Sustainable Application of Waste Sludges from the Wastewater Treatment Plant Generated during the Production of Heating Devices in the Construction Industry

Abstract

:1. Introduction

2. Materials and Methods

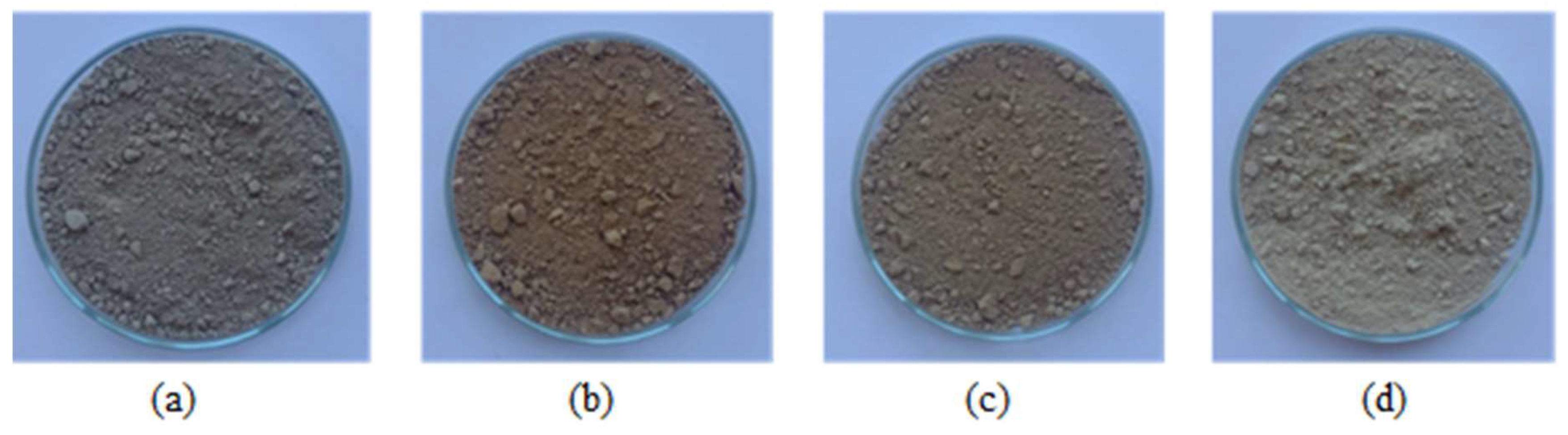

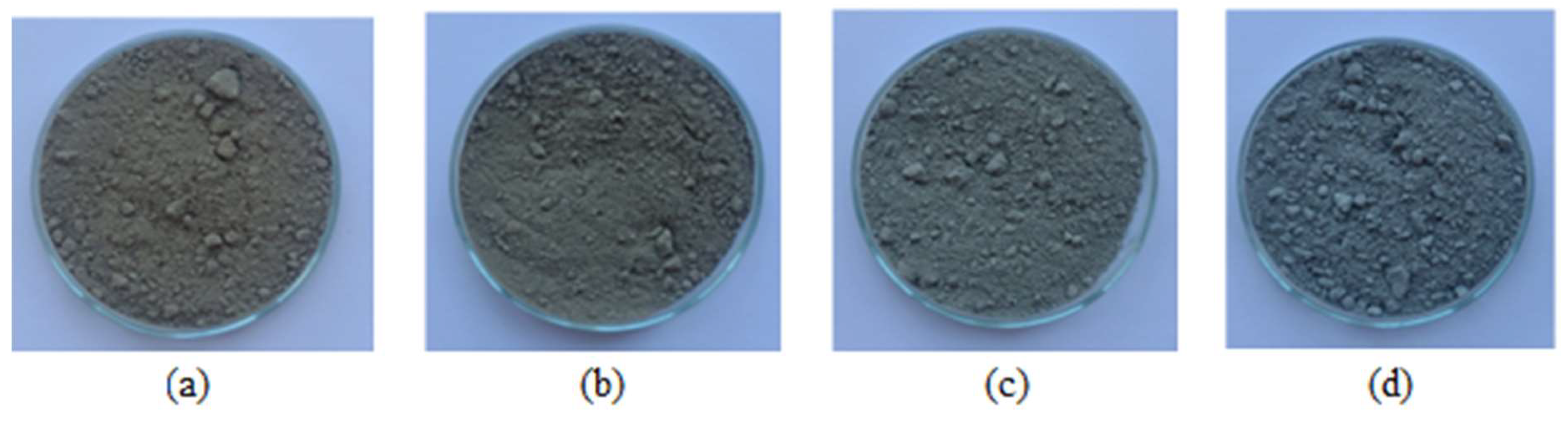

2.1. Materials

2.2. Characterization Methods

2.2.1. X-ray Powder Diffraction

2.2.2. Determination of the Heavy Metal Content

2.2.3. Determination of the Specific Surface Area

2.2.4. Fourier-Transform Infrared Spectroscopy with Attenuated Total Reflection

2.2.5. Field Emission Scanning Electron Microscopy

2.3. Investigation of the Pozzolanic Activity, Cement Paste Parameters, Mortar, Concrete, and Self-Compacting Concrete Produced with Addition of Waste Sludges

2.3.1. Investigation of the Pozzolanic Activity and Cement Paste Parameters with Addition of Waste Sludges

2.3.2. Investigation of the Mortar Parameters Based on Portland Cement, Natural Sand, and the Admixture of Waste Sludge WSEP

2.3.3. Investigation of the Concrete Parameters Based on Portland Cement, Natural Sand, Coarse Crushed Aggregate, and Added Waste Sludge WSEP

2.3.4. Investigation of SSC Parameters Produced with the Addition of Waste Sludge WSLP

3. Results and Discussion

3.1. XRPD

3.2. Chemical Composition

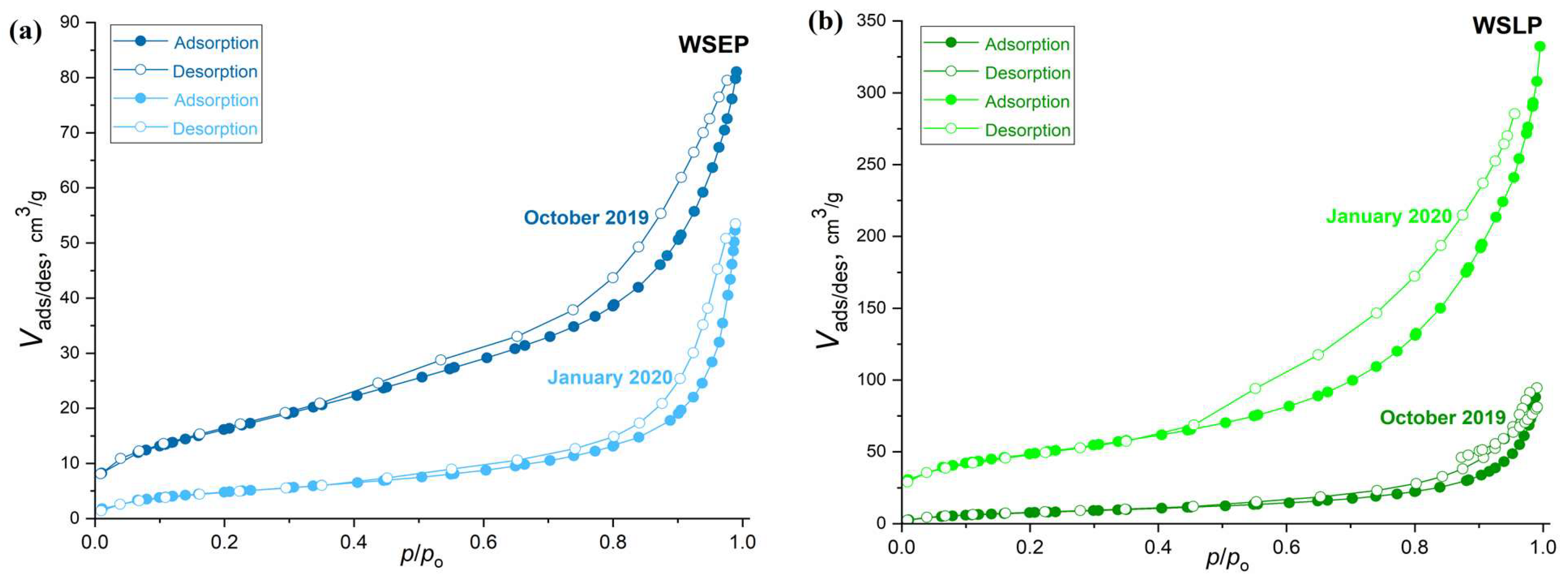

3.3. The Specific Surface Area

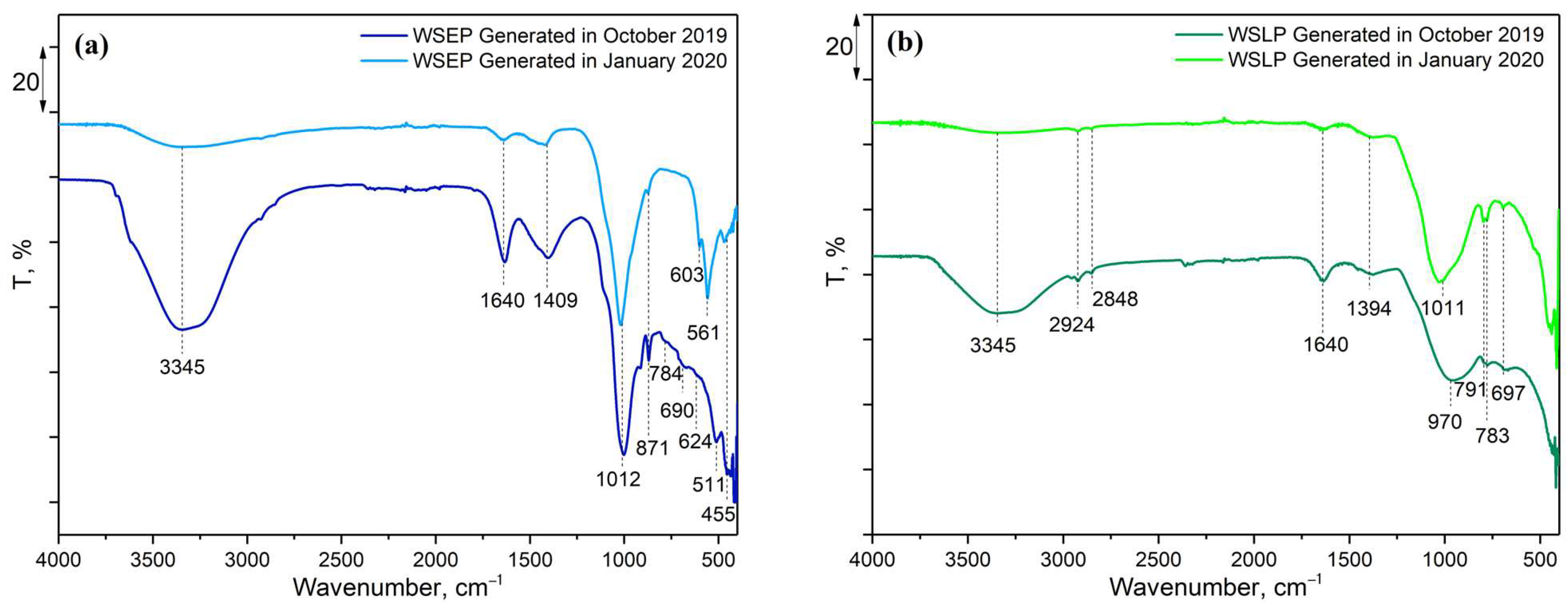

3.4. FTIR

3.5. FE-SEM

4. The Pozzolanic Activity, Cement Paste Parameters, Mortar, Concrete, and SSC Concrete Produced with Addition of Waste Sludges

4.1. The Pozzolanic Activity and the Impact of Cement Replacement by Waste Sludges WSEP and WSLP on the Cement Paste Properties

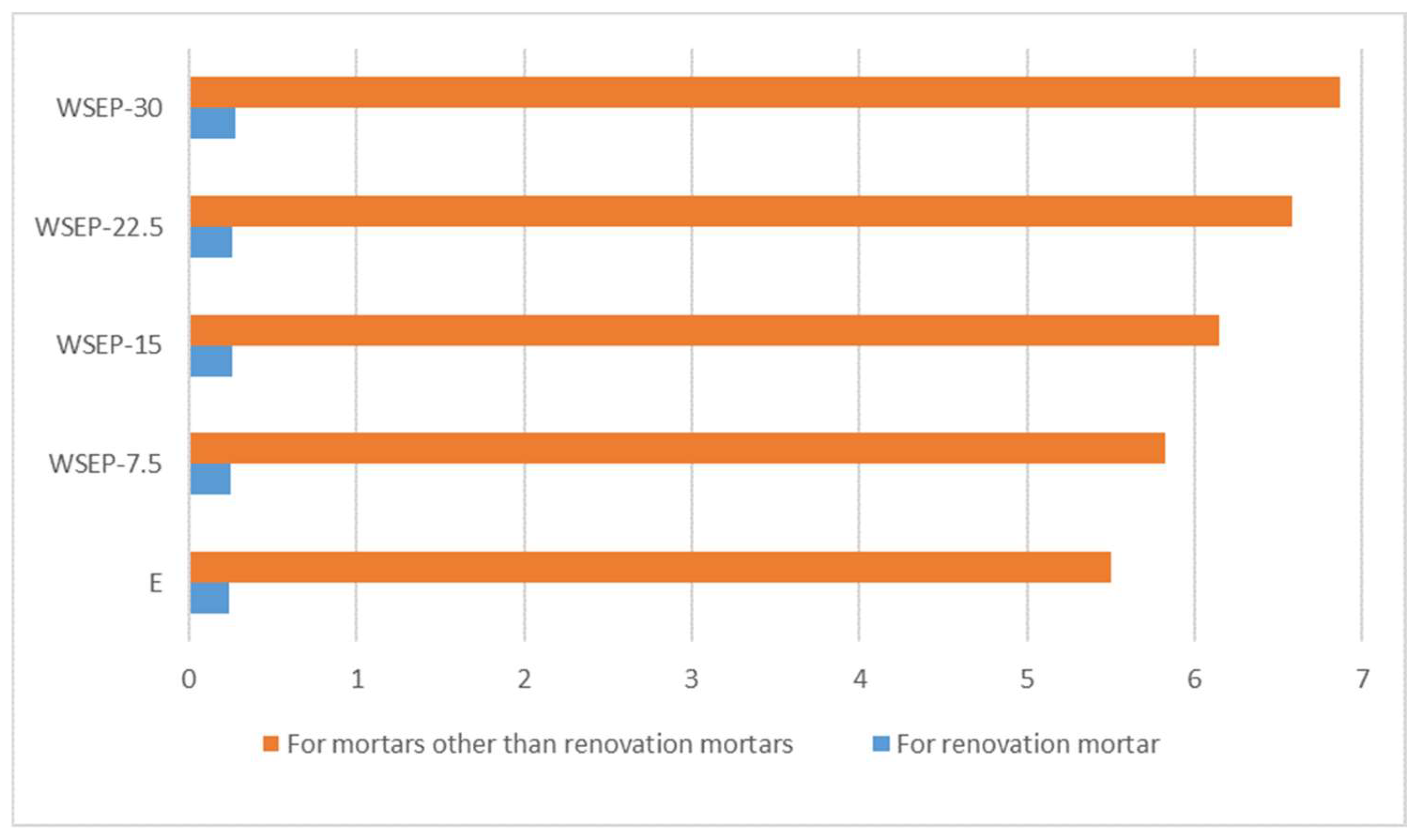

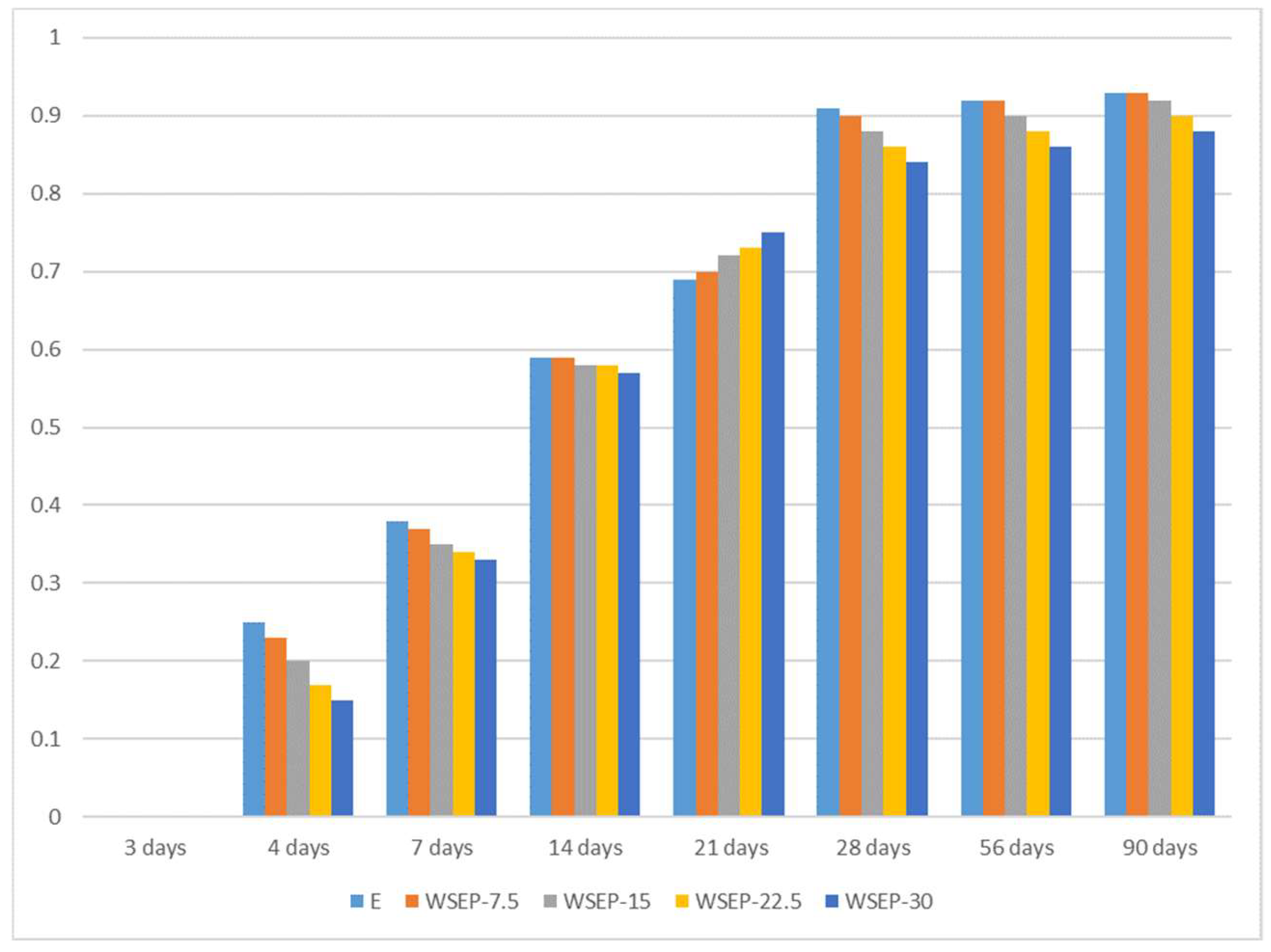

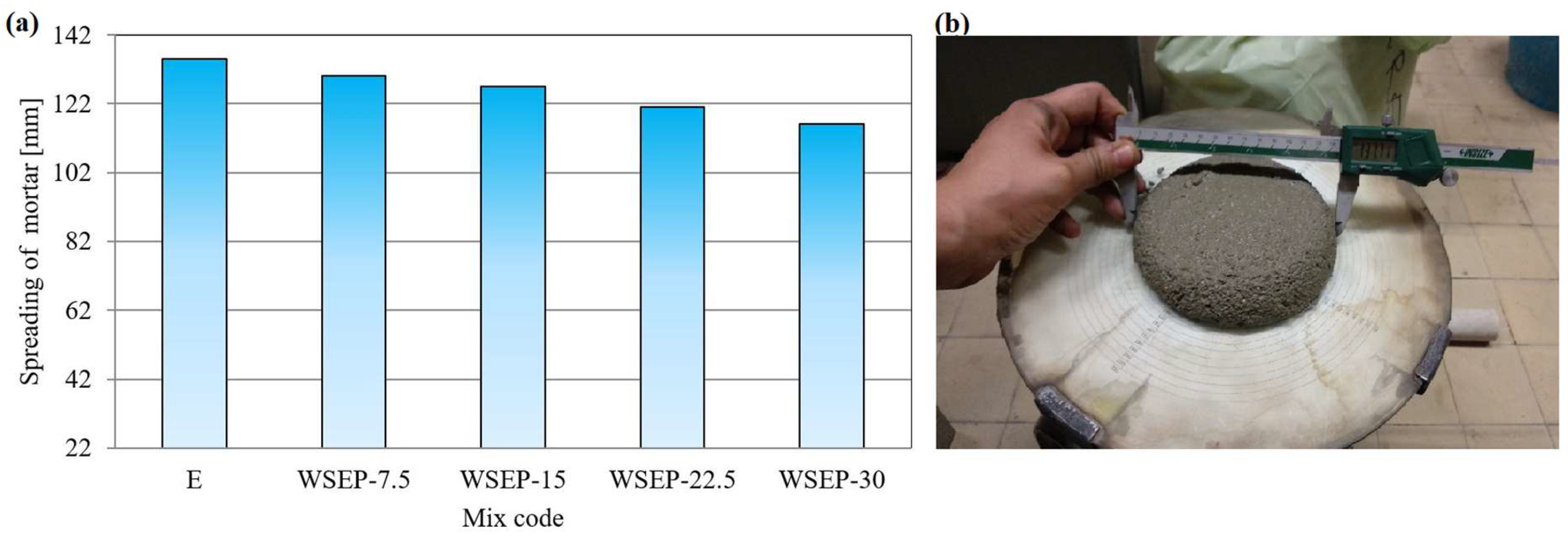

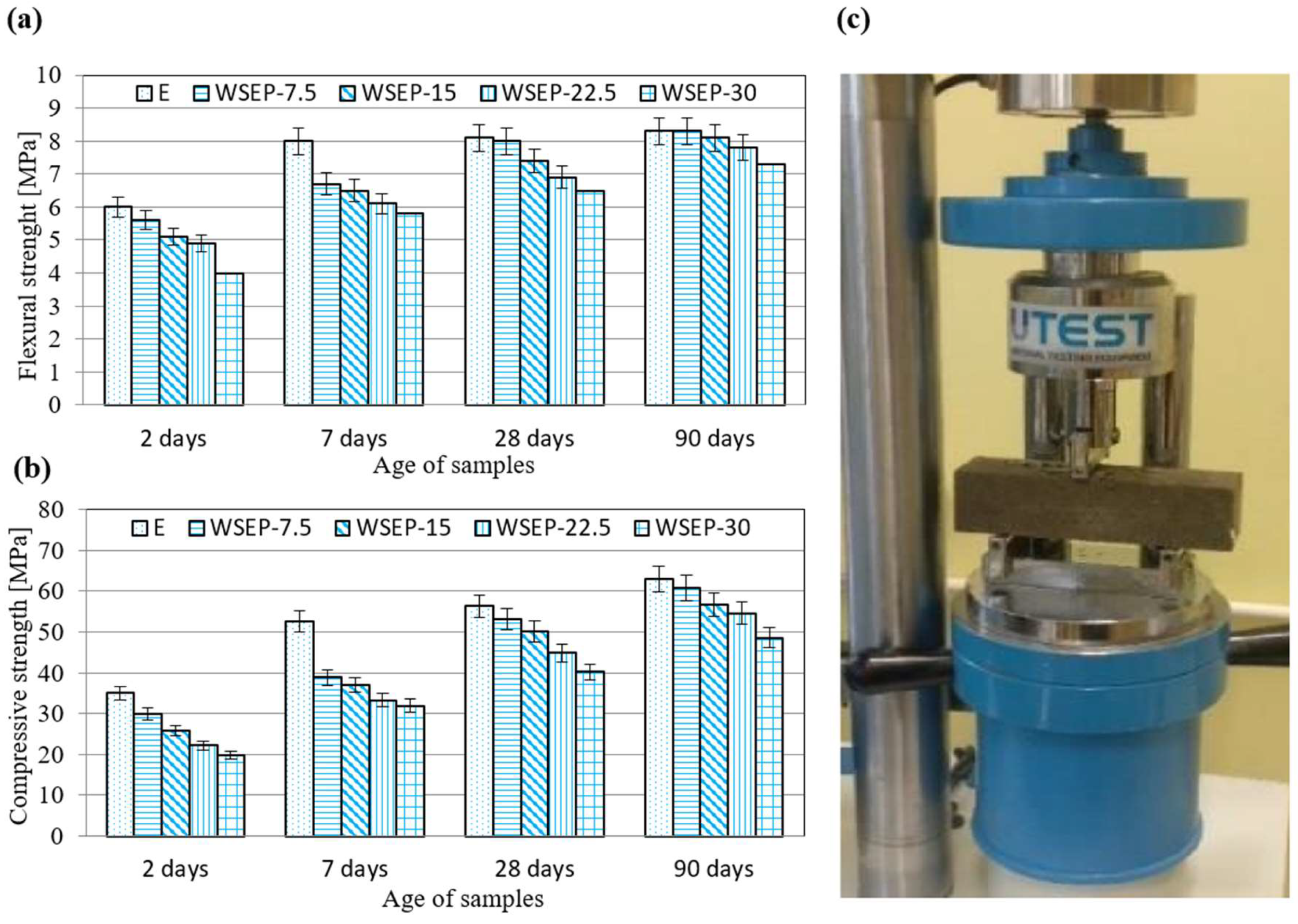

4.2. Mortar Parameters Based on Portland Cement, Natural Sand, and Added Waste Sludge WSEP

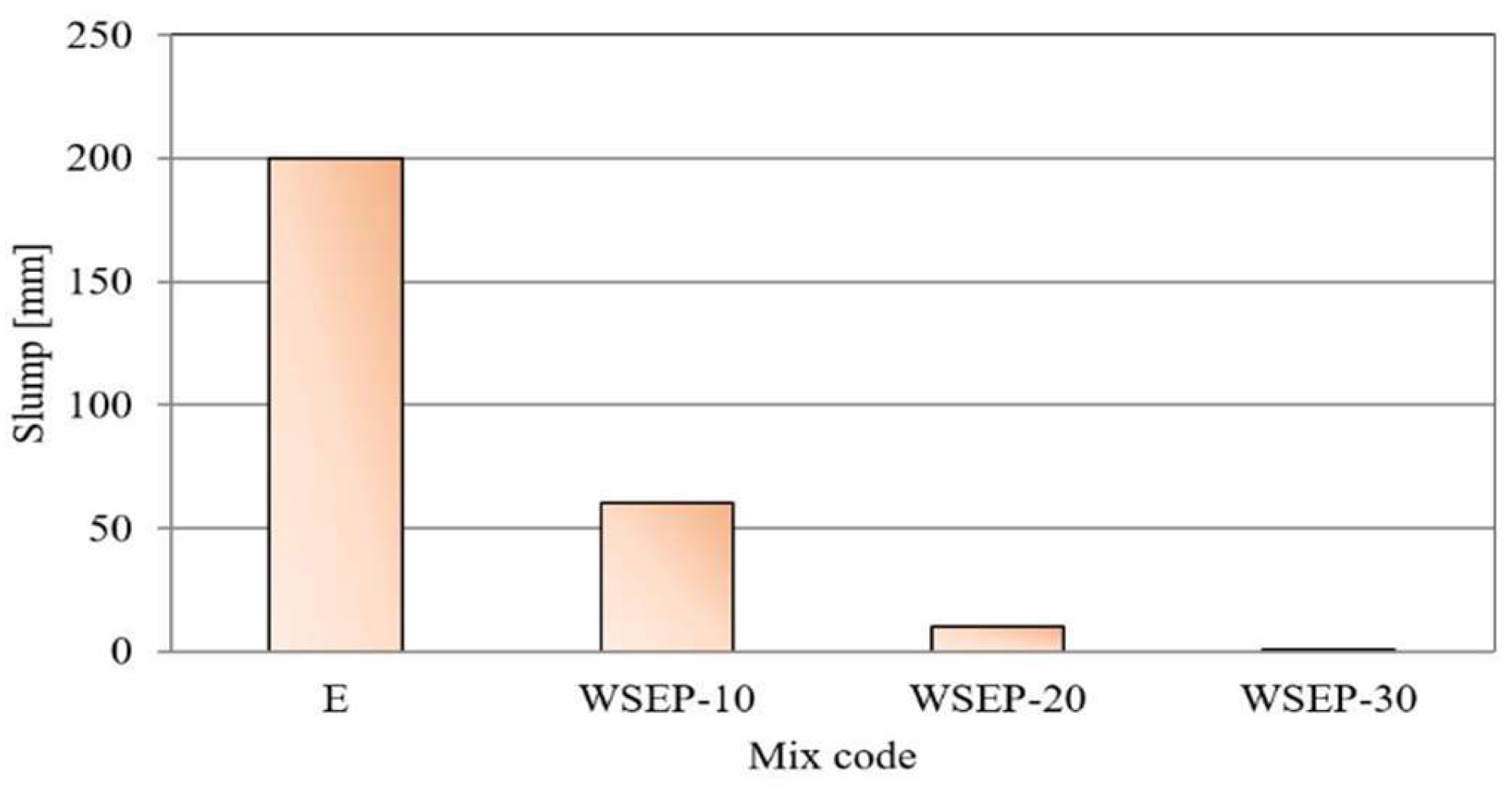

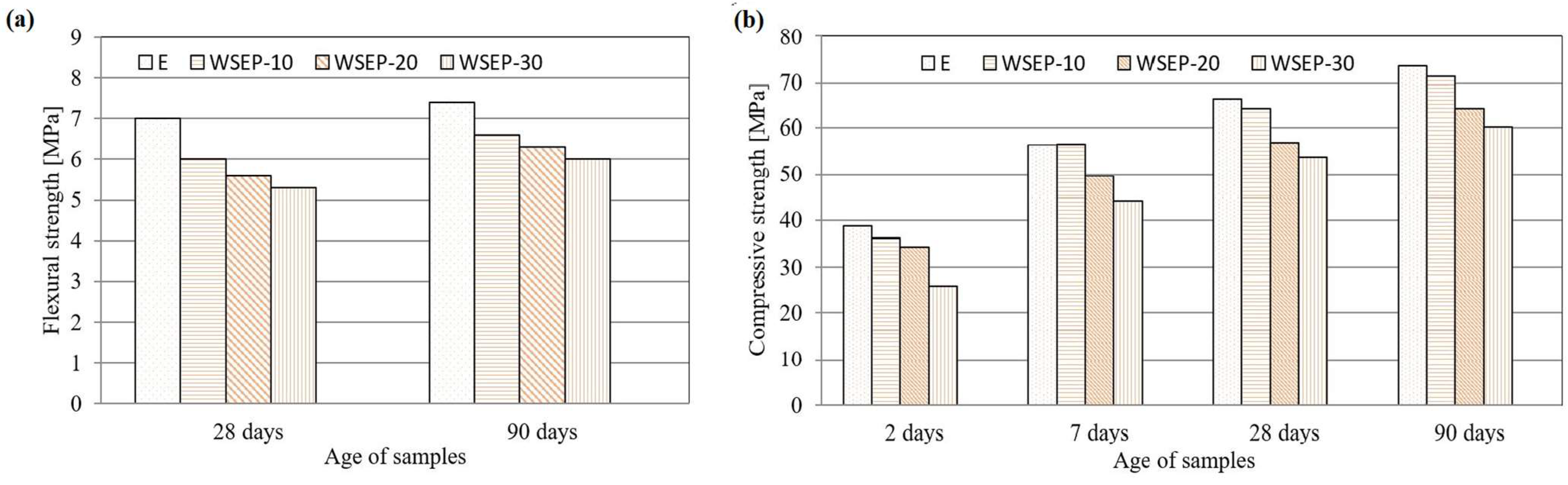

4.3. Parameters of Concrete Based on Portland Cement, Natural Sand, Large Crushed Aggregate, and Added Waste Sludge WSEP

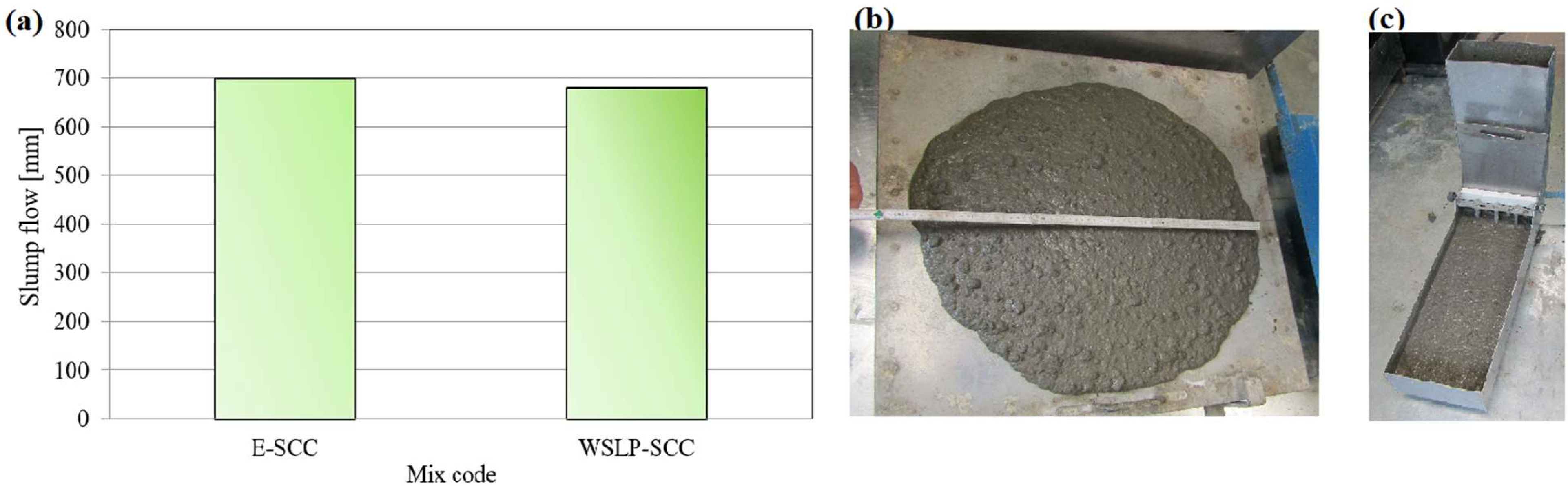

4.4. Parameters of Self-Compacting Concrete (SSC) Produced with Waste Sludge WSLP as a Powder Mineral Additive

5. Conclusions with Recommendations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Usman, M.; Balsalobre-Lorente, D. Environmental concern in the era of industrialization: Can financial development, renewable energy and natural resources alleviate some load? Energy Policy 2022, 162, 112780. [Google Scholar] [CrossRef]

- Opoku, E.E.O.; Aluko, O.A. Heterogeneous effects of industrialization on the environment: Evidence from panel quantile regression. Struct. Change Econ. Dyn. 2021, 59, 174–184. [Google Scholar] [CrossRef]

- Sillanpää, M.; Ncibi, C. Chapter Four—Circular economy in action: Case studies about the transition from the linear economy in the chemical, mining, textile, agriculture, and water treatment industries. In The Circular Economy; Sillanpää, M., Ncibi, C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 111–206. [Google Scholar] [CrossRef]

- Charef, R.; Lu, W.; Hall, D. The transition to the circular economy of the construction industry: Insights into sustainable approaches to improve the understanding. J. Clean. Prod. 2022, 364, 132421. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Thomas, M.; Surapaneni, A.; Moon, E.M.; Milne, N.A. Beneficial reuse of water treatment sludge in the context of circular economy. Environ. Technol. Innov. 2022, 28, 102651. [Google Scholar] [CrossRef]

- Baldassarre, B.; Schepers, M.; Bocken, N.; Cuppen, E.; Korevaar, G.; Calabretta, G. Industrial Symbiosis: Towards a design process for eco-industrial clusters by integrating Circular Economy and Industrial Ecology perspectives. J. Clean. Prod. 2019, 216, 446–460. [Google Scholar] [CrossRef]

- Gherghel, A.; Teodosiu, C.; De Gisi, S. A review on wastewater sludge valorisation and its challenges in the context of circular economy. J. Clean. Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, Q.; Xie, X.; Xue, G.; Du, F.; Ning, Q.; Huang, L. Utilization of the sludge derived from dyestuff-making wastewater coagulation for unfired bricks. Constr. Build. Mater. 2011, 25, 1699–1706. [Google Scholar] [CrossRef]

- Basu, D.; Pal, P.; Prakash, A. Utilization of waste sludge in cementitious matrix: A feasibility study. Mater. Today Proc. 2022, 65, 1375–1381. [Google Scholar] [CrossRef]

- Zat, T.; Bandieira, M.; Sattler, N.; Segadães, A.M.; Cruz, R.C.; Mohamad, G.; Rodríguez, E.D. Potential re-use of sewage sludge as a raw material in the production of eco-friendly bricks. J. Environ. Manag. 2021, 297, 113238. [Google Scholar] [CrossRef] [PubMed]

- Abouelela, A.R.; Mussa, A.A.; Talhami, M.; Das, P.; Hawari, A.H. Industrial sludge valorization and decontamination via lipid extraction and heavy metals removal using low-cost protic ionic liquid. Sci. Total Environ. 2022, 835, 155451. [Google Scholar] [CrossRef]

- Hussain, C.M.; Paulraj, M.S.; Nuzhat, S. Source Reduction and Waste Minimization; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 9780128243213. [Google Scholar]

- Gomes, S.D.C.; Zhou, J.L.; Li, W.; Long, G. Progress in manufacture and properties of construction materials incorporating water treatment sludge: A review. Resour. Conserv. Recycl. 2019, 145, 148–159. [Google Scholar] [CrossRef]

- Simón, D.; Battistessa, C.P.; Arduzzo, D.C.; Gass, S.; Cristóbal, A. Valorization of sludge from the effluent treatment of the dairy industry as clay substitutes in building bricks. Constr. Build. Mater. 2021, 307, 124955. [Google Scholar] [CrossRef]

- Heniegal, A.M.; Ramadan, M.A.; Naguib, A.; Agwa, I.S. Study on properties of clay brick incorporating sludge of water treatment plant and agriculture waste. Case Stud. Constr. Mater. 2022, 13, e00397. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Recycled wastewater treatment plant sludge as a construction material additive to ecological lightweight earth bricks. Clean. Eng. Technol. 2021, 2, 100050. [Google Scholar] [CrossRef]

- Santos, P.; Martins, C.; Julio, E. Enhancement of the thermal performance of perforated clay brick walls through the addition of industrial nano-crystalline aluminium sludge. Constr. Build. Mater. 2015, 101, 227–238. [Google Scholar] [CrossRef]

- Trang, N.T.M.; Ho, N.A.D.; Babel, S. Reuse of waste sludge from water treatment plants and fly ash for manufacturing of adobe bricks. Chemosphere 2021, 284, 131367. [Google Scholar] [CrossRef] [PubMed]

- Meda, S.R.; Sharma, S.K.; Tyagi, G.D. Utilization of waste sludge as a construction material-a review. Mater. Today Proc. 2021, 46, 4195–4202. [Google Scholar] [CrossRef]

- Rodrigues, L.P.; De Holanda, J.N.F. Valorization of municipal waterworks sludge to produce ceramic floor tiles. Recycling 2018, 3, 10. [Google Scholar] [CrossRef]

- Rabie, G.M.; Abd El-Halim, H.; Rozaik, E.H. Influence of using dry and wet wastewater sludge in concrete mix on its physical and mechanical properties. Ain Shams Eng. J. 2019, 10, 705–712. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Thornberg, D.; Cohen, Y.; Stiernström, S. Utilization of acid-washed sewage sludge ash as sand or cement replacement in concrete. Resour. Conserv. Recycl. 2022, 176, 105943. [Google Scholar] [CrossRef]

- Ching, C.Y.; Bashir, M.J.; Aun, N.C.; Aldahdooh, M.A.A. Sustainable production of concrete with treated alum sludge. Constr. Build. Mater. 2021, 282, 122703. [Google Scholar] [CrossRef]

- Sogancioglu, M.; Yel, E.; Aksoy, S.; Unal, V.E. Enhancement of concrete properties by waste physicochemical treatment sludge of travertine processing wastewater. J. Clean. Prod. 2016, 112, 575–580. [Google Scholar] [CrossRef]

- Zdeb, T.; Tracz, T.; Adamczyk, M. Physical, mechanical properties and durability of cement mortars containing fly ash from the sewage sludge incineration process. J. Clean. Prod. 2022, 345, 131055. [Google Scholar] [CrossRef]

- Varinder, K.; Siby, J. Use of electroplating industry sludge as a construction material. MOJ Civ. Eng. 2017, 2, 28–34. [Google Scholar] [CrossRef]

- Naamane, S.; Alaoui, M.S.H.; Taleb, M.; Haboubi, K.; Rais, Z. Leachability of cement mortars containing sewage sludge ash. Mater. Today Proc. 2022, 58, 1098–1103. [Google Scholar] [CrossRef]

- Goyal, S.; Siddique, R.; Sharma, D.; Jain, G. Reutilization of textile sludge stabilized with low grade-MgO as a replacement of cement in mortars. Constr. Build. Mater. 2022, 338, 127643. [Google Scholar] [CrossRef]

- SRPS B.C1.018:2015; Non-Metallic Mineral Raws—Pozzolanic Materials—Constituents for Cement Production—Classification, Technical Conditions and Test. Institute for Standardization: Belgrade, Serbia, 2015.

- SRPS EN 450-1:2014; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. Institute for Standardization: Belgrade, Serbia, 2014.

- SRPS EN 196-3:2017; Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness. Institute for Standardization: Belgrade, Serbia, 2017.

- SRPS EN 1015-3:2008; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). Institute for Standardization: Belgrade, Serbia, 2008.

- SRPS EN 1015-10:2008/A1:2008; Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar. Institute for Standardization: Belgrade, Serbia, 2008.

- SRPS EN 196-1:2017; Methods of Testing Cement—Part 1: Determination of Strength. Institute for Standardization: Belgrade, Serbia, 2017.

- SRPS EN 1015-11:2019; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Institute for Standardization: Belgrade, Serbia, 2019.

- SRPS EN 13755:2009; Natural Stone Test Methods—Determination of Water Absorption at Atmospheric Pressure. Institute for Standardization: Belgrade, Serbia, 2009.

- SRPS EN 1015-18:2008; Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. Institute for Standardization: Belgrade, Serbia, 2008.

- SRPS B.C8.029:1979; Cements—Dry Shrinkage of Cement Mortars. Institute for Standardization: Belgrade, Serbia, 1979.

- ASTM C596-23; Standard Test Method for Drying Shrinkage of Mortar Containing Hydraulic Cement. ASTM: West Conshohocken, PA, USA, 2023.

- SRPS EN 1015-12:2016; Methods of Test for Mortar for Masonry—Part 12: Determination of Adhesive Strength of Hardened Rendering and Plastering Mortars on Substrates. Institute for Standardization: Belgrade, Serbia, 2016.

- SRPS EN 12457-2:2008; Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size below 4 mm (without or with Size Reduction). Institute for Standardization: Belgrade, Serbia, 2008.

- SRPS EN 12350-2:2019; Testing Fresh Concrete—Part 2: Slump Test. Institute for Standardization: Belgrade, Serbia, 2019.

- SRPS EN 12350-7:2019; Testing Fresh Concrete—Part 7: Air Content—Pressure Methods. Institute for Standardization: Belgrade, Serbia, 2019.

- SRPS EN 12350-6:2019; Testing Fresh Concrete—Part 6: Density. Institute for Standardization: Belgrade, Serbia, 2019.

- SRPS EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. Institute for Standardization: Belgrade, Serbia, 2019.

- SRPS EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. Institute for Standardization: Belgrade, Serbia, 2019.

- SRPS EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Institute for Standardization: Belgrade, Serbia, 2019.

- SRPS EN 12390-6:2012; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. Institute for Standardization: Belgrade, Serbia, 2012.

- SRPS EN 12390-13:2021; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. Institute for Standardization: Belgrade, Serbia, 2021.

- SRPS EN 12390-8:2019; Testing Hardened Concrete—Part 8: Depth of Penetration of Water under Pressure. Institute for Standardization: Belgrade, Serbia, 2019.

- CEN/TS 12390-9:2017; Testing Hardened Concrete—Part 9: Freeze-Thaw Resistance with De-Icing Salts—Scaling. Institute for Standardization: Belgrade, Serbia, 2017.

- SRPS EN 12504-2:2012; Testing Concrete in Structures—Part 2: Non-Destructive Testing—Determination of Rebound Number. Institute for Standardization: Belgrade, Serbia, 2012.

- SRPS EN 12504-4:2008; Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity. Institute for Standardization: Belgrade, Serbia, 2008.

- SRPS EN 12350-10:2010; Testing Fresh Concrete—Part 10: Self-Compacting Concrete—L Box Test. Institute for Standardization: Belgrade, Serbia, 2010.

- SRPS EN 12350-11:2010; Testing Fresh Concrete—Part 11: Self-Compacting Concrete—Sieve Segregation Test. Institute for Standardization: Belgrade, Serbia, 2010.

- Nišić, N.; Kragović, M.; Gulicovski, J.; Žunić, M.; Basoli, F.; Gordić, M.; Stojmenović, M. Incorporation of Waste Sludge into the Production of High-Temperature-Resistant Adhesive Ceramic Materials. Appl. Sci. 2023, 13, 9044. [Google Scholar] [CrossRef]

- Rouquerol, F.; Rouquerol, J.; Sing, K. Adsorption by Powders & Porous Solids; Academic Press: London, UK, 1999; ISBN 9780080526010. [Google Scholar]

- EN 13263-1:2005+A1:2009; Silica Fume for Concrete—Part 1: Definitions, Requirements and Conformity Criteria. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2009.

- Saravanan, S.; Dubey, R.S. Synthesis of SiO2 nanoparticles by sol-gel method and their optical and structural properties. Rom. J. Inf. Sci. Technol. 2020, 23, 105–112. [Google Scholar]

- Kaviyarasu, K.; Sajan, D.; Devarajan, P.A. A rapid and versatile method for solvothermal synthesis of Sb2O3 nanocrystals under mild conditions. Appl. Nanosci. 2013, 3, 529–533. [Google Scholar] [CrossRef]

- Fard, G.C.; Mirjalili, M.; Najafi, F. Preparation of nano-cellulose/A-Fe2O3 hybrid nanofiber for the cationic dyes removal: Optimization characterization, kinetic, isotherm and error analysis. Bulg. Chem. Commun. 2018, 50, 251–261. [Google Scholar]

- Al-Amin, M.; Dey, S.C.; Rashid, T.U.; Ashaduzzaman, M.; Shamsuddin, S.M. Solar assisted photocatalytic degradation of reactive azo dyes in presence of anatase titanium dioxide. Int. J. Latest Res. Eng. Technol. 2016, 2, 14–21. [Google Scholar]

- Varughese, A.; Kaur, R.; Singh, P. Green synthesis and characterization of copper oxide nanoparticles using Psidium guajava leaf extract. IOP Conf. Ser. Mater. Sci. Eng. 2020, 961, 12011. [Google Scholar] [CrossRef]

- Zahir, M.H.; Rahman, M.M.; Irshad, K.; Rahman, M.M. Shape-stabilized phase change materials for solar energy storage: MgO and Mg(OH)2 mixed with polyethylene glycol. Nanomaterials 2019, 9, 1773. [Google Scholar] [CrossRef] [PubMed]

- Database of ATR-FT-IR Spectra of Various Materials. Available online: https://spectra.chem.ut.ee/paint/fillers/quartz/2023 (accessed on 5 September 2023).

- IR Spectroscopy Tutorial: Alkanes. Available online: https://orgchemboulder.com/Spectroscopy/irtutor/alkanesir.shtml (accessed on 6 September 2023).

- Fourier Transform Infrared Spectroscopy (FTIR), EAG Laboratories. Available online: https://www.eag.com/techniques/spectroscopy/fourier-transform-infrared-spectroscopy-ftir/ (accessed on 6 September 2023).

- Balasubramanian, J.; Sabumon, P.C.; Lazar, J.U.; Ilangovan, R. Reuse of textile effluent treatment plant sludge in building materials. Waste Manag. 2006, 26, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Begum, B.S.S.; Gandhimathi, R.; Ramesh, S.T.; Nidheesh, P.V. Utilization of textile effluent wastewater treatment plant sludge as brick material. J. Mater. Cycles Waste Manag. 2013, 15, 564. [Google Scholar] [CrossRef]

- Rahman, M.M.; Khan, M.M.R.; Uddin, M.T.; Islam, M.A. Textile effluent treatment plant sludge: Characterization and utilization in building materials. Arab. J. Sci. Eng. 2017, 42, 1435–1442. [Google Scholar] [CrossRef]

- Patel, H.; Pandey, S. Evaluation of physical stability and leachability of Portland Pozzolona Cement (PPC) solidified chemical sludge generated from textile wastewater treatment plants. J. Hazard. Mater. 2012, 207, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Gervais, C.; Ouki, S.K. Performance study of cementitious systems containing zeolite and silica fume: Effects of four metal nitrates on the setting time, strength and leaching characteristics. J. Hazard. Mater. 2002, 93, 187–200. [Google Scholar] [CrossRef]

- Cubukcuoglu, B.; Ouki, S.K. Solidification/stabilisation of electric arc furnace waste using low grade MgO. Chemosphere 2012, 86, 789–796. [Google Scholar] [CrossRef]

- Spinosa, L. From sludge to resources through biosolids. Water Sci. Technol. 2004, 50, 1–9. [Google Scholar] [CrossRef]

| Type of Waste Sludge | Tests Conducted | Waste Share | Ref. No. |

|---|---|---|---|

| Sewage and PAC Sludge | Compressive Strength, Density. | 10% of sewage sludge and 5% of PAC sludge as a substitution for cement | [9] |

| Sewage Sludge | Slump Test, Compressive Strength, Dry Density. | 5% of the cement weight in the concrete mix | [21] |

| Acid-washed Sewage Sludge | Compressive Strength, Evaluation of Hydraulic and Pozzolanic Properties. | 10% of sludge as a replacement for cement in concrete and mortar | [22] |

| Alum Sludge | Slump test, Mechanical and Durability Properties (Compressive and Flexural Strength), Water Absorption, Gas Permeability, Chloride Penetration, Leaching Concentration of Aluminum. | 4% or 8% replacement level of cement by alum sludge | [23] |

| Physicochemical Wastewater Sludge (from Marble Processing Plant) | Slump test, Compressive Strength, the Freeze/Thaw Resistance, Water Absorption, Capillary Suction, Porosity. | 15% admixing level of sludge by weight of cement | [24] |

| Municipal Wastewater Treatment Sludge | Compressive and Flexural Tensile Strength, Density and Total Porosity, Leachability of Heavy Metals. | Up to 30% of waste sludge replacement for the cement. | [25] |

| Electroplating Industry Sludge | Compressive Strength | Up to 15% replacement of sand in cement mortar. Up to 20% replacement of sand in cement concrete. | [26] |

| Content, mg/kg | ||||||

|---|---|---|---|---|---|---|

| Br. | Parameter | October 2019 [56] | November 2019 | December 2019 | January 2019 | Reference Values |

| 1. | Mo | 7.5 | 7.5 | 9.5 | 6.5 | 10 * 30 ** |

| 2. | Hg | <0.15 | <0.15 | <0.15 | <0.15 | 0.2 * 2.0 ** |

| 3. | Sb | 85.5 | 86.5 | 81.5 | 79.5 | 0.7 * 5.0 ** |

| 4. | Se | 2.5 | 3.5 | 2.5 | 35 | 0.5 * 7.0 ** |

| 5. | Sr | 130.0 | 135.0 | 132.5 | 131.0 | /*/** |

| 6. | Ba | 23.5 | 22.5 | 23.0 | 33.5 | 100 * 300 ** |

| 7. | Ca | 8000.0 | 8002.0 | 8081.0 | 8002.0 | /*/** |

| 8. | Mg | 430.0 | 431.0 | 433.0 | 438.0 | /*/** |

| 9. | Ti | 1850 | 1840 | 1851 | 1860 | /*/** |

| 10. | V | 14.5 | 12.0 | 13.0 | 13.5 | /*/** |

| 11. | Mn | 4855.0 | 4859.0 | 4850.0 | 4812.0 | /*/** |

| 12. | Fe | 13,250.0 | 13,270.0 | 13,324.0 | 13,257.0 | /*/** |

| 13. | Co | 2330.0 | 2382.0 | 2334.0 | 2339.0 | /*/** |

| 14. | Cu | 2050.0 | 2048.0 | 2055.0 | 2040.0 | 50 * 100 ** |

| 15. | Zn | 175.5 | 179.5 | 178.5 | 174.0 | 50 * 200 ** |

| 16. | Ni | 186.0 | 173.0 | 188.0 | 194.0 | 10 * 40 ** |

| 17. | Cd | 6.0 | 6.0 | 6.5 | 6.0 | 1 * 5.0 ** |

| 18. | Al | 1315.0 | 1313.0 | 1358.0 | 1312.0 | /*/** |

| 19. | Pb | 37.0 | 37.0 | 35.0 | 38.0 | 10 * 50 ** |

| 20. | As | <0.5 | <0.5 | <0.5 | <0.5 | 2 * 25 ** |

| 21. | Be | <0.05 | <0.05 | <0.05 | <0.05 | /*/** |

| 22. | Cr | 22.0 | 28.0 | 23.0 | 23.0 | 10 * 70 ** |

| 23. | Tl | 2.5 | 2.5 | 2.5 | 2.5 | /*/** |

| 24. | Sn | <1.0 | <1.0 | <1.0 | <1.0 | /*/** |

| 25. | Si | 50,409.0 | 48,888.0 | 48,384.0 | 47,856.0 | /*/** |

| 26. | MoO3 | 11.25 | 11.25 | 14.25 | 9.75 | /*/** |

| 27. | HgO | <0.15 | <0.15 | <0.15 | <0.15 | /*/** |

| 28. | Sb2O3 | 204.69 | 207.09 | 195.12 | 190.33 | /*/** |

| 29. | SeO2 | 3.51 | 4.92 | 3.51 | 49.18 | /*/** |

| 30. | SrO | 153.73 | 159.64 | 156.69 | 154.91 | /*/** |

| 31. | BaO | 0.00 | 25.12 | 25.68 | 37.40 | /*/** |

| 32. | CaO | 11,198.80 | 11,201.60 | 11,312.19 | 11,201.60 | /*/** |

| 33. | MgO | 713.02 | 714.68 | 718.00 | 726.29 | /*/** |

| 34. | TiO2 | 3093.23 | 3076.51 | 3094.90 | 3109.95 | /*/** |

| 35. | V2O5 | 51.76 | 42.84 | 46.41 | 48.19 | /*/** |

| 36. | MnO | 6268.38 | 6273.54 | 6261.92 | 6212.86 | /*/** |

| 37. | Fe2O3 | 37,883.38 | 37,940.56 | 38,094.95 | 37,903.39 | /*/** |

| 38. | Co3O4 | 9608.37 | 9822.81 | 9624.87 | 9645.49 | /*/** |

| 39. | CuO | 2565.94 | 2563.43 | 2572.19 | 2553.42 | /*/** |

| 40. | ZnO | 218.43 | 223.40 | 222.16 | 216.56 | /*/** |

| 41. | NiO | 236.48 | 219.95 | 239.02 | 246.65 | /*/** |

| 42. | CdO | 6.85 | 6.85 | 7.42 | 6.85 | /*/** |

| 43. | Al2O3 | 4885.05 | 4877.62 | 5044.79 | 4873.91 | /*/** |

| 44. | PbO | 39.86 | 39.86 | 37.70 | 40.93 | /*/** |

| 45. | As2O3 | <0.5 | <0.5 | <0.5 | <0.5 | /*/** |

| 46. | BeO | <0.05 | <0.05 | <0.05 | <0.05 | /*/** |

| 47. | Cr2O3 | 64.30 | 81.84 | 67.22 | 67.22 | /*/** |

| 48. | Tl2O3 | 5.59 | 5.59 | 5.59 | 5.59 | /*/** |

| 49. | SnO2 | <1.0 | <1.0 | <1.0 | <1.0 | /*/** |

| 50. | SiO2 | 108,012.0 | 104,761.0 | 103,685.0 | 102,654.8 | /*/** |

| Content, mg/kg | ||||||

|---|---|---|---|---|---|---|

| Br. | Parameter | October 2019 [56] | November 2019 | December 2019 | January 2019 | Reference Values |

| 1. | Mo | 0.15 | 0.15 | 0.15 | 0.15 | 10 * 30 ** |

| 2. | Hg | <0.15 | <0.15 | <0.15 | <0.15 | 0.2 * 2.0 ** |

| 3. | Sb | 0.85 | 0.85 | 0.75 | 0.95 | 0.7 * 5.0 ** |

| 4. | Se | <0.2 | <0.2 | <0.3 | <0.2 | 0.5 * 7.0 ** |

| 5. | Sr | 42.0 | 41.0 | 44.0 | 39.0 | /*/** |

| 6. | Ba | 52.0 | 51.0 | 52.0 | 51.0 | 100 * 300 ** |

| 7. | Ca | 46,700.0 | 46,708.0 | 46,735.0 | 46,778.0 | /*/** |

| 8. | Mg | 2920.0 | 2925.0 | 2944.0 | 2933.0 | /*/** |

| 9. | Ti | 56.0 | 53.0 | 51.0 | 55.0 | /*/** |

| 10. | V | 5.5 | 65 | 5.0 | 5.0 | /*/** |

| 11. | Mn | 600.0 | 609.0 | 620.0 | 602.0 | /*/** |

| 12. | Fe | 18,750.0 | 18,755.0 | 18,745.0 | 18,752.0 | /*/** |

| 13. | Co | 3.5 | 4.5 | 4.5 | 0.5 | /*/** |

| 14. | Cu | 20.5 | 22.5 | 22.5 | 19.5 | 50 * 100 ** |

| 15. | Zn | 37.0 | 32.0 | 33.0 | 35.0 | 50 * 200 ** |

| 16. | Ni | 8.0 | 9.0 | 9.0 | 8.0 | 10 * 40 ** |

| 17. | Cd | 2.5 | 2.5 | 3.5 | 2.5 | 1 * 5.0 ** |

| 18. | Al | 2045.0 | 2042.0 | 2023.0 | 2075.0 | /*/** |

| 19. | Pb | 10.0 | 11.0 | 12.0 | 10.0 | 10 * 50 ** |

| 20. | As | 2.5 | 2.5 | 2.5 | 2.5 | 2 * 25 ** |

| 21. | Be | <0.05 | <0.05 | <0.05 | <0.05 | /*/** |

| 22. | Cr | 8.0 | 9.0 | 7.0 | 5.0 | 10 * 70 ** |

| 23. | Tl | <0.5 | <0.5 | <0.5 | <0.5 | /*/** |

| 24. | Sn | <1.0 | <1.0 | <1.0 | <1.0 | /*/** |

| 25. | Si | 9193.3 | 10,112.7 | 9653.0 | 9009.5 | /*/** |

| 26. | MoO3 | 0.23 | 0.23 | 0.23 | 0.23 | /*/** |

| 27. | HgO | <0.15 | <0.15 | <0.15 | <0.15 | /*/** |

| 28. | Sb2O3 | 2.03 | 2.03 | 1.80 | 2.27 | /*/** |

| 29. | SeO2 | <0.2 | <0.2 | <0.3 | <0.2 | /*/** |

| 30. | SrO | 49.67 | 48.48 | 52.03 | 46.12 | /*/** |

| 31. | BaO | 58.06 | 56.94 | 58.06 | 56.94 | /*/** |

| 32. | CaO | 65,373.00 | 65,384.19 | 65,421.99 | 65,482.18 | /*/** |

| 33. | MgO | 4841.91 | 4850.20 | 4881.71 | 4863.47 | /*/** |

| 34. | TiO2 | 93.63 | 88.62 | 85.27 | 91.96 | /*/** |

| 35. | V2O5 | 19.63 | 232.04 | 17.85 | 17.85 | /*/** |

| 36. | MnO | 774.67 | 786.29 | 800.49 | 777.25 | /*/** |

| 37. | Fe2O3 | 53,608.55 | 53,622.85 | 53,594.25 | 53,614.27 | /*/** |

| 38. | Co3O4 | 14.43 | 18.56 | 18.56 | 2.06 | /*/** |

| 39. | CuO | 25.66 | 28.16 | 28.16 | 24.41 | /*/** |

| 40. | ZnO | 46.05 | 39.83 | 41.07 | 43.56 | /*/** |

| 41. | NiO | 10.17 | 11.44 | 11.44 | 10.17 | /*/** |

| 42. | CdO | 2.86 | 2.86 | 4.00 | 2.86 | /*/** |

| 43. | Al2O3 | 7596.90 | 7585.76 | 7515.18 | 7708.35 | /*/** |

| 44. | PbO | 10.77 | 11.85 | 12.93 | 10.77 | /*/** |

| 45. | As2O3 | 6.60 | 6.60 | 6.60 | 6.60 | /*/** |

| 46. | BeO | <0.05 | <0.05 | <0.05 | <0.05 | /*/** |

| 47. | Cr2O3 | 23.38 | 26.30 | 20.46 | /*/** | |

| 48. | Tl2O3 | <0.5 | <0.5 | <0.5 | <0.5 | /*/** |

| 49. | SnO2 | <1.0 | <1.0 | <1.0 | <1.0 | /*/** |

| 50. | SiO2 | 19,722.0 | 21,673.0 | 20,685.2 | 19,306.6 | /*/** |

| Batch | October 2019 | November 2019 | ||||||||||

| Sample | Sp, m2/g | Vtotal, cm3/g | Vmeso, cm3/g | Vmicro, cm3/g | Dsr, nm | Dmax, nm | Sp, m2/g | Vtotal, cm3/g | Vmeso, cm3/g | Vmicro, cm3/g | Dsr, nm | Dmax, nm |

| WSEP | 60.7 | 0.1230 | 0.1152 | 0.0156 | 7.43 | 2.86 | 59.9 | 0.1301 | 0.1092 | 0.0209 | 8.02 | 2.79 |

| WSLP | 29.7 | 0.1413 | 0.1374 | 0.0069 | 14.06 | 3.62 | 33.6 | 0.1422 | 0.1279 | 0.0143 | 12.12 | 3.29 |

| Batch | December 2019 | January 2020 | ||||||||||

| Sample | Sp, m2/g | Vtotal, cm3/g | Vmeso, cm3/g | Vmicro, cm3/g | Dsr, nm | Dmax, nm | Sp, m2/g | Vtotal, cm3/g | Vmeso, cm3/g | Vmicro, cm3/g | Dsr, nm | Dmax, nm |

| WSEP | 23.2 | 0.1230 | 0.1152 | 0.0156 | 8.01 | 2.87 | 18.06 | 0.0786 | 0.0757 | 0.0046 | 13.90 | 2.82 |

| WSLP | 128.3 | 0.1411 | 0.1362 | 0.0079 | 12.27 | 3.33 | 168.5 | 0.4920 | 0.4935 | 0.0545 | 8.55 | 3.74 |

| Class of Pozzolanic Materials | Activity Index | Water Requirement | Standard Consistence | Initial Setting Time Final Setting Time | Soundness | |

|---|---|---|---|---|---|---|

| Standard | SRPS B.C1.018 | EN 450-1 (25% Cement Replacement) | EN 450-1 Annex B | EN 196-3 (25% Cement Replacement) | EN 196-3 (25% Cement Replacement) | EN 196-3 (30% Cement Replacement) |

| November 2019 | Flexural strength— 2.23 MPa > 2.0 MPa (Requirements SRPS B.C1.018 p. 5.3 for class 5) | 28 days—75.14% > 75% (Requirements EN 450-1 p. 5.3.2) | 104% < 95% (Requirements EN 450-1 p. 5.3.6) | 33.5% (100% cement—29.0%) ((Not meet the condition for standard consistence) | 315 min < 2 × 100% cement (100% cement—115 min) (Requirements EN 450-1 p. 5.3.5) | 1.0 mm (100% cement—1.0 mm) < 10 mm (Requirements EN 450-1 p. 5.3.3) |

| Compressive strength— 7.90 MPa > 5.0 MPa (Requirements SRPS B.C1.018 p. 5.3 for class 5) | 90 days—86.0 > 85% (Requirements EN 450-1 p. 5.3.2) | 340 min (100% cement—150 min) (Not meet the condition for final setting time) | ||||

| Criteria | Satisfied (Class 5 of pozzolanic materials) | Satisfied | Not satisfied | / | Not satisfied | Satisfied |

| Satisfied (Class 5 of pozzolanic materials) | Satisfied | / |

| Class of Pozzolanic Materials | Activity Index | Water Requirement | Standard Consistence | Initial Setting Time Final Setting Time | Soundness | |

|---|---|---|---|---|---|---|

| Standard | SRPS B.C1.018 | EN 450-1 (25% Cement Replacement) | EN 450-1 Annex B | EN 196-3 (25% Cement Replacement) | EN 196-3 (25% Cement Replacement) | EN 196-3 (30% Cement Replacement) |

| November 2019 | Flexural strength— 0.20 MPa > 2.0 MPa (Requirements SRPS B.C1.018 p. 5.3 for class 5) | 28 days—57.24% > 75% (Requirements EN 450-1 p. 5.3.2) | 135% < 95% (Requirements EN 450-1 p. 5.3.6) | 43.0% (100% cement—29.0%) ((Not meet the condition for standard consistence) | 440 min < 2 × 100% cement (100% cement—115 min) (Requirements EN 450-1 p. 5.3.5) | 3.0 mm (100% cement—1.0 mm) < 10 mm (Requirements EN 450-1 p. 5.3.3) |

| Compressive strength— 0.62 MPa > 5.0 MPa (Requirements SRPS B.C1.018 p. 5.3 for class 5) | 90 days—61.23 > 85% (Requirements EN 450-1 p. 5.3.2) | 500 min (100% cement—150 min) (Not meet the condition for final setting time) | ||||

| Criteria | Not satisfied (without pozzolanic activity) | Not satisfied | Not satisfied | / | Not satisfied | Satisfied |

| Not satisfied (without pozzolanic activity | Not satisfied | / |

| No. | Property | Standard | Designation | Results | |

|---|---|---|---|---|---|

| 1. | Consistency—by flow table | EN 1015-3 | E | 135 mm | |

| WSEP-7.5 | 130 mm | ||||

| WSEP-15 | 127 mm | ||||

| WSEP-22.5 | 121 mm | ||||

| WSEP-30 | 116 mm | ||||

| 2. | Bulk density of fresh mortar | EN 1015-6 | E | 2299 kg/m3 | |

| WSEP-7.5 | 2290 kg/m3 | ||||

| WSEP-15 | 2285 kg/m3 | ||||

| WSEP-22.5 | 2360 kg/m3 | ||||

| WSEP-30 | 2254 kg/m3 | ||||

| 3. | Dry bulk density of hardened mortar | EN 1015-10 | E | 2294 kg/m3 | |

| WSEP-7.5 | 2287 kg/m3 | ||||

| WSEP-15 | 2280 kg/m3 | ||||

| WSEP-22.5 | 2357 kg/m3 | ||||

| WSEP-30 | 2250 kg/m3 | ||||

| 4. | Water absorption | EN 13755 | E | 7.54% | |

| WSEP-7.5 | 7.80% | ||||

| WSEP-15 | 8.26% | ||||

| WSEP-22.5 | 8.79% | ||||

| WSEP-30 | 9.27% | ||||

| 5. | Water absorption | EN 1015-18 | Results are given in Figure 7. | ||

| 6. | Shrinkage | SRPS B.C8.029:1979 (ASTM C 596) | Results are given in Figure 8. | ||

| 7. | Adhesion of a concrete substrate | EN 1015-12 | E | 2.0 N/mm2 | |

| WSEP-7.5 | 1.9 N/mm2 | ||||

| WSEP-15 | 1.8 N/mm2 | ||||

| WSEP-22.5 | 1.5 N/mm2 | ||||

| WSEP-30 | 1.4 N/mm2 | ||||

| 8. | Leaching test | EN 12457-2 | Element | Concentration (mg/dm3) | MDK |

| Mo | <0.05 | - | |||

| Hg | <0.001 | <0.001 * | |||

| Sb | 0.49 | - | |||

| Se | <0.05 | - | |||

| Sr | 1.794 | - | |||

| Ba | 0.549 | - | |||

| Ca | 1.588(100×) | - | |||

| Mg | 0.063 | - | |||

| Ti | 0.40 | - | |||

| V | <0.010 | - | |||

| Mn | <0.05 | - | |||

| Fe | <0.05 | - | |||

| Co | <0.05 | - | |||

| Cu | <0.05 | <0.1 | |||

| Zn | <0.05 | <1.0 | |||

| Ni | 0.02 | <0.1 * | |||

| Cd | <0.01 | <0.01 * | |||

| Al | 47.50 | - | |||

| Pb | <0.05 | <0.1 * | |||

| As | <0.05 | <0.05 * | |||

| Be | <0.05 | - | |||

| Cr | <0.05 | <0.5 * | |||

| Tl | <0.05 | - | |||

| Sn | <0.05 | - | |||

| Si | 213.54 | - | |||

| Testing of the Mix-Design of the Concrete Based on Portland Cement, Natural Sand, Coarse Crushed Aggregate, and the Addition of Waste Sludge WSEP (November 2019) | ||||

|---|---|---|---|---|

| 1. | Consistency—slump test; density of fresh concrete | EN 12350-2 | E | 200 mm |

| WSEP-10 | 60 mm | |||

| WSEP-20 | 10 mm | |||

| WSEP-30 | 0 mm | |||

| 2. | Density of fresh concrete | EN 12350-6 | E | 2466 kg/m3 |

| WSEP-10 | 2479 kg/m3 | |||

| WSEP-20 | 2485 kg/m3 | |||

| WSEP-30 | 2470 kg/m3 | |||

| 3. | Air content in fresh concrete | EN 12350-7 | E | 2.6% |

| WSEP-10 | 2.3% | |||

| WSEP-20 | 2.1% | |||

| WSEP-30 | 1.8% | |||

| 4. | Density of hardened concrete (water-saturated) | EN 12390-7 | E | 2455 kg/m3 |

| WSEP-10 | 2471 kg/m3 | |||

| WSEP-20 | 2480 kg/m3 | |||

| WSEP-30 | 2465 kg/m3 | |||

| 5. | Flexural strength | EN 12390-5 | E | 7.0 MPa (28 days), 7.4 MPa (90 days) |

| WSEP-10 | 6.0 MPa (28 days), 6.6 MPa (90 days) | |||

| WSEP-20 | 5.6 MPa (28 days), 6.3 MPa (90 days) | |||

| WSEP-30 | 5.3 MPa (28 days), 6.0 MPa (90 days) | |||

| 6. | Compressive strength | EN 12390-3 | E | 38.8 MPa (2 days), 56.3 MPa (7 days), 66.5 MPa (28 days), 73.6 MPa (90 days) |

| WSEP-10 | 36.2 MPa (2 days), 56.5 MPa (7 days), 64.5 MPa (28 days), 71.3 MPa (90 days) | |||

| WSEP-20 | 34.4 MPa (2 days), 49.6 MPa (7 days), 56.9 MPa (28 days), 64.4 MPa (90 days) | |||

| WSEP-30 | 25.8 MPa (2 days), 44.1 MPa (7 days), 53.7 MPa (28 days), 60.2 MPa (90 days) | |||

| 7. | Tensile splitting strength | EN 12390-6 | E | 3.9 MPa (28 days) |

| WSEP-10 | 3.6 MPa (28 days) | |||

| WSEP-20 | 3.3 MPa (28 days) | |||

| WSEP-30 | 3.2 MPa (28 days) | |||

| 8. | Secant modulus of elasticity | EN 12390-13 | E | 33.0 GPa (28 days) |

| WSEP-10 | 33.3 GPa (28 days) | |||

| WSEP-20 | 33.1 GPa (28 days) | |||

| WSEP-30 | 32.7 GPa (28 days) | |||

| 9. | Depth of penetration of water under pressure | EN 12390-8 | E | 12 mm |

| WSEP-10 | 14 mm | |||

| WSEP-20 | 17 mm | |||

| WSEP-30 | 19 mm | |||

| 10. | Freeze–thaw resistance with de-icing salts—scaling | CEN-TS_12390-9 | E | 0.14 mg/mm2 |

| WSEP-10 | 0.15 mg/mm2 | |||

| WSEP-20 | 0.18 mg/mm2 | |||

| WSEP-30 | 0.20 mg/mm2 | |||

| 11. | Determination of rebound number | EN 12504-2 | E | 48.6 |

| WSEP-10 | 47.0 | |||

| WSEP-20 | 45.7 | |||

| WSEP-30 | 42.4 | |||

| 12. | Determination of ultrasonic pulse velocity | EN 12504-4 | E | 5.21 km/s |

| WSEP-10 | 5.18 km/s | |||

| WSEP-20 | 5.15 km/s | |||

| WSEP-30 | 5.13 km/s | |||

| Testing of SCC Produced with Waste Sludge WSLP as Mineral Admixture (November 2019) | ||||

|---|---|---|---|---|

| 1. | Consistency—slump flow test | EN 12350-8 | E-SCC | 700 mm |

| WSLP-SCC | 680 mm | |||

| 2. | T500 test | EN 12350-8 | E-SCC | 4.2 s |

| WSLP-SCC | 9.1 s | |||

| 3. | L-box passing ratio (H2/H1) | EN 12350-10 | E-SCC | 0.94 (mm/mm) |

| WSLP-SCC | 0.81 (mm/mm) | |||

| 4. | Testing segregation using sieves | EN 12350-11 | E-SCC | 12.6% |

| WSLP-SCC | 3.1% | |||

| 5. | Density of fresh concrete | EN 12350-6 | E-SCC | 2460 kg/m3 |

| WSLP-SCC | 2400 kg/m3 | |||

| 6. | Air content in fresh concrete | EN 12350-7 | E-SCC | 2.2% |

| WSLP-SCC | 1.8% | |||

| 7. | Density of hardened concrete (water-saturated) | EN 12390-7 | E-SCC | 2457 kg/m3 |

| WSLP-SCC | 2392 kg/m3 | |||

| 8. | Flexural strength | EN 12390-5 | E-SCC | 6.0 MPa (28 days), 6.3 MPa (90 days) |

| WSLP-SCC | 3.4 MPa (28 days), 4.1 MPa (90 days) | |||

| 9. | Compressive strength | EN 12390-3 | E-SCC | 37.2 MPa (2 days), 49.1 MPa (7 days), 59.7 MPa (28 days), 64.2 MPa (90 days) |

| WSLP-SCC | 17.6 MPa (2 days), 26.2 MPa (7 days), 38.8 MPa (28 days), 51.1 MPa (90 days) | |||

| 10. | Tensile splitting strength | EN 12390-6 | E-SCC | 4.1 MPa (28 days) |

| WSLP-SCC | 2.8 MPa (28 days) | |||

| 11. | Secant modulus of elasticity | EN 12390-13 | E-SCC | 29.5 GPa (28 days) |

| WSLP-SCC | 26.3 GPa (28 days) | |||

| 12. | Depth of penetration of water under pressure | EN 12390-8 | E-SCC | 6 mm |

| WSLP-SCC | 10 mm | |||

| 13. | Freeze–thaw resistance with de-icing salts—scaling | CEN-TS_12390-9 | E-SCC | 0.14 kg/m2 |

| WSLP-SCC | 0.26 kg/m2 | |||

| 14. | Determination of rebound number | EN 12504-2 | E-SCC | 45.6 |

| WSLP-SCC | 42.1 | |||

| 15. | Determination of ultrasonic pulse velocity | EN 12504-4 | E-SCC | 4.87 km/s |

| WSLP-SCC | 4.70 km/s | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stojmenović, M.; Gulicovski, J.; Nišić, N.; Ristić, N.; Liu, S.; Loredo, J.; Kragović, M. Sustainable Application of Waste Sludges from the Wastewater Treatment Plant Generated during the Production of Heating Devices in the Construction Industry. Materials 2024, 17, 1089. https://doi.org/10.3390/ma17051089

Stojmenović M, Gulicovski J, Nišić N, Ristić N, Liu S, Loredo J, Kragović M. Sustainable Application of Waste Sludges from the Wastewater Treatment Plant Generated during the Production of Heating Devices in the Construction Industry. Materials. 2024; 17(5):1089. https://doi.org/10.3390/ma17051089

Chicago/Turabian StyleStojmenović, Marija, Jelena Gulicovski, Neda Nišić, Nenad Ristić, Shanke Liu, Jorge Loredo, and Milan Kragović. 2024. "Sustainable Application of Waste Sludges from the Wastewater Treatment Plant Generated during the Production of Heating Devices in the Construction Industry" Materials 17, no. 5: 1089. https://doi.org/10.3390/ma17051089

APA StyleStojmenović, M., Gulicovski, J., Nišić, N., Ristić, N., Liu, S., Loredo, J., & Kragović, M. (2024). Sustainable Application of Waste Sludges from the Wastewater Treatment Plant Generated during the Production of Heating Devices in the Construction Industry. Materials, 17(5), 1089. https://doi.org/10.3390/ma17051089