Recycled Waste as Polyurethane Additives or Fillers: Mini-Review

Abstract

:1. Introduction

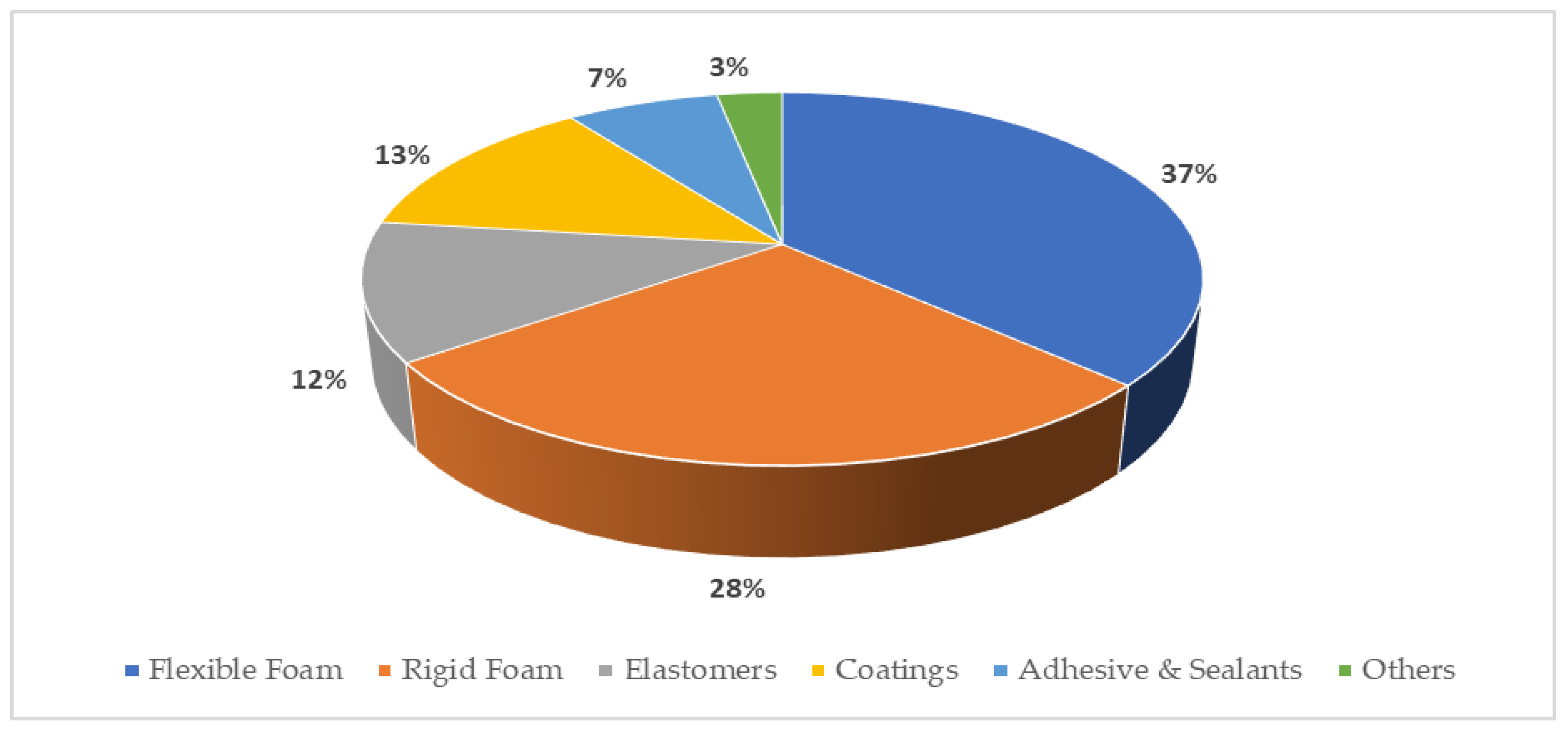

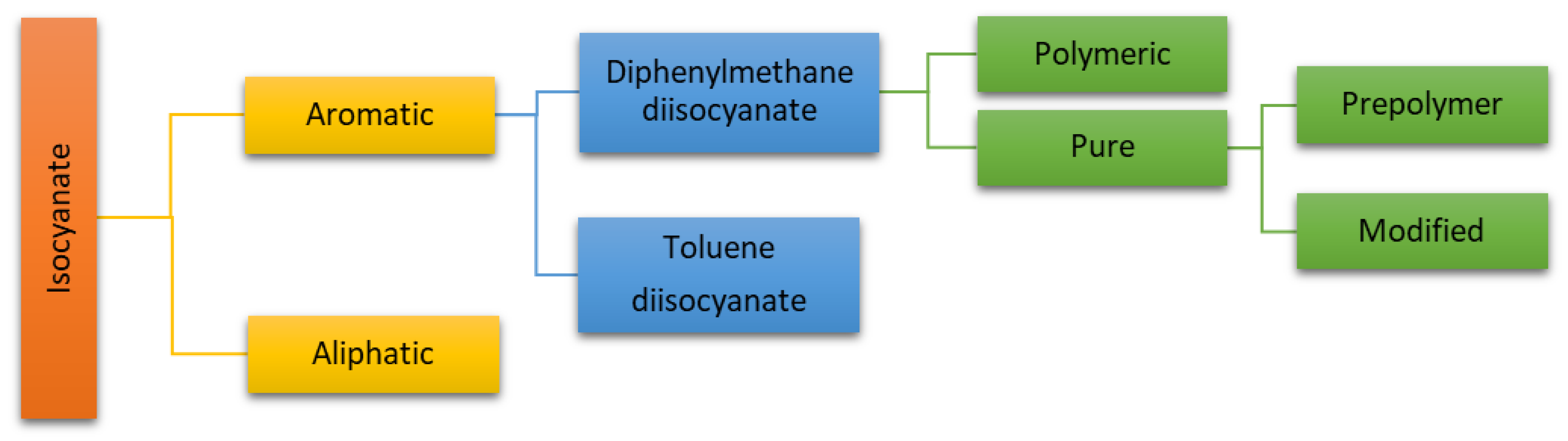

2. Polyurethane Classification, Structure and Properties

3. Circular Economy Principles

4. Possibilities of Waste Recycling in Polyurethanes

5. Adverse Effects of Using Waste Materials—Critical Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bayer, O. Das Di-Isocyanat-Polyadditionsverfahren (Polyurethane). Angew. Chem. 1947, 59, 257–272. [Google Scholar] [CrossRef]

- Bellis, M. The History of Polyurethane—Otto Bayer. Available online: https://www.thoughtco.com/history-of-polyurethane-otto-bayer-4072797 (accessed on 13 December 2022).

- Stachak, P.; Łukaszewska, I.; Hebda, E.; Pielichowski, K. Recent Advances in Fabrication of Non-Isocyanate Polyurethane-Based Composite Materials. Materials 2021, 14, 3497. [Google Scholar] [CrossRef] [PubMed]

- Suryawanshi, Y.; Sanap, P.; Wani, V. Advances in the synthesis of non-isocyanate polyurethanes. Polym. Bull. 2019, 76, 3233–3246. [Google Scholar] [CrossRef]

- Islam, M.R.; Beg, M.D.H.; Jamari, S.S. Development of vegetable-oil-based polymers. J. Appl. Polym. Sci. 2014, 131, 40787. [Google Scholar] [CrossRef]

- Brzeska, J.; Piotrowska-Kirschling, A. A Brief Introduction to the Polyurethanes According to the Principles of Green Chemistry. Processes 2021, 9, 1929. [Google Scholar] [CrossRef]

- Kaur, R.; Singh, P.; Tanwar, S.; Varshney, G.; Yadav, S. Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation. Macromol 2022, 2, 284–314. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Das, A.; Mahanwar, P. A brief discussion on advances in polyurethane applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Polyurethane Market Size, Share, Growth & Trends 2030. Available online: https://www.fortunebusinessinsights.com/industry-reports/polyurethane-pu-market-101801 (accessed on 14 December 2023).

- Polyurethane Market Size, Trends, Share, Growth, Report 2032. Available online: https://www.precedenceresearch.com/polyurethane-market. (accessed on 5 December 2023).

- Polyurethane Foam Market Size & Trends. Available online: https://www.grandviewresearch.com/industry-analysis/polyurethane-foam-market (accessed on 20 December 2023).

- Reghunadhan, A.; Thomas, S. Polyurethanes. In Polyurethane Polymers; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–16. [Google Scholar] [CrossRef]

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes, 2nd ed.; Smithers Rapra Technology Ltd.: Shrewsbury, UK, 2016. [Google Scholar]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed]

- Wirpsza, Z. Poliuretany: Chemia, Technologia, Zastosowanie; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1991; pp. 16–85. [Google Scholar]

- Petrie, E.M. Handbook of Adhesive and Sealants, 2nd ed.; The McGraw-Hill Companies: New York, NY, USA, 2007; pp. 337–425. [Google Scholar]

- Janik, H.; Sienkiewicz, M.; Kucinska-Lipka, J. Polyurethanes. In Handbook of Thermoset Plastics; Elsevier: Amsterdam, The Netherlands, 2014; pp. 253–295. [Google Scholar] [CrossRef]

- Product Portal PCC Group. Available online: https://www.products.pcc.eu/pl/ (accessed on 23 December 2023).

- Six, C.; Richter, F. Isocyanates, Organic. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar] [CrossRef]

- Sharmin, E.; Zafar, F. Polyurethane: An Introduction. In Polyurethane; InTech: Houston, TX, USA, 2012. [Google Scholar] [CrossRef]

- Golling, F.E.; Pires, R.; Hecking, A.; Weikard, J.; Richter, F.; Danielmeier, K.; Dijkstra, D. Polyurethanes for coatings and adhesives—Chemistry and applications. Polym. Int. 2019, 68, 848–855. [Google Scholar] [CrossRef]

- Dodge, J. Polyurethanes and Polyureas. In Synthetic Methods in Step-Growth Polymers; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; pp. 197–263. [Google Scholar] [CrossRef]

- European Adhesives and Sealants Market Report-2023–2028 a Quantitative Demand a Quantitative Demand Analysis and Trend Forecast Analysis and Trend Forecast. 2023. Available online: www.feica.eu (accessed on 1 January 2024).

- Balaras, C.A.; Dascalaki, E.G.; Patsioti, M.; Droutsa, K.G.; Kontoyiannidis, S.; Cholewa, T. Carbon and Greenhouse Gas Emissions from Electricity Consumption in European Union Buildings. Buildings 2023, 14, 71. [Google Scholar] [CrossRef]

- European Innovation Council and SMEs Executive Agency (European Commission); Maciej, L.; Alexandre, P.; Sivasegaram, M.; Roumen, B. Identification of Emerging Technologies and Breakthrough Innovations; European Union: Maastricht, The Netherlands, 2022. [Google Scholar]

- Paraskar, P.M.; Prabhudesai, M.S.; Hatkar, V.M.; Kulkarni, R.D. Vegetable oil based polyurethane coatings—A sustainable approach: A review. Prog. Org. Coat. 2021, 156, 106267. [Google Scholar] [CrossRef]

- Deloitte. Available online: https://www2.deloitte.com/pl/pl/pages/zarzadzania-procesami-i-strategiczne/articles/sustainability-insights/czym-jest-gospodarka-o-obiegu-zamknietym.html (accessed on 3 January 2023).

- GOZ. Available online: https://gozwpraktyce.pl/ (accessed on 8 January 2023).

- European Parliament and Council (EU). 2018/851 of 30 May 2018 Amending Directive 2008/98/EC on Waste. Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/?uri=COM%3A2020%3A98%3AFIN, (accessed on 10 January 2022).

- IAL Consultants. Global Overview of the Spray Polyurethane Foam (SPF) and One Component Foam (OCF) Markets; IAL Consultants: London, UK, 2016. [Google Scholar]

- Uram, K.; Kurańska, M.; Andrzejewski, J.; Prociak, A. Rigid Polyurethane Foams Modified with Biochar. Materials 2021, 14, 5616. [Google Scholar] [CrossRef]

- Yu, Z.; Xiao, Y.; Tian, H.; Liu, S.; Zeng, J.; Luo, X. Bagasse as functional fillers to improve and control biodegradability of soy oil-based rigid polyurethane foams. Korean J. Chem. Eng. 2019, 36, 1740–1745. [Google Scholar] [CrossRef]

- Luo, X.; Mohanty, A.; Misra, M. Lignin as a reactive reinforcing filler for water-blown rigid biofoam composites from soy oil-based polyurethane. Ind. Crops Prod. 2013, 47, 13–19. [Google Scholar] [CrossRef]

- Sternberg, J.; Sequerth, O.; Pilla, S. Structure-property relationships in flexible and rigid lignin-derived polyurethane foams: A review. Mater. Today Sustain. 2024, 25, 100643. [Google Scholar] [CrossRef]

- Santos, O.S.H.; da Silva, M.C.; Silva, V.R.; Mussel, W.N.; Yoshida, M.I. Polyurethane foam impregnated with lignin as a filler for the removal of crude oil from contaminated water. J. Hazard. Mater. 2017, 324, 406–413. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Xiao, Y.; Wu, Q.; Zeng, J. Development of high-performance biodegradable rigid polyurethane foams using all bioresource-based polyols: Lignin and soy oil-derived polyols. Int. J. Biol. Macromol. 2018, 115, 786–791. [Google Scholar] [CrossRef] [PubMed]

- Jonjaroen, V.; Ummartyotin, S.; Chittapun, S. Algal cellulose as a reinforcement in rigid polyurethane foam. Algal. Res. 2020, 51, 102057. [Google Scholar] [CrossRef]

- Jabber, L.J.Y.; Grumo, J.C.; Alguno, A.C.; Lubguban, A.A.; Capangpangan, R.Y. Influence of cellulose fibers extracted from pineapple (Ananas comosus) leaf to the mechanical properties of rigid polyurethane foam. Mater. Today Proc. 2021, 46, 1735–1739. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Członka, S.; Strakowska, A.; Kairyte, A. Application of walnut shells-derived biopolyol in the synthesis of rigid polyurethane foams. Materials 2020, 13, 2687. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L.; Kurańska, M.; Prociak, A.; Leszczyński, M.K.; Gloc, M.; Antos-Bielska, M.; Mizera, K. Cooperative effect of rapeseed oil-based polyol and egg shells on the structure and properties of rigid polyurethane foams. Polym. Test. 2020, 90, 106696. [Google Scholar] [CrossRef]

- Husainie, S.M.; Deng, X.; Ghalia, M.A.; Robinson, J.; Naguib, H.E. Natural fillers as reinforcement for closed-molded polyurethane foam plaques: Mechanical, morphological, and thermal properties. Mater. Today Commun. 2021, 27, 102187. [Google Scholar] [CrossRef]

- Ebereonwu, P.U.; Dashak, D.A.; Ogah, E. Investigation and Characterization of Flexible Polyurethane Foams from the use of Chicken Eggshells as Fillers. Polym. Sci. 2022. [Google Scholar] [CrossRef]

- Victor, E.I.; Alfred, N. Use of Chicken Eggshells as Fillers in Flexible Polyurethane Foam Production. 2019. Available online: https://www.researchgate.net/publication/361965680 (accessed on 10 December 2023).

- Aranberri, I.; Montes, S.; Wesołowska, E.; Rekondo, A.; Wrześniewska-Tosik, K.; Grande, H.-J. Improved Thermal Insulating Properties of Renewable Polyol Based Polyurethane Foams Reinforced with Chicken Feathers. Polymers 2019, 11, 2002. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Sun, S.; Yuan, D.; Wang, Z.; Xie, H.; Su, Z. Chicken feather protein for the thermal stability and combustion performance of rigid polyurethane foam. Int. Polym. Process. 2023, 38, 593–605. [Google Scholar] [CrossRef]

- Khaleel, M.; Soykan, U.; Çetin, S. Influences of turkey feather fiber loading on significant characteristics of rigid polyurethane foam: Thermal degradation, heat insulation, acoustic performance, air permeability and cellular structure. Constr. Build. Mater. 2021, 308, 125014. [Google Scholar] [CrossRef]

- Soykan, U.; Cetin, S.; Yahsi, U. Detailed investigation on the insulation and permeability characteristics of rigid polyurethane foam loaded with micron-sized Turkey feather powder depending on the free volume change. Cell. Polym. 2023, 42, 204–225. [Google Scholar] [CrossRef]

- Kuźnia, M.; Magiera, A.; Zygmunt-Kowalska, B.; Kaczorek-Chrobak, K.; Pielichowska, K.; Szatkowski, P.; Benko, A.; Ziąbka, M.; Jerzak, W. Fly ash as an eco-friendly filler for rigid polyurethane foams modification. Materials 2021, 14, 6604. [Google Scholar] [CrossRef]

- Akkoyun, M.; Akkoyun, S. Blast furnace slag or fly ash filled rigid polyurethane composite foams: A comprehensive investigation. J. Appl. Polym. Sci. 2019, 136, 47433. [Google Scholar] [CrossRef]

- Polimera, S.; Gali, A.; Rahaman, A.; Chandan, M.R.; Balakumaran, S.J.; Nath, S.K. Thermo-mechanical property enhancement of rigid polyurethane foam composite using low cost, environment friendly fly ash over silica particles. J. Vinyl. Addit. Technol. 2024, 30, 156–171. [Google Scholar] [CrossRef]

- Kuźnia, M.; Zygmunt-Kowalska, B.; Szajding, A.; Magiera, A.; Stanik, R.; Gude, M. Comparative Study on Selected Properties of Modified Polyurethane Foam with Fly Ash. Int. J. Mol. Sci. 2022, 23, 9725. [Google Scholar] [CrossRef] [PubMed]

- Kowalska, B.Z.; Szajding, A.; Zakrzewska, P.; Kuźnia, M.; Stanik, R.; Gude, M. Disposal of rigid polyurethane foam with fly ash as a method to obtain sustainable thermal insulation material. Constr. Build. Mater. 2024, 417, 135329. [Google Scholar] [CrossRef]

- Kuźnia, M.; Magiera, A.; Pielichowska, K.; Ziąbka, M.; Benko, A.; Szatkowski, P.; Jerzak, W. Fluidized bed combustion fly ash as filler in composite polyurethane materials. Waste Manag. 2019, 92, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Mosiewicki, M.A.; Dell’Arciprete, G.A.; Aranguren, M.I.; Marcovich, N.E. Polyurethane Foams Obtained from Castor Oil-based Polyol and Filled with Wood Flour. J. Compos. Mater. 2009, 43, 3057–3072. [Google Scholar] [CrossRef]

- Bradai, H.; Koubaa, A.; Bouafif, H.; Langlois, A.; Samet, B. Synthesis and Characterization of Wood Rigid Polyurethane Composites. Materials 2022, 15, 4316. [Google Scholar] [CrossRef]

- Yuan, J.; Shi, S.Q. Effect of the addition of wood flours on the properties of rigid polyurethane foam. J. Appl. Polym. Sci. 2009, 113, 2902–2909. [Google Scholar] [CrossRef]

- Augaitis, N.; Vaitkus, S.; Członka, S.; Kairytė, A. Research of Wood Waste as a Potential Filler for Loose-Fill Building Insulation: Appropriate Selection and Incorporation into Polyurethane Biocomposite Foams. Materials 2020, 13, 5336. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Bertino, M.F.; Strzelec, K.; Strąkowska, A.; Masłowski, M. Rigid polyurethane foams reinforced with solid waste generated in leather industry. Polym. Test. 2018, 69, 225–237. [Google Scholar] [CrossRef]

- Andre, T.; Couvreur, R.; Tamrakar, S.; Mielewski, D.; Kiziltas, A. Closed-loop recycling of additive manufacturing waste for value-added automotive foam applications. Polym. Compos. Apr. 2023. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M. Evaluation of the Effect of Waste from Agricultural Production on the Properties of Flexible Polyurethane Foams. Polymers 2023, 15, 3529. [Google Scholar] [CrossRef] [PubMed]

- Recupido, F.; Lama, G.C.; Lavorgna, M.; Buonocore, G.G.; Marzella, R.; Verdolotti, L. Post-consumer recycling of Tetra Pak®: Starting a ‘new life’ as filler in sustainable polyurethane foams. Food Packag. Shelf Life 2023, 40, 101175. [Google Scholar] [CrossRef]

- Bartczak, P.; Stachowiak, J.; Szmitko, M.; Grząbka-Zasadzińska, A.; Borysiak, S. Multifunctional Polyurethane Composites with Coffee Grounds and Wood Sawdust. Materials 2022, 16, 278. [Google Scholar] [CrossRef] [PubMed]

- Głowacz-Czerwonka, D.; Zakrzewska, P.; Oleksy, M.; Pielichowska, K.; Kuźnia, M.; Telejko, T. The influence of biowaste-based fillers on the mechanical and fire properties of rigid polyurethane foams. Sustain. Mater. Technol. 2023, 36, e00610. [Google Scholar] [CrossRef]

- da Silva, V.R.; Mosiewicki, M.A.; Yoshida, M.I.; da Silva, M.C.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash I: Synthesis and physical chemical characterization. Polym. Test. 2013, 32, 438–445. [Google Scholar] [CrossRef]

- da Silva, V.R.; Mosiewicki, M.A.; Yoshida, M.I.; da Silva, M.C.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash II: Mechanical characterization. Polym. Test. 2013, 32, 665–672. [Google Scholar] [CrossRef]

- Acosta, A.P.; Kairytė, A.; Członka, S.; Miedzińska, K.; Aramburu, A.B.; Barbosa, K.T.; Amico, S.C.; de Avila Delucis, R. Rigid Polyurethane Biofoams Filled with Pine Seed Shell and Yerba Mate Wastes. Polymers 2023, 15, 2194. [Google Scholar]

- Dukarska, D.; Walkiewicz, J.; Derkowski, A.; Mirski, R. Properties of Rigid Polyurethane Foam Filled with Sawdust from Primary Wood Processing. Materials 2022, 15, 5361. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid polyurethane foams reinforced with industrial potato protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Liszkowska, J. The effect of ground coffee on the mechanical and application properties of rigid polyurethane-polyisocyanurate foams (Rapid communication). Polimery 2018, 63, 305–310. [Google Scholar] [CrossRef]

- Silva, N.G.S.; Cortat, L.I.C.O.; Orlando, D.; Mulinari, D.R. Evaluation of rubber powder waste as reinforcement of the polyurethane derived from castor oil. Waste Manag. 2020, 116, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Yan, N. Application of Western red cedar (Thuja plicata) tree bark as a functional filler in pMDI wood adhesives. Ind. Crops Prod. 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Borrero-López, A.M.; Valencia, C.; Domínguez, G.; Eugenio, M.E.; Franco, J.M. Rheology and adhesion performance of adhesives formulated with lignins from agricultural waste straws subjected to solid-state fermentation. Ind. Crops Prod. 2021, 171, 113876. [Google Scholar] [CrossRef]

- Costa, A.P.O.; Silva, R.B.; Gerbase, A.E.; Petzhold, C.L. Synthesis and characterization of soybean-oil-based polyurethane composites containing industrial and agricultural residual wastes as fillers. J. Appl. Polym. Sci. 2012, 123, 1370–1376. [Google Scholar] [CrossRef]

- Lei, W.; Fang, C.; Zhou, X.; Li, Y.; Pu, M. Polyurethane elastomer composites reinforced with waste natural cellulosic fibers from office paper in thermal properties. Carbohydr. Polym. 2018, 197, 385–394. [Google Scholar] [CrossRef] [PubMed]

- Kamaruzzaman, W.M.I.; Shaifudin, M.S.; Nasir, N.A.M.; Hamidi, N.A.S.M.; Yusof, N.; Adnan, A.; Jew, L.O.; Nik, W.M.N.W.; Ghazali, M.S.M. Eggshells biowaste filler for improving the anticorrosive behaviour of waterborne polyurethane coatings on mild steel in artificial seawater. J. Mater. Res. Technol. 2022, 21, 3815–3827. [Google Scholar] [CrossRef]

- Shang, S.; Chiu, K.L.; Yuen, M.C.W.; Jiang, S. The potential of cuttlebone as reinforced filler of polyurethane. Compos. Sci. Technol. 2014, 93, 17–22. [Google Scholar] [CrossRef]

- Jakubíková, K.H.; Hodul, J.; Hermann, R.; Drochytka, R. Development of a Hydrophobic Polymer Coating in Polyurethane Organic–Mineral Base Containing Waste from Fibreglass Production. Coatings 2023, 13, 1934. [Google Scholar] [CrossRef]

- Şişmanoğlu, S.; Kanbur, Y.; Popescu, C.M.; Kindzera, D.; Tayfun, Ü. Beneficial use of mussel shell as a bioadditive for TPU green composites by the valorization of an aqueous waste. Waste Dispos. Sustain. Energy 2023. [Google Scholar] [CrossRef]

- Mohammed, A.J.; Muhsen, M.C.; Malik, F.H.; Jalal, M.A.; Ibrahim, I.K. Study the Effect of Adding Vulcanized Rubber Powder on the Mechanical Properties and Fire Retardant of Polyurethane Polymer. Metall. Mater. Eng. 2023, 29, 9–19. [Google Scholar] [CrossRef]

- European Commission. Commission Decision of 18 December 2014, amending Decision 2000/ 532/ EC on the list of waste pursuant to Directive 2008/98/EC of the European Parliament and of the Council—(2014/ 955/ EU). Off. J. Eur. Union 2014, 370, 44–86. [Google Scholar]

- Polyurethane Adhesives Market. Available online: https://www.vantagemarketresearch.com/industry-report/polyurethane-adhesives-market-1121 (accessed on 10 January 2023).

- Cho, S.; Lee, K.-T.; Choi, Y.I.; Jung, S.J.; Park, S.-J.; Bae, S.; Kim, J. Networking human biomarker and hazardous chemical elements from building materials: Systematic literature review and in vivo test. Build. Environ. 2021, 192, 107603. [Google Scholar] [CrossRef]

- Wei, W.; Ramalho, O.; Mandin, C. Indoor air quality requirements in green building certifications. Build. Environ. 2015, 92, 10–19. [Google Scholar] [CrossRef]

- Certyfikacja Zielonych Budynków. Raport. 2020. Available online: https://inzynierbudownictwa.pl/certyfikacja-zielonych-budynkow-raport-2020/ (accessed on 4 January 2024).

- Al-Moameri, H.; Marhoon, I.I.; Rasheed, A.K.; Abdulrehman, M.A.; Al-Sharify, Z.T. Impact of waste fillings on the thermoset rigid polyurethane foam. In Proceedings of the AIP Conference Proceedings, Istanbul, Turkey, 28–29 March 2022; p. 040020. [Google Scholar] [CrossRef]

- Kuram, E. UV and thermal weathering of green composites: Comparing the effect of different agricultural waste as fillers. J. Compos. Mater. 2020, 54, 3683–3697. [Google Scholar] [CrossRef]

- Bello, D.; Herrick, C.A.; Smith, T.J.; Woskie, S.R.; Streicher, R.P.; Cullen, M.R.; Liu, Y.; Redlich, C.A. Skin exposure to isocyanates: Reasons for concern. Environ. Health Perspect. 2007, 115, 328–335. [Google Scholar] [CrossRef]

- Rother, D.; Schlüter, U. Occupational Exposure to Diisocyanates in the European Union. In Annals of Work Exposures and Health; Oxford University Press: Oxford, UK, 2021; Volume 65, pp. 893–907. [Google Scholar] [CrossRef]

| Waste | Product | Max Amount of Filler [%] | Advantages of Using Waste |

|---|---|---|---|

| biochar [32] | rigid polyurethane foams (RPUF) | 20 |

|

| bagasse [33] | rigid polyurethane foams (RPUF) | 12.5 |

|

| waste lignin [34,35,36,37] | polyurethane foams | 20 |

|

| residual algal cellulose [38] | rigid polyurethane foam | 1.6 |

|

| residual pineapple cellulose [39] | rigid polyurethane foam | 5 |

|

| walnut shells/silanized walnut shells [40,41] | polyurethane foam | 5 |

|

| basalt waste [42] | rigid polyurethane foam | 40 |

|

| eggshells [43,44,45,46,47] | polyurethane foam | 25 |

|

| chicken feathers [48,49] | rigid polyurethane foams | 15 |

|

| turkey feather fiber [50,51] | rigid polyurethane foams | 15 |

|

| fly ash [52,53,54,55,56,57] | rigid polyurethane foams | 15 |

|

| wood flour [58,59,60,61] | rigid polyurethane foams | 15 |

|

| buffing dust [62] | rigid polyurethane foams | 5 |

|

| thermoplastic elastomers and thermoplastic polyurethane [63] | rigid polyurethane foams | 2.5 |

|

| ground corncake [64] | flexible polyurethane foams | 10 |

|

| Tetra Pak® [65] | polyurethane foams | 20 |

|

| coffee grounds [66] | rigid polyurethane foams | 20 |

|

| sunflower husks, rice husks and buckwheat hulls [67,68,69] | rigid polyu-re-thane foams | 15 |

|

| pine seed shells [70] | polyurethane foams | 15 |

|

| yerba mate [70] | polyurethane foams | 15 |

|

| sawdust [71] | polyurethane foams | 20 |

|

| potato protein [72] | rigid polyurethane foams | 5 |

|

| ground coffee [73] | polyurethane-polyisocyanurate | 15 |

|

| waste tire rubber [74] | polyurethane foams | 20 |

|

| the bark of Western Red Cedar [75] | adhesives | 20 |

|

| waste lignin [76] | adhesive | 10 |

|

| rice husk ash/coconut husk ash [77] | elastomeric PU | 10 |

|

| cellulose [77] | elastomeric PU | 5 |

|

| eggshell [78] | waterborne polyurethane coatings | 20 |

|

| cuttlebone [79] | waterborne polyurethane coatings | 7 |

|

| glass fibers [80] | polyurethane coatings | 60 |

|

| mussel shell [81] | TPU | 30 |

|

| ground rubber powder [82] | polyurethane sealant | 25 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pęczek, E.; Pamuła, R.; Białowiec, A. Recycled Waste as Polyurethane Additives or Fillers: Mini-Review. Materials 2024, 17, 1013. https://doi.org/10.3390/ma17051013

Pęczek E, Pamuła R, Białowiec A. Recycled Waste as Polyurethane Additives or Fillers: Mini-Review. Materials. 2024; 17(5):1013. https://doi.org/10.3390/ma17051013

Chicago/Turabian StylePęczek, Edyta, Renata Pamuła, and Andrzej Białowiec. 2024. "Recycled Waste as Polyurethane Additives or Fillers: Mini-Review" Materials 17, no. 5: 1013. https://doi.org/10.3390/ma17051013

APA StylePęczek, E., Pamuła, R., & Białowiec, A. (2024). Recycled Waste as Polyurethane Additives or Fillers: Mini-Review. Materials, 17(5), 1013. https://doi.org/10.3390/ma17051013