Interfacial Enhancement and Composite Manufacturing of Continuous Carbon-Fiber-Reinforced PA6T Composites via PrePA6T Ultrafine Powder

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Sample Preparation for Micro-Bond Test

2.3. Preparation of prePA6T Hyperfine Powder and Emulsion

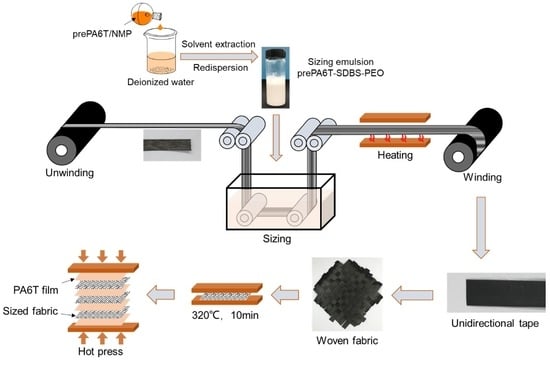

2.4. Preparation of CF/PA6T Composites

2.5. Characterization

3. Results and Discussion

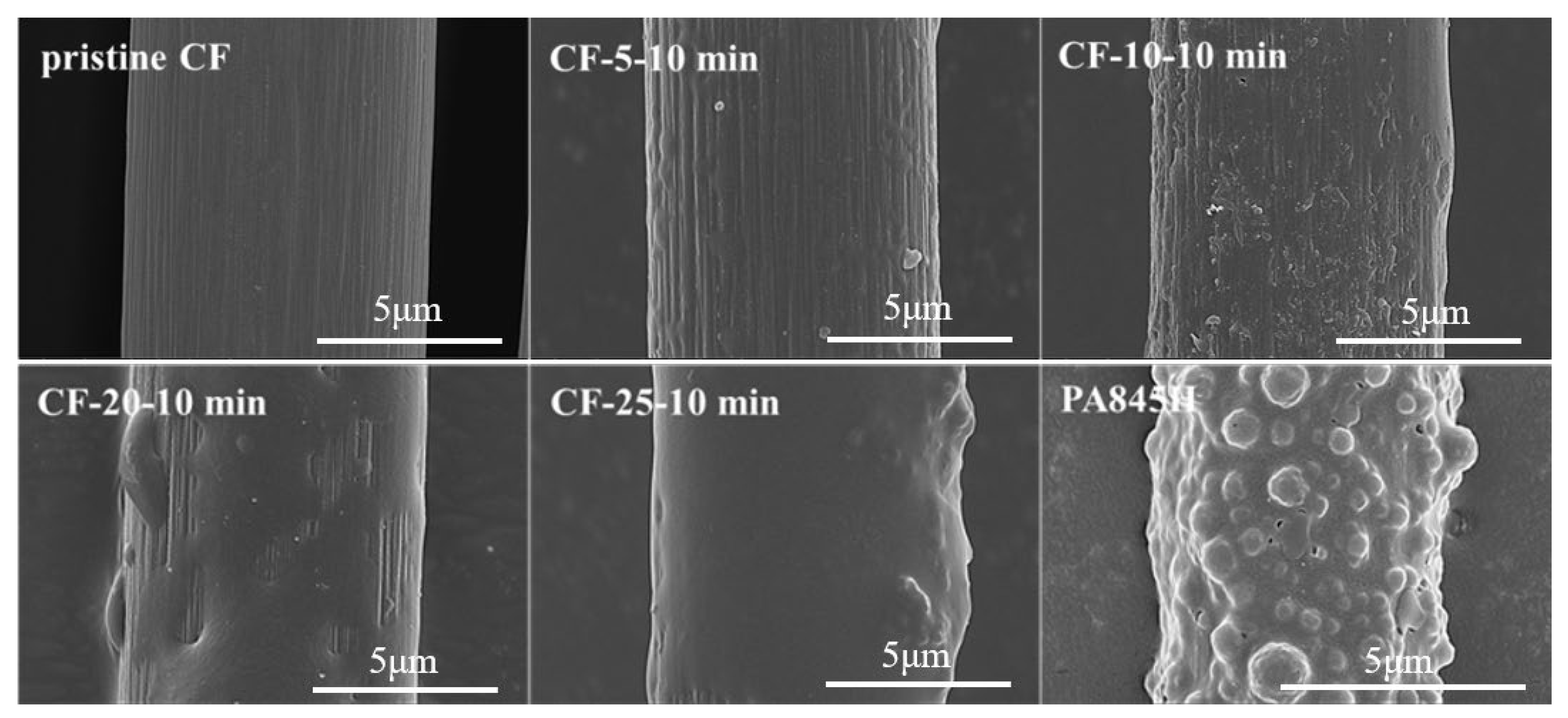

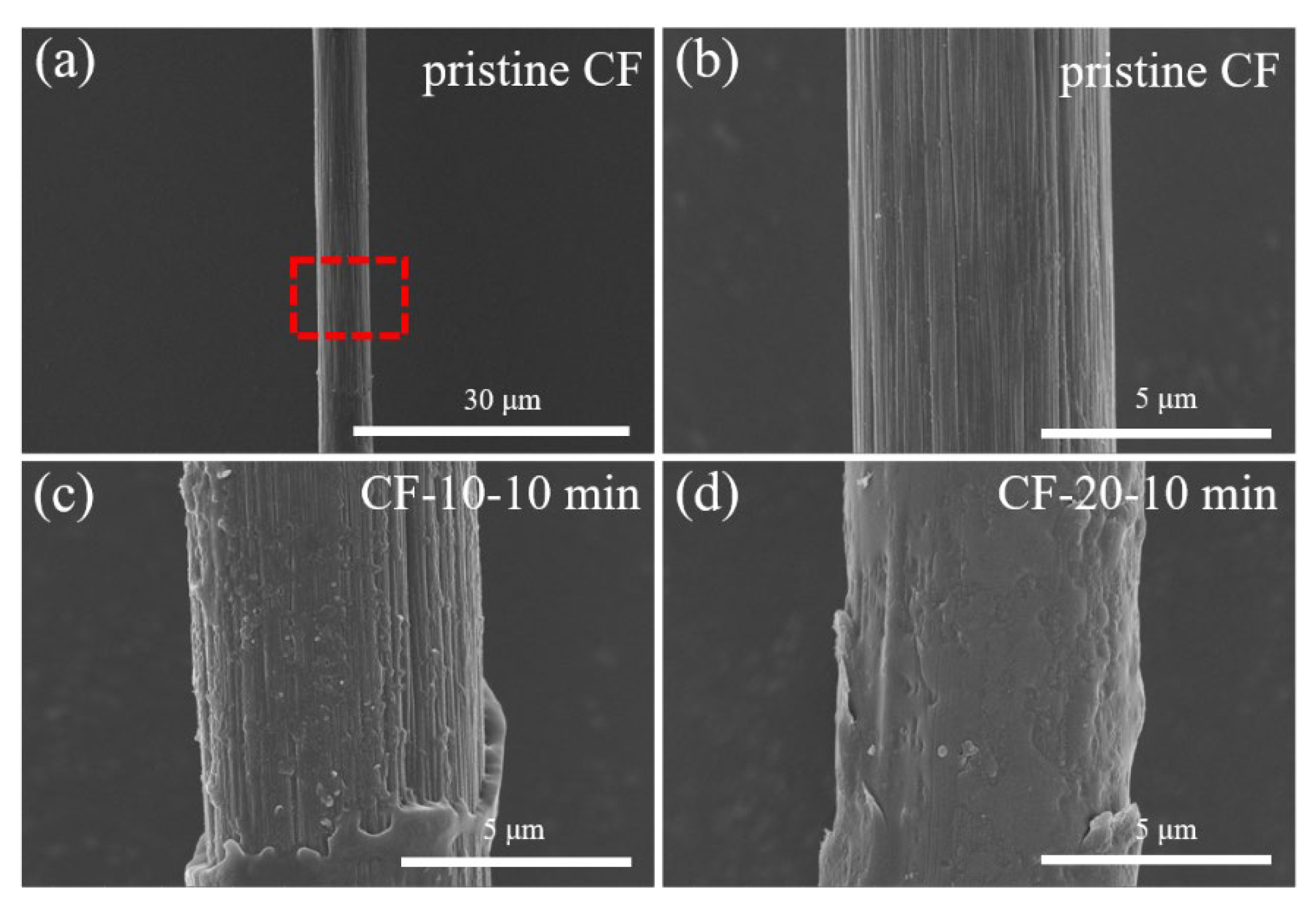

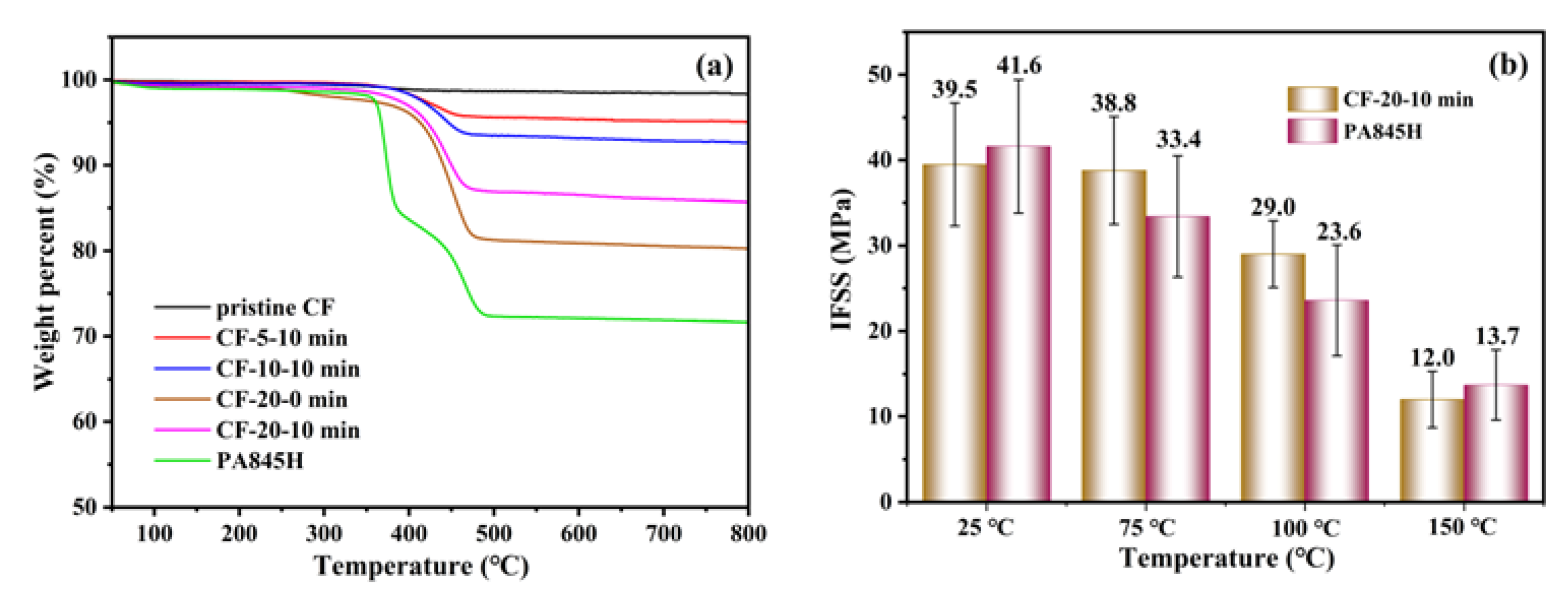

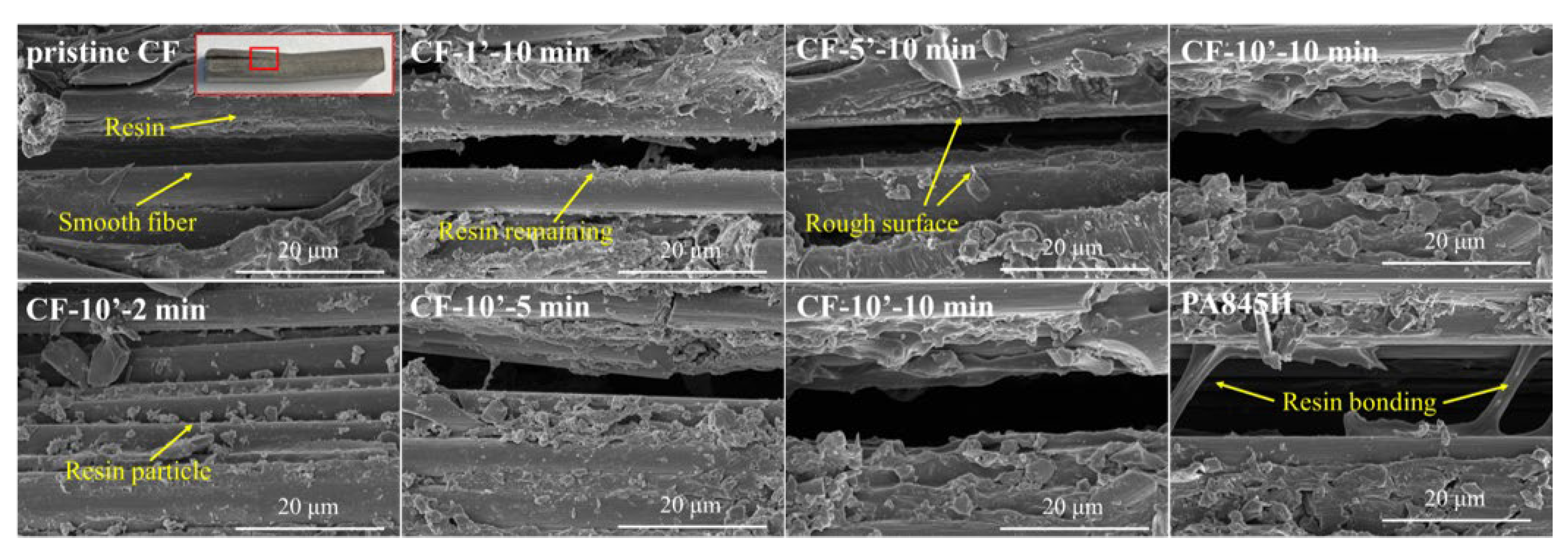

3.1. The Morphology and IFSS of Sized Single CF

3.2. Interfacial Properties at Elevated Temperatures

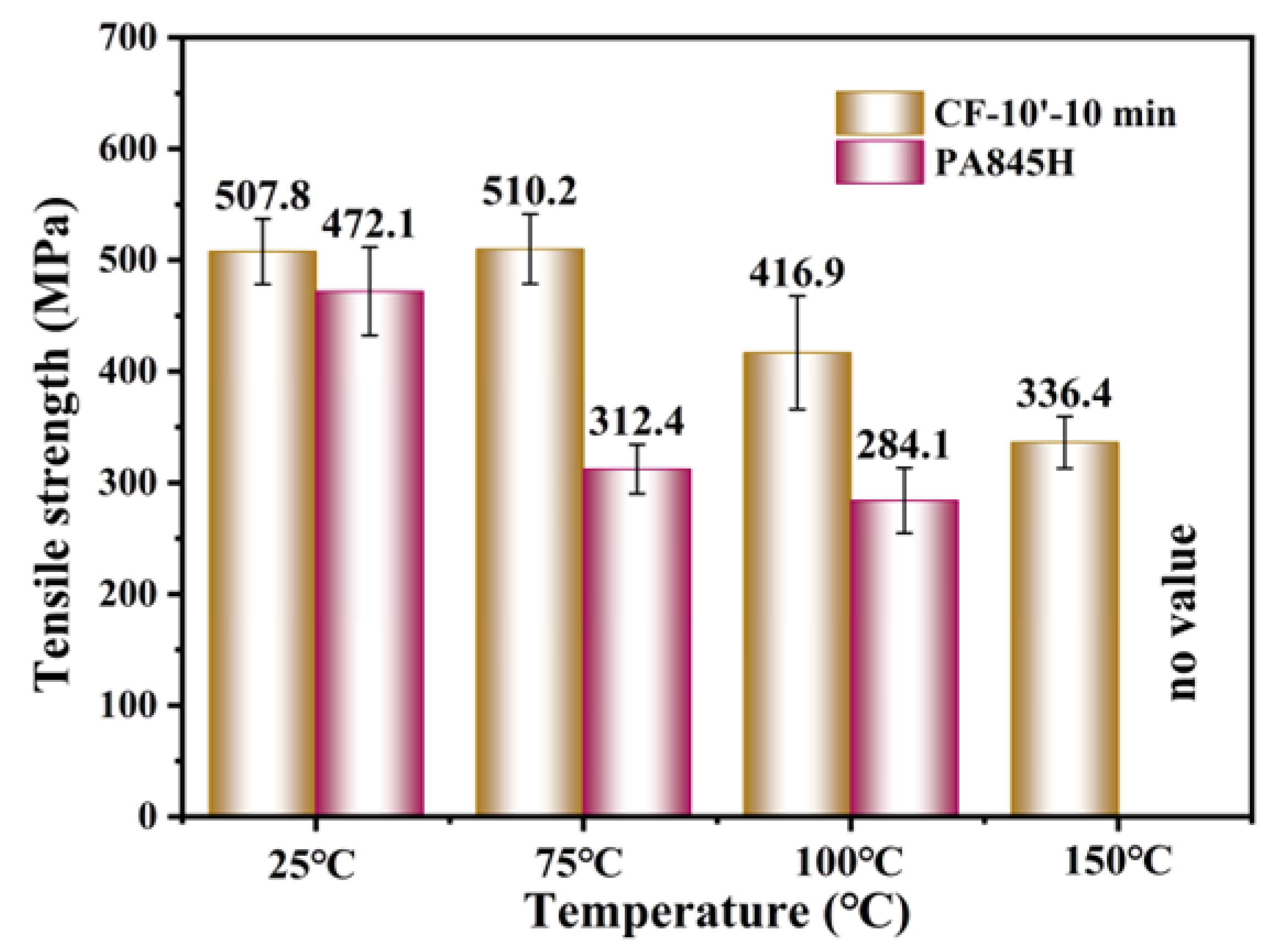

3.3. PrePA6T Particle Size Distribution and Emulsion Preparation

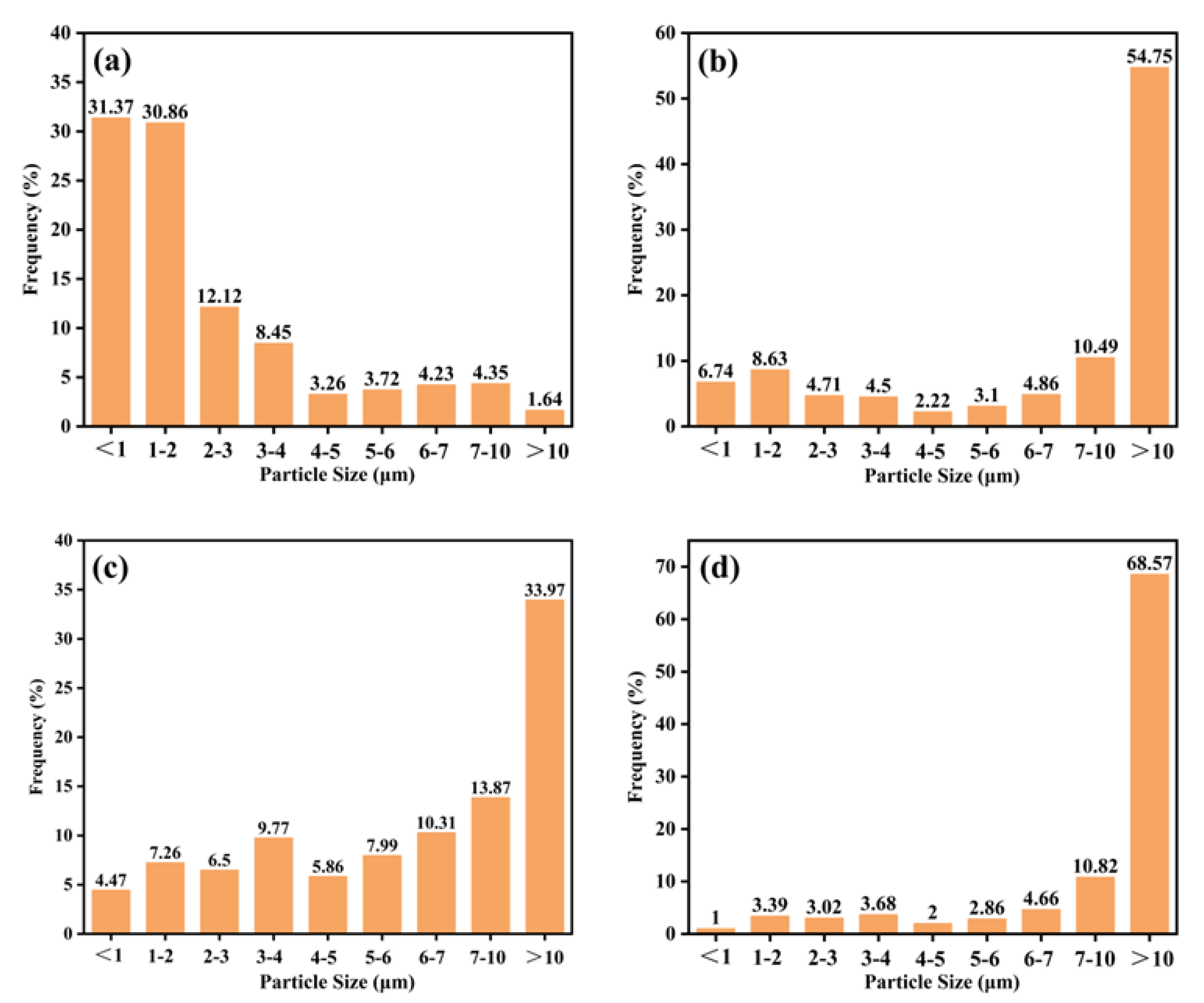

3.4. Morphologies of Emulsion-Coated CF Unidirectional Tapes

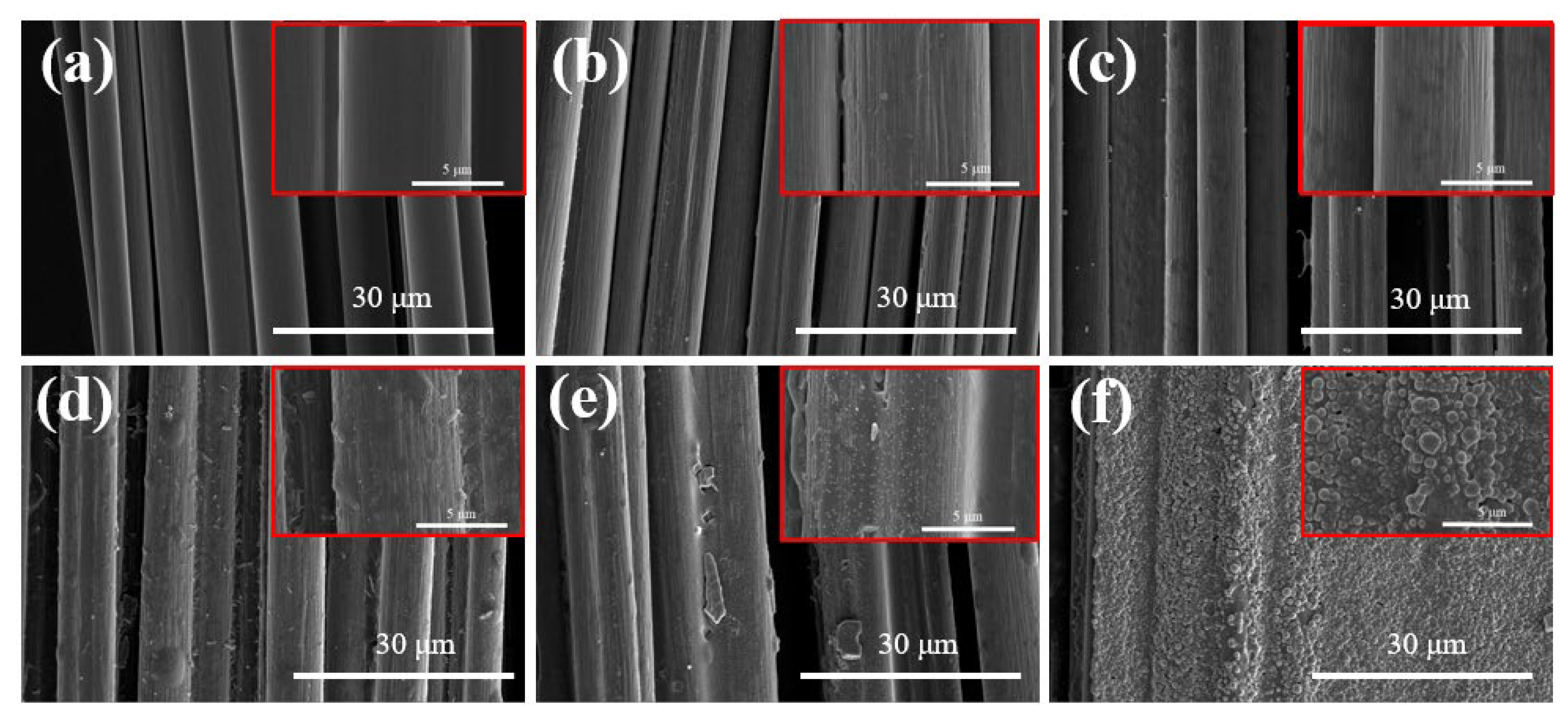

3.5. Mechanical Properties of Fabric PA6T/CF Composites

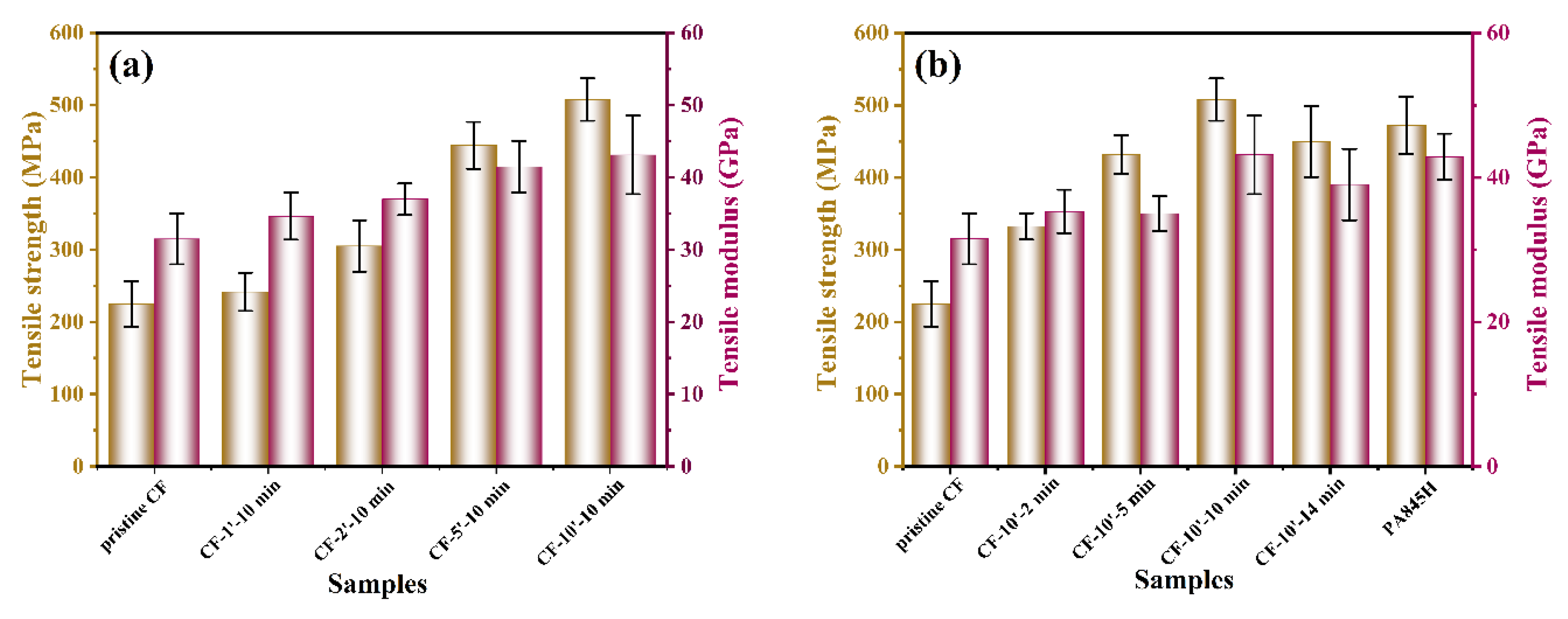

3.6. ILSS of Fabric Laminated Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soutis, C. Fibre Reinforced Composites in Aircraft Construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.; Wang, K.; Peng, Y.; Wang, D.; Yao, S.; Wang, J. Materials Selection of 3D-Printed Continuous Carbon Fiber Reinforced Composites Considering Multiple Criteria. Mater. Des. 2020, 196, 109140. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent Advances in Carbon-Fiber-Reinforced Thermoplastic Composites: A Review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Li, R.; Ye, L.; Mai, Y.-W. Application of Plasma Technologies in Fibre-Reinforced Polymer Composites: A Review of Recent Developments. Compos. Part A Appl. Sci. Manuf. 1997, 28, 73–86. [Google Scholar] [CrossRef]

- Shim, J.-W.; Park, S.-J.; Ryu, S.-K. Effect of Modification with HNO3 and NaOH on Metal Adsorption by Pitch-Based Activated Carbon Fibers. Carbon 2001, 39, 1635–1642. [Google Scholar] [CrossRef]

- Pittman, C.U.; He, G.-R.; Wu, B.; Gardner, S.D. Chemical Modification of Carbon Fiber Surfaces by Nitric Acid Oxidation Followed by Reaction with Tetraethylenepentamine. Carbon 1997, 35, 317–331. [Google Scholar] [CrossRef]

- Xu, B.; Wang, X.; Lu, Y. Surface Modification of Polyacrylonitrile-Based Carbon Fiber and Its Interaction with Imide. Appl. Surf. Sci. 2006, 253, 2695–2701. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Xu, Z.; Wang, Z. High-Energy Radiation Technique Treat on the Surface of Carbon Fiber. Mater. Chem. Phys. 2005, 94, 315–321. [Google Scholar] [CrossRef]

- Clough, R.L. High-Energy Radiation and Polymers: A Review of Commercial Processes and Emerging Applications. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2001, 185, 8–33. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Z.; Zhang, G.; Liu, S.; Long, S.; Yang, J.; Yang, J.; Wang, X. Improvement of Interfacial Interaction between Poly(Arylene Sulfide Sulfone) and Carbon Fiber via Molecular Chain Grafting. Compos. Sci. Technol. 2022, 224, 109463. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.; Mäder, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon Fiber Surfaces and Composite Interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Pamula, E.; Rouxhet, P.G. Bulk and Surface Chemical Functionalities of Type III PAN-Based Carbon Fibres. Carbon 2003, 41, 1905–1915. [Google Scholar] [CrossRef]

- Jiang, D.; Liu, L.; Long, J.; Xing, L.; Huang, Y.; Wu, Z.; Yan, X.; Guo, Z. Reinforced Unsaturated Polyester Composites by Chemically Grafting Amino-POSS onto Carbon Fibers with Active Double Spiral Structural Spiralphosphodicholor. Compos. Sci. Technol. 2014, 100, 158–165. [Google Scholar] [CrossRef]

- Shin, H.K.; Park, M.; Kim, H.-Y.; Park, S.-J. An Overview of New Oxidation Methods for Polyacrylonitrile-Based Carbon Fibers. Carbon Lett. 2015, 16, 11–18. [Google Scholar] [CrossRef]

- Fernandez, B.; Arbelaiz, A.; Valea, A.; Mujika, F.; Mondragon, I. A Comparative Study on the Influence of Epoxy Sizings on the Mechanical Performance of Woven Carbon Fiber-epoxy Composites. Polym. Compos. 2004, 25, 319–330. [Google Scholar] [CrossRef]

- Dai, Z.; Shi, F.; Zhang, B.; Li, M.; Zhang, Z. Effect of Sizing on Carbon Fiber Surface Properties and Fibers/Epoxy Interfacial Adhesion. Appl. Surf. Sci. 2011, 257, 6980–6985. [Google Scholar] [CrossRef]

- Bowman, S.; Jiang, Q.; Memon, H.; Qiu, Y.; Liu, W.; Wei, Y. Effects of Styrene-Acrylic Sizing on the Mechanical Properties of Carbon Fiber Thermoplastic Towpregs and Their Composites. Molecules 2018, 23, 547. [Google Scholar] [CrossRef] [PubMed]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.-F.M. A Critical Review on 3D Printed Continuous Fiber-Reinforced Composites: History, Mechanism, Materials and Properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Wang, Z.; Dong, Y.; Yang, J.; Wang, X.; Zhang, M.; Zhang, G.; Long, S.; Liu, S.; Yang, J. Improved Interfacial Shear Strength in Carbon Fiber Enhanced Semi-Aromatic Polyamide 6T Composite via in-Situ Polymerization on Fiber Surface. Compos. Sci. Technol. 2022, 223, 109401. [Google Scholar] [CrossRef]

- Gabrion, X.; Placet, V.; Trivaudey, F.; Boubakar, L. About the Thermomechanical Behaviour of a Carbon Fibre Reinforced High-Temperature Thermoplastic Composite. Compos. Part B Eng. 2016, 95, 386–394. [Google Scholar] [CrossRef]

- Giraud, I.; Franceschi-Messant, S.; Perez, E.; Lacabanne, C.; Dantras, E. Preparation of Aqueous Dispersion of Thermoplastic Sizing Agent for Carbon Fiber by Emulsion/Solvent Evaporation. Appl. Surf. Sci. 2013, 266, 94–99. [Google Scholar] [CrossRef]

- Wu, G.M.; Schultz, J.M. Processing and Properties of Solution Impregnated Carbon Fiber Reinforced Polyethersulfone Composites. Polym. Compos. 2000, 21, 223–230. [Google Scholar] [CrossRef]

- Duchoslav, J.; Unterweger, C.; Steinberger, R.; Fürst, C.; Stifter, D. Investigation on the Thermo-Oxidative Stability of Carbon Fiber Sizings for Application in Thermoplastic Composites. Polym. Degrad. Stab. 2016, 125, 33–42. [Google Scholar] [CrossRef]

- Barkanov, E.; Akishin, P.; Namsone-Sile, E. Effectiveness and Productivity Improvement of Conventional Pultrusion Processes. Polymers 2022, 14, 841. [Google Scholar] [CrossRef] [PubMed]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef]

- Padaki, S.; Drzal, L.T. A Simulation Study on the Effects of Particle Size on the Consolidation of Polymer Powder Impregnated Tapes. Compos. Part A Appl. Sci. Manuf. 1999, 30, 325–337. [Google Scholar] [CrossRef]

- Vaidya, U.K.; Chawla, K.K. Processing of Fibre Reinforced Thermoplastic Composites. Int. Mater. Rev. 2013, 53, 185–218. [Google Scholar] [CrossRef]

- Cho, B.-G.; Ram Joshi, S.; Hun Han, J.; Kim, G.-H.; Park, Y.-B. Interphase Strengthening of Carbon Fiber/Polyamide 6 Composites through Mixture of Sizing Agent and Reduced Graphene Oxide Coating. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106521. [Google Scholar] [CrossRef]

- Bernet, N.; Michaud, V.; Bourban, P.E.; Manson, J.A.E. An Impregnation Model for the Consolidation of Thermoplastic Composites Made from Commingled Yarns. J. Compos. Mater. 1999, 33, 751–772. [Google Scholar] [CrossRef]

- Schäfer, J.; Stolyarov, O.; Ali, R.; Greb, C.; Seide, G.; Gries, T. Process–Structure Relationship of Carbon/Polyphenylene Sulfide Commingled Hybrid Yarns Used for Thermoplastic Composites. J. Ind. Txtiles 2016, 45, 1661–1673. [Google Scholar] [CrossRef]

- Song, H.; Zhou, D.; Guo, J. Thermal-Oxidative Aging Effects on the Properties of Long Glass Fiber Reinforced Polyamide 10T Composites. Polym. Compos. 2018, 39, 2117–2125. [Google Scholar] [CrossRef]

- Shi, K.; Ye, L.; Li, G. Thermal Oxidative Aging Behavior and Stabilizing Mechanism of Highly Oriented Polyamide 6. J. Therm. Anal. Calorim. 2016, 126, 795–805. [Google Scholar] [CrossRef]

- Yang, K.; Liu, Y.; Zheng, Z.; Lu, G.; Tang, Z.; Chen, X. Synthesis and Thermal Degradation Mechanism of a Semi-Aromatic Copolyamide from Renewable Sources. Polym. Degrad. Stab. 2022, 203, 110089. [Google Scholar] [CrossRef]

- Zuo, X.; Zhang, K.; Lei, Y.; Qin, S.; Hao, Z.; Guo, J. Influence of Thermooxidative Aging on the Static and Dynamic Mechanical Properties of Long-Glass-Fiber-Reinforced Polyamide 6 Composites. J. Appl. Polym. Sci. 2014, 131, 39594. [Google Scholar] [CrossRef]

- Zhang, R.L.; Huang, Y.D.; Su, D.; Liu, L.; Tang, Y.R. Influence of Sizing Molecular Weight on the Properties of Carbon Fibers and Its Composites. Mater. Des. 2012, 34, 649–654. [Google Scholar] [CrossRef]

- Wu, Z.; Cui, H.; Chen, L.; Jiang, D.; Weng, L.; Ma, Y.; Li, X.; Zhang, X.; Liu, H.; Wang, N.; et al. Interfacially Reinforced Unsaturated Polyester Carbon Fiber Composites with a Vinyl Ester-Carbon Nanotubes Sizing Agent. Compos. Sci. Technol. 2018, 164, 195–203. [Google Scholar] [CrossRef]

- Cheng, T.H.; Zhang, J.; Yumitori, S.; Jones, F.R.; Anderson, C.W. Sizing Resin Structure and Interphase Formation in Carbon Fibre Composites. Composites 1994, 25, 661–670. [Google Scholar] [CrossRef]

- Zhang, R.L.; Huang, Y.D.; Liu, L.; Tang, Y.R.; Su, D.; Xu, L.W. Effect of the Molecular Weight of Sizing Agent on the Surface of Carbon Fibres and Interface of Its Composites. Appl. Surf. Sci. 2011, 257, 1840–1844. [Google Scholar] [CrossRef]

- Cui, X.; Ma, L.; Wu, G. Mussel-Inspired Co-Deposition of Polydopamine/Silica Nanoparticles onto Carbon Fiber for Improved Interfacial Strength and Hydrothermal Aging Resistance of Composites. Polymers 2020, 12, 712. [Google Scholar] [CrossRef]

- Li, N.; Wu, Z.; Yang, X.; Wang, C.; Zong, L.; Pan, Y.; Wang, J.; Jian, X. One-Pot Strategy for Covalent Construction of POSS-Modified Silane Layer on Carbon Fiber to Enhance Interfacial Properties and Anti-Hydrothermal Aging Behaviors of PPBES Composites. J. Mater. Sci. 2018, 53, 16303–16317. [Google Scholar] [CrossRef]

- Thomason, J.L.; Yang, L. Temperature Dependence of the Interfacial Shear Strength in Glass–Fibre Polypropylene Composites. Compos. Sci. Technol. 2011, 71, 1600–1605. [Google Scholar] [CrossRef]

- Krause, B.; Kroschwald, L.; Pötschke, P. The Influence of the Blend Ratio in PA6/PA66/MWCNT Blend Composites on the Electrical and Thermal Properties. Polymers 2019, 11, 122. [Google Scholar] [CrossRef] [PubMed]

- Dechet, M.A.; Baumeister, I.; Schmidt, J. Development of Polyoxymethylene Particles via the Solution-Dissolution Process and Application to the Powder Bed Fusion of Polymers. Materials 2020, 13, 1535. [Google Scholar] [CrossRef]

- Kim, B.-J.; Cha, S.-H.; Kong, K.; Ji, W.; Park, H.W.; Park, Y.-B. Synergistic Interfacial Reinforcement of Carbon Fiber/Polyamide 6 Composites Using Carbon-Nanotube-Modified Silane Coating on ZnO-Nanorod-Grown Carbon Fiber. Compos. Sci. Technol. 2018, 165, 362–372. [Google Scholar] [CrossRef]

- Botelho, E.C.; Figiel, Ł.; Rezende, M.C.; Lauke, B. Mechanical Behavior of Carbon Fiber Reinforced Polyamide Composites. Compos. Sci. Technol. 2003, 63, 1843–1855. [Google Scholar] [CrossRef]

- Liu, T.; Tian, X.; Zhang, Y.; Cao, Y.; Li, D. High-Pressure Interfacial Impregnation by Micro-Screw in-Situ Extrusion for 3D Printed Continuous Carbon Fiber Reinforced Nylon Composites. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105770. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, G.; Shi, X.; Wang, X. Effects of Carbon Nanotubes on the Interlaminar Shear Strength and Fracture Toughness of Carbon Fiber Composite Laminates: A Review. J. Mater. Sci. 2022, 57, 2388–2410. [Google Scholar] [CrossRef]

| Samples | CF/PA6 [44] | CF(40 vol%)/PA66 [45] | CF(31.9vol%)/PA12 [46] | CF(36.2% vol%)/PA6T this Work |

|---|---|---|---|---|

| Processing method | T-RTM (fabric) | Interfacial polymerization (fabric) | 3D printing (UD) | Powder + compression molding (fabric) |

| Tensile strength (MPa) | 431.2 | 408 | 530.1 | 507.8 |

| Tensile modulus (GPa) | 34.7 | 35.4 | 54.8 | 43.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, J.; Wang, Z.; Yang, J.; Wang, X.; Yang, J. Interfacial Enhancement and Composite Manufacturing of Continuous Carbon-Fiber-Reinforced PA6T Composites via PrePA6T Ultrafine Powder. Materials 2024, 17, 1557. https://doi.org/10.3390/ma17071557

Yao J, Wang Z, Yang J, Wang X, Yang J. Interfacial Enhancement and Composite Manufacturing of Continuous Carbon-Fiber-Reinforced PA6T Composites via PrePA6T Ultrafine Powder. Materials. 2024; 17(7):1557. https://doi.org/10.3390/ma17071557

Chicago/Turabian StyleYao, Jiahong, Zhao Wang, Jiacao Yang, Xiaojun Wang, and Jie Yang. 2024. "Interfacial Enhancement and Composite Manufacturing of Continuous Carbon-Fiber-Reinforced PA6T Composites via PrePA6T Ultrafine Powder" Materials 17, no. 7: 1557. https://doi.org/10.3390/ma17071557

APA StyleYao, J., Wang, Z., Yang, J., Wang, X., & Yang, J. (2024). Interfacial Enhancement and Composite Manufacturing of Continuous Carbon-Fiber-Reinforced PA6T Composites via PrePA6T Ultrafine Powder. Materials, 17(7), 1557. https://doi.org/10.3390/ma17071557