Formation of Corrugated Damage on Bearing Race under Different AC Shaft Voltages

Abstract

:1. Introduction

2. Experimental Method

2.1. Test Method for Electrical Erosion of Bearings

2.2. Surface Analysis

3. Results and Discussion

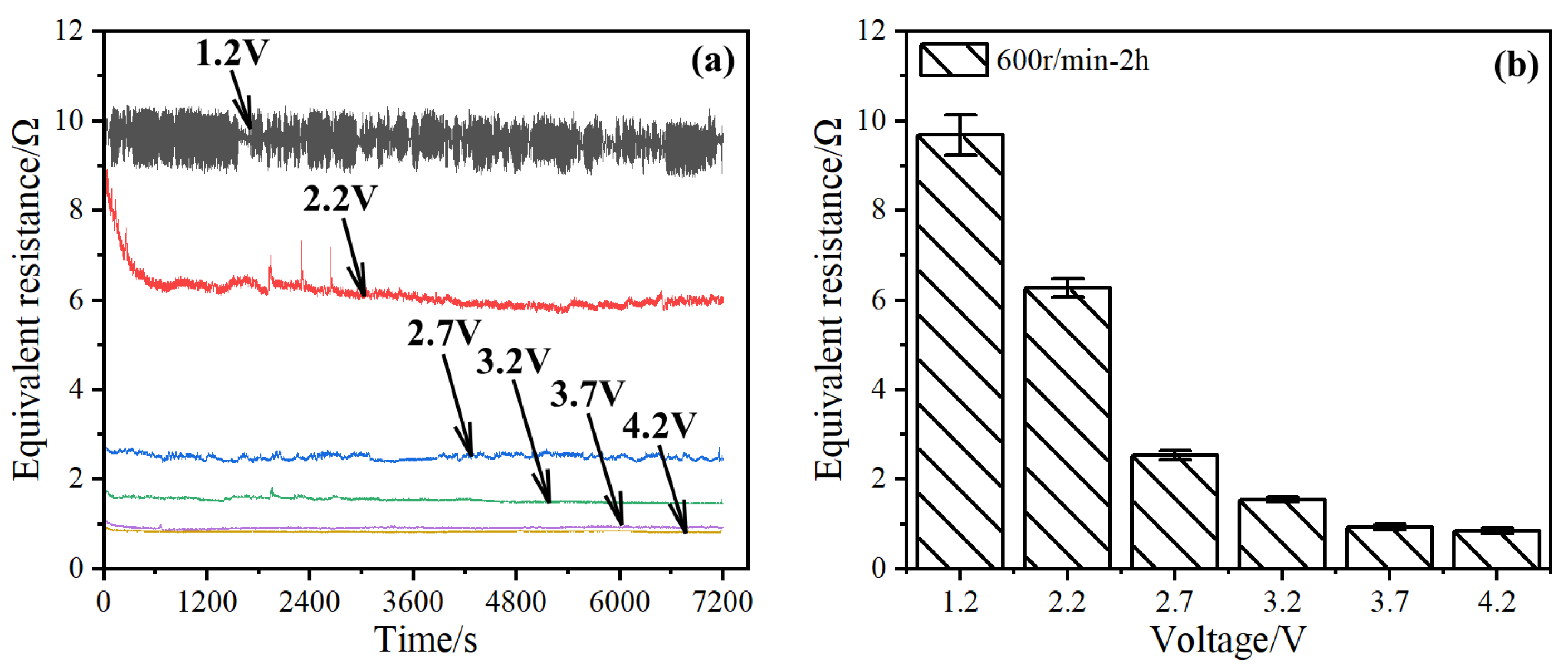

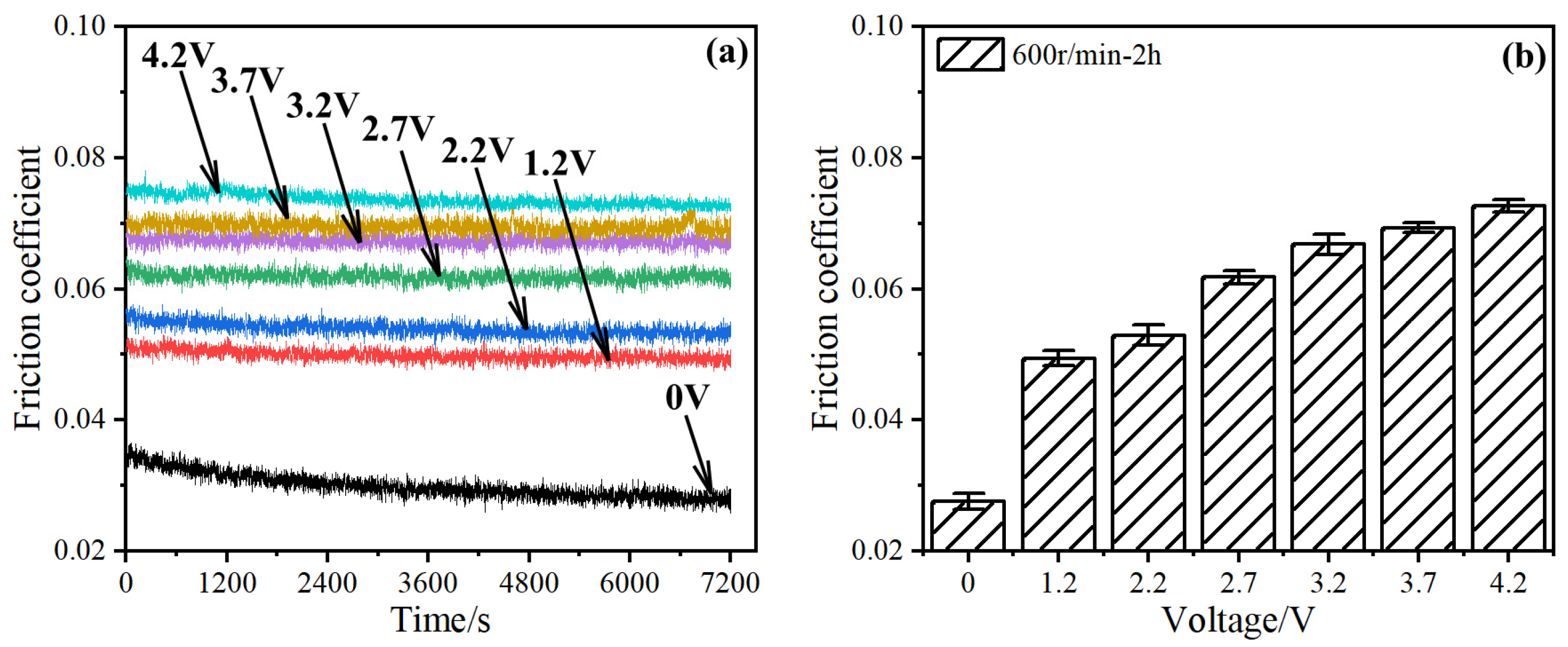

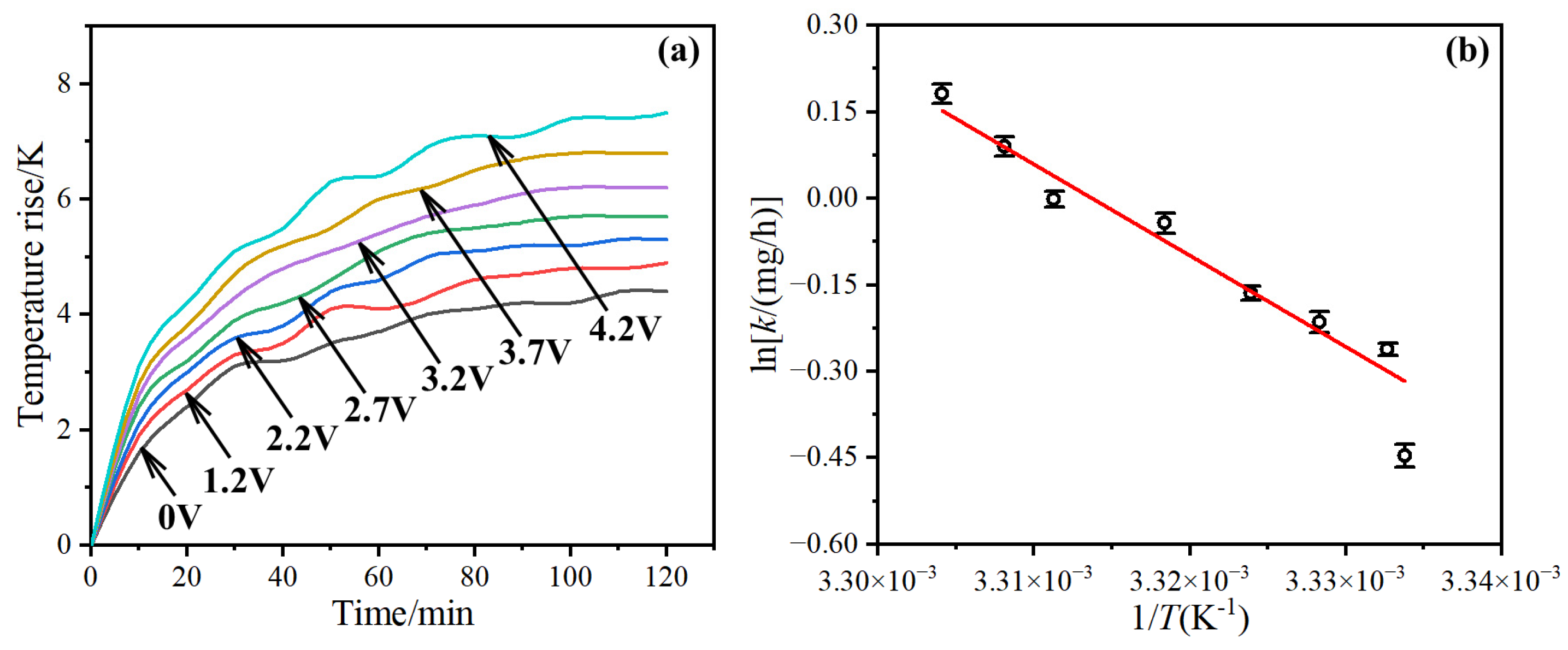

3.1. Effect of Voltage Amplitude on Current-Carrying Tribological Performance

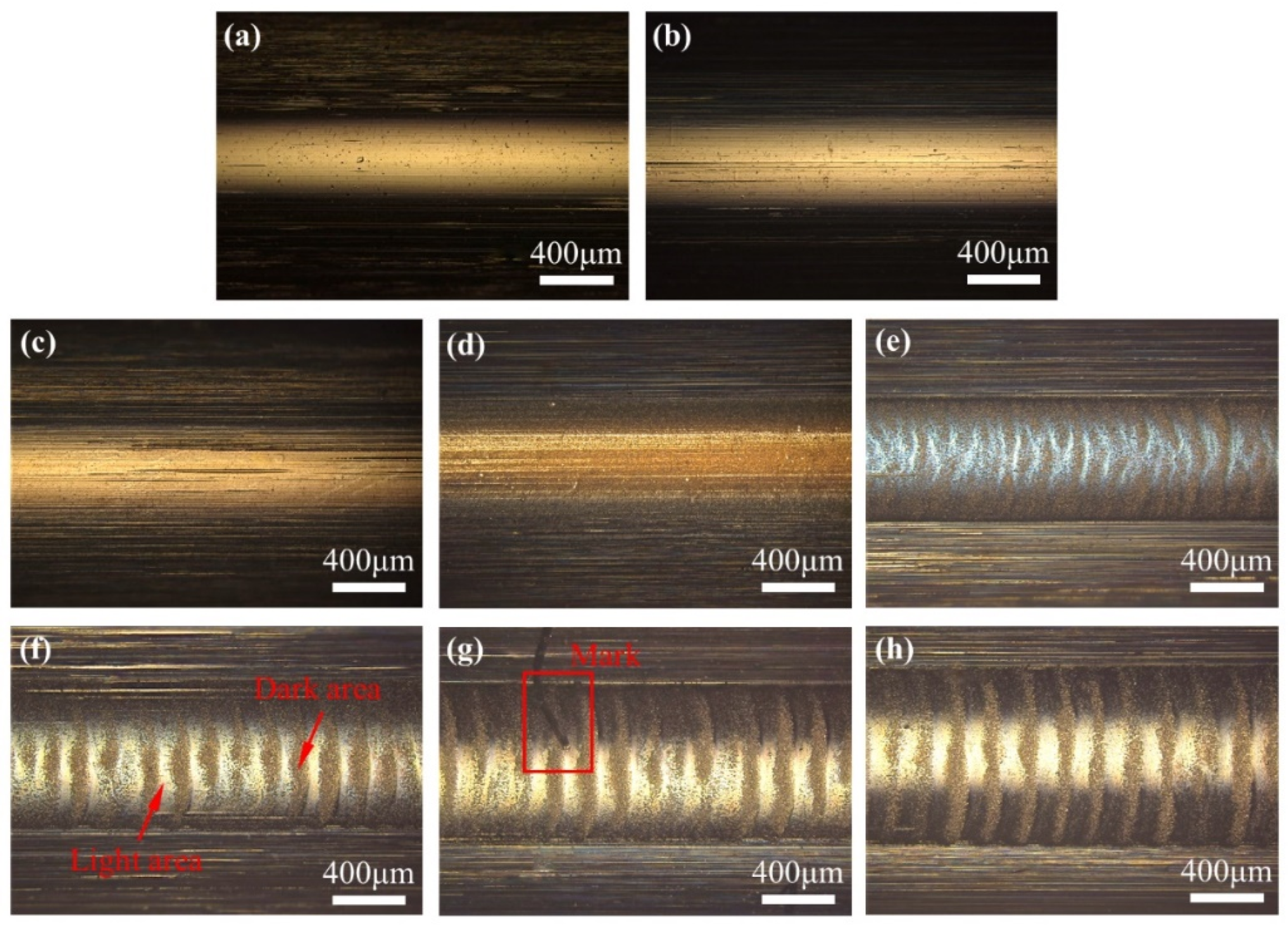

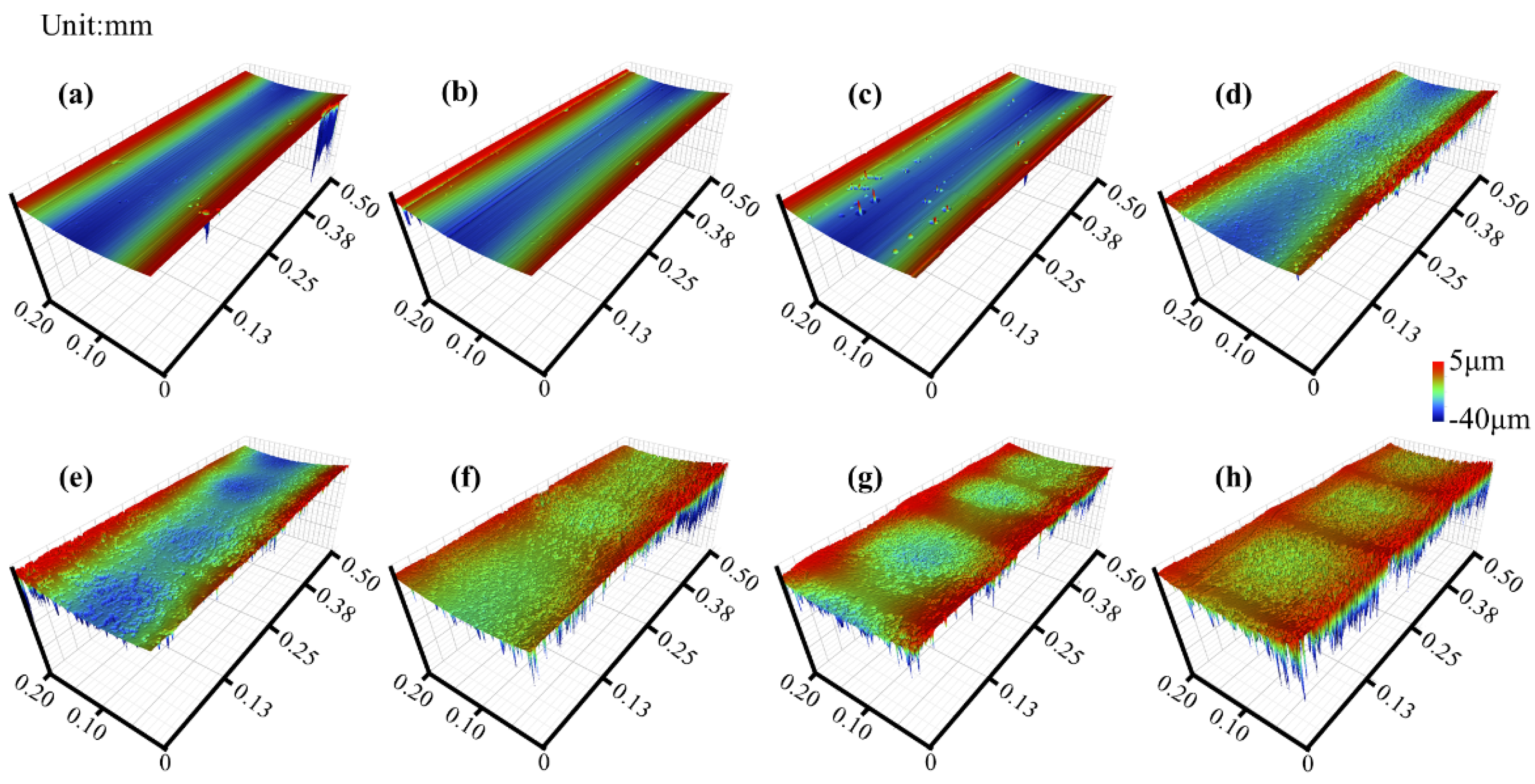

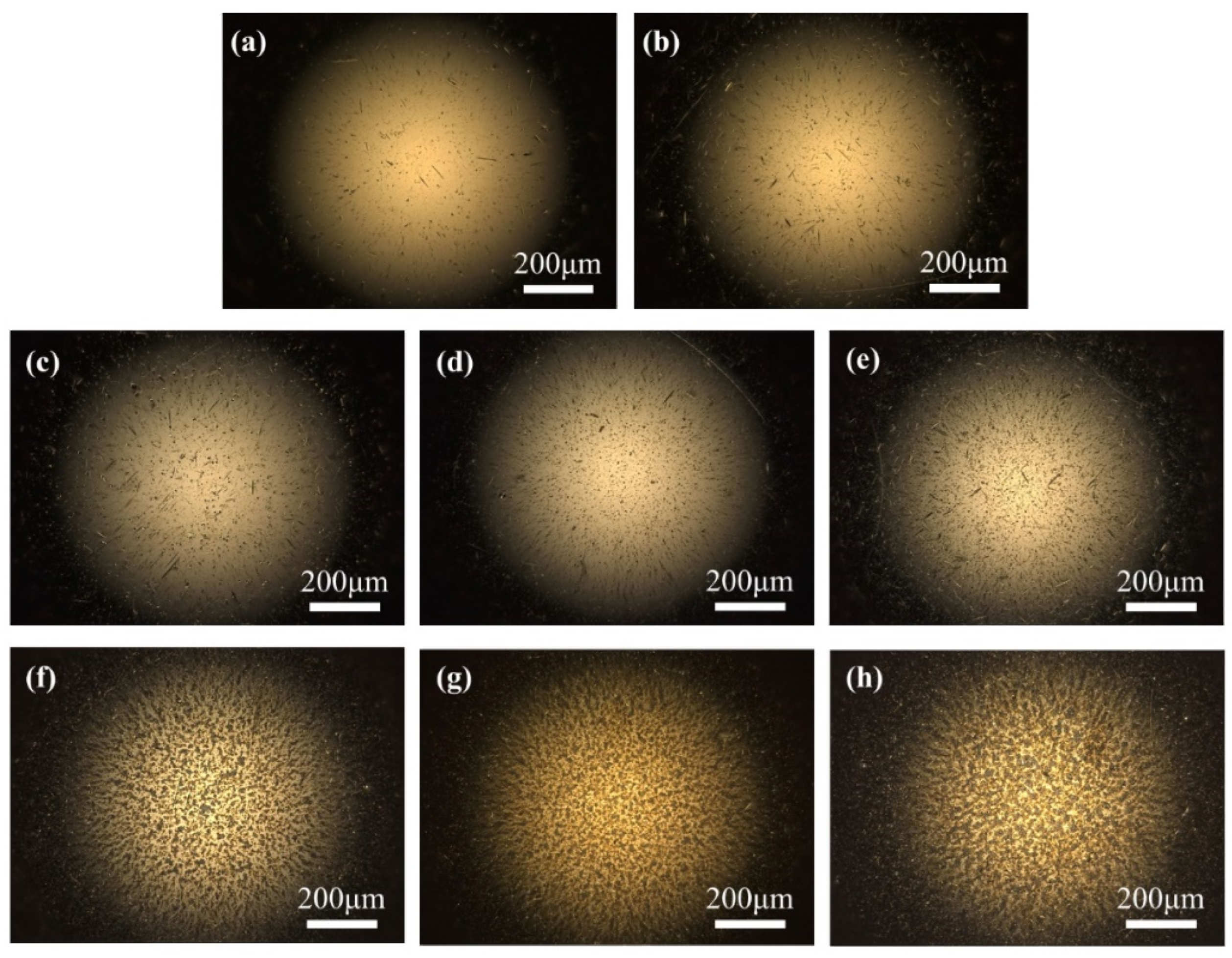

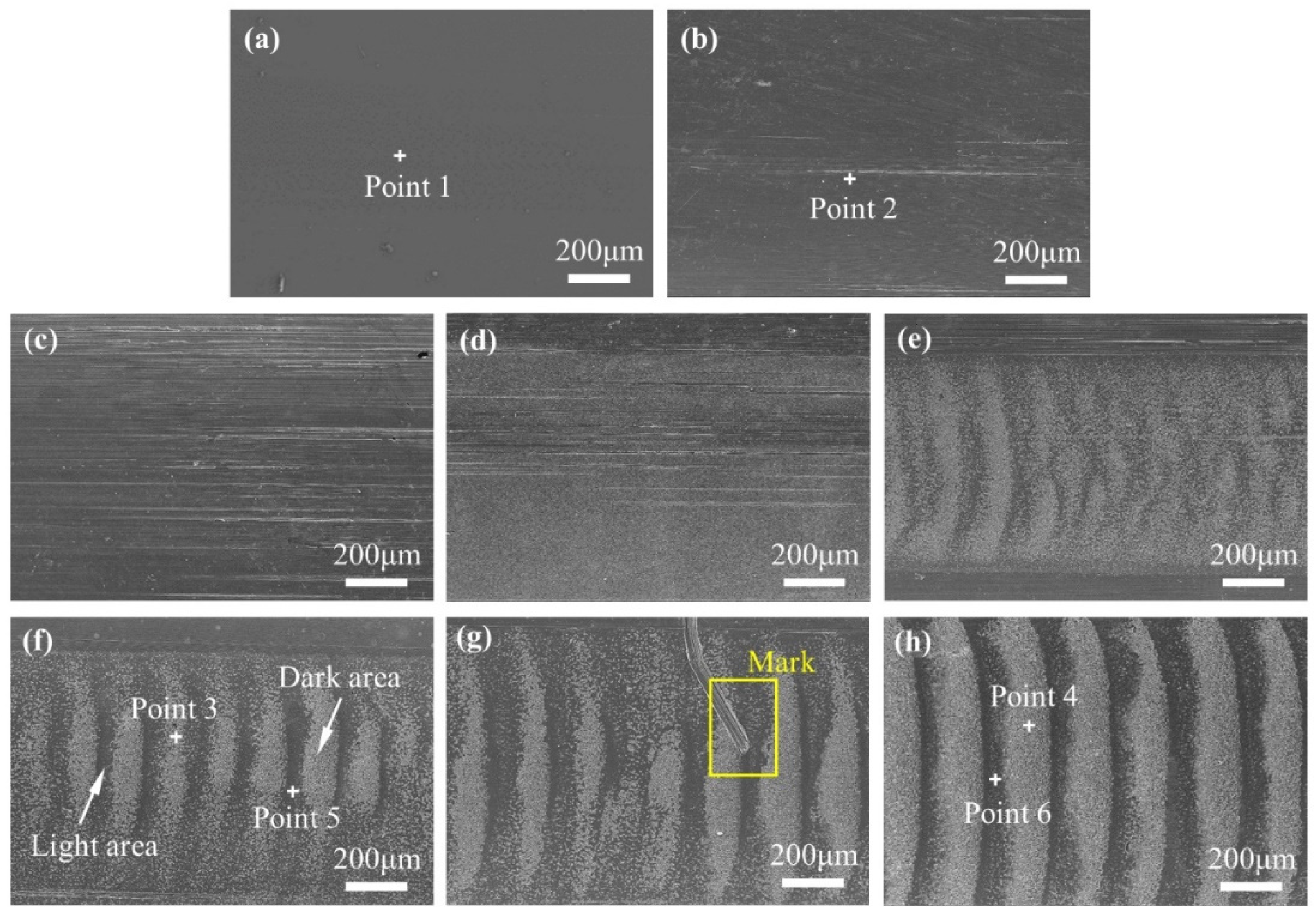

3.2. The Effect of Voltage Amplitude on the Formation of Corrugated Damage

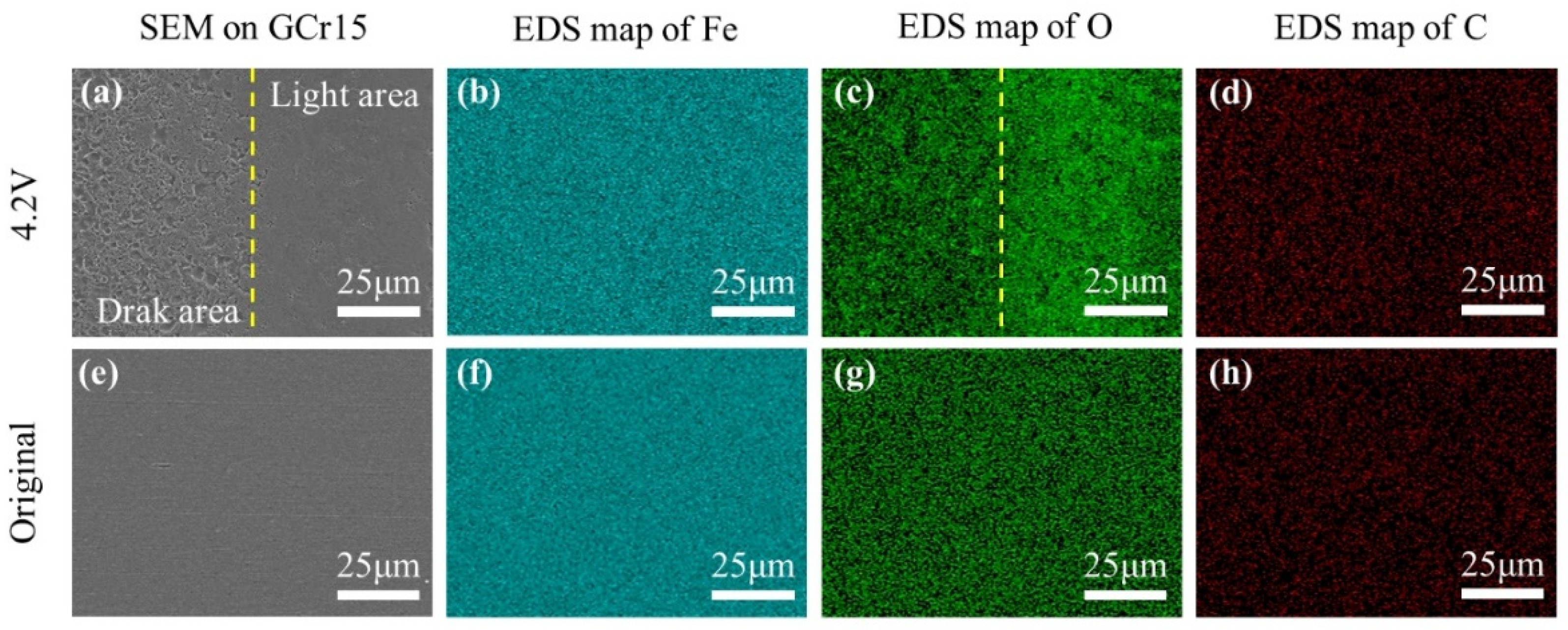

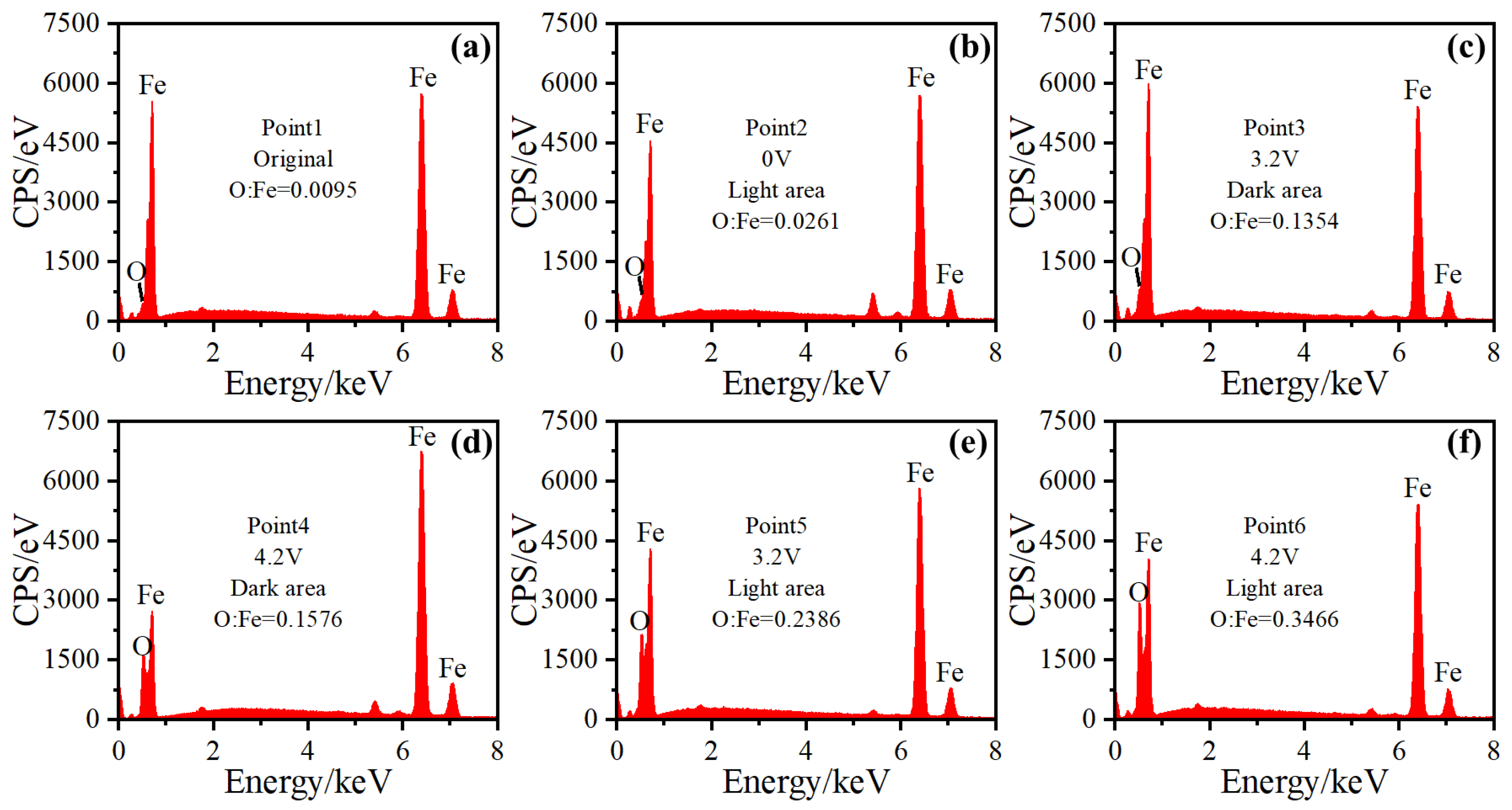

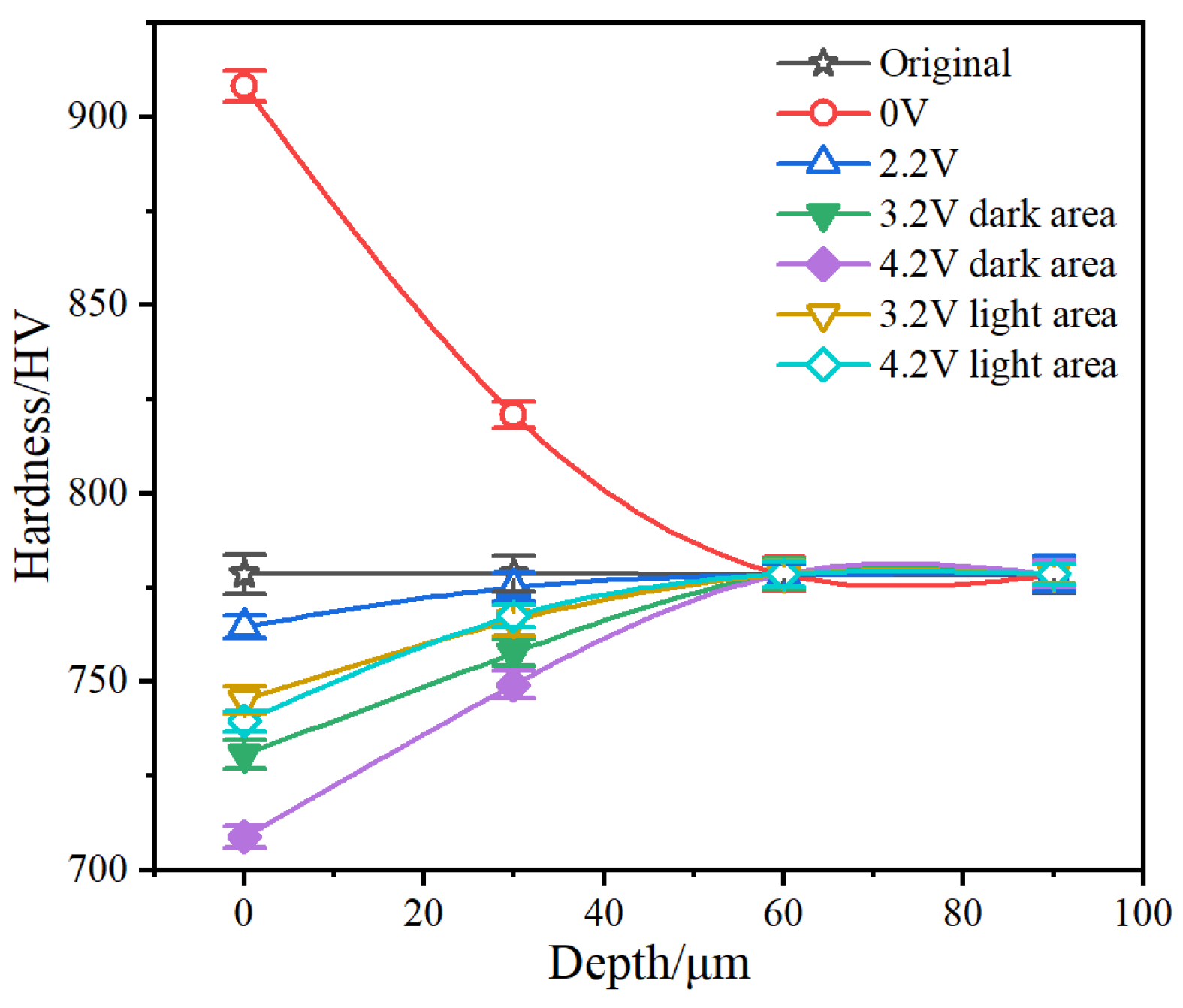

3.3. Effect of Voltage Amplitude on the Microstructural Changes

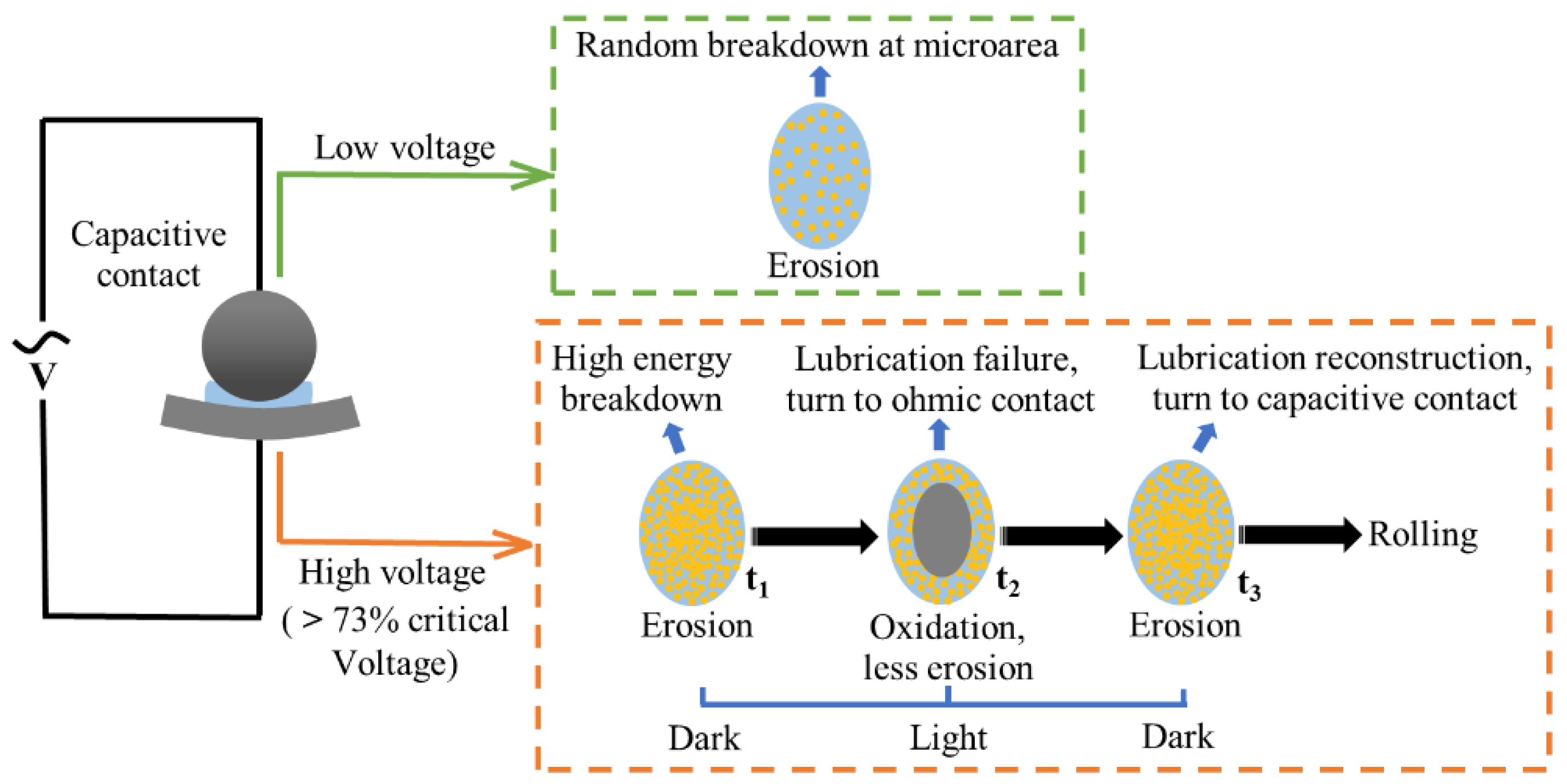

3.4. The Possible Formation Mechanism of Corrugated Damage

- i

- The discharge energy was high enough to breakdown the lubrication film, and a large number of erosion pits were formed (Figure 15, t1). Electrical erosion dominants the surface damage

- ii

- Then, the lubrication film could be pushed out of the contact area owing to high-temperature vaporization, an ohmic contact could form, and the current could directly pass through the contact area, decreasing the degree of erosion (Figure 15, t2). Because of the loss of lubrication coverage, oxygen in the atmosphere could come into contact with the metal, causing oxidation. Wear and oxidation dominants the surface damage.

- iii

- As the roller continued to move forward, the surrounding grease filled the contact area, and the lubrication film was re-established, inducing the next round of erosion (Figure 15, t3).

4. Conclusions

- As the voltage applied to the bearing increased from 0 V to 4.2 V, the equivalent resistance decreased, and the friction coefficient increased. The temperature rise of the outer ring slowly rises but eventually stabilizes after 100 min. The average rate of lubrication leakage satisfies the Arrhenius equation. The critical breakdown voltage of the bearing was 3.7 V under these experimental conditions.

- Corrugated damage could be produced in the outer race when the voltage reached 73% of the complete breakdown voltage. The light area in the images obtained using optical microscope and three-dimensional profiler appeared dark in those by a scanning electron microscope. Greater erosion, lower oxidation, and lower height were observed in the dark area. However, the erosion pits were evenly distributed on the balls and inner race.

- The tempering effect of the discharge caused decomposition of the subsurface martensite, leading to the enrichment of carbides on the subsurface, a decrease in residual stress hardness. When the voltage applied to the bearing increased from 2.2 to 4.2 V, the residual compressive stress decreased from 430.46 to 215.27 MPa after rolling, which was lower than the original 570.01 MPa. As a comparison, the residual stress increased to 628.27 MPa after mechanical rolling.

- A possible formation mechanism for corrugated damage was proposed to explain the experimental phenomenon. Under capacitive contact, a sufficiently high voltage (>73% of the complete breakdown voltage) not only caused metal erosion of the bearing, but also destroyed the bearing lubrication film. Then, the capacitive contact transformed into a resistive contact, reducing electrical erosion but intensifying oxidation. Subsequently, the lubricating film was reconstructed during rolling, inducing the next round of electrical corrosion. The periodic characteristics of corrugated damage may be related to the cyclic switching between capacitive contact and resistive contact in bearings.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Turnbull, R.; Rahmani, R.; Paul, S.; Rahnejat, H. Electrotribodynamics of ball bearings in electrical machines. Tribol. Int. 2023, 188, 108817. [Google Scholar] [CrossRef]

- Vostrov, K.; Pyrhonen, J.; Niemela, M.; Lindh, P.; Ahola, J. On the Application of Extended Grounded Slot Electrodes to Reduce Noncirculating Bearing Currents. IEEE Trans. Ind. Electron. 2023, 70, 2286–2295. [Google Scholar] [CrossRef]

- Berhausen, S.; Jarek, T. Method of Limiting Shaft Voltages in AC Electric Machines. Energies 2021, 14, 3326. [Google Scholar] [CrossRef]

- He, F.; Xie, G.; Luo, J. Electrical bearing failures in electric vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Teshale, A.; Biru, G. Overview of shaft voltage and bearing current mitigation methods applied on the victim machine. Electr. Eng. 2023, 1–13. [Google Scholar] [CrossRef]

- Liu, W. The prevalent motor bearing premature failures due to the high frequency electric current passage. Eng. Fail. Anal. 2014, 45, 118–127. [Google Scholar] [CrossRef]

- Zika, T.; Gebeshuber, I.C.; Buschbeck, F.; Preisinger, G.; Gröschl, M. Surface analysis on rolling bearings after exposure to defined electric stress. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 223, 787–797. [Google Scholar] [CrossRef]

- Ma, J.; Xue, Y.; Han, Q.; Li, X.; Yu, C. Motor Bearing Damage Induced by Bearing Current: A Review. Machines 2022, 10, 1167. [Google Scholar] [CrossRef]

- Oliver, J.A.; Guerrero, G.; Goldman, J. Ceramic Bearings for Electric Motors: Eliminating Damage with New Materials. IEEE Ind. Appl. Mag. 2017, 23, 14–20. [Google Scholar] [CrossRef]

- Kudelina, K.; Vaimann, T.; Rassolkin, A.; Kallaste, A.; Asad, B.; Demidova, G. Induction Motor Bearing Currents—Causes and Damages. In Proceedings of the 2021 28th International Workshop on Electric Drives: Improving Reliability of Electric Drives (IWED), Moscow, Russia, 27–29 January 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Liu, Z.; Song, C.; Li, J.; Hou, X.; Wang, L.; Zhang, Y. Effect of Rotation Speed on Electric Damage of Copper Tribo/Electric Rolling Pairs under Lubricated Single-Point Contact. Mater. Trans. 2020, 61, 111–118. [Google Scholar] [CrossRef]

- Niu, K.; Song, C.; Lou, Z.; Pang, X.; Lu, H.; Du, S.; Zhang, Y. Electric damage of bearing under AC shaft voltage at different rotation speeds. Tribol. Int. 2023, 177, 108008. [Google Scholar] [CrossRef]

- Chen, T.; Song, C.; Liu, Z.; Wang, L.; Sun, C.; Pang, X.; Zhang, Y. Effect of Elastic Contact Force on Tribological Characteristics of Current-carrying Roll Rings in Rotating Conductive Joints. Tribol. Trans. 2023, 66, 175–184. [Google Scholar] [CrossRef]

- Seferi, Y.; Blair, S.M.; Mester, C.; Stewart, B.G. A Novel Arc Detection Method for DC Railway Systems. Energies 2021, 14, 444. [Google Scholar] [CrossRef]

- Derosa, S.; Nåvik, P.; Collina, A.; Bucca, G.; Rønnquist, A. A heuristic wear model for the contact strip and contact wire in pantograph—Catenary interaction for railway operations under 15 kV 16.67 Hz AC systems. Wear 2020, 456–457, 203401. [Google Scholar] [CrossRef]

- Li, N.; Cui, C.; Zhao, Y.; Zhang, Q.; Bai, L. Structure and properties of GCr15 modified by multiphase ceramic nanoparticles /Fe-C composite inoculants. Mater. Sci. Eng. A 2018, 738, 63–74. [Google Scholar] [CrossRef]

- Ren, X.; Liu, R.; Yang, E. Modelling of the bearing breakdown resistance in bearing currents problem of AC motors. Energies 2019, 12, 1121. [Google Scholar] [CrossRef]

- Romanenko, A.; Muetze, A.; Ahola, J. Effects of electrostatic discharges on bearing grease dielectric strength and composition. IEEE Trans. Ind. Appl. 2016, 52, 4835–4842. [Google Scholar] [CrossRef]

- Hanrahan, B.; Misra, S.; Waits, C.M.; Ghodssi, R. Wear mechanisms in microfabricated ball bearing systems. Wear 2015, 326, 1–9. [Google Scholar] [CrossRef]

- Yang, S.; Li, C.; Jiang, M.; Pei, S. A study of inlet temperature models of a large size tilting thrust bearing comparison between theory and experiment. Tribol. Int. 2019, 140, 105881. [Google Scholar] [CrossRef]

- Lugt, P.M. On the use of the Arrhenius equation to describe the impact of temperature on grease life. Tribol. Int. 2023, 179, 108142. [Google Scholar] [CrossRef]

- Ma, Z.-M.; Zhu, H.; Cao, Y.-B.; Yang, S.-P. Evolution of microstructure and mechanical properties of the high-speed train bearing under different service periods. Mater. Sci. Eng. A 2020, 800, 140345. [Google Scholar] [CrossRef]

- Lugt, P.M. A review on grease lubrication in rolling bearings. Tribol. Trans. 2009, 52, 470–480. [Google Scholar] [CrossRef]

- Romanenko, A.; Ahola, J.; Muetze, A. Influence of electric discharge activity on bearing lubricating grease degradation. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Schwack, F.; Bader, N.; Leckner, J.; Demaille, C.; Poll, G. A study of grease lubricants under wind turbine pitch bearing conditions. Wear 2020, 454, 203335. [Google Scholar] [CrossRef]

- Srinidhi, S.; Tiwari, M.; Burra, R.; Gowda, H.; Siemers, P.A. Bearing wear due to mechanical stresses and electrical currents. In Proceedings of the International Joint Tribology Conference, Memphis, TN, USA, 19–21 October 2009. [Google Scholar]

- Spikes, H.A. Triboelectrochemistry: Influence of applied electrical potentials on friction and wear of lubricated contacts. Tribol. Lett. 2020, 68, 1–27. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Erdemir, A.; Cao-Romero-Gallegos, J.A.; Alam, I.; Lee, S. Electrification effects on dry and lubricated sliding wear of bearing steel interfaces. Wear 2023, 516, 204592. [Google Scholar] [CrossRef]

- Arakere, N.K. Gigacycle rolling contact fatigue of bearing steels: A review. Int. J. Fatigue 2016, 93, 238–249. [Google Scholar] [CrossRef]

- Morales-Espejel, G.; Gabelli, A. A model for rolling bearing life with surface and subsurface survival: Surface thermal effects. Wear 2020, 460, 203446. [Google Scholar] [CrossRef]

- Goett, G.; Gericke, A.; Henkel, K.-M.K.-M.; Uhrlandt, D. Determining the arc temperature in submerged arc welding using the Bartels method. J. Phys. D Appl. Phys. 2020, 53, 435208. [Google Scholar] [CrossRef]

- Mashloosh, K.; Eyre, T. Abrasive wear and its application to digger teeth. Tribol. Int. 1985, 18, 259–266. [Google Scholar] [CrossRef]

- Muzyka, M.R.; Boiko, A.V. Method of Evaluating Residual Stresses in the Product Material. Strength Mater. 2020, 52, 939–946. [Google Scholar] [CrossRef]

- Muetze, A.; Binder, A. Calculation of Motor Capacitances for Prediction of the Voltage Across the Bearings in Machines of Inverter-Based Drive Systems. IEEE Trans. Ind. Appl. 2007, 43, 665–672. [Google Scholar] [CrossRef]

- Esmaeili, K.; Wang, L.; Harvey, T.J.; White, N.M.; Holweger, W. Electrical Discharges in Oil-Lubricated Rolling Contacts and Their Detection Using Electrostatic Sensing Technique. Sensors 2022, 22, 392. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Values |

|---|---|

| Outer diameter D/mm | 52 |

| Inner diameter d/mm | 40 |

| Thickness B/mm | 7 |

| Ball diameter/mm | 3.14 |

| Number of bearing balls | 24 |

| Weight/g | About 34 |

| Limiting speed (r/min) | 16,000 |

| Rated dynamic load/N | 4200 |

| Rated static load/N | 4950 |

| Fatigue limit load /N | 186 |

| Elements | C | Mn | Si | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|

| Contents | 0.95–1.05 | 0.20–0.40 | 0.15–0.35 | 1.30–1.65 | ≤0.10 | ≤0.30 | Bal. |

| Test Conditions | Original | 0 V | 1.2 V | 2.2 V | 2.7 V | 3.2 V | 3.7 V | 4.2 V |

|---|---|---|---|---|---|---|---|---|

| Width of light area/μm | / | / | / | / | 36.16 ± 2.42 | 41.62 ± 4.79 | 44.17 ± 4.28 | 46.50 ± 6.36 |

| Width of dark area/μm | / | / | / | / | 89.97 ± 2.19 | 98.50 ± 5.81 | 105.54 ± 6.25 | 139.02 ± 6.74 |

| Height difference between corrugation/μm | / | / | / | / | 0.30 ± 0.07 | 1.26 ± 0.41 | 1.39 ± 0.57 | 2.66 ± 0.72 |

| Surface roughness Ra/μm | 0.59 ± 0.15 | 0.70 ± 0.18 | 0.72 ± 0.16 | 0.80 ± 0.18 | 0.81 ± 0.13 | 1.05 ± 0.11 | 1.09 ± 0.25 | 1.64 ± 0.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, Z.; Song, C.; Ren, Y.; Pang, X.; Lu, H.; Du, S.; Zhang, Y. Formation of Corrugated Damage on Bearing Race under Different AC Shaft Voltages. Materials 2024, 17, 859. https://doi.org/10.3390/ma17040859

Lou Z, Song C, Ren Y, Pang X, Lu H, Du S, Zhang Y. Formation of Corrugated Damage on Bearing Race under Different AC Shaft Voltages. Materials. 2024; 17(4):859. https://doi.org/10.3390/ma17040859

Chicago/Turabian StyleLou, Zhihao, Chenfei Song, Yulong Ren, Xianjuan Pang, Huanhuan Lu, Sanming Du, and Yongzhen Zhang. 2024. "Formation of Corrugated Damage on Bearing Race under Different AC Shaft Voltages" Materials 17, no. 4: 859. https://doi.org/10.3390/ma17040859

APA StyleLou, Z., Song, C., Ren, Y., Pang, X., Lu, H., Du, S., & Zhang, Y. (2024). Formation of Corrugated Damage on Bearing Race under Different AC Shaft Voltages. Materials, 17(4), 859. https://doi.org/10.3390/ma17040859