Innovative CF/PVC Foam Applicated for Automotive Synthetic Leather with High-Performance and Reduced VOC Emissions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

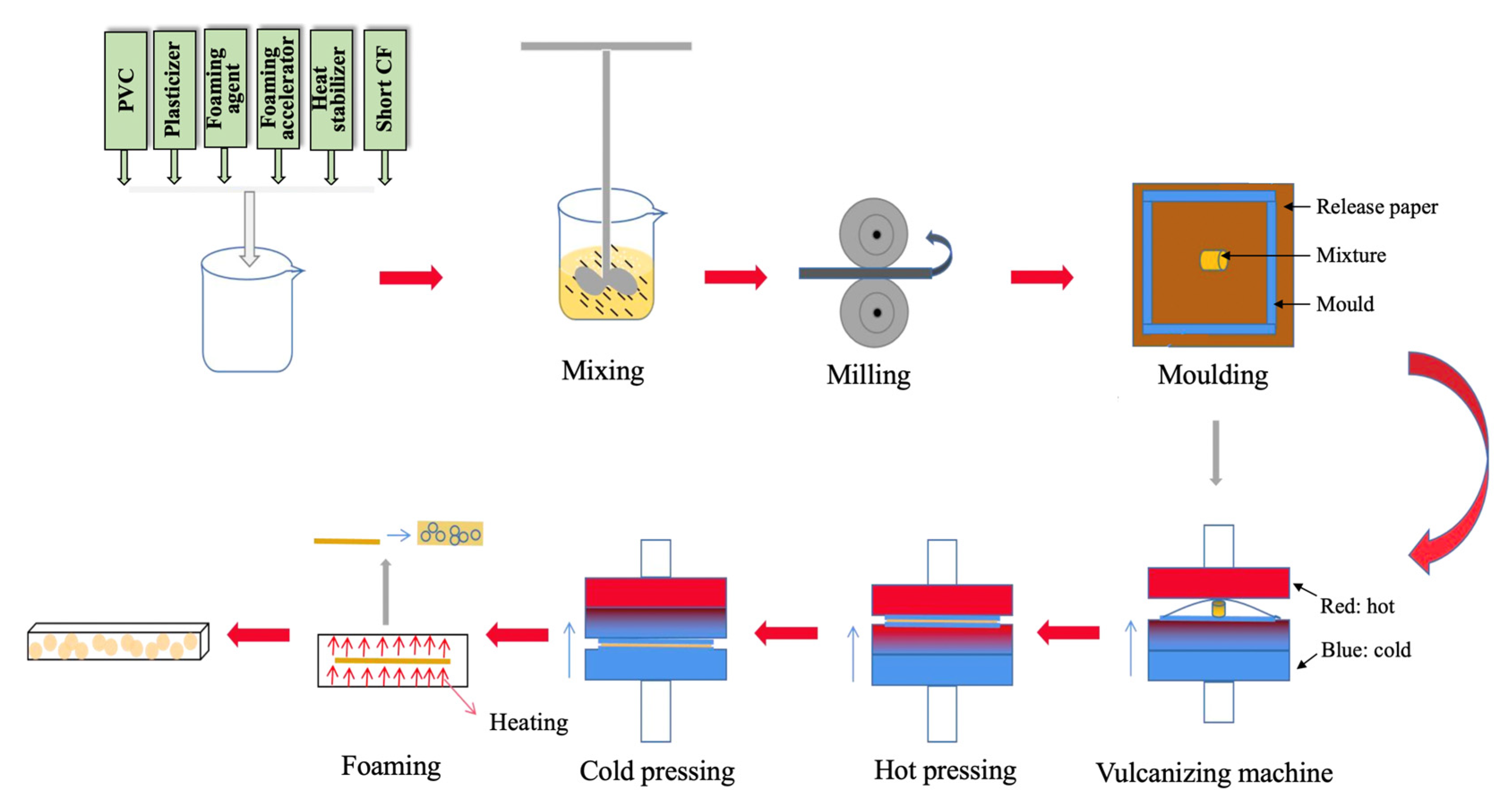

2.2. Preparation of PVC Foam

2.3. Preparation of CF/PVC Composite Foam

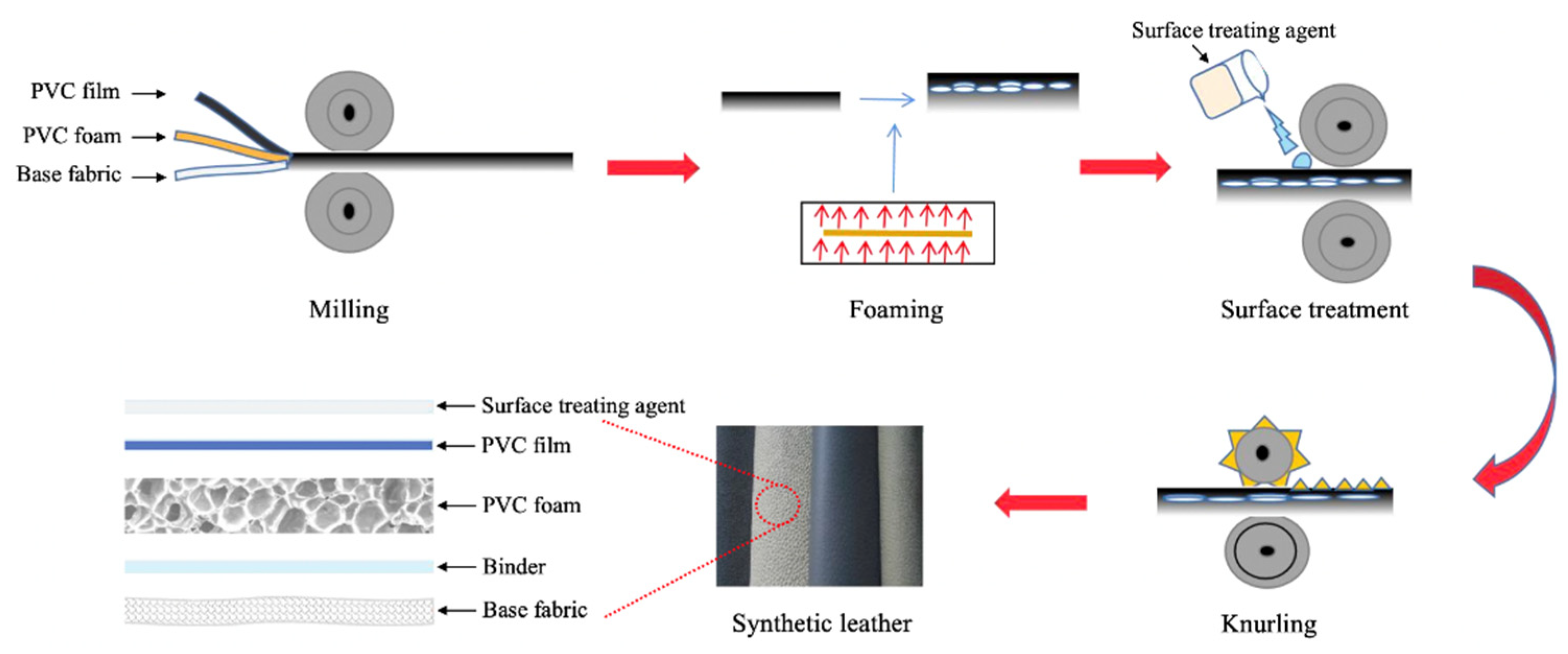

2.4. Preparation of PVC Foam Synthetic Leather

2.5. Characterizations and Tests

3. Results and Discussion

3.1. Properties of PVC Foam

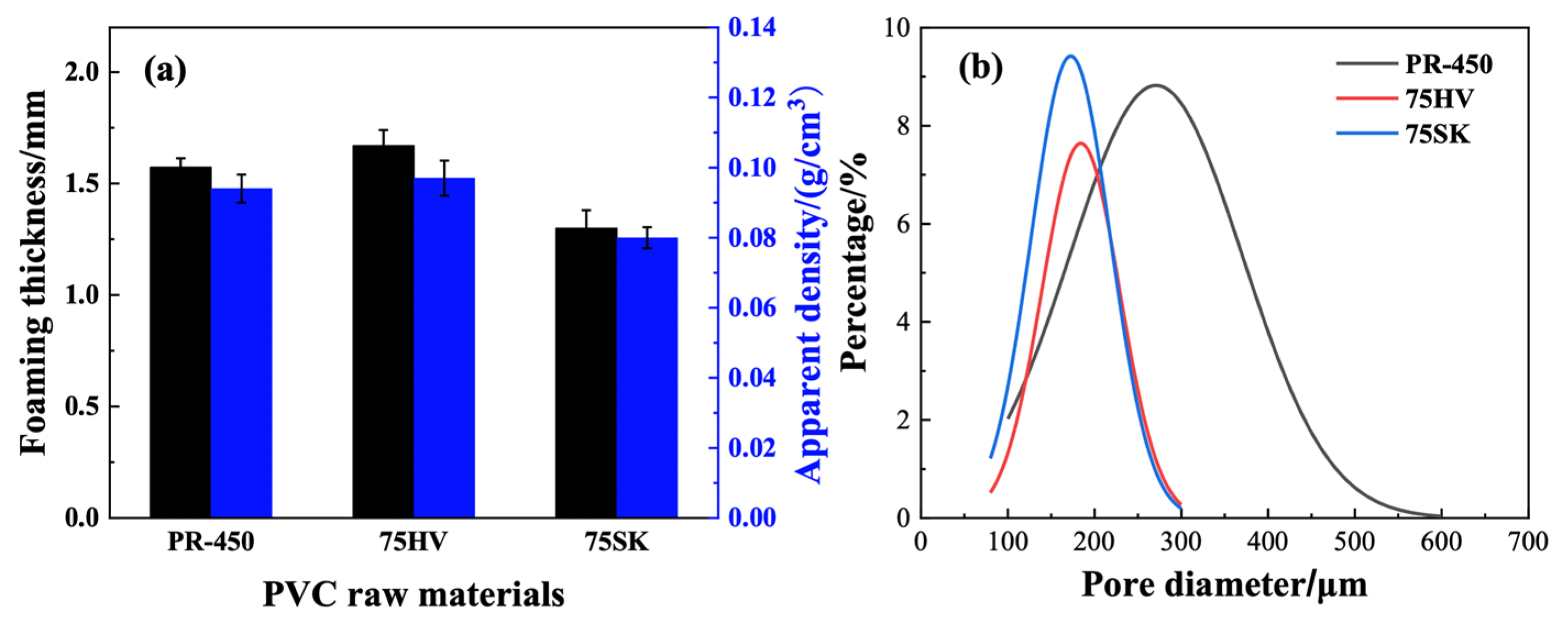

3.1.1. The Influence of PVC Raw Materials on Foaming

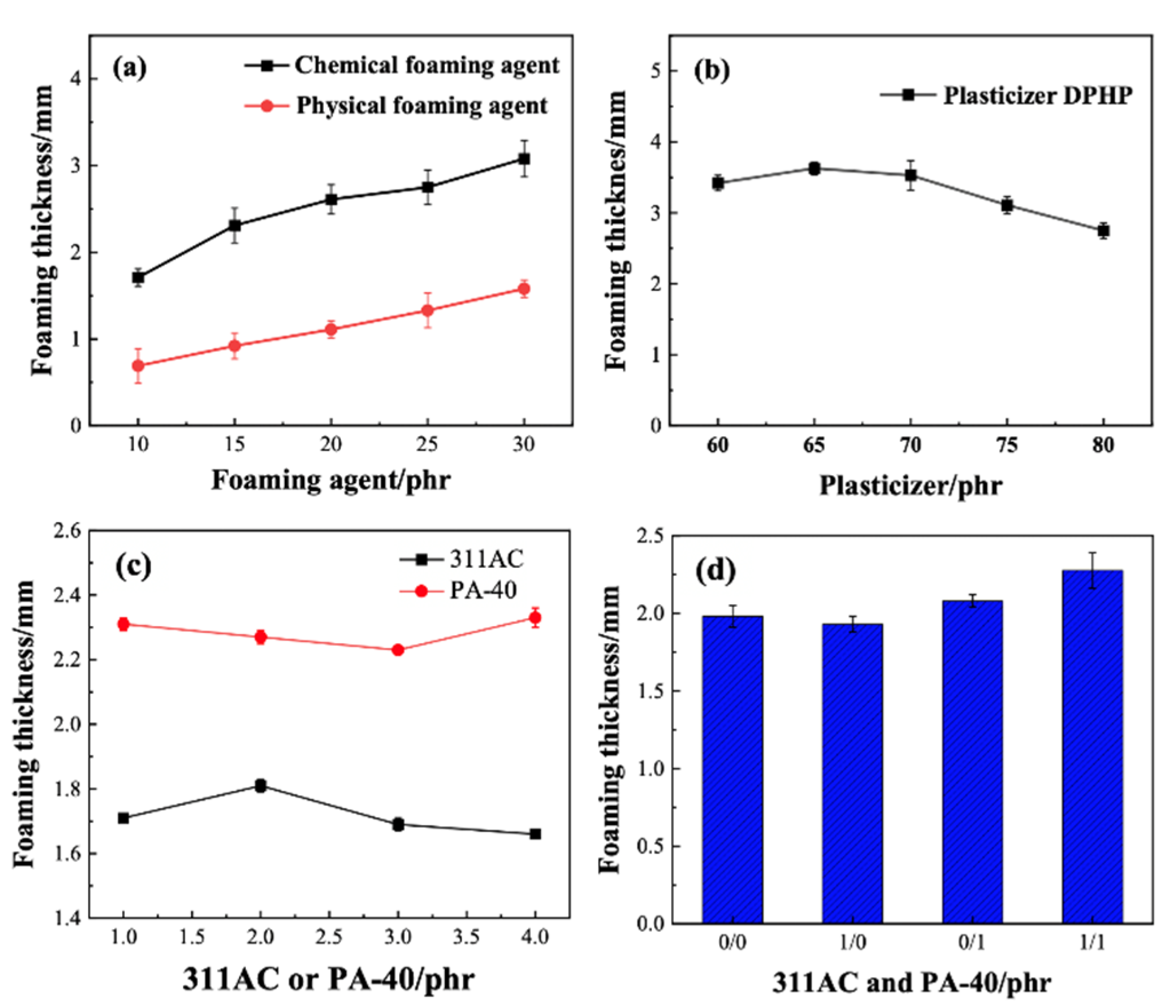

3.1.2. The Influence of Functional Additives on PVC Foaming

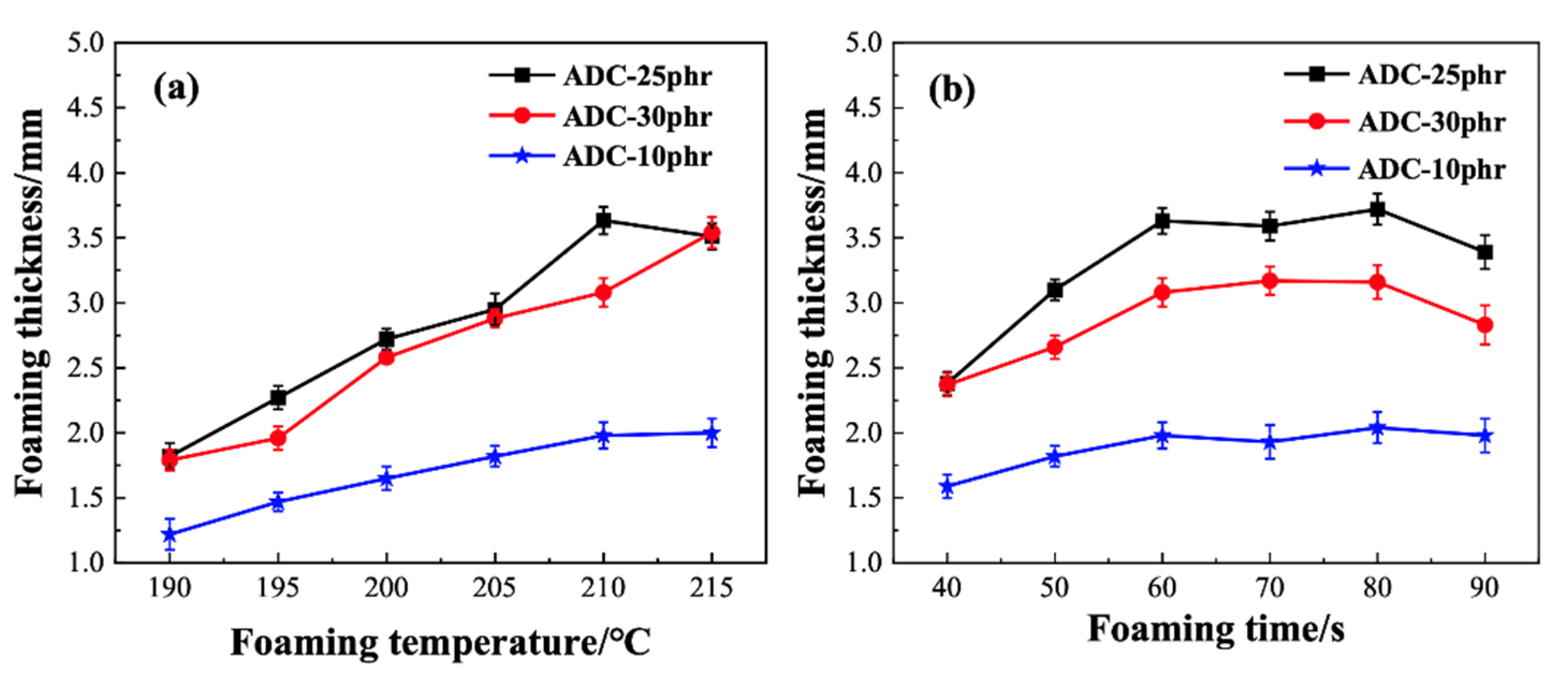

3.1.3. The Influence of Foaming Process on PVC Foaming

3.2. Properties of CF/PVC Composite Foam

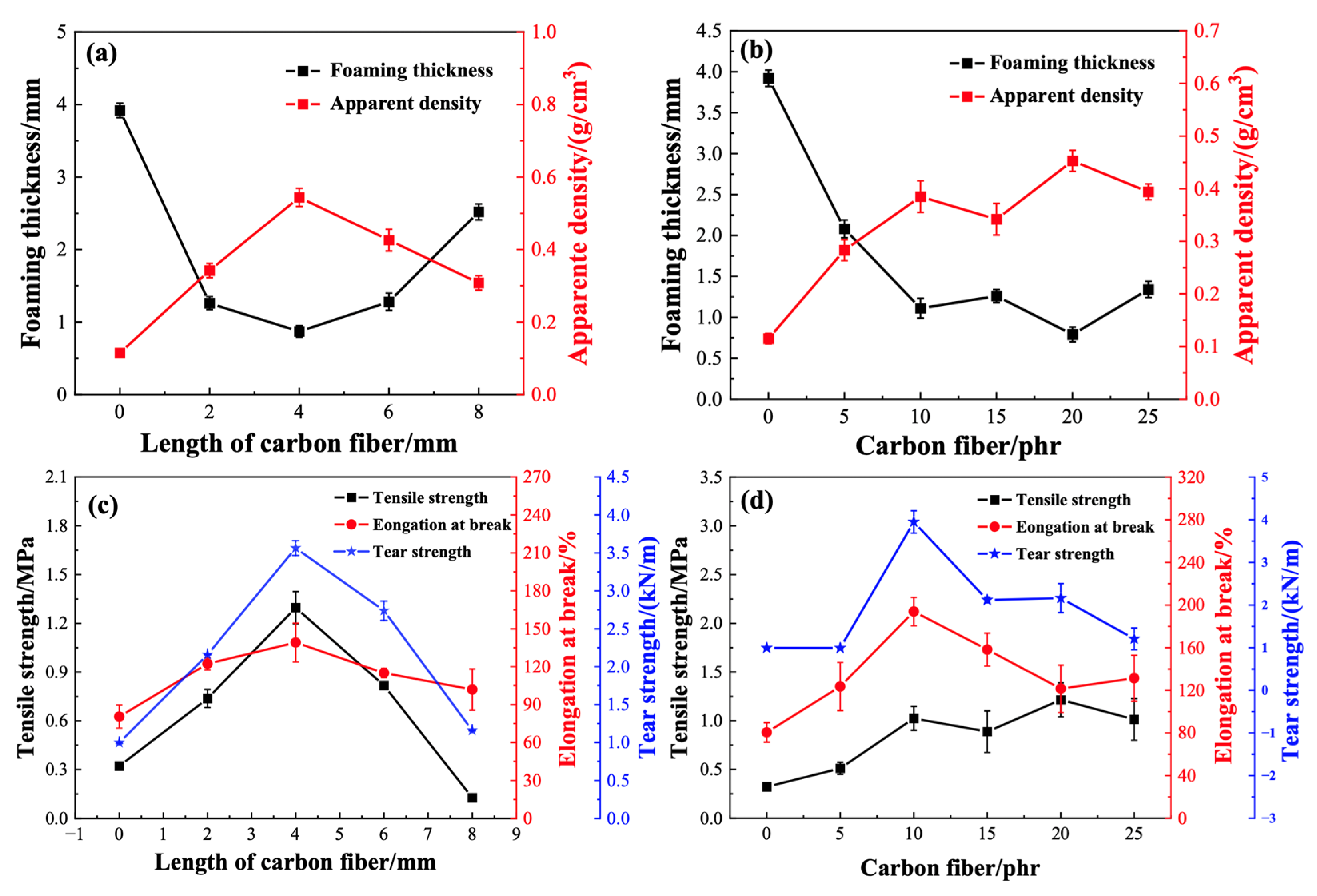

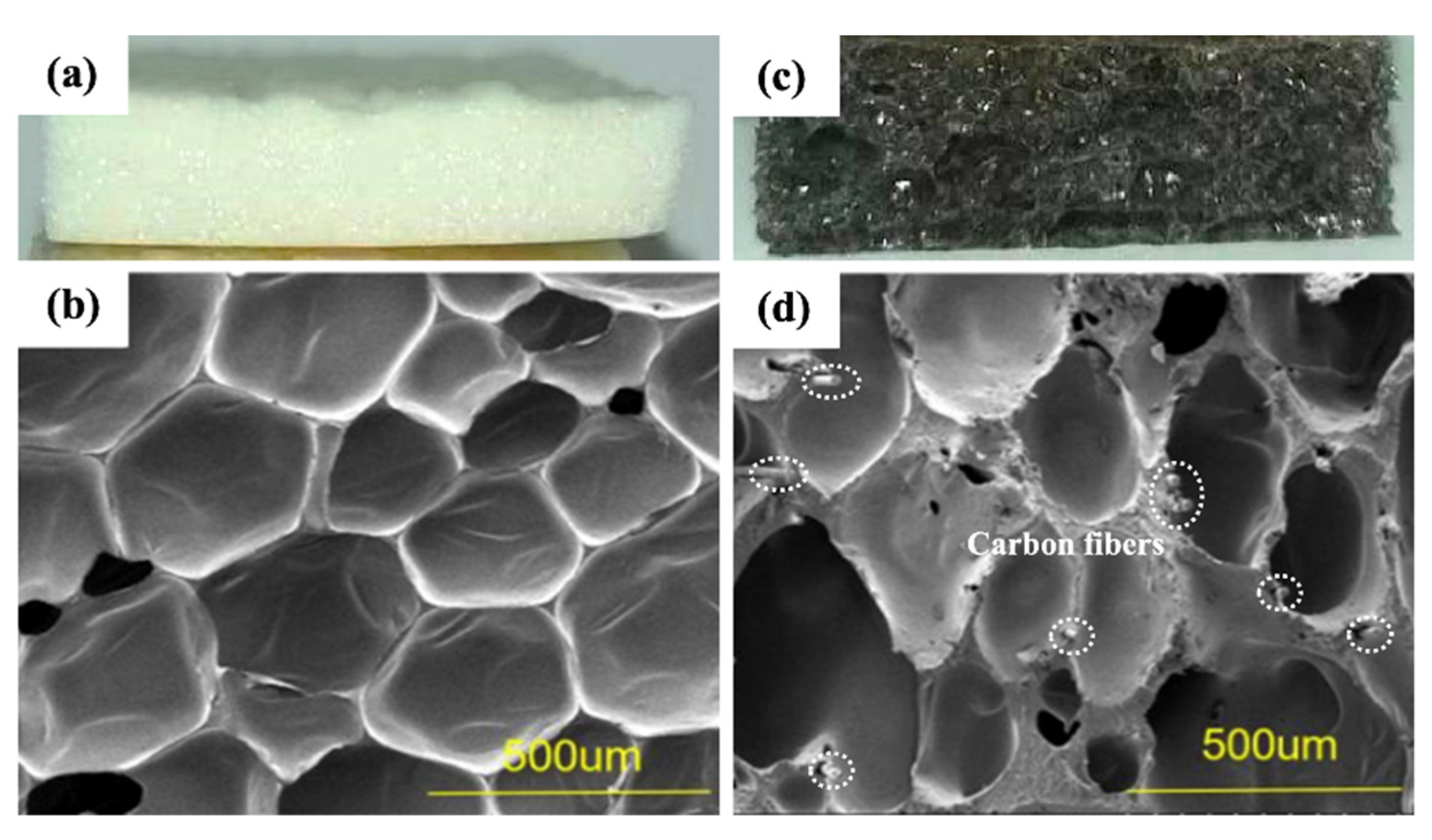

3.2.1. The Influence of Carbon Fibers on PVC Foaming

3.2.2. The Influence of Carbon Fibers on the Mechanical Properties of PVC Foam

3.3. CF/PVC Composite Foam Synthetic Leather

3.3.1. Areal Density and Mechanical Properties

- Areal density: The areal density of automotive PVC foam synthetic leather should be below 800 ± 80 g/m2 [37]. In this study, the average areal densities of the PVC foam synthetic leather and CF/PVC composite foam synthetic leather prepared were 765 g/m2 and 773 g/m2, respectively, meeting the requirements.

- Tensile properties: The tensile strength of synthetic leather made from PVC foam material is 32.6 MPa. In contrast, the tensile strength of synthetic leather prepared from CF/PVC composite foam increased to 48.9 MPa, a 50% improvement. This is attributed to the increased tensile strength of the foamed layer, and the addition of short fibers results in a rougher sample surface, enhancing the bonding between the PVC foam layer and other layers of PVC synthetic leather, thereby improving the overall tensile strength. However, the break elongation of synthetic leather prepared using CF/PVC foam material is reduced. Specifically, the elongation at break for synthetic leather prepared from PVC foam material is 214%, while for CF/PVC composite foam it decreases to 185%. The addition of carbon fibers reduces the mobility of PVC molecular chains during deformation, resulting in decreased plasticity, ultimately leading to a reduction in the elongation at break of PVC synthetic leather and a slight decrease in flexibility. Nevertheless, automotive-grade PVC foam synthetic leather requires a tensile strength greater than 35 MPa and a break elongation of 180–215% [33]. The tensile strength and break elongation of CF/PVC composite synthetic leather in this study still comply with the specified criteria.

- Tear resistance: The tear strength of synthetic leather prepared from neat PVC foam material is 11.4 kN/m, whereas synthetic leather prepared from CF/PVC composite foam material shows an increased tear strength of 14.7 kN/m. This improvement is attributed to the addition of fibers, which hinder the expansion of cracks, requiring greater tearing force to rupture PVC foam synthetic leather and, thus, enhancing tear resistance. Automotive-grade PVC foam synthetic leather requires tear strength greater than 10 kN/m [34], and the tear strength of CF/PVC foam synthetic leather in this study also meets the requirements.

3.3.2. VOC Emissions Evaluation

4. Conclusions

- The types and ratios of PVC raw materials, plasticizers, foaming agents, and processing aids significantly impact the foaming performance of PVC foam materials. The optimal foaming formulation for PVC was determined as follows: using 75HV as the base material, adding 65 phr plasticizer, 25 phr foaming agent, 1 phr foaming assistant, 1 phr processing aid, and 1 phr thermal stabilizer.

- The tensile strength and tear strength of CF/PVC composite foam synthetic leather were improved compared to PVC foam synthetic leather, increasing from 32.6 MPa to 48.9 MPa and from 11.4 kN/m to 14.7 kN/m, respectively. Although the elongation at break decreased from 214% to 185%, it still met the requirements for automotive interior applications. High performance implies reduced PVC usage and lower VOC emissions.

- Due to the hindering effect of carbon fiber on PVC molecular chain movement, the aging of PVC foam was inhibited, resulting in a reduction in total VOC emissions from 5.505 mg/m3 for PVC foam synthetic leather to 3.975 mg/m3 for CF/PVC composite foam synthetic leather.

- The CF/PVC composite foam synthetic leather production process presented in this study demonstrates excellent scalability. Future endeavors could focus on optimizing cost implications to enhance its market competitiveness, for instance, by incorporating recycled carbon fibers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tang, Y.; Zhang, W.; Jiang, X.; Zhao, J.; Xie, W.; Chen, T. Experimental investigations on phenomenological constitutive model of closed-cell PVC foam considering the effects of density, strain rate and anisotropy. Compos. Part. B-Eng. 2022, 238, 109885. [Google Scholar] [CrossRef]

- You, J.; Xing, H.; Xue, J.; Jiang, Z.; Tang, T. Preparation of rigid cross-linked PVC foam with excellent thermal insulation through adding high-reflectivity IR opacifier. Compos. Sci. Technol. 2021, 203, 108566. [Google Scholar] [CrossRef]

- Balıkoğlu, F.; Demircioğlu, T. Flexural behaviour of the composite sandwich beams with grid-scored foam: Experimental and theoretical approach. Thin-Walled Struct. 2022, 171, 108691. [Google Scholar] [CrossRef]

- Luong, D.D.; Pinisetty, D.; Gupta, N. Compressive properties of closed-cell polyvinyl chloride foams at low and high strain rates: Experimental investigation and critical review of state of the art. Compos. Part. B-Eng. 2013, 44, 403–416. [Google Scholar] [CrossRef]

- Zattini, G.; Ballardini, S.; Benelli, T.; Mazzocchetti, L.; Giorgini, L. Safer plasticized polyvinyl chloride synthetic leathers for the automotive industry: Evaluation of alternatives to antimony compounds as flame retardants. Polym. Eng. Sci. 2019, 59, 2488–2497. [Google Scholar] [CrossRef]

- Altindag, I.A.; Akdogan, Y. Spectrophotometric characterization of plasticizer migration in poly (vinyl chloride)-based artificial leather. Mater. Chem. Phys. 2021, 258, 123954. [Google Scholar] [CrossRef]

- Zhang, J.P.; Zhang, C.C.; Zhang, F.-S. A novel process for waste polyvinyl chloride recycling: Plant growth substrate development. J. Environ. Chem. Eng. 2021, 9, 105475. [Google Scholar] [CrossRef]

- Defonseka, C. Polymeric Coating Systems for Artificial Leather: Standard and Latest Technologies; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2022. [Google Scholar]

- Xu, M.; Cao, C.; Hu, H.; Ren, Y.; Guo, G.; Gong, L.; Zhang, J.; Zhang, T.; Yao, H. Perspective on the disposal of PVC artificial leather via pyrolysis: Thermodynamics, kinetics, synergistic effects and reaction mechanism. Fuel 2022, 327, 125082. [Google Scholar] [CrossRef]

- David, E.; Niculescu, V.C. Volatile organic compounds (VOCs) as environmental pollutants: Occurrence and mitigation using nanomaterials. Int. J. Environ. Res. Public Health 2021, 18, 13147. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

- Health Care Without Harm Europe. The Polyvinyl Chloride Debate: Why PVC Remains a Problematic Material; Health Care Without Harm Europe: Bruxelles, Belgium, 2021. [Google Scholar]

- Xue, J.; Cai, H.; Li, W.; Pei, Y.; Guan, H.; Guo, Z.; Wu, C.; Qu, C.; Li, W.; Liu, J. Emissions of VOCs and SVOCs from polyvinyl chloride building materials: Contribution to indoor odor and inhalation health risks. Build. Environ. 2023, 229, 109958. [Google Scholar] [CrossRef]

- Wang, Q.; Shen, J.; Cao, T.; Du, J.; Dong, H.; Shen, X. Emission characteristics and health risks of volatile organic compounds and odor from PVC-overlaid particleboard. BioResources 2019, 14, 4385–4402. [Google Scholar] [CrossRef]

- Khalil, H.A.; Tehrani, M.; Davoudpour, Y.; Bhat, A.; Jawaid, M.; Hassan, A. Natural fiber reinforced poly(vinyl chloride) composites: A review. J. Reinf. Plast. Compos. 2013, 32, 330–356. [Google Scholar] [CrossRef]

- Demir, H.; Sipahioğlu, M.; Balköse, D.; Ülkü, S. Effect of additives on flexible PVC foam formation. J. Mater. Proc. Technol. 2008, 195, 144–153. [Google Scholar] [CrossRef]

- Shi, Y.; Yao, Y.; Lu, S.; Chen, L.; Chen, S.; He, H.; Ma, M.; Wang, X. Synergistic effect of two plasticizers on thermal stability, transparency, and migration resistance of zinc arginine stabilized PVC. Polymers 2022, 14, 4560. [Google Scholar] [CrossRef] [PubMed]

- Maia, I.; Santos, J.; Abreu, M.J.; Miranda, T.; Carneiro, N.; Soares, G. PVC-based synthetic leather to provide more comfortable and sustainable vehicles. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 254, p. 122006. [Google Scholar]

- Alshammari, B.A.; Alsuhybani, M.S.; Almushaikeh, A.M.; Alotaibi, B.M.; Alenad, A.M.; Alqahtani, N.B.; Alharbi, A.G. Comprehensive review of the properties and modifications of carbon fiber-reinforced thermoplastic composites. Polymers 2021, 13, 2474. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.-S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part. B-Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Ho, X.; Yu, Y.; Wang, N. Preparation and properties of glass fiber/polyvinyl chloride composites. Chin. Adhes. 2016, 25, 43–46. [Google Scholar]

- Hassan, A.; Akbari, A.; Hing, N.K.; Ratnam, C.T. Mechanical and thermal properties of ABS/PVC composites: Effect of particles size and surface treatment of ground calcium carbonate. Polym.-Plast. Technol. Eng. 2012, 51, 473–479. [Google Scholar] [CrossRef]

- Fu, S.; Lauke, B.; Mäder, E.; Yue, C.; Hu, X. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Zhao, H.; Jiang, S. Study on properties of PVC based materials reinforced by glass fiber. Guangzhou Chem. 2012, 40, 57–59. [Google Scholar]

- Kabir, S.F.; Mathur, K.; Seyam, A.F.M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Li, J.; Cai, C.L. Friction and wear properties of carbon fiber reinforced polypropylene composites. Adv. Mater. Res. 2011, 284, 2380–2383. [Google Scholar] [CrossRef]

- Yunus, R.B.; Zahari, N.; Salleh, M.; Ibrahim, N.A. Mechanical properties of carbon fiber-reinforced polypropylene composites. Key Eng. Mater. 2011, 471, 652–657. [Google Scholar] [CrossRef]

- Rezaei, F.; Yunus, R.; Ibrahim, N. Effect of fiber length on thermomechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Des. 2009, 30, 260–263. [Google Scholar] [CrossRef]

- Gogoi, R.; Maurya, A.K.; Manik, G. A review on recent development in carbon fiber reinforced polyolefin composites. Compos. Part C Open Access 2022, 8, 100279. [Google Scholar] [CrossRef]

- Wang, C.; Ying, S.; Xiao, Z. Preparation of short carbon fiber/polypropylene fine-celled foams in supercritical CO2. J. Cell. Plast. 2013, 49, 65–82. [Google Scholar] [CrossRef]

- Abedi, M.M.; Nedoushan, R.J.; Yu, W.R. Enhanced compressive and energy absorption properties of braided lattice and polyurethane foam hybrid composites. Int. J. Mech. Sci. 2021, 207, 106627. [Google Scholar] [CrossRef]

- Sebaey, T.A.; Rajak, D.K.; Mehboob, H. Internally stiffened foam-filled carbon fiber reinforced composite tubes under impact loading for energy absorption applications. Compos. Struct. 2021, 255, 112910. [Google Scholar] [CrossRef]

- GMW3010-2019; General Motors Company Worldwide Engineering Standards: Determination of Tensile and Elongation Properties. General Motors Company: Detroit, MI, USA, 2019.

- ISO 13937; Tear Properties of Fabrics. ISO: Geneva, Switzerland, 2000.

- Degefu, D.M.; Liao, Z.; Berardi, U.; Doan, H. Salient parameters affecting the performance of foamed geopolymers as sustainable insulating materials. Constr. Build. Mater. 2021, 313, 125400. [Google Scholar] [CrossRef]

- Verdu, J.; Zoller, A.; Marcilla, A. Plastisol foaming process. Decomposition of the foaming agent, polymer behavior in the corresponding temperature range and resulting foam properties. Polym. Eng. Sci. 2013, 53, 1712–1718. [Google Scholar] [CrossRef]

- GMW3182-2022; General Motors Company Worldwide Engineering Standards: Determination of Mass per Area. General Motors Company: Detroit, MI, USA, 2022.

- GMW3205-2023; General Motors Company Worldwide Engineering Standards: Determining the Resistance to Odor Propagation of Interior Materials. General Motors Company: Detroit, MI, USA, 2023.

- Li, Z.; Wei, X.; Liu, J.; Han, H.; Jia, H.; Song, J. Mechanical properties and VOC emission of hemp fibre reinforced polypropylene composites: Natural freezing-mechanical treatment and interface modification. Fibers Polym. 2021, 22, 1050–1062. [Google Scholar] [CrossRef]

- Gu, R.; Sain, M.M.; Konar, S.K. A feasibility study of polyurethane composite foam with added hardwood pulp. Ind. Crops Prod. 2013, 42, 273–279. [Google Scholar] [CrossRef]

- Kada, D.; Koubaa, A.; Tabak, G.; Migneault, S.; Garnier, B.; Boudenne, A. Tensile properties, thermal conductivity, and thermal stability of short carbon fiber reinforced polypropylene composites. Polym. Compos. 2018, 39, E664–E670. [Google Scholar] [CrossRef]

| Material | Role | Weight Ratio (phr) |

|---|---|---|

| PVC | Resin | 100 |

| DPHP | Plasticizer | 65 |

| ADC | Foaming agent | 25 |

| 311AC | Foaming accelerator | 1 |

| PA-40 | Processing agent | 1 |

| Stab5 | Heat stabilizer | 1 |

| PVC Foam | CF/PVC Foam | Requirements | |

|---|---|---|---|

| Areal density (g/m2) | 765 | 773 | 800 ± 80 [37] |

| Tensile strength (MPa) | 32.6 | 48.9 | >35 [33] |

| Elongation at break (%) | 214 | 185 | 180–215 [33] |

| Tear strength (kN/m) | 11.4 | 14.7 | >10 [34] |

| PVC Foam Materials | Methanal | Acrolein | Acetaldehyde | Benzene | Methylbenzene | Styrene | Xylene | Ethylbenzene | Total VOC 1 |

|---|---|---|---|---|---|---|---|---|---|

| PVC foam | 0.005 | 0.000 | 0.022 | 0.002 | 0.019 | 0.000 | 0.000 | 0.000 | 5.505 |

| CF/PVC foam | 0.009 | 0.000 | 0.030 | 0.005 | 0.025 | 0.000 | 0.029 | 0.000 | 3.975 |

| Requirements [38] | ≤0.10 | ≤0.05 | ≤0.05 | ≤0.11 | ≤1.10 | ≤0.26 | ≤1.50 | ≤1.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wu, Y.; Wu, L.; Cui, C.; Niu, K. Innovative CF/PVC Foam Applicated for Automotive Synthetic Leather with High-Performance and Reduced VOC Emissions. Materials 2024, 17, 1076. https://doi.org/10.3390/ma17051076

Li H, Wu Y, Wu L, Cui C, Niu K. Innovative CF/PVC Foam Applicated for Automotive Synthetic Leather with High-Performance and Reduced VOC Emissions. Materials. 2024; 17(5):1076. https://doi.org/10.3390/ma17051076

Chicago/Turabian StyleLi, Hongfu, Ying Wu, Lingyan Wu, Changwei Cui, and Kangmin Niu. 2024. "Innovative CF/PVC Foam Applicated for Automotive Synthetic Leather with High-Performance and Reduced VOC Emissions" Materials 17, no. 5: 1076. https://doi.org/10.3390/ma17051076

APA StyleLi, H., Wu, Y., Wu, L., Cui, C., & Niu, K. (2024). Innovative CF/PVC Foam Applicated for Automotive Synthetic Leather with High-Performance and Reduced VOC Emissions. Materials, 17(5), 1076. https://doi.org/10.3390/ma17051076