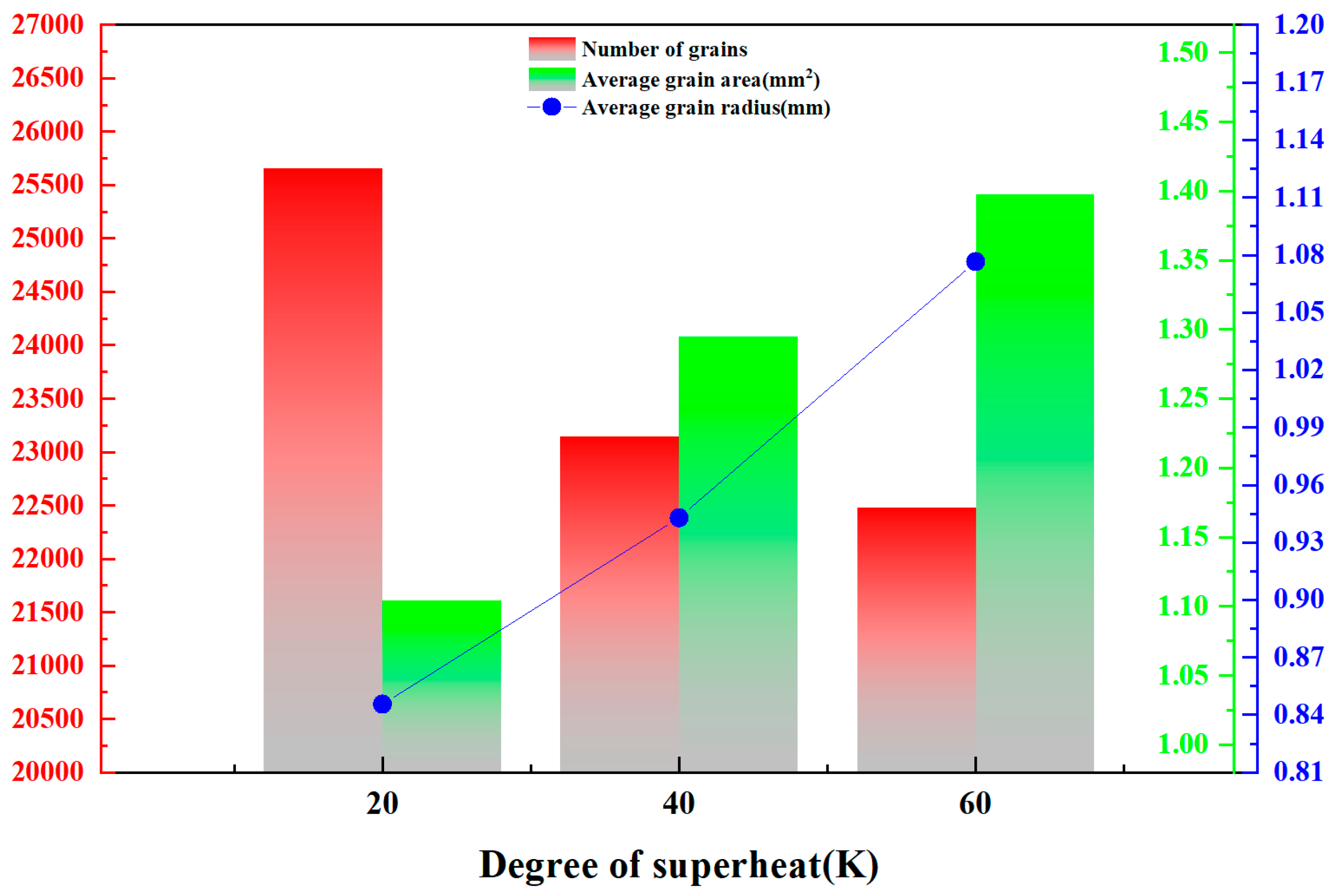

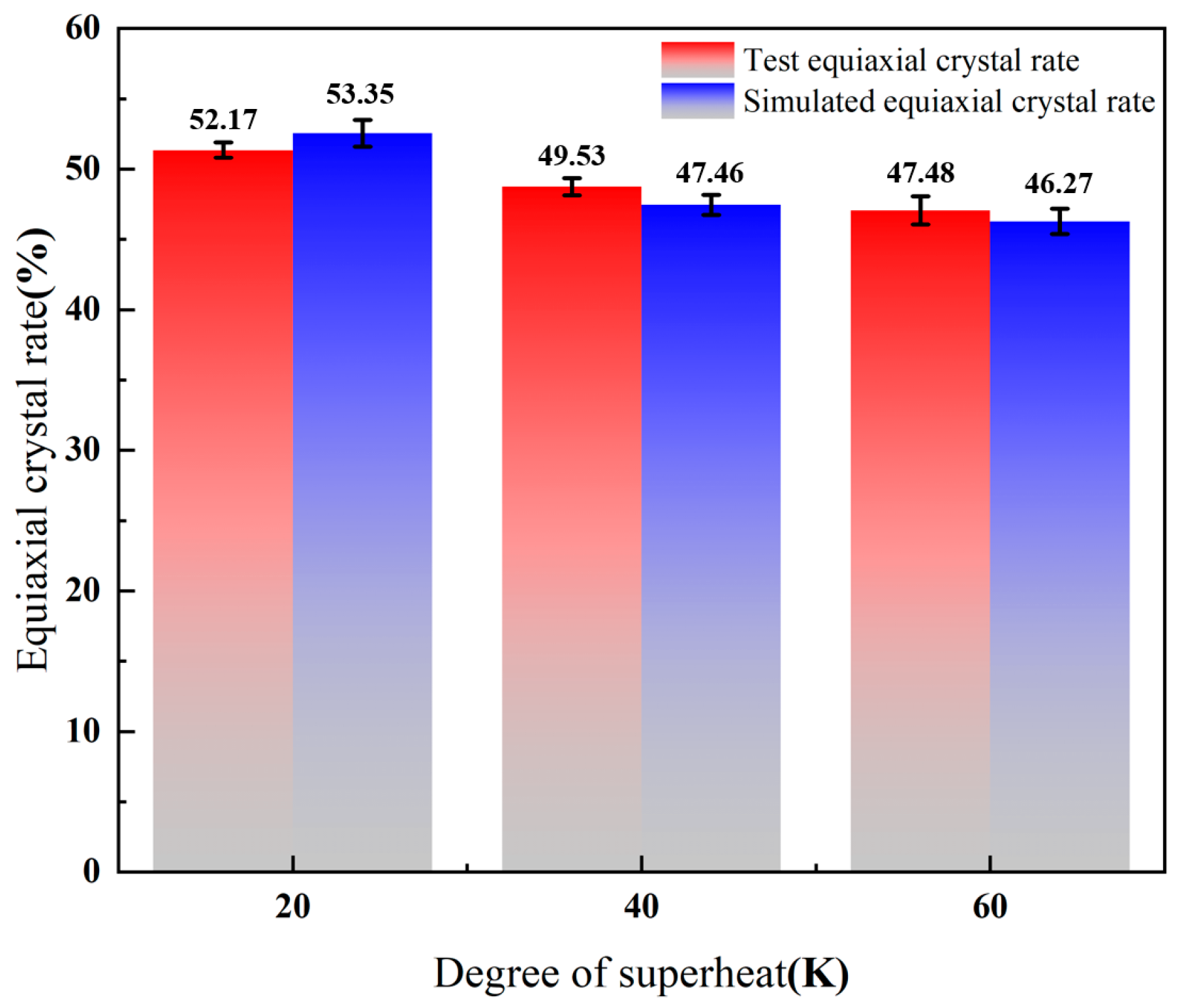

- The simulation results of solidification microstructure evolution during the solidification process of casting billet with different superheats indicate that increasing superheat can inhibit the growth of equiaxed crystals and reduce the size of equiaxed crystals. The lower the superheat, the lower the edge temperature gradient, and the slower the solidification rate of the billet, which is more conducive to the growth of the medium axis of the billet. When the superheat increases from 20 K to 60 K, the proportion of the equiaxed crystal region decreases from 53.35% to 46.27%. This relationship reflects the influence of superheat on the solidification process of casting billet.

- (2)

- The experimental study of the effect of different superheats on the solidification structure of the casting billet shows that under the same conditions, the difference in equiaxed crystal rate is not significant between the simulated results and the field test results. The proportion of the equiaxed crystal region at low magnification shows that the equiaxed crystal region decreases and the columnar crystal region increases when the superheat is increased from 20 K to 60 K. Under the test condition that the superheat is increased from 20 K to 60 K, the equiaxed crystal rate decreases from 52.17% to 47.48%. When the simulated superheat increases from 20 K to 60 K, the equiaxed crystal rate decreases from 53.35% to 46.27%, indicating that the effect of different superheats on the solidification structure is consistent with the simulated results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zaeem, M.A.; Yin, H.; Felicelli, S.D. Modeling dendritic solidification of Al–3%Cu using cellular automaton and phase-field methods. Appl. Math. Model. 2013, 37, 3495–3503. [Google Scholar] [CrossRef]

- Böttger, B.; Apel, M.; Santillana, B.; Eskin, D. Phase-Field Modelling of Microstructure Formation during the Solidification of Continuously Cast Low Carbon and HSLA Steels; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2012; p. 012107. [Google Scholar]

- Reuther, K.; Rettenmayr, M. Perspectives for cellular automata for the simulation of dendritic solidification—A review. Comput. Mater. Sci. 2014, 95, 213–220. [Google Scholar] [CrossRef]

- Sun, T.; Yue, F.; Wu, H.J.; Guo, C.; Li, Y.; Ma, Z.C. Solidification Structure of Continuous Casting Large Round Billets under Mold Electromagnetic Stirring. J. Iron Steel Res. 2016, 23, 9. [Google Scholar] [CrossRef]

- Fang, Q.; Ni, H.; Zhang, H.; Wang, B.; Liu, C. Numerical Study on Solidification Behavior and Structure of Continuously Cast U71Mn Steel. Metals 2017, 7, 483. [Google Scholar] [CrossRef]

- Stefanescu, D.M. Science and Engineering of Casting Solidification; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Zhong, H.; Wang, R.; Han, Q.; Fang, M.; Yuan, H.; Song, L.; Xie, X.; Zhai, Q. Solidification structure and central segregation of 6Cr13Mo stainless steel under simulated continuous casting conditions. J. Mater. Res. Technol. 2022, 20, 3408–3419. [Google Scholar] [CrossRef]

- Sheng, Y.; Meng, X.; Liu, X.; Zhou, Z. Numerical Simulation of Solidification Structures Influenced by Cooling Spraying and Process Parameters Based on Cellular Automaton Finite-Element Model. Steel Res. Int. 2023, 94, 2200874. [Google Scholar] [CrossRef]

- Cao, J.; Hou, Z.; Guo, Z.; Guo, D.; Tang, P. Effect of Superheat on Integral Morphology Characteristics of Solidification Structure and Permeability in Bearing Steel Billet. Acta Met. Sin. 2021, 57, 586–594. [Google Scholar]

- Zhao, Y.; Chen, D.; Ma, M.; Wan, X.; Li, Y.; Qin, R. A Cellular Automaton Model Coupled with Finite Element Method for Solidification Process of Beam Blank Continuous Casting. In Proceedings of the EPD Congress 2015, Orlando, FL, USA, 15–18 May 2015; Springer: Berlin/Heidelberg, Germany, 2016; pp. 41–47. [Google Scholar]

- An, H.; Bao, Y.; Wang, M.; Yang, Q.; Dang, Y. Numerical and experimental investigation of solidification structure evolution and reduction of centre segregation in continuously cast GCr15 bloom. Ironmak. Steelmak. 2020, 47, 1063–1077. [Google Scholar] [CrossRef]

- Xiao, Z.; Dong, S.; Nie, S.; Ma, Z.; Lv, Z. Simulation of the Solidification Organization of X15CrNiSi20-12 Alloy Castings during Investment Casting Based on the CAFE Model; IOP Publishing Ltd.: Bristol, UK, 2023. [Google Scholar]

- Yamazaki, M.; Natsume, Y.; Harada, H.; Ohsasa, K. Numerical simulation of solidification structure formation during continuous casting in fe-0.7mass%c alloy using cellular automaton method. ISIJ Int. 2018, 46, 903–908. [Google Scholar] [CrossRef]

- Kalikmanov, V.I. Classical nucleation theory. In Nucleation Theory; Springer: Berlin/Heidelberg, Germany, 2012; pp. 17–41. [Google Scholar]

- Domitner, J.; Kharicha, A.; Wu, M.; Ludwig, A. Application of microprobe analysis to the reconstruction and characterization of dendritic structures. Metall. Mater. Trans. A 2013, 44, 607–616. [Google Scholar] [CrossRef]

- Yasuda, H.; Yamamoto, Y.; Nakatsuka, N.; Yoshiya, M.; Nagira, T.; Sugiyama, A.; Ohnaka, I.; Uesugi, K.; Umetani, K. In situ observation of solidification phenomena in Al–Cu and Fe–Si–Al alloys. Int. J. Cast Met. Res. 2009, 22, 15–21. [Google Scholar] [CrossRef]

- Davis, S.H. Theory of Solidification; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- Fallah, V.; Amoorezaei, M.; Provatas, N.; Corbin, S.; Khajepour, A. Phase-field simulation of solidification morphology in laser powder deposition of Ti–Nb alloys. Acta Mater. 2012, 60, 1633–1646. [Google Scholar] [CrossRef]

- Böttger, B.; Schmitz, G.; Santillana, B. Multi-phase-field modeling of solidification in technical steel grades. Trans. Indian Inst. Met. 2012, 65, 613–615. [Google Scholar] [CrossRef]

- Elahi, S.; Tavakoli, R.; Romero, I.; Tourret, D. Grain growth competition during melt pool solidification—Comparing phase-field and cellular automaton models. Comput. Mater. Sci. 2023, 216, 111882. [Google Scholar] [CrossRef]

- Saunders, N.; Miodownik, A. CALPHAD (Calculation of Phase Diagrams): A Comprehensive Guide; Pergamon Materials Series; Pergamon: Oxford, UK, 1998; p. 465. [Google Scholar]

- Soar, P.; Kao, A.; Pericleous, K. The impact of two and three dimensional assumptions on coupled structural mechanics and microstructure solidification modelling. Crystals 2023, 13, 114. [Google Scholar] [CrossRef]

- Kurz, W.; Giovanola, B.; Trivedi, R. Theory of microstructural development during rapid solidification. Acta Metall. 1986, 34, 823–830. [Google Scholar] [CrossRef]

- Esaka, H.; Wakabayashi, T.; Shinozuka, K.; Tamura, M. Origin of equiaxed grains and their motion in the liquid phase. ISIJ Int. 2003, 43, 1415–1420. [Google Scholar] [CrossRef]

- Sterkhova, I.; Kamaeva, L.V.; Lad’yanov, V.I.; Chtchelkatchev, N. Structure and solidification of the (Fe0. 75B0. 15Si0. 1) 100-xTax (x= 0–2) melts: Experiment and machine learning. J. Phys. Chem. Solids 2023, 174, 111143. [Google Scholar] [CrossRef]

- Khosroaghayani, M.; Khorasanian, M.; Alavi Zaree, S.; Eskandari, M. Investigation of microstructure and mechanical properties of AZ91 magnesium alloy produced by directional solidification method in different angles using cafe simulation. Int. J. Met. 2023, 17, 195–209. [Google Scholar] [CrossRef]

- Ji, K.; Dorari, E.; Clarke, A.J.; Karma, A. Microstructural pattern formation during far-from-equilibrium alloy solidification. Phys. Rev. Lett. 2023, 130, 026203. [Google Scholar] [CrossRef]

- Mohammed, W.; Firoozbakht, M.; Bührig–Polaczek, A. Study of the Solidification Behavior and Homogenization Heat Treatment of the Investment-Cast Al–Cu Foams: Experimental and Modelling Investigations. In Proceedings of the TMS Annual Meeting & Exhibition, San Diego, CA, USA, 19–23 March 2023; Springer: Berlin/Heidelberg, Germany, 2023; pp. 627–634. [Google Scholar]

- Jeong, J.J.; Lee, H.; Yun, D.W.; Jeong, H.W.; Yoo, Y.-S.; Seo, S.-M.; Lee, J.H. Analysis of a Single Crystal Solidification Process of an Ni-based Superalloy using a CAFE Model. Korean J. Met. Mater. 2023, 61, 126–136. [Google Scholar] [CrossRef]

- Cao, J.; Zeng, Z.; Zhang, F.; Guo, D.; Hou, Z. Effect of Cooling Rates on the Local—Overall Morphology Characteristics of Solidification Structure at Different Stages for High Carbon Steel. Metals 2021, 11, 1291. [Google Scholar] [CrossRef]

- Cao, J.; Hou, Z.; Guo, D.; Guo, Z.; Tang, P. Morphology characteristics of solidification structure in high-carbon steel billet based on fractal theory. J. Mater. Sci. 2019, 54, 12851–12862. [Google Scholar] [CrossRef]

- Wang, W.; Hou, Z.-B.; Chang, Y.; Cao, J.-H. Effect of superheat on quality of central equiaxed grain zone of continuously cast bearing steel billet based on two-dimensional segregation ratio. J. Iron Steel Res. Int. 2018, 25, 9–18. [Google Scholar] [CrossRef]

| Element | Content (wt.%) | k | m | D/m2·s−1 |

|---|---|---|---|---|

| C | 0.200 | 0.170784 | −82.6456 | 3 × 10−9 |

| Si | 0.270 | 0.594312 | −16.3372 | 3 × 10−9 |

| Mn | 0.500 | 0.710554 | −5.22204 | 3 × 10−9 |

| P | 0.035 | 0.310875 | −27.0198 | 3 × 10−9 |

| S | 0.035 | 0.036319 | −39.9102 | 3 × 10−9 |

| Cr | 0.010 | 0.884948 | −2.20964 | 3 × 10−9 |

| Ni | 0.010 | 0.818543 | −3.33588 | 3 × 10−9 |

| Cu | 0.010 | 0.827207 | −3.48933 | 3 × 10−9 |

| Nucleation Parameter | nv, max/K | ΔTv, max/K | ΔTv, σ/K | ns, max/K | ΔTs, max/K | ΔTs, σ/K |

|---|---|---|---|---|---|---|

| Value | 1 × 109 | 10 | 1 | 3 × 107 | 10 | 1 |

| Statistical Items | Superheat 20 K | Superheat 40 K | Superheat 60 K |

|---|---|---|---|

| Number of grains | 25,662 | 23,146 | 22,476 |

| Average grain area/mm2 | 1.104 | 1.295 | 1.398 |

| Average grain radius/mm | 0.84556 | 0.94281 | 1.07653 |

| Percentage of radial equiaxed crystal region/% | 53.35 | 47.46 | 46.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, N.; Zhang, G.; Yan, P.; Li, P.; Feng, Z.; Wang, X. Simulation and Experimental Study on the Effect of Superheat on Solidification Microstructure Evolution of Billet in Continuous Casting. Materials 2024, 17, 682. https://doi.org/10.3390/ma17030682

Tian N, Zhang G, Yan P, Li P, Feng Z, Wang X. Simulation and Experimental Study on the Effect of Superheat on Solidification Microstructure Evolution of Billet in Continuous Casting. Materials. 2024; 17(3):682. https://doi.org/10.3390/ma17030682

Chicago/Turabian StyleTian, Nan, Guifang Zhang, Peng Yan, Pengchao Li, Zhenhua Feng, and Xiaoliang Wang. 2024. "Simulation and Experimental Study on the Effect of Superheat on Solidification Microstructure Evolution of Billet in Continuous Casting" Materials 17, no. 3: 682. https://doi.org/10.3390/ma17030682

APA StyleTian, N., Zhang, G., Yan, P., Li, P., Feng, Z., & Wang, X. (2024). Simulation and Experimental Study on the Effect of Superheat on Solidification Microstructure Evolution of Billet in Continuous Casting. Materials, 17(3), 682. https://doi.org/10.3390/ma17030682