Optimizing Structural and Mechanical Properties of an Industrial Ti-6246 Alloy below β-Transus Transition Temperature through Thermomechanical Processing

Abstract

:1. Introduction

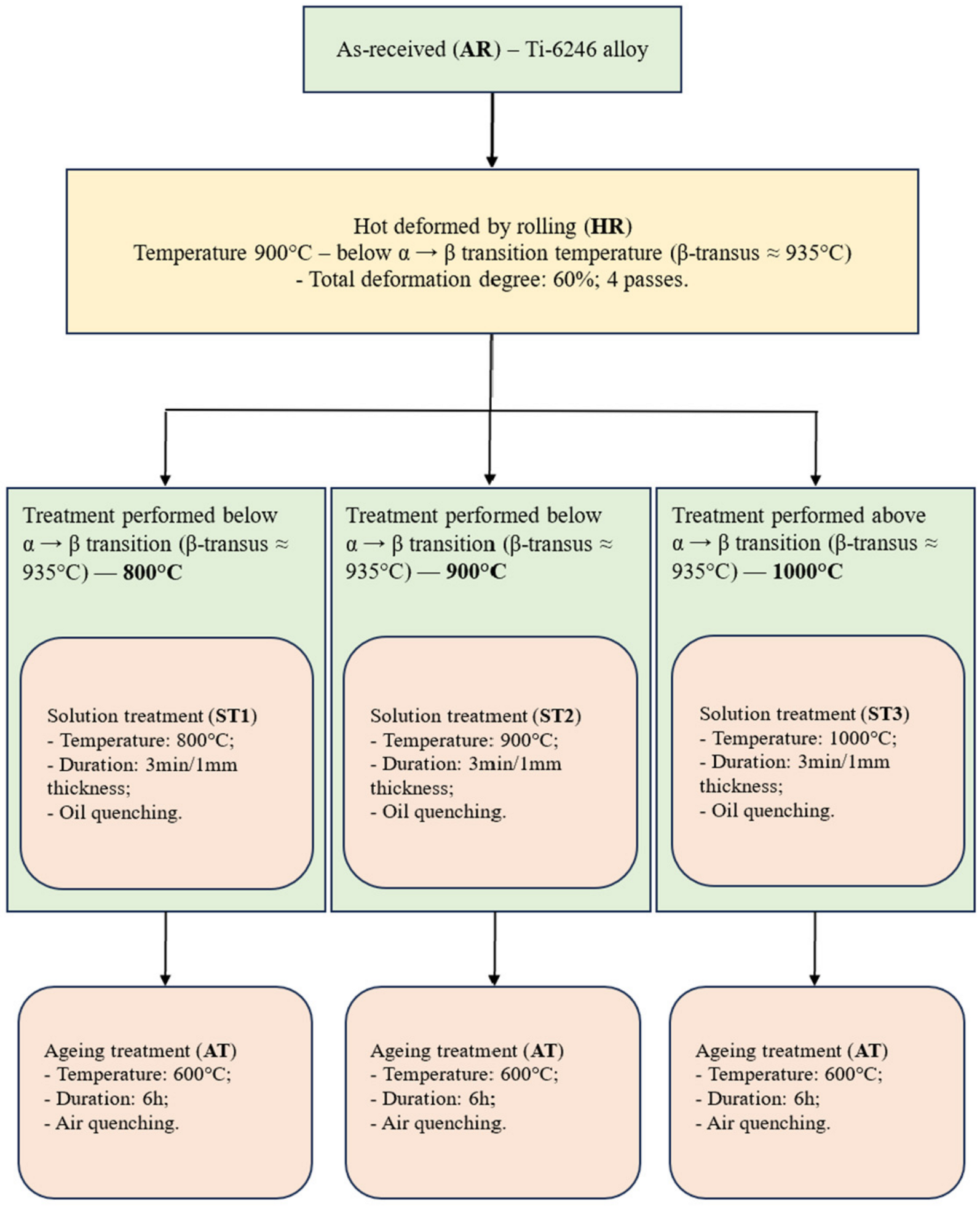

2. Materials and Methods

3. Results and Discussion

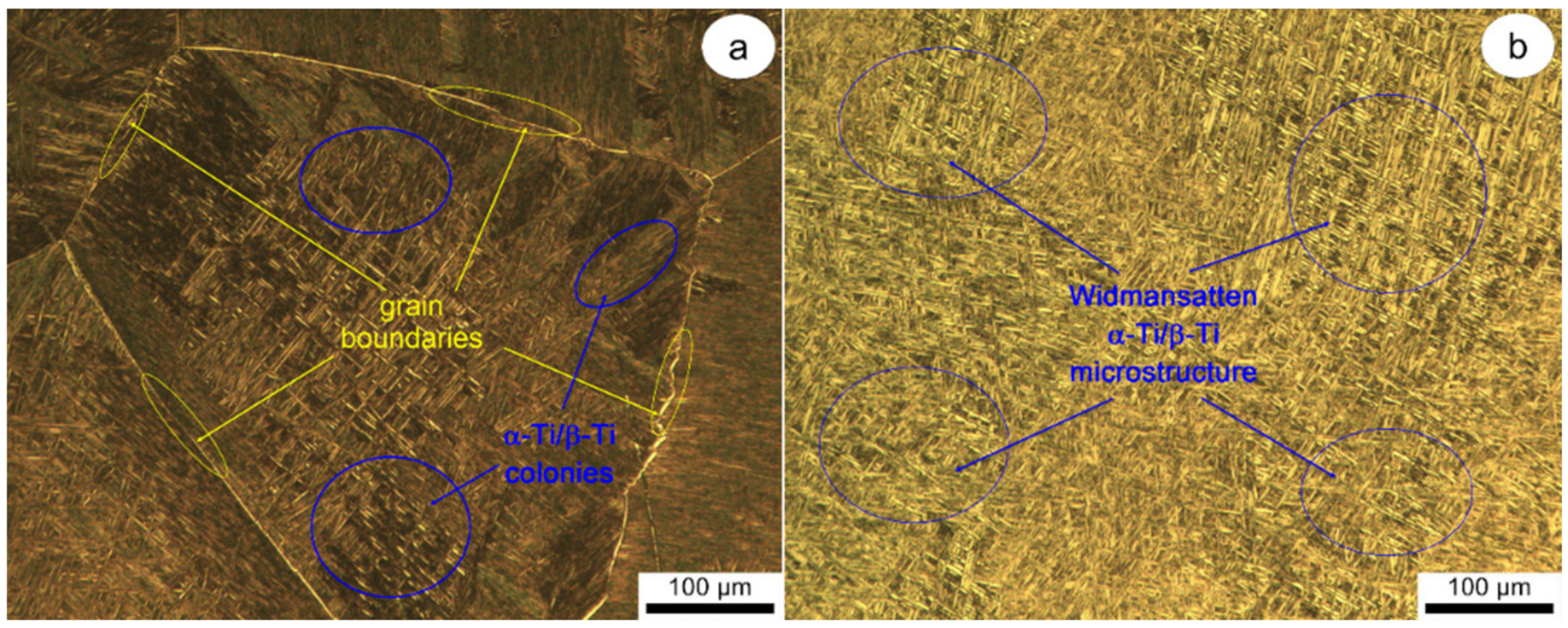

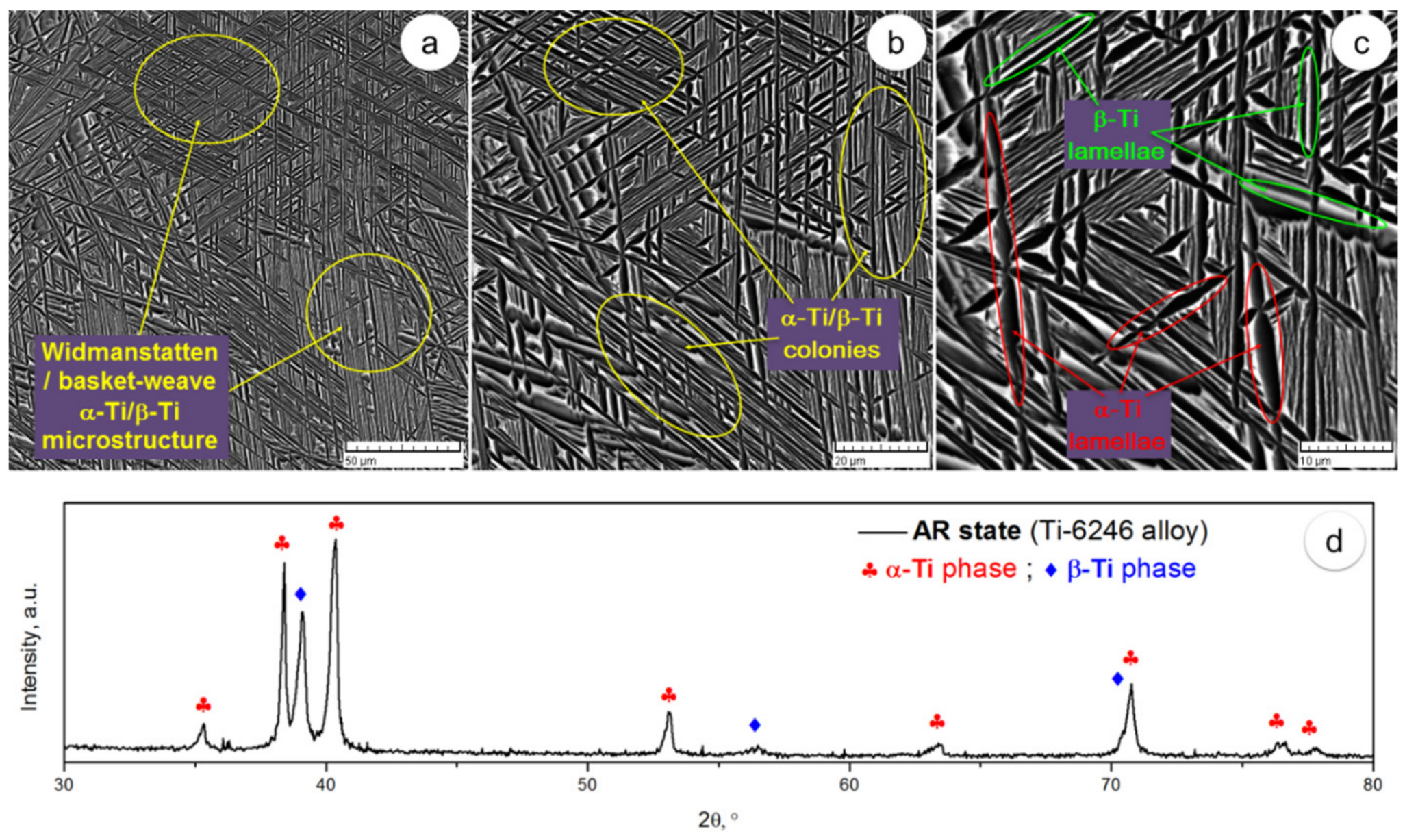

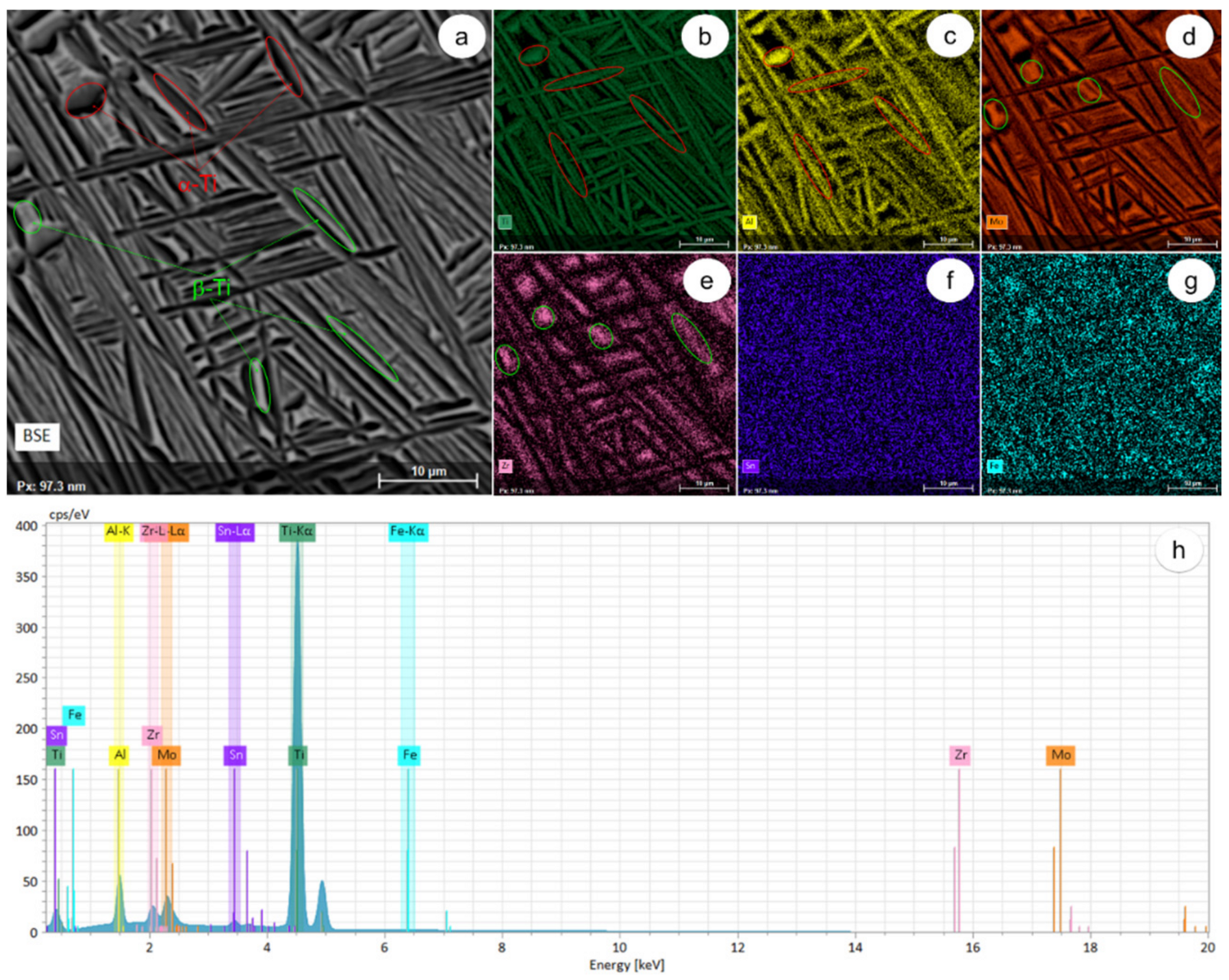

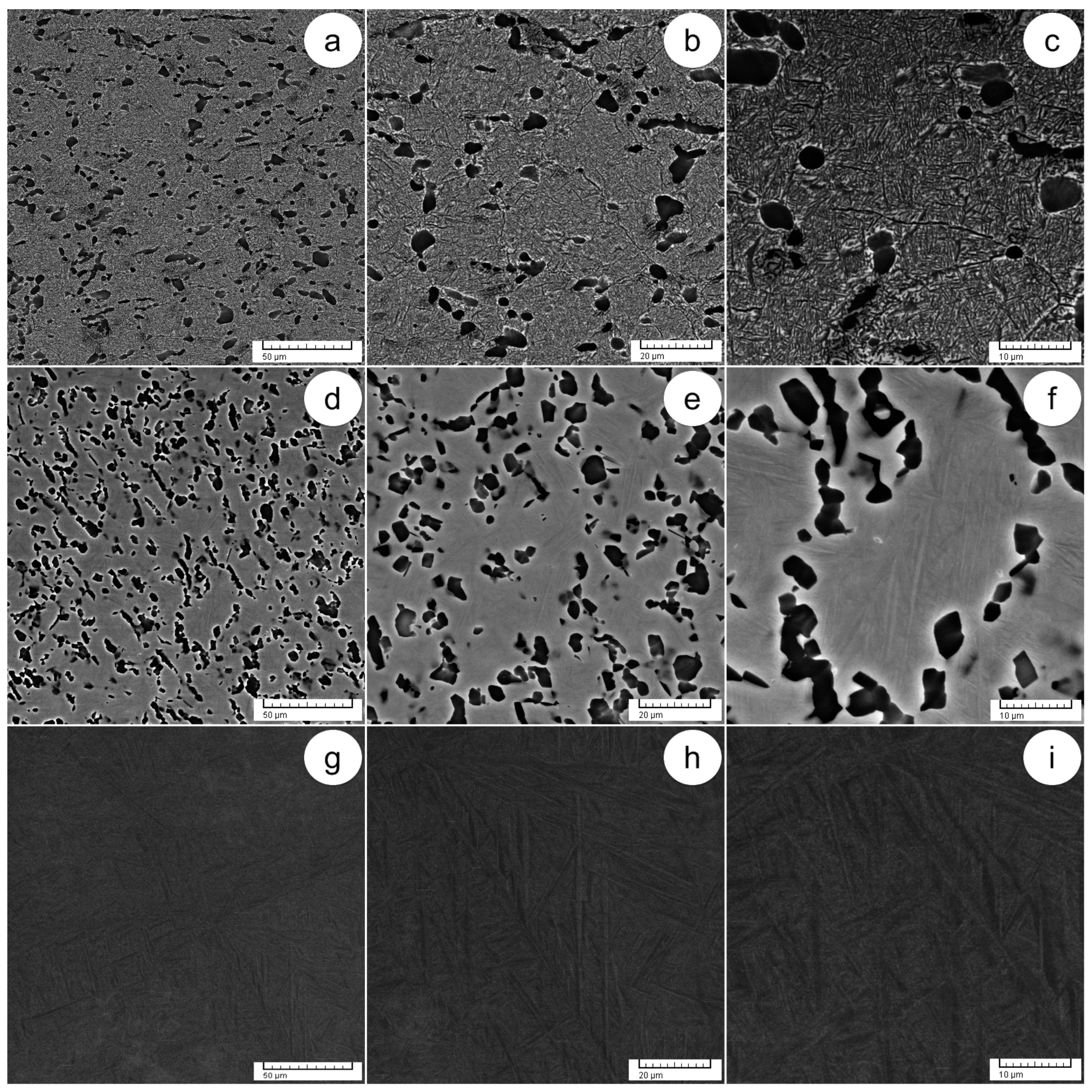

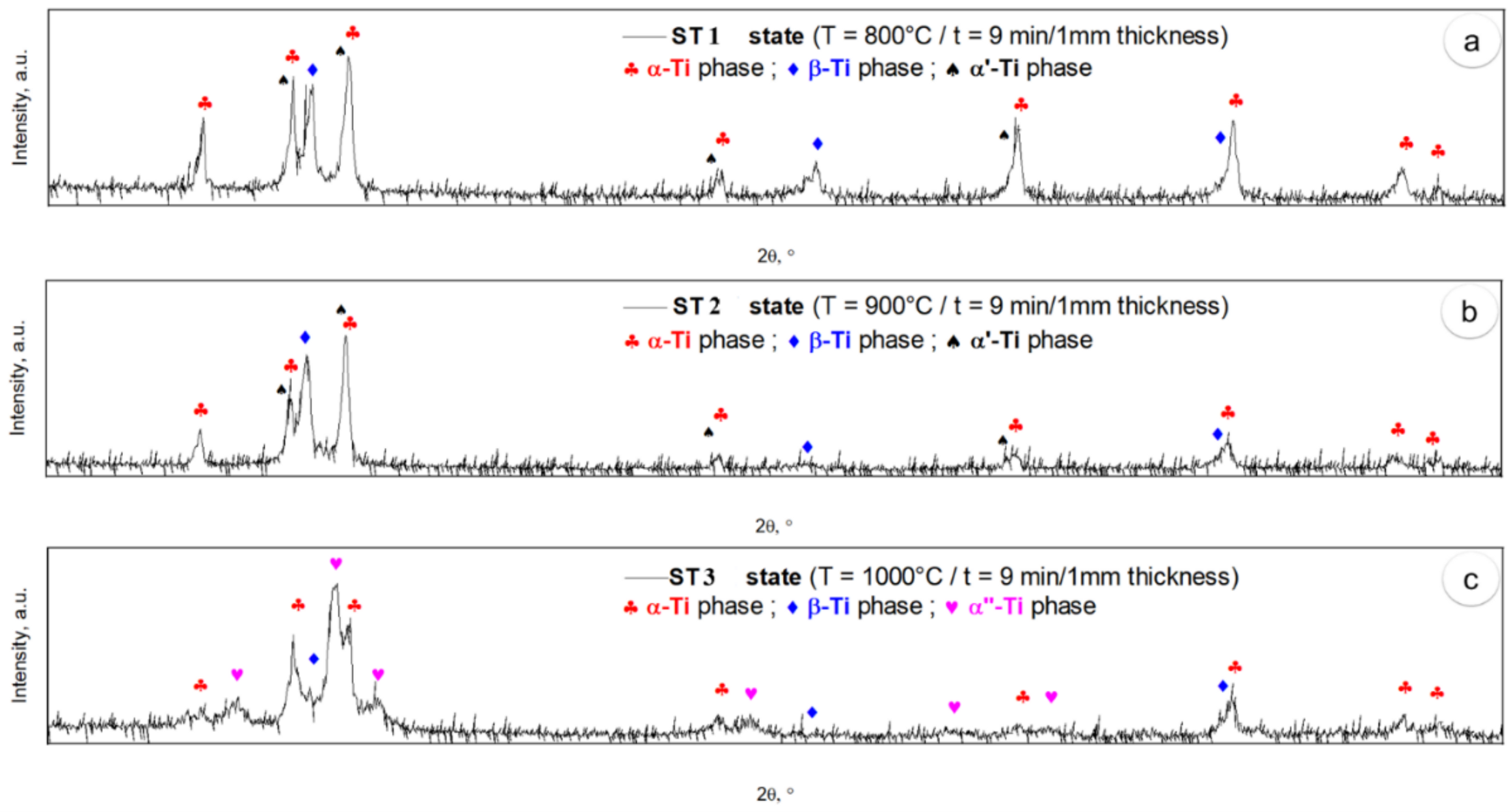

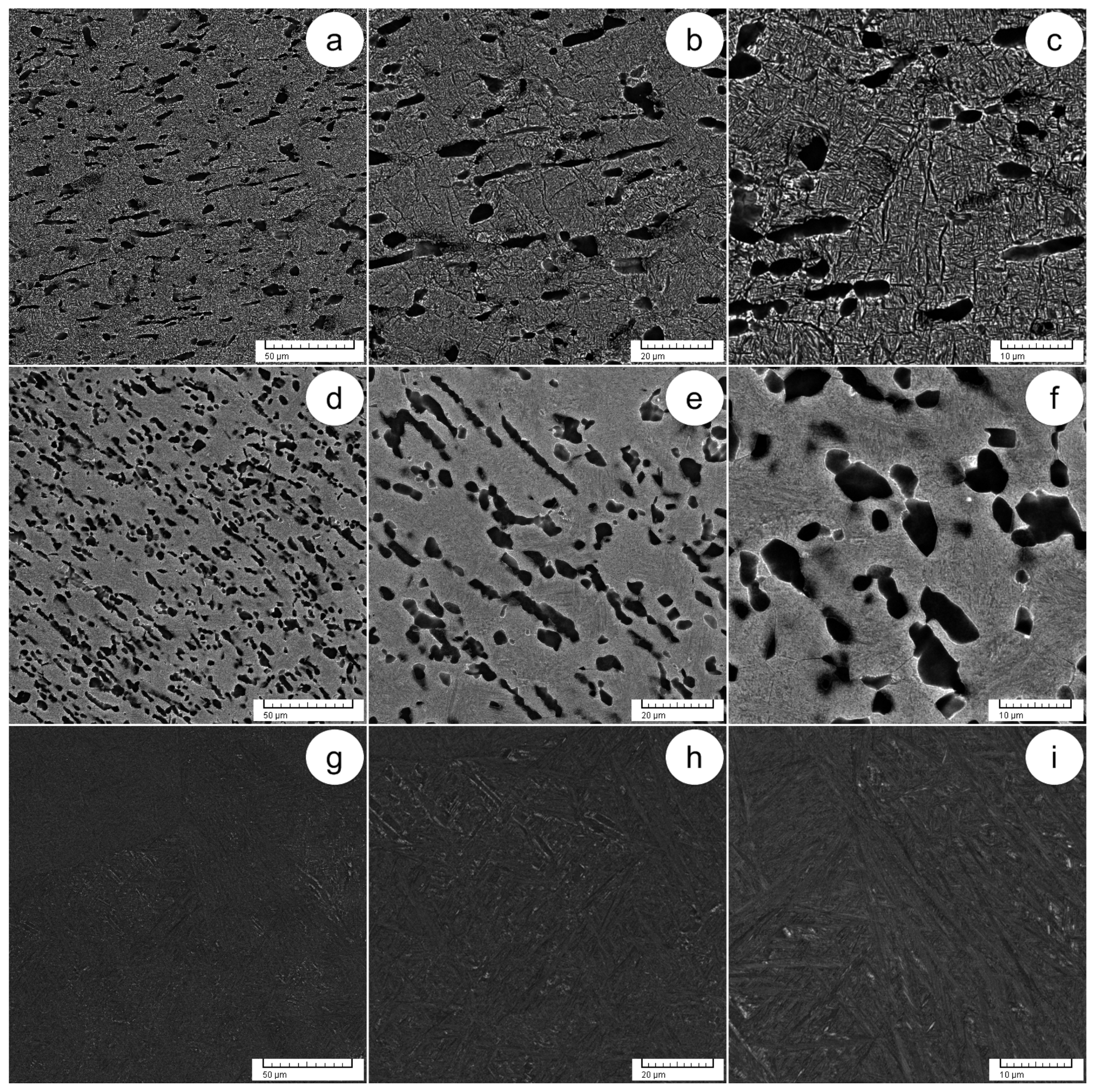

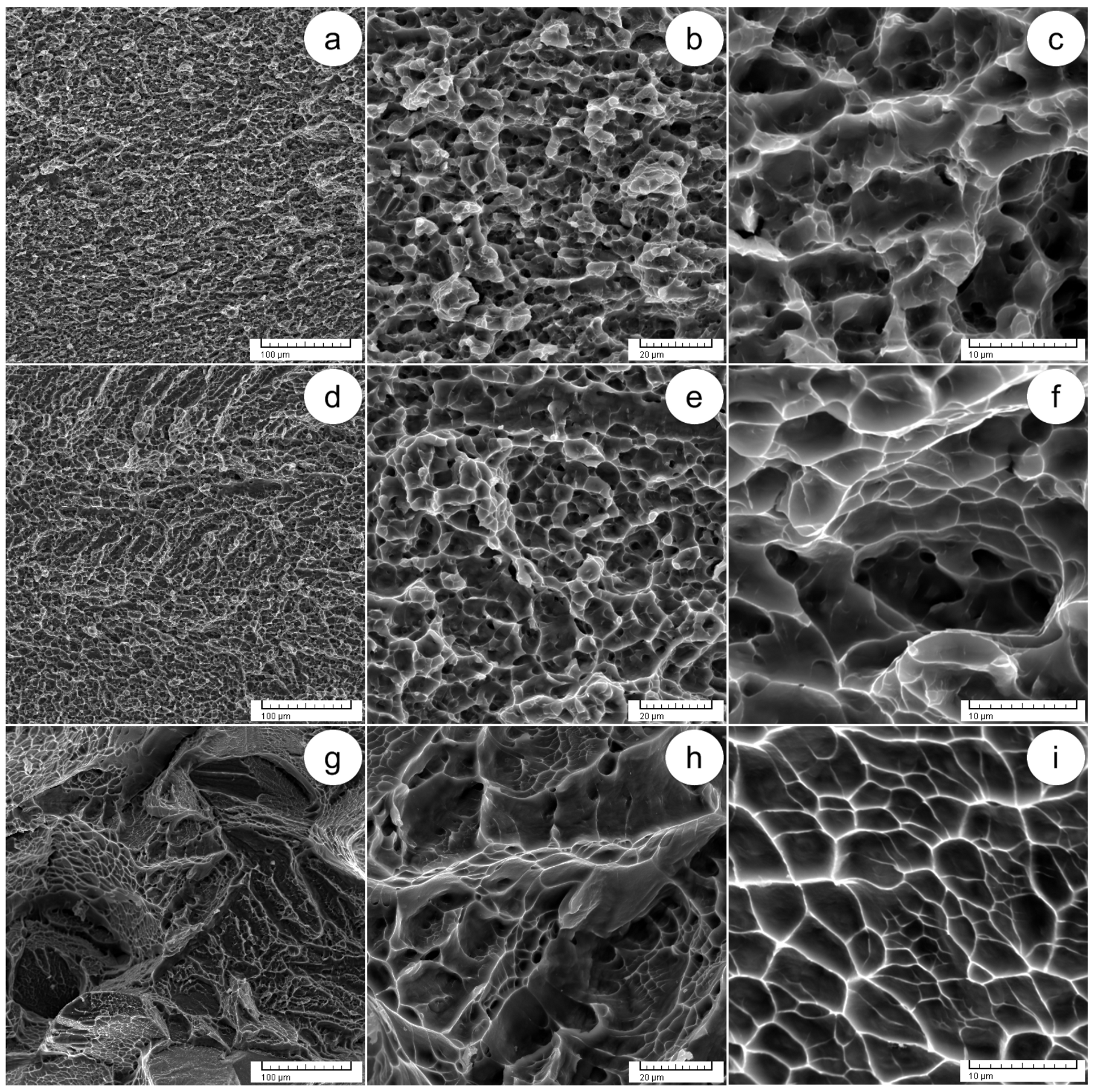

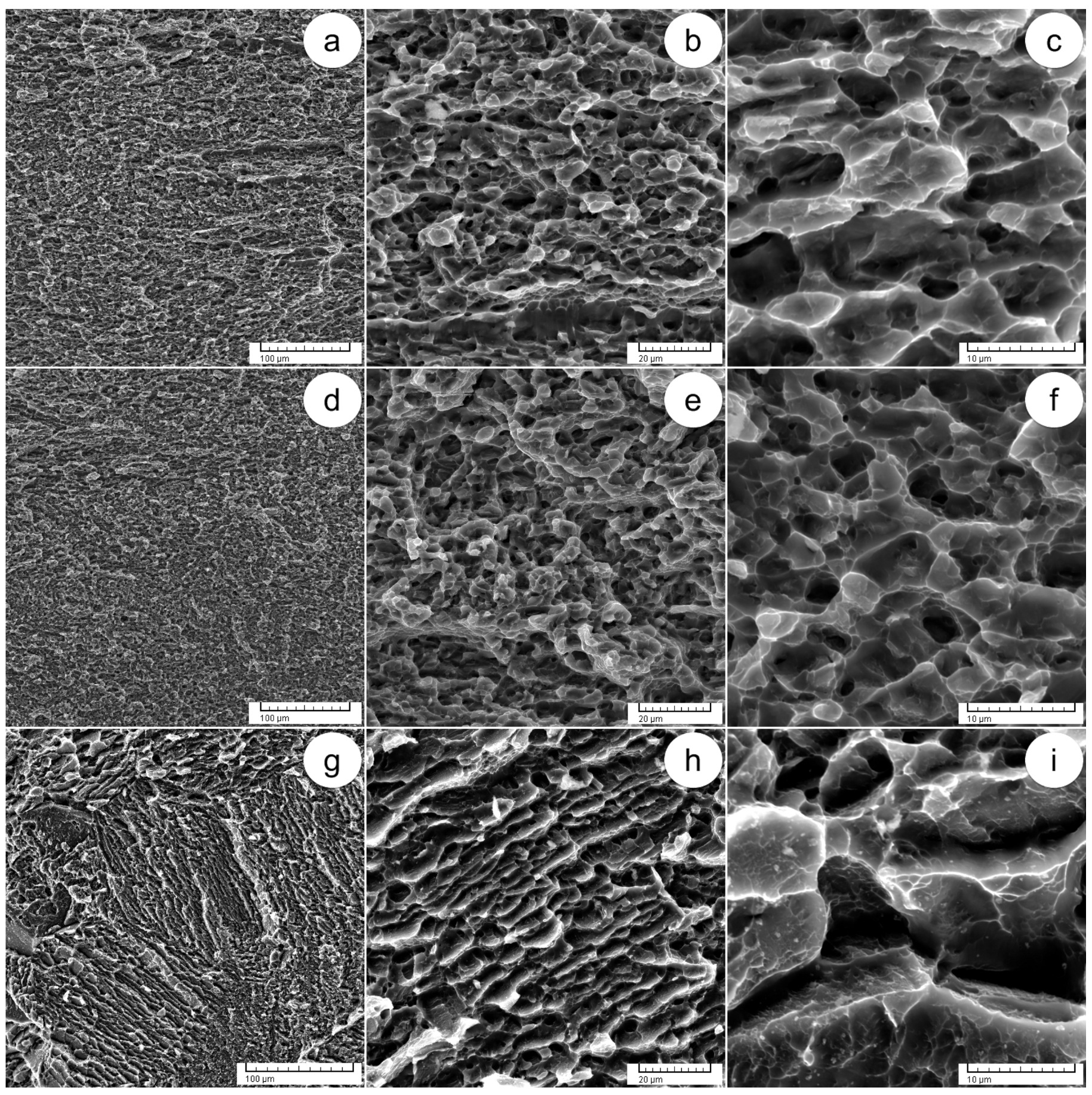

3.1. Structural Development

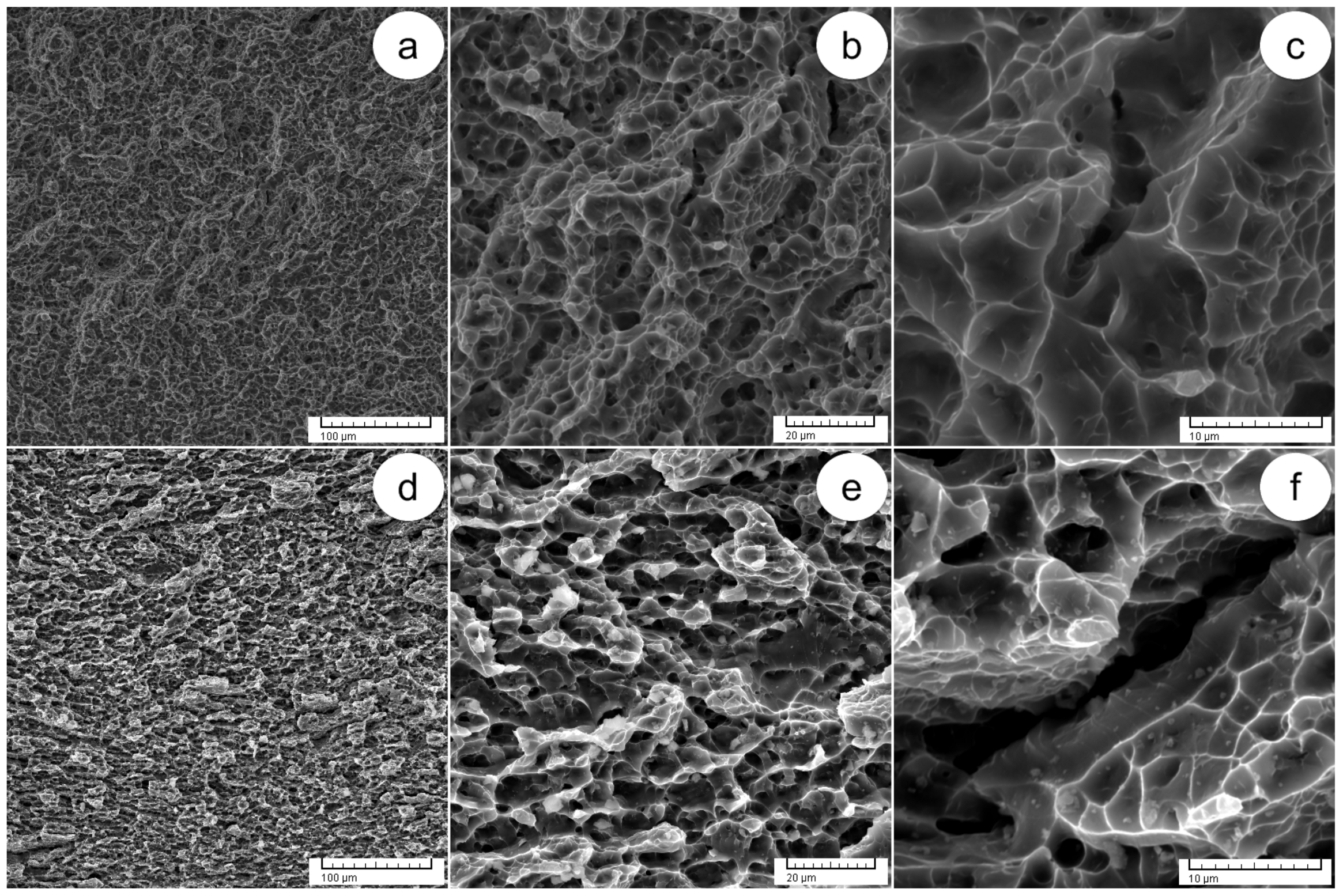

3.2. Mechanical Properties Development

4. Conclusions

- The generation of the secondary α phase (α′-Ti), which affects the mechanical behavior of Ti-6246 alloy through improving both strength and ductility properties in comparison to the state of hot deformation, is induced by a solution treatment temperature that is maintained below the threshold of the β-transus transition temperature. It should be noted that the solution treatment temperature, which is performed close to the threshold of the β-transus transition temperature, achieves a high strength property.

- The generation of the secondary α phase (α″-Ti), which affects the mechanical behavior of Ti-6246 alloy through reducing strength and increasing ductility, is induced by the solution treatment temperature, which is performed above the threshold of the β-transus transition temperature.

- As a result of stress relief, dispersion-precipitation-strengthening mechanisms and the phase transitions α′-Ti/α″-Ti → α-Ti/β-Ti and β-Ti → α-Ti/ω-Ti, which occurred during ageing treatment, it is possible to nuancedly control the mechanical behavior of Ti-6246 alloy. This approach allows for the achievement of an optimal synergy between strength, ductility and microhardness properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alluaibi, M.H.I. Specific Aspects Regarding the Behaviour of Some Titanium Based Alloys during Thermomechanical Processing. Ph.D. Thesis, Politehnica University of Bucharest, Bucharest, Romania, 2021. [Google Scholar]

- Campbell, F.C. Lightweight Materials: Understanding the Basics; ASM International Digital Library: Detroit, MI, USA, 2012; p. 672. [Google Scholar]

- Singh, N.; Hameed, P.; Ummethala, R.; Manivasagam, G.; Prashanth, K.G.; Eckert, J. Selective laser manufacturing of Ti-based alloys and composites: Impact of process parameters, application trends, and future prospects. Mater. Today Adv. 2020, 8, 100097. [Google Scholar] [CrossRef]

- Nawaya, T.; Beck, W.; von Hehl, A. Tensile properties of α-titanium alloys at elevated temperatures. MATEC Web Conf. 2020, 321, 04016. [Google Scholar] [CrossRef]

- Ma, F.; Lu, W.; Qin, J.; Zhang, D. Microstructure evolution of near-α titanium alloys during thermomechanical processing. Mater. Sci. Eng. A 2006, 416, 59–65. [Google Scholar] [CrossRef]

- Chandravanshi, V.K.; Sarkar, R.; Kamat, S.V.; Nandy, T.K. Effect of boron on microstructure and mechanical properties of thermomechanically processed near alpha titanium alloy Ti-1100. J. Alloys Compd. 2011, 509, 5506–5514. [Google Scholar] [CrossRef]

- Balasundar, I.; Raghu, T.; Kashyap, B.P. Hot working and geometric dynamic recrystallisation behaviour of a near-α titanium alloy with acicular microstructure. Mater. Sci. Eng. A 2014, 600, 135–144. [Google Scholar] [CrossRef]

- Jia, W.; Zeng, W.; Yu, H. Effect of ageing on the tensile properties and microstructures of a near-alpha titanium alloy. Mater. Des. 2014, 58, 108–115. [Google Scholar] [CrossRef]

- Jackson, M.; Dashwood, R.J.; Christodoulou, L.; Flower, H.M. Isothermal subtransus forging of Ti-6Al-2Sn-4Zr-6Mo. J. Light Met. 2002, 2, 185–195. [Google Scholar] [CrossRef]

- Filip, R.; Kubiak, k.; Ziaja, W.; Sieniawski, J. The effect of microstructure on the mechanical properties of two-phase titanium alloys. J. Mater. Process. Technol. 2003, 133, 84–89. [Google Scholar] [CrossRef]

- Zitanasky, M.; Caplovic, L. Effect of the thermomechanical treatment on the structure of titanium alloy Ti6Al4V. J. Mater. Process. Technol. 2004, 157–158, 643–649. [Google Scholar] [CrossRef]

- Stella, P.; Giovanetti, I.; Masi, G.; Leoni, M.; Molinarii, A. Microstructure and microhardness of heat-treated Ti-6Al-2Sn-4Zr-6Mo alloy. J. Alloys Compd. 2013, 567, 134–140. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, G.; Li, D.; Guo, D.; Zhang, Z.; Wei, B.; Li, J.; Zhang, X. Effect of heat treatment on the microstructure and tensile properties of deformed α/β Tie47Zre5Ale3V alloy. J. Alloys Compd. 2016, 665, 1–6. [Google Scholar] [CrossRef]

- Furuhara, T.; Maki, T.; Makion, T. Microstructure control by thermomechanical processing in β-Ti-15-3 alloy. J. Mater. Process. Technol. 2001, 117, 318–323. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.k.; Muraleedharan, K.; Gogia, A.K.; Asokamani, R. Effect of thermomechanical processing on microstructure of a Ti–13Nb–13Zr alloy. J. Alloys Compd. 2001, 329, 264–271. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.k.; Gogia, A.K.; Asokamani, R. Effect of thermomechanical processing on evolution of various phases in Ti–Nb–Zr alloys. J. Alloys Compd. 2004, 384, 131–144. [Google Scholar] [CrossRef]

- Matsumoto, H.; Watanabe, S.; Hanada, S. Microstructures and mechanical properties of metastable β TiNbSn alloys cold rolled and heat treated. J. Alloys Compd. 2007, 439, 146–155. [Google Scholar] [CrossRef]

- Manshadi, A.D.; Dippenaaar, R.J. Development of α-phase morphologies during low temperature isothermal heat treatment of a Ti-5Al-5Mo-5V-3Cr alloy. Mater. Sci. Eng. A 2011, 528, 1833–1839. [Google Scholar] [CrossRef]

- Li, C.; Chen, J.; Ren, Y.J.; Li, W.; He, J.J.; Chen, J.H. Effect of solution heat treatment on the stress-induced martensite transformation in two new titanium alloys. J. Alloys Compd. 2015, 641, 192–200. [Google Scholar] [CrossRef]

- Ahmed, M.; Li, T.; Casillas, G.; Cairney, J.M.; Wexler, D.; Pereloma, E.V. The evolution of microstructure and mechanical properties of Ti–5Al–5Mo–5V–2Cr–1Fe during ageing. J. Alloys Compd. 2015, 629, 260–273. [Google Scholar] [CrossRef]

- Liu, C.; Yu, L.; Zhang, A.; Tian, X.; Liu, D.; Ma, S. Beta heat treatment of laser melting deposited high strength near β titanium alloy. Mater. Sci. Eng. A 2016, 673, 185–192. [Google Scholar] [CrossRef]

- Costa, F.H.; Salvador, C.A.F.; Mello, M.G.; Caram, R. Alpha phase precipitation in Ti-30Nb-1Fe alloys—Phase transformations in continuous heating and aging heat treatments. Mater. Sci. Eng. A 2016, 677, 222–229. [Google Scholar] [CrossRef]

- Boyer, R.; Collings, E.W.; Welsch, G.; Lampman, S. Materials Properties Handbook: Titanium Alloys, 1st ed.; ASM International: Materials Park, OH, USA, 1994; p. 788. [Google Scholar]

- Donachie, M.J. Titanium: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000; p. 216. [Google Scholar]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys—Fundamentals and Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003; p. 532. [Google Scholar]

- Joshi, V.A. Titanium Alloys: An Atlas of Structures and Fracture Features; Taylor & Francis Group: Abingdon, UK; CRC Press: Boca Raton, FL, USA, 2006; p. 247. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; p. 449. [Google Scholar]

- Sha, W.; Malinov, S. Titanium Alloys: Modeling of Microstructure, Properties and Applications, 1st ed.; Taylor & Francis Group: Abingdon, UK; CRC Press: Boca Raton, FL, USA, 2009; p. 598. [Google Scholar]

- Froes, F.H. Titanium: Physical Metallurgy Processing and Applications, 1st ed.; ASM International: Materials Park, OH, USA, 2015; p. 417. [Google Scholar]

- Manesh, S.H.; Ahmadabadi, M.N.; Ghasemiarmaki, H.; Jafarian, H.R. Effect of initial microstructure and further thermomechanical processing on microstructural evolution in a Ti–47Al–2Cr alloy. J. Alloys Compd. 2007, 436, 200–203. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Inagaki, I.; Takechi, T.; Shirai, Y.; Ariyasu, N. Application and Features of Titanium for the Aerospace Industry; Nippon Steel & Sumitomo Metal Technical Report No. 106; Nippon Steel Corporation: Tokyo, Japan, 2014; pp. 22–27. Available online: https://www.nipponsteel.com/en/tech/report/nssmc/pdf/106-05.pdf (accessed on 18 December 2023).

- Alluaibi, M.H.I.; Cojocaru, E.M.; Rusea, A.; Serban, N.; Coman, G.; Cojocaru, V.D. Microstructure and Mechanical Properties Evolution during Solution and Ageing Treatment for a Hot Deformed, above β-transus, Ti-6246 Alloy. Metals 2020, 10, 1114. [Google Scholar] [CrossRef]

- Alluaibi, M.H.; Rusea, A.; Cojocaru, V.D. Influence of thermomechanical processing at temperatures above β-transus on the microstructural and mechanical characteristics of the Ti-6246 alloy. UPB Sci. Bull. B Chem. Mater. Sci. 2018, 80, 245–258. [Google Scholar]

- Alluaibi, M.H.; Alturaihi, S.S.; Rusea, A.; Cojocaru, E.M. The response of microstructure and mechanical properties of Ti-6246 alloy to thermomechanical processing. UPB Sci. Bull. B Chem. Mater. Sci. 2021, 83, 231–242. [Google Scholar]

- Vahidshad, Y.; Khodabakhshi, A.H. Effect of Solution Treatment and Aging Temperature on α′ and Ti3Al(α2) Phase Formation and Mechanical Properties of Water-Quenched Ti-6Al-4V. Metallogr. Microstruct. Anal. 2022, 11, 59–71. [Google Scholar] [CrossRef]

- Kent, D.; Wang, G.; Wang, W.; Dargusch, M.S. Influence of ageing temperature and heating rate on the properties and microstructure of β Ti alloy, Ti-6Cr-5Mo-5V-4Al. Mater. Sci. Eng. A 2012, 531, 98–106. [Google Scholar] [CrossRef]

- Devaraj, A.; Nag, S.; Srinivasan, R.; Williams, R.E.A.; Banerjee, S.; Banerjee, R.; Fraser, H.L. Experimental evidence of concurrent compositional and structural instabilities leading to ω precipitation in titanium-molybdenum alloys. Acta Mater. 2012, 60, 596–609. [Google Scholar] [CrossRef]

- Guo, Y.; Wei, S.; Yang, S.; Ke, Y.; Zhang, X.; Zhou, K. Precipitation Behavior of ω Phase and ω→α Transformation in Near β Ti-5Al-5Mo-5V-1Cr-1Fe Alloy during Aging Process. Metals 2021, 11, 273. [Google Scholar] [CrossRef]

- Sauer, C.; Lutjering, G. Processing, Microstructure and Properties of Ti-6246. In Proceedings of the 9th World Conference on Titanium: Titanium’99 Science and Technology, Saint-Petersburg, Russia, 7–11 June 1999; Gorynin, I.V., Ushkov, S.S., Eds.; Central Research Institute of Structural Materials (CRISM) “PROMETEY”: Saint-Petersburg, Russia, 1999. [Google Scholar]

| Elemental Components | %, wt. | %, at | Abs. Error [%] | Rel. Error [%] |

|---|---|---|---|---|

| Ti | 81.54 | 82.55 | 2.44 | 2.76 |

| Al | 6.33 | 11.36 | 0.33 | 4.77 |

| Sn | 1.85 | 0.75 | 0.05 | 2.94 |

| Zr | 3.91 | 2.08 | 0.16 | 3.79 |

| Mo | 6.24 | 3.15 | 0.24 | 3.54 |

| Fe | 0.14 | 0.12 | 0.12 | 2.77 |

| Structural Issue | Mechanical Properties | |||

|---|---|---|---|---|

| Microhardness, HV1 | Ultimate Tensile Strength, σUTS [MPa] | 0.2% Yield Strength, σ0.2% [MPa] | Fracture Elongation, εf [%] | |

| AR standard state | 305.2 ± 16.9 | 1057 ± 14 | 967 ± 11 | 12.9 ± 1.8 |

| HR | 399.8 ± 13.7 | 1154 ± 14 | 996 ± 13 | 3.8 ± 0.8 |

| ST1 | 373.5 ± 5.4 | 1165 ± 13 | 1008 ± 12 | 5.3 ± 1.1 |

| ST2 | 301.8 ± 5.8 | 1357 ± 14 | 1174 ± 12 | 6.9 ± 1.2 |

| ST3 | 320.4 ± 5.9 | 984 ± 13 | 785 ± 13 | 9.7 ± 1.2 |

| ST1 + AT | 397.8 ± 9.1 | 1089 ± 11 | 966 ± 13 | 8.1 ± 1.3 |

| ST2 + AT | 428.1 ± 5.3 | 1284 ± 12 | 1101 ± 14 | 15.4 ± 1.2 |

| ST3 + AT | 442.6 ± 3.7 | 1170 ± 11 | 986 ± 13 | 6.9 ± 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alluaibi, M.H.I.; Balkan, I.V.; Șerban, N.; Cinca, I.; Angelescu, M.L.; Cojocaru, E.M.; Alturaihi, S.S.; Cojocaru, V.D. Optimizing Structural and Mechanical Properties of an Industrial Ti-6246 Alloy below β-Transus Transition Temperature through Thermomechanical Processing. Materials 2024, 17, 1145. https://doi.org/10.3390/ma17051145

Alluaibi MHI, Balkan IV, Șerban N, Cinca I, Angelescu ML, Cojocaru EM, Alturaihi SS, Cojocaru VD. Optimizing Structural and Mechanical Properties of an Industrial Ti-6246 Alloy below β-Transus Transition Temperature through Thermomechanical Processing. Materials. 2024; 17(5):1145. https://doi.org/10.3390/ma17051145

Chicago/Turabian StyleAlluaibi, Mohammed Hayder Ismail, Irina Varvara Balkan, Nicolae Șerban, Ion Cinca, Mariana Lucia Angelescu, Elisabeta Mirela Cojocaru, Saleh Sabah Alturaihi, and Vasile Dănuț Cojocaru. 2024. "Optimizing Structural and Mechanical Properties of an Industrial Ti-6246 Alloy below β-Transus Transition Temperature through Thermomechanical Processing" Materials 17, no. 5: 1145. https://doi.org/10.3390/ma17051145